ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1437 of 1672

WIPERS AND WASHERS

84-16 DESCRIPTION AND OPERATION

Operation

Front intermittent wipe variable delay

The front intermittent wipe variable delay operation allows the driver to adjust the interval between wipes to suit local

conditions. Front variable delay operation activates when the following conditions are met:

lIgnition switch in position I or II.

lFront wash/ wipe switch is in the intermittent position.

The BCU receives the front intermittent wipe signal from the front wash/ wipe switch. The BCU receives a separate

signal from the variable delay switch, determines the delay interval from the front wash/ wipe switch position and

passes it on to the IDM. The IDM energises the front wiper relay to activate the front wiper motor.

If the delay duration is decreased during front variable delay operation, the wipers immediately operate once and then

the delay cycle is reset to the new duration.

If the delay duration is increased during front variable delay operation, the delay cycle is automatically increased by

the BCU.

Front low speed

Front low-speed operation activates when the following conditions are met:

lIgnition switch is in position I or II.

lFront wipe/ wash switch is in low speed position.

Selecting low-speed on the front wash/ wipe switch signals the IDM to energises the front wiper relay, which provides

power to the front wiper motor assembly.

Front high speed

Front high-speed operation activates when the following conditions are met:

lIgnition switch is in position I or II.

lFront wipe/ wash switch is in high speed position.

Selecting high speed on the front wash/ wipe switch allows power to flow from the switch directly to the wiper motor.

The high-speed input goes to a set of brushes in the wiper motor that are closer together than the low speed brushes.

These brushes allow the motor to run at a faster speed but with less torque.

Front washer

Front washer operation will only activate when the following conditions are met:

lIgnition switch is in position I or II.

lFront washer switch operated.

Flicking the front washer switch energises the front washer pump motor for 0.4 second. Holding the front washer

switch for longer than 0.4 second allows the front washer pump motor to run as long as the switch is held.

There are two front washer configurations. If the vehicle is fitted with programme wash/ wipe, and the front washer

pump motor is active for more than 0.5 second, the front wipers operate at low speed. The wipers continue to operate

for 4 seconds after the washer switch is released. In some markets, the driver must activate the front wipers after a

front washer operation.

The front washer operation has a higher priority than the variable delay operation. This means that if intermittent wipe

is active when a front washer operation is initiated, the wash cycle executes and the intermittent wipe is re-instated

at the end of the wash operation.

Page 1439 of 1672

WIPERS AND WASHERS

84-18 DESCRIPTION AND OPERATION

Rear wipe

Rear wipe operation will only activate when the following conditions are met:

lIgnition switch is in position II.

lRear wipe switch is operated.

Operating the rear wiper switch provides an earth input to the BCU. The BCU tells the IDM to activate the rear wiper

relay, which provides battery voltage to the wiper motor through the normally closed contacts of the park switch.

Rear wash

Rear wash will only operate when the following conditions are met:

lIgnition switch is in position II.

lRear wash switch operated.

Operating the rear washer switch for longer than 0.4 second allows the rear washer pump motor and rear wipers to

run as long as the switch is held. The wipers run for 4 seconds after the rear washer switch is released. Flicking the

rear washer switch energises the rear washer pump motor for 0.4 second.

The rear washer operation has a higher priority than the intermittent wipe operation. If the intermittent wipe is active

when a rear washer operation is initiated, the wash cycle executes and the intermittent wipe is re-instated at the end

of the washer operation.

Wiper park switch

The park switch allows the wipers to come to rest in the park position when the wipe switch is turned off in mid-wipe.

The park switch consists of a positive and a negative contact. These two contacts are described as closed at park

and closed when operating. When the wipers first start, the park switch is in the closed at park position. A relay

controls battery voltage to the motor. Battery voltage passes through this relay contact to move the wiper motor from

the park position.

When the motor moves, the park switch moves to the closed when operating position. Battery voltage to this relay

contact is direct from fuse 19. Battery voltage passes through this contact to keep the wiper motor running. The wiper

motor operates for one complete revolution until the park switch moves to the closed at park position again.

Switching off the wipers removes battery voltage from the closed at park contact. When the wipers reach the closed

at park switch an earth is applied and the motor stops abruptly.

Headlamp power wash

Headlamp power wash activates when the following conditions are met:

lIgnition switch in position II.

lHeadlamps switched on.

lFront wash switch operated.

lBCU counter allows headlamp power wash.

Operating the front washer switch with the headlamps switched on energises the IDM, supplying a voltage to the

headlamp powerwash relay, which operates the headlamp powerwash pump and increments a counter within the

BCU. This counter prevents the headlamp powerwash pump from operating every time the front washer switch is

activated. Headlamp powerwash is only operational every third front wash cycle, providing the headlamps are on.

The counter resets when the ignition switch is turned off.

When the BCU permits headlamp power wash operation, the pump motor operates only for 0.5 second.

Page 1440 of 1672

WIPERS AND WASHERS

REPAIRS 84-19

REPAIRS

Reservoir - washer - up to 03MY

$% 84.10.03

Remove

1.Remove front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

2.Remove front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

3.Disconnect multiplug from headlamp washer

pump.

4.Identify multiplugs for refit and disconnect from

rear screen and windscreen washer pumps.

5.Identify hoses for refit and disconnect hoses

from rear screen and windscreen washer

pumps.

6.Release clip securing washer hose to

headlamp washer pump. 7.Remove 2 nuts and 1 bolt securing reservoir,

release reservoir from filler neck and remove

reservoir assembly.

8.Remove filler neck grommet.

NOTE: Do not carry out further dismantling if

component is removed for access only.

9.Remove fluid level indicator.

10.Remove washer pumps from reservoir,

remove and discard pump seals.

Refit

1.Use new seals and fit washer pumps to new

reservoir.

2.Fit filler neck grommet to reservoir.

3.Fit level indicator into filler neck.

4.Fit reservoir assembly and secure with nuts

and bolt.

5.Connect hoses to rear screen pump,

windscreen washer pump and headlamp

washer pump. Secure hoses with clips.

6.Identify and connect multiplugs to washer

pumps.

7.Fit front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

8.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

9.Refill reservoir

+ MAINTENANCE, PROCEDURES,

Wipers and washers.

Page 1441 of 1672

WIPERS AND WASHERS

84-20 REPAIRS

Reservoir - washer - from 03MY

$% 84.10.03

Remove

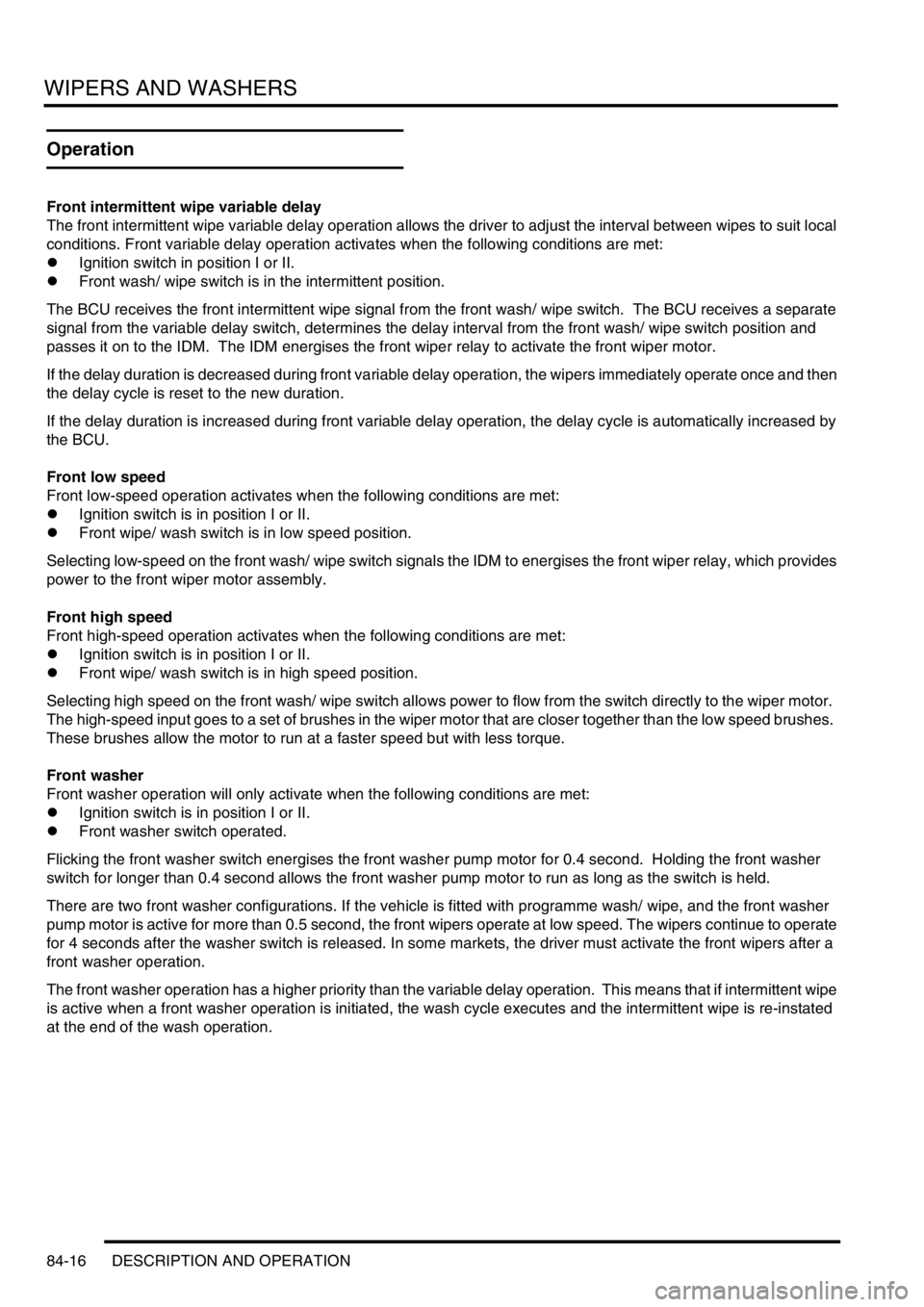

1.Remove the front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

2.Disconnect multiplug from the headlamp

washer pump.

3.Place a container beneath vehicle to collect any

spillage.

4.Noting fitted position disconnect multiplugs and

washer hoses from the front and rear

windscreen washer pumps.

5.Remove 2 nuts and 2 bolts securing the washer

reservoir to the body.6.Release washer reservoir from filler neck.

Remove the washer reservoir.

7.Remove and discard the washer reservoir filler

neck seal.

NOTE: Do not carry out further dismantling if

component is removed for access only.

8.Remove washer pumps from washer reservoir

and discard the seals.

Refit

1.Clean washer pump and filler neck seal

recesses.

2.Fit new washer pump and filler neck seals to

the washer reservoir.

3.Fit and secure washer pumps to the washer

reservoir.

4.Fit washer reservoir to the filler neck, fit and

tighten the nuts and bolts.

5.Connect multiplugs and washer hoses to the

windscreen washer pumps.

6.Remove container from beneath the vehicle.

7.Fit the front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

Page 1442 of 1672

WIPERS AND WASHERS

REPAIRS 84-21

Jet - washer - windscreen

$% 84.10.08

Remove

1.Carefully pull the elbow from the washer jet.

2.Place a protective covering around the washer

jet, then release and remove washer jet.

Refit

1.Fit washer jet to its location in the bonnet, and

remove the protective material.

2.Connect the washer tube, ensuring that it is

pushed fully onto the stub pipe.

Pump - washer - screen and headlamp

$% 84.10.21

The following procedure also covers removal of the

rear screen washer pump and the headlamp washer

pump.

Remove

1. Headlamp washer pump: Remove front

bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

2. Front and rear screen washer pumps:

Remove 7 screws securing LH front wheel arch

liner extension to liner and bumper valance and

remove liner extension.

3.Position container under washer reservoir to

collect fluid spillage.

Page 1443 of 1672

WIPERS AND WASHERS

84-22 REPAIRS

4.Disconnect multiplug from washer pump.

5.Release clip and disconnect washer hose from

washer pump.

6.Remove washer pump from reservoir and

remove and discard pump seal.

Refit

1.Use a new seal and fit pump to reservoir.

2.Connect hose to pump and secure with clip.

3.Connect multiplug to pump.

4. Front and rear screen washer pumps:Fit

wheel arch liner extension, secure to bumper

valance and liner with screws.

5. Headlamp washer pump:Fit front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

6.Fill reservoir with washer fluid.

Motor and linkage - wiper - windscreen

$% 84.15.11

Remove

1.Remove plenum air intake.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

2.Remove 4 nuts and one bolt securing motor

mounting plate to body.

3.Remove nut and bolt securing linkage to body.

4.Release motor and linkage from body and

disconnect multiplug from windscreen wiper

motor.

5.Remove motor and linkage.

Page 1444 of 1672

WIPERS AND WASHERS

REPAIRS 84-23

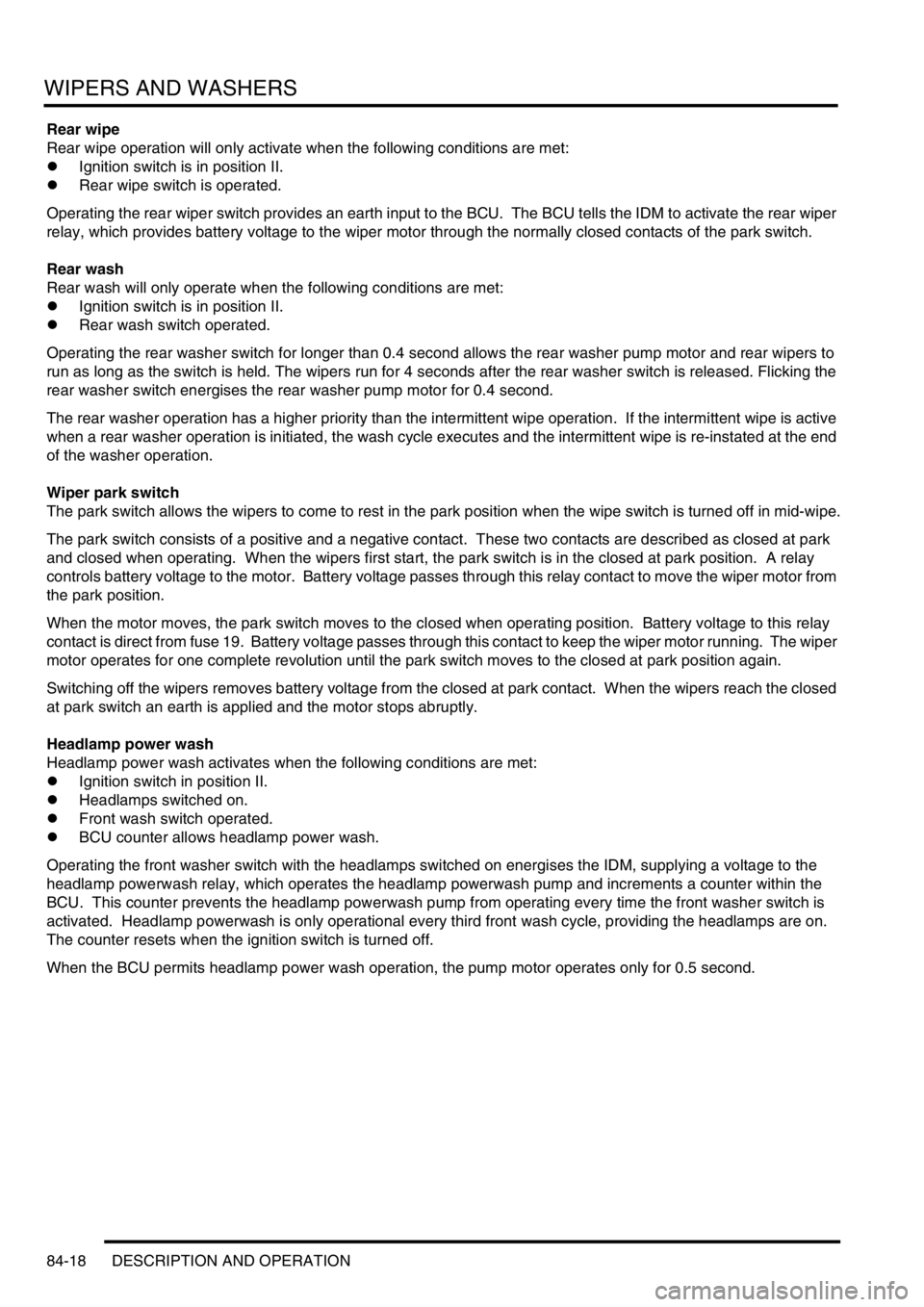

6.Remove nut securing linkage connecting rod to

wiper motor spindle.

7.Release link from motor spindle.

8.Remove 3 bolts securing motor to mounting

plate and remove motor.

Refit

1.Fit new wiper motor to mounting plate and

secure with bolts.

2.Connect link to motor spindle and tighten nut to

7 Nm (5.2 lbf.ft).

3.Fit motor and linkage to body, connect

multiplug. Tighten all fixings to 2.5 Nm (1.8

lbf.ft).

4.Fit plenum air intake.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

Switch - wiper and washer - windscreen

$% 84.15.34

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

Remove

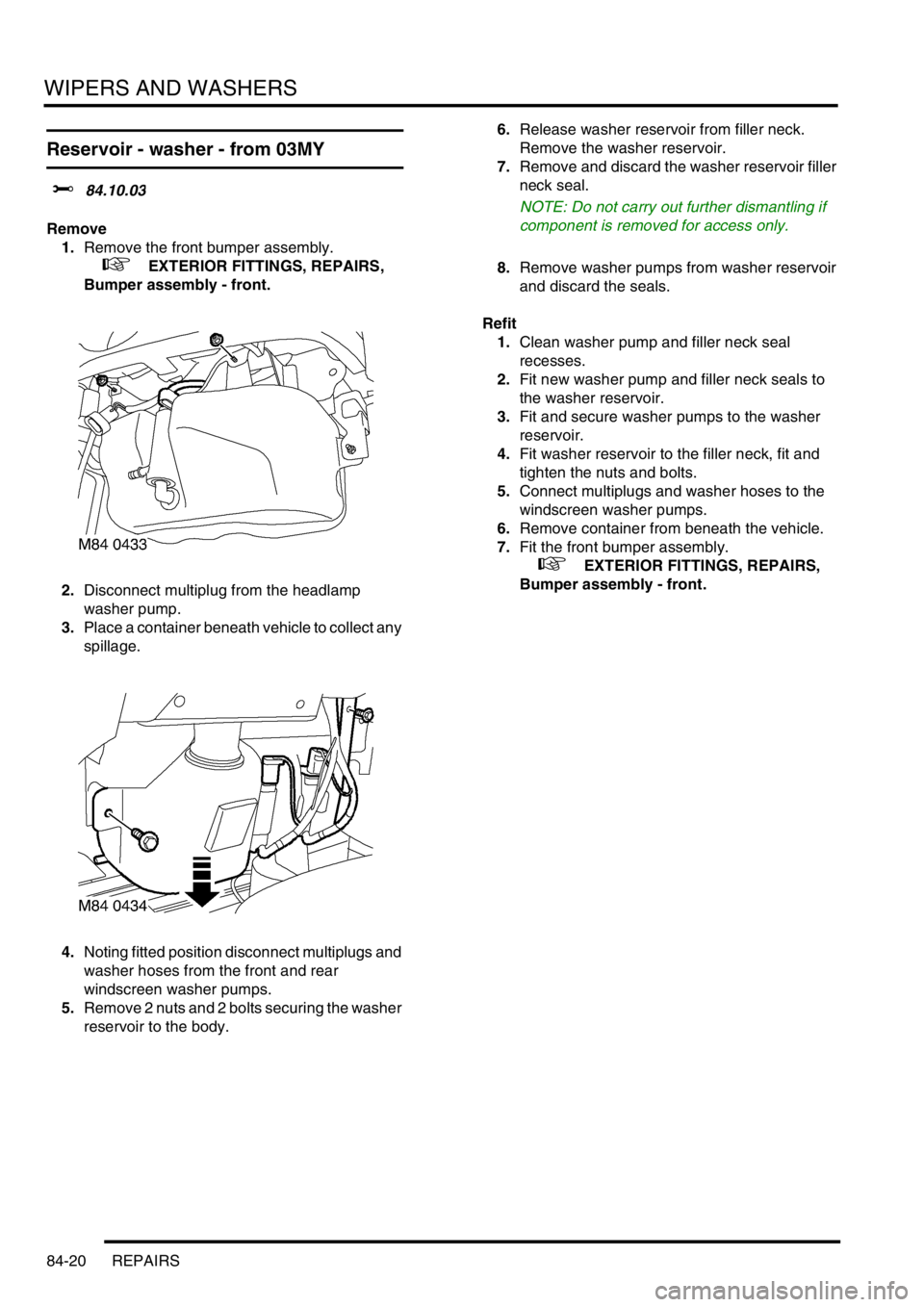

1.Remove rotary coupler.

+ RESTRAINT SYSTEMS, REPAIRS,

Rotary coupler.

2.Release passive coil from steering column lock

and lower the coil without disconnecting the

harness.

3.Release front wiper delay multiplug from

column switch mounting bracket and

disconnect from harness.

4.Disconnect harness multiplug from wiper

switch.

5.Remove 2 screws securing switch, carefully

raise edge of switch bracket to clear location

peg and remove switch.

Refit

1.Fit new switch to bracket and secure with

screws.

2.Connect harness multiplug to switch.

Page 1445 of 1672

WIPERS AND WASHERS

84-24 REPAIRS

3.Connect front wiper delay multiplug and fit

multiplug to switch bracket.

4.Fit passive coil to column lock.

5.Fit rotary coupler.

+ RESTRAINT SYSTEMS, REPAIRS,

Rotary coupler.

Jet - washer - headlamp

$% 84.20.08

The procedure to remove the headlamp washer jet

on 03MY vehicles is detailed in the front bumper

finisher job.

+ EXTERIOR FITTINGS, REPAIRS, Trim

finisher - bumper - front - from 03MY.

Remove

1.Remove retaining screw cover from jet

housing.

2.Remove screw securing jet to bumper.

3.Release jet and withdraw sufficiently to gain

access to washer tube. Disconnect tube from

jet and remove jet.

Refit

1.Connect jet to washer tube, ensuring it is

pushed fully home.

2.Locate jet in bumper, retain with screw and fit

screw cover.

Page 1447 of 1672

WIPERS AND WASHERS

84-26 REPAIRS

Motor - wiper - rear screen

$% 84.35.12

Remove

1.Remove spare wheel from taildoor.

2.Remove tail door trim casing.

+ DOORS, REPAIRS, Trim casing - tail

door.

3.Remove tail door water shedder.

4.Disconnect washer tube

5.Raise nut cover, remove nut and release wiper

arm.

6.Remove spindle nut and flat washer and

discard rubber seal.

7.Disconnect taildoor harness multiplug from

wiper motor.

8.Remove 2 bolts securing wiper motor to tail

door.

9.Remove wiper motor. Refit

1.Position wiper motor to door and secure with

bolts.

2.Connect tail door harness multiplug to wiper

motor.

3.Fit rubber seal, flat washer and spindle nut.

Tighten spindle nut to 3 Nm (2.2 lbf.ft).

4.Position wiper arm to tail door and connect

washer tube.

5.Tighten wiper arm nut to 20 Nm (15 lbf.ft) and

fit nut cover.

6.Fit tail door water shedder.

7.Fit tail door trim casing.

+ DOORS, REPAIRS, Trim casing - tail

door.

8.Fit spare wheel to tail door.

Page 1448 of 1672

WIPERS AND WASHERS

REPAIRS 84-27

Switch - wiper - rear - up to 03MY

$% 84.35.33

Remove

1.Carefully remove switch from instrument cowl.

2.Disconnect multiplug and remove switch.

Refit

1.Position new switch and connect multiplug.

2.Carefully push switch into instrument cowl.

Switch - wiper - rear - from 03MY

$% 843533

Remove

1.Remove 2 screws securing instrument cowl to

fascia and release the cowl from the retaining

clips.

2.Disconnect multiplug from the rear wiper

switch.

3.Remove the rear wiper switch from the

instrument cowl.

Refit

1.Fit and secure the rear wiper switch to the

instrument cowl and connect the multiplug.

2.Fit the instrument cowl to the fascia and secure

with screws.