alarm LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 7 of 1007

CONTENTS

4CONTENTS

MAINTENANCE ........................................................................................ 10-1

MAINTENANCE

Td4 - Diesel Engine - Under Bonnet View ...................................................................................... 10-1

K1.8 – Petrol Engine – Under Bonnet View .................................................................................... 10-2

KV6 – Petrol Engine – Under Bonnet View .................................................................................... 10-3

Seats and Seat Belts ...................................................................................................................... 10-4

Lamps, Horns and Warning Indicators ........................................................................................... 10-4

Wipers and Washers ...................................................................................................................... 10-5

Handbrake ...................................................................................................................................... 10-5

Alarm Handset Battery.................................................................................................................... 10-6

Road Wheels .................................................................................................................................. 10-6

Tyres ............................................................................................................................................... 10-7

Brake Pads and Calipers ................................................................................................................ 10-7

Brake Fluid...................................................................................................................................... 10-9

Road Wheel Speed Sensors .......................................................................................................... 10-9

Fuel Filter - Petrol ........................................................................................................................... 10-10

Fuel Filter - Diesel........................................................................................................................... 10-10

Fuel Pump and Filter assembly - Diesel - 03 Model Year onwards ................................................ 10-10

Fuel Sedimenter - Diesel - 03 Model Year onwards ....................................................................... 10-10

Door Locks, Hinges, Check Straps and Bonnet Catch ................................................................... 10-11

Anti-freeze ...................................................................................................................................... 10-12

Cooling System and Intercooler...................................................................................................... 10-12

Vent filter - turbocharger boost control solenoid valve - Td4 .......................................................... 10-13

Spark Plugs – K1.8 ......................................................................................................................... 10-13

Spark Plugs – KV6.......................................................................................................................... 10-13

Air Cleaner – Petrol Models ............................................................................................................ 10-13

Ancillary Drive Belt – Td4 ............................................................................................................... 10-14

Ancillary Drive Belt – K1.8 .............................................................................................................. 10-14

Ancillary Drive Belt – KV6 ............................................................................................................... 10-15

Camshaft Timing Belt – K1.8 .......................................................................................................... 10-15

Camshaft Timing Belt – KV6........................................................................................................... 10-16

Brake/Clutch Reservoir ................................................................................................................... 10-16

PAS Fluid Level .............................................................................................................................. 10-17

Intermediate Reduction Drive - Non NAS models .......................................................................... 10-17

Intermediate Reduction Drive - NAS models .................................................................................. 10-18

Manual Gearbox – PG1 .................................................................................................................. 10-18

Manual Gearbox – GETRAG .......................................................................................................... 10-19

Automatic Gearbox – JATCO ......................................................................................................... 10-19

Rear Axle ........................................................................................................................................ 10-20

Clutch Pipes and Unions ................................................................................................................ 10-21

Windscreen and Rear Washer Reservoir ....................................................................................... 10-21

Battery ............................................................................................................................................ 10-21

Engine Oil and Filter – Td4 ............................................................................................................. 10-22

Engine Oil and Filter – K1.8 ............................................................................................................ 10-23

Engine Oil and Filter – KV6 ............................................................................................................ 10-24

Fuel Hoses and Pipes..................................................................................................................... 10-25

Brake Hoses and Pipes ................................................................................................................. 10-26

Check Exhaust System................................................................................................................... 10-26

Suspension ..................................................................................................................................... 10-27

Steering ......................................................................................................................................... 10-28

Road Test ....................................................................................................................................... 10-28

Endorse Service Record ................................................................................................................. 10-30

Report any Unusual Features ......................................................................................................... 10-30

Page 23 of 1007

CONTENTS

20 CONTENTS

LIGHTING.................................................................................................. 86-2-1

ADJUSTMENTS

Headlamps - pair - align beam - up to 04MY .................................................................................. 86-2-1

Headlamps - pair - align beam - from 04MY ................................................................................... 86-2-1

REPAIRS

Headlamp assembly - up to 04MY.................................................................................................. 86-2-3

Headlamp assembly - from 04MY .................................................................................................. 86-2-4

Lamp assembly - flasher side repeater - front ................................................................................ 86-2-5

Lamp assembly - tail ....................................................................................................................... 86-2-5

Lamp assembly - number plate ...................................................................................................... 86-2-6

Lamp assembly - fog/driving - from 04MY ...................................................................................... 86-2-6

Lamp assembly - rear ..................................................................................................................... 86-2-7

Lamp assembly - centre high mounted stop (CHMSL) ................................................................... 86-2-7

Lamp assembly - glove compartment ............................................................................................. 86-2-8

Lamp assembly - load space .......................................................................................................... 86-2-8

Switch - headlamp levelling ............................................................................................................ 86-2-9

Switch - glove compartment ........................................................................................................... 86-2-9

Switch - hazard warning ................................................................................................................. 86-2-10

Switch - combined direction indicator/headlight/horn ..................................................................... 86-2-10

Switch - rear fog lamp ..................................................................................................................... 86-2-11

CONTROL UNITS ..................................................................................... 86-3-1

REPAIRS

Control unit - window lift ................................................................................................................. 86-3-1

Relay - power folding mirrors - from 02MY ..................................................................................... 86-3-1

Central Control Unit (CCU) ............................................................................................................. 86-3-2

Control Unit - power fold mirrors - up to 02MY ............................................................................... 86-3-3

SECURITY................................................................................................. 86-4-1

REPAIRS

Solenoid/motor - taildoor................................................................................................................. 86-4-1

Switch/push - horn .......................................................................................................................... 86-4-2

Horn ................................................................................................................................................ 86-4-2

Immobilisation - electronic control unit (ECU) - ............................................................................. 86-4-3

Sensor - volumetric - alarm system - 3 door ................................................................................... 86-4-3

Module (ECU) - volumetric - alarm system - 5 door - without sunroof ........................................... 86-4-5

Module (ECU) - volumetric - alarm system - 5 door - with sunroof ................................................ 86-4-7

Receiver - alarm system ................................................................................................................. 86-4-10

Coil - passive immobilisation - alarm system .................................................................................. 86-4-10

Page 36 of 1007

GENERAL INFORMATION

03-5

Local issues

A number of environmental issues will be of

particular concern to residents and other neighbours

close to the site. The sensitivity of these issues will

depend on the proximity of the site and the layout

and amount of activity carried on at the site.

Noise is a major concern and therefore consideration

should be given to the time spent carrying out noisy

activities and the location of those activities that can

cause excessive noise.

Car alarm testing, panel beating, hammering and

other such noisy activities should, whenever

possible, be carried out indoors with doors and

windows shut, or as far away from houses as

possible.

Running vehicle engines may be an outside activity

which could cause nuisance to neighbours because

of both noise and smell.

Be sensitive to the time of day when these activities

are carried out and minimise the time of the noisy

operation, particularly in the early morning and late

evening.

Another local concern will be the smell from the

various materials used. Using less solvent, paint and

petrol could help prevent this annoyance.

Local residents and other business users will also be

concerned about traffic congestion, noise and

exhaust fumes, be sensitive to these concerns and

try to minimise inconvenience from deliveries,

customers and servicing operations.

Checklist

Always adhere to the following:

lidentify where the neighbours who are likely to

be affected are situated;

lminimise noise, smells and traffic nuisance;

lprevent litter by putting waste in the correct

containers;

lhave waste skips emptied regularly.Use of resource

Another environmental concern is the waste of

materials and energy that can occur in day to day

activities.

Electricity for heating, lighting and compressed air

uses resources and releases pollution during its

generation.

Fuel used for heating, running cars or vans and

mobile plant is another limited resource which

consumes large amounts of energy during its

extraction and refining processes.

Water has to be cleaned, piped to site and disposed

of, all of which creates more potential pollution;

Oil, spares, paint etc., have all produced pollution in

the process of manufacture and they become a

waste disposal problem if discarded.

Checklist

Always adhere to the following:

Electricity and heating –

lkeep doors and windows closed in the winter;

lswitch off machinery or lights when not needed;

luse energy efficient heating systems;

lswitch off computers and photocopiers when

not needed.

Fuel –

ldon't run engines unnecessarily;

lthink about whether journeys are necessary and

drive to conserve fuel.

Water –

ldon't leave taps and hose pipes running;

lmend leaks quickly, don't be wasteful.

Compressed air –

ldon't leave valves open;

lmend leaks quickly;

ldon't leave the compressor running when not

needed.

Use of environmentally damaging materials –

lcheck whether a less toxic material is available.

Handling and storage of materials –

lhave the correct facilities available for handling

liquids to prevent spillage and wastage as listed

above;

lprovide suitable locations for storage to prevent

frost damage or other deterioration.

Page 50 of 1007

GENERAL INFORMATION

03-19

Electrical precautions

General

The following guidelines are intended to ensure the

safety of the operator and ensure the prevention of

damage to the electrical and electronic components

fitted to the vehicle. Where necessary, specific

precautions are detailed in the individual procedures

of this manual.

Equipment

Prior to commencing any test procedure on the

vehicle, ensure that the relevant test equipment is

working correctly and any harness or connectors are

in good condition. It is particularly important to check

the condition of the lead and plugs of mains operated

equipment.

Polarity

Never reverse connect the vehicle battery and

always ensure the correct polarity when connecting

test equipment.

High Voltage Circuits

Whenever disconnecting live ht circuits, always use

insulated pliers and never allow the open end of the

ht lead to contact other components, particularly

ECU's.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, high

voltage spikes can occur on these terminals.

Connectors and harnesses

The engine compartment of a vehicle is a particularly

hostile environment for electrical components and

connectors:

lAlways ensure electrically related items are dry

and oil free before disconnecting and

connecting test equipment.

lEnsure disconnected multiplugs and sensors

are protected from being contaminated with oil,

coolant or other solutions. Contamination could

impair performance or result in catastrophic

failure.

lNever force connectors apart using tools to

prise apart or by pulling on the wiring harness.

lAlways ensure locking tabs are disengaged

before disconnection, and match orientation to

enable correct reconnection.

lEnsure that any protection (covers, insulation

etc.) is replaced if disturbed.Having confirmed a component to be faulty:

lSwitch off the ignition and disconnect the

battery.

lRemove the component and support the

disconnected harness.

lWhen replacing the component, keep oily hands

away from electrical connection areas and push

connectors home until any locking tabs fully

engage.

Battery disconnection

Before disconnecting the battery, disable the alarm

system and switch off all electrical equipment. If the

radio is to be serviced, ensure the security code has

been deactivated.

CAUTION: To prevent damage to electrical

components, always disconnect the battery

when working on the vehicle's electrical system.

The ground lead must be disconnected first and

reconnected last.

CAUTION: Always ensure that battery leads are

routed correctly and are not close to any

potential chafing points.

Battery charging

Only recharge the battery with it removed from the

vehicle. Always ensure any battery charging area is

well ventilated and that every precaution is taken to

avoid naked flames and sparks.

Ignition system safety precautions

The vehicle's ignition system produces high voltages

and the following precautions should be observed

before carrying out any work on the system:

WARNING: Before commencing work on an

ignition system, ensure all high tension

terminals, adapters and diagnostic equipment

are adequately insulated and shielded to prevent

accidental personal contacts and minimise the

risk of shock. Wearers of surgically implanted

pacemaker devices should not be in close

proximity of ignition circuits or diagnostic

equipment.

Page 153 of 1007

MAINTENANCE

10-6 MAINTENANCE

Alarm Handset Battery

Replace

1.Insert the blade of a small, flat bladed

screwdriver into the slot at the keyring end of

the handset and carefully prise the two halves

of the handset apart.

2.Slide the battery out of the clip taking care not

to touch the circuit board or the battery

contacts.

3.Press and hold each button in turn for at least 5

seconds to drain any residual power from the

handset.

4.Fit the replacement battery (Land Rover

STC4080 or Panasonic CR2032) ensuring the

correct polarity is maintained (+) side facing

upwards. Avoid touching the flat surfaces of the

battery.

5.Press the 2 halves of the handset together,

making sure the two halves click into place

correctly.

6.Check the operation of the handset.

Road Wheels

Remove

1.Loosen wheel nuts. Raise vehicle for wheel

free condition and remove the wheel nuts.

2.Mark the wheel to stud relationship to ensure

that the wheels are refitted in the same

orientation.

Refit

1.Apply a thin coat of anti-seize compound to

wheel hub centre.

2.Refit wheels to original hub position.

NOTE: When refitting road wheel nuts, do not

overtighten using powered tools. Ensure the

wheel nuts are correctly torqued in the correct

sequence.

3.Tighten wheel nuts to 115 Nm (85 lbf.ft).

Page 950 of 1007

SECURITY

REPAIRS 86-4-3

Immobilisation - electronic control unit

(ECU) -

$% 86.77.07

Remove

1.Disconnect battery earth lead.

2.Remove fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

3.Remove 2 plastic nuts securing immobilisation

ECU and disconnect multiplug. Remove

immobilisation ECU.

Refit

1.Connect multiplug to immobilisation ECU.

2.Position ECU, fit and tighten 2 plastic nuts.

3.Fit fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

4.Connect battery earth lead.

5.Initiate using TestBook/T4.

Sensor - volumetric - alarm system - 3

door

$% 86.77.29

Remove

1.Remove roof lamp lens.

2.Remove 2 screws, release roof lamp and

disconnect multiplug.

3.Release headlining rear finisher from roof panel

and remove finisher.

M86 5633

Page 952 of 1007

SECURITY

REPAIRS 86-4-5

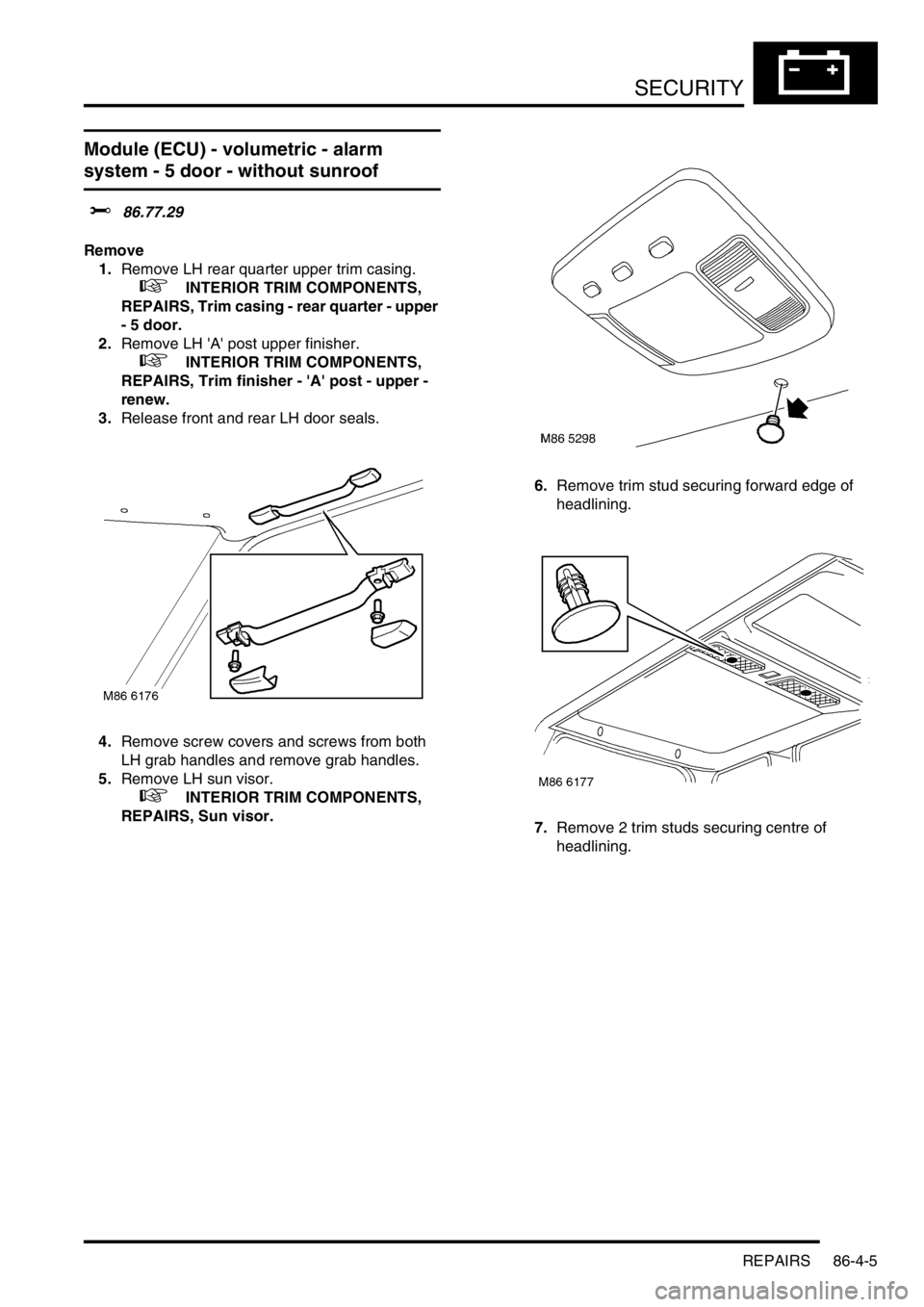

Module (ECU) - volumetric - alarm

system - 5 door - without sunroof

$% 86.77.29

Remove

1.Remove LH rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

2.Remove LH 'A' post upper finisher.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

3.Release front and rear LH door seals.

4.Remove screw covers and screws from both

LH grab handles and remove grab handles.

5.Remove LH sun visor.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Sun visor.6.Remove trim stud securing forward edge of

headlining.

7.Remove 2 trim studs securing centre of

headlining.

Page 954 of 1007

SECURITY

REPAIRS 86-4-7

Refit

1.Fit volumetric sensor and secure with screws.

2.Connect multiplug to sensor.

3.Raise headlining and secure with trim studs.

4. Up to 04MY: Position front interior lamp and

connect multiplug.

5. Up to 04MY: Fit Torx bolts securing interior

lamp and tighten to 6 Nm (4.4 lbf.ft).

6. Up to 04MY: Fit lens to front interior lamp.

7. From 04MY: Position front interior lamp and

connect multiplug.

8. From 04MY: Fit and secure front interior lamp

to headlining.

9.Position 'B/C' post upper finisher and secure

with clips.

10.Fit sun visor.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Sun visor.

11.Fit grab handles, tighten screws and fit screw

covers.

12.Fit 'A' post upper finisher.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

13.Fit rear quarter upper trim casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

14.Secure front and rear door seals.

Module (ECU) - volumetric - alarm

system - 5 door - with sunroof

$% 86.77.29

Remove

1.Release front and rear door aperture seals.

2.Remove 'A' post upper finishers.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

3.Remove screw covers, remove 6 screws

securing front and both rear grab handles and

remove grab handles.

4.Remove grab handle blanking plugs.

Page 957 of 1007

SECURITY

86-4-10 REPAIRS

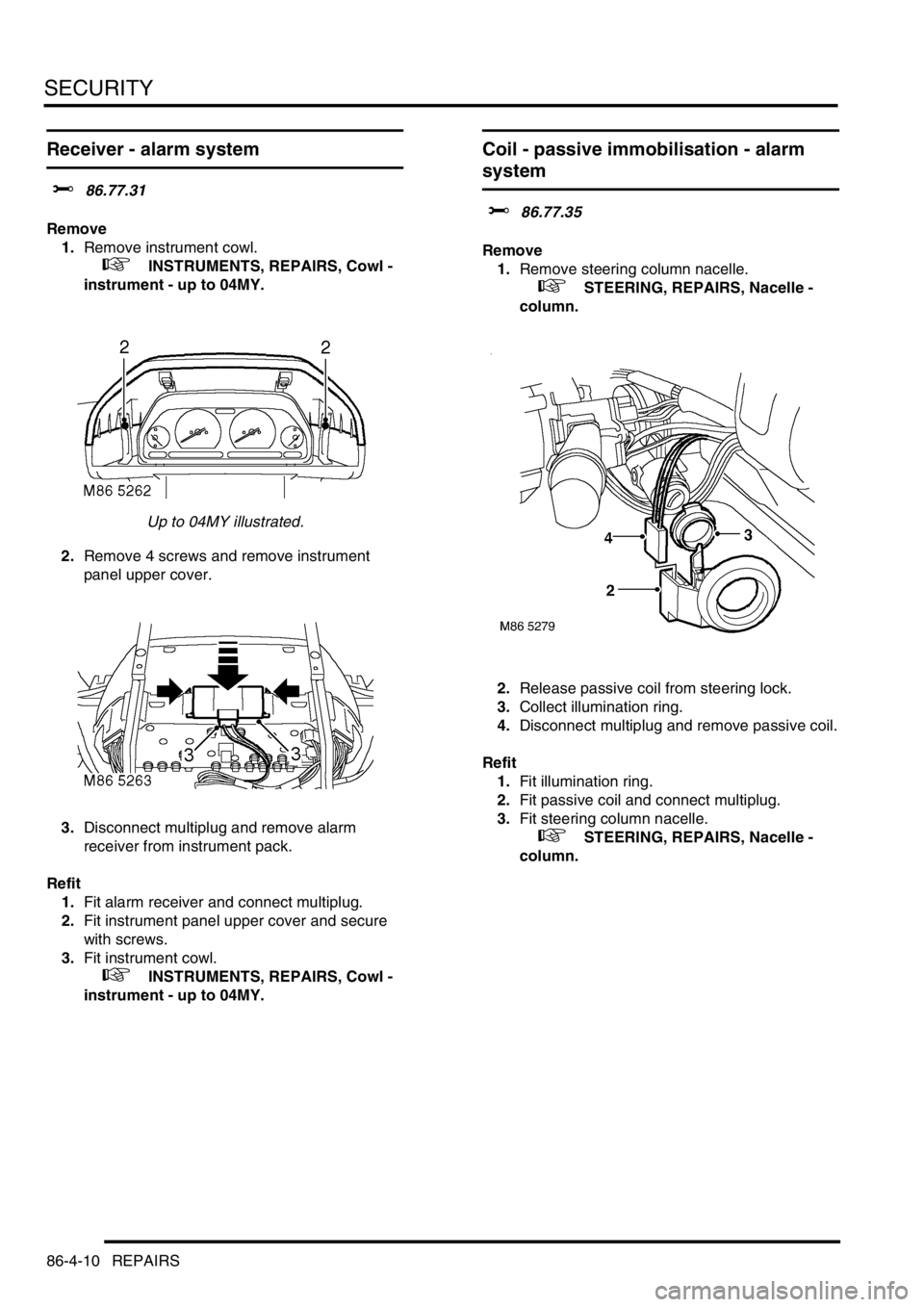

Receiver - alarm system

$% 86.77.31

Remove

1.Remove instrument cowl.

+ INSTRUMENTS, REPAIRS, Cowl -

instrument - up to 04MY.

Up to 04MY illustrated.

2.Remove 4 screws and remove instrument

panel upper cover.

3.Disconnect multiplug and remove alarm

receiver from instrument pack.

Refit

1.Fit alarm receiver and connect multiplug.

2.Fit instrument panel upper cover and secure

with screws.

3.Fit instrument cowl.

+ INSTRUMENTS, REPAIRS, Cowl -

instrument - up to 04MY.

Coil - passive immobilisation - alarm

system

$% 86.77.35

Remove

1.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

2.Release passive coil from steering lock.

3.Collect illumination ring.

4.Disconnect multiplug and remove passive coil.

Refit

1.Fit illumination ring.

2.Fit passive coil and connect multiplug.

3.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.