ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1018 of 1672

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-13

Air supply unit

1Compressor electrical connector

2Electric motor

3Air intake hose

4Compressor

5Air dryer

6Pressure limiting valve

7Exhaust hose

8Exhaust valve electrical connector (black

harness connector)

9Exhaust valve10LH air valve electrical connector (blue harness

connector)

11LH air valve

12LH air spring supply pipe

13Air supply/exhaust pipe

14RH air spring supply pipe

15RH air valve

16RH air valve electrical connector (natural

harness connector)

17Housing

The air supply unit is located in a central position on the outside of the left hand chassis longitudinal. The unit is

contained in a plastic housing attached to the chassis. The housing has a removable lid which is secured with Dzus

fasteners for access to the unit.

Page 1019 of 1672

REAR SUSPENSION

64-14 DESCRIPTION AND OPERATION

The air supply unit comprises a 12 V electric motor, a compressor and air dryer unit, a pressure limiting valve, an

exhaust valve and two air supply control valves. The exhaust and control valves are solenoid operated responding to

signals from the SLABS ECU. The electric motor, compressor, air dryer and pressure limiting and exhaust valve are

mounted on flexible rubber mountings to reduce operating noise.

The electric motor drives a crank with an eccentric pin to which a connecting rod is attached. The connecting rod has

a piston which fits in the bore of the compressor. Operation of the motor rotates the crank, moving the piston in the

bore of the compressor.

The compressor is attached with Allen bolts to the motor housing and sealed with an O-ring. Attached to the

compressor is the air dryer which contains a silicate box for removing moisture from the compressed air. Air supplied

to inflate the air springs passes through the air dryer. When the air springs are deflated, the exhaust air also passes

through the air dryer, removing the moisture from the unit and expelling it to atmosphere.

Attached to end of the air dryer unit is the pressure limiting valve. The valve protects the air springs from over inflation.

The pressure limiting valve also operates when the exhaust valve is opened. The valve is pneumatically operated,

responding to air pressure applied to it.

The exhaust valve is also located with the pressure limiting valve. The exhaust valve is solenoid operated by the ECU

and directs air from the air springs and control valves to atmosphere when required.

The two air control valves for the LH and RH air springs are located at the forward end of the housing. Each valve is

connected to the compressor/air dryer unit through a shared single pipe which directs air to and from the air springs.

Each control valve is individually operated by the ECU.

All air connections to and from the air supply unit are made through the SLS air harness which is located along the

left hand chassis longitudinal.

If faults occur with the air supply unit, fault codes are stored in the SLABS ECU. These fault codes cover the

compressor power supply and the LH and RH air control valves and the exhaust valve. The current and past fault

codes can be retrieved with TestBook. TestBook can also be used to operate the compressor and the valves for

diagnostic purposes.

Air intake filter

The air intake filter is located in the left hand 'E' post, behind the tail lamp assembly. The filter comprises a plastic

moulded housing which contains two filters of differing density to remove particulate matter from the air drawn in by

the compressor. The air intake filter has a pipe which is connected to the SLS air harness by a quick release

connector. The air intake filter must be replaced as an assembly.

Air intake/Exhaust silencer

The air intake/exhaust silencer is located on the outside of the left hand chassis longitudinal, behind the air supply

unit. The silencer is an integral part of the SLS air harness and cannot be serviced individually.

The intake and exhaust air to and from the compressor passes through the silencer. The plastic moulded silencer has

two chambers. One chamber reduces system exhaust noise and the other dampens intake air pulses produced by

the compressor.

Page 1020 of 1672

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-15

Height sensors

1Spacer

2Link end

3Link

4Link end

5Arm

6Sensor body

Two height sensors are located on the outside of each chassis longitudinal forward of the rear axle. Each sensor body

is attached to a fabricated bracket and secured with two screws. The sensor is attached to the top of each radius arm

by an arm, a link and two link ends. The link ends allow articulation of the arm to allow for suspension travel. The lower

link arm is attached to a lug of the top of the radius arm and is secured with a bolt and locknut.

The sensor body and arm are manufactured from moulded nylon. The two link ends are made from natural rubber

and the link is made from mild steel. The rubber link ends allow flexibility of the arm and resistance to damage.

Each sensor is connected to the main chassis harness by a multiplug. The three pin multiplug provides an earth, a 5

V supply voltage and an output signal voltage to the SLABS ECU.

Each sensor operates on the Hall effect principle. A magnet is attached to the shaft and rotates with movement of the

arm. The magnetic flux generated acts on a Hall effect sensor and depending on its position varies the current across

the sensor. This current is measured and amplified and passed to the SLABS ECU as a linear output voltage signal,

which varies depending on the angular position of the sensor. The signal information is processed and the ECU can

determine the vehicle height.

When the sensors are replaced or removed for any reason, a calibration procedure is required to recalibrate the

sensors and the SLABS ECU. The calibration procedure requires the use of TestBook and calibration blocks to set

the axle to chassis height to a known value.

If faults occur with the height sensors, fault codes are stored in the SLABS ECU. The current and past fault codes can

be retrieved with TestBook.

Page 1021 of 1672

REAR SUSPENSION

64-16 DESCRIPTION AND OPERATION

Air springs

1Top plate

2Voss connector

3Air bag

4Piston

On vehicles without SLS, coil springs are used. On vehicles with SLS two air springs are fitted between the chassis

and the rear axle to replace the coil springs. Each air spring is located at its base on a fabricated platform on the rear

axle. The top of the spring locates in a fabricated bracket attached to the outside of each chassis longitudinal.

The plastic base piston is recessed with a boss with two lugs moulded in the centre for attachment to the axle. The

piston is secured by locating the lugs in a slotted hole in the axle platform and rotating the spring through 90

°, locating

the lugs in the slot. The plastic top plate has two grooved pins which locate through holes in the chassis bracket. Two

spring clips locate on the grooved pins and retain the top of the spring in position.

Each air spring comprises a top plate, an air bag and a base piston. The air bag is attached to the top plate and the

piston with crimped rings.

The air bag is made from a fibre reinforced flexible rubber material which allows the spring to expand with air pressure

and deform under load. The top plate comprises the two bonded grooved pins and a female Voss connector in the

centre. The Voss connector allows for the attachment of the air supply pipe from the air supply unit. The piston is also

made from plastic and is shaped to optimise the springs characteristics.

Page 1022 of 1672

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-17

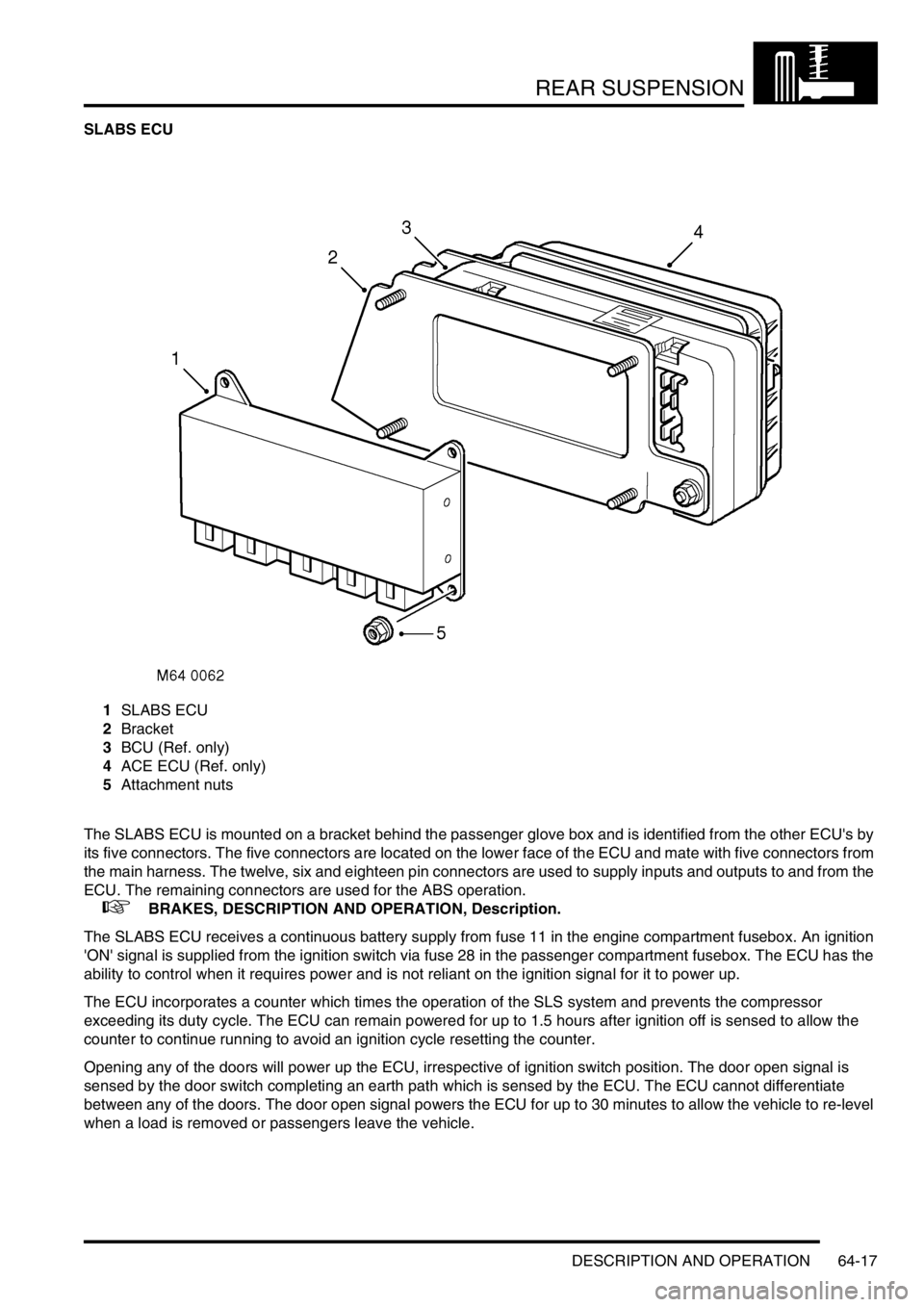

SLABS ECU

1SLABS ECU

2Bracket

3BCU (Ref. only)

4ACE ECU (Ref. only)

5Attachment nuts

The SLABS ECU is mounted on a bracket behind the passenger glove box and is identified from the other ECU's by

its five connectors. The five connectors are located on the lower face of the ECU and mate with five connectors from

the main harness. The twelve, six and eighteen pin connectors are used to supply inputs and outputs to and from the

ECU. The remaining connectors are used for the ABS operation.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

The SLABS ECU receives a continuous battery supply from fuse 11 in the engine compartment fusebox. An ignition

'ON' signal is supplied from the ignition switch via fuse 28 in the passenger compartment fusebox. The ECU has the

ability to control when it requires power and is not reliant on the ignition signal for it to power up.

The ECU incorporates a counter which times the operation of the SLS system and prevents the compressor

exceeding its duty cycle. The ECU can remain powered for up to 1.5 hours after ignition off is sensed to allow the

counter to continue running to avoid an ignition cycle resetting the counter.

Opening any of the doors will power up the ECU, irrespective of ignition switch position. The door open signal is

sensed by the door switch completing an earth path which is sensed by the ECU. The ECU cannot differentiate

between any of the doors. The door open signal powers the ECU for up to 30 minutes to allow the vehicle to re-level

when a load is removed or passengers leave the vehicle.

Page 1023 of 1672

REAR SUSPENSION

64-18 DESCRIPTION AND OPERATION

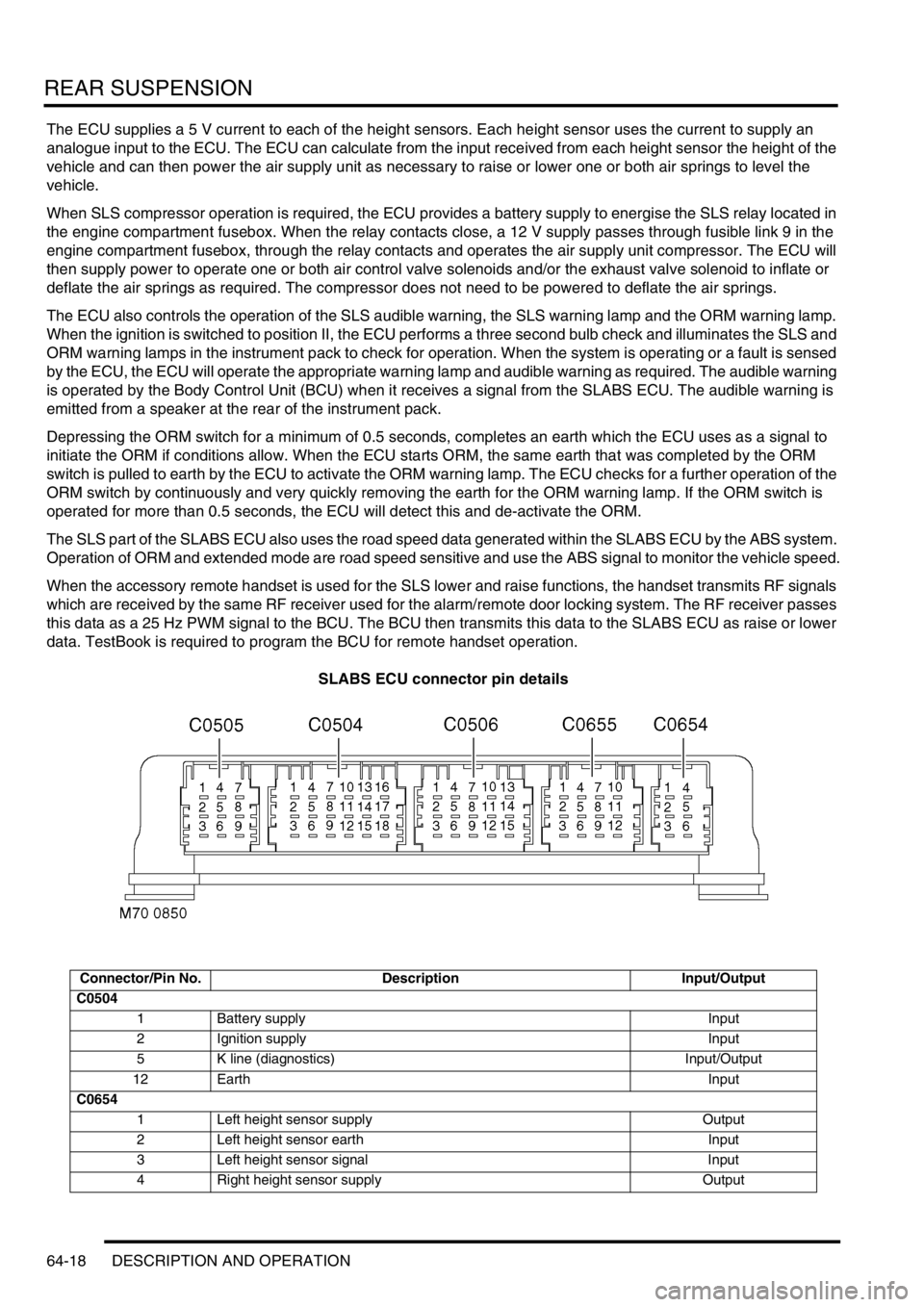

The ECU supplies a 5 V current to each of the height sensors. Each height sensor uses the current to supply an

analogue input to the ECU. The ECU can calculate from the input received from each height sensor the height of the

vehicle and can then power the air supply unit as necessary to raise or lower one or both air springs to level the

vehicle.

When SLS compressor operation is required, the ECU provides a battery supply to energise the SLS relay located in

the engine compartment fusebox. When the relay contacts close, a 12 V supply passes through fusible link 9 in the

engine compartment fusebox, through the relay contacts and operates the air supply unit compressor. The ECU will

then supply power to operate one or both air control valve solenoids and/or the exhaust valve solenoid to inflate or

deflate the air springs as required. The compressor does not need to be powered to deflate the air springs.

The ECU also controls the operation of the SLS audible warning, the SLS warning lamp and the ORM warning lamp.

When the ignition is switched to position II, the ECU performs a three second bulb check and illuminates the SLS and

ORM warning lamps in the instrument pack to check for operation. When the system is operating or a fault is sensed

by the ECU, the ECU will operate the appropriate warning lamp and audible warning as required. The audible warning

is operated by the Body Control Unit (BCU) when it receives a signal from the SLABS ECU. The audible warning is

emitted from a speaker at the rear of the instrument pack.

Depressing the ORM switch for a minimum of 0.5 seconds, completes an earth which the ECU uses as a signal to

initiate the ORM if conditions allow. When the ECU starts ORM, the same earth that was completed by the ORM

switch is pulled to earth by the ECU to activate the ORM warning lamp. The ECU checks for a further operation of the

ORM switch by continuously and very quickly removing the earth for the ORM warning lamp. If the ORM switch is

operated for more than 0.5 seconds, the ECU will detect this and de-activate the ORM.

The SLS part of the SLABS ECU also uses the road speed data generated within the SLABS ECU by the ABS system.

Operation of ORM and extended mode are road speed sensitive and use the ABS signal to monitor the vehicle speed.

When the accessory remote handset is used for the SLS lower and raise functions, the handset transmits RF signals

which are received by the same RF receiver used for the alarm/remote door locking system. The RF receiver passes

this data as a 25 Hz PWM signal to the BCU. The BCU then transmits this data to the SLABS ECU as raise or lower

data. TestBook is required to program the BCU for remote handset operation.

SLABS ECU connector pin details

Connector/Pin No. Description Input/Output

C0504

1 Battery supply Input

2 Ignition supply Input

5 K line (diagnostics) Input/Output

12 EarthInput

C0654

1 Left height sensor supply Output

2 Left height sensor earth Input

3 Left height sensor signal Input

4 Right height sensor supply Output

Page 1025 of 1672

REAR SUSPENSION

64-20 DESCRIPTION AND OPERATION

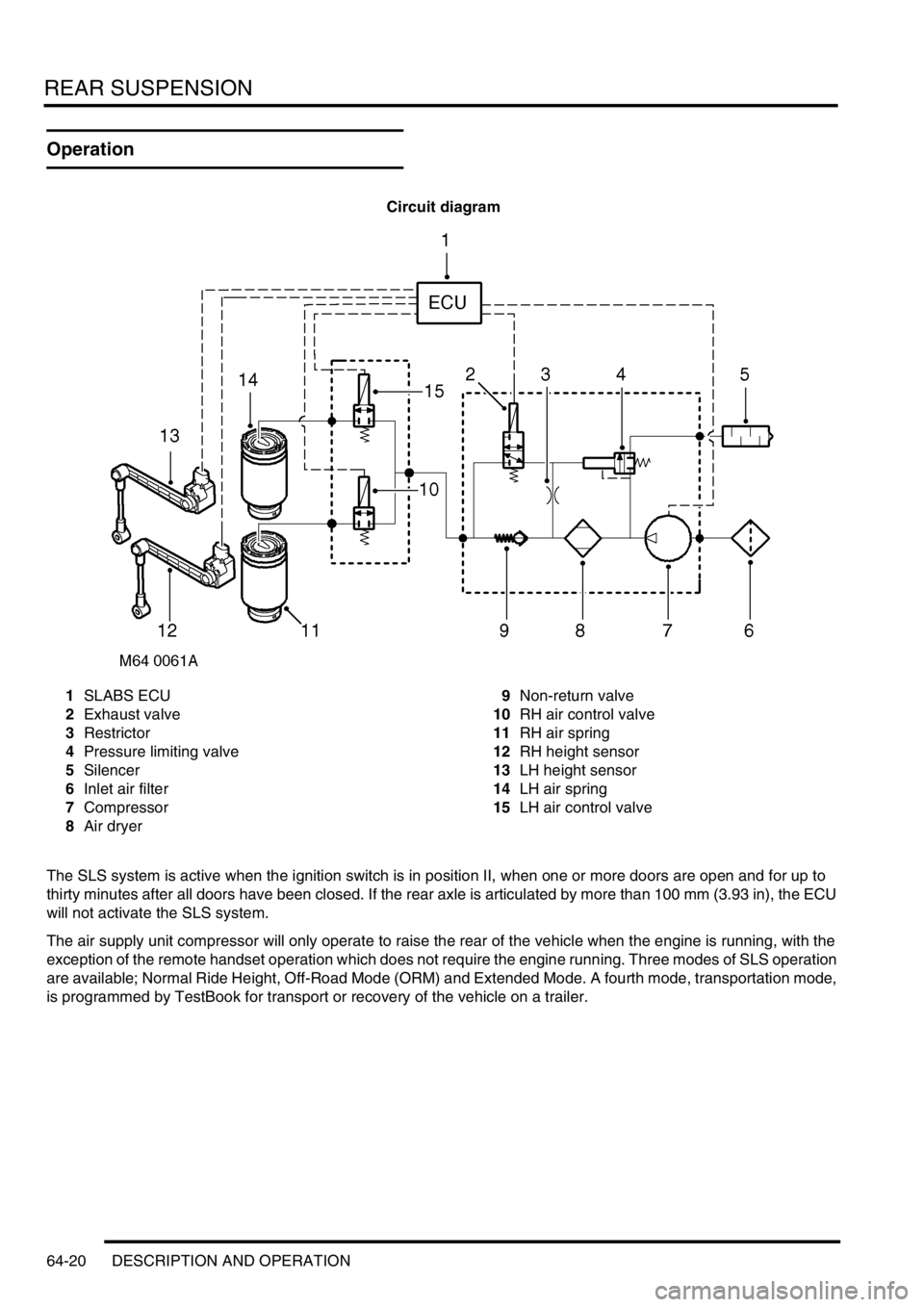

Operation

Circuit diagram

1SLABS ECU

2Exhaust valve

3Restrictor

4Pressure limiting valve

5Silencer

6Inlet air filter

7Compressor

8Air dryer9Non-return valve

10RH air control valve

11RH air spring

12RH height sensor

13LH height sensor

14LH air spring

15LH air control valve

The SLS system is active when the ignition switch is in position II, when one or more doors are open and for up to

thirty minutes after all doors have been closed. If the rear axle is articulated by more than 100 mm (3.93 in), the ECU

will not activate the SLS system.

The air supply unit compressor will only operate to raise the rear of the vehicle when the engine is running, with the

exception of the remote handset operation which does not require the engine running. Three modes of SLS operation

are available; Normal Ride Height, Off-Road Mode (ORM) and Extended Mode. A fourth mode, transportation mode,

is programmed by TestBook for transport or recovery of the vehicle on a trailer.

Page 1026 of 1672

REAR SUSPENSION

DESCRIPTION AND OPERATION 64-21

Normal ride height

When the vehicle is stationary, a door is open and the ignition is off, the SLS system will allow the rear of the vehicle

to lower to within 20 mm of the normal ride height as load is removed from the vehicle. The SLS system will only

operate the compressor to raise the rear of the vehicle when the engine is running, unless requested using the remote

handset.

Off-road mode (ORM)

ORM is used to raise the rear of the vehicle from normal ride height to the ORM ride height of 100 mm between the

tip of the bump stop and the axle.

ORM is activated by depressing the ORM switch located on the fascia for not less than 0.5 seconds. With the engine

running, all doors closed and the vehicle speed below 18 mph (30 km/h), the audible warning will sound once and the

ORM warning lamp in the instrument pack will start to flash when the switch is released. The compressor will be

started and the air control valves will be energised by the ECU to inflate the air springs and raise the rear of the vehicle.

When the full ORM height is reached, the ECU will terminate compressor operation and close the air valves. The ORM

warning lamp will stop flashing and remain continuously illuminated to inform the driver that the SLS system is in ORM.

When ORM is no longer required, depressing the ORM switch for not less than 0.5 seconds with all doors closed will

lower the SLS to normal ride height. The audible warning will sound once and the ORM warning lamp will flash as the

suspension lowers. The ECU energises the air control valves and the exhaust valve to release air pressure from the

air springs. When standard ride height is reached the ORM warning lamp will extinguish and the ECU will de-energise

the air control valves and the exhaust valve solenoids.

If the SLS is in ORM and the vehicle speed exceeds 18 mph (30 km/h), the ECU will lower the SLS to standard ride

height. The driver will be informed of this by an audible warning and the ORM warning lamp flashing as the suspension

lowers. When normal ride height is achieved, the ORM warning lamp will extinguish.

At sea level, the time to change the SLS from normal ride height to ORM or visa versa will take between 15 and 20

seconds.

If the ECU determines that conditions are not correct for SLS operation, i.e.; axle articulation or system fault, the

audible warning will sound three times to inform the driver that the ORM request has not been granted.

Extended mode

The extended mode is automatically operated by the ECU and requires no input from the driver. Extended mode

operates when the chassis is grounded causing the rear wheels to spin. This information is generated by the ABS

function of the SLABS ECU.

When the ECU senses that the chassis is grounded and the vehicle speed is less than 6 mph (10 km/h), the ECU will

operate the compressor and energise the air control valves for 25 seconds to raise the rear of the vehicle. This

operates irrespective of the mode that the SLS system is in at that time. To inform the driver, the ORM warning lamp

will flash continuously at all times that the system is in extended mode.

The driver can exit the extended mode by depressing the ORM switch for not less than 0.5 seconds or by exceeding

8 mph (13 km/h).

Remote handset SLS control

The remote handset is an accessory item which allows the SLS to be operated between normal ride height and bump

stop height to allow easier connection and disconnection of trailers. The remote handset is similar in appearance to

that of the remote door locking handset but does not have an integral key. A circular button with an arrow is used to

raise the SLS and an oval button with the 'Land Rover' logo is used to lower the SLS.

The remote handset control requires all doors to be closed and the ignition to be in position II, but the engine does

not need to be running.

Page 1027 of 1672

REAR SUSPENSION

64-22 DESCRIPTION AND OPERATION

Pressing the lower button will signal the SLABS ECU, via the RF receiver and the BCU, to energise the exhaust valve

and air control valves. The SLS will lower up to 60 mm (2.36 in) below normal ride height if the button is held. If the

button is released the SLS will stop at that point.

Pressing the raise button will signal the SLABS ECU, via the RF receiver and the BCU, to start the compressor and

energise the exhaust valve and air control valves. The SLS will raise to normal ride height if the button is held. If the

button is released the SLS will stop at that point.

When raising or lowering the SLS using the remote handset, the SLS warning lamp will flash and the audible warning

will sound when the system is operating. When the SLS is fully lowered the warning lamp will stay illuminated. The

SLS will reset to normal ride height if the vehicle speed exceeds 3 mph (5 km/h) for 10 seconds when the SLS is

lowered.

Transportation mode

Transportation mode must be used when the vehicle is transported on a trailer and secured by the chassis. The

transportation mode can only be enabled and disabled with TestBook.

The transportation mode lowers the rear suspension onto the bump stops with the engine not running. When the

suspension is in transportation mode, the SLS warning lamp is continuously illuminated when the ignition is in position

II.

When the engine is started in transportation mode, the SLS system will raise the rear suspension until a gap of 25

mm (1 in.) exists between the bump stop and the axle. The SLS warning lamp will flash continuously while the SLS

system is raising the suspension. When the gap between the bump stop and the axle is achieved, the warning lamp

will illuminate continuously.

When TestBook is used to disable the transportation mode, the rear suspension will raise to normal ride height when

the engine is running.

Page 1030 of 1672

REAR SUSPENSION

REPAIRS 64-25

REPAIRS

Wheel hub

$% 64.15.01

Models with SLS:

WARNING: Ensure the air suspension system is

made safe before commencing work. Otherwise

the chassis may lower onto the bump stops

during repair.

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Release stake in drive shaft nut.

4.With an assistant depressing the brake pedal,

remove and discard drive shaft nut.

5.Remove rear brake disc.

+ BRAKES, REPAIRS, Brake disc -

rear.6.Disconnect ABS sensor multiplug.

7.Release harness from brake hose and hose

bracket.

8.Remove 4 bolts securing wheel hub to axle.

9.Release and remove wheel hub and drive shaft

assembly from axle. Remove and discard 'O'

ring from wheel hub.