warning LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 645 of 1007

EXTERIOR FITTINGS

76-2-4 REPAIRS

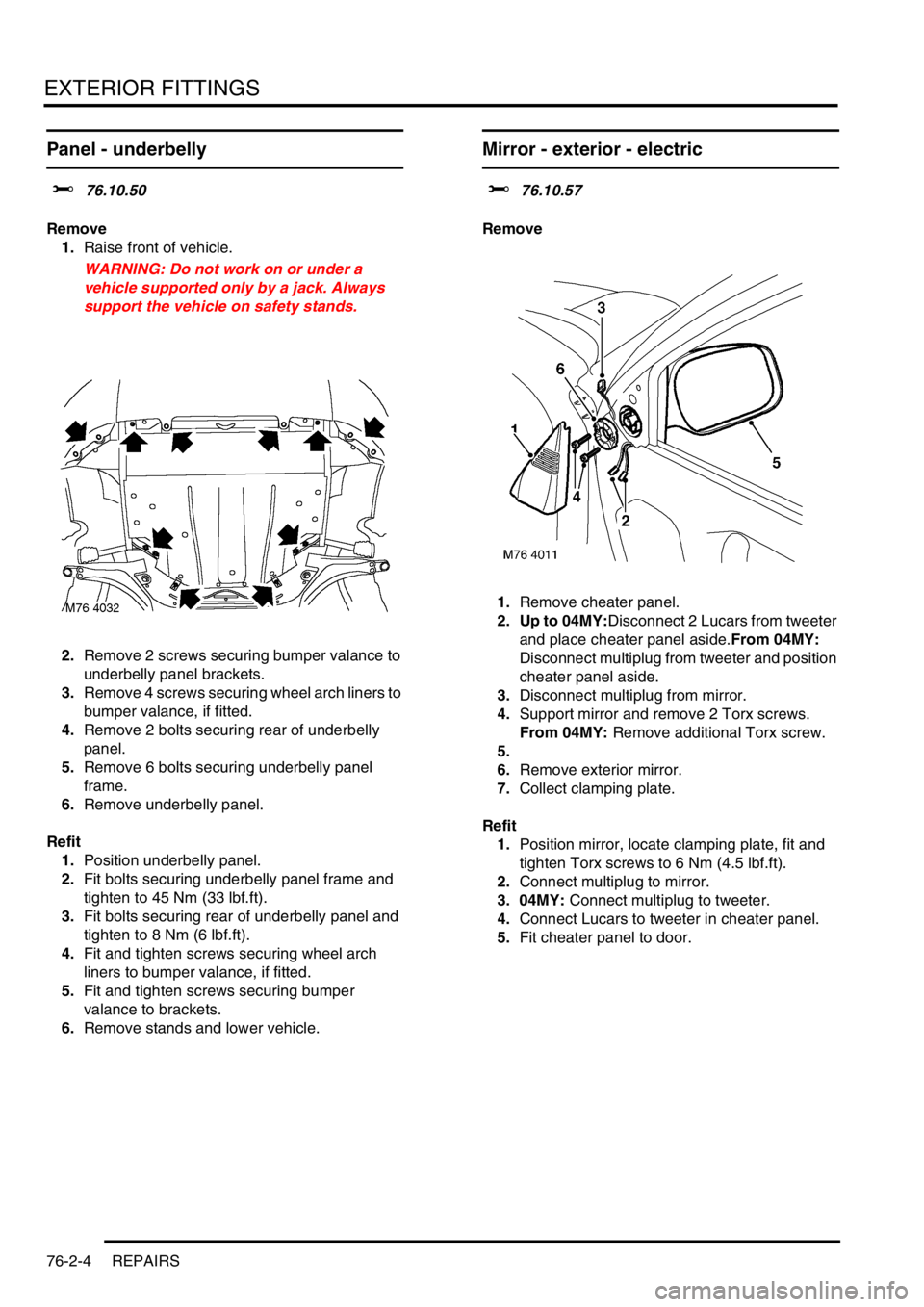

Panel - underbelly

$% 76.10.50

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove 2 screws securing bumper valance to

underbelly panel brackets.

3.Remove 4 screws securing wheel arch liners to

bumper valance, if fitted.

4.Remove 2 bolts securing rear of underbelly

panel.

5.Remove 6 bolts securing underbelly panel

frame.

6.Remove underbelly panel.

Refit

1.Position underbelly panel.

2.Fit bolts securing underbelly panel frame and

tighten to 45 Nm (33 lbf.ft).

3.Fit bolts securing rear of underbelly panel and

tighten to 8 Nm (6 lbf.ft).

4.Fit and tighten screws securing wheel arch

liners to bumper valance, if fitted.

5.Fit and tighten screws securing bumper

valance to brackets.

6.Remove stands and lower vehicle.

Mirror - exterior - electric

$% 76.10.57

Remove

1.Remove cheater panel.

2. Up to 04MY:Disconnect 2 Lucars from tweeter

and place cheater panel aside.From 04MY:

Disconnect multiplug from tweeter and position

cheater panel aside.

3.Disconnect multiplug from mirror.

4.Support mirror and remove 2 Torx screws.

From 04MY: Remove additional Torx screw.

5.

6.Remove exterior mirror.

7.Collect clamping plate.

Refit

1.Position mirror, locate clamping plate, fit and

tighten Torx screws to 6 Nm (4.5 lbf.ft).

2.Connect multiplug to mirror.

3. 04MY: Connect multiplug to tweeter.

4.Connect Lucars to tweeter in cheater panel.

5.Fit cheater panel to door.

Page 657 of 1007

EXTERIOR FITTINGS

76-2-16 REPAIRS

Finisher - sill - lower

$% 76.43.28

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove both jacking point covers.

3.Remove 7 scrivets securing sill finisher to body.

4.Release and remove finisher from sill.Refit

1.Clean mating faces of finisher.

2.Position finisher to sill, locate over jacking

points and secure with scrivets.

3.Fit jacking point covers.

4.Remove stands and lower vehicle.

Page 681 of 1007

INTERIOR TRIM COMPONENTS

76-3-20 REPAIRS

10.Disconnect 2 multiplugs from fuse box.

11.Close glove box.

12.Remove clock.

+ INSTRUMENTS, REPAIRS, Clock.

13.Remove hazard warning switch.

+ DRIVER CONTROLS, REPAIRS,

Switch - hazard warning - from 04MY.

14.Remove both 'A' post upper trim finishers.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

15.Remove passenger airbag.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - fascia - passenger - from 04MY.

16.Disconnect 2 multiplugs from fascia harness.17.Remove 14 bolts securing fascia.

18.With assistance remove fascia.

NOTE: Do not carry out further dismantling if

component is removed for access only.

19.Disconnect 4 multiplugs from fascia switch

assembly.

20.Remove 4 switches from fascia switch carrier.

M76 4722

M76 4714

Page 683 of 1007

INTERIOR TRIM COMPONENTS

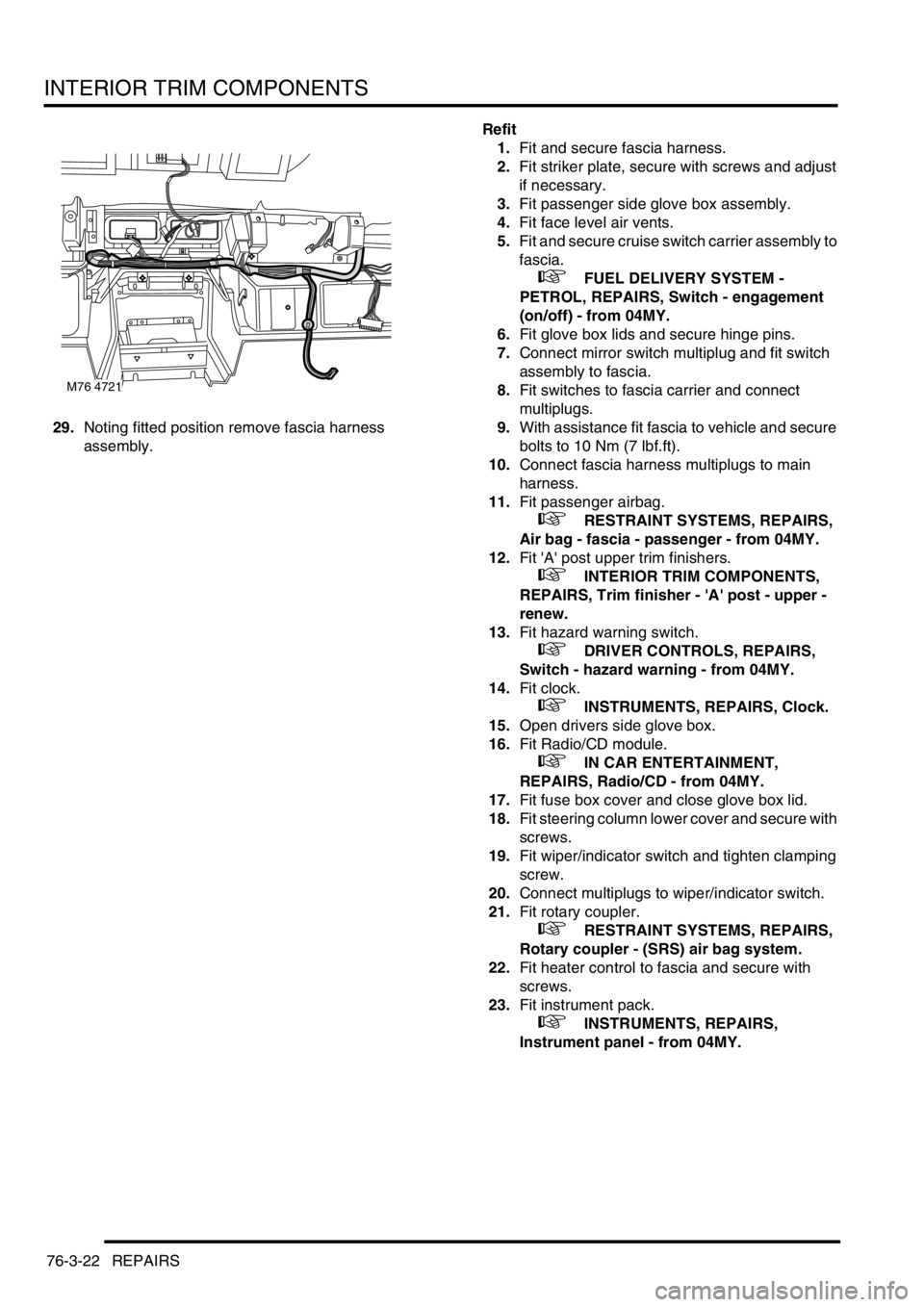

76-3-22 REPAIRS

29.Noting fitted position remove fascia harness

assembly.Refit

1.Fit and secure fascia harness.

2.Fit striker plate, secure with screws and adjust

if necessary.

3.Fit passenger side glove box assembly.

4.Fit face level air vents.

5.Fit and secure cruise switch carrier assembly to

fascia.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Switch - engagement

(on/off) - from 04MY.

6.Fit glove box lids and secure hinge pins.

7.Connect mirror switch multiplug and fit switch

assembly to fascia.

8.Fit switches to fascia carrier and connect

multiplugs.

9.With assistance fit fascia to vehicle and secure

bolts to 10 Nm (7 lbf.ft).

10.Connect fascia harness multiplugs to main

harness.

11.Fit passenger airbag.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - fascia - passenger - from 04MY.

12.Fit 'A' post upper trim finishers.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

13.Fit hazard warning switch.

+ DRIVER CONTROLS, REPAIRS,

Switch - hazard warning - from 04MY.

14.Fit clock.

+ INSTRUMENTS, REPAIRS, Clock.

15.Open drivers side glove box.

16.Fit Radio/CD module.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio/CD - from 04MY.

17.Fit fuse box cover and close glove box lid.

18.Fit steering column lower cover and secure with

screws.

19.Fit wiper/indicator switch and tighten clamping

screw.

20.Connect multiplugs to wiper/indicator switch.

21.Fit rotary coupler.

+ RESTRAINT SYSTEMS, REPAIRS,

Rotary coupler - (SRS) air bag system.

22.Fit heater control to fascia and secure with

screws.

23.Fit instrument pack.

+ INSTRUMENTS, REPAIRS,

Instrument panel - from 04MY.

M76 4721

Page 710 of 1007

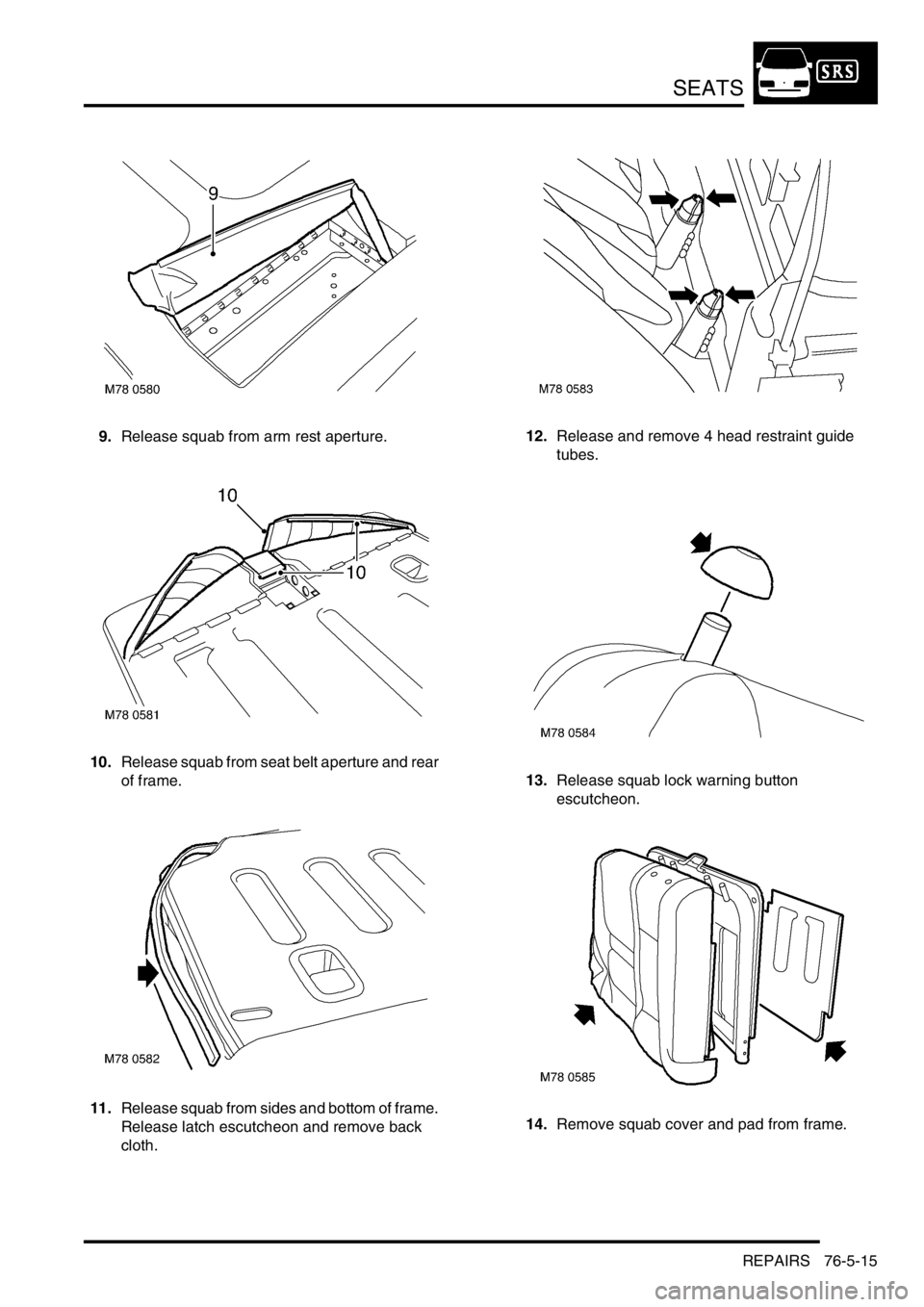

SEATS

REPAIRS 76-5-15

9.Release squab from arm rest aperture.

10.Release squab from seat belt aperture and rear

of frame.

11.Release squab from sides and bottom of frame.

Release latch escutcheon and remove back

cloth.12.Release and remove 4 head restraint guide

tubes.

13.Release squab lock warning button

escutcheon.

14.Remove squab cover and pad from frame.

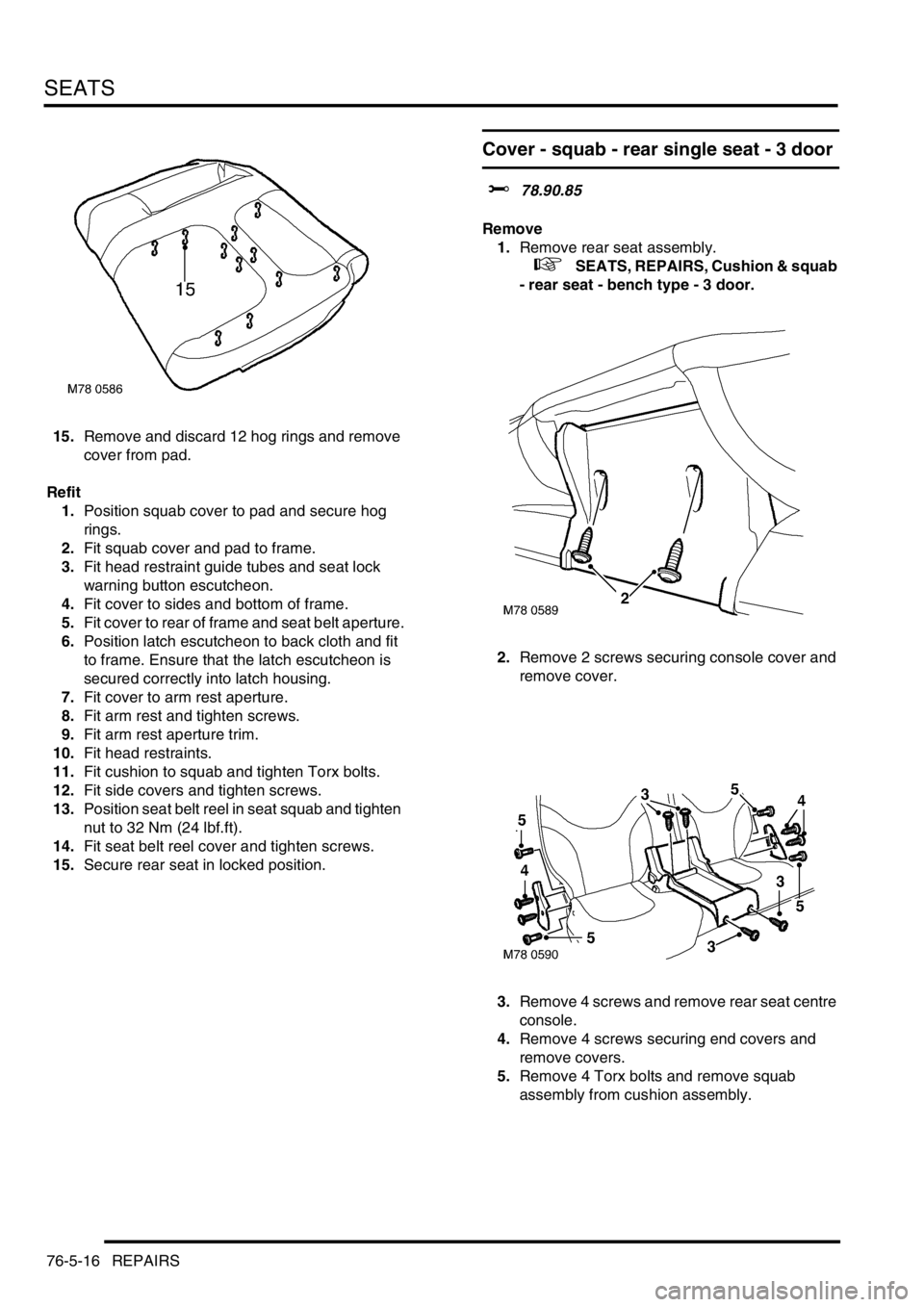

Page 711 of 1007

SEATS

76-5-16 REPAIRS

15.Remove and discard 12 hog rings and remove

cover from pad.

Refit

1.Position squab cover to pad and secure hog

rings.

2.Fit squab cover and pad to frame.

3.Fit head restraint guide tubes and seat lock

warning button escutcheon.

4.Fit cover to sides and bottom of frame.

5.Fit cover to rear of frame and seat belt aperture.

6.Position latch escutcheon to back cloth and fit

to frame. Ensure that the latch escutcheon is

secured correctly into latch housing.

7.Fit cover to arm rest aperture.

8.Fit arm rest and tighten screws.

9.Fit arm rest aperture trim.

10.Fit head restraints.

11.Fit cushion to squab and tighten Torx bolts.

12.Fit side covers and tighten screws.

13.Position seat belt reel in seat squab and tighten

nut to 32 Nm (24 lbf.ft).

14.Fit seat belt reel cover and tighten screws.

15.Secure rear seat in locked position.

Cover - squab - rear single seat - 3 door

$% 78.90.85

Remove

1.Remove rear seat assembly.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

2.Remove 2 screws securing console cover and

remove cover.

3.Remove 4 screws and remove rear seat centre

console.

4.Remove 4 screws securing end covers and

remove covers.

5.Remove 4 Torx bolts and remove squab

assembly from cushion assembly.

Page 714 of 1007

SUNROOF

REPAIRS 76-6-1

SUNROOF REPAIRS

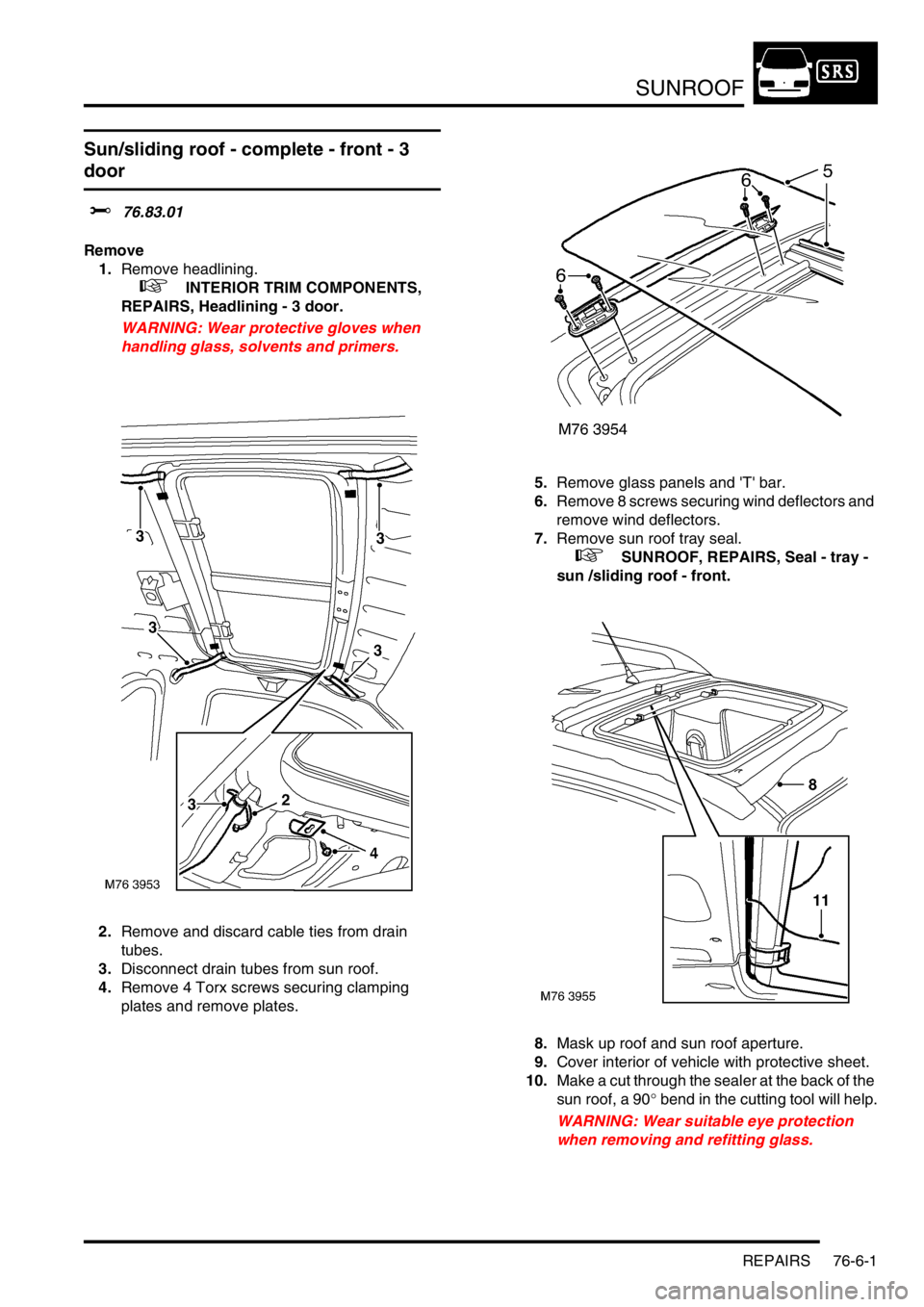

Sun/sliding roof - complete - front - 3

door

$% 76.83.01

Remove

1.Remove headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 3 door.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

2.Remove and discard cable ties from drain

tubes.

3.Disconnect drain tubes from sun roof.

4.Remove 4 Torx screws securing clamping

plates and remove plates.5.Remove glass panels and 'T' bar.

6.Remove 8 screws securing wind deflectors and

remove wind deflectors.

7.Remove sun roof tray seal.

+ SUNROOF, REPAIRS, Seal - tray -

sun /sliding roof - front.

8.Mask up roof and sun roof aperture.

9.Cover interior of vehicle with protective sheet.

10.Make a cut through the sealer at the back of the

sun roof, a 90° bend in the cutting tool will help.

WARNING: Wear suitable eye protection

when removing and refitting glass.

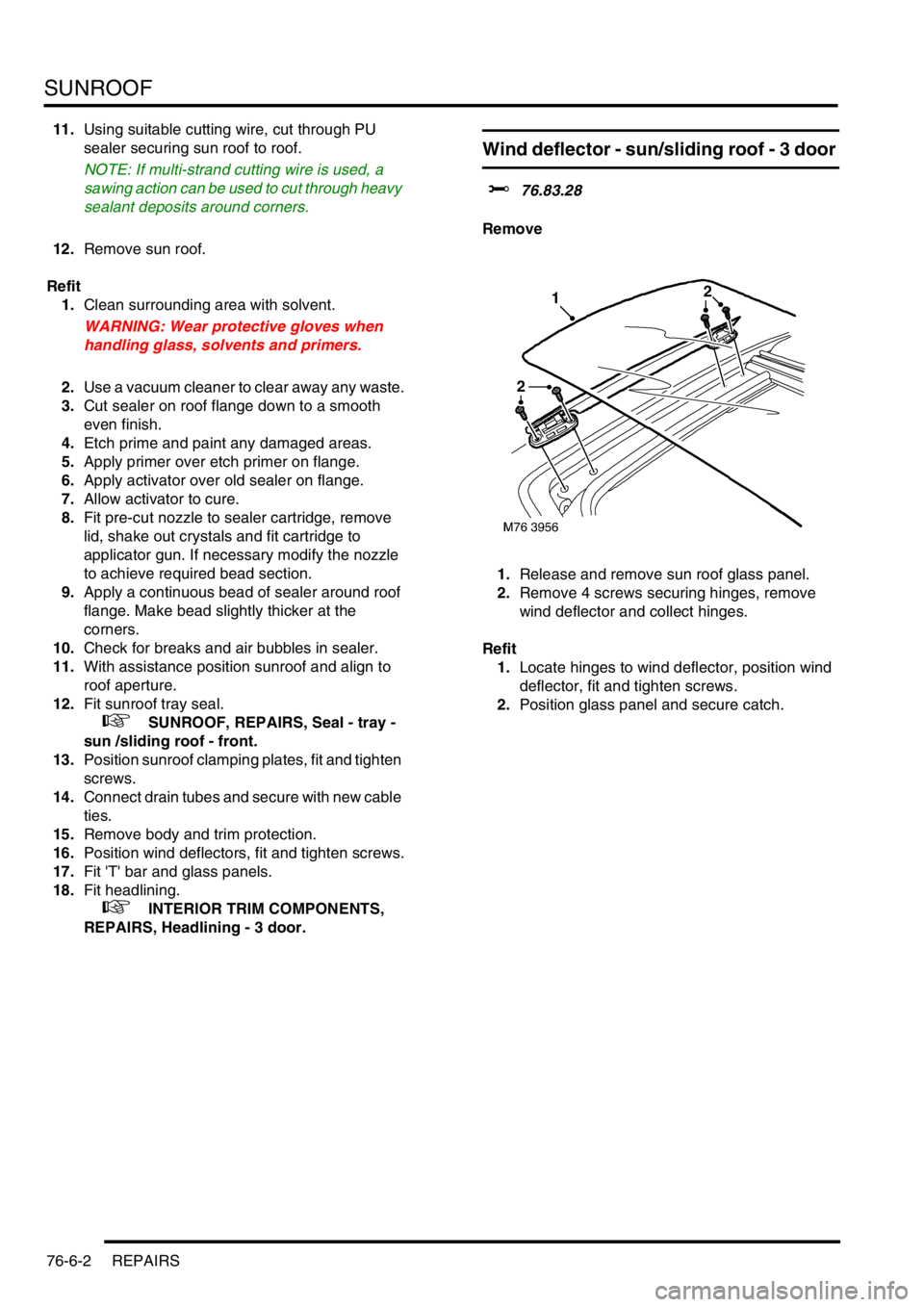

Page 715 of 1007

SUNROOF

76-6-2 REPAIRS

11.Using suitable cutting wire, cut through PU

sealer securing sun roof to roof.

NOTE: If multi-strand cutting wire is used, a

sawing action can be used to cut through heavy

sealant deposits around corners.

12.Remove sun roof.

Refit

1.Clean surrounding area with solvent.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

2.Use a vacuum cleaner to clear away any waste.

3.Cut sealer on roof flange down to a smooth

even finish.

4.Etch prime and paint any damaged areas.

5.Apply primer over etch primer on flange.

6.Apply activator over old sealer on flange.

7.Allow activator to cure.

8.Fit pre-cut nozzle to sealer cartridge, remove

lid, shake out crystals and fit cartridge to

applicator gun. If necessary modify the nozzle

to achieve required bead section.

9.Apply a continuous bead of sealer around roof

flange. Make bead slightly thicker at the

corners.

10.Check for breaks and air bubbles in sealer.

11.With assistance position sunroof and align to

roof aperture.

12.Fit sunroof tray seal.

+ SUNROOF, REPAIRS, Seal - tray -

sun /sliding roof - front.

13.Position sunroof clamping plates, fit and tighten

screws.

14.Connect drain tubes and secure with new cable

ties.

15.Remove body and trim protection.

16.Position wind deflectors, fit and tighten screws.

17.Fit 'T' bar and glass panels.

18.Fit headlining.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Headlining - 3 door.

Wind deflector - sun/sliding roof - 3 door

$% 76.83.28

Remove

1.Release and remove sun roof glass panel.

2.Remove 4 screws securing hinges, remove

wind deflector and collect hinges.

Refit

1.Locate hinges to wind deflector, position wind

deflector, fit and tighten screws.

2.Position glass panel and secure catch.

Page 886 of 1007

HEATING AND VENTILATION

REPAIRS 80-21

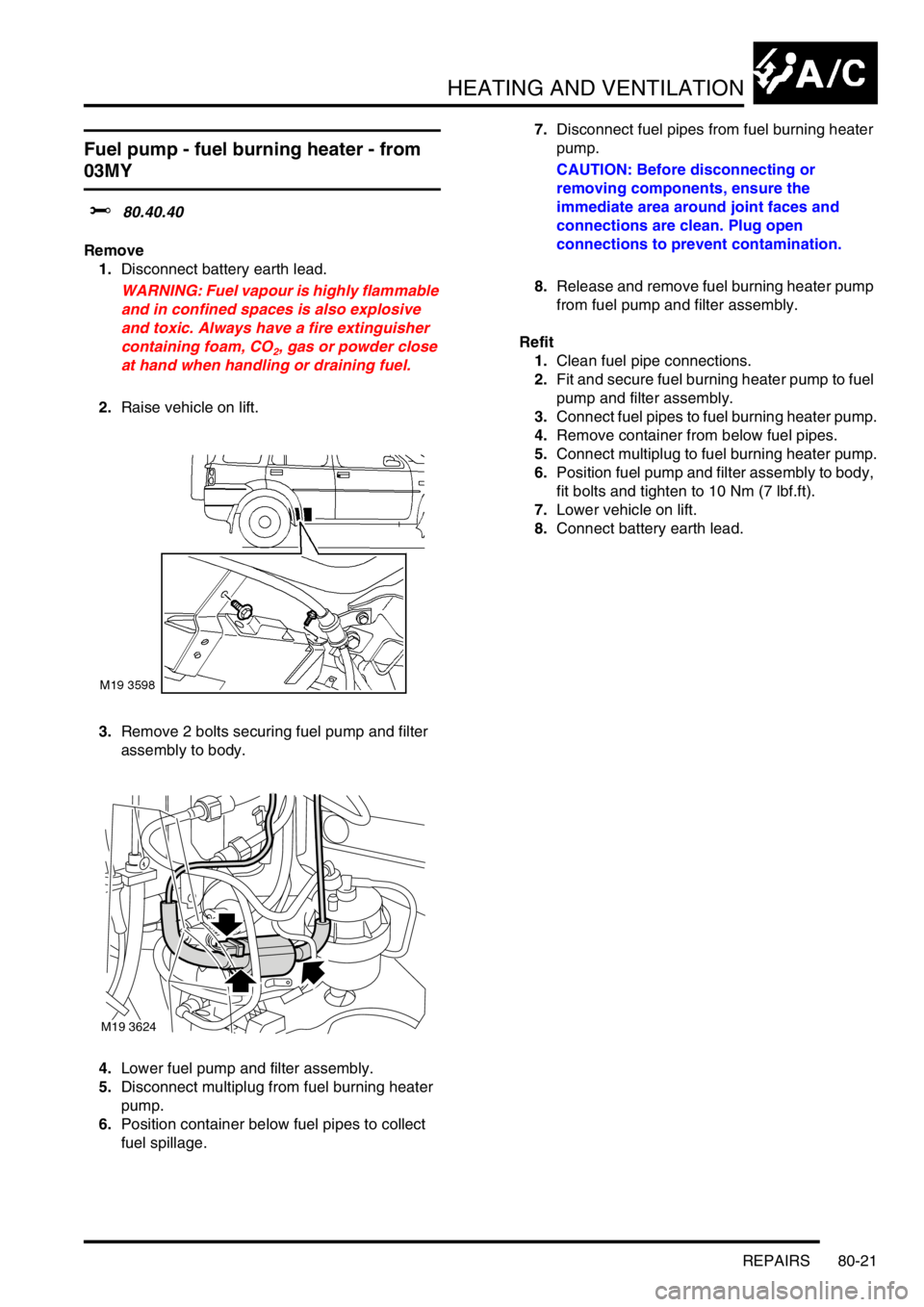

Fuel pump - fuel burning heater - from

03MY

$% 80.40.40

Remove

1.Disconnect battery earth lead.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

2.Raise vehicle on lift.

3.Remove 2 bolts securing fuel pump and filter

assembly to body.

4.Lower fuel pump and filter assembly.

5.Disconnect multiplug from fuel burning heater

pump.

6.Position container below fuel pipes to collect

fuel spillage.7.Disconnect fuel pipes from fuel burning heater

pump.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

8.Release and remove fuel burning heater pump

from fuel pump and filter assembly.

Refit

1.Clean fuel pipe connections.

2.Fit and secure fuel burning heater pump to fuel

pump and filter assembly.

3.Connect fuel pipes to fuel burning heater pump.

4.Remove container from below fuel pipes.

5.Connect multiplug to fuel burning heater pump.

6.Position fuel pump and filter assembly to body,

fit bolts and tighten to 10 Nm (7 lbf.ft).

7.Lower vehicle on lift.

8.Connect battery earth lead.

M19 3624

Page 888 of 1007

AIR CONDITIONING

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING 82-1

AIR CONDITIONING REFRIGERANT RECOVERY, RECYCLING AND RECHARGING

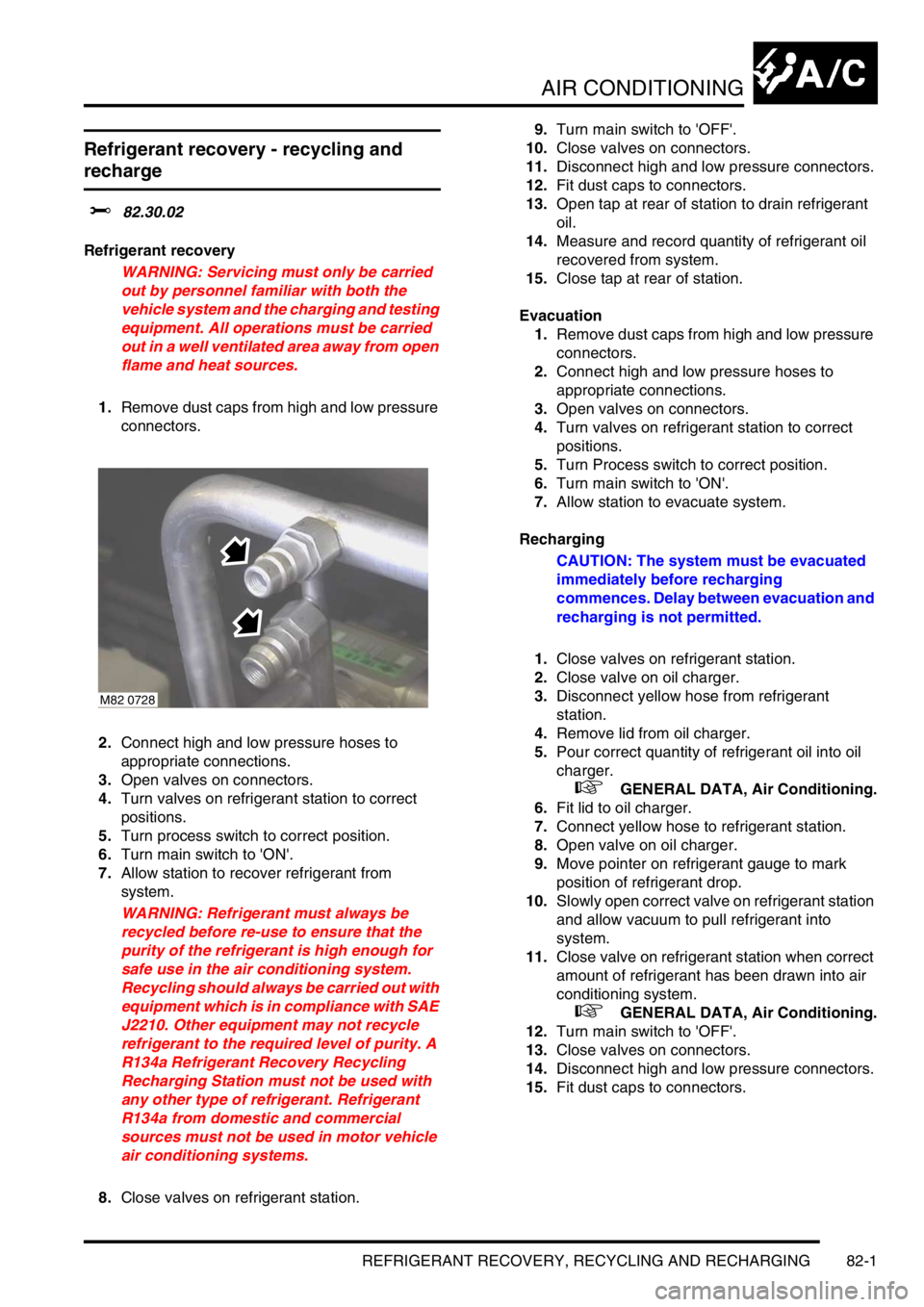

Refrigerant recovery - recycling and

recharge

$% 82.30.02

Refrigerant recovery

WARNING: Servicing must only be carried

out by personnel familiar with both the

vehicle system and the charging and testing

equipment. All operations must be carried

out in a well ventilated area away from open

flame and heat sources.

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to recover refrigerant from

system.

WARNING: Refrigerant must always be

recycled before re-use to ensure that the

purity of the refrigerant is high enough for

safe use in the air conditioning system.

Recycling should always be carried out with

equipment which is in compliance with SAE

J2210. Other equipment may not recycle

refrigerant to the required level of purity. A

R134a Refrigerant Recovery Recycling

Recharging Station must not be used with

any other type of refrigerant. Refrigerant

R134a from domestic and commercial

sources must not be used in motor vehicle

air conditioning systems.

8.Close valves on refrigerant station.9.Turn main switch to 'OFF'.

10.Close valves on connectors.

11.Disconnect high and low pressure connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant

oil.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to evacuate system.

Recharging

CAUTION: The system must be evacuated

immediately before recharging

commences. Delay between evacuation and

recharging is not permitted.

1.Close valves on refrigerant station.

2.Close valve on oil charger.

3.Disconnect yellow hose from refrigerant

station.

4.Remove lid from oil charger.

5.Pour correct quantity of refrigerant oil into oil

charger.

+ GENERAL DATA, Air Conditioning.

6.Fit lid to oil charger.

7.Connect yellow hose to refrigerant station.

8.Open valve on oil charger.

9.Move pointer on refrigerant gauge to mark

position of refrigerant drop.

10.Slowly open correct valve on refrigerant station

and allow vacuum to pull refrigerant into

system.

11.Close valve on refrigerant station when correct

amount of refrigerant has been drawn into air

conditioning system.

+ GENERAL DATA, Air Conditioning.

12.Turn main switch to 'OFF'.

13.Close valves on connectors.

14.Disconnect high and low pressure connectors.

15.Fit dust caps to connectors.

M82 0728