ECU LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1493 of 1672

BODY CONTROL UNIT

86-3-24 DESCRIPTION AND OPERATION

Heated screens

The heated screen time-outs and logical operations are controlled by the BCU.

Heated front screen

The BCU provides an output to the heated front screen relay and a 'heated front screen active signal' for the heated

front screen warning lamp. The BCU uses the status of the following inputs to determine the appropriate logical

operations for this feature:

lIgnition state.

lEngine running (link from instrument pack).

lHeated front screen selected (non-latched button pressed).

If the ignition switch is not in position II, or the engine running signal is OFF, the heated front screen will not be active.

The heated front screen operation period and voltage supply is controlled by the BCU. The BCU receives a voltage

supply feed from the engine compartment fuse box and an ignition switched supply through a fuse in the passenger

compartment fuse box. When the heated front screen switch is operated, it completes a path to earth, signalling a

request for heated screen operation to the BCU. The BCU then supplies a feed to the heated front screen switch to

light the switch indicator, and earths the supply from the coil of the heated screen relay to turn the heated front screen

on. The BCU maintains a supply for a predetermined time (5 minutes), then opens the earth path after the time out

period to turn the heated screen off. During the timeout period, if the heated front screen switch is pressed a second

time, the circuit is also interrupted to turn off the supply to the heated front screen.

On vehicles fitted with air conditioning, the heated front screen is also operated by the ATC ECU when DEF (defrost)

is selected. In this case the ATC ECU provides the trigger signal to the BCU to turn the heated front screen circuit on

or, if it is already on, to re-start the time out period.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

In the event of a communications link failure occurring while the heated front screen relay is on, the relay and lamp

will remain on until the ignition switch is turned off or the time-out period elapses or the heated front screen switch is

pressed.

Heated rear window

The heated rear window will only function when the engine is running, and is operated by a non-latching switch on the

instrument pack cowl.

The BCU provides a 'heated rear window enable output' and a 'heated rear window active warning lamp signal' based

on the logic status of the following inputs:

lIgnition state.

lEngine running (link from instrument pack).

lHeated rear window selected (non-latched button pressed).

If the ignition switch is not in position II, or the engine running signal is OFF, the heated rear window will not be active.

The heated rear window operation period and voltage supply is controlled by the BCU. The BCU receives a voltage

supply feed from the engine compartment fuse box and an ignition switched supply through a fuse in the passenger

compartment fuse box. When the heated rear window switch is operated, it completes a path to earth, signalling a

request for heated rear window operation to the BCU. The BCU then supplies a feed to the heated rear window switch

to light the switch indicator, and earths the supply from the coil of the heated rear window relay via the IDM to turn the

heated rear window elements on. The BCU maintains a supply for a predetermined time (15 minutes), then opens the

earth path after the time-out period to turn the heated rear window operation off. If the heated rear window switch is

pressed a second time, the circuit is also interrupted to turn off the supply to the heated front screen.

On vehicles fitted with air conditioning, the heated rear window is also operated by the ATC ECU when DEF (defrost)

is selected. In this case the ATC ECU provides the trigger signal to the BCU to turn the heated rear window circuit on

or, if it is already on, to re-start the time out period.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

In the event of a communications link failure occurring while the heated rear window enable is on, the relay and lamp

will be de-activated.

Page 1497 of 1672

BODY CONTROL UNIT

86-3-28 DESCRIPTION AND OPERATION

The BCU can be configured whether or not to provide bulb failure warnings.

When the direction indicators are operating, instrument pack direction indicators flash in sequence with the exterior

direction indicators. If a failure of an indicator bulb occurs, the corresponding instrument pack indication lamp will flash

quickly to warn of the problem.

The IDM monitors the current drawn through the circuit to detect for the occurrence of a lamp failure. If an indicator

lamp fails, the IDM detects the drop in current drawn through the resistor and operates the indicator relay at a faster

speed. The fast flash is demonstrated on the instrument pack direction indicator warning lamps to bring attention to

the driver that a direction indicator bulb failure has occurred. The current sense for the related indicator lamps (RH or

LH) are checked when a direction indicator request has been made that lasts for at least 160 ms. The current level

sensed is relative to the number of working bulbs and determines the request generated by the BCU.

The output is signalled to the instrument pack using the serial communications link. If the hazard warning lamps are

operating, both sets of direction indicators are checked using the current sensing functions to check the number of

bulbs on each side of the vehicle.

If the BCU detects that a direction indicator request has not been made, but one or other of the current sense inputs

indicate that current is flowing, a 'Relay stuck' output is generated.

Hazard lamps

The BCU controls the operation of the hazard warning lamps via the IDM and dedicated relays. The hazard warning

lamps are activated under the following conditions:

lThe vehicle is locked and the security system is set (the hazard warning lamps flash three times if the

superlocking feature is used, once if not).

lThe vehicle is unlocked (the hazard warning lamps flash once for a duration of two seconds).

lThe anti-theft alarm system is triggered (the hazard warning lamps flash in phase with and for the duration of the

audible warning).

lThe hazard warning switch is pressed (the hazard warning lamps flash until the hazard warning switch is pressed

for a second time).

lThe inertia switch is triggered (the hazard warning lamps flash until the inertia switch has been reset).

The hazard warning lamp operation may differ dependent on market and customer configuration options.

The hazard warning lamps are operated from a latching pushbutton switch located on the fascia. When the switch is

pressed, both left and right indicator lamps in the instrument pack flash to show that the hazard warning lamps are

operating and all hazard warning lamps flash simultaneously. If a trailer is fitted, the ICM detects this and a trailer

symbol in the instrument pack also flashes to show correct operation of the trailer direction indicators and hazard

warning lamps.

The BCU supplies a reference voltage to the hazard warning switch. When the hazard warning switch is operated an

earth path is completed which signals the BCU that a request for hazard lamp operation has been made. The BCU

then sends a signal to the IDM via the serial data bus to communicate the request. The IDM supplies an earth path

for both direction indicator relay coils simultaneously so that the hazard warning lamps are turned on concurrently.

The IDM controls the timing of the flash operations by continually removing and restoring the earth path to both

direction indicator relay coils simultaneously.

Number of working bulbs Request generated

3 Trailer detected

2 None (bulbs okay)

1 Bulb failure detected

0 Direction indicator short circuit detected

Page 1501 of 1672

BODY CONTROL UNIT

86-3-32 DESCRIPTION AND OPERATION

Odometer update

The BCU can be programmed for one of two options:

lOption 1 – no odometer error warning.

lOption 2 – odometer error warning.

In order to provide an LCD flash request to the instrument pack via the communications link, the following inputs are

checked:

lIgnition state.

lInstrument pack odometer value (via the communications link).

lBCU odometer value.

The function is only active when the ignition state is on. The maximum allowed value is 999,999 miles (1,608,999

km).If the instrument pack odometer value is greater than the maximum allowed value, the maximum value is

assumed. The BCU odometer value is stored in EEPROM. If 16 identical values of the instrument pack odometer

reading is received consecutively, the instrument pack odometer value is compared with the BCU odometer value. If

the consecutive readings from the instrument pack differ, the BCU odometer value is incremented accordingly. If the

BCU odometer value is less than the instrument pack odometer value by up to 10 km, the BCU odometer value is set

equal to the instrument pack odometer value.

If the odometer warning option is enabled, and the contents of the instrument pack odometer value buffer is identical

to, or greater than BCU odometer value

± 10 km, the BCU sends an LED flash request to the instrument pack.

In the event of a communications link failure, this function will be unable to operate.

Gear position indicator illumination

On automatic gearbox models, two variations of illumination for the gear position indicators on the selector lever can

be programmed into the BCU. In option 1, illumination is provided when the ignition is on. In option 2, illumination is

enabled when the ignition is on and the side lamps are off.

Starter relay

The BCU checks the status of the following inputs and internal BCU conditions to determine whether or not to provide

an output to enable the starter relay:

lAutostart inhibit (vehicles with automatic gearbox only).

lSecurity start inhibit (immobilisation check).

lEngine running (link to instrument pack).

lEEPROM locked (internal check).

lIDM and BCU matched.

When the BCU receives a crank signal from the ignition switch, an earth path is completed to the starter relay coil,

provided that the security system has been de-activated. If the ECM has not received a valid unlock/ remobilise signal,

the starter relay will be disengaged and the engine stopped. The BCU also receives an engine running signal from

the instrument pack, so that if the ignition key is turned to the crank position while the engine is running, the starter

motor relay will not be engaged.

If the logic conditions are correct to allow starter operation, the completion of the earth path from the starter relay coil

to the BCU energises the coil and the relay contacts close to supply battery power to the starter motor.

When the ignition switch is released from the crank position, the power supply feed from the ignition switch to the

starter relay coil is interrupted and the relay contacts open to prevent further battery feed to the starter motor.

If a communications link failure is experienced, the BCU will be prevented from detecting the 'engine running'

condition and the BCU will default to assume that the engine is not running.

Page 1505 of 1672

BODY CONTROL UNIT

86-3-36 DESCRIPTION AND OPERATION

Key-in warning

The BCU can be programmed to one of two options:

lOption 1 – no timeout.

lOption 2 – no key-in warning.

The BCU issues an audible warning No. 2 request, depending on the status of the following inputs:

lIgnition state.

lIgnition key inserted.

lDriver's door open.

If the key-in warning is programmed into the BCU for operation, audible warning No.2 will be requested if the ignition

switch is off, the ignition key inserted signal is on and the driver's door open signal is ON.

In the event of a communications link failure occurring, the audible warning request is not sent to the instrument pack.

SLABS HDC warning

The BCU issues an audible warning No. 3 request, depending on the status of the following inputs:

lIgnition state.

lSLABS HDC warning.

The SLABS warning transmitted by the SLABS ECU is a 2 Hz signal, audible warning No. 3 is requested on every

falling edge of this signal. If the signal from the SLABS ECU stays low for more than 650 ms, audible warning No. 3

is requested every 2 seconds, for 30 seconds, while the signal stays low.

In the event of a communications link failure occurring, the audible warning request is not sent to the instrument pack.

Transfer box in neutral warning

If the transfer box is in the neutral position and the ignition switch is on, the BCU issues an audible warning No. 4

request. The BCU checks for the following inputs:

lTransfer box neutral selected.

lIgnition on.

The transfer box in neutral warning is activated by communicating with the instrument pack via the serial datalink. If

a communications link failure occurs while the transfer box in neutral warning is active, the audible warning will not

operate.

Lights on warning

If the ignition switch is off while the side lamps or headlamps on and the driver's door is opened, the BCU issues an

audible warning No. 5 request.

The BCU checks for the following inputs:

lDriver's door open.

lIgnition on.

lSide lamps.

lDipped beam state.

lMain beam state.

The lights on warning is activated by communicating with the instrument pack via the serial datalink. If a

communications link failure occurs while the lights on warning is active, the audible warning will not operate.

Page 1508 of 1672

BODY CONTROL UNIT

REPAIRS 86-3-39

REPAIRS

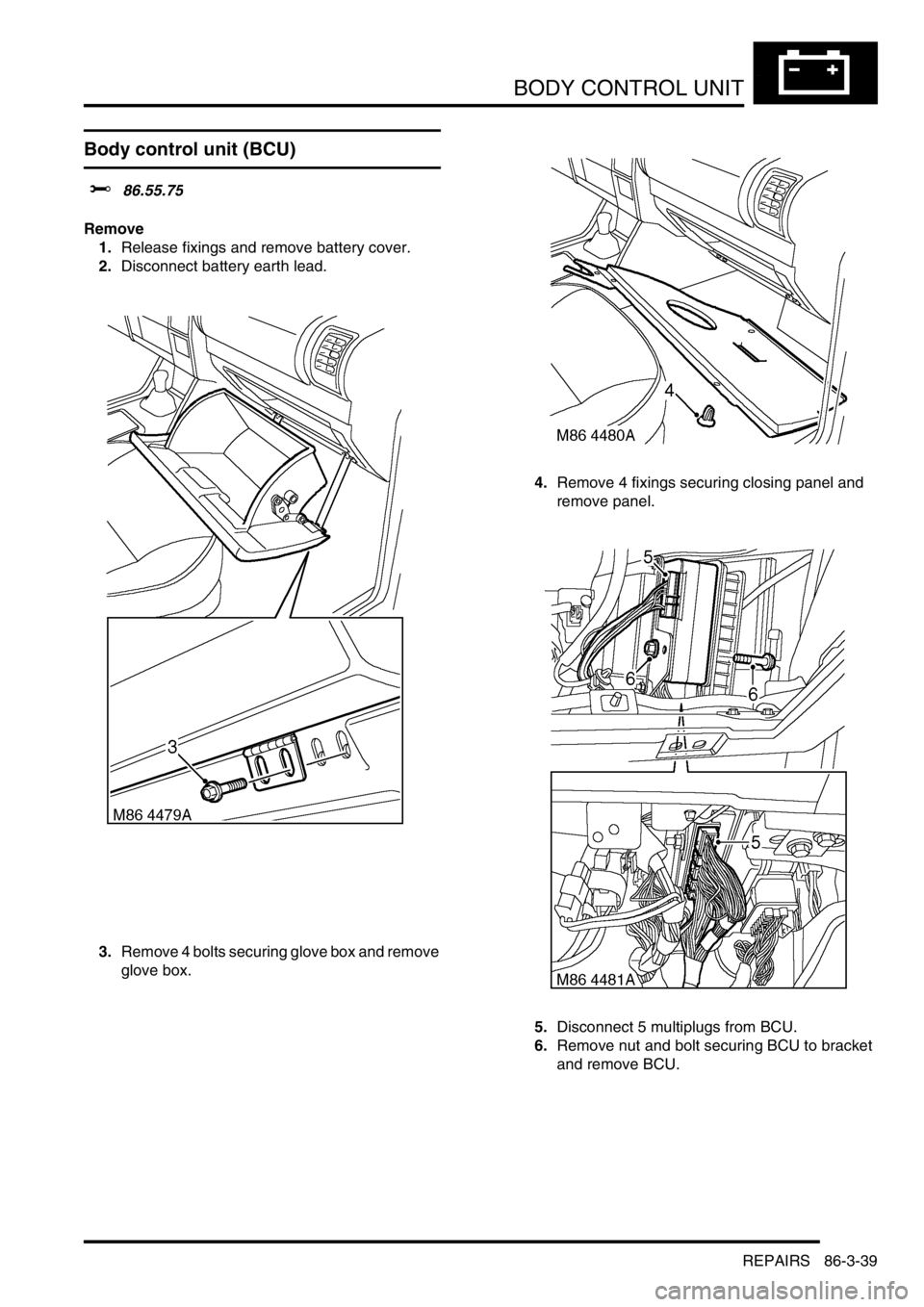

Body control unit (BCU)

$% 86.55.75

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Remove 4 bolts securing glove box and remove

glove box. 4.Remove 4 fixings securing closing panel and

remove panel.

5.Disconnect 5 multiplugs from BCU.

6.Remove nut and bolt securing BCU to bracket

and remove BCU.

Page 1509 of 1672

BODY CONTROL UNIT

86-3-40 REPAIRS

7.Remove rubber ring from locating peg. Refit

1.Fit rubber ring to new BCU.

2.Fit BCU to bracket and secure with nut and bolt.

3.Connect multiplugs to BCU.

4.Fit closing panel and secure with fixings.

5.Fit glove box and secure with bolts.

6.Connect battery earth lead.

7.Fit battery cover and secure with fixings.

8.Programme and calibrate new BCU using

TestBook.

Page 1525 of 1672

ALARM SYSTEM AND HORN

86-4-16 DESCRIPTION AND OPERATION

Operation

Standard system functions

All vehicles have the following functions as standard.

lLocking.

lUnlocking.

lFuel cut off switch unlocking.

lInternal locking.

lElectric fuel flap release.

Locking

The doors are locked by pressing the lock button on the handset or by locking the vehicle from the driver's door with

the key.

In order to lock the vehicle, the following conditions must be met:

lThe driver's door is closed.

lThe ignition is off.

lThe fuel cut off switch is not tripped.

lThe bonnet is closed.

lThe vehicle is not super locked.

Depending on system configuration a mislock occurs if these conditions are not met. The doors may lock (depending

on condition not met) and the system may not fully arm, depending on configuration of the system. If a mislock occurs

an audible warning is emitted and the vehicle becomes partially armed.

Unlocking

The doors are unlocked by pressing the unlock button on the handset or by unlocking the vehicle from the driver's

door with the key. This may unlock only the driver's door or it may unlock all doors depending on system configuration.

Fuel cut off switch unlocking

In the event that the vehicle experiences a force strong enough to actuate the switch, all the doors on the vehicle

immediately unlock. The following conditions must be met for this to occur:

lThe security system is not armed.

lThe ignition is on.

This same action causes the fuel pump to shut off and disables the Engine Control Module (ECM). In some markets,

this action may also cause the direction indicators lights to flash.

Page 1530 of 1672

ALARM SYSTEM AND HORN

DESCRIPTION AND OPERATION 86-4-21

Emergency key access

If the handset fails to operate, the engine can be remobilised by using the key to enter a unique four digit Emergency

Key Access (EKA) code.

There are three configurations for emergency key access:

lEKA not active (no immobiliser fitted).

lEKA active.

lEKA with super locking on receiving good passive remobilisation exciter coil signal.

The code is recorded on the security information card and is entered as follows:

1Using the key, turn the driver's door lock to the UNLOCK position and hold in this position for at least 5 seconds.

An audible warning is then emitted to indicate that the body control unit is ready to accept the code. Return the

key to the centre position. It is now possible to use the key to enter the separate numerical values of the four

digits that make up the EKA code.

2Enter the first digit of the code. If the first digit is 4, turn the key to the UNLOCK position 4 times. Ensure the

key is fully returned to the centre position after each turn of the key.

3Enter the second digit of the code. If the second digit is 3, turn the key to the LOCK position 3 times. Ensure

the key is fully returned to the centre position after each turn of the key.

4Enter the third digit of the code. If the third digit is 2, turn the key to the UNLOCK position twice. Ensure the key

is fully returned to the centre position after each turn of the key.

5Enter the fourth digit of the code. If the fourth digit is 1, turn the key to the LOCK position once. Ensure the key

is fully returned to the centre position after each turn of the key.

6Finally, turn the key to the UNLOCK position and back to the centre position, a double bleep will indicate that

the code has been entered correctly. A single bleep indicates that the code has been entered incorrectly.

Then, before opening the door, wait 5 minutes for the alarm and immobiliser to be de-activated. During the 5

minute wait for the alarm and immobiliser to be de-activated, the alarm indicator LED in the instrument pack

continues to flash (one flash every 2 seconds). DO NOT OPEN THE DOOR OR ATTEMPT TO ENTER THE

CAR until the full delay period has elapsed.

When the 5 minute wait has elapsed, the alarm indicator LED stops flashing. Immediately open the door, insert

the key in the ignition switch and turn the switch to position II. If the ignition switch is not turned to position II

within 30 seconds of the end of the 5 minute wait, the engine is automatically immobilised again.

The EKA code will not be recognised if there is an interval of 10 seconds or more between key turns or if the key is

held turned for 5 seconds or more during the procedure.

In some system configurations a successful EKA code entry is indicated by the audible warning device pulsing twice

for a period of 50 ms on, 200 ms off. The theft deterrent LED is switched on for 1 second, all doors unlock, the alarm

disarms and the vehicle is remobilised allowing the engine to start.

If an incorrect code is entered, an audible warning is emitted and the procedure must be repeated. Up to a maximum

of 10 attempts to enter the code is possible. After 10 attempts, the BCU will not allow any further codes to be entered

for a period of 10 minutes.

Single point entry

Single point entry (SPE) allows the driver to unlock the driver's door while leaving all other doors locked.

There are two configurations for single point entry:

lSPE not active.

lSPE active.

To use SPE, press the unlock button on the handset once. Depressing the unlock button a second time in the space

of one minute unlocks the remaining doors. SPE is also possible by turning the key in the driver's door lock to the

unlock position once. Turning the key to the unlock position again within one minute unlocks the remaining doors.

In order for SPE to operate, the following conditions must be met:

lThe ignition is off.

lAll doors are locked.

Page 1534 of 1672

ALARM SYSTEM AND HORN

REPAIR 86-4-25

REPAIR

Switch - central door locking

$% 86.26.30

Remove

1.Carefully remove clock assembly from louvre

panel.

2.Disconnect multiplug from door lock switch.

3.Remove door lock switch from clock.

Refit

1.Fit door lock switch to clock assembly.

2.Connect multiplug to door lock switch.

3.Position clock assembly and push to secure in

position.

Switches - horn

$% 86.30.01

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

1.Disconnect both battery leads, negative lead

first, and wait 10 minutes.

2.Remove driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

3.Release horn switch multiplugs and leads from

steering wheel base.

4.Disconnect horn switch multiplugs from

harness.

5.Disconnect horn switch multiplug from rotary

coupler harness.

6.Remove screw securing earth leads to steering

wheel.

7.Using a broad round edged tool, carefully prise

horn switches from steering wheel.

Refit

1.Fit to steering wheel and connect multiplugs.

2.Fit earth leads and secure with screw.

3.Secure leads and multiplugs to base of steering

wheel.

4.Fit driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

Page 1535 of 1672

ALARM SYSTEM AND HORN

86-4-26 REPAIR

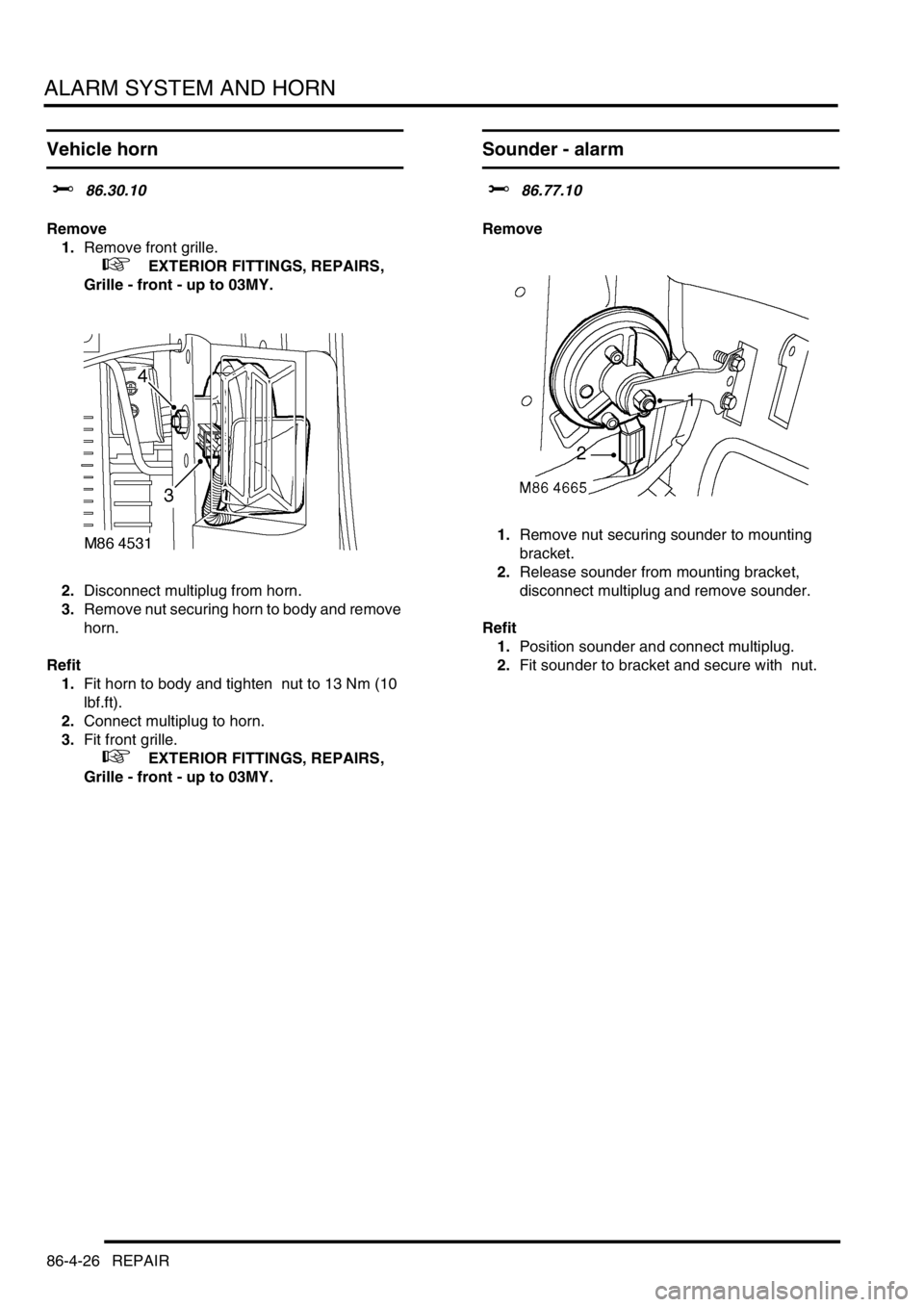

Vehicle horn

$% 86.30.10

Remove

1.Remove front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

2.Disconnect multiplug from horn.

3.Remove nut securing horn to body and remove

horn.

Refit

1.Fit horn to body and tighten nut to 13 Nm (10

lbf.ft).

2.Connect multiplug to horn.

3.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

Sounder - alarm

$% 86.77.10

Remove

1.Remove nut securing sounder to mounting

bracket.

2.Release sounder from mounting bracket,

disconnect multiplug and remove sounder.

Refit

1.Position sounder and connect multiplug.

2.Fit sounder to bracket and secure with nut.