ABS LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 749 of 1672

TRANSFER BOX - LT230SE

41-16 DESCRIPTION AND OPERATION

Functionality – Vehicles from 03 model year only

The differential lock must be engaged for 2 wheel rolling road testing. It will also be necessary to disconnect the

propeller shaft from the transfer box output shaft driving the axle whose wheels are NOT on the rolling road. In

addition, the ETC system must be deactivated by either, removing a fuse (10A fuse 28 in the passenger compartment

fusebox, labelled ABS) or disconnecting the ABS modulator pump. This must be done with the ignition switched off.

Note that the SLABS ECU may record a system fault.

The lock can be engaged or disengaged using the selector lever. Vehicles not fitted with a differential lock can be

identified by a high/low range selector lever with no differential lock functionality and the cover and selector shaft

(arrowed), not visible on the front output housing.

WARNING: VEHICLES NOT FITTED WITH A DIFFERENTIAL LOCK MUST NOT BE TESTED ON A ROLLING

ROAD WHERE THE ROLLERS ARE DRIVEN BY THE VEHICLE.

Differential lock warning lamp switch - if fitted - Vehicles up to 03 model year

A differential lock warning lamp switch connected to the SLABS ECU and operated by movement of the selector fork

and shaft is screwed into the top of the output housing. The switch connects to earth when the differential lock is

engaged.

Differential lock warning lamp switches - if fitted - Vehicles from 03 model year

Vehicles from 03 model year are fitted with two differential lock warning lamp switches.

One switch is of a new design and is fitted into the top of the front output housing in the same position as on previous

models. The switch is connected to the SLABS ECU and is operated by movement of the selector fork and shaft.

The second switch is located in a threaded hole on the forward face of the front output housing. The switch is also

connected to the SLABS ECU and is operated by movement of the selector shaft.

Both switches have an aluminium washer which seals the switch to the casing and also sets the switch position,

removing the requirement for a setting procedure.

Both switches are connected in parallel to earth when the differential lock is engaged. This earth is sensed by the

SLABS ECU which illuminates the differential lock warning lamp in the instrument pack.

Differential lock warning lamp - Vehicles up to 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a warning to the driver when the

ignition is switched on that the differential lock is engaged. The warning lamp illuminates in a Red colour.

With the lock engaged, the traction control and electronic brake distribution warning lamps will also be illuminated.

Disengagement of the differential lock should be carried out with the ignition switched off. The warning lamps must

be extinguished when the ignition is switched on again.

Differential lock warning lamp – vehicles from 03 model year – if fitted

The differential lock warning lamp is located in the instrument pack and provides a visual warning to the driver, when

the ignition is on, the differential lock is engaged. The warning lamp illuminates in an amber colour.

When the lock is engaged, the warning lamp is illuminated and the instrument pack sounder emits three audible

chimes. When the lock is disengaged, the warning lamp is extinguished and the instrument pack sounder emits three

audible chimes.

Rear output housing

The rear output housing carries the output shaft and flange. A cable operated transmission brake is attached to the

housing, the brake drum being attached to the output flange.

The rear output shaft is supported in the housing by a single bearing and is splined into the differential rear sun gear.

Page 809 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-12 DESCRIPTION AND OPERATION

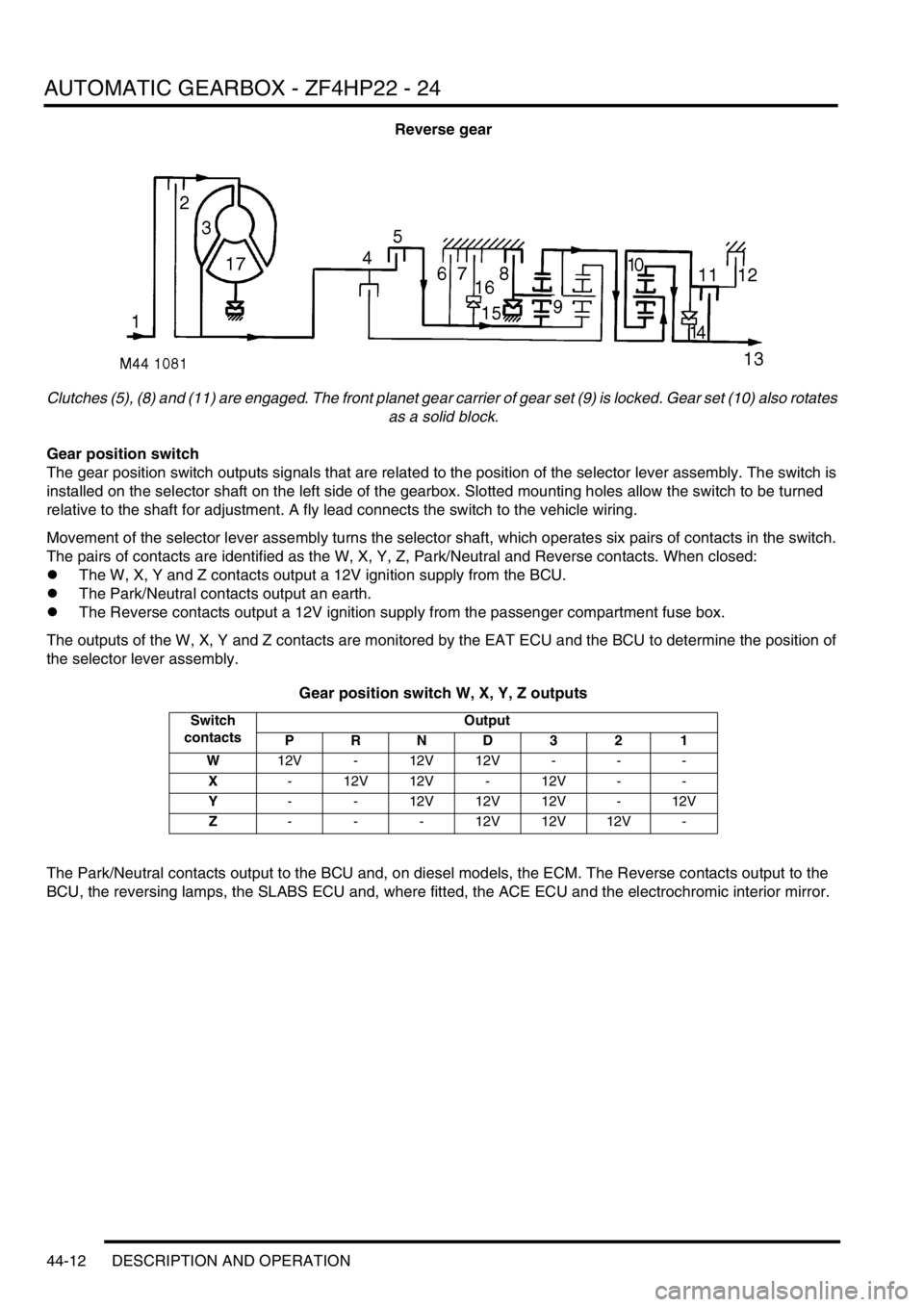

Reverse gear

Clutches (5), (8) and (11) are engaged. The front planet gear carrier of gear set (9) is locked. Gear set (10) also rotates

as a solid block.

Gear position switch

The gear position switch outputs signals that are related to the position of the selector lever assembly. The switch is

installed on the selector shaft on the left side of the gearbox. Slotted mounting holes allow the switch to be turned

relative to the shaft for adjustment. A fly lead connects the switch to the vehicle wiring.

Movement of the selector lever assembly turns the selector shaft, which operates six pairs of contacts in the switch.

The pairs of contacts are identified as the W, X, Y, Z, Park/Neutral and Reverse contacts. When closed:

lThe W, X, Y and Z contacts output a 12V ignition supply from the BCU.

lThe Park/Neutral contacts output an earth.

lThe Reverse contacts output a 12V ignition supply from the passenger compartment fuse box.

The outputs of the W, X, Y and Z contacts are monitored by the EAT ECU and the BCU to determine the position of

the selector lever assembly.

Gear position switch W, X, Y, Z outputs

The Park/Neutral contacts output to the BCU and, on diesel models, the ECM. The Reverse contacts output to the

BCU, the reversing lamps, the SLABS ECU and, where fitted, the ACE ECU and the electrochromic interior mirror.

Switch

contactsOutput

PRND 3 2 1

W12V - 12V 12V - - -

X- 12V 12V - 12V - -

Y- - 12V 12V 12V - 12V

Z- - - 12V 12V 12V -

Page 842 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-45

Filter - oil

$% 44.24.07

Remove

1.Remove oil sump gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - oil sump.

2.Remove Torx screw securing oil pick-up tube

and remove tube.

3.Remove 2 Torx screws securing filter to valve

body and discard 'O' rings.

Refit

1.Clean filter and pick-up tube using a lint free

cloth.

2.Fit new 'O' rings to filter.

3.Position filter and tighten Torx screws to 8 Nm

(6 lbf.ft).

4.Position oil pick-up tube and tighten Torx

screw to 8 Nm (6 lbf.ft).

5.Fit oil sump gasket.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gasket - oil sump.

Cooler - fluid - Td5

$% 44.24.10

Remove

1.Remove intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

2.Disconnect fluid temperature sensor multiplug.

3.Position absorbent cloth under each gearbox

cooler hose connection to collect spillage.

4.Push against coupling release ring and

disconnect both fluid hoses from cooler.

5.Remove screw and release cooler from

radiator.

6.Carefully remove cooler.

Page 843 of 1672

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-46 REPAIRS

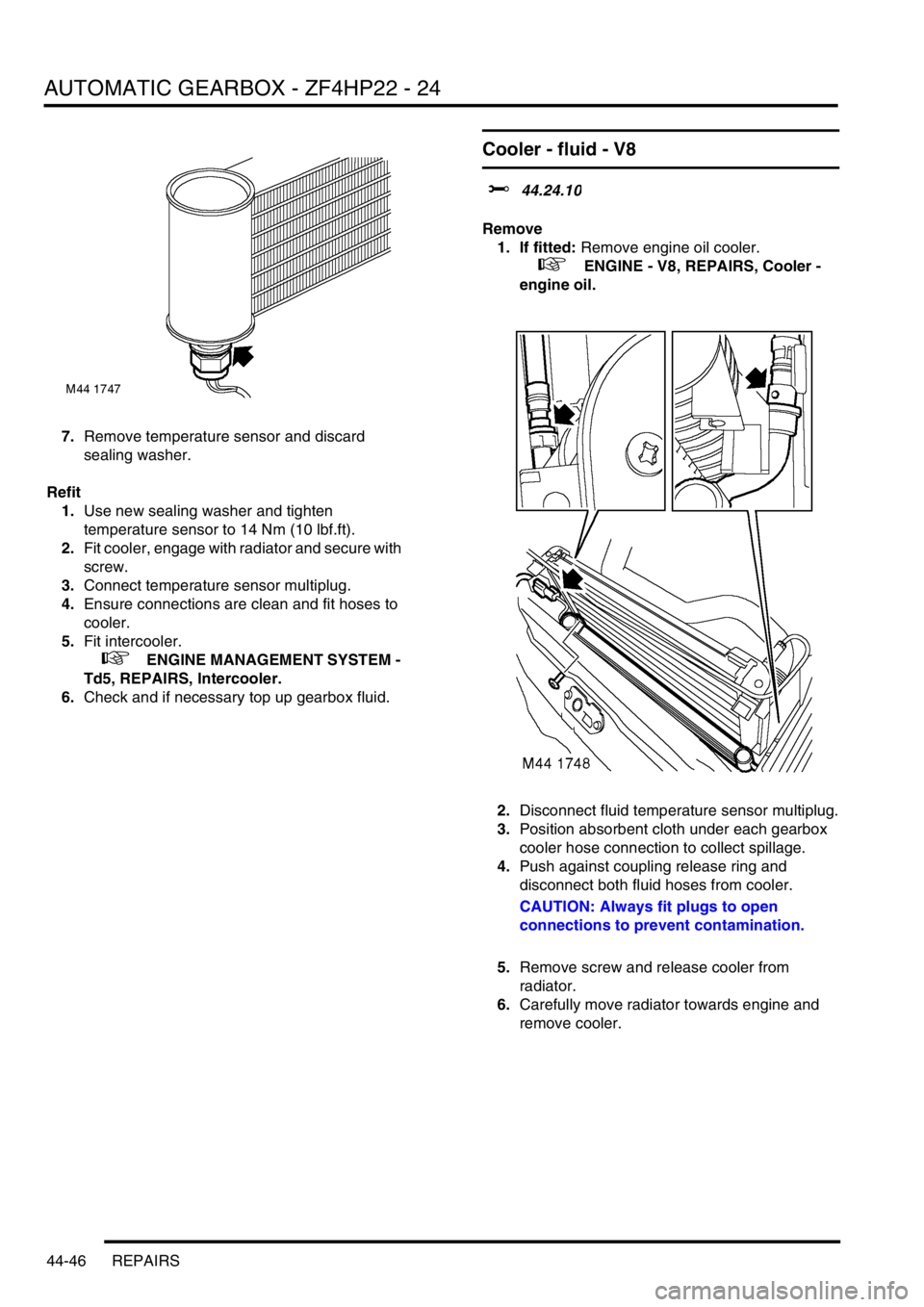

7.Remove temperature sensor and discard

sealing washer.

Refit

1.Use new sealing washer and tighten

temperature sensor to 14 Nm (10 lbf.ft).

2.Fit cooler, engage with radiator and secure with

screw.

3.Connect temperature sensor multiplug.

4.Ensure connections are clean and fit hoses to

cooler.

5.Fit intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

6.Check and if necessary top up gearbox fluid.

Cooler - fluid - V8

$% 44.24.10

Remove

1. If fitted: Remove engine oil cooler.

+ ENGINE - V8, REPAIRS, Cooler -

engine oil.

2.Disconnect fluid temperature sensor multiplug.

3.Position absorbent cloth under each gearbox

cooler hose connection to collect spillage.

4.Push against coupling release ring and

disconnect both fluid hoses from cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove screw and release cooler from

radiator.

6.Carefully move radiator towards engine and

remove cooler.

Page 862 of 1672

REAR AXLE

DESCRIPTION AND OPERATION 51-3

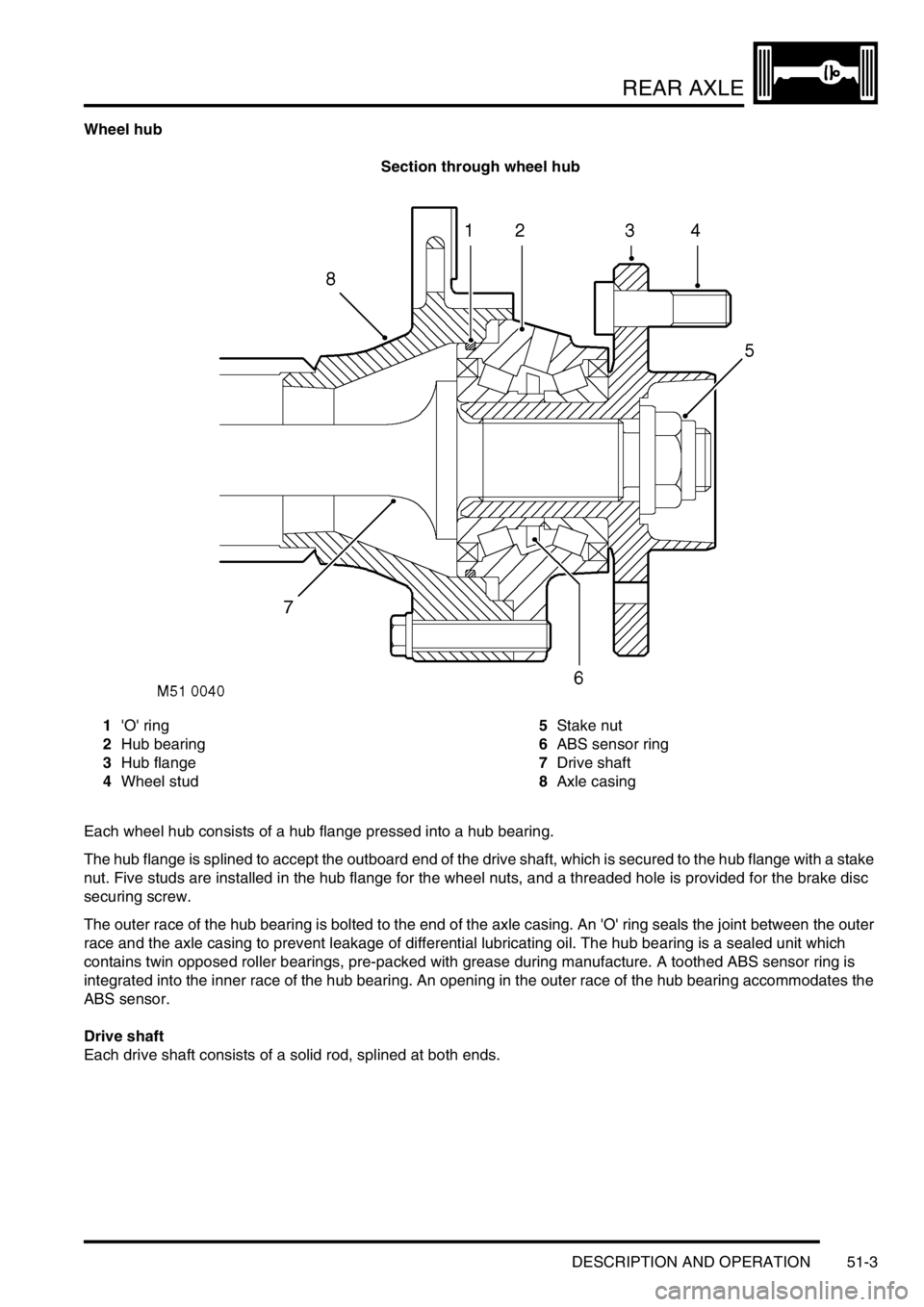

Wheel hub

Section through wheel hub

1'O' ring

2Hub bearing

3Hub flange

4Wheel stud5Stake nut

6ABS sensor ring

7Drive shaft

8Axle casing

Each wheel hub consists of a hub flange pressed into a hub bearing.

The hub flange is splined to accept the outboard end of the drive shaft, which is secured to the hub flange with a stake

nut. Five studs are installed in the hub flange for the wheel nuts, and a threaded hole is provided for the brake disc

securing screw.

The outer race of the hub bearing is bolted to the end of the axle casing. An 'O' ring seals the joint between the outer

race and the axle casing to prevent leakage of differential lubricating oil. The hub bearing is a sealed unit which

contains twin opposed roller bearings, pre-packed with grease during manufacture. A toothed ABS sensor ring is

integrated into the inner race of the hub bearing. An opening in the outer race of the hub bearing accommodates the

ABS sensor.

Drive shaft

Each drive shaft consists of a solid rod, splined at both ends.

Page 864 of 1672

REAR AXLE

REPAIRS 51-5

REPAIRS

Differential - assembly

$% 51.15.01

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Drain oil from differential.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

3.If same components are to be refitted,

reference mark propeller shaft and mating

components.

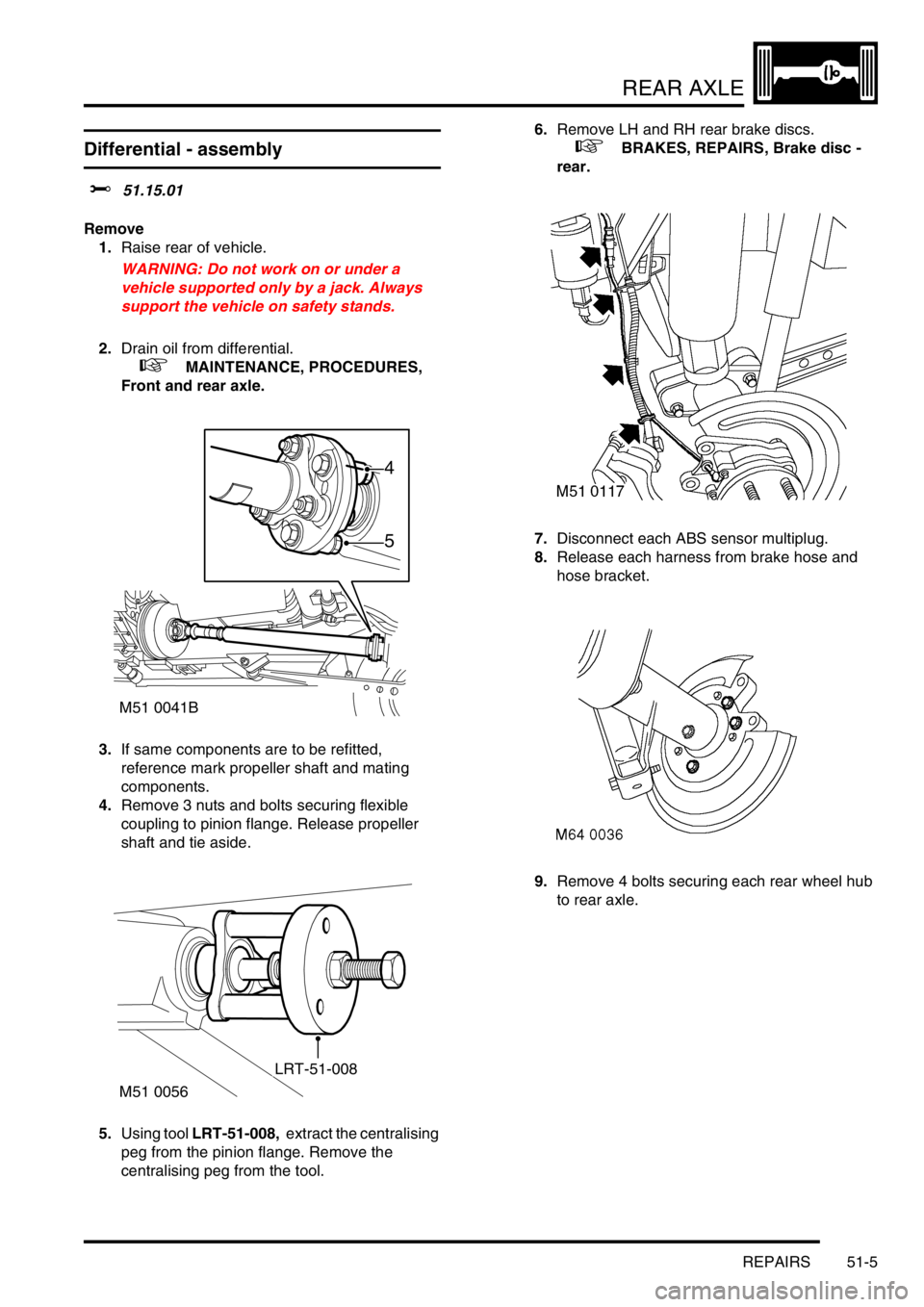

4.Remove 3 nuts and bolts securing flexible

coupling to pinion flange. Release propeller

shaft and tie aside.

5.Using tool LRT-51-008, extract the centralising

peg from the pinion flange. Remove the

centralising peg from the tool.6.Remove LH and RH rear brake discs.

+ BRAKES, REPAIRS, Brake disc -

rear.

7.Disconnect each ABS sensor multiplug.

8.Release each harness from brake hose and

hose bracket.

9.Remove 4 bolts securing each rear wheel hub

to rear axle.

M51 0041B

5

4

M51 0056

LRT-51-008

Page 865 of 1672

REAR AXLE

51-6 REPAIRS

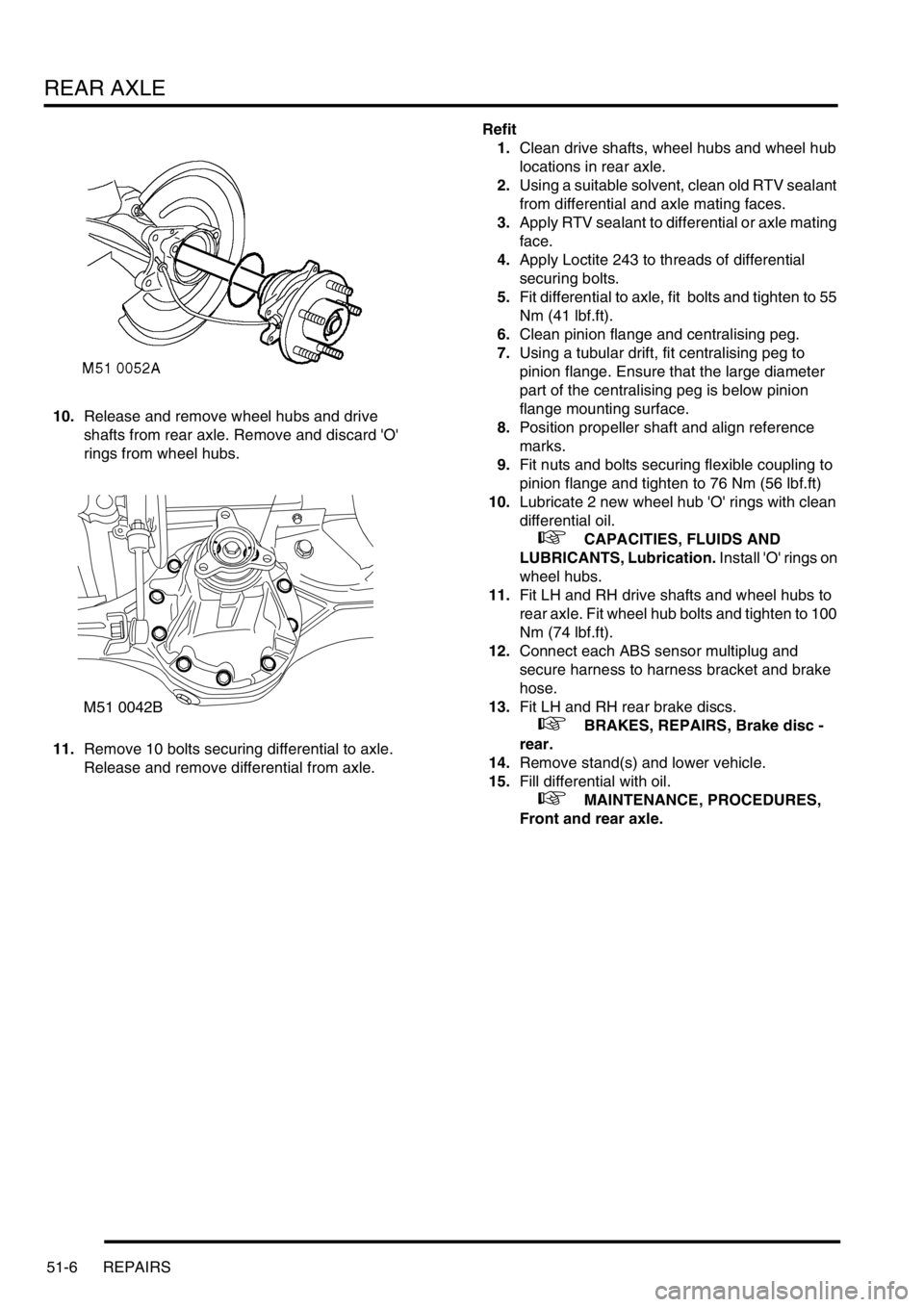

10.Release and remove wheel hubs and drive

shafts from rear axle. Remove and discard 'O'

rings from wheel hubs.

11.Remove 10 bolts securing differential to axle.

Release and remove differential from axle. Refit

1.Clean drive shafts, wheel hubs and wheel hub

locations in rear axle.

2.Using a suitable solvent, clean old RTV sealant

from differential and axle mating faces.

3.Apply RTV sealant to differential or axle mating

face.

4.Apply Loctite 243 to threads of differential

securing bolts.

5.Fit differential to axle, fit bolts and tighten to 55

Nm (41 lbf.ft).

6.Clean pinion flange and centralising peg.

7.Using a tubular drift, fit centralising peg to

pinion flange. Ensure that the large diameter

part of the centralising peg is below pinion

flange mounting surface.

8.Position propeller shaft and align reference

marks.

9.Fit nuts and bolts securing flexible coupling to

pinion flange and tighten to 76 Nm (56 lbf.ft)

10.Lubricate 2 new wheel hub 'O' rings with clean

differential oil.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication. Install 'O' rings on

wheel hubs.

11.Fit LH and RH drive shafts and wheel hubs to

rear axle. Fit wheel hub bolts and tighten to 100

Nm (74 lbf.ft).

12.Connect each ABS sensor multiplug and

secure harness to harness bracket and brake

hose.

13.Fit LH and RH rear brake discs.

+ BRAKES, REPAIRS, Brake disc -

rear.

14.Remove stand(s) and lower vehicle.

15.Fill differential with oil.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

M51 0042B

Page 876 of 1672

FRONT AXLE

DESCRIPTION AND OPERATION 54-3

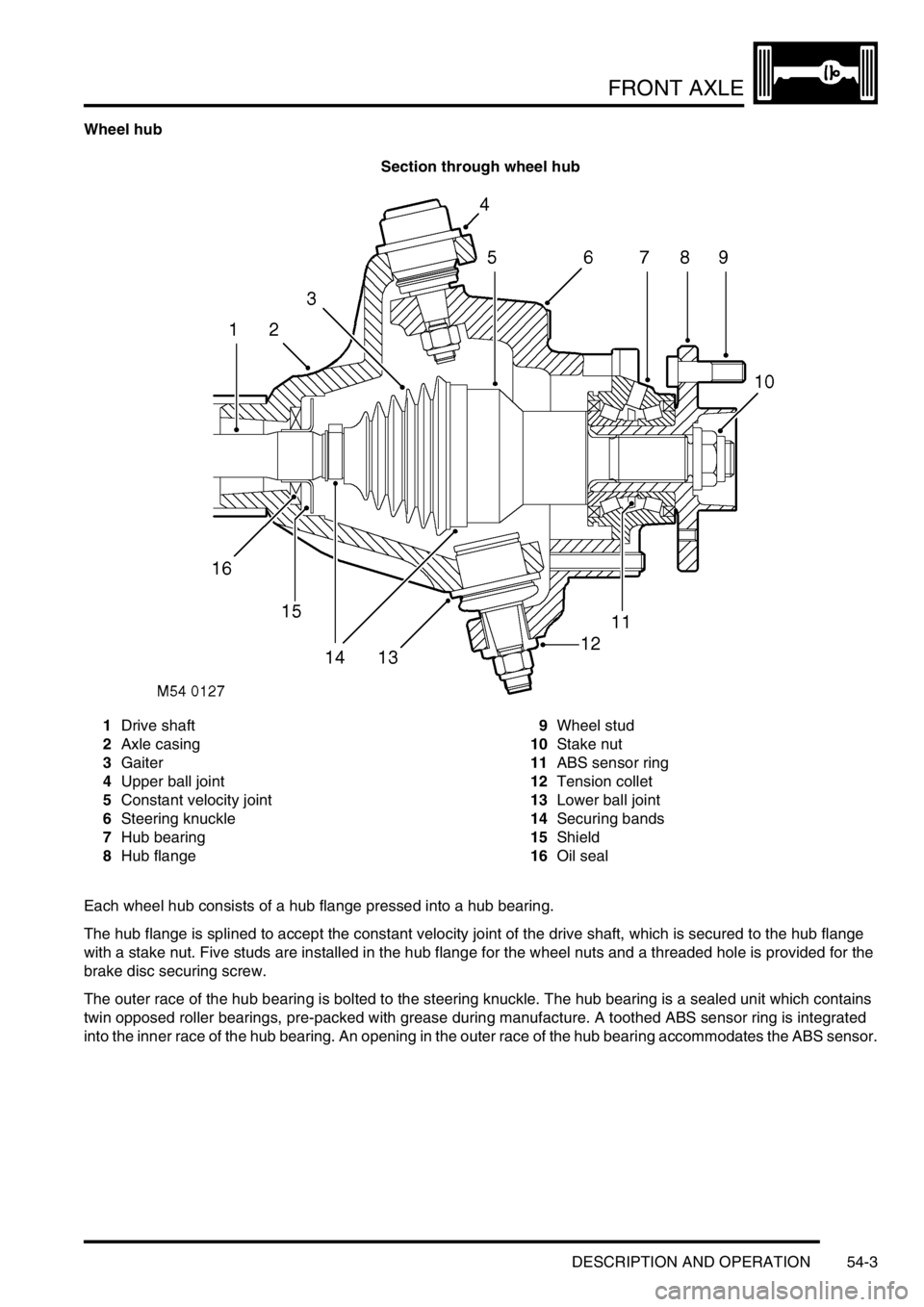

Wheel hub

Section through wheel hub

1Drive shaft

2Axle casing

3Gaiter

4Upper ball joint

5Constant velocity joint

6Steering knuckle

7Hub bearing

8Hub flange9Wheel stud

10Stake nut

11ABS sensor ring

12Tension collet

13Lower ball joint

14Securing bands

15Shield

16Oil seal

Each wheel hub consists of a hub flange pressed into a hub bearing.

The hub flange is splined to accept the constant velocity joint of the drive shaft, which is secured to the hub flange

with a stake nut. Five studs are installed in the hub flange for the wheel nuts and a threaded hole is provided for the

brake disc securing screw.

The outer race of the hub bearing is bolted to the steering knuckle. The hub bearing is a sealed unit which contains

twin opposed roller bearings, pre-packed with grease during manufacture. A toothed ABS sensor ring is integrated

into the inner race of the hub bearing. An opening in the outer race of the hub bearing accommodates the ABS sensor.

Page 878 of 1672

FRONT AXLE

REPAIRS 54-5

REPAIRS

Differential - assembly

$% 54.10.01

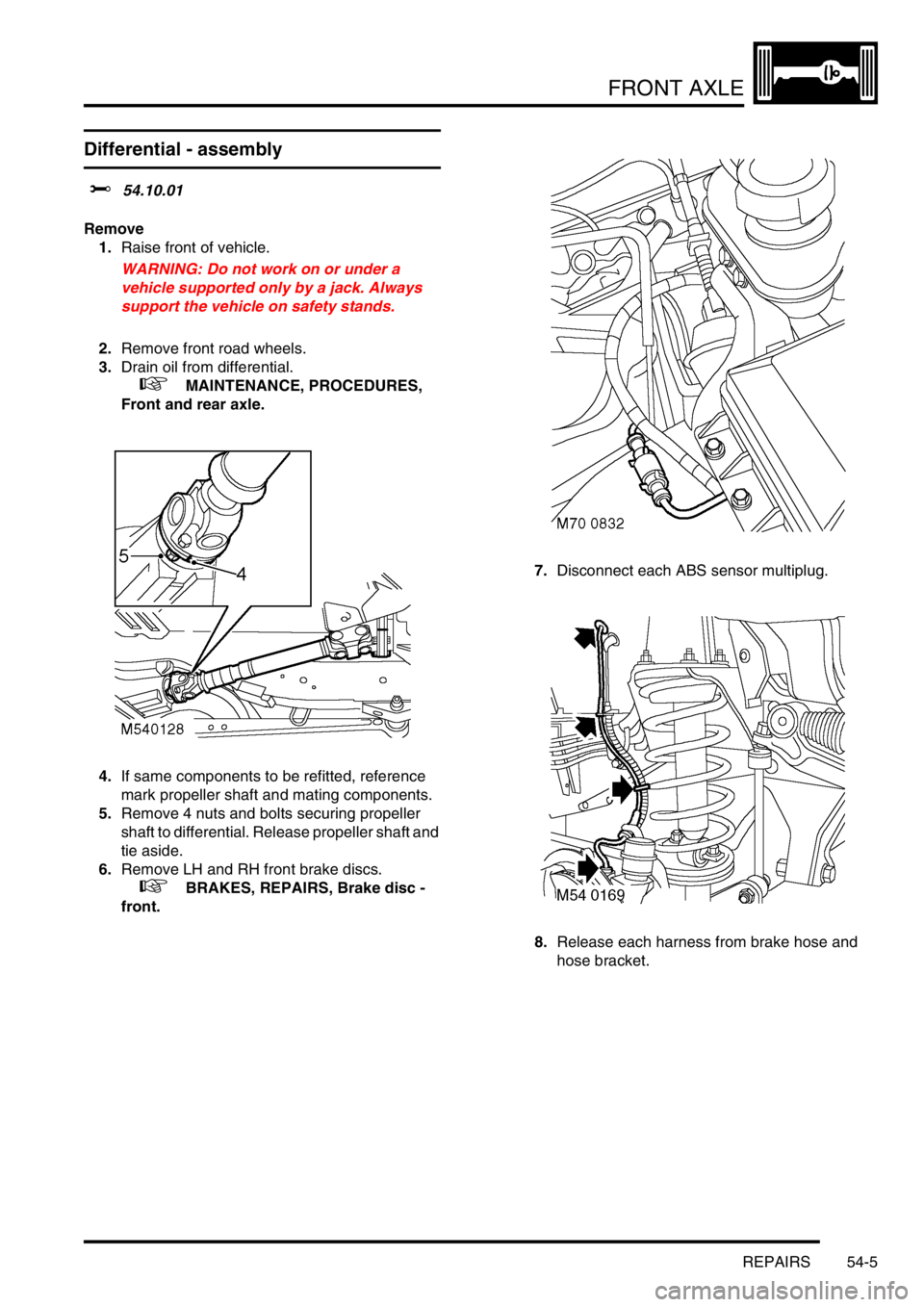

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheels.

3.Drain oil from differential.

+ MAINTENANCE, PROCEDURES,

Front and rear axle.

4.If same components to be refitted, reference

mark propeller shaft and mating components.

5.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

6.Remove LH and RH front brake discs.

+ BRAKES, REPAIRS, Brake disc -

front.7.Disconnect each ABS sensor multiplug.

8.Release each harness from brake hose and

hose bracket.

Page 879 of 1672

FRONT AXLE

54-6 REPAIRS

9.Remove 4 bolts securing each front wheel hub

to front axle.

10.Release wheel hubs from front axle. Remove

wheel hubs and drive shafts from front axle.

11.Remove oil seal from axle casing.

12.Remove 10 bolts securing differential to axle

casing. Release and remove differential from

axle casing.Refit

1.Clean drive shaft oil seal recess, oil seal

running surface, wheel hub and axle mating

faces.

2.Using a suitable solvent, clean old RTV sealant

from differential and axle mating faces.

3.Apply RTV sealant to differential or axle mating

face.

4.Apply Loctite 243 to threads of differential

securing bolts.

5.Fit differential to axle, fit bolts and tighten to 55

Nm (41 lbf.ft).

6.Position propeller shaft and align reference

marks. Fit bolts and tighten to 47 Nm (35 lbf.ft).

7.Lubricate oil seal lip and running surface with

clean differential oil.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Lubrication.

8.Using LRT-54-012 and LRT-99-003, fit new

drive shaft oil seal to axle casing.

9.Apply anti-seize compound to wheel hub and

steering knuckle mating faces.

10.Ensure ABS harnesses are located in cut out in

steering knuckles.

11.Fit drive shafts in axle casing and align wheel

hubs with steering knuckles. Fit wheel hub bolts

and tighten to 100 Nm (74 lbf.ft).

12.Connect each ABS sensor multiplug and

secure harness to harness bracket and brake

hose.