Brakes and speed sensors LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 399 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-6 DESCRIPTION AND OPERATION

Description

General

An engine control module (ECM) controls the five-cylinder direct injection diesel engine, and works on the drive by

wire principle. This means there is no throttle cable, the ECM controls the drivers needs via a signal from the Throttle

Position (TP) sensor on the throttle pedal.

The ECM is a full authoritative diesel specific microprocessor that also incorporates features for cruise control and air

conditioning control. In addition, the ECM supplies output control for the exhaust gas recirculation and turbocharger

boost pressure. The ECM has a self-diagnostic function, which is able to provide backup strategies for most sensor

failures.

The ECM processes information from the following input sources:

lMass air flow sensor.

lAmbient air pressure sensor.

lManifold absolute pressure/inlet air temperature sensor.

lEngine coolant temperature sensor.

lCrankshaft speed and position sensor.

lThrottle position sensor.

lFuel temperature sensor.

lAir conditioning request.

lAir conditioning fan request.

lBrake pedal switch.

lClutch switch.

lCruise control master switch.

lCruise control SET+ switch.

lCruise control RES switch.

lHigh/low ratio switch.

The input from the sensors constantly updates the ECM with the current operating condition of the engine. Once the

ECM has compared current information with stored information within its memory, it can make any adjustment it

requires to the operation of the engine via the following:

lAir conditioning clutch relay.

lAir conditioning cooling fan relay.

lElectronic vacuum regulator solenoid.

lMalfunction indicator lamp.

lFuel pump relay.

lGlow plug warning lamp.

lGlow plugs.

lFuel injectors.

lMain relay.

lTurbocharger wastegate modulator.

lTemperature gauge.

The ECM interfaces with the following:

lElectronic Automatic Transmission (EAT).

lSelf Levelling and Anti-lock Brakes System (SLABS).

lSerial communication link.

lInstrument cluster.

lBody Control Unit (BCU).

Page 1063 of 1672

BRAKES

70-18 DESCRIPTION AND OPERATION

The SLABS ECU continually calculates vehicle speed using the wheel speed inputs from all four ABS sensors. The

calculated vehicle speed is then used as a reference against which individual wheel speeds are monitored for

unacceptable acceleration or deceleration. The ABS sensor inputs are also used by the SLABS ECU to detect vehicle

deceleration rate, vehicle cornering rate and rough terrain.

The engaged forward gear and (on manual gearbox models) the clutch status are computed from the engine data

input, the engine speed input and vehicle speed. Reverse gear status is provided by an input from the reverse lamp

switch (manual gearbox models) or the BCU (automatic gearbox models). On automatic models, the BCU also

provides the neutral selected input.

In addition to controlling the brake related functions, the SLABS ECU:

lControls the operation of the self levelling suspension (SLS) system (where fitted).

+ REAR SUSPENSION, DESCRIPTION AND OPERATION, Description.

lOn V8 models, outputs a rough road signal to the ECM when traversing rough terrain.

lOutputs a vehicle speed signal.

The vehicle speed signal is output to the following systems (where fitted):

lActive Cornering Enhancement.

+ FRONT SUSPENSION, DESCRIPTION AND OPERATION, Description - ACE.

lAir conditioning.

+ AIR CONDITIONING, DESCRIPTION AND OPERATION, Description.

lCruise control.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

lEngine management.

+ ENGINE MANAGEMENT SYSTEM - Td5, DESCRIPTION AND OPERATION, Description.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

lIn-car entertainment.

+ IN CAR ENTERTAINMENT, DESCRIPTION AND OPERATION, Description.

lInstrument pack.

+ INSTRUMENTS, DESCRIPTION AND OPERATION, Description.

ABS sensors

The ABS sensors supply the SLABS ECU with a sinusoidal speed signal from each wheel. An inductive sensor,

installed in the hub bearing of each wheel, senses off a 60 tooth exciter ring integrated into the inner race of the hub

bearing. Each ABS sensor has a fly-lead connecting it to the vehicle wiring.

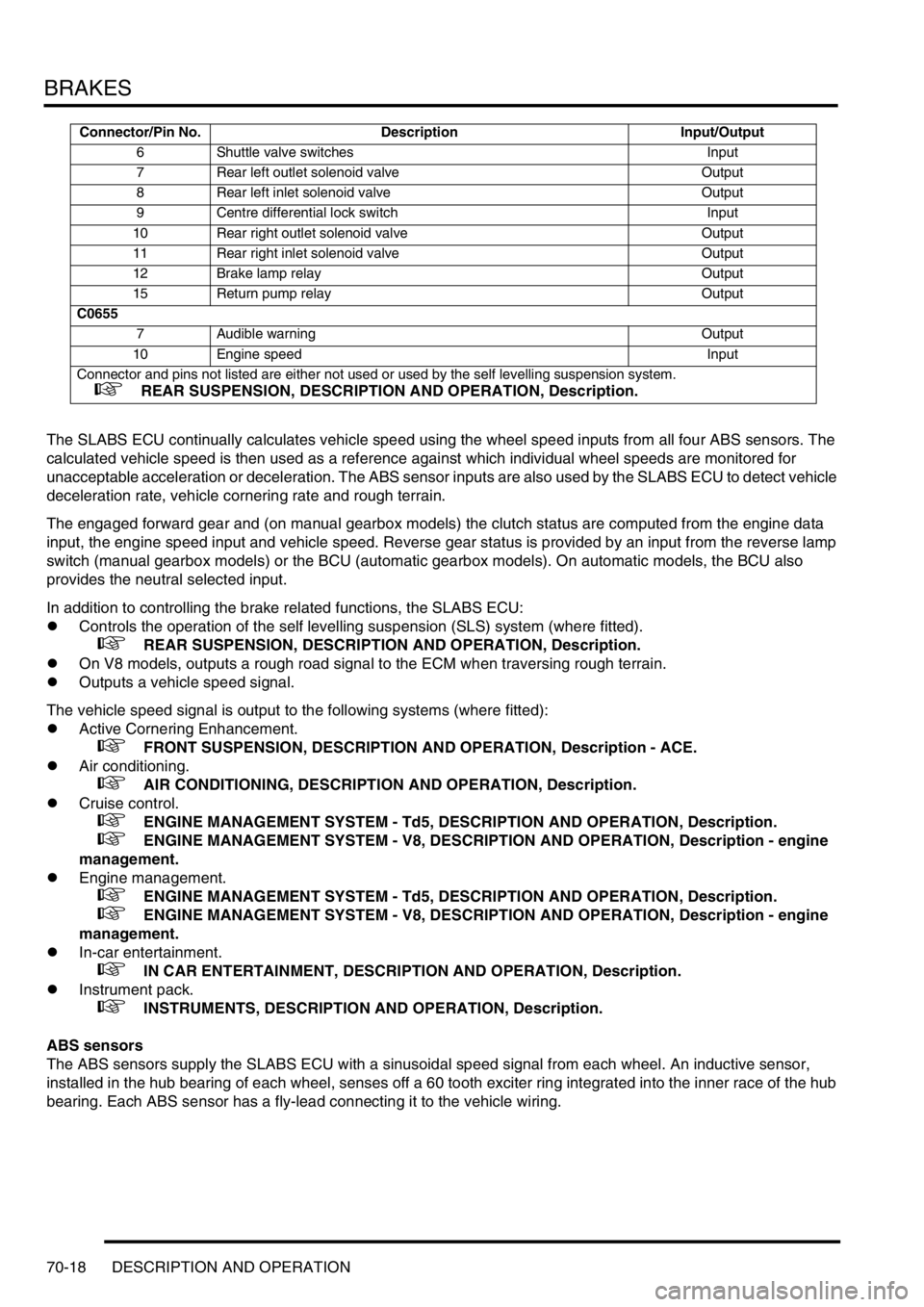

6 Shuttle valve switches Input

7 Rear left outlet solenoid valve Output

8 Rear left inlet solenoid valve Output

9 Centre differential lock switch Input

10 Rear right outlet solenoid valve Output

11 Rear right inlet solenoid valve Output

12 Brake lamp relay Output

15 Return pump relay Output

C0655

7 Audible warning Output

10 Engine speed Input

Connector and pins not listed are either not used or used by the self levelling suspension system.

+ REAR SUSPENSION, DESCRIPTION AND OPERATION, Description.

Connector/Pin No. Description Input/Output

Page 1068 of 1672

BRAKES

DESCRIPTION AND OPERATION 70-23

Typical disabled times

Diagnostics

While the ignition is on, the diagnostics function of the SLABS ECU monitors the system for faults. In addition, the

return pump is tested by pulsing it briefly immediately after the engine starts provided vehicle speed exceeded 4.4

mph (7 km/h) during the previous ignition cycle. If a fault exists in a warning lamp circuit, the lamp will not illuminate

during the lamp check at ignition on but, provided there are no other faults, the related function will otherwise be fully

operational. If a fault is detected during the power up, the SLABS ECU stores a related fault code in memory and

illuminates the appropriate fault warning lamps. If a fault is detected later in the drive cycle, the SLABS ECU also

sounds the audible warning three times.

Fault codes and diagnostic routines can be accessed by connecting Testbook to the vehicle's diagnostic connector

in the driver's footwell.

Warning lamp fault operation

After detecting a fault, the SLABS ECU selects an appropriate default strategy which, where possible, retains some

operational capability. A shuttle valve switch fault and throttle position signal fault are classified as permanent faults.

If a permanent fault is detected, the related warning lamp illumination and default strategies are automatically

employed in subsequent ignition cycles, even if the fault is intermittent, until the fault has been rectified and cleared

from memory. If a non permanent fault is detected, the related warning lamp illumination and default strategies will

only be employed in subsequent ignition cycles if the fault is still present.

After rectification of an ABS sensor fault, the ABS and ETC functions are disabled, and the ABS warning lamp remains

illuminated after the lamp check, until vehicle speed exceeds 9.4 mph (15 km/h) (to allow additional checks to be

performed).

Vehicle speed, mph (km/h) Time, minutes

1.3 (2) 40

12.5 (20) 33

15.6 (25) 17

25.0 (40) 9

31.3 (50) 6

Item Check Warning lamp

ABS Brake ETC HDC

fault

ABS sensors Resistance (to check status) On On On On

Brake lamps relay Open/Short circuit Off Off Off On

Engine data Sticking throttle, signal failure, data corruption Off Off On On

Inlet solenoid valves Open/Short circuit On On On On

Outlet solenoid valves Open/Short circuit On On On On

Reference earth Connection to earth On On On On

Return pump monitor Correct pump operation On On On On

Return pump relay Open/Short circuit On On On On

Shuttle valve switches Open/Short circuit On On On On

SLABS ECU Internal failure On On On On

Supply voltages Range (10 to 16 V) On On On On