automatic transmission LAND ROVER DISCOVERY 2002 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 817 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-20 DESCRIPTION AND OPERATION

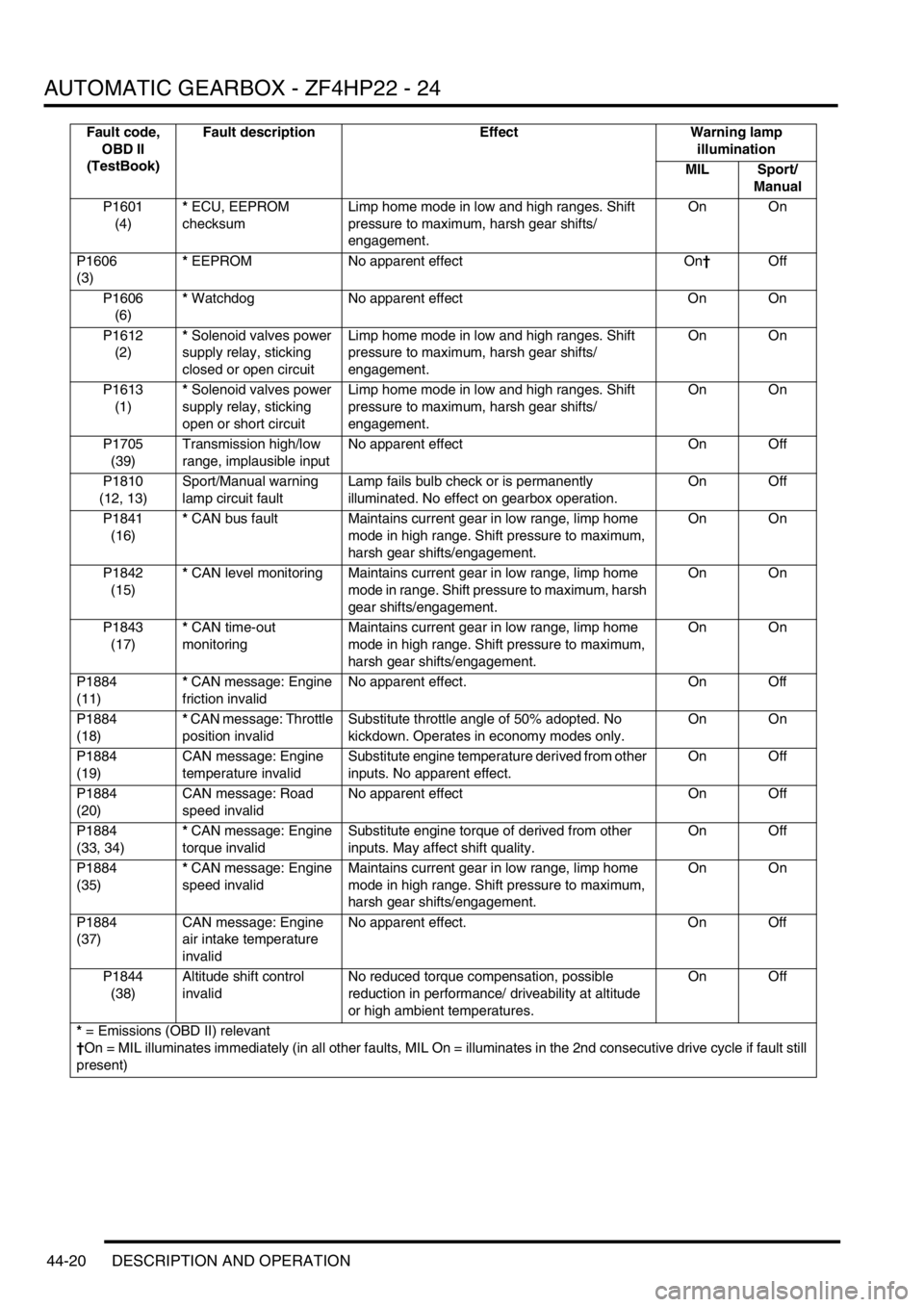

P1601

(4)* ECU, EEPROM

checksumLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1606

(3)* EEPROM No apparent effect On†Off

P1606

(6)* Watchdog No apparent effect On On

P1612

(2)* Solenoid valves power

supply relay, sticking

closed or open circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1613

(1)* Solenoid valves power

supply relay, sticking

open or short circuitLimp home mode in low and high ranges. Shift

pressure to maximum, harsh gear shifts/

engagement.On On

P1705

(39)Transmission high/low

range, implausible inputNo apparent effect On Off

P1810

(12, 13)Sport/Manual warning

lamp circuit faultLamp fails bulb check or is permanently

illuminated. No effect on gearbox operation.On Off

P1841

(16)* CAN bus fault Maintains current gear in low range, limp home

mode in high range. Shift pressure to maximum,

harsh gear shifts/engagement.On On

P1842

(15)* CAN level monitoring Maintains current gear in low range, limp home

mode in range. Shift pressure to maximum, harsh

gear shifts/engagement.On On

P1843

(17)* CAN time-out

monitoringMaintains current gear in low range, limp home

mode in high range. Shift pressure to maximum,

harsh gear shifts/engagement.On On

P1884

(11)* CAN message: Engine

friction invalidNo apparent effect. On Off

P1884

(18)* CAN message: Throttle

position invalidSubstitute throttle angle of 50% adopted. No

kickdown. Operates in economy modes only.On On

P1884

(19)CAN message: Engine

temperature invalidSubstitute engine temperature derived from other

inputs. No apparent effect.On Off

P1884

(20)CAN message: Road

speed invalidNo apparent effect On Off

P1884

(33, 34)* CAN message: Engine

torque invalidSubstitute engine torque of derived from other

inputs. May affect shift quality.On Off

P1884

(35)* CAN message: Engine

speed invalidMaintains current gear in low range, limp home

mode in high range. Shift pressure to maximum,

harsh gear shifts/engagement.On On

P1884

(37)CAN message: Engine

air intake temperature

invalidNo apparent effect. On Off

P1844

(38)Altitude shift control

invalidNo reduced torque compensation, possible

reduction in performance/ driveability at altitude

or high ambient temperatures.On Off

* = Emissions (OBD II) relevant

†On = MIL illuminates immediately (in all other faults, MIL On = illuminates in the 2nd consecutive drive cycle if fault still

present)Fault code,

OBD II

(TestBook)Fault description Effect Warning lamp

illumination

MIL Sport/

Manual

Page 832 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-35

Refit

1.Clean oil seal running surfaces.

2.Lubricate oil seal with transmission fluid.

3.Fit new seal into converter housing using tool

LRT-44-001.

4.Fit tool LRT-44-010 to torque converter.

5.Align oil pump drive and fit torque converter to

gearbox.

6.Remove tool LRT-44-010 from torque

converter.

7.Fit torque converter retaining strap.

8.Fit automatic gearbox.

l

+ AUTOMATIC GEARBOX -

ZF4HP22 - 24, REPAIRS, Gearbox -

convertor and transfer gearbox - Diesel.

l

+ AUTOMATIC GEARBOX -

ZF4HP22 - 24, REPAIRS, Gearbox -

convertor and transfer gearbox - V8.

Housing - torque converter

$% 44.17.01

Remove

1.Remove torque converter oil seal.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Torque converter and oil

seal.

2.Remove 18 bolts and plain washers securing

torque converter and intermediate plate to

gearbox casing. Note the position of the 4 bolts

that have sealant applied to the bolt threads

and 6 bolts, (outer ring), which are shorter.

3.Hold input shaft in position and carefully

remove the converter housing and intermediate

plate from gearbox casing.

4.Note the position of the Torrington race on the

forward clutch hub and the thrust washer which

will stay attached to the intermediate plate by

fluid adhesion.

5.Remove and discard intermediate plate gasket.

6.Remove thrust washer from intermediate plate.

7.Separate converter housing from intermediate

plate.

M44 1343

M44 1345

Page 836 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-39

7.Note position and remove pump locating dowel.

8.Remove and discard 'O' ring from pump

housing.

9.Remove 6 bolts securing converter housing to

intermediate plate, and release intermediate

plate from converter housing.Refit

1.Clean intermediate plate and mating faces with

a lint free cloth.

2.Position intermediate plate to converter

housing, fit bolts and tighten evenly to 46 Nm

(34 lbf.ft)

3.Fit new sealing washers to M14 Allen plugs, fit

plugs and tighten to 40 Nm (30 lbf.ft).

4.Fit new sealing washers to M20 plugs, fit plugs

and tighten to 50 Nm (37 lbf.ft).

5.Fit oil cooler adaptors and tighten to 42 Nm (30

lbf.ft)

6.Clean pump housing and mating face on

intermediate plate with lint free cloth.

7.Lubricate new 'O' ring with transmission fluid

and fit to pump housing.

8.Position pump locating dowel into intermediate

plate.

9.Align pump to dowel and position in

intermediate plate.

10.Fit bolts and tighten in a diagonal sequence to

10 Nm (7 lbf.ft)

11.Position LRT-44-003/1 into pump and check

that the pump rotors turn freely.

12.Fit intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

M44 1341

M44 1357

M44 1342

LRT-44-003/1

Page 837 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-40 REPAIRS

Pump - fluid

$% 44.32.01

Remove

1.Remove intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

2.Remove 8 bolts securing fluid pump to

intermediate plate and carefully remove pump

from intermediate plate.

3.Note position and remove pump locating dowel.

4.Remove and discard 'O' ring from pump

housing.

Refit

1.Clean pump housing and mating face on

intermediate plate with lint free cloth.

2.Lubricate new 'O' ring with transmission fluid

and fit to pump housing.

3.Position pump locating dowel into intermediate

plate.

4.Align fluid pump to dowel and position in

intermediate plate.5.Fit bolts and tighten in a diagonal sequence to

10 Nm (7 lbf.ft)

6.Position LRT-44-003/1 into pump and check

that the pump rotors turn freely.

7.Fit intermediate plate gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - intermediate plate.

M44 1336

M44 1341

M44 1342

LRT-44-003/1

Page 838 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-41

Seal - rear extension housing

$% 44.20.18

Remove

1.Remove transfer box

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

2.Drain automatic gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

3.Remove rear extension housing oil seal from

gearbox.

Refit

1.Clean oil seal recess in gearbox and running

surface on input shaft.

2.Lubricate oil seal running surface with

transmission oil. 3.Using tool LRT-44-001 fit oil seal to extension

housing.

4.Fit transfer box

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

5.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Page 850 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-53

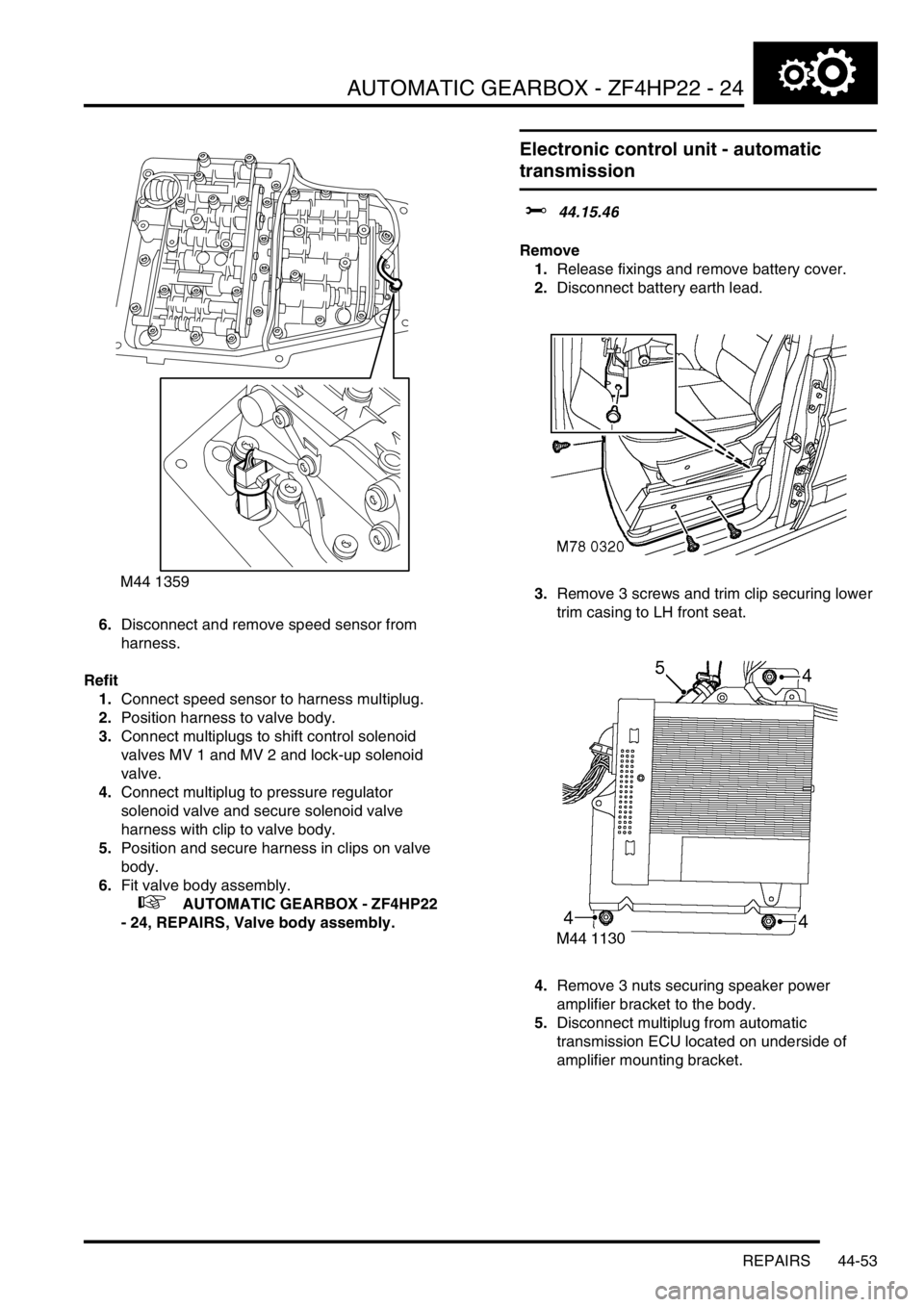

6.Disconnect and remove speed sensor from

harness.

Refit

1.Connect speed sensor to harness multiplug.

2.Position harness to valve body.

3.Connect multiplugs to shift control solenoid

valves MV 1 and MV 2 and lock-up solenoid

valve.

4.Connect multiplug to pressure regulator

solenoid valve and secure solenoid valve

harness with clip to valve body.

5.Position and secure harness in clips on valve

body.

6.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

Electronic control unit - automatic

transmission

$% 44.15.46

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 3 screws and trim clip securing lower

trim casing to LH front seat.

4.Remove 3 nuts securing speaker power

amplifier bracket to the body.

5.Disconnect multiplug from automatic

transmission ECU located on underside of

amplifier mounting bracket.

M44 1359

Page 1081 of 1672

BRAKES

70-36 REPAIRS

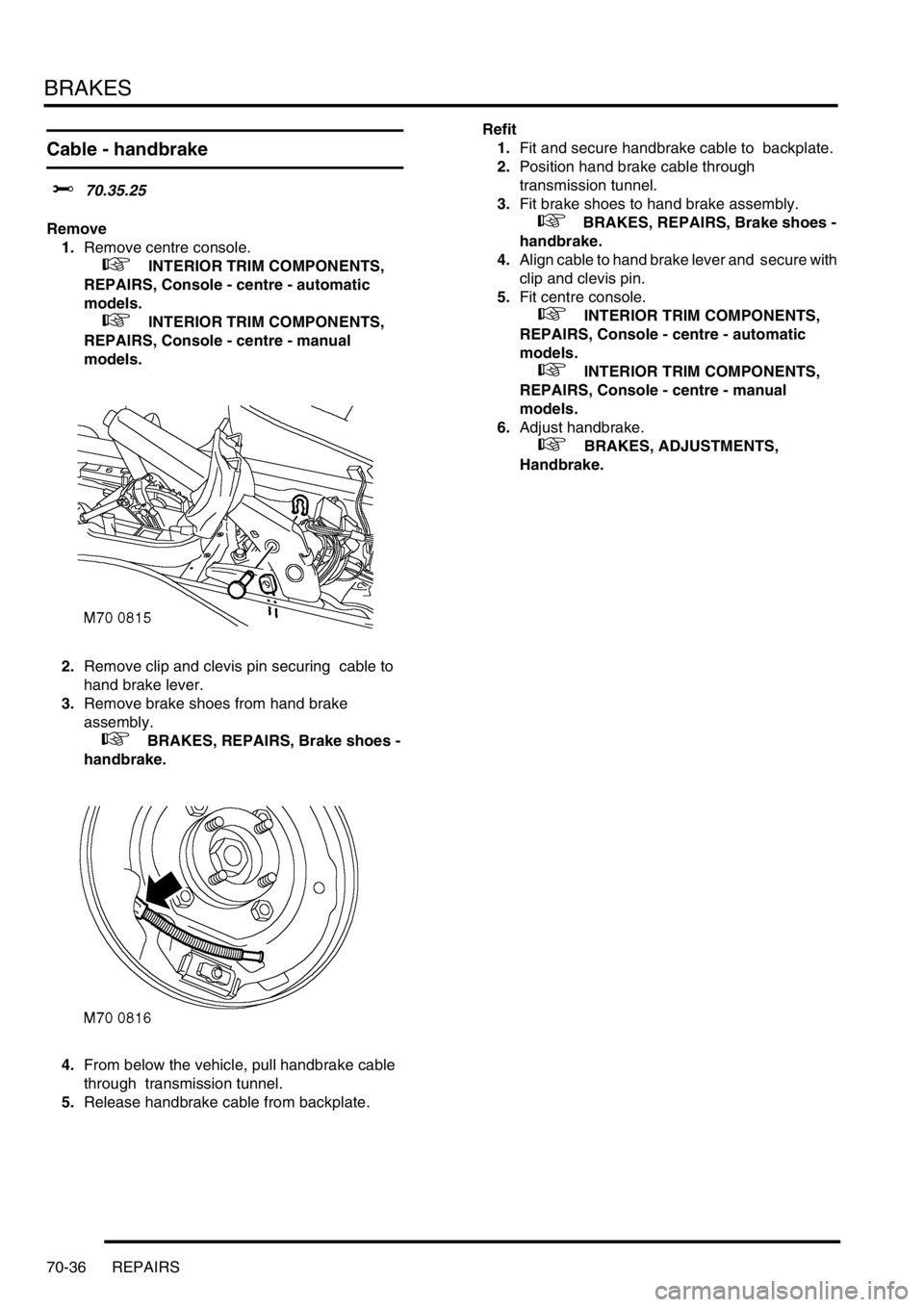

Cable - handbrake

$% 70.35.25

Remove

1.Remove centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

2.Remove clip and clevis pin securing cable to

hand brake lever.

3.Remove brake shoes from hand brake

assembly.

+ BRAKES, REPAIRS, Brake shoes -

handbrake.

4.From below the vehicle, pull handbrake cable

through transmission tunnel.

5.Release handbrake cable from backplate. Refit

1.Fit and secure handbrake cable to backplate.

2.Position hand brake cable through

transmission tunnel.

3.Fit brake shoes to hand brake assembly.

+ BRAKES, REPAIRS, Brake shoes -

handbrake.

4.Align cable to hand brake lever and secure with

clip and clevis pin.

5.Fit centre console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

6.Adjust handbrake.

+ BRAKES, ADJUSTMENTS,

Handbrake.

Page 1162 of 1672

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-9

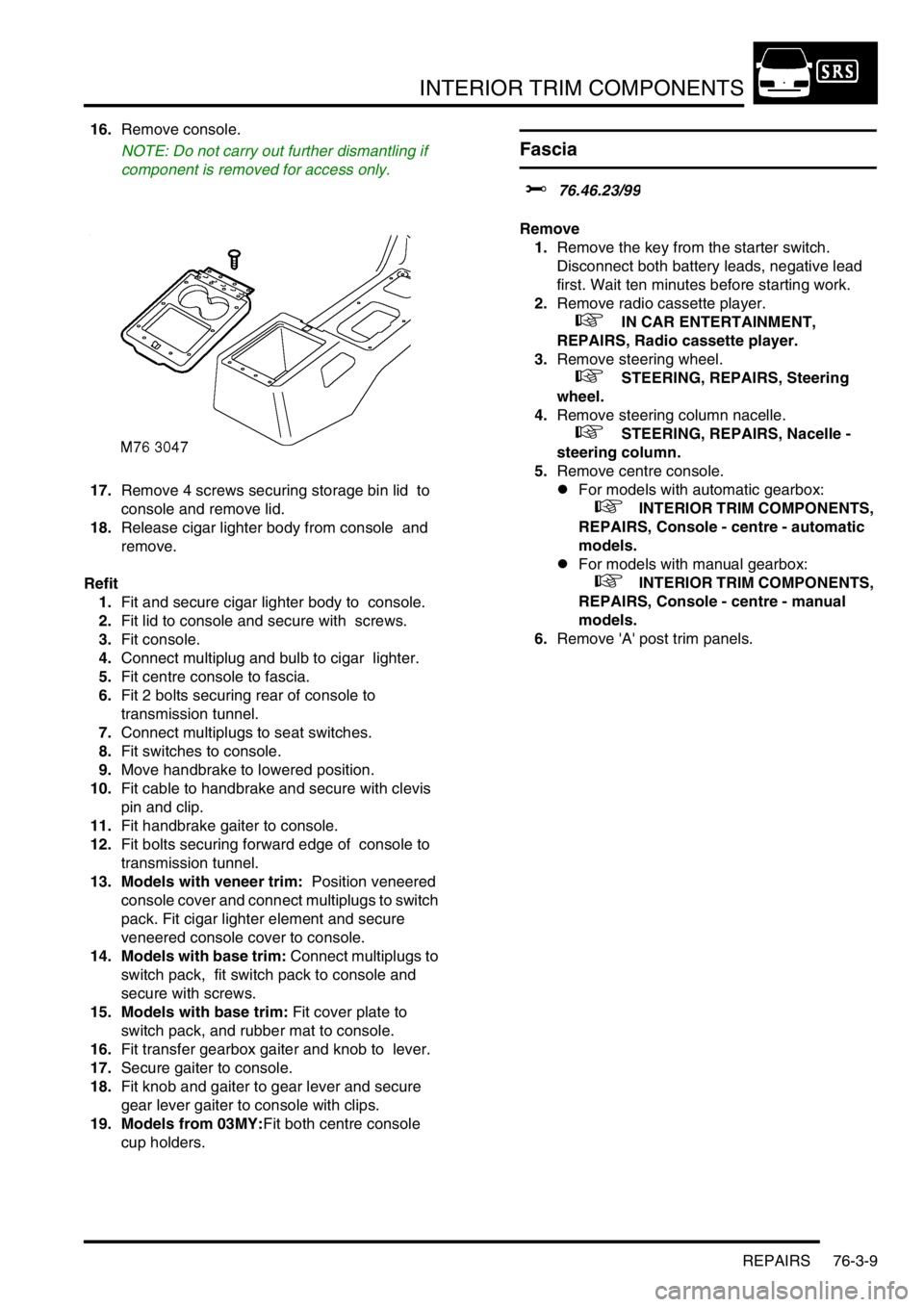

16.Remove console.

NOTE: Do not carry out further dismantling if

component is removed for access only.

17.Remove 4 screws securing storage bin lid to

console and remove lid.

18.Release cigar lighter body from console and

remove.

Refit

1.Fit and secure cigar lighter body to console.

2.Fit lid to console and secure with screws.

3.Fit console.

4.Connect multiplug and bulb to cigar lighter.

5.Fit centre console to fascia.

6.Fit 2 bolts securing rear of console to

transmission tunnel.

7.Connect multiplugs to seat switches.

8.Fit switches to console.

9.Move handbrake to lowered position.

10.Fit cable to handbrake and secure with clevis

pin and clip.

11.Fit handbrake gaiter to console.

12.Fit bolts securing forward edge of console to

transmission tunnel.

13. Models with veneer trim: Position veneered

console cover and connect multiplugs to switch

pack. Fit cigar lighter element and secure

veneered console cover to console.

14. Models with base trim: Connect multiplugs to

switch pack, fit switch pack to console and

secure with screws.

15. Models with base trim: Fit cover plate to

switch pack, and rubber mat to console.

16.Fit transfer gearbox gaiter and knob to lever.

17.Secure gaiter to console.

18.Fit knob and gaiter to gear lever and secure

gear lever gaiter to console with clips.

19. Models from 03MY:Fit both centre console

cup holders.

Fascia

$% 76.46.23/99

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove radio cassette player.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio cassette player.

3.Remove steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

4.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

5.Remove centre console.

lFor models with automatic gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

lFor models with manual gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

6.Remove 'A' post trim panels.

Page 1165 of 1672

INTERIOR TRIM COMPONENTS

76-3-12 REPAIRS

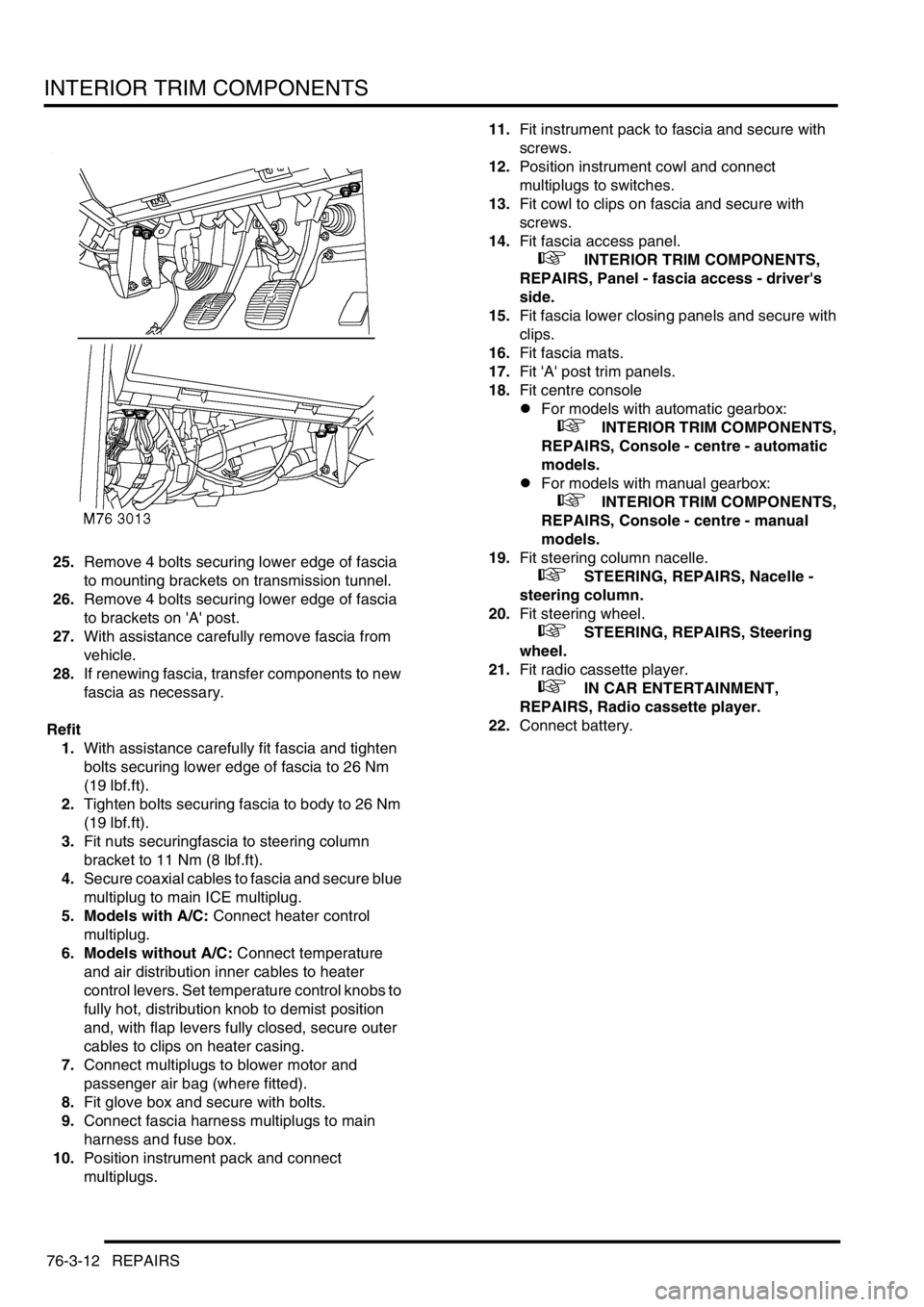

25.Remove 4 bolts securing lower edge of fascia

to mounting brackets on transmission tunnel.

26.Remove 4 bolts securing lower edge of fascia

to brackets on 'A' post.

27.With assistance carefully remove fascia from

vehicle.

28.If renewing fascia, transfer components to new

fascia as necessary.

Refit

1.With assistance carefully fit fascia and tighten

bolts securing lower edge of fascia to 26 Nm

(19 lbf.ft).

2.Tighten bolts securing fascia to body to 26 Nm

(19 lbf.ft).

3.Fit nuts securingfascia to steering column

bracket to 11 Nm (8 lbf.ft).

4.Secure coaxial cables to fascia and secure blue

multiplug to main ICE multiplug.

5. Models with A/C: Connect heater control

multiplug.

6. Models without A/C: Connect temperature

and air distribution inner cables to heater

control levers. Set temperature control knobs to

fully hot, distribution knob to demist position

and, with flap levers fully closed, secure outer

cables to clips on heater casing.

7.Connect multiplugs to blower motor and

passenger air bag (where fitted).

8.Fit glove box and secure with bolts.

9.Connect fascia harness multiplugs to main

harness and fuse box.

10.Position instrument pack and connect

multiplugs.11.Fit instrument pack to fascia and secure with

screws.

12.Position instrument cowl and connect

multiplugs to switches.

13.Fit cowl to clips on fascia and secure with

screws.

14.Fit fascia access panel.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Panel - fascia access - driver's

side.

15.Fit fascia lower closing panels and secure with

clips.

16.Fit fascia mats.

17.Fit 'A' post trim panels.

18.Fit centre console

lFor models with automatic gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

lFor models with manual gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

19.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

20.Fit steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

21.Fit radio cassette player.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio cassette player.

22.Connect battery.

Page 1170 of 1672

INTERIOR TRIM COMPONENTS

REPAIRS 76-3-17

9.Fit drinks tray.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Drink tray assembly - centre

fascia.

10.Fit and secure radio DIN socket.

11.Fit screw cover to radio aperture.

12.Fit radio cassette player.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio cassette player.

Carpet - front

$% 76.49.02

Remove

1. Models with premium ICE: Remove power

amplifier.

+ IN CAR ENTERTAINMENT,

REPAIRS, Amplifier - power.

2. Models with premium ICE: Remove CD

autochanger.

+ IN CAR ENTERTAINMENT,

REPAIRS, CD autochanger.

3.Remove centre console.

lFor models with manual gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

lFor models with automatic gearbox:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

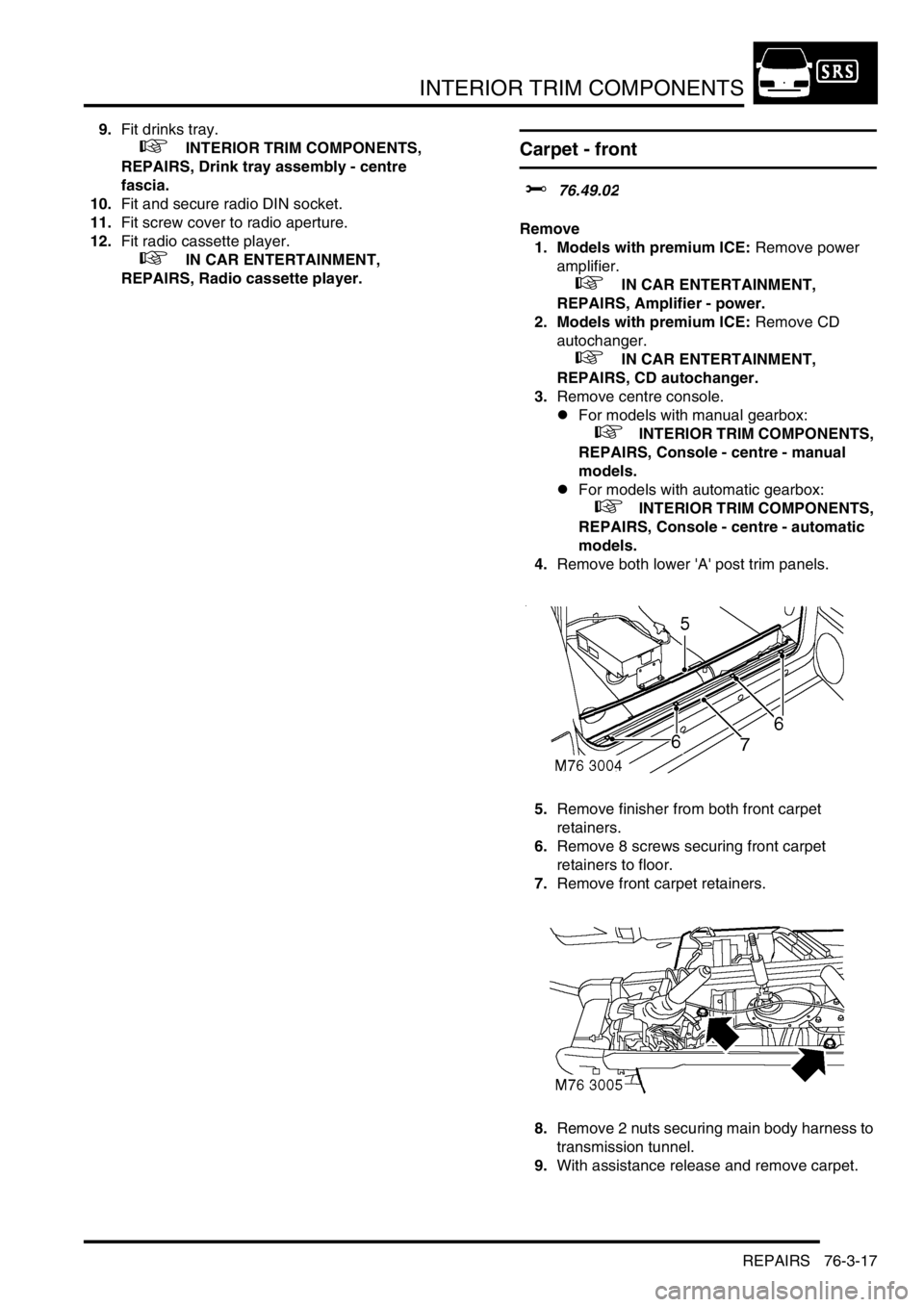

4.Remove both lower 'A' post trim panels.

5.Remove finisher from both front carpet

retainers.

6.Remove 8 screws securing front carpet

retainers to floor.

7.Remove front carpet retainers.

8.Remove 2 nuts securing main body harness to

transmission tunnel.

9.With assistance release and remove carpet.