ESP LAND ROVER DISCOVERY 2002 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1487 of 1672

BODY CONTROL UNIT

86-3-18 DESCRIPTION AND OPERATION

Self levelling suspension and ABS

The BCU communicates with the SLABS ECU for several functions:

lAn output is provided from the SLABS ECU to the BCU to provide the logic conditions for issuing the SLS audible

warning.

lThe BCU receives an input from the SLABS ECU relating to the raise/ lower command from the remote handset.

+ REAR SUSPENSION, DESCRIPTION AND OPERATION, Description - SLS.

Hill descent control

The BCU provides an output signal to the SLABS ECU for automatic transmission in neutral for HDC control. The

BCU checks the status of the ignition and 'gearbox state' inputs and provides a 'Neutral selected' output. If the ignition

is on and 'gearbox state' is Neutral, the 'Neutral selected' output is on, otherwise 'Neutral selected' is off.

+ BRAKES, DESCRIPTION AND OPERATION, Description.

Heated screens

The Heated Front Screen (HFS) is fitted for some market destinations and is operated from a non-latching switch

located on the instrument pack cowl. The BCU will only allow the heated front screen to operate when the engine is

running and controls the time-out period for switching the circuit off.

The heated front screen operation can also be controlled from the Automatic Temperature Control (ATC) ECU on

vehicles fitted with air conditioning.

The heated rear window will only function when the engine is running, and is operated by a non-latching switch on the

instrument pack cowl. The heated rear window can also be operated by the ATC ECU on vehicles fitted with air

conditioning.

Interior courtesy lamps

The BCU controls the operation of the interior courtesy lamps. The courtesy lamps are situated in the front, mid and

rear areas of the headlining.

Fuel flap actuator

The BCU provides an earth path to the fuel flap release solenoid to allow the fuel filler flap to be opened. This is only

allowed if the alarm system is not set and all other conditions have been satisfied. The fuel flap release switch is

located in the fascia switch pack and it receives a voltage supply from the passenger compartment fuse box.

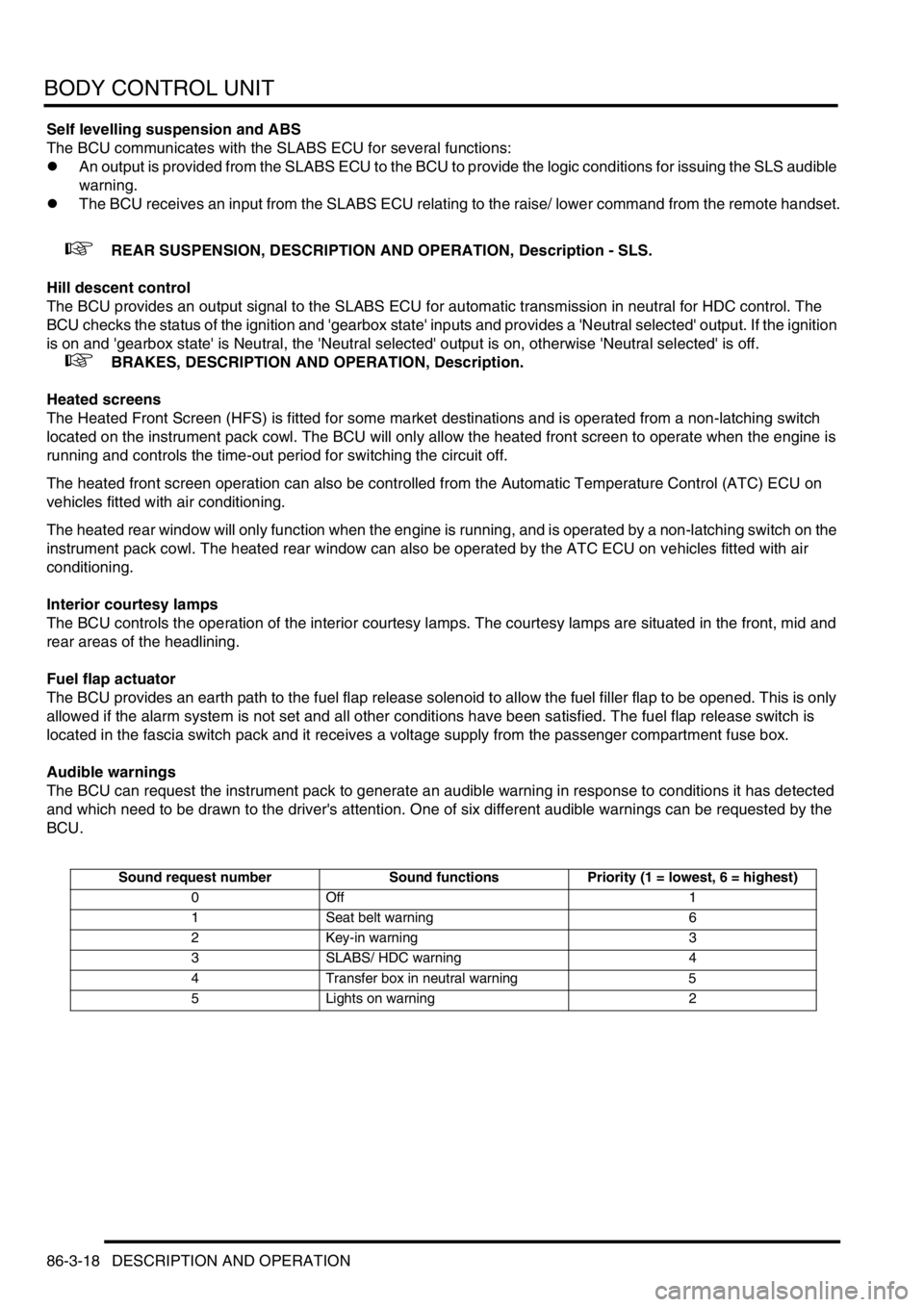

Audible warnings

The BCU can request the instrument pack to generate an audible warning in response to conditions it has detected

and which need to be drawn to the driver's attention. One of six different audible warnings can be requested by the

BCU.

Sound request number Sound functions Priority (1 = lowest, 6 = highest)

0Off 1

1 Seat belt warning 6

2 Key-in warning 3

3 SLABS/ HDC warning 4

4 Transfer box in neutral warning 5

5 Lights on warning 2

Page 1497 of 1672

BODY CONTROL UNIT

86-3-28 DESCRIPTION AND OPERATION

The BCU can be configured whether or not to provide bulb failure warnings.

When the direction indicators are operating, instrument pack direction indicators flash in sequence with the exterior

direction indicators. If a failure of an indicator bulb occurs, the corresponding instrument pack indication lamp will flash

quickly to warn of the problem.

The IDM monitors the current drawn through the circuit to detect for the occurrence of a lamp failure. If an indicator

lamp fails, the IDM detects the drop in current drawn through the resistor and operates the indicator relay at a faster

speed. The fast flash is demonstrated on the instrument pack direction indicator warning lamps to bring attention to

the driver that a direction indicator bulb failure has occurred. The current sense for the related indicator lamps (RH or

LH) are checked when a direction indicator request has been made that lasts for at least 160 ms. The current level

sensed is relative to the number of working bulbs and determines the request generated by the BCU.

The output is signalled to the instrument pack using the serial communications link. If the hazard warning lamps are

operating, both sets of direction indicators are checked using the current sensing functions to check the number of

bulbs on each side of the vehicle.

If the BCU detects that a direction indicator request has not been made, but one or other of the current sense inputs

indicate that current is flowing, a 'Relay stuck' output is generated.

Hazard lamps

The BCU controls the operation of the hazard warning lamps via the IDM and dedicated relays. The hazard warning

lamps are activated under the following conditions:

lThe vehicle is locked and the security system is set (the hazard warning lamps flash three times if the

superlocking feature is used, once if not).

lThe vehicle is unlocked (the hazard warning lamps flash once for a duration of two seconds).

lThe anti-theft alarm system is triggered (the hazard warning lamps flash in phase with and for the duration of the

audible warning).

lThe hazard warning switch is pressed (the hazard warning lamps flash until the hazard warning switch is pressed

for a second time).

lThe inertia switch is triggered (the hazard warning lamps flash until the inertia switch has been reset).

The hazard warning lamp operation may differ dependent on market and customer configuration options.

The hazard warning lamps are operated from a latching pushbutton switch located on the fascia. When the switch is

pressed, both left and right indicator lamps in the instrument pack flash to show that the hazard warning lamps are

operating and all hazard warning lamps flash simultaneously. If a trailer is fitted, the ICM detects this and a trailer

symbol in the instrument pack also flashes to show correct operation of the trailer direction indicators and hazard

warning lamps.

The BCU supplies a reference voltage to the hazard warning switch. When the hazard warning switch is operated an

earth path is completed which signals the BCU that a request for hazard lamp operation has been made. The BCU

then sends a signal to the IDM via the serial data bus to communicate the request. The IDM supplies an earth path

for both direction indicator relay coils simultaneously so that the hazard warning lamps are turned on concurrently.

The IDM controls the timing of the flash operations by continually removing and restoring the earth path to both

direction indicator relay coils simultaneously.

Number of working bulbs Request generated

3 Trailer detected

2 None (bulbs okay)

1 Bulb failure detected

0 Direction indicator short circuit detected

Page 1504 of 1672

BODY CONTROL UNIT

DESCRIPTION AND OPERATION 86-3-35

Fuel flap release

The fuel flap release solenoid only operates when the ignition switch is switched off, the anti-theft system is not

activated and the fuel flap release switch is pressed. If the BCU detects that these conditions have been satisfied, it

provides a path to earth for the fuel flap solenoid, so allowing the fuel flap to be opened.

To decide the correct conditions for providing a fuel flap enable output, the BCU checks the following input conditions:

lIgnition state.

lPerimetric alarm state.

If the battery state is not normal, the electric fuel flap enable is switched off.

Audible warnings

The BCU can request the instrument pack to generate an audible warning in response to logic conditions which have

been detected by the BCU and which need to be drawn to the driver's attention.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

Seat belt warning

The BCU can be programmed to include seat belt warning using one of four options:

lOption 1 – warning on for 6 seconds.

lOption 2 – warning on for 6 seconds or until the seat belt is fastened.

lOption 3 – warning on for 6 seconds unless the seat belt is fastened.

lOption 4 – no warning.

The BCU checks the status of the following inputs:

lIgnition on.

lSeat belt fastened.

Depending on the logic conditions of the inputs, the BCU provides the following outputs:

lAudible warning No.1 requested.

lSeat belt not fastened warning on instrument pack (via datalink to the instrument pack).

When programmed for option 1 operation, audible warning No. 1 is requested when the ignition switch is turned from

off to position II. The audible warning remains active for 6 seconds and a warning lamp on the instrument pack is

illuminated for the same duration.

When programmed for option 2 operation, audible warning No. 1 is requested when the ignition switch is turned from

off to position II. The audible warning remains active for 6 seconds or until the seat belt fastened signal is on and a

warning lamp on the instrument pack is illuminated for the same duration.

When programmed for option 3 operation, audible warning No. 1 is requested when the ignition switch is turned from

off to position II. The audible warning remains active for 6 seconds if the seat belt fastened signal is off; a warning

lamp on the instrument pack is illuminated for the same duration.

In the event of a communications link failure occurring, the audible and visual warning requests are not sent to the

instrument pack.

Page 1529 of 1672

ALARM SYSTEM AND HORN

86-4-20 DESCRIPTION AND OPERATION

Mislock

Mislock alerts the driver that a failed attempt has been made to lock the vehicle because of the doors or the bonnet

not being fully closed.

There are six audible configurations for mislock:

lNo audible warning.

lAlarm sounder.

lVehicle horn.

lAlarm sounder and vehicle horn.

lBBUS.

lAlarm sounder, vehicle horn and BBUS.

When a failed attempt has been made to lock the vehicle, the audible warning device is switched on for 50 ms and

off for 200 ms. The BCU allows the audible warning device to operate 3 times.

Passive immobilisation

Passive immobilisation prevents the vehicle from being started unless the authorised key is used to start the vehicle.

There are only two configurations for passive immobilisation:

lpassive immobilisation not active

lpassive immobilisation active

When the ignition is switched off, the vehicle remains mobilised for up to a maximum of 5 minutes. If however the

driver's door is opened, after 2 minutes 30 seconds, the vehicle remains in a mobilised state for a further 30 seconds.

When the timer in the BCU has expired, the vehicle is immobilised.

Once the ignition is switched on, the BCU transmits a coded signal to the ECM. If the coded signal does not

correspond to the programmed code in the ECM, the ECM is inhibited and the BCU inhibits the starting circuit.

In order for passive immobilisation to occur, the following conditions must be met:

lDriver's door closed.

lFuel cut-off switch not tripped.

lKey not inserted in ignition.

Passive remobilisation

Whenever the vehicle is immobilised, passive remobilisation of the engine occurs when the ignition is switched on,

allowing the vehicle to be started.

There are three configurations for passive remobilisation:

lPassive immobilisation not active.

lPassive immobilisation active.

lEKA with super locking on receiving good passive remobilisation exciter coil signal.

The BCU controls the passive remobilisation exciter coil (located around the ignition barrel) to generate a magnetic

field which causes the handset to transmit a remobilisation signal. The BCU receives the signal and allows the vehicle

to be started. If a valid signal from the handset is not received within one minute of the ignition being switched to

position II, the BCU stops the passive coil from generating the magnetic field.

Page 1606 of 1672

DRIVING AIDS

DESCRIPTION AND OPERATION 86-8-7

Sensors

Four sensors are positioned in the rear bumper. Each sensor comprises an outer housing with an angled rubber trim

which differs between the inner and outer sensors and the sensor body. The outer housing has a slot which engages

with a pin on the sensor body and is locked by rotating the sensor. A coil spring around the sensor is compressed

when the sensor is installed in the bumper and maintains the sensor housing engaged on the pin. The sensor housing

has a raised lip at the top which locates in a corresponding groove in the bumper mounting hole and sets the correct

orientation for the sensor body.

Each sensor has a three pin connector which connects into a common harness linking all four sensors. This harness

is connected to the main vehicle body harness. The three pins are for sensor negative and positive feeds and a signal

line.

Each sensor comprises a plastic housing which contains a piezoelectric disc. The disc resonates at a frequency of

38.4kHz, producing an ultrasonic signal output. The disc also receives the reflected echo signal.

The PDC ECU controls the operating mode of each sensor by output of a digital signal on the signal line. Each sensor

has two modes of operation; combined transmitter and receiver mode or receiver mode only.

Page 1634 of 1672

INSTRUMENTS

DESCRIPTION AND OPERATION 88-7

LCD odometer/trip meter

The LCD has 3 different display elements:

lOdometer.

lTrip meter.

lSelected gear (on vehicles with automatic gearboxes).

The odometer displays units in either miles or kilometres. It has a range from 0 to 999,999 units, only full units are

displayed irrespective of the type of units selected, the display will stop at 999,999 units. TestBook can be used to

reset the odometer. This is allowed only once and must be carried out before 150 miles (240 km) from new, after this

distance the feature is disabled. The odometer may lose up to one km (0.6 miles) when the battery is reconnected,

this is due to the software incorporated into the instrument pack to prevent anyone tampering with the odometer

reading.

The trip meter displays units in either miles or kilometres and has a range of 0.0 to 999.9 units. The display rolls over

from 999.9 to 0.0 units. Units down to one tenth of a mile or one tenth of a kilometre are displayed. The trip meter

displays 0.0 when the battery is reconnected or charged from a discharged state.

A push button located next to the LCD is utilised to reset the trip meter to zero and to change the units from miles to

kilometres. Pressing the button for less than 2 seconds allows the display to reset to zero. Pressing the button for

more than 2 seconds changes the units from miles to kilometres and vice versa. The units will only change for UK,

NAS and Canadian market vehicles.

The selected gear displays when the automatic gearbox is in park, reverse, neutral, drive 3,2,1, by using the letters

or numbers PRND321 in the display.

The data input for the LCD odometer/trip meter is from the SLABS ECU for the distance input and from the BCU for

the gear position. The instrument pack provides the earth path to illuminate the gear position warning lamp.

If a replacement instrument pack is required TestBook must be used to retrieve the odometer reading, so that when

the new instrument pack is fitted the odometer reading can be programmed in.

Page 1646 of 1672

INSTRUMENTS

DESCRIPTION AND OPERATION 88-19

High engine coolant temperature warning lamp

The high engine coolant temperature warning lamp within the instrument pack utilises a red LED and a clear legend.

The ECM illuminates the LED when it detects the engine coolant has exceeded a temperature of 121

°C (250 °F) and

switches it off when the coolant temperature drops below 118

°C (244 °F). The ECM also illuminates the high engine

coolant temperature warning lamp when it detects the PWM duty cycle to the temperature gauge is out of range. If it

is greater than 94% duty cycle when the engine is hot, or less than 8% duty cycle when the engine is cold, the engine

coolant temperature gauge pointer will indicate cold, thus alerting the driver with an additional visible warning.

When the ignition is switched on, the ECM illuminates the LED to provide a self-check, providing there is no fault it

will remain illuminated for 3 seconds or until the ignition is switched off.

The response of the engine high temperature warning lamp varies according to engine type and market, there are

three conditions:

lV8 - Gulf.

lV8 - all markets except Gulf.

lDiesel - all markets.

The vehicle configuration determines which condition is set.

The PWM duty cycle thresholds for illuminating and extinguishing the warning lamp are given in the table below.

The power input for the LED is supplied by the instrument pack via fuse 27. The ECM controls the earth path to

illuminate the warning lamp.

Market Lamp on Lamp off

V8 - Gulf 79.8 ± 2% 77.8 ± 2%

V8 - all markets except Gulf 77.8 ± 2% 75.7 ± 2%

Diesel - all markets 78.8 ± 2% 76.8 ± 2%

Page 1660 of 1672

INSTRUMENTS

DESCRIPTION AND OPERATION 88-33

Engine oil pressure warning lamp

The engine oil pressure warning lamp within the instrument pack utilises a red LED and a clear legend. The LED

illuminates when the engine oil pressure is below the specified pressure (see table), providing the driver with a visible

warning that the engine oil pressure has fallen below the specified minimum reading.

There is no self-test performed at ignition on for this warning lamp.

The power input for the LED is supplied by the instrument pack via fuse 27. The oil pressure switch located on the

engine provides the earth path to illuminate the warning lamp, it will remain illuminated until the engine is started and

the oil pressure exceeds the appropriate threshold and opens the switch contacts.

Low oil pressure switch operating pressures

The response to the voltage signal at the instrument pack is as follows:

l< 1.8 volts = warning lamp on.

l> 7.7 volts = warning lamp off.

Engine type Switch opening pressure, bar (lbf.in2)

V8 0.22 to 0.59 (3.0 to 8.5)

Diesel 0.25 to 0.42 (3.5 to 6.0)

Page 1661 of 1672

INSTRUMENTS

88-34 DESCRIPTION AND OPERATION

Alternator charge warning lamp

The alternator charge warning lamp within the instrument pack utilises a red LED and a clear legend. The LED

illuminates when the alternator output voltage is less than 2 volts. When the alternator output is greater than 7.6 volts

the LED is extinguished, providing the driver with a visible warning that the alternator is charging.

When the ignition is switched on, and the LED illuminates, it will remain illuminated until the engine is started and

voltage is above the predetermined parameter, or the ignition is switched off providing there is no fault.

The power input for the LED is supplied by the instrument pack via fuse 27. The alternator provides a signal to

illuminate the warning lamp by means of a hard wired connection to the instrument pack.

The response to the voltage signal at the instrument pack is as follows:

l< 2.0 volts = warning lamp on.

l> 7.6 volts = warning lamp off.

Page 1665 of 1672

INSTRUMENTS

88-38 DESCRIPTION AND OPERATION

Gearbox manual/sport mode warning lamps

The gearbox manual/sport mode warning lamps within the instrument pack each utilise a green LED and a clear

legend. On vehicles fitted with an automatic gearbox, operating the manual mode switch instructs the Electronic

Automatic Transmission (EAT) ECU to illuminate the manual mode LED. Operating the sport mode switch instructs

the EAT ECU to illuminate the sport mode LED.

There is no self-test performed at ignition on for this warning lamp.

If the EAT ECU detects a fault it will cause both warning lamps to flash.

The power input for the LED's is supplied by the instrument pack. The EAT ECU applies a high or low voltage to the

instrument pack microprocessor which measures the applied voltage from the ECU and illuminates the appropriate

warning lamp.

The voltage on the earth paths from the EAT ECU to the instrument pack has the following functions:

Warning lamp response Manual earth path, volts Sport earth path, volts

No lamps > 7.7 > 7.7

Sport warning > 7.7 < 1.8

Manual warning < 1.8 > 7.7

Both lamps flash < 1.8 < 1.8