brake fluid LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 150 of 1007

MAINTENANCE

MAINTENANCE 10-3

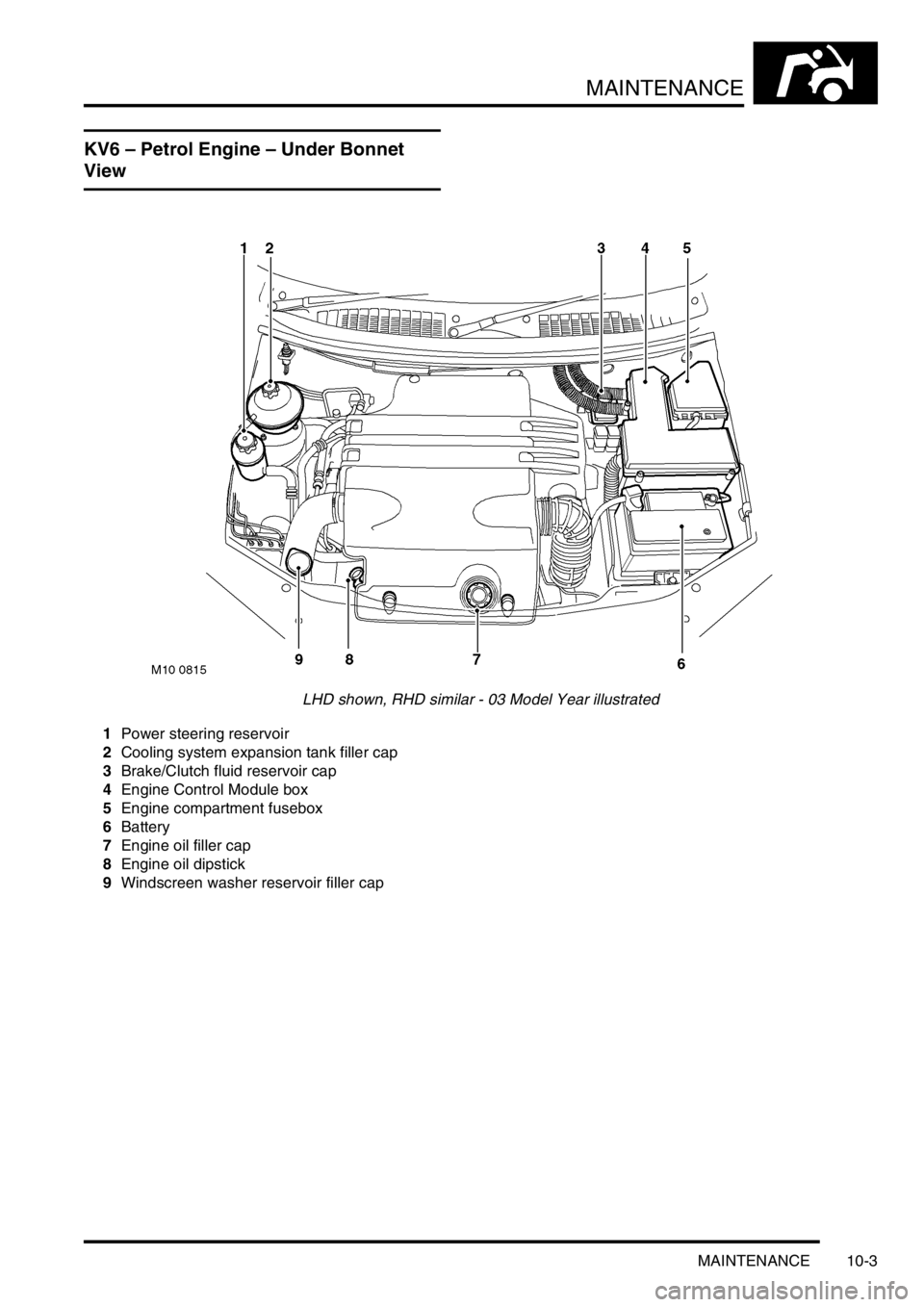

KV6 – Petrol Engine – Under Bonnet

View

LHD shown, RHD similar - 03 Model Year illustrated

1Power steering reservoir

2Cooling system expansion tank filler cap

3Brake/Clutch fluid reservoir cap

4Engine Control Module box

5Engine compartment fusebox

6Battery

7Engine oil filler cap

8Engine oil dipstick

9Windscreen washer reservoir filler cap

Page 154 of 1007

MAINTENANCE

MAINTENANCE 10-7

Tyres

Check

1.Check for any apparent damage to tyres,

paying particular attention to side walls.

2.Look at tyre treads and check for any unusual

wear patterns which may indicate out of

specification adjustment of steering or

suspension.

NOTE: Any adjustments to steering or

suspension will be subject to additional labour

and/or material cost and should not be carried

out without the authorisation of the customer.

3.Measure the tread depth across the width of the

tyre and around the circumference. Annotate

the maintenance check sheet with the lowest

figure obtained from each tyre.

NOTE: Any requirement to replace tyres should

be advised to the customer before any remedial

work is carried out. This will be subject to

additional labour and/or material cost and

should not be carried out without the

authorisation of the customer.

CAUTION: If new tyres are to be fitted,

ensure that they are fitted to the rear axle

only or to both front and rear axles. DO NOT

fit new tyres to front axle only.

Brake Pads and Calipers

Brake Pads

1.With front road wheels removed, check brake

pad thickness and ensure that both pads are

wearing evenly.

2.Check brake discs for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirement to replace brake pads

or brake discs should be advised to the

customer as this will be subject to additional

labour and/or material cost and should not be

carried out without the authorisation of the

customer.

3.Check for any signs of brake fluid leakage from

caliper seals, hoses or unions.

4.Using brake cleaner, remove excessive

deposits of brake dust from pads, calipers and

disc shields.

Page 155 of 1007

MAINTENANCE

10-8 MAINTENANCE

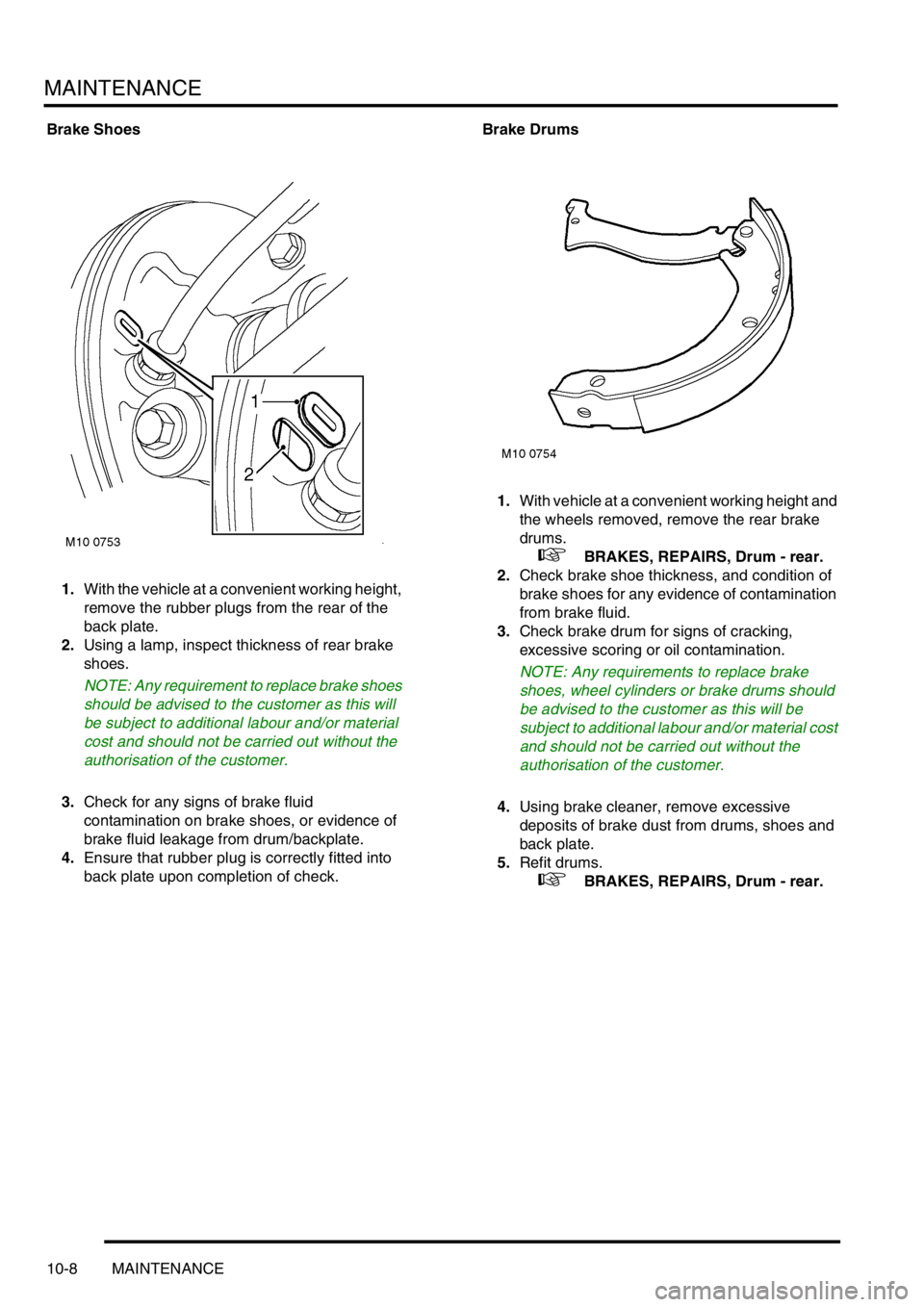

Brake Shoes

1.With the vehicle at a convenient working height,

remove the rubber plugs from the rear of the

back plate.

2.Using a lamp, inspect thickness of rear brake

shoes.

NOTE: Any requirement to replace brake shoes

should be advised to the customer as this will

be subject to additional labour and/or material

cost and should not be carried out without the

authorisation of the customer.

3.Check for any signs of brake fluid

contamination on brake shoes, or evidence of

brake fluid leakage from drum/backplate.

4.Ensure that rubber plug is correctly fitted into

back plate upon completion of check.Brake Drums

1.With vehicle at a convenient working height and

the wheels removed, remove the rear brake

drums.

+ BRAKES, REPAIRS, Drum - rear.

2.Check brake shoe thickness, and condition of

brake shoes for any evidence of contamination

from brake fluid.

3.Check brake drum for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirements to replace brake

shoes, wheel cylinders or brake drums should

be advised to the customer as this will be

subject to additional labour and/or material cost

and should not be carried out without the

authorisation of the customer.

4.Using brake cleaner, remove excessive

deposits of brake dust from drums, shoes and

back plate.

5.Refit drums.

+ BRAKES, REPAIRS, Drum - rear.

Page 156 of 1007

MAINTENANCE

MAINTENANCE 10-9

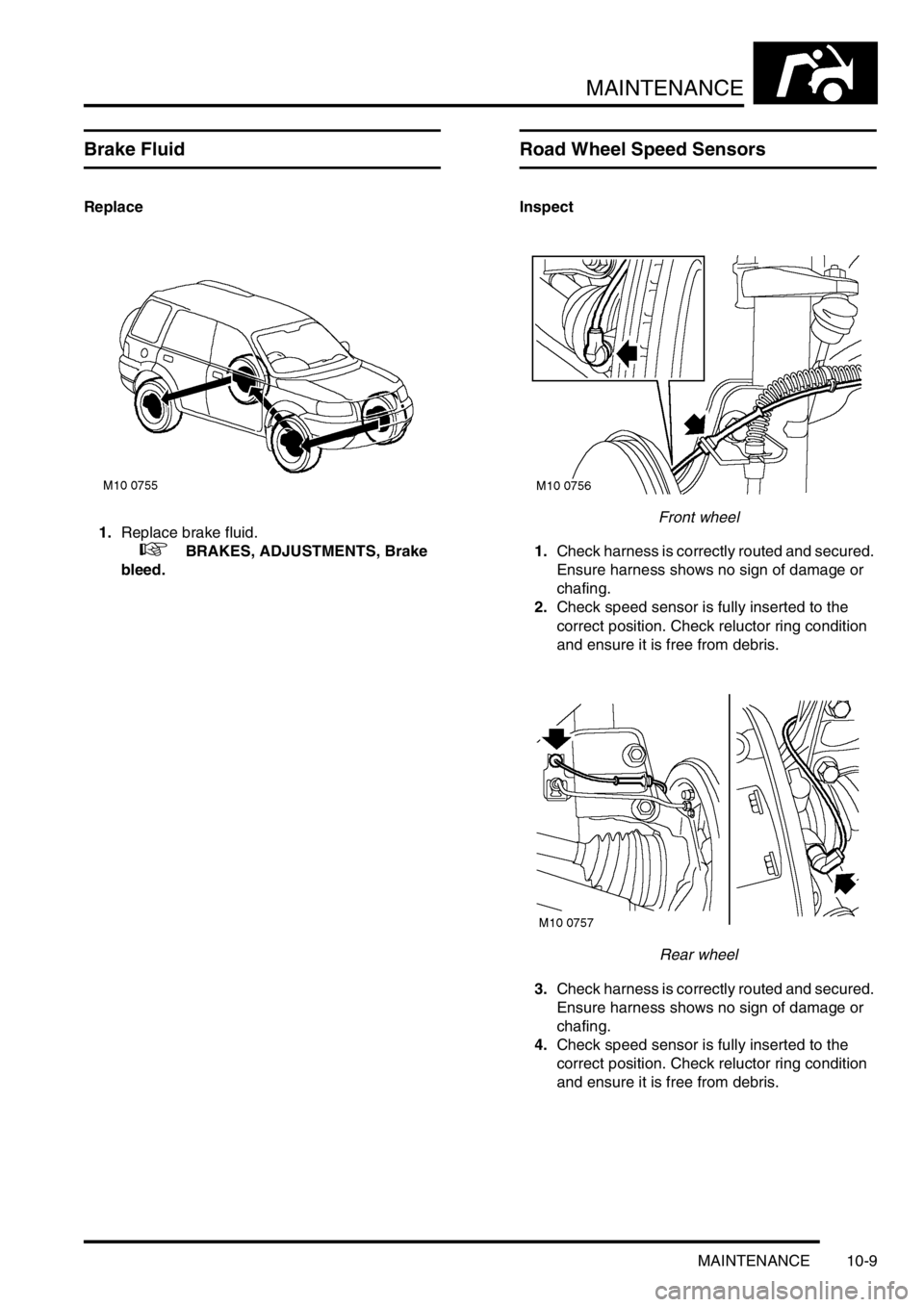

Brake Fluid

Replace

1.Replace brake fluid.

+ BRAKES, ADJUSTMENTS, Brake

bleed.

Road Wheel Speed Sensors

Inspect

Front wheel

1.Check harness is correctly routed and secured.

Ensure harness shows no sign of damage or

chafing.

2.Check speed sensor is fully inserted to the

correct position. Check reluctor ring condition

and ensure it is free from debris.

Rear wheel

3.Check harness is correctly routed and secured.

Ensure harness shows no sign of damage or

chafing.

4.Check speed sensor is fully inserted to the

correct position. Check reluctor ring condition

and ensure it is free from debris.

Page 163 of 1007

MAINTENANCE

10-16 MAINTENANCE

Camshaft Timing Belt – KV6

Check

1.Check camshaft drive belt and renew if

necessary.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

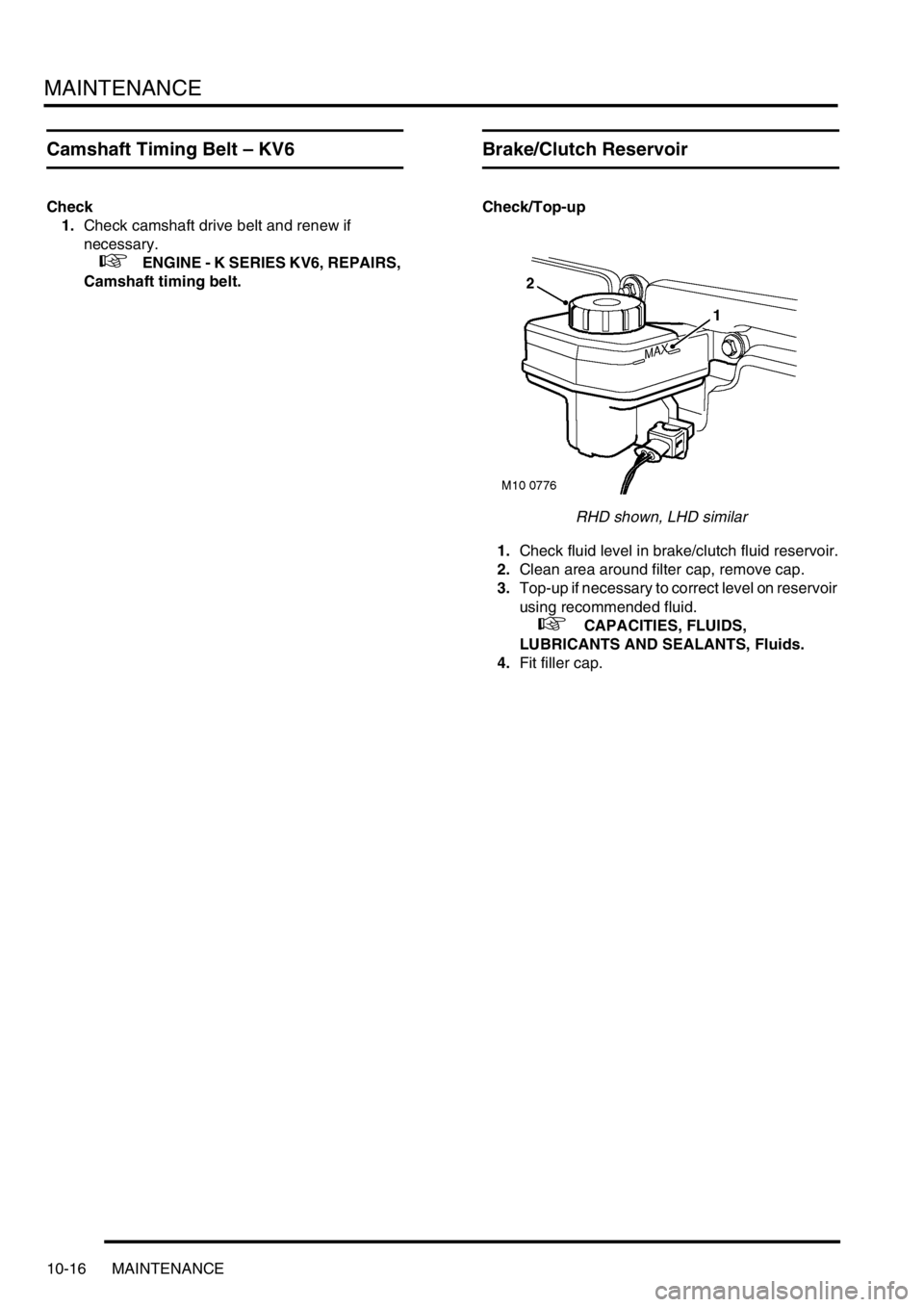

Brake/Clutch Reservoir

Check/Top-up

RHD shown, LHD similar

1.Check fluid level in brake/clutch fluid reservoir.

2.Clean area around filter cap, remove cap.

3.Top-up if necessary to correct level on reservoir

using recommended fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

4.Fit filler cap.

Page 166 of 1007

MAINTENANCE

MAINTENANCE 10-19

Manual Gearbox – GETRAG

Replace Fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.Replace gearbox fluid.

+ MANUAL GEARBOX - GETRAG,

ADJUSTMENTS, Gearbox oil - drain and

refill.

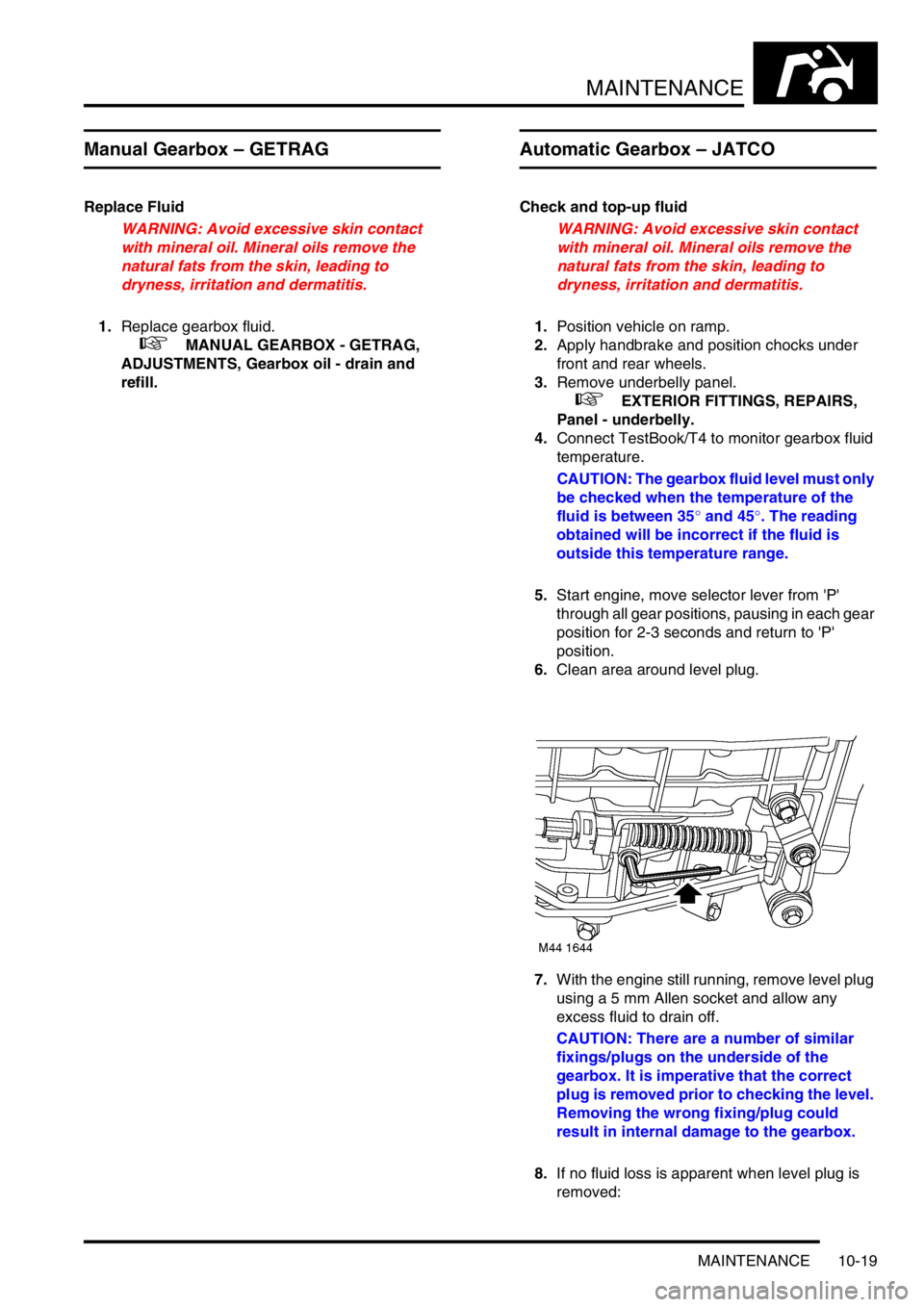

Automatic Gearbox – JATCO

Check and top-up fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.Position vehicle on ramp.

2.Apply handbrake and position chocks under

front and rear wheels.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Connect TestBook/T4 to monitor gearbox fluid

temperature.

CAUTION: The gearbox fluid level must only

be checked when the temperature of the

fluid is between 35° and 45°. The reading

obtained will be incorrect if the fluid is

outside this temperature range.

5.Start engine, move selector lever from 'P'

through all gear positions, pausing in each gear

position for 2-3 seconds and return to 'P'

position.

6.Clean area around level plug.

7.With the engine still running, remove level plug

using a 5 mm Allen socket and allow any

excess fluid to drain off.

CAUTION: There are a number of similar

fixings/plugs on the underside of the

gearbox. It is imperative that the correct

plug is removed prior to checking the level.

Removing the wrong fixing/plug could

result in internal damage to the gearbox.

8.If no fluid loss is apparent when level plug is

removed:

Page 173 of 1007

MAINTENANCE

10-26 MAINTENANCE

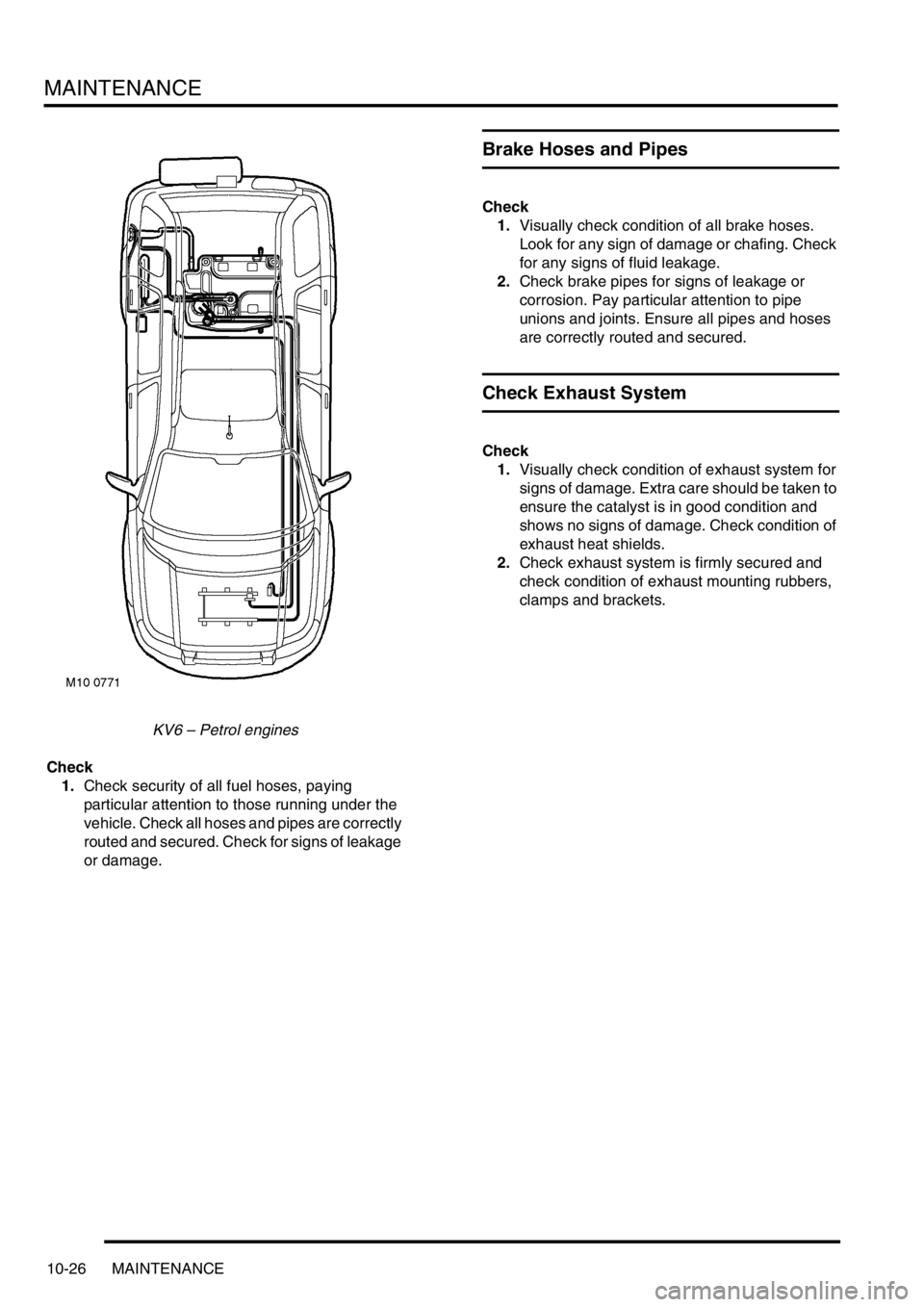

KV6 – Petrol engines

Check

1.Check security of all fuel hoses, paying

particular attention to those running under the

vehicle. Check all hoses and pipes are correctly

routed and secured. Check for signs of leakage

or damage.

Brake Hoses and Pipes

Check

1.Visually check condition of all brake hoses.

Look for any sign of damage or chafing. Check

for any signs of fluid leakage.

2.Check brake pipes for signs of leakage or

corrosion. Pay particular attention to pipe

unions and joints. Ensure all pipes and hoses

are correctly routed and secured.

Check Exhaust System

Check

1.Visually check condition of exhaust system for

signs of damage. Extra care should be taken to

ensure the catalyst is in good condition and

shows no signs of damage. Check condition of

exhaust heat shields.

2.Check exhaust system is firmly secured and

check condition of exhaust mounting rubbers,

clamps and brackets.

Page 176 of 1007

MAINTENANCE

MAINTENANCE 10-29

Gear Change and Parking Pawl Engagement –

(Automatic only, normal driving conditions)

1.Select 'R' and check for smooth take up.

2.Select 'D' and check for smooth up-changes of

ratio from rest.

3.Slow down vehicle and check for smooth down-

changes of ratio.

4.Stop vehicle on a slope.

5.Select 'P' and release handbrake.

6.Check that vehicle does not move and that

selector does not slip out of 'P'.

7.Carry out a similar check with vehicle facing in

the opposite direction.

Steering

1.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from the power steering

pump or drive belt.

Suspension

1.Check for noise, irregularity in ride (e.g.

dampers) and wheel imbalance.

Foot brake

1.Check for pedal effort, travel, braking

efficiency, pulling and binding.

Handbrake

1.Apply handbrake firmly, check travel and

ratchet hold and release.

Instruments

1.Check for correct operation of all instruments

and warning devices where practical.

Body

1.Check for abnormal body noise.

Seat Belts

1.Check for operation of inertia reels.Road Test

1.Drive vehicle on a short road test. Check all

vehicle systems for correct operation. Pay

particular attention to:

lEngine noise

lGearbox noise

lSuspension noise

lBody noise

lBraking system operation

lGear selection

lEngine performance

2.Where possible, check for correct operation of

Hill Descent Control (HDC) system. This should

not be carried out if excessive journey time is

required.

3.After road test, carry out a final inspection of the

vehicle on vehicle ramps.

4.Check all underbonnet fluid levels and top-up if

necessary.

Page 177 of 1007

MAINTENANCE

10-30 MAINTENANCE

Endorse Service Record

Check

1.Insert date and mileage of next service.

2.Insert current mileage.

3.Tick one of the boxes on the brake fluid

replacement indicator.

4.Tick one of the boxes on the camshaft drive belt

indicator.

5.Endorse service record with dealer stamp.

6.Sign and date the service record.

7.Sign and date the maintenance check sheet.

Report any Unusual Features

Check

1.Produce a written report detailing additional

work necessary, or items which may require

attention prior to the next service.

Page 206 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-29

33.With an assistant depressing the brake pedal,

remove and discard LH and RH drive shaft

nuts.

34.Remove rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

35.Remove exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

36.Raise one rear wheel for rotation of propeller

shaft to access bolts.

37.Reference mark position of viscous coupling

flange to IRD unit flange to aid reassembly.

38.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

39.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.40.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

41.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

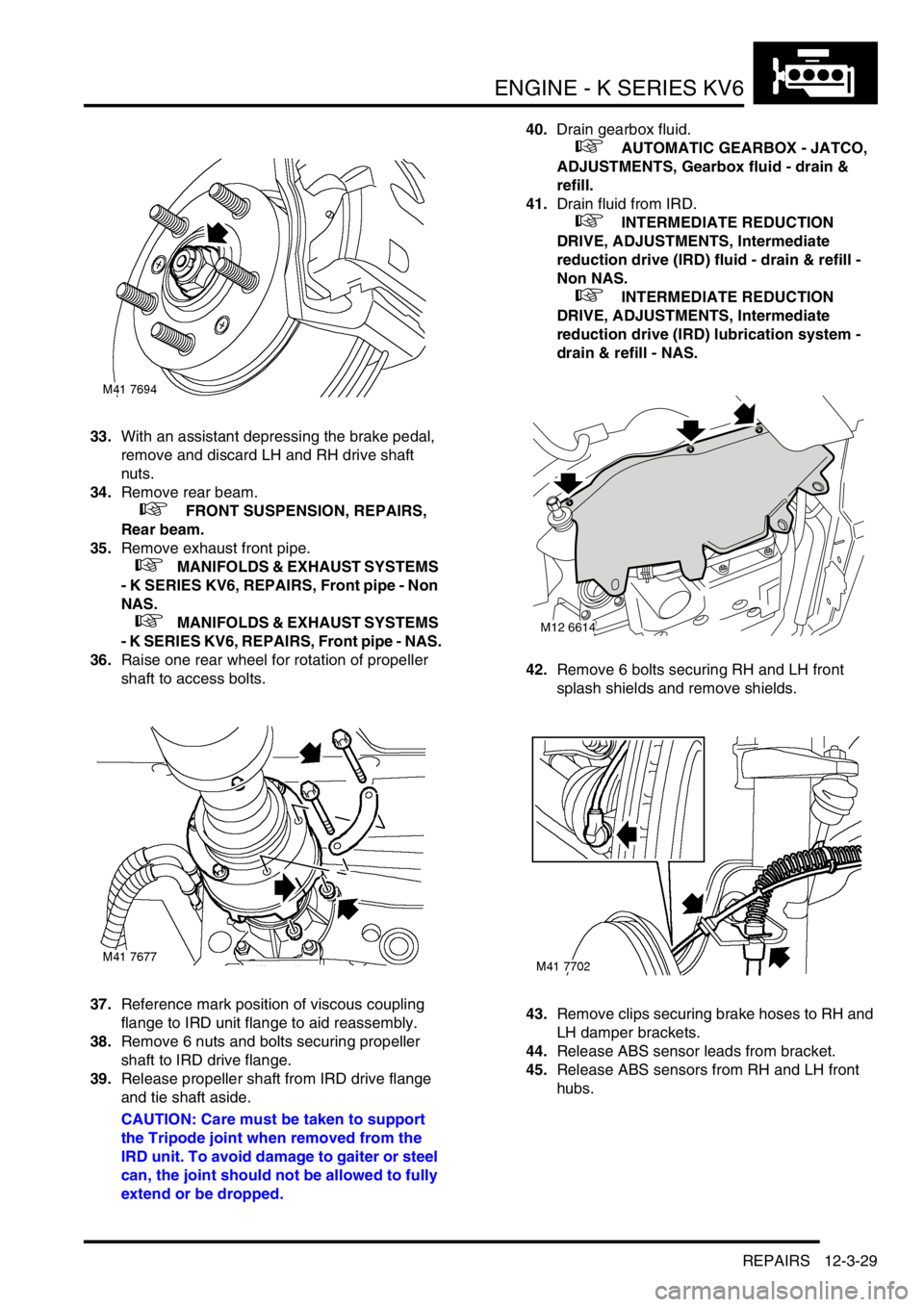

42.Remove 6 bolts securing RH and LH front

splash shields and remove shields.

43.Remove clips securing brake hoses to RH and

LH damper brackets.

44.Release ABS sensor leads from bracket.

45.Release ABS sensors from RH and LH front

hubs.

M12 6614