wheel LAND ROVER DISCOVERY 2002 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 506 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-49

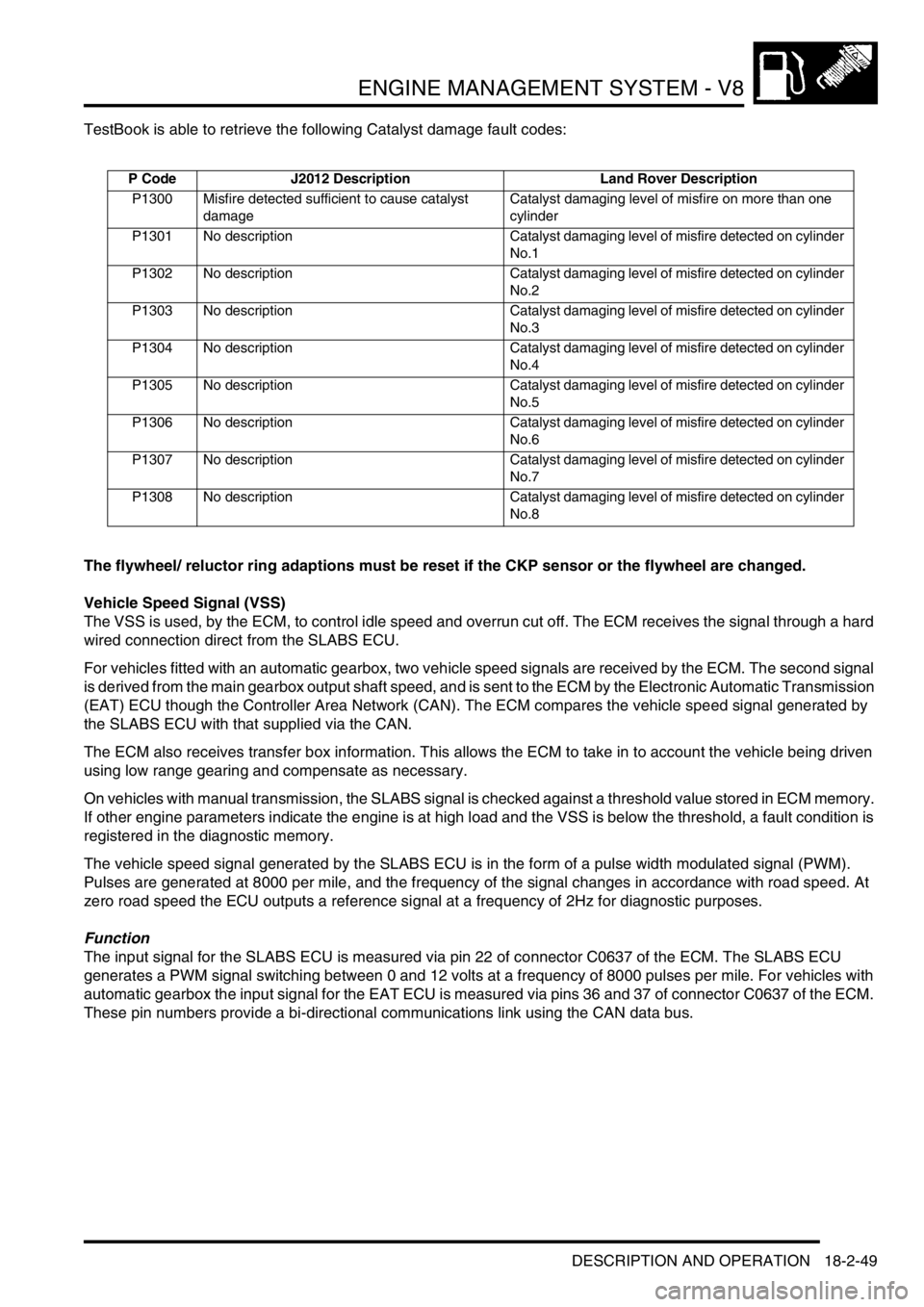

TestBook is able to retrieve the following Catalyst damage fault codes:

The flywheel/ reluctor ring adaptions must be reset if the CKP sensor or the flywheel are changed.

Vehicle Speed Signal (VSS)

The VSS is used, by the ECM, to control idle speed and overrun cut off. The ECM receives the signal through a hard

wired connection direct from the SLABS ECU.

For vehicles fitted with an automatic gearbox, two vehicle speed signals are received by the ECM. The second signal

is derived from the main gearbox output shaft speed, and is sent to the ECM by the Electronic Automatic Transmission

(EAT) ECU though the Controller Area Network (CAN). The ECM compares the vehicle speed signal generated by

the SLABS ECU with that supplied via the CAN.

The ECM also receives transfer box information. This allows the ECM to take in to account the vehicle being driven

using low range gearing and compensate as necessary.

On vehicles with manual transmission, the SLABS signal is checked against a threshold value stored in ECM memory.

If other engine parameters indicate the engine is at high load and the VSS is below the threshold, a fault condition is

registered in the diagnostic memory.

The vehicle speed signal generated by the SLABS ECU is in the form of a pulse width modulated signal (PWM).

Pulses are generated at 8000 per mile, and the frequency of the signal changes in accordance with road speed. At

zero road speed the ECU outputs a reference signal at a frequency of 2Hz for diagnostic purposes.

Function

The input signal for the SLABS ECU is measured via pin 22 of connector C0637 of the ECM. The SLABS ECU

generates a PWM signal switching between 0 and 12 volts at a frequency of 8000 pulses per mile. For vehicles with

automatic gearbox the input signal for the EAT ECU is measured via pins 36 and 37 of connector C0637 of the ECM.

These pin numbers provide a bi-directional communications link using the CAN data bus.

P Code J2012 Description Land Rover Description

P1300 Misfire detected sufficient to cause catalyst

damageCatalyst damaging level of misfire on more than one

cylinder

P1301 No description Catalyst damaging level of misfire detected on cylinder

No.1

P1302 No description Catalyst damaging level of misfire detected on cylinder

No.2

P1303 No description Catalyst damaging level of misfire detected on cylinder

No.3

P1304 No description Catalyst damaging level of misfire detected on cylinder

No.4

P1305 No description Catalyst damaging level of misfire detected on cylinder

No.5

P1306 No description Catalyst damaging level of misfire detected on cylinder

No.6

P1307 No description Catalyst damaging level of misfire detected on cylinder

No.7

P1308 No description Catalyst damaging level of misfire detected on cylinder

No.8

Page 507 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-50 DESCRIPTION AND OPERATION

In the case of a VSS failure on vehicles with automatic gearboxes, the ECM applies default values derived from the

EAT ECU. There are no default values for manual gearbox vehicles.

The VSS can fail in the following ways:

lWiring short circuit to vehicle supply.

lWiring short circuit to vehicle earth.

lWiring open circuit.

In the event of a VSS failure, any of the following symptoms may be observed:

lMIL illuminated after 2 driving cycles (NAS only).

lVehicle speed limiting disabled (manual transmission vehicles only).

lSLABS/HDC warning lamp on and audible warning.

Should a malfunction of the component occur the following fault codes may be evident and can be retrieved by

TestBook:

Rough road signal

When the vehicle travels across rough terrain, or on rough roads instability becomes evident in the drive train. The

ECM could interpret these vibrations as a 'false misfire'. To counteract this 'false misfire' the SLABS ECU generates

a rough road signal, sends it to the ECM so that the ECM can suspend misfire detection for as long as the vehicle is

travelling on the 'rough road'.

Function

Input for the rough road signal is measured via pin 34 of connector C0637 of the ECM. The SLABS ECU generates

a PWM signal that varies in accordance with changing road conditions. The rough road PWM signal operates at a

frequency of 2.33 Hz

± 10%. The significance of changes in the PWM signal are shown in the following table:

The rough road signal can fail in the following ways:

lHarness or connector damage

lSLABS failure — wheel speed sensor

A rough road signal failure may be evident from the following:

lHDC / ABS warning light on

P Code J2012 Description Land Rover Description

P0500 Vehicle speed sensor malfunction VSS short or open circuit

P0501 Vehicle speed sensor range/performance VSS implausible

PWM signal Indication

<10% Electrical short circuit to ground

25% ± 5 % Smooth road

50% ± 5 % SLABS error

75% ± 5% Rough road

>90% Electrical short circuit to battery voltage

Page 516 of 1672

ENGINE MANAGEMENT SYSTEM - V8

DESCRIPTION AND OPERATION 18-2-59

ECU operating parameters (connector connected and cruise control master switch on)

Cruise control ECU

The cruise control ECU controls the cruise control system.

Most functions of the cruise control ECU are described under other components.

Input/Output

The diagnostic line for the cruise control system is between cruise control ECU and diagnostic socket.

The cruise control ECU does not generate fault codes however the following system information is available via

TestBook:

lLast switch off reason, which was due to unacceptable speed input.

lSpeed signal detected.

lBelow minimum speed threshold.

lCurrent vehicle speed.

lRecorded SET road speed.

ECU operating parameters (connector connected)

Pin No. Condition Volts Ohms

15 Road wheels stopped 0

15 Road wheels turning 0 - 12 Volts with a

frequency of 8,000

pulses per mile 1.6 km)

Pin No. Condition Volts Ohms

18 All conditions Less than 0.5 to earth

Page 517 of 1672

ENGINE MANAGEMENT SYSTEM - V8

18-2-60 DESCRIPTION AND OPERATION

SET+/RES switches

The cruise control system uses two steering wheel switches labelled SET+ and RES.

The SET+ switch performs the set speed, tap up and accelerator functions. The RES switch performs the resume and

suspend functions.

With the cruise control master switch on and the vehicle in the cruise control operating speed range, one press of the

SET+ switch stores a speed value in the cruise control ECU. If the switch is pressed and held while the vehicle is

under cruise control operation, speed increases until the switch is released. At this point the cruise control ECU stores

the new speed value. If the switch is tapped (held down for less than 0.5 second) the cruise control ECU increases

vehicle speed by 1 mph (1.5 km/h).

If the RES switch is pressed while the systems is inactive (no stored values) the system will not respond. If there is

a stored value in the cruise control ECU memory and the switch is pressed, the cruise control system operates and

holds the vehicle at the stored road speed. If the cruise control system is active and the RES switch is depressed,

the cruise control ECU deactivates cruise operation but maintains the current set speed value.

Input/Output

The input from the SET+ switch to the cruise control ECU is either 12 Volts or an open circuit.

The input from the RES switch to the cruise control ECU is either 12 Volts or an open circuit.

The following diagnostic information is available through TestBook:

lThe state of operator switch SET+.

lThe state of operator switch RES.

ECU operating parameters (connector connected)

Pin No. Condition Volts Ohms

4 Ignition in position II, SET+ switch

releasedMore than 10,000

4 Ignition in position II, SET+ switch

pressed12

2 Ignition in position II, RES switch

releasedMore than 10,000

2 Ignition in position II, RES switch

pressed12

Page 544 of 1672

ENGINE MANAGEMENT SYSTEM - V8

REPAIRS 18-2-87

Switch - cruise control (on/off)

$% 19.75.30

Remove

1.Carefully remove switch from instrument cowl.

2.Disconnect multiplug and remove switch.

Refit

1.Position new switch and connect multiplug.

2.Carefully push switch into instrument cowl.

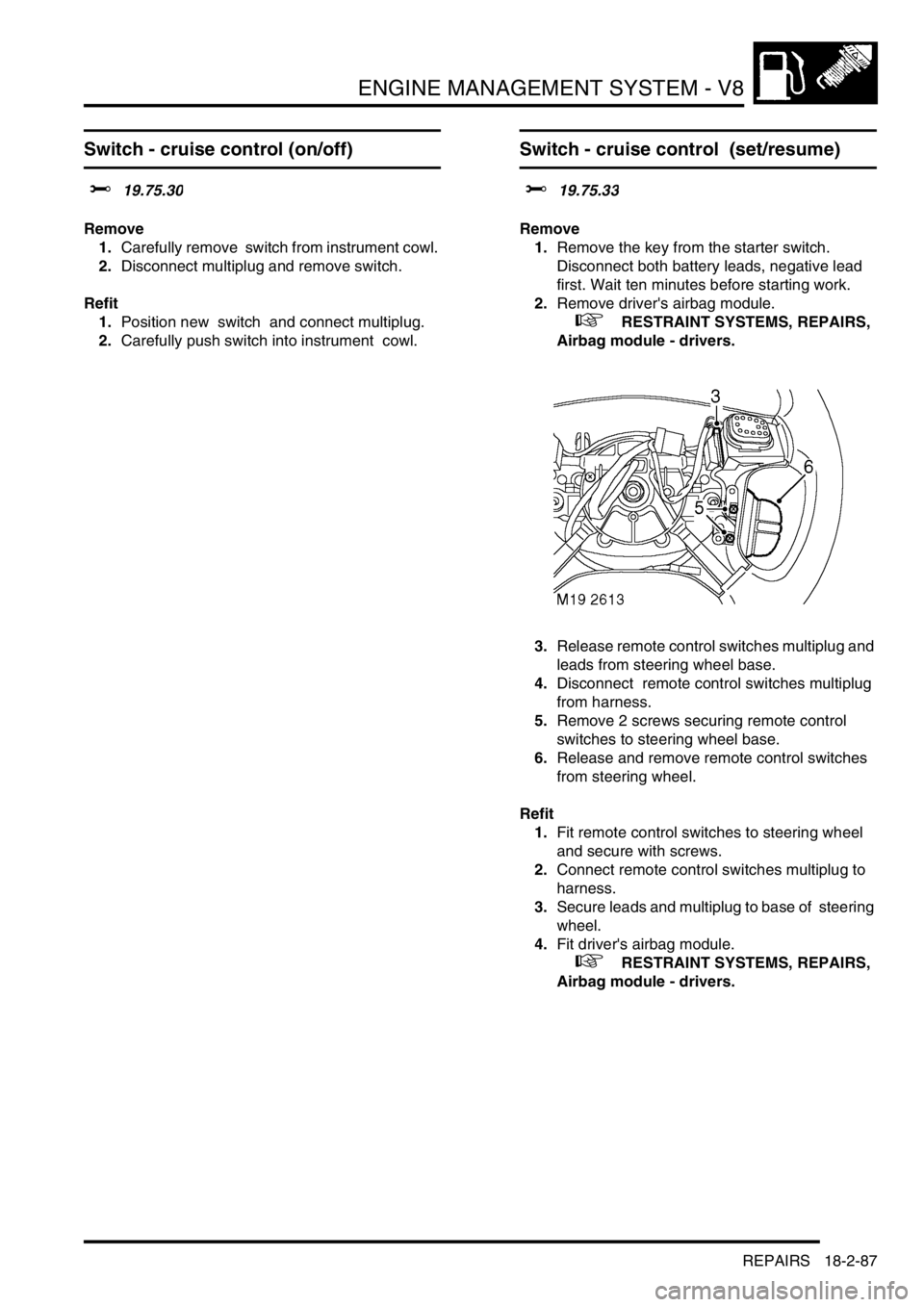

Switch - cruise control (set/resume)

$% 19.75.33

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

3.Release remote control switches multiplug and

leads from steering wheel base.

4.Disconnect remote control switches multiplug

from harness.

5.Remove 2 screws securing remote control

switches to steering wheel base.

6.Release and remove remote control switches

from steering wheel.

Refit

1.Fit remote control switches to steering wheel

and secure with screws.

2.Connect remote control switches multiplug to

harness.

3.Secure leads and multiplug to base of steering

wheel.

4.Fit driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

Page 592 of 1672

COOLING SYSTEM - TD5

DESCRIPTION AND OPERATION 26-1-9

Viscous fan

1Idler pulley drive attachment

2Fan blades

3Bi-metallic coil

4Body

The viscous fan provides a means of controlling the speed of the fan relative to the operating temperature of the

engine. The fan rotation draws air through the radiator, reducing engine coolant temperatures when the vehicle is

stationary or moving slowly.

The viscous fan is attached to an idler pulley at the front of the engine which is driven at crankshaft speed by the

auxiliary drive belt. The fan is secured to the pulley by a nut. The nut is positively attached to the fan spindle which

is supported on bearings in the fan body. The viscous drive comprises a circular drive plate attached to the spindle

and driven from the idler pulley. The drive plate and body have interlocking annular grooves with a small clearance

which provides the drive when silicone fluid enters the fluid chamber. A bi-metallic coil is fitted externally on the

forward face of the body. The coil is connected to and operates a valve in the body. The valve operates on a valve

plate with ports that connect the reservoir to the fluid chamber. The valve plate also has return ports which, when the

valve is closed, scoop fluid from the fluid chamber and push it into the reservoir under centrifugal force.

Silicone fluid is retained in a reservoir at the front of the body. When the engine is off and the fan is stationary, the

silicone fluid level stabilises between the reservoir and the fluid chamber. This will result in the fan operating when the

engine is started, but the drive will be removed quickly after the fan starts rotating and the fan will 'freewheel'.

At low radiator temperatures, the fan operation is not required and the bi-metallic coil keeps the valve closed,

separating the silicone fluid from the drive plate. This allows the fan to 'freewheel' reducing the load on the engine,

improving fuel consumption and reducing noise generated by the rotation of the fan.

When the radiator temperature increases, the bi-metallic coil reacts and moves the valve, allowing silicone fluid to

flow into the fluid chamber. The resistance to shear of the silicone fluid creates drag on the drive plate and provides

drive to the body and the fan blades.

Page 594 of 1672

COOLING SYSTEM - TD5

DESCRIPTION AND OPERATION 26-1-11

Viscous fan operation

A= Cold, B= Hot

1Drive plate

2Fan body

3Clearance

4Valve plate

5Valve

6Bi-metallic coil7Fluid seals

8Ball race

9Fluid chamber

10Reservoir

11Return port

When the engine is off and the fan is not rotating, the silicone fluid stabilises within the fluid chamber and the reservoir.

The fluid levels equalise due to the return port in the valve plate being open between the fluid chamber and the

reservoir. In this condition, when the engine is started, silicone fluid is present in the fluid chamber and causes drag

to occur between the drive plate and the body. This causes the fan to operate initially when the engine is started.

As the fan speed increases, centrifugal force and a scoop formed on the fluid chamber side of the valve plate, pushes

the silicone fluid through the return port in the valve plate into the reservoir. As the fluid chamber empties, the drag

between the drive plate and the body is reduced, causing the drive plate to slip. This reduces the rotational speed of

the fan and allows it to 'freewheel'.

When the coolant temperature is low, the heat emitted from the radiator does not affect the bi-metallic coil. The valve

remains closed, preventing fluid escaping from the reservoir into the fluid chamber. In this condition the fan will

'freewheel' at a slow speed.

Page 610 of 1672

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-9

Viscous fan

1Coolant pump pulley drive attachment

2Fan blades

3Bi-metallic coil

4Body

The viscous fan provides a means of controlling the speed of the fan relative to the operating temperature of the

engine. The fan rotation draws air through the radiator, reducing engine coolant temperatures when the vehicle is

stationary or moving slowly.

The viscous fan is attached to the coolant pump drive pulley and secured to the pulley by a nut. The nut is positively

attached to a spindle which is supported on bearings in the fan body. The viscous drive comprises a circular drive

plate attached to the spindle and driven from the coolant pump pulley and the coupling body. The drive plate and the

body have interlocking annular grooves with a small clearance which provides the drive when silicone fluid enters the

fluid chamber. A bi-metallic coil is fitted externally on the forward face of the body. The coil is connected to and

operates a valve in the body. The valve operates on a valve plate with ports that connect the reservoir to the fluid

chamber. The valve plate also has return ports which, when the valve is closed, scoop fluid from the fluid chamber

and push it into the reservoir under centrifugal force.

Silicone fluid is retained in a reservoir at the front of the body. When the engine is off and the fan is stationary, the

silicone fluid level stabilises between the reservoir and the fluid chamber. This will result in the fan operating when the

engine is started, but the drive will be removed quickly after the fan starts rotating and the fan will 'freewheel'.

At low radiator temperatures, the fan operation is not required and the bi-metallic coil keeps the valve closed,

separating the silicone fluid from the drive plate. This allows the fan to 'freewheel' reducing the load on the engine,

improving fuel consumption and reducing noise generated by the rotation of the fan.

When the radiator temperature increases, the bi-metallic coil reacts and moves the valve, allowing the silicone fluid

to flow into the fluid chamber. The resistance to shear of the silicone fluid creates drag on the drive plate and provides

drive to the body and the fan blades.

Page 612 of 1672

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-11

Viscous fan operation

A = Cold, B = Hot

1Drive plate

2Fan body

3Clearance

4Valve plate

5Valve

6Bi-metallic coil7Fluid seals

8Ball race

9Fluid chamber

10Reservoir

11Return port

When the engine is off and the fan is not rotating, the silicone fluid stabilises within the fluid chamber and the reservoir.

The fluid levels equalise due to the return port in the valve plate being open between the fluid chamber and the

reservoir. In this condition, when the engine is started, silicone fluid is present in the fluid chamber and causes drag

to occur between the drive plate and the body. This causes the fan to operate initially when the engine is started.

As the fan speed increases, centrifugal force and a scoop formed on the fluid chamber side of the valve plate, pushes

the silicone fluid through the return port in the valve plate into the reservoir. As the fluid chamber empties, the drag

between the drive plate and body is reduced, causing the drive plate to slip. This reduces the rotational speed of the

fan and allows it to 'freewheel'.

When the coolant temperature is low, the heat emitted from the radiator does not affect the bi-metallic coil. The valve

remains closed, preventing fluid escaping from the reservoir into the fluid chamber. In this condition the fan will

'freewheel' at a slow speed.

Page 654 of 1672

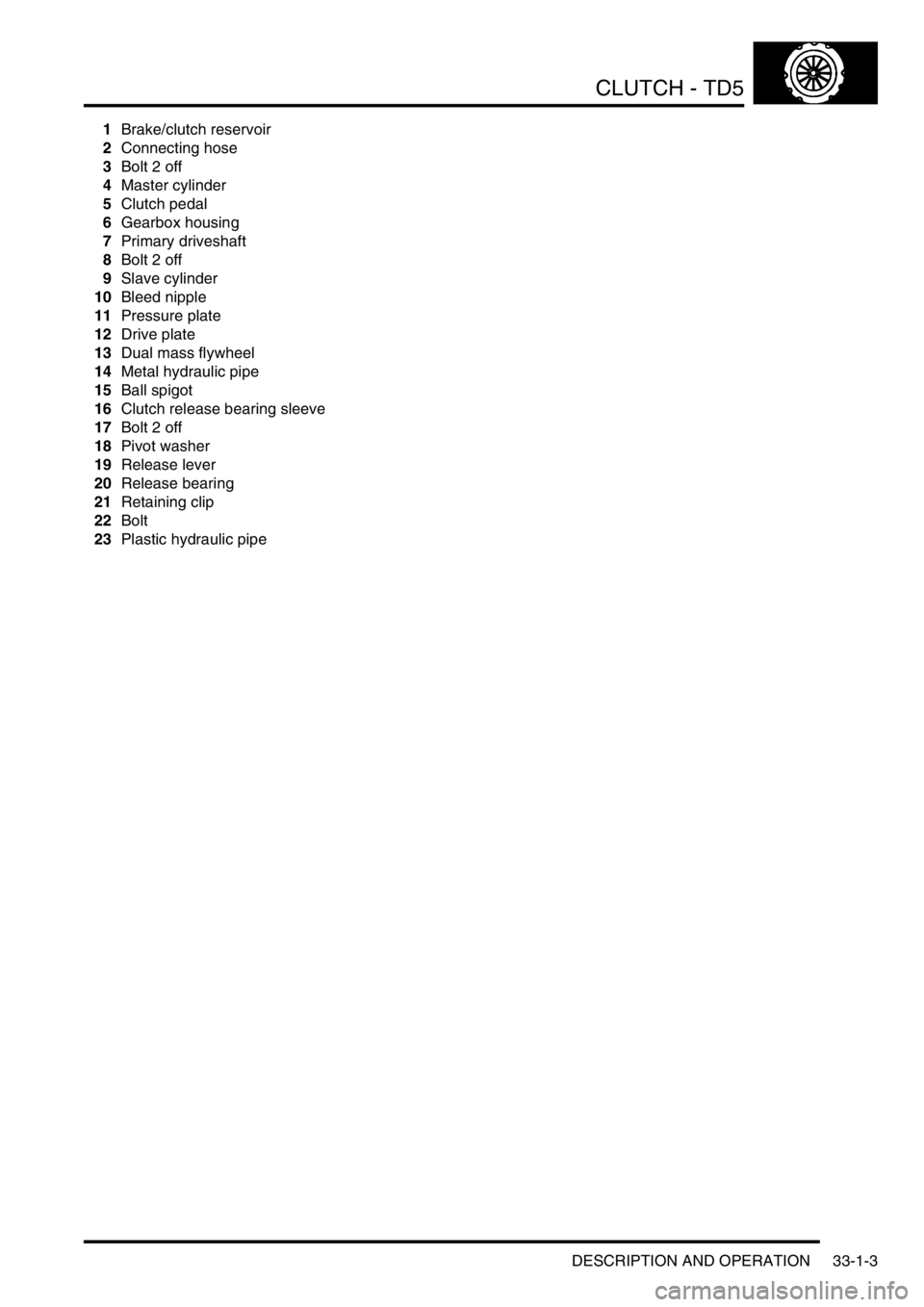

CLUTCH - TD5

DESCRIPTION AND OPERATION 33-1-3

1Brake/clutch reservoir

2Connecting hose

3Bolt 2 off

4Master cylinder

5Clutch pedal

6Gearbox housing

7Primary driveshaft

8Bolt 2 off

9Slave cylinder

10Bleed nipple

11Pressure plate

12Drive plate

13Dual mass flywheel

14Metal hydraulic pipe

15Ball spigot

16Clutch release bearing sleeve

17Bolt 2 off

18Pivot washer

19Release lever

20Release bearing

21Retaining clip

22Bolt

23Plastic hydraulic pipe