engine oil LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 306 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-1

ENGIN E MANAGEMENT SY STEM - SIEMENS REPAIRS

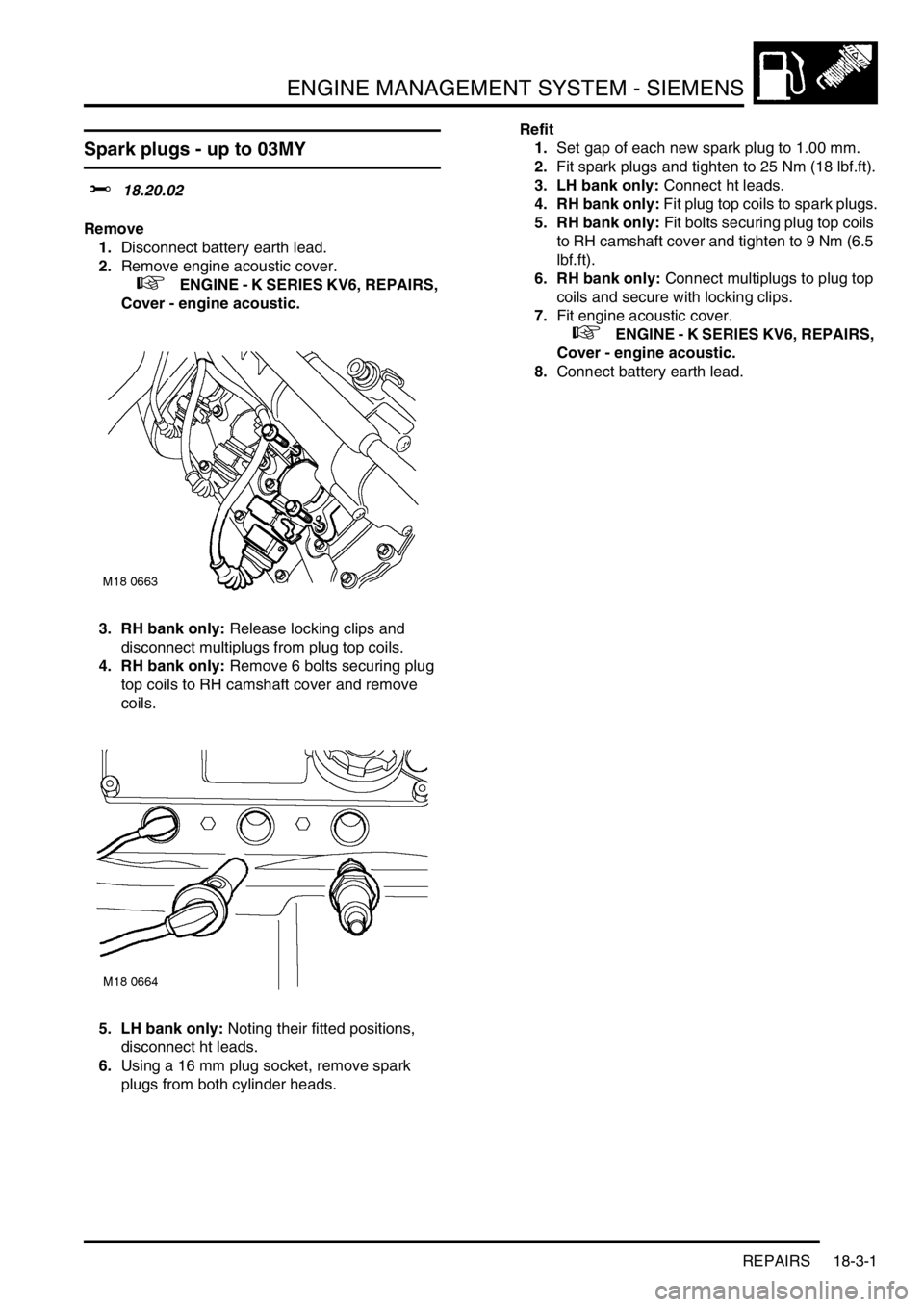

Spark plugs - up to 03MY

$% 18.20.02

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3. RH bank only: Release locking clips and

disconnect multiplugs from plug top coils.

4. RH bank only: Remove 6 bolts securing plug

top coils to RH camshaft cover and remove

coils.

5. LH bank only: Noting their fitted positions,

disconnect ht leads.

6.Using a 16 mm plug socket, remove spark

plugs from both cylinder heads.Refit

1.Set gap of each new spark plug to 1.00 mm.

2.Fit spark plugs and tighten to 25 Nm (18 lbf.ft).

3. LH bank only: Connect ht leads.

4. RH bank only: Fit plug top coils to spark plugs.

5. RH bank only: Fit bolts securing plug top coils

to RH camshaft cover and tighten to 9 Nm (6.5

lbf.ft).

6. RH bank only: Connect multiplugs to plug top

coils and secure with locking clips.

7.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

8.Connect battery earth lead.

Page 307 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-2 REPAIRS

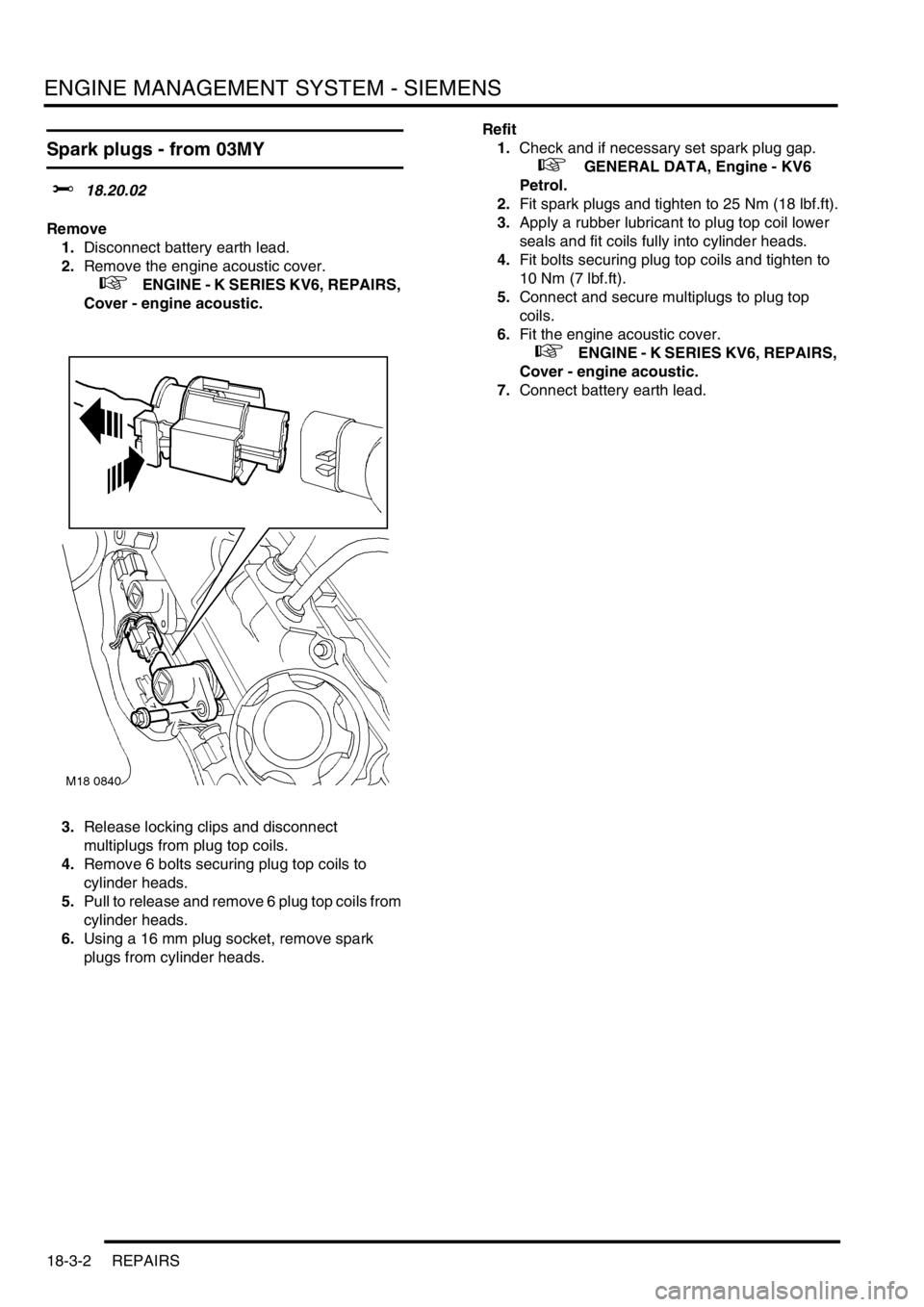

Spark plugs - from 03MY

$% 18.20.02

Remove

1.Disconnect battery earth lead.

2.Remove the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release locking clips and disconnect

multiplugs from plug top coils.

4.Remove 6 bolts securing plug top coils to

cylinder heads.

5.Pull to release and remove 6 plug top coils from

cylinder heads.

6.Using a 16 mm plug socket, remove spark

plugs from cylinder heads.Refit

1.Check and if necessary set spark plug gap.

+ GENERAL DATA, Engine - KV6

Petrol.

2.Fit spark plugs and tighten to 25 Nm (18 lbf.ft).

3.Apply a rubber lubricant to plug top coil lower

seals and fit coils fully into cylinder heads.

4.Fit bolts securing plug top coils and tighten to

10 Nm (7 lbf.ft).

5.Connect and secure multiplugs to plug top

coils.

6.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 308 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

REPAIRS 18-3-3

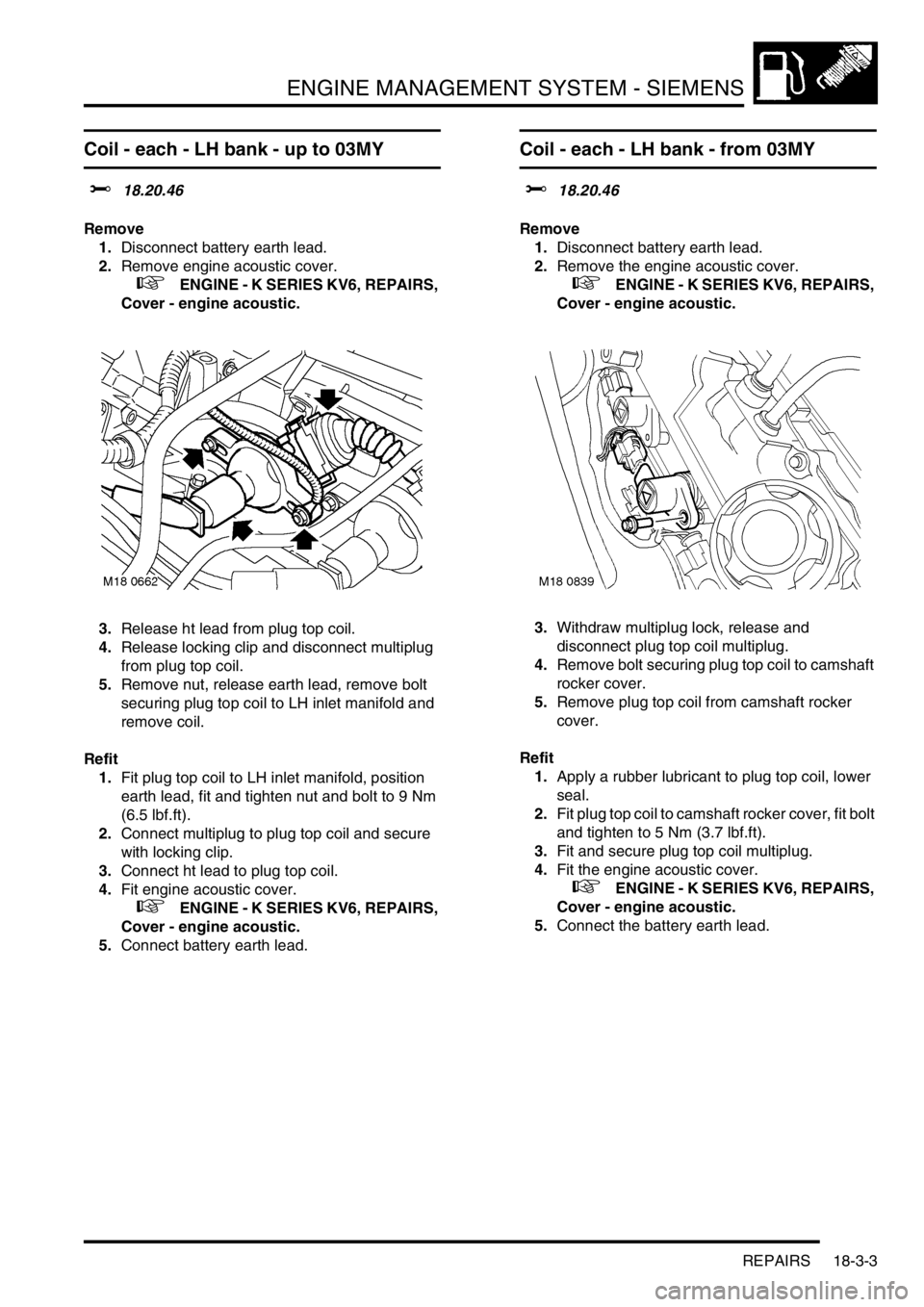

Coil - each - LH bank - up to 03MY

$% 18.20.46

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release ht lead from plug top coil.

4.Release locking clip and disconnect multiplug

from plug top coil.

5.Remove nut, release earth lead, remove bolt

securing plug top coil to LH inlet manifold and

remove coil.

Refit

1.Fit plug top coil to LH inlet manifold, position

earth lead, fit and tighten nut and bolt to 9 Nm

(6.5 lbf.ft).

2.Connect multiplug to plug top coil and secure

with locking clip.

3.Connect ht lead to plug top coil.

4.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

5.Connect battery earth lead.

Coil - each - LH bank - from 03MY

$% 18.20.46

Remove

1.Disconnect battery earth lead.

2.Remove the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Withdraw multiplug lock, release and

disconnect plug top coil multiplug.

4.Remove bolt securing plug top coil to camshaft

rocker cover.

5.Remove plug top coil from camshaft rocker

cover.

Refit

1.Apply a rubber lubricant to plug top coil, lower

seal.

2.Fit plug top coil to camshaft rocker cover, fit bolt

and tighten to 5 Nm (3.7 lbf.ft).

3.Fit and secure plug top coil multiplug.

4.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

5.Connect the battery earth lead.

Page 309 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-4 REPAIRS

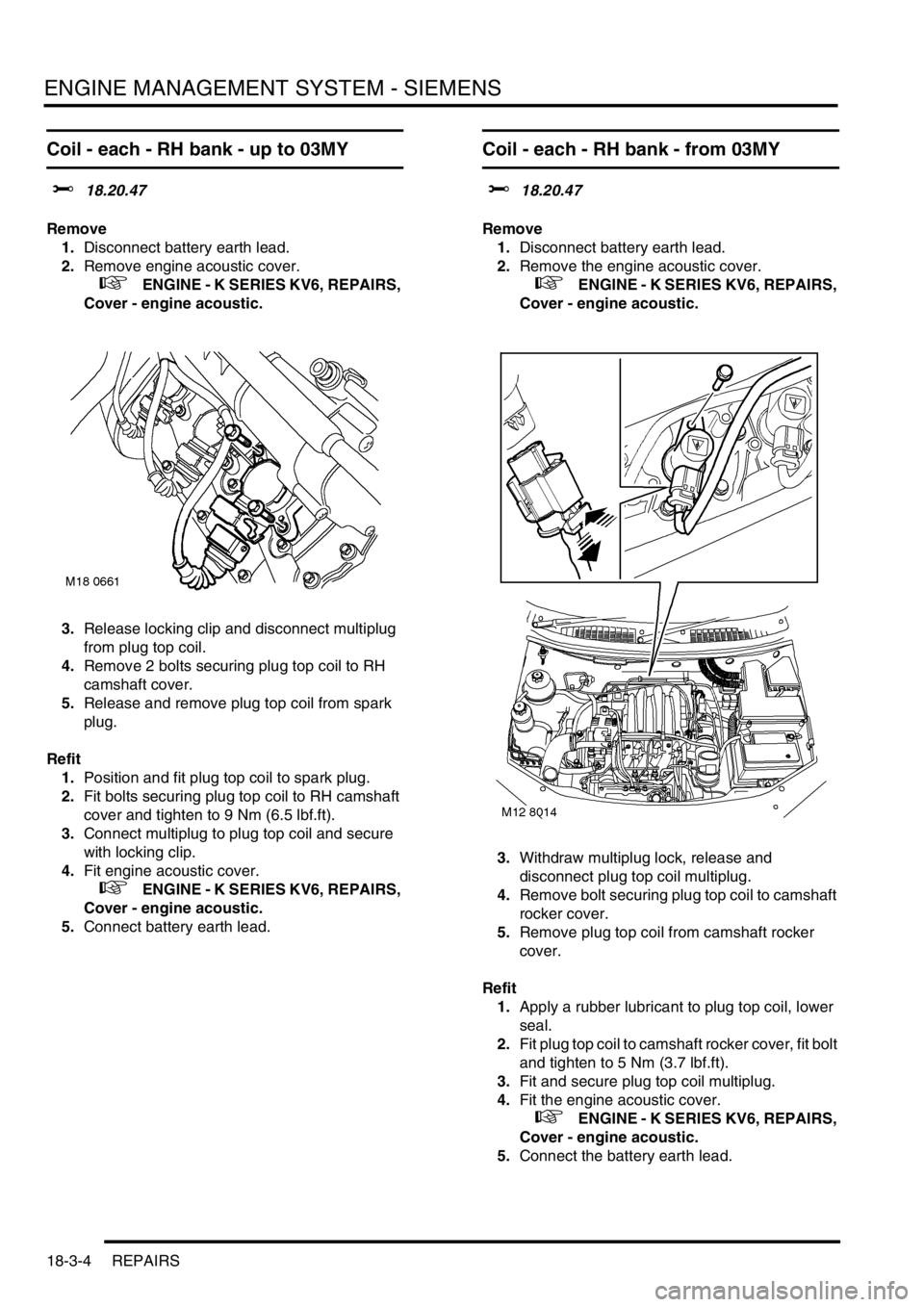

Coil - each - RH bank - up to 03MY

$% 18.20.47

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release locking clip and disconnect multiplug

from plug top coil.

4.Remove 2 bolts securing plug top coil to RH

camshaft cover.

5.Release and remove plug top coil from spark

plug.

Refit

1.Position and fit plug top coil to spark plug.

2.Fit bolts securing plug top coil to RH camshaft

cover and tighten to 9 Nm (6.5 lbf.ft).

3.Connect multiplug to plug top coil and secure

with locking clip.

4.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

5.Connect battery earth lead.

Coil - each - RH bank - from 03MY

$% 18.20.47

Remove

1.Disconnect battery earth lead.

2.Remove the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Withdraw multiplug lock, release and

disconnect plug top coil multiplug.

4.Remove bolt securing plug top coil to camshaft

rocker cover.

5.Remove plug top coil from camshaft rocker

cover.

Refit

1.Apply a rubber lubricant to plug top coil, lower

seal.

2.Fit plug top coil to camshaft rocker cover, fit bolt

and tighten to 5 Nm (3.7 lbf.ft).

3.Fit and secure plug top coil multiplug.

4.Fit the engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

5.Connect the battery earth lead.

Page 317 of 1007

ENGINE MANAGEMENT SYSTEM - SIEMENS

18-3-12 REPAIRS

Sensor - camshaft position (CMP)

$% 18.30.24

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release CMP multiplug from bracket and

disconnect multiplug.

4.Remove bolt securing CMP sensor multiplug

bracket and release CMP sensor lead from

behind bracket.

5.Remove bolt securing CMP sensor to camshaft

cover.

6.Remove CMP sensor and discard seal.Refit

1.Clean CMP sensor and mating face.

2.Lubricate new seal with clean engine oil and fit

to CMP sensor.

3.Position CMP sensor, fit and tighten bolt to 8

Nm (6 lbf.ft).

4.Feed CMP sensor lead behind multiplug

bracket, align bracket, fit bolt and tighten to 8

Nm (6 lbf.ft).

5.Connect CMP sensor multiplug and secure to

bracket.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 324 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-3

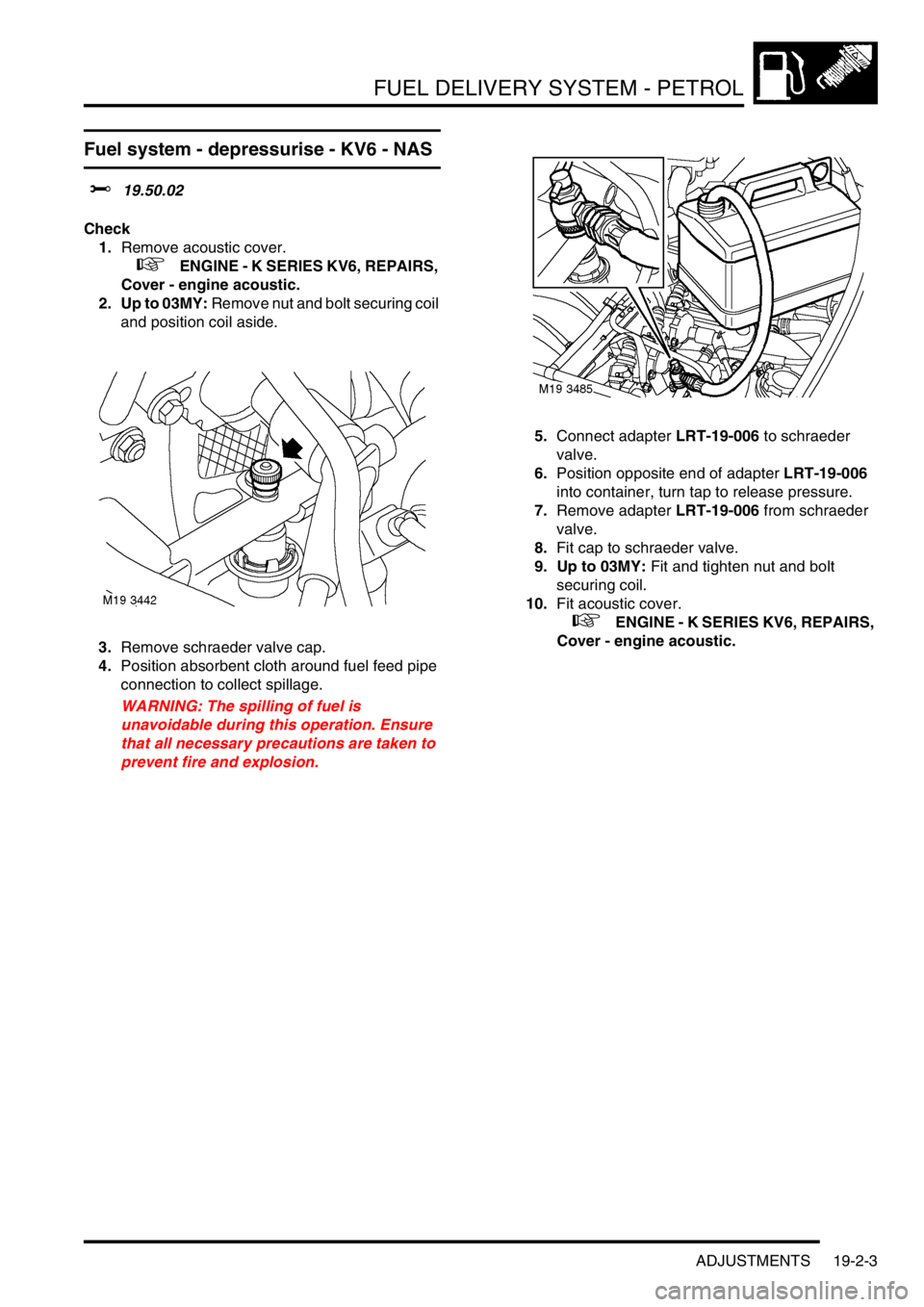

Fuel system - depressurise - KV6 - NAS

$% 19.50.02

Check

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

3.Remove schraeder valve cap.

4.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.5.Connect adapter LRT-19-006 to schraeder

valve.

6.Position opposite end of adapter LRT-19-006

into container, turn tap to release pressure.

7.Remove adapter LRT-19-006 from schraeder

valve.

8.Fit cap to schraeder valve.

9. Up to 03MY: Fit and tighten nut and bolt

securing coil.

10.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Page 326 of 1007

FUEL DELIVERY SYSTEM - PETROL

ADJUSTMENTS 19-2-5

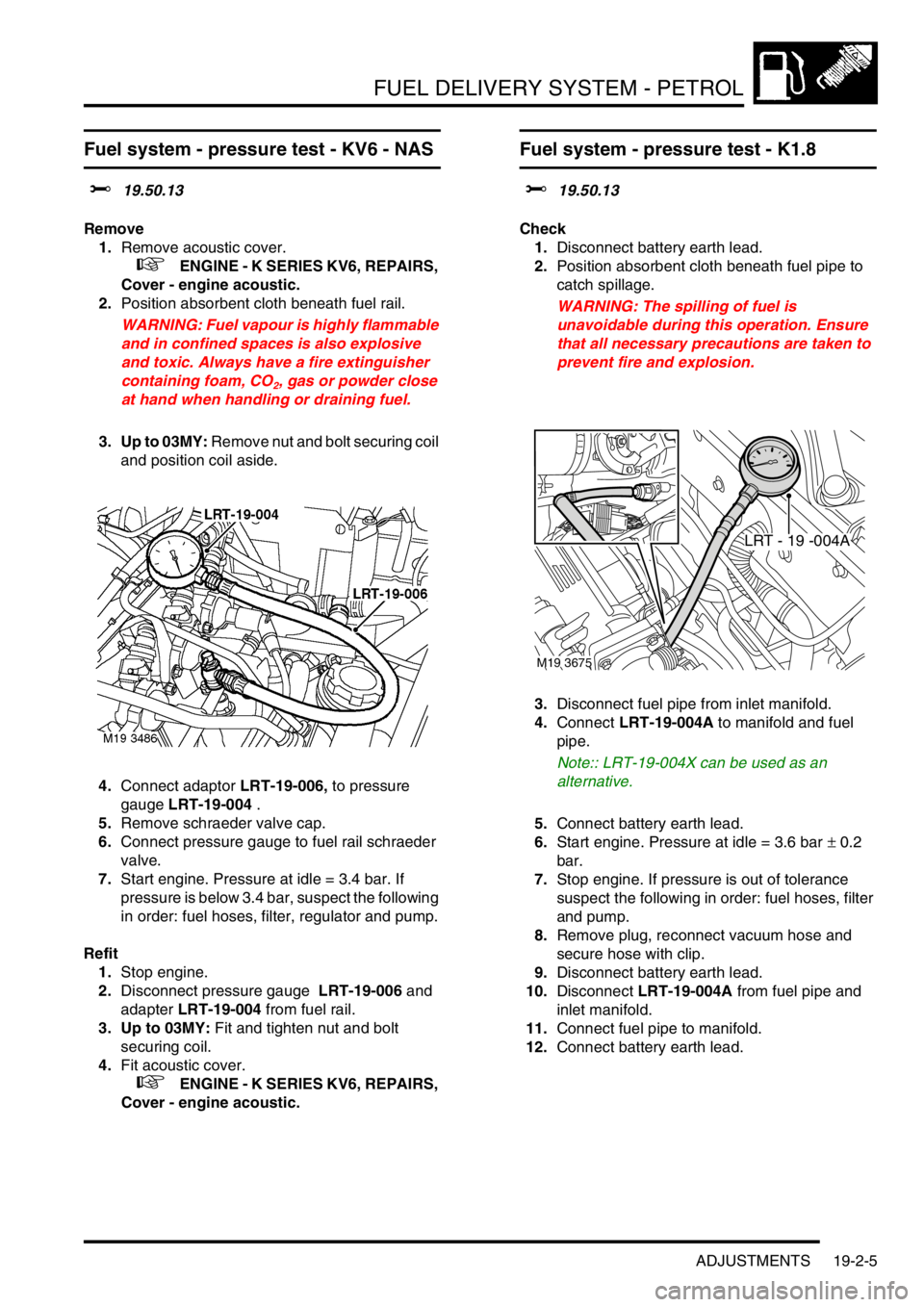

Fuel system - pressure test - KV6 - NAS

$% 19.50.13

Remove

1.Remove acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Position absorbent cloth beneath fuel rail.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3. Up to 03MY: Remove nut and bolt securing coil

and position coil aside.

4.Connect adaptor LRT-19-006, to pressure

gauge LRT-19-004 .

5.Remove schraeder valve cap.

6.Connect pressure gauge to fuel rail schraeder

valve.

7.Start engine. Pressure at idle = 3.4 bar. If

pressure is below 3.4 bar, suspect the following

in order: fuel hoses, filter, regulator and pump.

Refit

1.Stop engine.

2.Disconnect pressure gauge LRT-19-006 and

adapter LRT-19-004 from fuel rail.

3. Up to 03MY: Fit and tighten nut and bolt

securing coil.

4.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

Fuel system - pressure test - K1.8

$% 19.50.13

Check

1.Disconnect battery earth lead.

2.Position absorbent cloth beneath fuel pipe to

catch spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

3.Disconnect fuel pipe from inlet manifold.

4.Connect LRT-19-004A to manifold and fuel

pipe.

Note:: LRT-19-004X can be used as an

alternative.

5.Connect battery earth lead.

6.Start engine. Pressure at idle = 3.6 bar ± 0.2

bar.

7.Stop engine. If pressure is out of tolerance

suspect the following in order: fuel hoses, filter

and pump.

8.Remove plug, reconnect vacuum hose and

secure hose with clip.

9.Disconnect battery earth lead.

10.Disconnect LRT-19-004A from fuel pipe and

inlet manifold.

11.Connect fuel pipe to manifold.

12.Connect battery earth lead.

LRT - 19 -004A

M19 3675

Page 360 of 1007

FUEL DELIVERY SYSTEM - PETROL

REPAIRS 19-2-39

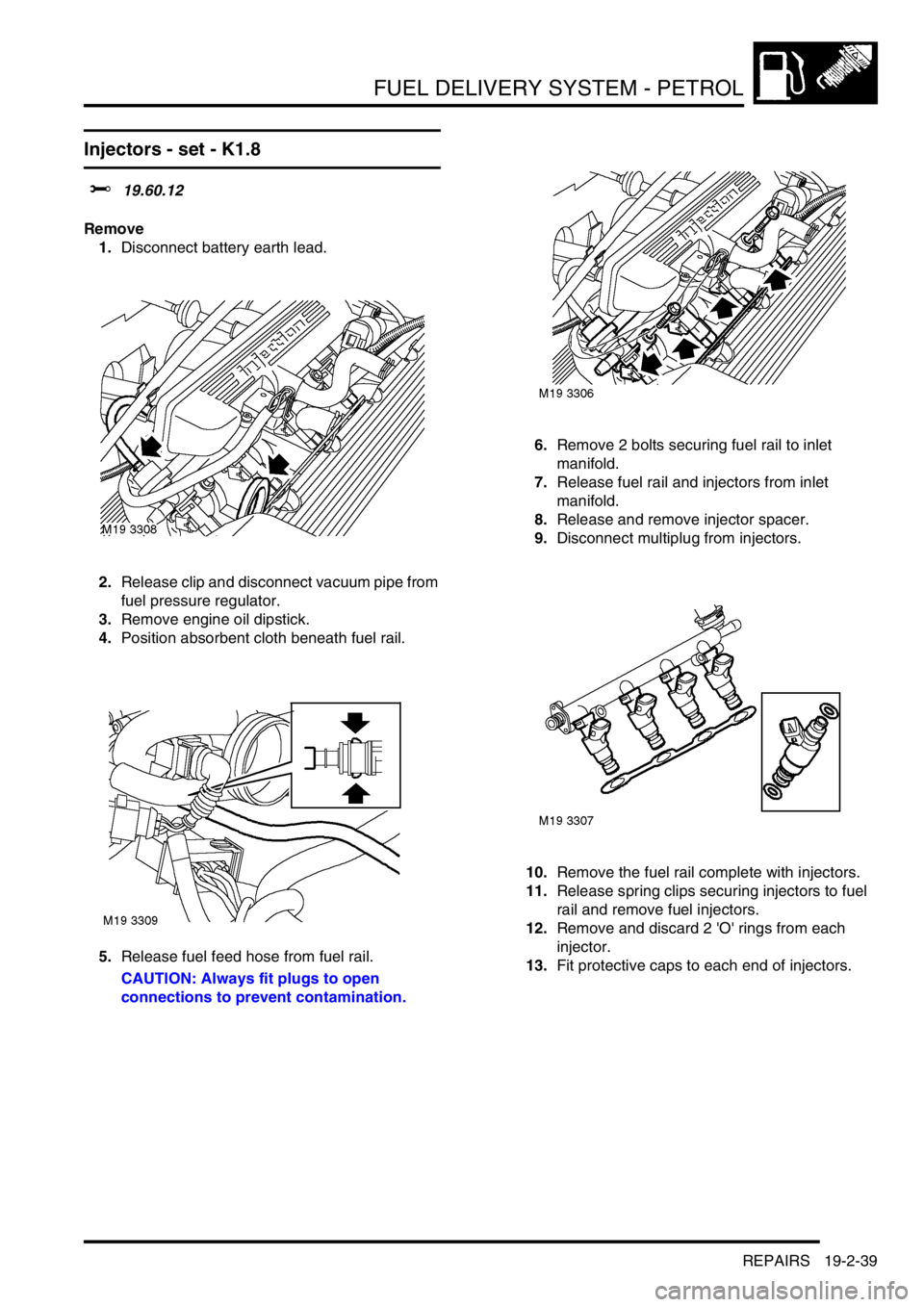

Injectors - set - K1.8

$% 19.60.12

Remove

1.Disconnect battery earth lead.

2.Release clip and disconnect vacuum pipe from

fuel pressure regulator.

3.Remove engine oil dipstick.

4.Position absorbent cloth beneath fuel rail.

5.Release fuel feed hose from fuel rail.

CAUTION: Always fit plugs to open

connections to prevent contamination.6.Remove 2 bolts securing fuel rail to inlet

manifold.

7.Release fuel rail and injectors from inlet

manifold.

8.Release and remove injector spacer.

9.Disconnect multiplug from injectors.

10.Remove the fuel rail complete with injectors.

11.Release spring clips securing injectors to fuel

rail and remove fuel injectors.

12.Remove and discard 2 'O' rings from each

injector.

13.Fit protective caps to each end of injectors.

Page 361 of 1007

FUEL DELIVERY SYSTEM - PETROL

19-2-40 REPAIRS

Refit

1.Remove protective caps from each injector.

2.Clean injectors and recesses in fuel rail and

inlet manifold.

3.Lubricate new 'O' ring with castor oil and fit to

injector.

4.Fit injectors to fuel rail and secure with spring

clips.

5.Position fuel rail assembly and connect injector

multiplugs.

6.Fit injector spacer.

7.Push each injector into inlet manifold.

8.Fit bolts securing fuel rail to inlet manifold and

tighten to 8 Nm ( 6 lbf.ft).

9.Connect fuel feed hose to fuel rail.

10.Fit engine oil dipstick.

11.Connect vacuum pipe to fuel pressure regulator

and secure with clip.

12.Connect battery earth lead.

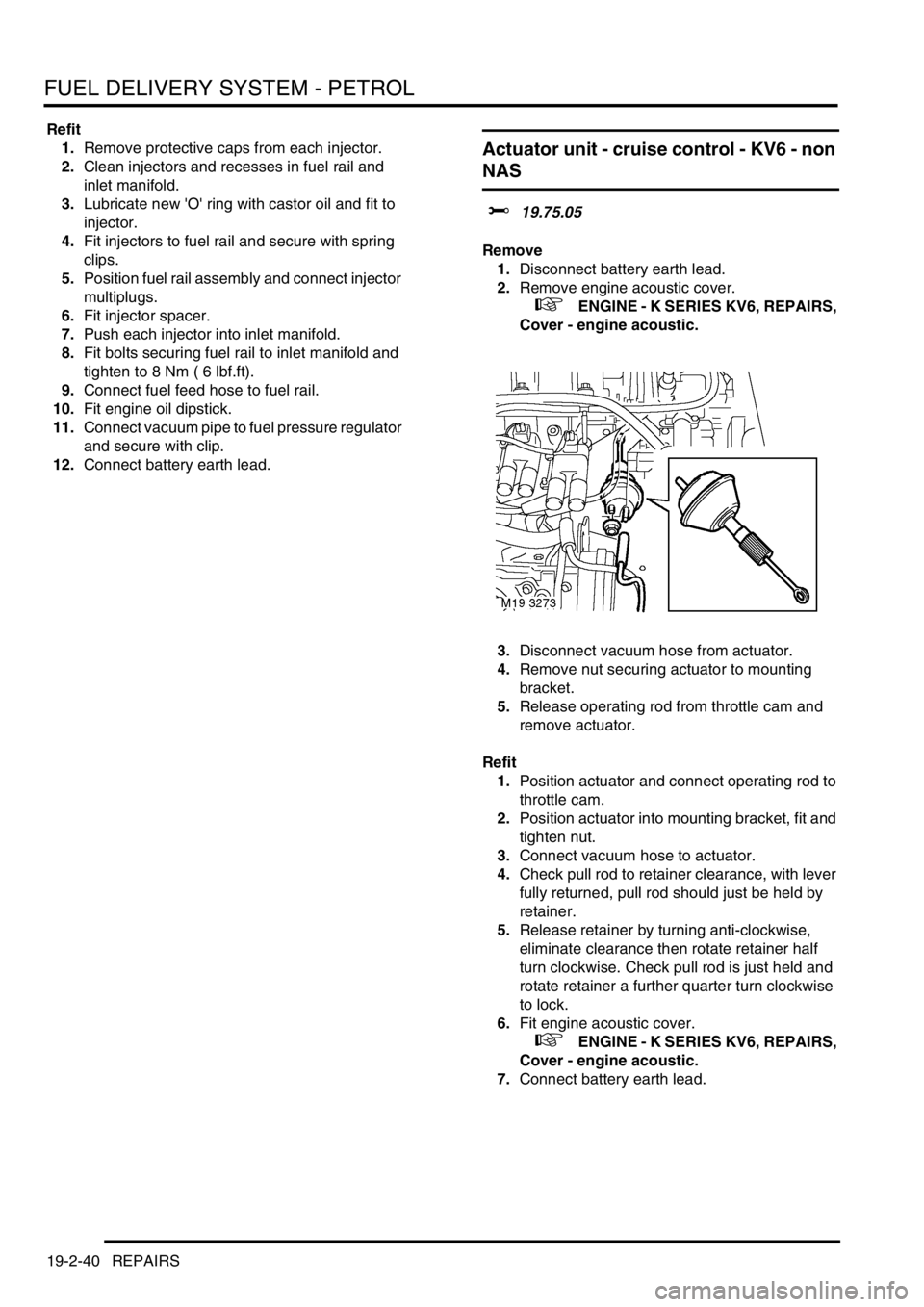

Actuator unit - cruise control - KV6 - non

NAS

$% 19.75.05

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Disconnect vacuum hose from actuator.

4.Remove nut securing actuator to mounting

bracket.

5.Release operating rod from throttle cam and

remove actuator.

Refit

1.Position actuator and connect operating rod to

throttle cam.

2.Position actuator into mounting bracket, fit and

tighten nut.

3.Connect vacuum hose to actuator.

4.Check pull rod to retainer clearance, with lever

fully returned, pull rod should just be held by

retainer.

5.Release retainer by turning anti-clockwise,

eliminate clearance then rotate retainer half

turn clockwise. Check pull rod is just held and

rotate retainer a further quarter turn clockwise

to lock.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 390 of 1007

MANIFOLDS & EXHAUST SYSTEMS - K SERIES KV6

REPAIRS 30-3-17

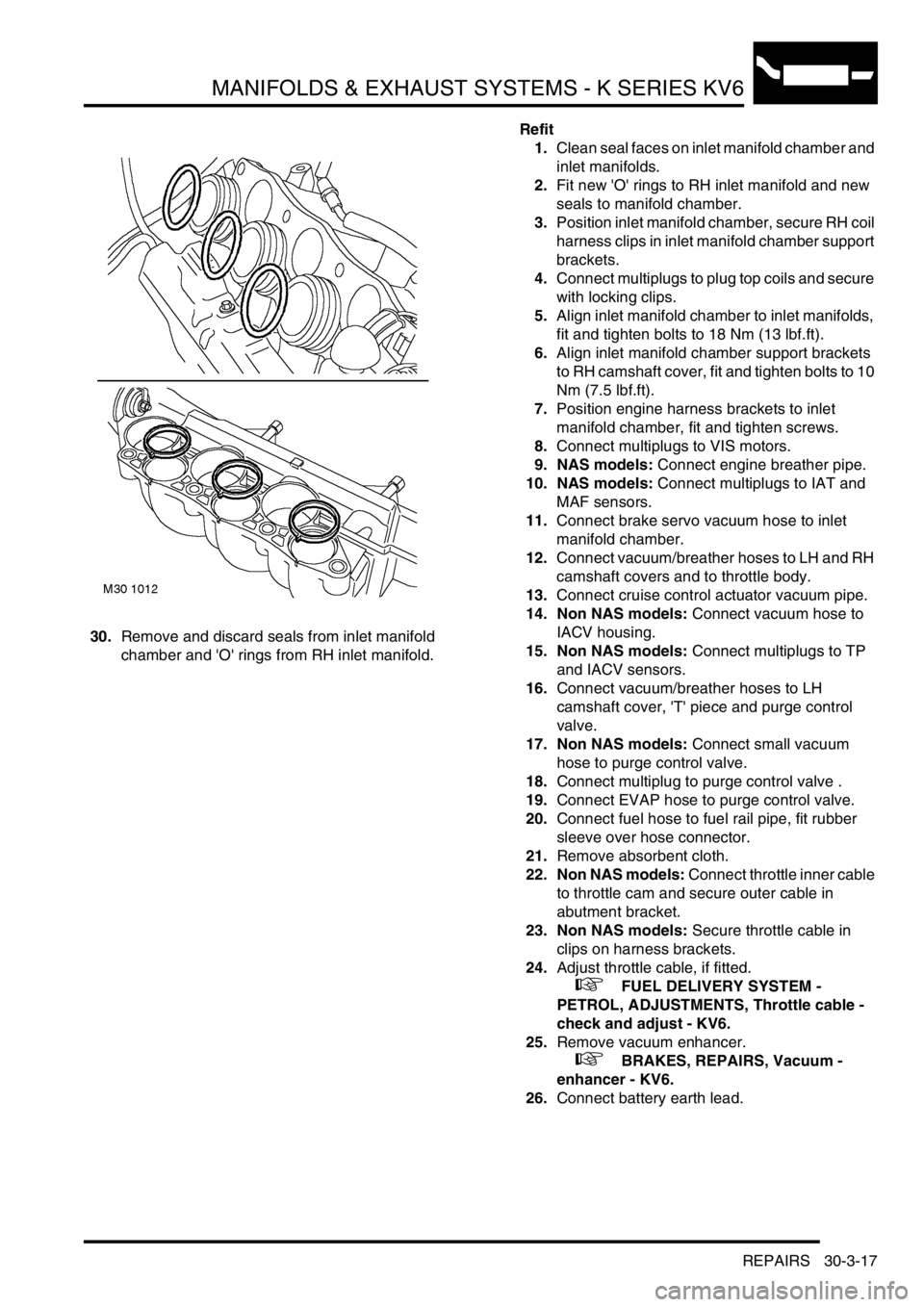

30.Remove and discard seals from inlet manifold

chamber and 'O' rings from RH inlet manifold.Refit

1.Clean seal faces on inlet manifold chamber and

inlet manifolds.

2.Fit new 'O' rings to RH inlet manifold and new

seals to manifold chamber.

3.Position inlet manifold chamber, secure RH coil

harness clips in inlet manifold chamber support

brackets.

4.Connect multiplugs to plug top coils and secure

with locking clips.

5.Align inlet manifold chamber to inlet manifolds,

fit and tighten bolts to 18 Nm (13 lbf.ft).

6.Align inlet manifold chamber support brackets

to RH camshaft cover, fit and tighten bolts to 10

Nm (7.5 lbf.ft).

7.Position engine harness brackets to inlet

manifold chamber, fit and tighten screws.

8.Connect multiplugs to VIS motors.

9. NAS models: Connect engine breather pipe.

10. NAS models: Connect multiplugs to IAT and

MAF sensors.

11.Connect brake servo vacuum hose to inlet

manifold chamber.

12.Connect vacuum/breather hoses to LH and RH

camshaft covers and to throttle body.

13.Connect cruise control actuator vacuum pipe.

14. Non NAS models: Connect vacuum hose to

IACV housing.

15. Non NAS models: Connect multiplugs to TP

and IACV sensors.

16.Connect vacuum/breather hoses to LH

camshaft cover, 'T' piece and purge control

valve.

17. Non NAS models: Connect small vacuum

hose to purge control valve.

18.Connect multiplug to purge control valve .

19.Connect EVAP hose to purge control valve.

20.Connect fuel hose to fuel rail pipe, fit rubber

sleeve over hose connector.

21.Remove absorbent cloth.

22. Non NAS models: Connect throttle inner cable

to throttle cam and secure outer cable in

abutment bracket.

23. Non NAS models: Secure throttle cable in

clips on harness brackets.

24.Adjust throttle cable, if fitted.

+ FUEL DELIVERY SYSTEM -

PETROL, ADJUSTMENTS, Throttle cable -

check and adjust - KV6.

25.Remove vacuum enhancer.

+ BRAKES, REPAIRS, Vacuum -

enhancer - KV6.

26.Connect battery earth lead.