ABS LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 45 of 1007

GENERAL INFORMATION

03-14

Self-locking nuts

Self-locking nuts, i.e. nylon insert or deferred thread

nuts can be re-used providing resistance can be felt

when the locking portion of the nut passes over the

thread of the bolt or stud.

DO NOT apply heat in an attempt to free deferred

thread nuts or fittings; as well as causing damage to

protective coatings, there is a risk of damage to

electronic equipment and brake linings from stray

heat.

Where self-locking nuts have been removed, it is

advisable to replace them with new ones of the same

type.

Where bearing pre-load is involved, nuts should be

tightened in accordance with special instructions.

Flexible pipes and hoses

General

When removing and installing flexible hydraulic pipes

and hoses, ensure that the following practices are

observed to ensure component serviceability:

lBefore removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

lObtain appropriate plugs or caps before

detaching hose end fittings, so that the ports

can be immediately covered to prevent the

ingress of dirt.

lClean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any faulty hoses.

lWhen refitting a hose, ensure that no

unnecessary bends are introduced, and that

hose is not twisted before or during tightening of

union nuts.

lFit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of

dirt.

lAbsolute cleanliness must be observed with

hydraulic components at all times.

lAfter any work on hydraulic systems, carefully

inspect for leaks underneath the vehicle while a

second operator applies maximum brake

pressure to the brakes (engine running) and

operates the steering.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

Page 48 of 1007

GENERAL INFORMATION

03-17

SPX Corporation,

665, Eisenhower Drive,

Owatonna,

MN 55060,

USA

( 0018 772979110

) 0018 005787375

Australia

SPX Australia,

28, Clayton Road,

Notting Hill,

Victoria 3168,

Australia

( 00 (61) 00395446222

) 00 (61) 0395445222

e-mail: [email protected]

Japan and East Asia

Jatek Ltd.,

5 - 53, Minawacho 2-chome,

Kohoku-ku,

Yokohama,

Kanagawa 223-0051,

Japan

( 0081 455627700

) 0081 455627800

Rolling road testing

General

IMPORTANT: Use a four wheel rolling road for

brake testing if possible.

The front and rear wheels cannot be driven

independently due to the viscous coupling. This

eliminates the need for differential lock by

progressively applying more torque to the rear

wheels if the front wheels start to slip.

DO NOT attempt to drive individual wheels with

vehicle supported on floor jacks or stands.

Four wheel rolling road

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing, except any that may apply to the tyres.

Before testing a vehicle with anti-lock brakes on a

four wheel rolling road, disconnect the ABS

modulator. The ABS function will not work, the ABS

warning light will illuminate. Normal braking will be

available.

Two wheel rolling road

ABS will not function on a two wheel rolling road. The

ABS light will illuminate during testing. Normal

braking will be available.

If brake testing on a two wheel rolling road is

necessary, the following precautions should be

taken:

lpropeller shaft to the rear axle is removed/

disconnected;

lneutral selected in gearbox;

lhill descent control not selected.

When checking brakes, run engine at idle speed to

maintain servo vacuum.

Page 50 of 1007

GENERAL INFORMATION

03-19

Electrical precautions

General

The following guidelines are intended to ensure the

safety of the operator and ensure the prevention of

damage to the electrical and electronic components

fitted to the vehicle. Where necessary, specific

precautions are detailed in the individual procedures

of this manual.

Equipment

Prior to commencing any test procedure on the

vehicle, ensure that the relevant test equipment is

working correctly and any harness or connectors are

in good condition. It is particularly important to check

the condition of the lead and plugs of mains operated

equipment.

Polarity

Never reverse connect the vehicle battery and

always ensure the correct polarity when connecting

test equipment.

High Voltage Circuits

Whenever disconnecting live ht circuits, always use

insulated pliers and never allow the open end of the

ht lead to contact other components, particularly

ECU's.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, high

voltage spikes can occur on these terminals.

Connectors and harnesses

The engine compartment of a vehicle is a particularly

hostile environment for electrical components and

connectors:

lAlways ensure electrically related items are dry

and oil free before disconnecting and

connecting test equipment.

lEnsure disconnected multiplugs and sensors

are protected from being contaminated with oil,

coolant or other solutions. Contamination could

impair performance or result in catastrophic

failure.

lNever force connectors apart using tools to

prise apart or by pulling on the wiring harness.

lAlways ensure locking tabs are disengaged

before disconnection, and match orientation to

enable correct reconnection.

lEnsure that any protection (covers, insulation

etc.) is replaced if disturbed.Having confirmed a component to be faulty:

lSwitch off the ignition and disconnect the

battery.

lRemove the component and support the

disconnected harness.

lWhen replacing the component, keep oily hands

away from electrical connection areas and push

connectors home until any locking tabs fully

engage.

Battery disconnection

Before disconnecting the battery, disable the alarm

system and switch off all electrical equipment. If the

radio is to be serviced, ensure the security code has

been deactivated.

CAUTION: To prevent damage to electrical

components, always disconnect the battery

when working on the vehicle's electrical system.

The ground lead must be disconnected first and

reconnected last.

CAUTION: Always ensure that battery leads are

routed correctly and are not close to any

potential chafing points.

Battery charging

Only recharge the battery with it removed from the

vehicle. Always ensure any battery charging area is

well ventilated and that every precaution is taken to

avoid naked flames and sparks.

Ignition system safety precautions

The vehicle's ignition system produces high voltages

and the following precautions should be observed

before carrying out any work on the system:

WARNING: Before commencing work on an

ignition system, ensure all high tension

terminals, adapters and diagnostic equipment

are adequately insulated and shielded to prevent

accidental personal contacts and minimise the

risk of shock. Wearers of surgically implanted

pacemaker devices should not be in close

proximity of ignition circuits or diagnostic

equipment.

Page 61 of 1007

GENERAL INFORMATION

03-30

Remedial actions

If an accident involving R134a should occur, conduct

the following remedial actions:

lIf liquid R134a enters the eye, do not rub it.

Gently run large quantities of eye wash over

affected eye to raise the temperature. If an eye

wash is not available, cool clean water may be

used to flush the eye. After rinsing, cover the

eye with a clean pad and seek immediate

medical attention.

lIf liquid R134a is splashed onto the skin, run

large quantities of water over the affected area

to raise the temperature. Implement the same

action if the skin comes in contact with

discharging cylinders. Wrap the contaminated

body parts in blankets (or similar materials) and

seek immediate medical attention.

lIf the debilitating effects of inhalation of R134a

vapour is suspected, seek fresh air. If the

affected person is unconscious, move them

away from the contaminated area to fresh air

and apply artificial respiration and/or oxygen

and seek immediate medical attention.

Service precautions

Observe the following precautions when handling

components used in the air conditioning system:

lAir conditioning units must not be lifted by their

hoses, pipes or capillary lines.

lHoses and lines must not be subjected to any

twist or stress - the efficiency of the system will

be impaired by kinks or restrictions. Ensure that

hoses are correctly positioned before tightening

couplings, and ensure that all clips and supports

are utilised.

lFlexible hoses should not be positioned close to

the exhaust manifold (less than 100mm) unless

protected by heat shielding.

lCompleted assemblies must be checked for

refrigeration lines touching metal panels. Any

direct contact of components and panels may

transmit noise and so must be eliminated.

lThe appropriate torque wrench must be used

when tightening refrigerant connections to the

stipulated value. An additional spanner must be

used to hold the union to prevent twisting of the

pipe when tightening connections.

lBefore connecting any hose or pipe, ensure that

refrigerant oil is applied to the seat of the new

'O' ring seals, BUT NOT to the threads of the

connection.

lAll protective plugs must remain in place to seal

the component until immediately prior to

connection.

lEnsure components are at room temperature

before uncapping, to prevent condensation of

moisture from the air that enters it.

lComponents must not remain uncapped for

longer than 15 minutes. In the event of a delay,

the caps must be fitted.

lWhen disconnecting, immediately cap all air

conditioning pipes to prevent ingress of dirt and

moisture into the system.

lThe modulator (receiver/drier) contains

desiccant which absorbs moisture. It must be

positively sealed at all times. A modulator that

has been left uncapped must not be used, fit a

new unit.

lThe modulator should be the last component

connected to the system to ensure optimum

dehydration and maximum moisture protection

of the system.

lWhenever the refrigerant system is opened, the

modulator must be renewed immediately before

evacuating and recharging the system.

lUse alcohol and a clean lint-free cloth to clean

dirty connections.

lEnsure that all new parts fitted are marked for

use with R134a.

Page 62 of 1007

GENERAL INFORMATION

03-31

When a major repair has been completed, a leak test

should be conducted; refer to the air conditioning

section of this manual for the correct procedure.

Refrigerant oil

Use an approved refrigerant lubricating oil:

ND Oil 8

CAUTION: Do not use any other type of

refrigerant oil.

CAUTION: Refrigerant oil easily absorbs water

and must not be stored for long periods. Do not

pour unused oil back into the container.

When renewing system components, add the

quantities of refrigerant oil recommended in the Air

Conditioning section of this manual.

Compressor

A new compressor is sealed and pressurised with

Nitrogen gas. When fitting a new compressor, slowly

release the sealing cap; gas pressure should be

heard to vent as the seal is broken.

CAUTION: A new compressor should always be

sealed and could be pressurised with nitrogen

gas. To avoid possible oil loss, release the

sealing cap(s) slowly. Do not remove the cap(s)

until immediately prior to connecting the air

conditioning pipes to the compressor.

Rapid refrigerant discharge

If the air conditioning system is involved in accident

damage and the system is punctured, the refrigerant

will discharge rapidly. The rapid discharge of

refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled in accordance with the 'Air

Conditioning Compressor Replacement Procedure'.

Air conditioning compressor

replacement

A new compressor is supplied filled with a full charge

of (X cm3) of refrigerant oil.

A new compressor is supplied with an oil fill (X cm) of

120 cm

3.

A calculated quantity of oil must be drained from the

new compressor before fitting. To calculate the

quantity of oil to be drained:

1Remove the drain plug from the old

compressor.

2Invert the compressor and gravity drain the oil

into a calibrated measuring cylinder. Rotate the

compressor clutch to ensure the compressor is

completely drained.

3Note the quantity of oil drained (Y cm

3).

4Calculate the quantity of oil to be drained from

the new compressor using the following

formula:

X cm

3 – (Y cm3 + 20 cm3) = Q cm3

5Remove the drain plug from the new

compressor and drain Q cm3 of oil.

6Fit and tighten the compressor drain plug.

System components

When renewing system components, add the

following quantities of refrigerant oil:

lCondenser = 40 cm

3

lEvaporator = 30 cm 3

lReceiver drier = 15 cm 3

lPipe or hose = 5 cm 3

Page 94 of 1007

GENERAL DATA

04-31

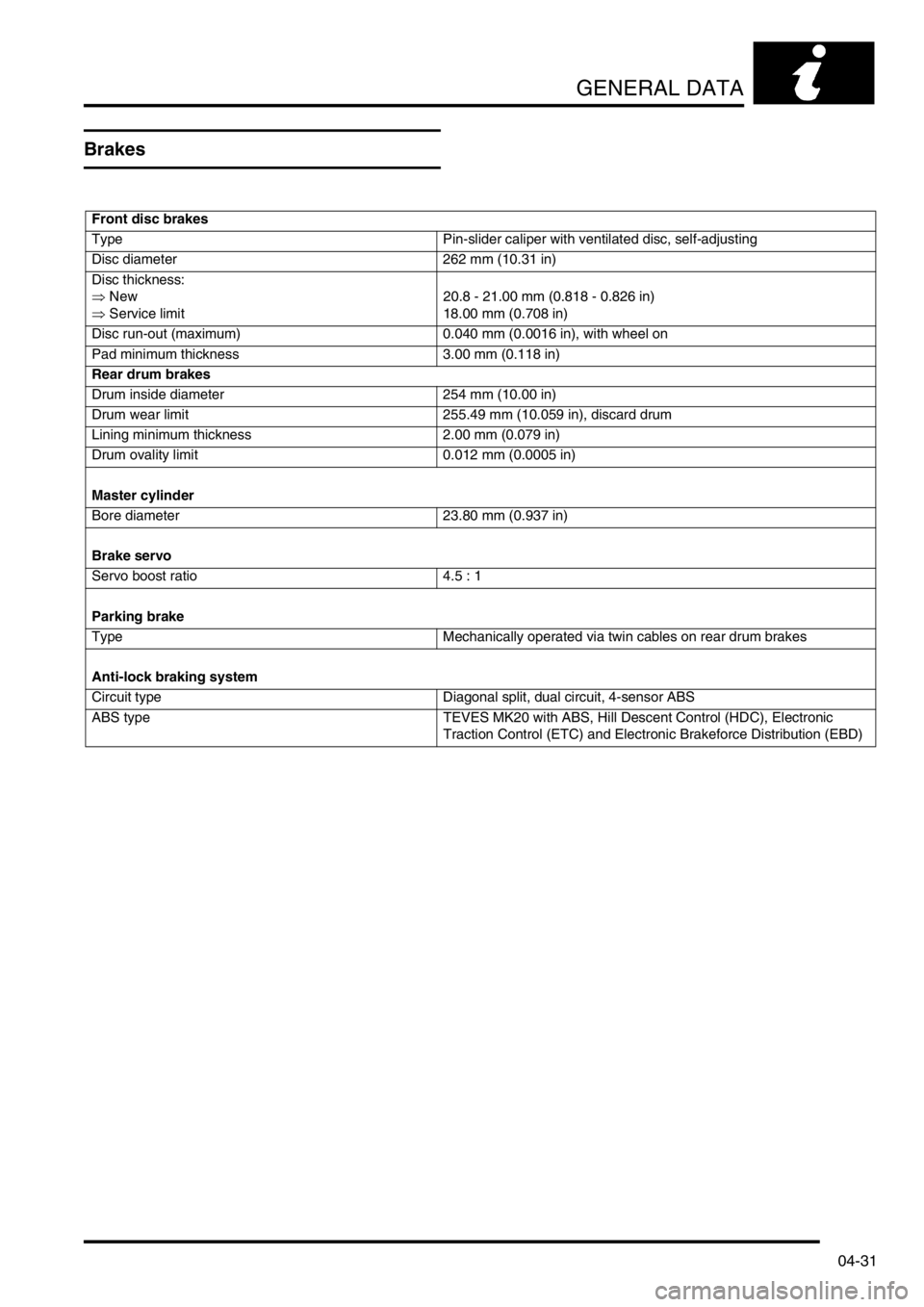

Brakes

Front disc brakes

Type Pin-slider caliper with ventilated disc, self-adjusting

Disc diameter 262 mm (10.31 in)

Disc thickness:

⇒ New

⇒ Service limit20.8 - 21.00 mm (0.818 - 0.826 in)

18.00 mm (0.708 in)

Disc run-out (maximum) 0.040 mm (0.0016 in), with wheel on

Pad minimum thickness 3.00 mm (0.118 in)

Rear drum brakes

Drum inside diameter 254 mm (10.00 in)

Drum wear limit 255.49 mm (10.059 in), discard drum

Lining minimum thickness 2.00 mm (0.079 in)

Drum ovality limit 0.012 mm (0.0005 in)

Master cylinder

Bore diameter 23.80 mm (0.937 in)

Brake servo

Servo boost ratio 4.5 : 1

Parking brake

Type Mechanically operated via twin cables on rear drum brakes

Anti-lock braking system

Circuit type Diagonal split, dual circuit, 4-sensor ABS

ABS type TEVES MK20 with ABS, Hill Descent Control (HDC), Electronic

Traction Control (ETC) and Electronic Brakeforce Distribution (EBD)

Page 116 of 1007

TORQUE WRENCH SETTINGS

06-13

Fuel delivery system – Petrol

1 Tighten in sequence using the procedure defined in 'Repairs' section.

+ ENGINE MANAGEMENT SYSTEM - SIEMENS, REPAIRS, Sensor - combined - manifold absolute

pressure/Intake air temperature (MAP/IAT).

TORQUE DESCRIPTION METRIC IMPERIAL

Air cleaner to battery tray bolts 9 Nm 7 lbf.ft

Fuel filler neck to body nuts and bolt 9 Nm 7 lbf.ft

Fuel pump/sender unit to tank locking ring 35 Nm 26 lbf.ft

Fuel rail to inlet manifold bolt 8 Nm 6 lbf.ft

Fuel tank to body bolts 40 Nm 29 lbf.ft

Heated Oxygen (HO

2S) Sensor 40 Nm 29 lbf.ft

Ignition coils to LH inlet manifold nuts and bolts - KV6 - Up to 03 Model Year 9 Nm 7 lbf.ft

Inertia (fuel cut-off) switch 2 Nm 1.5 lbf.ft

Intake Air Control Valve (IACV) to throttle body Allen screws 6 Nm 4.5 lbf.ft

Subframe to body bolts 190 Nm 140 lbf.ft

Throttle housing to inlet manifold bolts

1 (K1.8)

⇒1st. stage4 Nm 3 lbf.ft

⇒2nd. stage9 Nm 7 lbf.ft

Throttle body to inlet manifold chamber Torx screws (KV6) 8 Nm 6 lbf.ft

Throttle actuator support bracket to throttle body Torx screws (vehicles with cruise

control only)9 Nm 7 lbf.ft

Throttle position sensor to housing Torx screws 1.5 Nm 1.1 lbf.ft

VIS motor to inlet manifold chamber screws (KV6 only) 8 Nm 6 lbf.ft

Page 131 of 1007

TORQUE WRENCH SETTINGS

06-28

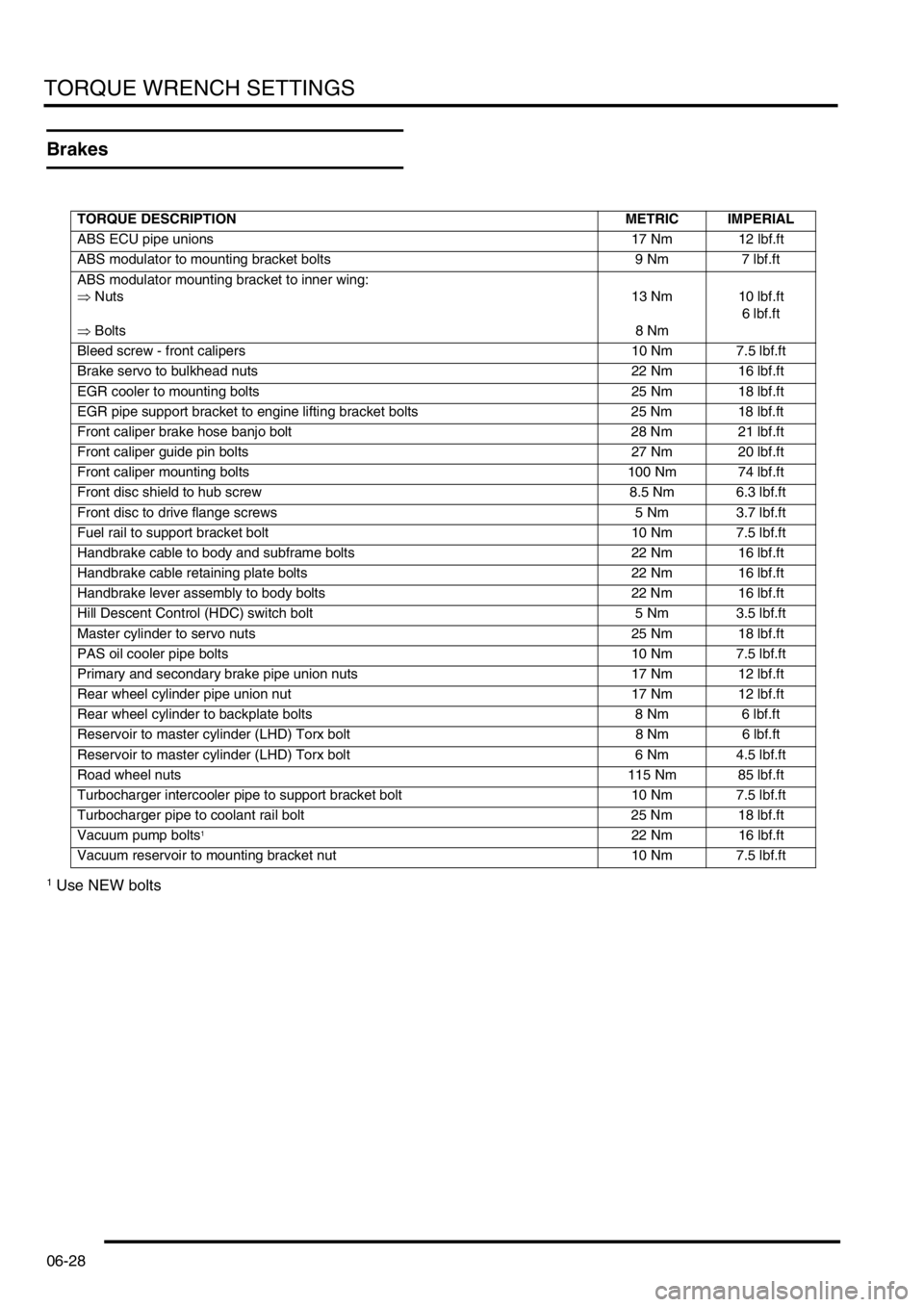

Brakes

1 Use NEW bolts

TORQUE DESCRIPTION METRIC IMPERIAL

ABS ECU pipe unions 17 Nm 12 lbf.ft

ABS modulator to mounting bracket bolts 9 Nm 7 lbf.ft

ABS modulator mounting bracket to inner wing:

⇒ Nuts

⇒ Bolts13 Nm

8 Nm10 lbf.ft

6 lbf.ft

Bleed screw - front calipers 10 Nm 7.5 lbf.ft

Brake servo to bulkhead nuts 22 Nm 16 lbf.ft

EGR cooler to mounting bolts 25 Nm 18 lbf.ft

EGR pipe support bracket to engine lifting bracket bolts 25 Nm 18 lbf.ft

Front caliper brake hose banjo bolt 28 Nm 21 lbf.ft

Front caliper guide pin bolts 27 Nm 20 lbf.ft

Front caliper mounting bolts 100 Nm 74 lbf.ft

Front disc shield to hub screw 8.5 Nm 6.3 lbf.ft

Front disc to drive flange screws 5 Nm 3.7 lbf.ft

Fuel rail to support bracket bolt 10 Nm 7.5 lbf.ft

Handbrake cable to body and subframe bolts 22 Nm 16 lbf.ft

Handbrake cable retaining plate bolts 22 Nm 16 lbf.ft

Handbrake lever assembly to body bolts 22 Nm 16 lbf.ft

Hill Descent Control (HDC) switch bolt 5 Nm 3.5 lbf.ft

Master cylinder to servo nuts 25 Nm 18 lbf.ft

PAS oil cooler pipe bolts 10 Nm 7.5 lbf.ft

Primary and secondary brake pipe union nuts 17 Nm 12 lbf.ft

Rear wheel cylinder pipe union nut 17 Nm 12 lbf.ft

Rear wheel cylinder to backplate bolts 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 8 Nm 6 lbf.ft

Reservoir to master cylinder (LHD) Torx bolt 6 Nm 4.5 lbf.ft

Road wheel nuts 115 Nm 85 lbf.ft

Turbocharger intercooler pipe to support bracket bolt 10 Nm 7.5 lbf.ft

Turbocharger pipe to coolant rail bolt 25 Nm 18 lbf.ft

Vacuum pump bolts

122 Nm 16 lbf.ft

Vacuum reservoir to mounting bracket nut 10 Nm 7.5 lbf.ft

Page 180 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-3

REPAIRS

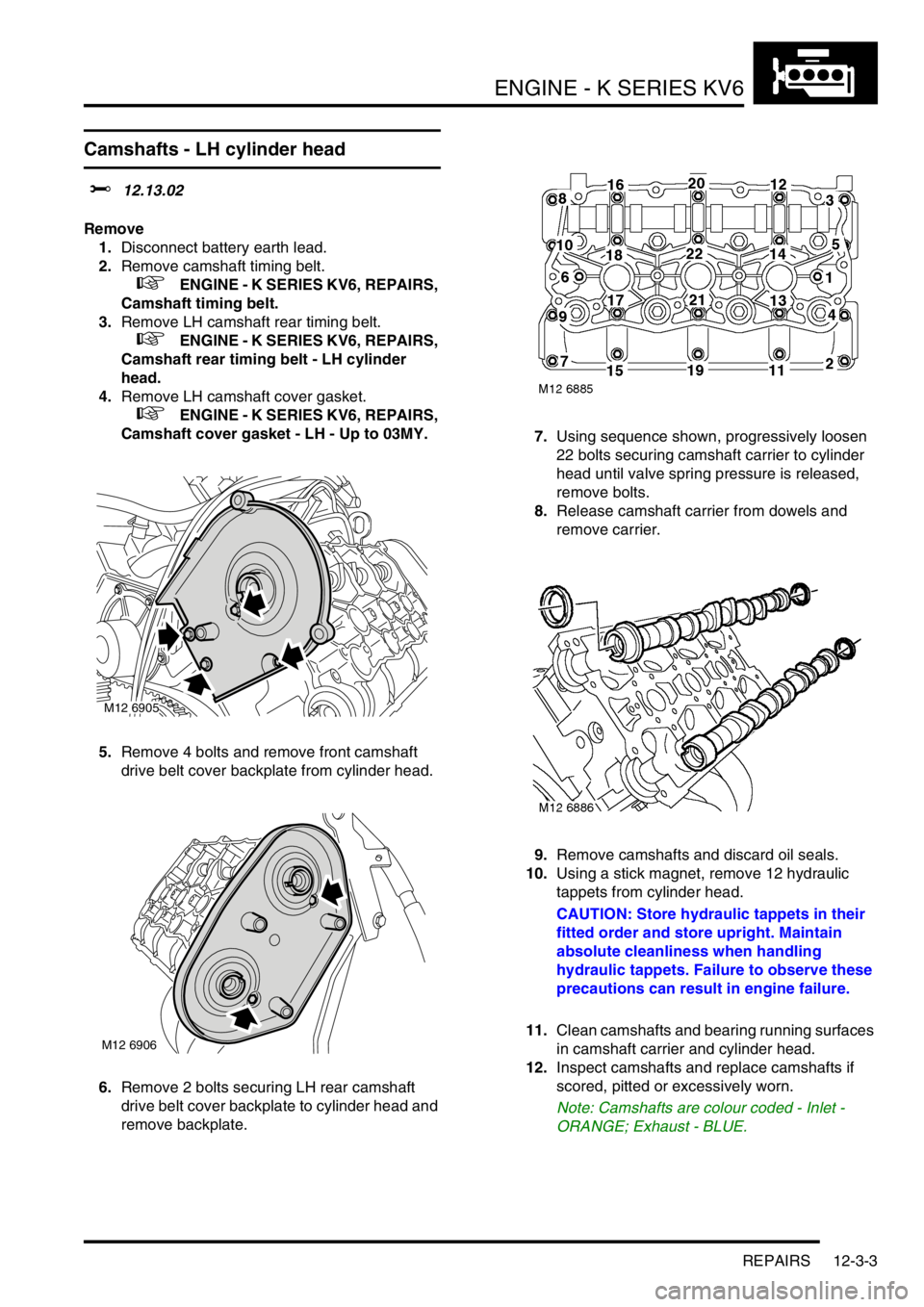

Camshafts - LH cylinder head

$% 12.13.02

Remove

1.Disconnect battery earth lead.

2.Remove camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

3.Remove LH camshaft rear timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft rear timing belt - LH cylinder

head.

4.Remove LH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - LH - Up to 03MY.

5.Remove 4 bolts and remove front camshaft

drive belt cover backplate from cylinder head.

6.Remove 2 bolts securing LH rear camshaft

drive belt cover backplate to cylinder head and

remove backplate.7.Using sequence shown, progressively loosen

22 bolts securing camshaft carrier to cylinder

head until valve spring pressure is released,

remove bolts.

8.Release camshaft carrier from dowels and

remove carrier.

9.Remove camshafts and discard oil seals.

10.Using a stick magnet, remove 12 hydraulic

tappets from cylinder head.

CAUTION: Store hydraulic tappets in their

fitted order and store upright. Maintain

absolute cleanliness when handling

hydraulic tappets. Failure to observe these

precautions can result in engine failure.

11.Clean camshafts and bearing running surfaces

in camshaft carrier and cylinder head.

12.Inspect camshafts and replace camshafts if

scored, pitted or excessively worn.

Note: Camshafts are colour coded - Inlet -

ORANGE; Exhaust - BLUE.

M12 6905

M12 6906

Page 183 of 1007

ENGINE - K SERIES KV6

12-3-6 REPAIRS

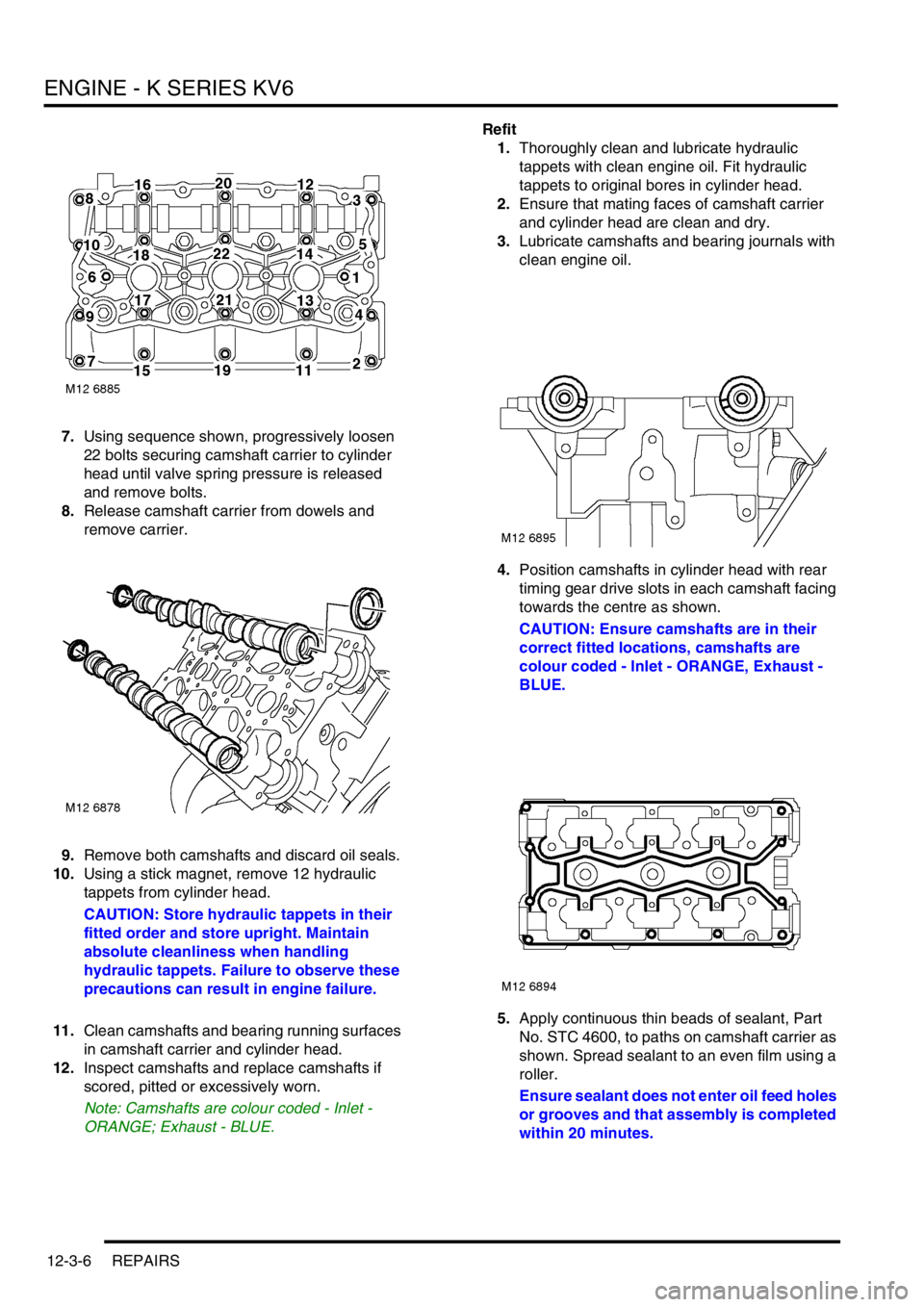

7.Using sequence shown, progressively loosen

22 bolts securing camshaft carrier to cylinder

head until valve spring pressure is released

and remove bolts.

8.Release camshaft carrier from dowels and

remove carrier.

9.Remove both camshafts and discard oil seals.

10.Using a stick magnet, remove 12 hydraulic

tappets from cylinder head.

CAUTION: Store hydraulic tappets in their

fitted order and store upright. Maintain

absolute cleanliness when handling

hydraulic tappets. Failure to observe these

precautions can result in engine failure.

11.Clean camshafts and bearing running surfaces

in camshaft carrier and cylinder head.

12.Inspect camshafts and replace camshafts if

scored, pitted or excessively worn.

Note: Camshafts are colour coded - Inlet -

ORANGE; Exhaust - BLUE.Refit

1.Thoroughly clean and lubricate hydraulic

tappets with clean engine oil. Fit hydraulic

tappets to original bores in cylinder head.

2.Ensure that mating faces of camshaft carrier

and cylinder head are clean and dry.

3.Lubricate camshafts and bearing journals with

clean engine oil.

4.Position camshafts in cylinder head with rear

timing gear drive slots in each camshaft facing

towards the centre as shown.

CAUTION: Ensure camshafts are in their

correct fitted locations, camshafts are

colour coded - Inlet - ORANGE, Exhaust -

BLUE.

5.Apply continuous thin beads of sealant, Part

No. STC 4600, to paths on camshaft carrier as

shown. Spread sealant to an even film using a

roller.

Ensure sealant does not enter oil feed holes

or grooves and that assembly is completed

within 20 minutes.