oil LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 144 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-5

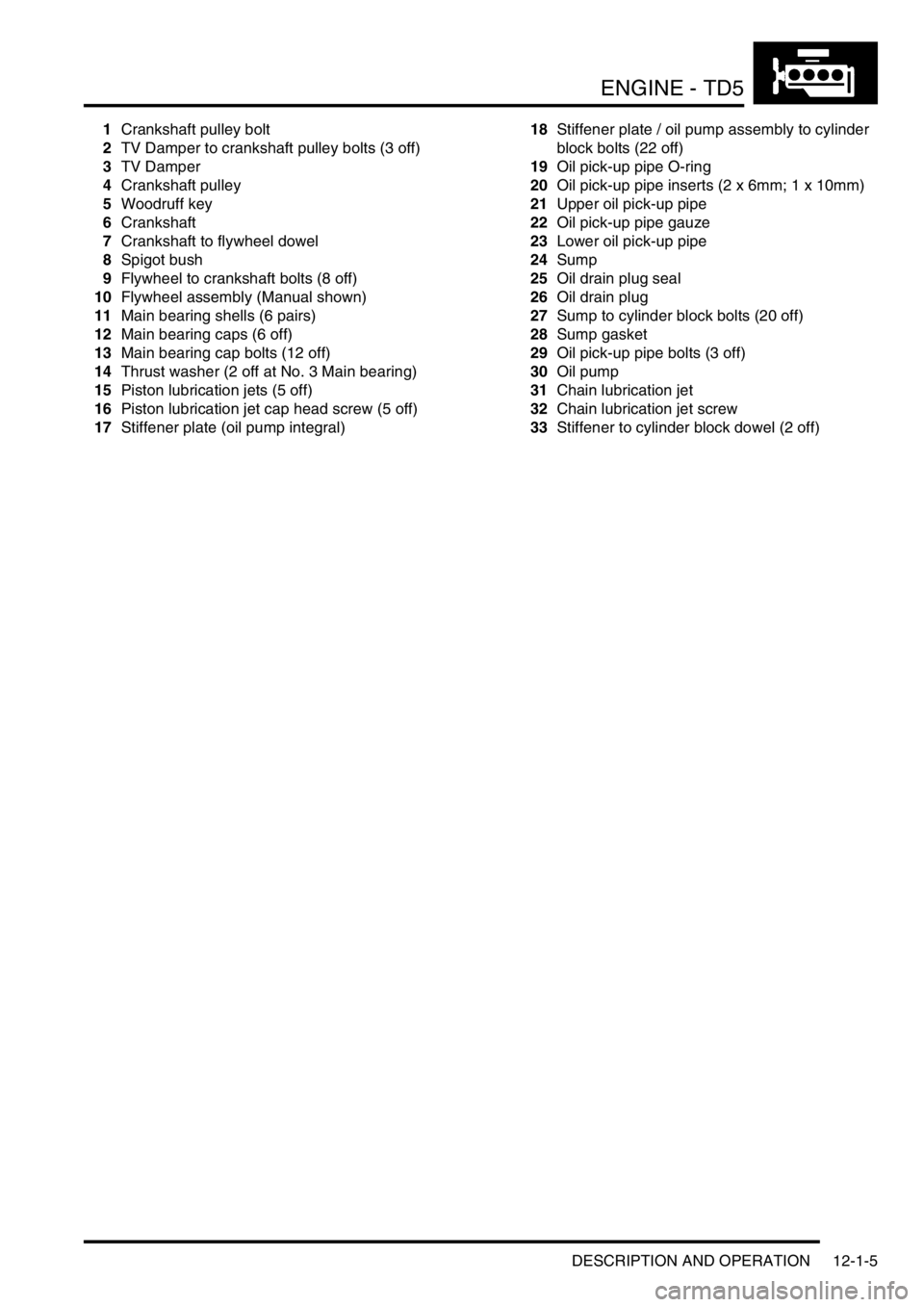

1Crankshaft pulley bolt

2TV Damper to crankshaft pulley bolts (3 off)

3TV Damper

4Crankshaft pulley

5Woodruff key

6Crankshaft

7Crankshaft to flywheel dowel

8Spigot bush

9Flywheel to crankshaft bolts (8 off)

10Flywheel assembly (Manual shown)

11Main bearing shells (6 pairs)

12Main bearing caps (6 off)

13Main bearing cap bolts (12 off)

14Thrust washer (2 off at No. 3 Main bearing)

15Piston lubrication jets (5 off)

16Piston lubrication jet cap head screw (5 off)

17Stiffener plate (oil pump integral)18Stiffener plate / oil pump assembly to cylinder

block bolts (22 off)

19Oil pick-up pipe O-ring

20Oil pick-up pipe inserts (2 x 6mm; 1 x 10mm)

21Upper oil pick-up pipe

22Oil pick-up pipe gauze

23Lower oil pick-up pipe

24Sump

25Oil drain plug seal

26Oil drain plug

27Sump to cylinder block bolts (20 off)

28Sump gasket

29Oil pick-up pipe bolts (3 off)

30Oil pump

31Chain lubrication jet

32Chain lubrication jet screw

33Stiffener to cylinder block dowel (2 off)

Page 148 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-9

1Acoustic cover

2Oil filler flap

3Rear acoustic cover

4Rear acoustic cover inserts (2 off)

5Rear acoustic cover grommets (2 off)

6Rear acoustic cover screws (2 off)

7Acoustic cover grommets (3 off)

8Acoustic cover bolts (3 off)

9Camshaft cover isolators (13 off)

10Camshaft cover flange screws (13 off)

11Breather hose clip

12Breather hose

13Breather hose to breather valve clip

14Breather valve

15Camshaft cover seal

16Oil separator plate

17Oil separator plate gasket

18Camshaft cover

19Acoustic cover to camshaft cover seal

20Oil filler cap and seal

Page 150 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-11

1Vacuum pump stub pipe

2Cylinder head to timing chain cover bolt

3Cylinder head to timing chain cover nut

4Cylinder head to timing chain cover stud

5Tensioner assembly pivot screw

6Tensioner adjuster

7Tensioner arm assembly

8Duplex timing chain – crankshaft to camshaft

sprocket

9Camshaft sprocket bolts (3 off)

10Camshaft sprocket

11Fixed chain guide

12Fixed guide pin

13Fixed chain guide to cylinder block screws

14Oil pump drive chain

15Oil pump sprocket

16Oil pump sprocket screw

17Crankshaft sprockets

18Bearing to viscous fan shaft

19Viscous fan to cover bearing

20Circlip

21Hub – viscous fan to bearing flange

22Timing chain cover

23Timing chain cover to crankshaft seal

24Timing cover to cylinder head screws (8 off)

Page 151 of 1672

ENGINE - TD5

12-1-12 DESCRIPTION AND OPERATION

Description

General

The Td5 diesel engine is a 2.5 litre, 5 cylinder, in-line direct injection unit having 2 valves per cylinder, operated by a

single overhead camshaft. The engine emissions, on pre EU3 models, comply with ECD2 (European Commission

Directive) and on EU3 models, comply with ECD3 legislative requirements. Both models employ electronic engine

management control, positive crankcase ventilation and exhaust gas recirculation to limit the emission of pollutants.

The unit is water cooled and turbo-charged and is controlled by an electronic engine management system.

The engine is a monobloc cast iron construction with an aluminium stiffening plate fitted to the bottom of the cylinder

block to improve lower structure rigidity. The cylinder head and sump are cast aluminium. An acoustic cover is fitted

over the upper engine to reduce engine generated noise.

The engine utilises the following features:

lElectronic Unit Injectors (EUI's) controlled by an Engine Management System for precise fuel delivery under

all prevailing operating conditions.

lTurbocharging which delivers compressed air to the combustion chambers via an intercooler for improved

power output.

lFuel Cooler

lOil Cooler

lCentrifuge Oil Filter

lHydraulic Lash Adjusters with independent finger followers

Cylinder block components

The cylinder block components are described below:

Cylinder Block

The cylinders and crankcase are contained in a single cast iron construction. The cylinders are direct bored and

plateau honed with lubrication oil supplied via lubrication jets for piston and gudgeon pin lubrication and cooling. It is

not possible to rebore the cylinder block if the cylinders become worn or damaged. Three metal core plugs are fitted

to the three centre cylinders on the right hand side of the cylinder block.

Lubrication oil is distributed throughout the block via the main oil gallery to critical moving parts through channels

bored in the block which divert oil to the main and big-end bearings via oil holes machined into the crankshaft. Oil is

also supplied from the cylinder block main gallery to the five lubrication jets which cool and lubricate the piston and

gudgeon pins. Plugs are used to seal both ends of the main oil gallery at front and rear of the engine block. An oil

cooler is fitted to the LH side of the engine block; ports in the oil cooler assembly mate with ports in the cylinder block

to facilitate coolant flow. Oil is diverted through the oil cooler, centrifuge filter and full-flow filter before supplying the

main oil gallery. A tapping in the oil filter housing provides a lubrication source for the turbocharger bearings and an

oil pressure switch is included in a tapping in the oil cooler housing which determines whether sufficient oil pressure

is available to provide engine lubrication and cooling.

Cylinder cooling is achieved by water circulating through chambers in the engine block casting. A threaded coolant

jacket plug is located at the front RH side of the cylinder block.

Cast mounting brackets are bolted to both sides of the engine block for mounting the engine to the chassis on the LH

and RH hydramount studs.

The gearbox bolts directly to the engine block; a gearbox shim plate is located between the adjoining faces of the

gearbox and the flywheel side of the engine block and is fixed to the rear of the engine block by two bolts. Two hollow

metal dowels locate the rear of the cylinder block to the gearbox shim plate. The gearbox casing provides the

mounting for the starter motor.

A port is included at the rear left hand side of the cylinder block which connects to the turbocharger oil drain pipe to

return lubrication oil to the sump.

A plug sealing the lubrication cross-drilling gallery is located at the front right hand side of the cylinder block and plugs

for the main lubrication gallery is included at the front and rear of the cylinder block.

Page 152 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-13

Two plastic dowels are used to locate the cylinder head to the cylinder block and must be replaced every time the

cylinder head is removed from the cylinder block.

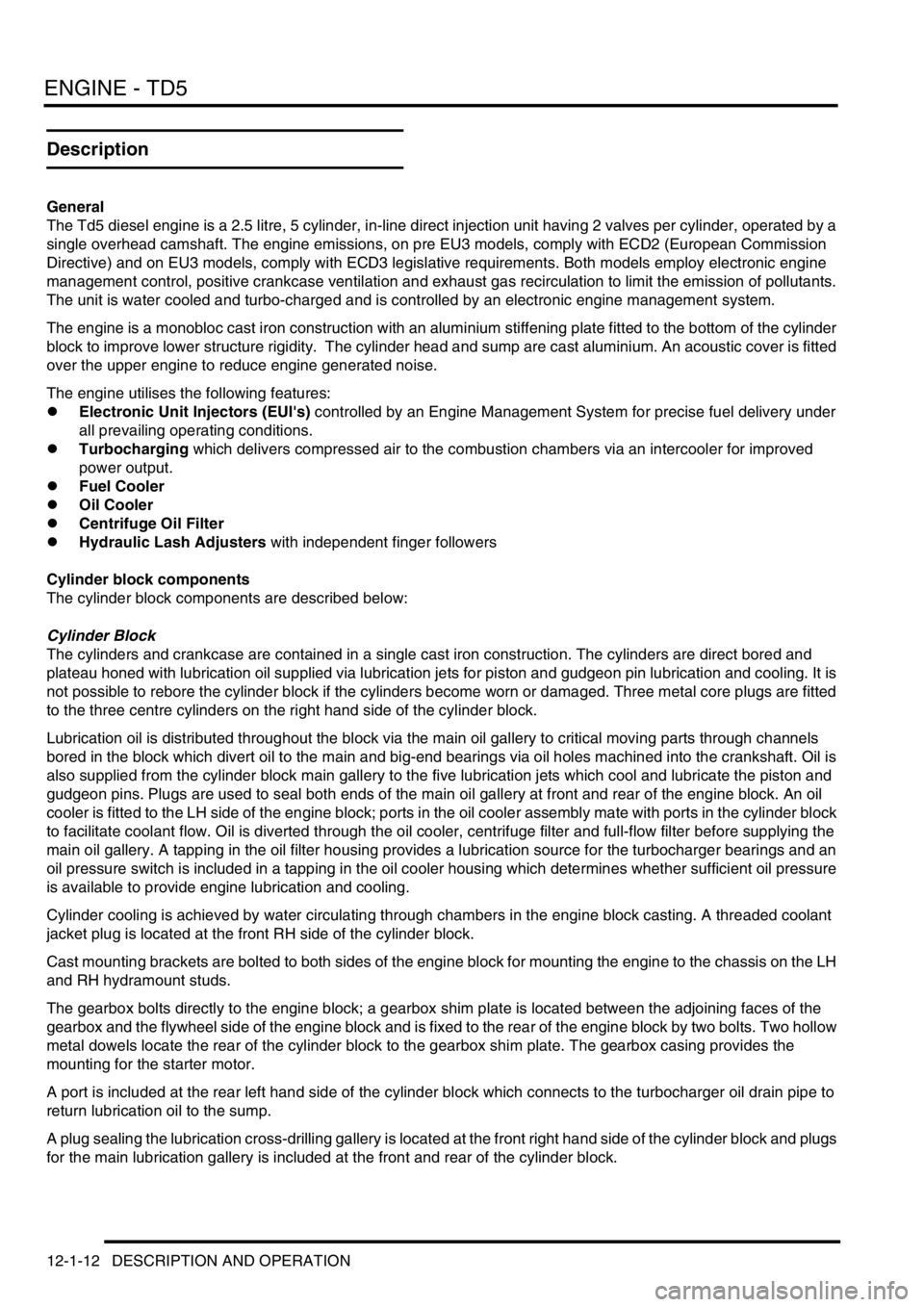

Connecting rods

1Small-end oil holes

2Small-end bushing

3Connecting rod

4Serrated fracture

The connecting rods are machined, H-sectioned steel forgings which feature a fracture-split at the big-end between

the connecting rod and the bearing cap. The connecting rod features a serrated fracture across the big-end at right

angles to the length of the connecting rod, this forms a unique mating surface between the connecting rod and the

fractured end which is used as the big-end cap. The use of a fracture-split in the big-end of the connecting rod ensures

a perfect match for assembly on the crankshaft bearing journals and provides the connecting rod with strong

resistance to lateral movement.

The end-cap fixing bolts are offset to ensure that the cap is fitted to the connecting rod in the correct orientation. If the

end-cap is fitted incorrectly and the end-cap bolts tightened, the connecting rod must be replaced, since the matching

serrations will have been damaged.

The big-end bearing shells are plain split halves without location tags. On EU2 models the two halves of the bearing

shells are of different construction. The upper half bearing shell fitted to the connecting rod is treated using the

sputtering process. The connecting rod bearing shell can be identified by having a slightly darker colouration than the

end cap bearing shell and the back of the connecting rod bearing shell has a shinier finish than the front face.

On EU3 models both bearing shells are of the same construction as the connecting rod bearing shell.

The small-end of the connecting rod has a bushed solid eye which is free to move on the gudgeon pin, the bushing

is a hand-push interference fit. The steel bushing has two slots machined in its upper surface for providing oil

lubrication to the moving surface with the gudgeon pin. The oil slots must be correctly aligned to the oil slots provided

in the small end of the connecting rod. The small-end lubrication is supplied by squirt feed from the piston lubrication

jets.

Page 153 of 1672

ENGINE - TD5

12-1-14 DESCRIPTION AND OPERATION

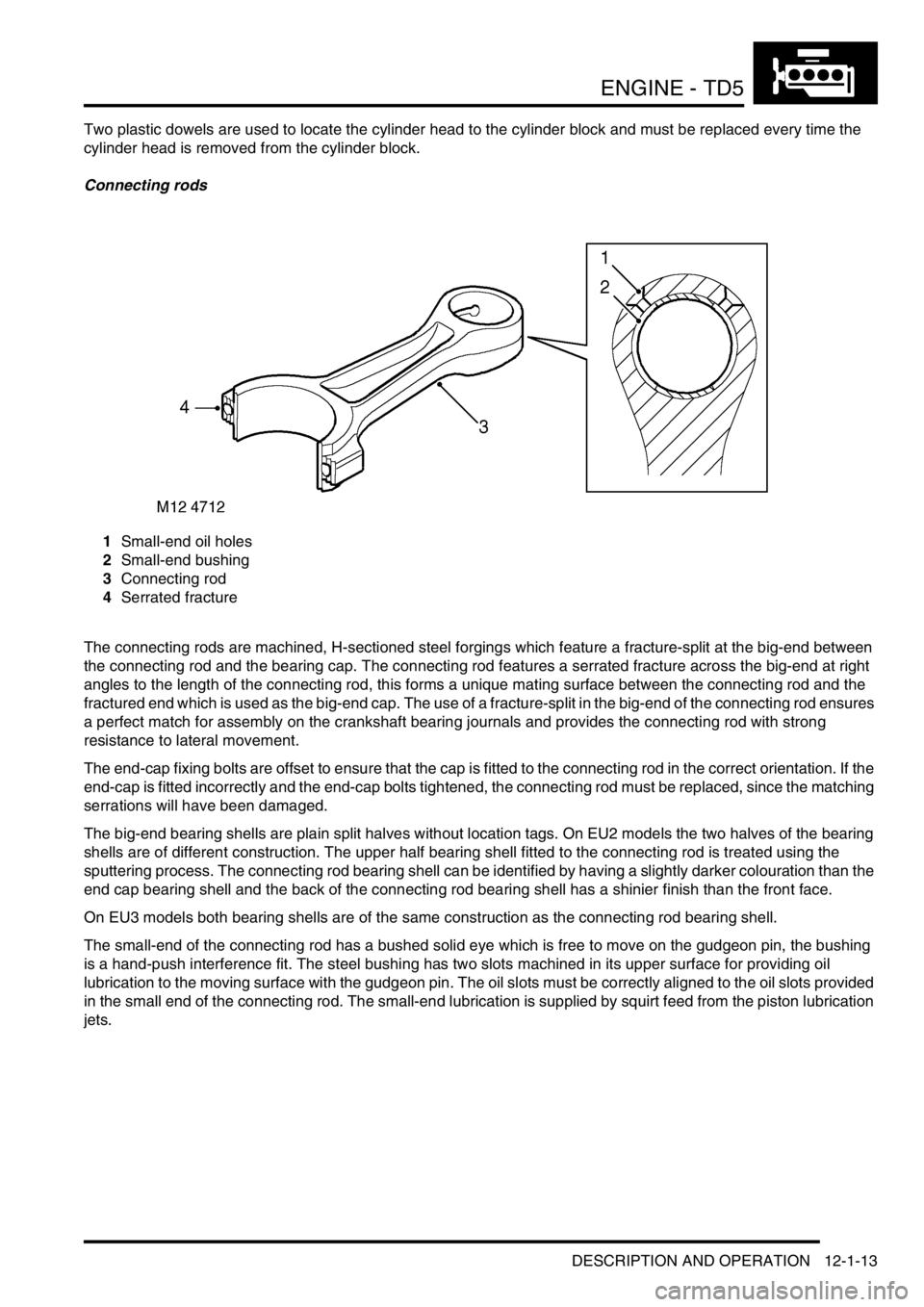

Pistons

1Bowl in piston head

2Piston ring grooves

3Graphite coated aluminium alloy skirt

4Gudgeon pin bore

The five pistons have graphite-compound coated aluminium alloy skirts which are gravity die cast and machined.

Each of the pistons has phosphated, shaped gudgeon pin bores and a swirl chamber (bowl-in-piston) machined in the

head which partly contains the inlet air that is compressed during the combustion process and helps provide

turbulence for efficient air/fuel mixture to promote complete combustion. The recesses in the piston's crown also

provide clearance for the valve heads.

Pre EU3 and EU3 pistons are not interchangeable due to the EU3 piston combustion bowl being offset.

The pistons are attached to the small-end of the connecting rods by fully floating gudgeon pins which are retained in

the piston gudgeon pin bushings by circlips.

The pistons and gudgeon pins are gallery cooled, oil being supplied under pressure from the piston lubrication jets

when the pistons are close to bottom dead centre.

Piston rings

Each piston is fitted with two compression rings and an oil control ring. The top compression ring is located in a steel

insert ring carrier which helps to provide a minimal reaction to compression forces.

The top ring is barrel-edged and chrome-plated, the 2nd compression ring is taper-faced and the oil control ring is

chrome-plated and features a bevelled ring with spring.

Page 154 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-15

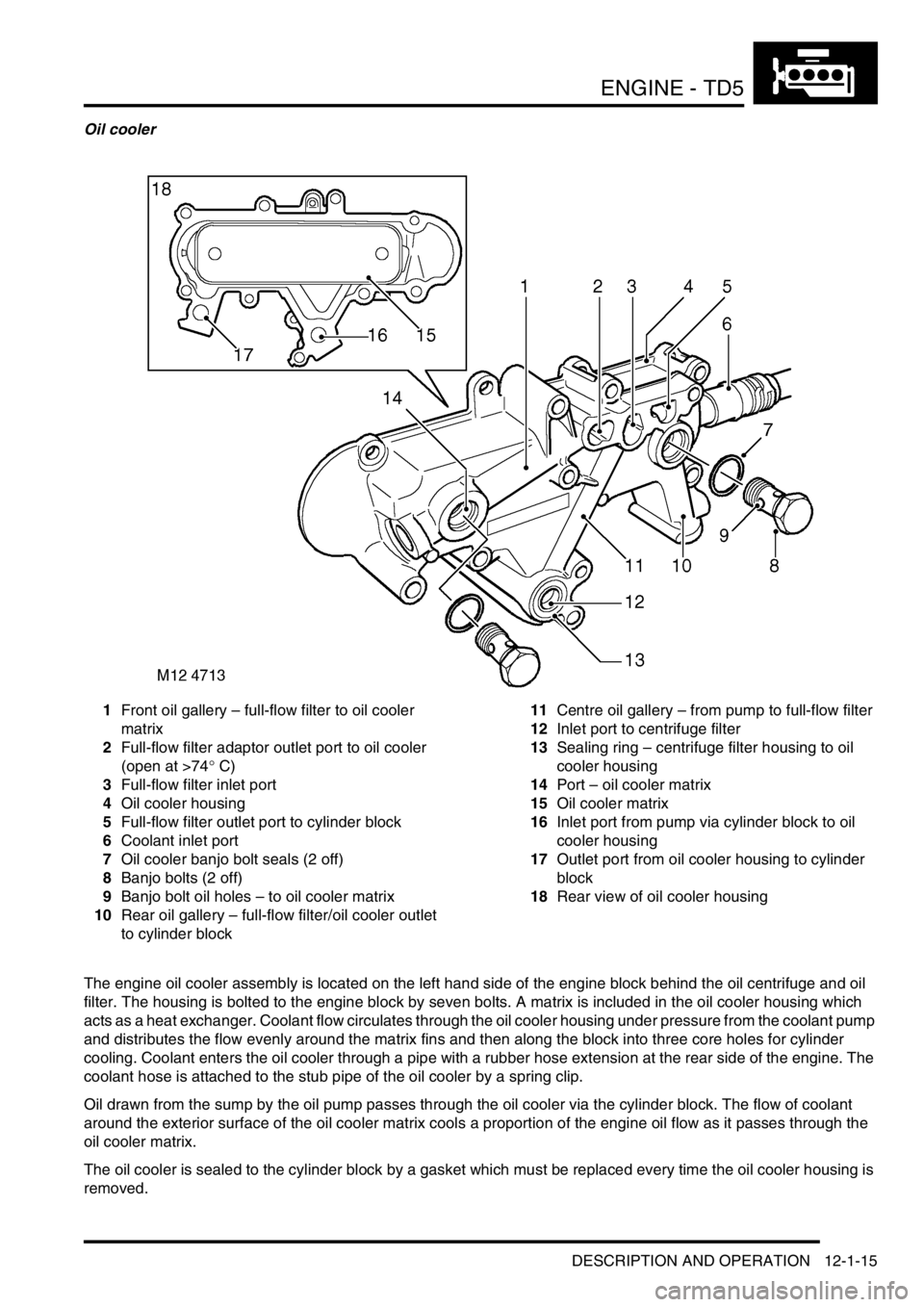

Oil cooler

1Front oil gallery – full-flow filter to oil cooler

matrix

2Full-flow filter adaptor outlet port to oil cooler

(open at >74

° C)

3Full-flow filter inlet port

4Oil cooler housing

5Full-flow filter outlet port to cylinder block

6Coolant inlet port

7Oil cooler banjo bolt seals (2 off)

8Banjo bolts (2 off)

9Banjo bolt oil holes – to oil cooler matrix

10Rear oil gallery – full-flow filter/oil cooler outlet

to cylinder block11Centre oil gallery – from pump to full-flow filter

12Inlet port to centrifuge filter

13Sealing ring – centrifuge filter housing to oil

cooler housing

14Port – oil cooler matrix

15Oil cooler matrix

16Inlet port from pump via cylinder block to oil

cooler housing

17Outlet port from oil cooler housing to cylinder

block

18Rear view of oil cooler housing

The engine oil cooler assembly is located on the left hand side of the engine block behind the oil centrifuge and oil

filter. The housing is bolted to the engine block by seven bolts. A matrix is included in the oil cooler housing which

acts as a heat exchanger. Coolant flow circulates through the oil cooler housing under pressure from the coolant pump

and distributes the flow evenly around the matrix fins and then along the block into three core holes for cylinder

cooling. Coolant enters the oil cooler through a pipe with a rubber hose extension at the rear side of the engine. The

coolant hose is attached to the stub pipe of the oil cooler by a spring clip.

Oil drawn from the sump by the oil pump passes through the oil cooler via the cylinder block. The flow of coolant

around the exterior surface of the oil cooler matrix cools a proportion of the engine oil flow as it passes through the

oil cooler matrix.

The oil cooler is sealed to the cylinder block by a gasket which must be replaced every time the oil cooler housing is

removed.

Page 155 of 1672

ENGINE - TD5

12-1-16 DESCRIPTION AND OPERATION

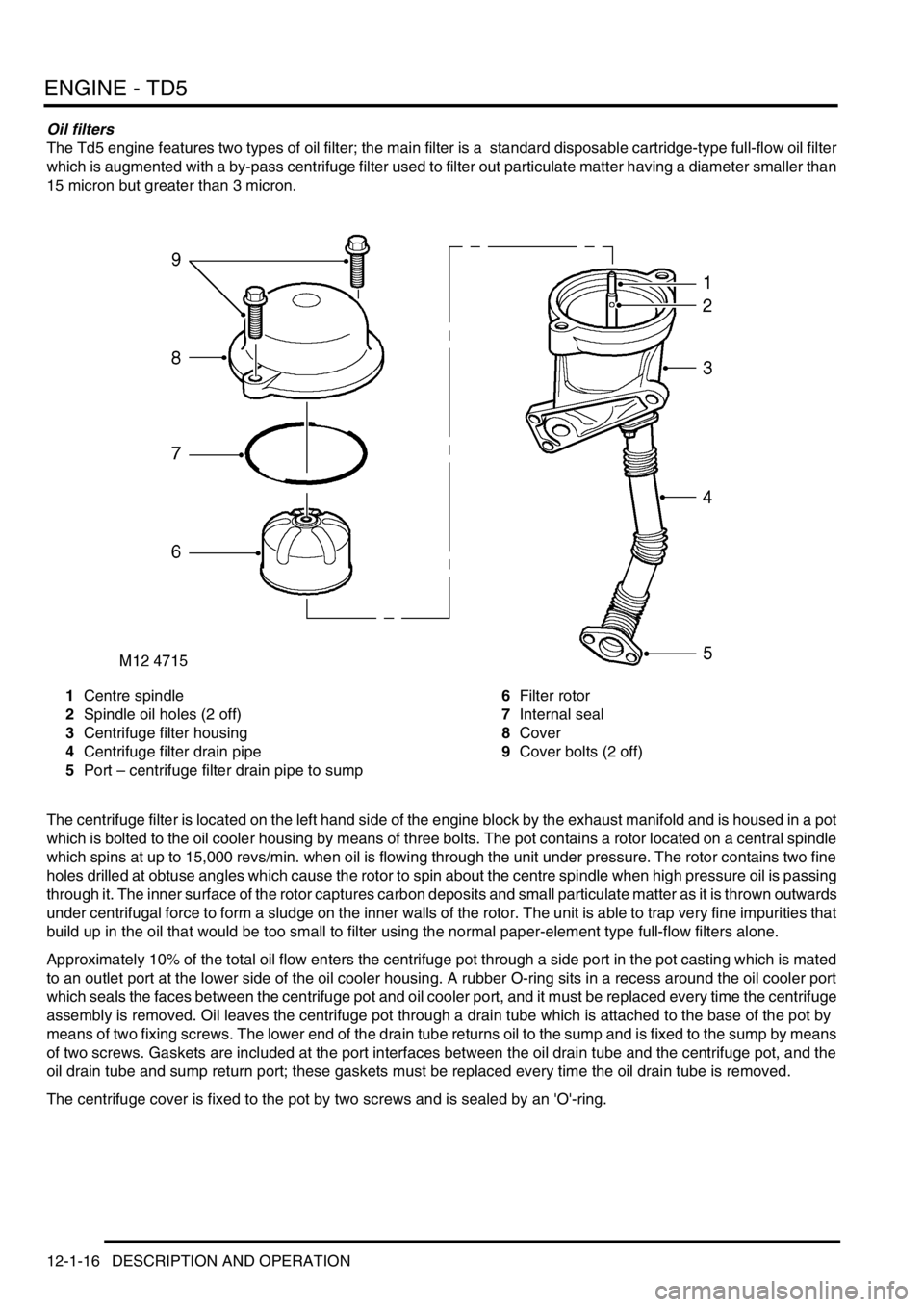

Oil filters

The Td5 engine features two types of oil filter; the main filter is a standard disposable cartridge-type full-flow oil filter

which is augmented with a by-pass centrifuge filter used to filter out particulate matter having a diameter smaller than

15 micron but greater than 3 micron.

1Centre spindle

2Spindle oil holes (2 off)

3Centrifuge filter housing

4Centrifuge filter drain pipe

5Port – centrifuge filter drain pipe to sump6Filter rotor

7Internal seal

8Cover

9Cover bolts (2 off)

The centrifuge filter is located on the left hand side of the engine block by the exhaust manifold and is housed in a pot

which is bolted to the oil cooler housing by means of three bolts. The pot contains a rotor located on a central spindle

which spins at up to 15,000 revs/min. when oil is flowing through the unit under pressure. The rotor contains two fine

holes drilled at obtuse angles which cause the rotor to spin about the centre spindle when high pressure oil is passing

through it. The inner surface of the rotor captures carbon deposits and small particulate matter as it is thrown outwards

under centrifugal force to form a sludge on the inner walls of the rotor. The unit is able to trap very fine impurities that

build up in the oil that would be too small to filter using the normal paper-element type full-flow filters alone.

Approximately 10% of the total oil flow enters the centrifuge pot through a side port in the pot casting which is mated

to an outlet port at the lower side of the oil cooler housing. A rubber O-ring sits in a recess around the oil cooler port

which seals the faces between the centrifuge pot and oil cooler port, and it must be replaced every time the centrifuge

assembly is removed. Oil leaves the centrifuge pot through a drain tube which is attached to the base of the pot by

means of two fixing screws. The lower end of the drain tube returns oil to the sump and is fixed to the sump by means

of two screws. Gaskets are included at the port interfaces between the oil drain tube and the centrifuge pot, and the

oil drain tube and sump return port; these gaskets must be replaced every time the oil drain tube is removed.

The centrifuge cover is fixed to the pot by two screws and is sealed by an 'O'-ring.

Page 156 of 1672

ENGINE - TD5

DESCRIPTION AND OPERATION 12-1-17

1Full-flow filter housing

2Thermostat

3Roll-pin

4Port – feed line to turbocharger

5Outlet port from full-flow filter (> 74

° C)

6Inlet port to full-flow filter

7Outlet port from full-flow filter (< 74

° C)

The main filter is a conventional full-flow cartridge-type filter containing a paper element able to trap particles greater

than 15 micron (0.015 mm) in diameter.

The cartridge is screwed to an adaptor casting by way of a hollow brass threaded insert which connects the filter outlet

port to the adaptor casting. A sealing ring seals the union between the oil filter cartridge and the adaptor casting.

Page 157 of 1672

ENGINE - TD5

12-1-18 DESCRIPTION AND OPERATION

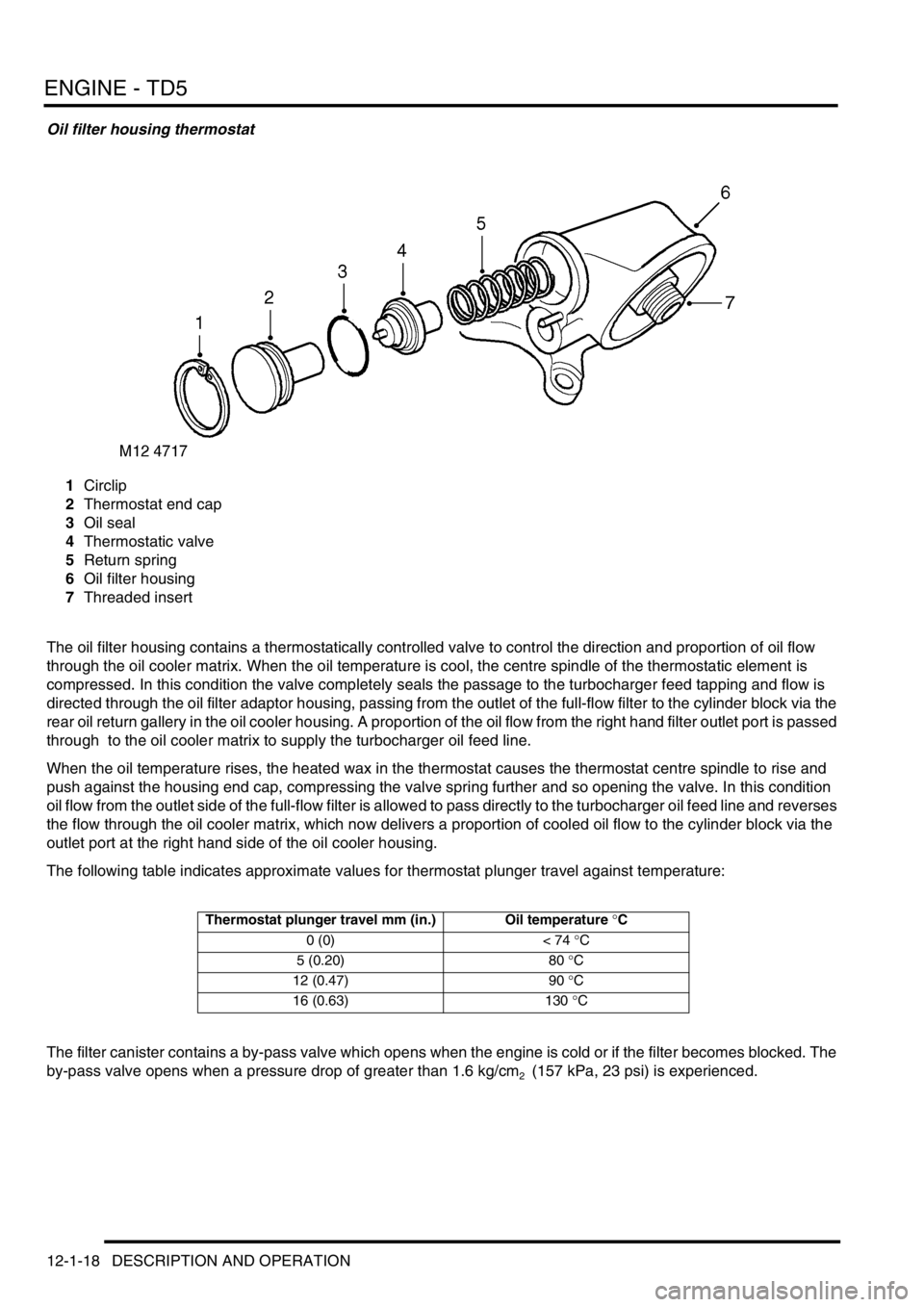

Oil filter housing thermostat

1Circlip

2Thermostat end cap

3Oil seal

4Thermostatic valve

5Return spring

6Oil filter housing

7Threaded insert

The oil filter housing contains a thermostatically controlled valve to control the direction and proportion of oil flow

through the oil cooler matrix. When the oil temperature is cool, the centre spindle of the thermostatic element is

compressed. In this condition the valve completely seals the passage to the turbocharger feed tapping and flow is

directed through the oil filter adaptor housing, passing from the outlet of the full-flow filter to the cylinder block via the

rear oil return gallery in the oil cooler housing. A proportion of the oil flow from the right hand filter outlet port is passed

through to the oil cooler matrix to supply the turbocharger oil feed line.

When the oil temperature rises, the heated wax in the thermostat causes the thermostat centre spindle to rise and

push against the housing end cap, compressing the valve spring further and so opening the valve. In this condition

oil flow from the outlet side of the full-flow filter is allowed to pass directly to the turbocharger oil feed line and reverses

the flow through the oil cooler matrix, which now delivers a proportion of cooled oil flow to the cylinder block via the

outlet port at the right hand side of the oil cooler housing.

The following table indicates approximate values for thermostat plunger travel against temperature:

The filter canister contains a by-pass valve which opens when the engine is cold or if the filter becomes blocked. The

by-pass valve opens when a pressure drop of greater than 1.6 kg/cm

2 (157 kPa, 23 psi) is experienced.

Thermostat plunger travel mm (in.) Oil temperature °C

0 (0) < 74 °C

5 (0.20) 80 °C

12 (0.47) 90 °C

16 (0.63) 130 °C