wiper fluid LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 5 of 1672

CONTENTS

2CONTENTS

IDENTIFICATION NUMBERS .................................................................. 05-1

Vehicle Identification Number ......................................................................................................... 05-1

Identification Number Locations ..................................................................................................... 05-3

TORQUE WRENCH SETTINGS .............................................................. 06-1

Maintenance ................................................................................................................................... 06-1

Engine Td5 ..................................................................................................................................... 06-2

Engine V8 ....................................................................................................................................... 06-4

Emission control - Td5 .................................................................................................................... 06-5

Emission control - V8 ...................................................................................................................... 06-5

Engine management system - Td5 ................................................................................................. 06-5

Engine management system - V8................................................................................................... 06-6

Cooling system ............................................................................................................................... 06-6

Manifolds and exhaust systems - Td5 ............................................................................................ 06-6

Manifolds and exhaust systems - V8 .............................................................................................. 06-7

Clutch.............................................................................................................................................. 06-7

Manual gearbox - R380 .................................................................................................................. 06-8

Transfer box - LT230SE ................................................................................................................. 06-8

Automatic gearbox - ZF4HP22/24 .................................................................................................. 06-9

Propeller shafts ............................................................................................................................... 06-9

Axles ............................................................................................................................................... 06-9

Steering .......................................................................................................................................... 06-10

Front suspension ............................................................................................................................ 06-11

Rear suspension ............................................................................................................................. 06-12

Brakes............................................................................................................................................. 06-12

Restraint systems ........................................................................................................................... 06-13

Body................................................................................................................................................ 06-14

Heating and air conditioning ........................................................................................................... 06-15

Wipers and washers ....................................................................................................................... 06-15

Electrical ......................................................................................................................................... 06-15

LIFTING AND TOWING ........................................................................... 08-1

LIFTING .......................................................................................................................................... 08-1

TOWING ......................................................................................................................................... 08-2

TRANSPORTING ........................................................................................................................... 08-3

CAPACITIES, FLUIDS AND LUBRICANTS ............................................ 09-1

Capacities ....................................................................................................................................... 09-1

Fluids .............................................................................................................................................. 09-2

Anti-Freeze Concentration .............................................................................................................. 09-3

Lubrication ...................................................................................................................................... 09-3

MAINTENANCE ........................................................................................ 10-1

PROCEDURES

V8 engine underbonnet view .......................................................................................................... 10-1

Diesel underbonnet view ................................................................................................................ 10-2

Seats and seat belts ...................................................................................................................... 10-3

Lamps, horns and warning indicators ........................................................................................... 10-5

Wipers and washers ...................................................................................................................... 10-5

Handbrake .................................................................................................................................. 10-6

Page 943 of 1672

FRONT SUSPENSION

60-4 DESCRIPTION AND OPERATION

Description

General

The front suspension comprises two dampers and coil springs, two radius arms, a Panhard rod and an anti-roll bar.

The front axle provides the location points for the dampers, springs, radius arms and the Panhard rod.

The anti-roll bar assembly is an essential part of the front suspension. On vehicles without Active Cornering

Enhancement (ACE) a conventional 'passive' anti-roll bar is fitted. On vehicles fitted with the ACE system, a thicker

diameter anti-roll bar, known as a torsion bar, is used with an actuator at one end.

+ FRONT SUSPENSION, DESCRIPTION AND OPERATION, Description - ACE.

The hydraulic dampers and coil springs provide springing for each front wheel. The long travel dampers, springs and

radius arms provide maximum axle articulation and wheel travel for off-road driving. The front axle is controlled

longitudinally by two forged steel radius arms and transversely by a Panhard rod.

Radius arms

Each radius arm is manufactured from forged steel. Two bushes are pressed into the forward end of the radius arm.

The forward end of the radius arm is located in a fabricated bracket on the axle and secured through the bushes with

two bolts and nuts. A bush is pressed into the rear of the radius arm which is also located in a fabricated bracket on

each chassis longitudinal and secured through the bush with a bolt and nut.

The radius arms prevent longitudinal movement of the front axle and because of their length allow maximum axle

articulation. The stiffness of the bushes in each radius arm also contributes to the vehicle roll stiffness.

Each radius arm has a notch on its lower edge which provides location for the vehicle jack.

Dampers

Two conventional telescopic dampers are used to control body/axle movement. A turret is located on a bracket welded

to the chassis. The upper spring seat has four studs which pass through holes in the bracket and align with

corresponding holes in the turret. Four nuts are screwed onto the studs and secure the turret and upper spring seat

to the chassis.

A fabricated platform is welded to the axle. The platform has two captive nuts which provide for the attachment of the

damper. A lower spring seat is located on the platform. Each spring seat is handed and has a bracket which secures

the ABS sensor harness and the front brake hose.

Each damper is fitted with a bush at its upper end. The bush locates in the top of the turret and is secured with a cross

bolt. The lower attachment point for the damper is also fitted with a bush. This bush has a spindle through its centre

with a hole at each end. The spindle is seated on the lower spring seat and the axle platform and secured with two

bolts. The coil spring is fitted in a compressed state between the upper and lower spring seats and assists the damper

in controlling the body/axle movement. The upper and lower bushes are replaceable items.

Rubber bump stops are fitted to the chassis above each end of the axle. The bump stops are progressive in their

compression and prevent the axle from contacting the chassis in the event of maximum suspension travel being

reached. The bump stops revert to their original shape once the compression load has been removed from them.

The damper functions by restricting the flow of a hydraulic fluid through internal galleries within the damper body. A

chromium plated rod moves axially within the damper. As the rod moves, its movement is limited by the flow of fluid

through the galleries thus providing damping of undulations in the terrain. The damper rod is sealed at its exit point

from the body to maintain fluid within the unit and prevent the ingress of dirt and moisture. The seal also acts as a

wiper to keep the rod outer diameter clean. A plastic shroud protects the rod and slides over the body as the damper

moves. The coil spring aids the damper to extend after being compressed and also aids the damping process.

Page 1270 of 1672

PANEL REPAIRS

REPAIRS 77-2-21

REPAIRS

Front bulkhead assembly

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

5. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

6. Diesel models: Remove gearbox fluid cooler.

7.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8.Release headlamp levelling motors and

position aside.

9.Release headlamp wiring and position aside.

10.Remove battery.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11.Remove battery tray.

12.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

13.Remove 2 earth leads from LH of front

bulkhead.

14.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

15. Models with A/C: Release and remove A/C

pipes.

16.Remove RH and LH crush cans.

17.Remove bonnet release cable.

18.Support bonnet in open position

19.Remove bonnet locking mechanism.

20.Remove VIN plate.

21.Remove 2 bolts securing front bulkhead

assembly to chassis.

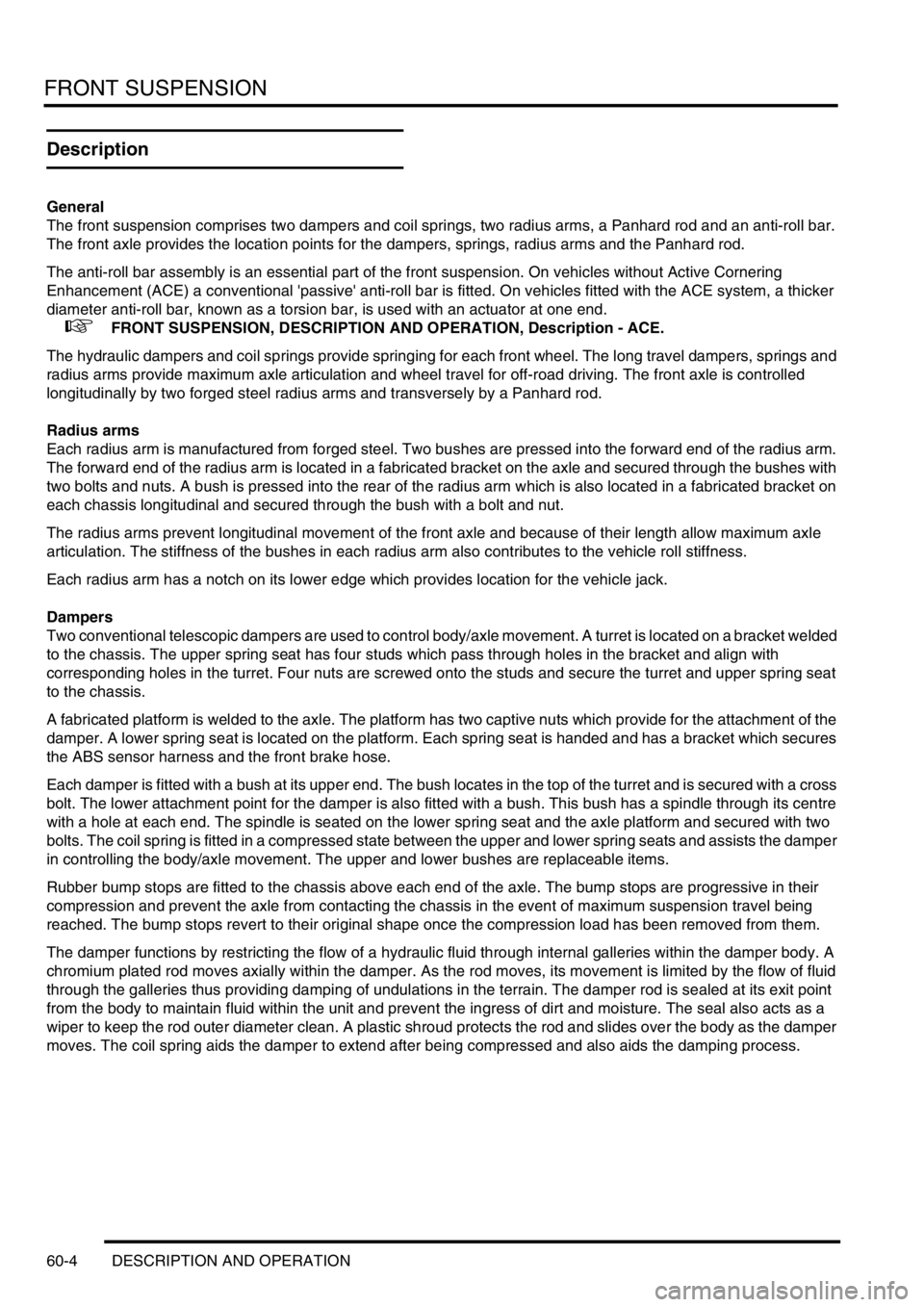

22.Remove centre braces.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten to 45 Nm (33 lbf.ft).

3.Fit VIN plate.

4.Fit bonnet locking mechanism.

5.Fit bonnet release cable.

6.Fit crush cans.

7. Models with A/C: Fit A/C pipes.

8.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

9.Fit 2 earth leads to LH of front bulkhead.

10.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Fit battery tray.

12.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

13.Fit headlamp wiring and headlamp levelling

motors.

14.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

15. Diesel models: Fit gearbox fluid cooler.

16. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

17.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

Page 1272 of 1672

PANEL REPAIRS

REPAIRS 77-2-23

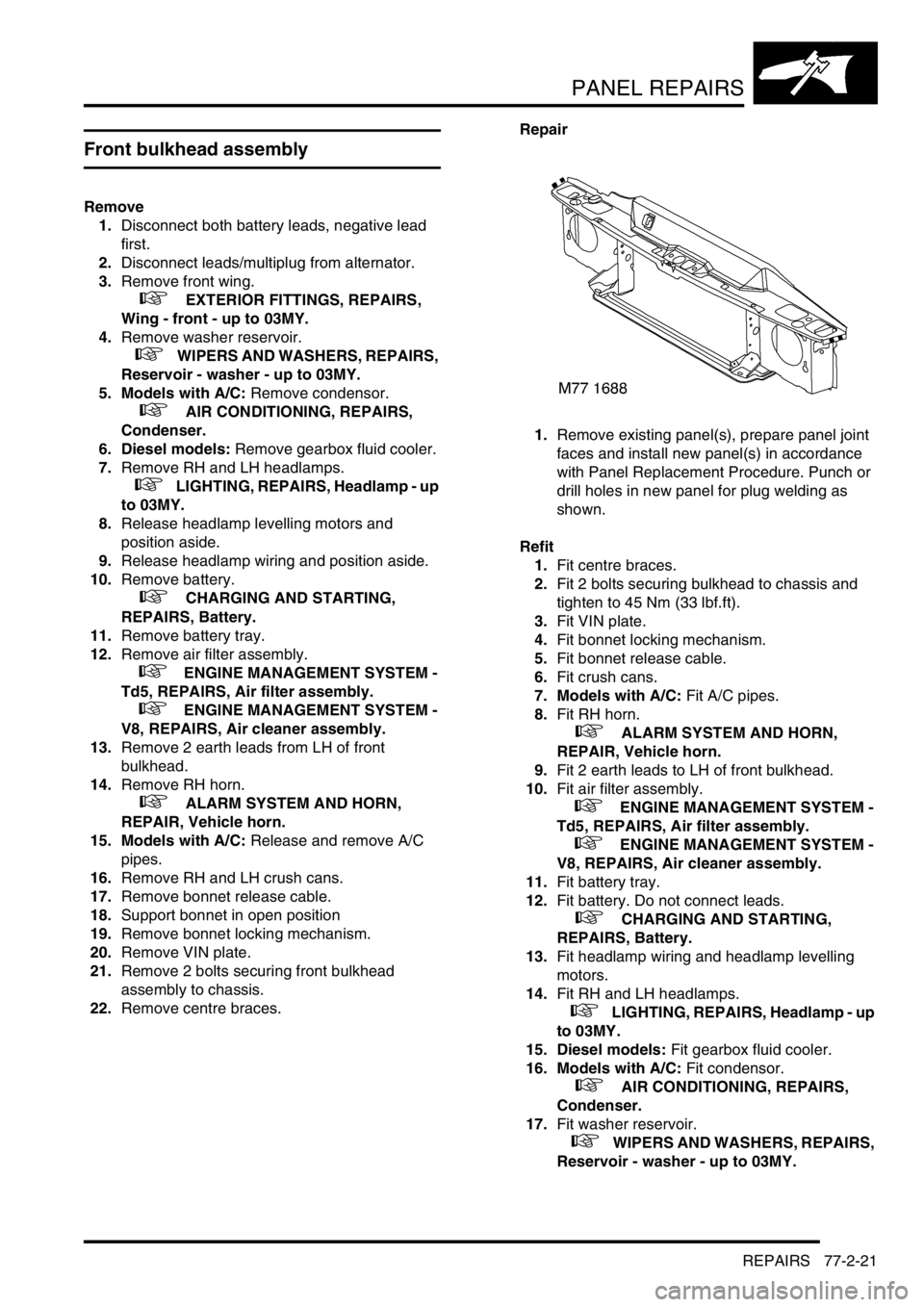

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre braces.

2.Fit VIN plate.

3.Fit bonnet locking mechanism.

4.Fit bonnet release cable.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

7.Fit battery tray.

8.Fit battery. Do not connect leads.

+ CHARGING AND STARTING,

REPAIRS, Battery.

9.Fit headlamp wiring.

10.Fit RH and LH repeater lamps.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

11.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Front cross member

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Release headlamp levelling motors and

position aside.

8.Release headlamp wiring and position aside.

9.Remove RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

10. Models with A/C: Release and remove A/C

pipes.

11.Remove RH and LH crush cans.

12.Remove 2 bolts securing front bulkhead

assembly to chassis.

13.Remove centre braces.

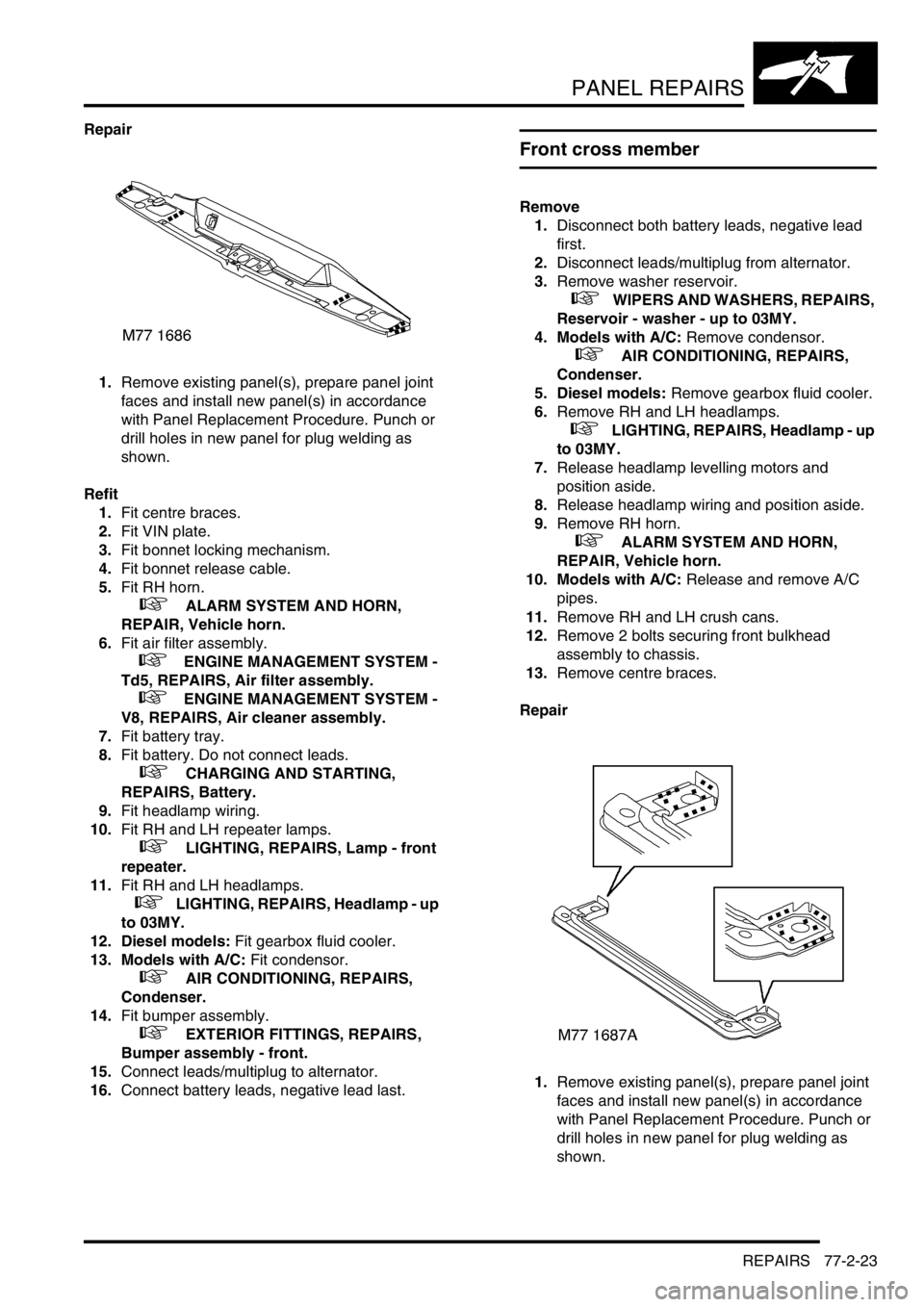

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Page 1273 of 1672

PANEL REPAIRS

77-2-24 REPAIRS

Refit

1.Fit centre braces.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit crush cans.

4. Models with A/C: Fit A/C pipes.

5.Fit RH horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

6.Fit headlamp wiring and headlamp levelling

motors.

7.Fit RH and LH headlamps.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

8. Diesel models: Fit gearbox fluid cooler.

9. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

10.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

11.Connect leads/multiplug to alternator.

12.Connect battery leads, negative lead last.

Headlamp mounting panel - RH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front bumper assembly.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove RH headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove RH repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp levelling motor and position

aside.

9.Release headlamp wiring and position aside.

10.Remove battery and battery tray.

+ CHARGING AND STARTING,

REPAIRS, Battery.

11.Remove horn.

+ ALARM SYSTEM AND HORN,

REPAIR, Vehicle horn.

12.Remove RH crush can.

13.Remove 2 bolts securing front bulkhead

assembly to chassis.

14.Remove RH centre brace.

Page 1275 of 1672

PANEL REPAIRS

77-2-26 REPAIRS

Headlamp mounting panel - LH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

4. Models with A/C: Remove condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

5. Diesel models: Remove gearbox fluid cooler.

6.Remove headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

7.Remove repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

8.Release headlamp levelling motor and position

aside.

9.Release headlamp wiring and position aside.

10.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

11.Remove 2 earth leads from LH of front

bulkhead.

12.Release and remove A/C pipes.

13.Remove crush can.

14.Remove bonnet release cable.

15.Remove 2 bolts securing front bulkhead

assembly to chassis.

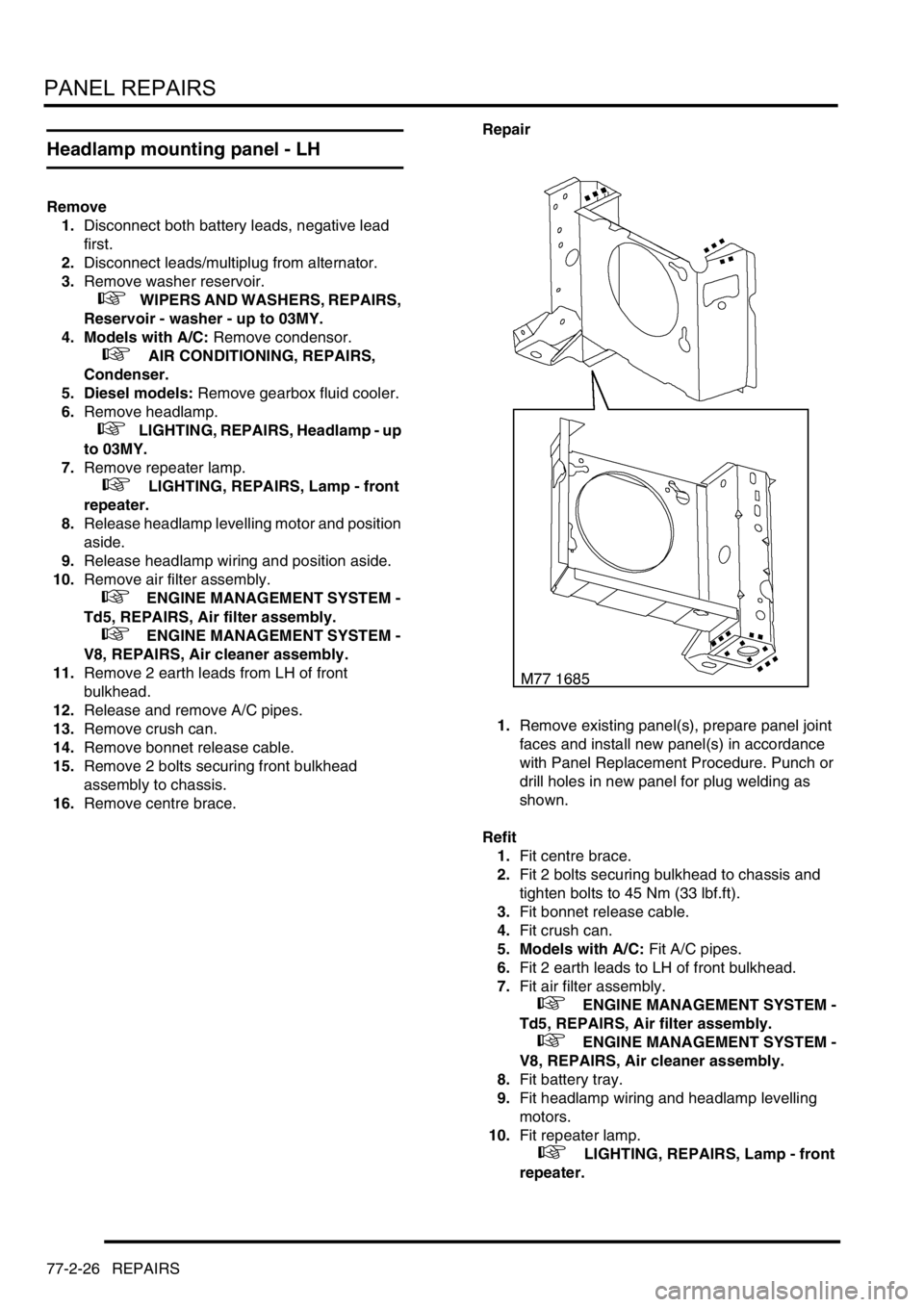

16.Remove centre brace.Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1.Fit centre brace.

2.Fit 2 bolts securing bulkhead to chassis and

tighten bolts to 45 Nm (33 lbf.ft).

3.Fit bonnet release cable.

4.Fit crush can.

5. Models with A/C: Fit A/C pipes.

6.Fit 2 earth leads to LH of front bulkhead.

7.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

8.Fit battery tray.

9.Fit headlamp wiring and headlamp levelling

motors.

10.Fit repeater lamp.

+ LIGHTING, REPAIRS, Lamp - front

repeater.

Page 1276 of 1672

PANEL REPAIRS

REPAIRS 77-2-27

11.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Valance upper assembly - LH

In this procedure, the front wing, the valance outer

reinforcement and the bonnet alarm switch mounting

bracket are replaced in conjunction with the LH

valance upper assembly.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

5.Remove PAS/ACE reservoir.

6.Remove ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

7.Remove brake pipes from valance.

8.Release harness from valance and position

aside.

9. Models with A/C: Depressurise A/C system

and remove pipes from valance.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

Page 1429 of 1672

WIPERS AND WASHERS

84-8 DESCRIPTION AND OPERATION

Description

General

All markets have a common wiper system with headlamp powerwash as an option.

The wipers system comprises two front wipers and one rear wiper which are powered by electric motors. A washer

reservoir is located in the front left hand wheel arch and is fitted with two electric pumps. Each pump supplies washer

fluid to either the front or rear screens. On certain models, a third pump can be fitted to operate a headlamp power

wash function. Operation of the front and rear wipers and washers is controlled by the driver using switches located

on a steering column stalk and push button switches on the fascia.

Control of the wipers and washers is achieved by the following components:

lBCU.

lIDM.

lFront wiper relay.

lFront wash/ wipe switch.

lVariable delay switch.

lFront wiper motor assembly.

lFront washer pump motor.

lRear wiper relay.

lRear wiper switch.

lRear washer switch.

lRear wiper motor.

lRear washer pump motor.

Both the Body Control Unit (BCU) and the Intelligent Driver Module (IDM) control the wiper system. The BCU controls

the time delay function of the wiper system and is located below and behind the passenger glovebox. During engine

cranking the BCU prevents wiper functions. Two relays are located in the passenger compartment fusebox. The

relays control the delay operation of the front and rear wipers. The relays are an integral part of the fusebox and

cannot be renewed separately.

Power for the wiper system is supplied by the IDM, which is integral with the passenger fusebox and cannot be

renewed as a component. A serial communication link allows communication between the IDM and the BCU.

The system has diagnostic capabilities through TestBook.

Front wipers

The two front windscreen wipers are operated by a linkage assembly and an electric motor located under the plenum

grill below the windscreen. The linkage and motor assembly is handed for left and right hand drive vehicles. The motor

is an integral part of the linkage and cannot be replaced separately.

The linkage comprises a pressed steel mounting plate which provides for the attachment of a wheel box at each end.

The mounting plate is secured to the bulkhead with flanged nuts which attach to a stud plate located behind the

bulkhead. A link arm is attached to each wheel box by a short link and secured with circlips. The link arm has an

attachment hole centrally located along its length for the electric motor drive link.

The electric motor is mounted in a recess in the bulkhead below a sealed cover plate. The drive spindle of the motor

protrudes through the cover plate and is fitted with a link. The link is attached to a tapered spline on the motor spindle

and is secured with a lock washer and nut. The opposite end of the link is attached to the central attachment point on

the link arm and secured with a circlip.

Each wheel box has a taper splined shaft which allows for the attachment of the wiper arm which is secured with a

washer and nut. The shaft of each wheel box is passed through a rubber sealed aperture in the plenum. The wiper

arm attachment to the splined shaft has a pivot to which the remainder of the arm is attached. The two parts of the

arm are connected by a spring which controls the pressure of the blade on the screen to a predetermined amount.

Page 1433 of 1672

WIPERS AND WASHERS

84-12 DESCRIPTION AND OPERATION

Rear wiper motor

The DC motor contains two permanent magnets and a park switch. An earth braid attached between the motor casing

and the brush pack is utilised to minimise radio interference during wiper functions.

The rear wiper switch provides an earth signal to the BCU, which determines the delay interval, if appropriate. The

BCU then signals the IDM to activate the rear wiper motor relay, which provides power to the rear wiper motor.

To allow the rear wiper to park when the rear wiper is switched off, power flows through the park switch until a cam

in the wiper motor assembly breaks the contact of the park switch. Triggering the park switch grounds the positive

side of the wiper motor causing it to stop abruptly

Washers

The washer system comprises a reservoir, washer pumps, hoses and washer jets. The front washers are controlled

from a stalk switch on the steering column and the rear washers are operated by a non-latching pushbutton switch on

the fascia adjacent to the instrument pack.

Reservoir

The reservoir is located behind the front bumper in the inner wheel arch and has a capacity of 6.0 litres (12.5 US pints).

A filler neck tube is connected to the reservoir with a seal and extends into the engine compartment on the front left

hand side. The filler neck tube contains a removable filter to prevent particle contamination and a yellow float to show

reservoir contents. The washer filler neck tube is sealed with a cap which is coloured blue for identification.

Two electric washer pumps are located on the rear face of the reservoir and supply washer fluid to the front

windscreen and the tail door window. Each pump is sealed to the reservoir with a rubber sealing grommet.

On vehicles with headlamp powerwash fitted, a third pump is fitted with a sealing grommet to the front face of the

reservoir.

The reservoir and filler neck tube are manufactured from moulded opaque nylon. The reservoir has moulded lugs for

attachment to the vehicle body. A bracket is attached to the top of the filler neck tube and locates in a hole in the body

to secure the top of the tube.

Page 1434 of 1672

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-13

Front screen washer jets

Two washer jets for the front windscreen are fitted to the top surface of the bonnet and held in place with plastic clips.

Each washer jet is connected via a hose to an in-line valve. The in-line valve prevents the washer fluid draining back

to the reservoir and ensures that the washers operate immediately the washer pump is operated. From each in-line

valve the washers are connected via a short hose to a 'T' connector. From the 'T' connector a single hose connects

to the outlet of the front washer pump. Each jet has two jets which can be adjusted to allow full fluid coverage of the

windscreen.

Rear screen washer jet

A single washer jet for the tail door window is fitted to the rear wiper blade. The jet has four spray orifices which direct

washer fluid to either side and along the length of the wiper blade. The jet is connected by a hose from the wiper blade,

through a sealing grommet in the tail door and connects with the rear washer hose from the rear washer pump. A non-

return valve is used to join the feed hose from the pump to the washer jet hose. The non-return valve prevents fluid

draining to the reservoir and ensures that the washer operates immediately the washer pump is operated. The hose

from the pump to the tail door is located inside the main harness.

Headlamp power washer jets

When fitted, a powerwash jet for each headlamp is located in a housing on the top surface of the front bumper. The

jets are fed with fluid at high pressure from the powerwash pump. A large diameter hose connects each jet to the

pump. Each connection is secured with a metal clip to secure the hose due to the high pressure from the pump. Each

jet directs the high pressure fluid in a wide spray onto the headlamp lens.

Rear washer switch

The rear washer switch is a non-latching pushbutton switch and is located on the RH side of the instrument pack.

Activating the rear washer switch provides battery voltage from fuse 30 in the passenger compartment fusebox to the

rear washer pump.