service LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 45 of 1007

GENERAL INFORMATION

03-14

Self-locking nuts

Self-locking nuts, i.e. nylon insert or deferred thread

nuts can be re-used providing resistance can be felt

when the locking portion of the nut passes over the

thread of the bolt or stud.

DO NOT apply heat in an attempt to free deferred

thread nuts or fittings; as well as causing damage to

protective coatings, there is a risk of damage to

electronic equipment and brake linings from stray

heat.

Where self-locking nuts have been removed, it is

advisable to replace them with new ones of the same

type.

Where bearing pre-load is involved, nuts should be

tightened in accordance with special instructions.

Flexible pipes and hoses

General

When removing and installing flexible hydraulic pipes

and hoses, ensure that the following practices are

observed to ensure component serviceability:

lBefore removing any brake or power steering

hose, clean end fittings and area surrounding

them as thoroughly as possible.

lObtain appropriate plugs or caps before

detaching hose end fittings, so that the ports

can be immediately covered to prevent the

ingress of dirt.

lClean hose externally and blow through with

airline. Examine carefully for cracks, separation

of plies, security of end fittings and external

damage. Reject any faulty hoses.

lWhen refitting a hose, ensure that no

unnecessary bends are introduced, and that

hose is not twisted before or during tightening of

union nuts.

lFit a cap to seal a hydraulic union and a plug to

its socket after removal to prevent ingress of

dirt.

lAbsolute cleanliness must be observed with

hydraulic components at all times.

lAfter any work on hydraulic systems, carefully

inspect for leaks underneath the vehicle while a

second operator applies maximum brake

pressure to the brakes (engine running) and

operates the steering.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

Page 47 of 1007

GENERAL INFORMATION

03-16

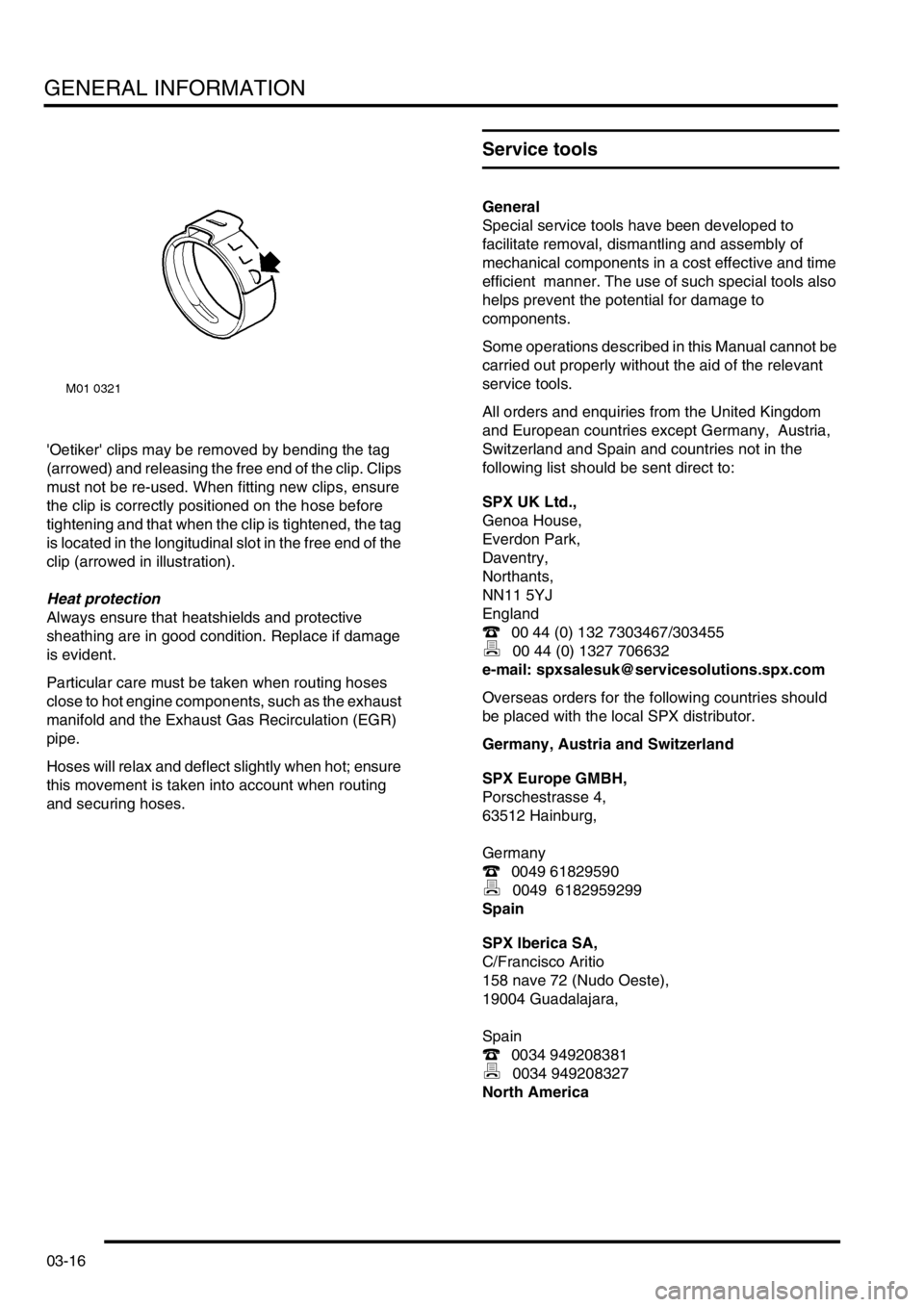

'Oetiker' clips may be removed by bending the tag

(arrowed) and releasing the free end of the clip. Clips

must not be re-used. When fitting new clips, ensure

the clip is correctly positioned on the hose before

tightening and that when the clip is tightened, the tag

is located in the longitudinal slot in the free end of the

clip (arrowed in illustration).

Heat protection

Always ensure that heatshields and protective

sheathing are in good condition. Replace if damage

is evident.

Particular care must be taken when routing hoses

close to hot engine components, such as the exhaust

manifold and the Exhaust Gas Recirculation (EGR)

pipe.

Hoses will relax and deflect slightly when hot; ensure

this movement is taken into account when routing

and securing hoses.

Service tools

General

Special service tools have been developed to

facilitate removal, dismantling and assembly of

mechanical components in a cost effective and time

efficient manner. The use of such special tools also

helps prevent the potential for damage to

components.

Some operations described in this Manual cannot be

carried out properly without the aid of the relevant

service tools.

All orders and enquiries from the United Kingdom

and European countries except Germany, Austria,

Switzerland and Spain and countries not in the

following list should be sent direct to:

SPX UK Ltd.,

Genoa House,

Everdon Park,

Daventry,

Northants,

NN11 5YJ

England

( 00 44 (0) 132 7303467/303455

) 00 44 (0) 1327 706632

e-mail: [email protected]

Overseas orders for the following countries should

be placed with the local SPX distributor.

Germany, Austria and Switzerland

SPX Europe GMBH,

Porschestrasse 4,

63512 Hainburg,

Germany

( 0049 61829590

) 0049 6182959299

Spain

SPX Iberica SA,

C/Francisco Aritio

158 nave 72 (Nudo Oeste),

19004 Guadalajara,

Spain

( 0034 949208381

) 0034 949208327

North America

Page 50 of 1007

GENERAL INFORMATION

03-19

Electrical precautions

General

The following guidelines are intended to ensure the

safety of the operator and ensure the prevention of

damage to the electrical and electronic components

fitted to the vehicle. Where necessary, specific

precautions are detailed in the individual procedures

of this manual.

Equipment

Prior to commencing any test procedure on the

vehicle, ensure that the relevant test equipment is

working correctly and any harness or connectors are

in good condition. It is particularly important to check

the condition of the lead and plugs of mains operated

equipment.

Polarity

Never reverse connect the vehicle battery and

always ensure the correct polarity when connecting

test equipment.

High Voltage Circuits

Whenever disconnecting live ht circuits, always use

insulated pliers and never allow the open end of the

ht lead to contact other components, particularly

ECU's.

Exercise caution when measuring the voltage on the

coil terminals while the engine is running, high

voltage spikes can occur on these terminals.

Connectors and harnesses

The engine compartment of a vehicle is a particularly

hostile environment for electrical components and

connectors:

lAlways ensure electrically related items are dry

and oil free before disconnecting and

connecting test equipment.

lEnsure disconnected multiplugs and sensors

are protected from being contaminated with oil,

coolant or other solutions. Contamination could

impair performance or result in catastrophic

failure.

lNever force connectors apart using tools to

prise apart or by pulling on the wiring harness.

lAlways ensure locking tabs are disengaged

before disconnection, and match orientation to

enable correct reconnection.

lEnsure that any protection (covers, insulation

etc.) is replaced if disturbed.Having confirmed a component to be faulty:

lSwitch off the ignition and disconnect the

battery.

lRemove the component and support the

disconnected harness.

lWhen replacing the component, keep oily hands

away from electrical connection areas and push

connectors home until any locking tabs fully

engage.

Battery disconnection

Before disconnecting the battery, disable the alarm

system and switch off all electrical equipment. If the

radio is to be serviced, ensure the security code has

been deactivated.

CAUTION: To prevent damage to electrical

components, always disconnect the battery

when working on the vehicle's electrical system.

The ground lead must be disconnected first and

reconnected last.

CAUTION: Always ensure that battery leads are

routed correctly and are not close to any

potential chafing points.

Battery charging

Only recharge the battery with it removed from the

vehicle. Always ensure any battery charging area is

well ventilated and that every precaution is taken to

avoid naked flames and sparks.

Ignition system safety precautions

The vehicle's ignition system produces high voltages

and the following precautions should be observed

before carrying out any work on the system:

WARNING: Before commencing work on an

ignition system, ensure all high tension

terminals, adapters and diagnostic equipment

are adequately insulated and shielded to prevent

accidental personal contacts and minimise the

risk of shock. Wearers of surgically implanted

pacemaker devices should not be in close

proximity of ignition circuits or diagnostic

equipment.

Page 51 of 1007

GENERAL INFORMATION

03-20

Disciplines

Switch off the ignition prior to making any connection

or disconnection in the system, to prevent electrical

surges caused by disconnecting 'live' connections

damaging electronic components.

Ensure hands and work surfaces are clean and free

of grease, swarf, etc. Grease collects dirt which can

cause electrical tracking (short-circuits) or high-

resistance contacts.

When handling printed circuit boards, treat with care

and hold by the edges only; note that some electronic

components are susceptible to body static.

Connectors should never be subjected to forced

removal or refit, especially inter-board connectors.

Damaged contacts can cause short-circuit and

open-circuit fault conditions.

Prior to commencing test, and periodically during a

test, touch a good vehicle body earth to discharge

static charge. Some electronic components are

vulnerable to the static electricity that may be

generated by the operator.

Grease for electrical connectors

Some under bonnet and under body connectors may

be protected against corrosion by the application of a

special grease during vehicle production. Should

connectors be disturbed in service, or repaired or

replaced, additional grease should be re-applied:

Part No. BAU 5811, available in 150 gm tubs.

NOTE: The use of greases other than BAU 5811

must be avoided as they can migrate into relays,

switches etc. contaminating the contacts and leading

to intermittent operation or failure.

Supplementary restraint system

precautions

General

The Supplementary Restraint System (SRS)

provides active protection for vehicle occupants in

the event of a serious collision. The system

components include airbags and pre-tensioner seat

belts which are automatically deployed when a

severe frontal crash condition is detected.

The SRS pyrotechnic components could be

potentially hazardous to the service engineer if not

handled correctly. The following guidelines are

intended to alert the service engineer to potential

sources of danger and emphasise the importance of

ensuring the integrity of SRS components fitted to

the vehicle.

In order to assure system integrity, it is essential that

the SRS system is regularly checked and maintained

so that it is ready for operation in the event of an

accident.

Where necessary, additional specific precautions are

detailed in the relevant sections of this Manual which

should be referred to prior to commencing repair

operations.

WARNING: Always follow the 'SRS Precautions'

and the correct procedures for working on SRS

components. Persons working on SRS systems

must be fully trained and have been issued with

copies of the Safety guidelines.

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: The airbag module contains sodium

azide which is poisonous and extremely

flammable. Contact with water, acid or heavy

metals may produce harmful or explosive

compounds. Do not dismantle, incinerate or

bring into contact with electricity, before the unit

has been deployed.

WARNING: Always replace a seat belt assembly

that has withstood the strain of a severe vehicle

impact, or if the webbing shows signs of fraying.

WARNING: Always disconnect the vehicle

battery before carrying out any electric welding

on a vehicle fitted with an SRS system.

CAUTION: Do not expose an airbag module or

seat belt pre-tensioner to heat exceeding 85º C

(185º F).

Page 52 of 1007

GENERAL INFORMATION

03-21

It should be noted that these precautions are not

restricted to operations performed when servicing

the SRS system, the same care should be exercised

when working on ancillary systems and components

located in the vicinity of SRS components; these

include but are not limited to:

lSteering system – steering wheel airbag,

rotary coupler.

lFront fascia – passenger front airbag (where

fitted); SRS DCU behind centre console, on

transmission tunnel under the HeVAC system.

lFront seats – seat belt pre-tensioners, integral

with seat belt buckle assembly.

lElectrical system – SRS harnesses, link leads

and connectors.

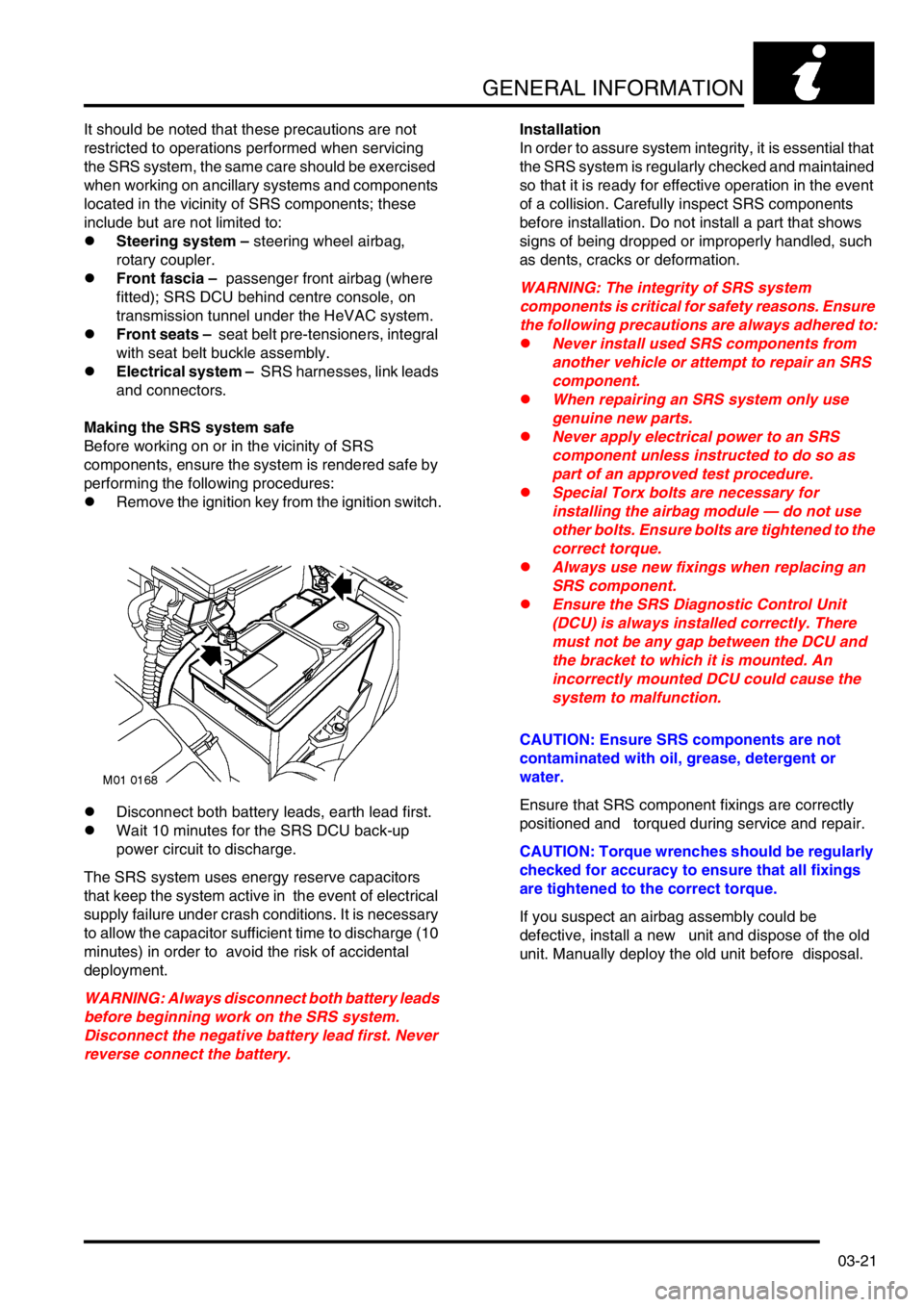

Making the SRS system safe

Before working on or in the vicinity of SRS

components, ensure the system is rendered safe by

performing the following procedures:

lRemove the ignition key from the ignition switch.

lDisconnect both battery leads, earth lead first.

lWait 10 minutes for the SRS DCU back-up

power circuit to discharge.

The SRS system uses energy reserve capacitors

that keep the system active in the event of electrical

supply failure under crash conditions. It is necessary

to allow the capacitor sufficient time to discharge (10

minutes) in order to avoid the risk of accidental

deployment.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.Installation

In order to assure system integrity, it is essential that

the SRS system is regularly checked and maintained

so that it is ready for effective operation in the event

of a collision. Carefully inspect SRS components

before installation. Do not install a part that shows

signs of being dropped or improperly handled, such

as dents, cracks or deformation.

WARNING: The integrity of SRS system

components is critical for safety reasons. Ensure

the following precautions are always adhered to:

lNever install used SRS components from

another vehicle or attempt to repair an SRS

component.

lWhen repairing an SRS system only use

genuine new parts.

lNever apply electrical power to an SRS

component unless instructed to do so as

part of an approved test procedure.

lSpecial Torx bolts are necessary for

installing the airbag module — do not use

other bolts. Ensure bolts are tightened to the

correct torque.

lAlways use new fixings when replacing an

SRS component.

lEnsure the SRS Diagnostic Control Unit

(DCU) is always installed correctly. There

must not be any gap between the DCU and

the bracket to which it is mounted. An

incorrectly mounted DCU could cause the

system to malfunction.

CAUTION: Ensure SRS components are not

contaminated with oil, grease, detergent or

water.

Ensure that SRS component fixings are correctly

positioned and torqued during service and repair.

CAUTION: Torque wrenches should be regularly

checked for accuracy to ensure that all fixings

are tightened to the correct torque.

If you suspect an airbag assembly could be

defective, install a new unit and dispose of the old

unit. Manually deploy the old unit before disposal.

Page 53 of 1007

GENERAL INFORMATION

03-22

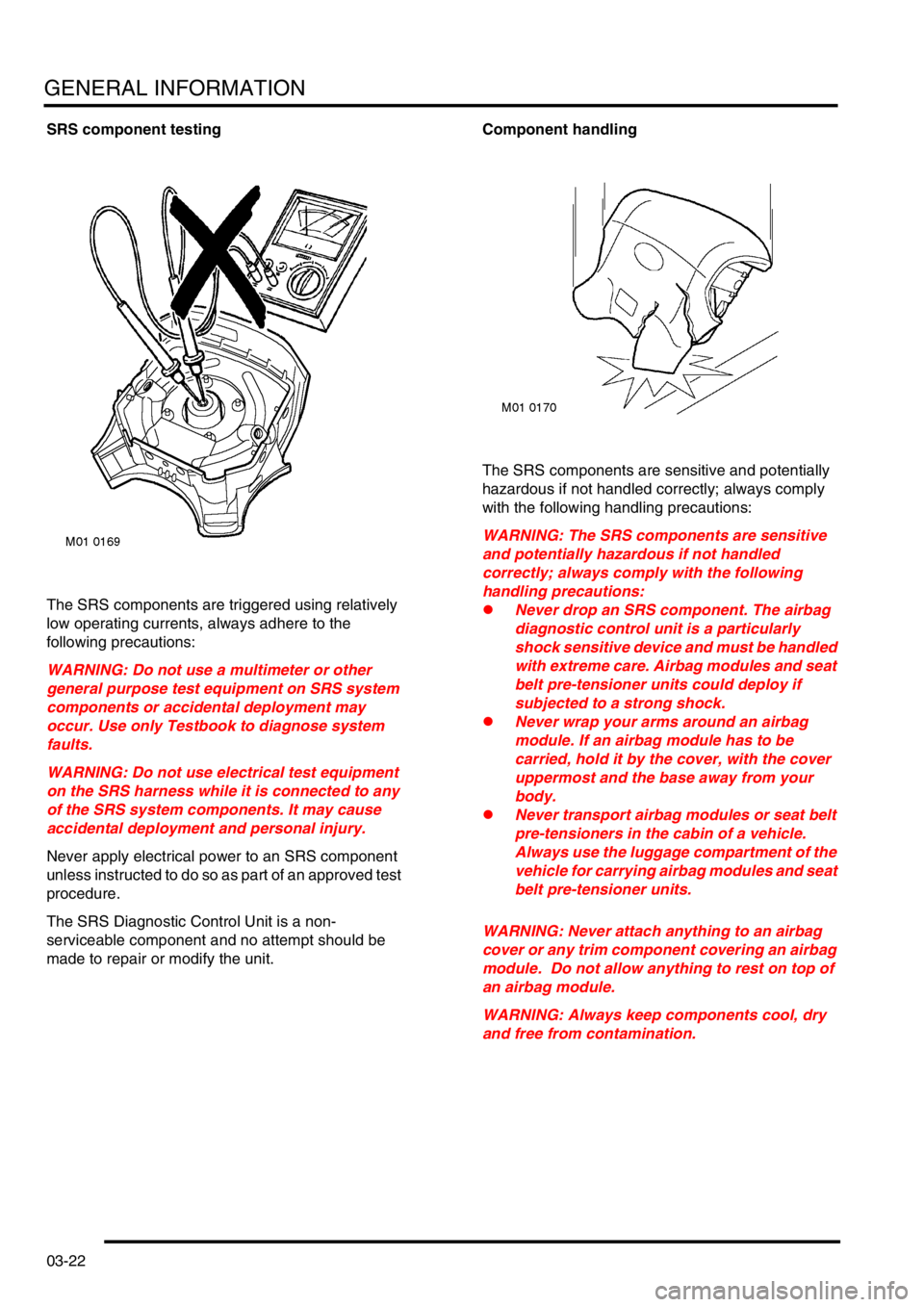

SRS component testing

The SRS components are triggered using relatively

low operating currents, always adhere to the

following precautions:

WARNING: Do not use a multimeter or other

general purpose test equipment on SRS system

components or accidental deployment may

occur. Use only Testbook to diagnose system

faults.

WARNING: Do not use electrical test equipment

on the SRS harness while it is connected to any

of the SRS system components. It may cause

accidental deployment and personal injury.

Never apply electrical power to an SRS component

unless instructed to do so as part of an approved test

procedure.

The SRS Diagnostic Control Unit is a non-

serviceable component and no attempt should be

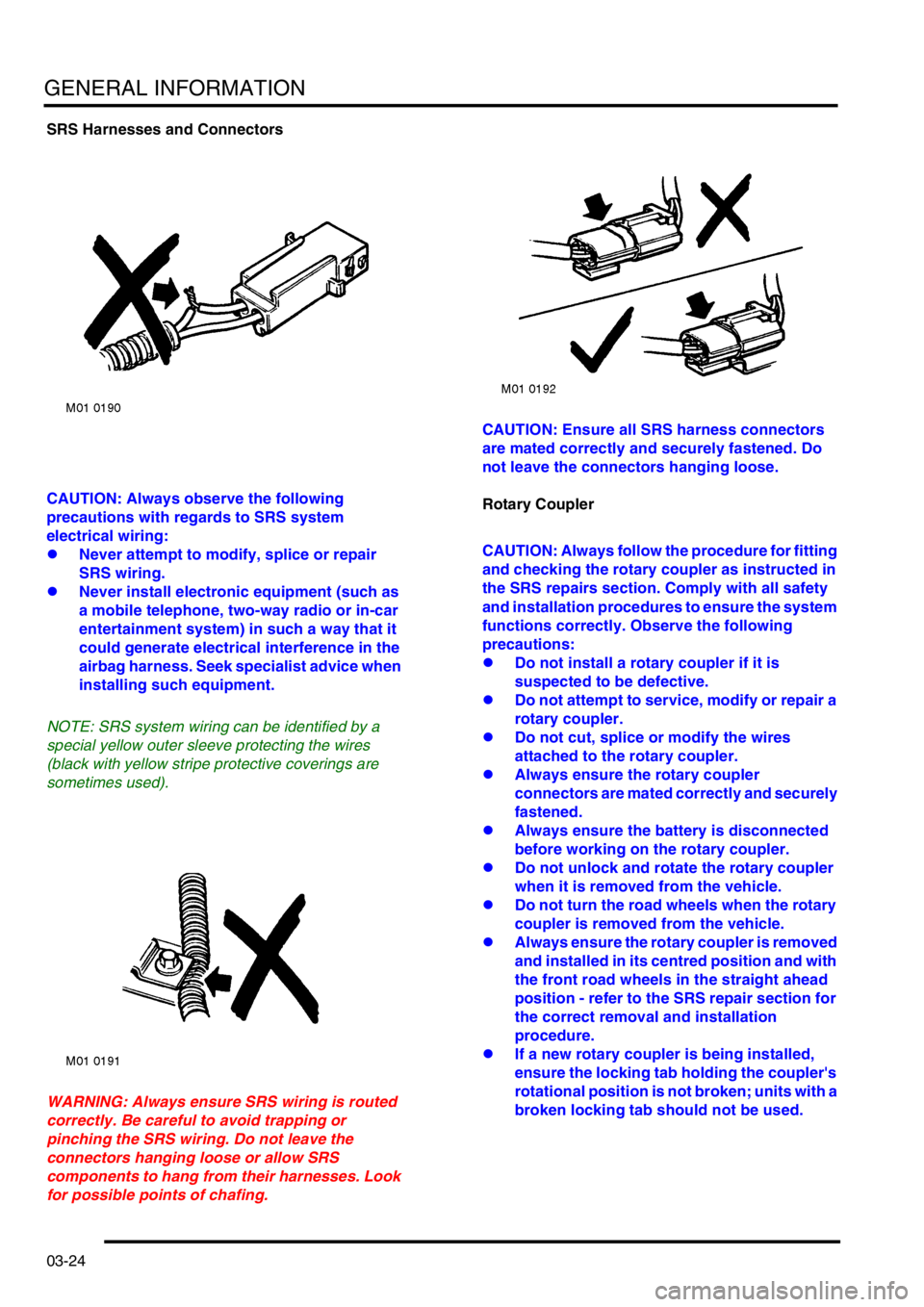

made to repair or modify the unit.Component handling

The SRS components are sensitive and potentially

hazardous if not handled correctly; always comply

with the following handling precautions:

WARNING: The SRS components are sensitive

and potentially hazardous if not handled

correctly; always comply with the following

handling precautions:

lNever drop an SRS component. The airbag

diagnostic control unit is a particularly

shock sensitive device and must be handled

with extreme care. Airbag modules and seat

belt pre-tensioner units could deploy if

subjected to a strong shock.

lNever wrap your arms around an airbag

module. If an airbag module has to be

carried, hold it by the cover, with the cover

uppermost and the base away from your

body.

lNever transport airbag modules or seat belt

pre-tensioners in the cabin of a vehicle.

Always use the luggage compartment of the

vehicle for carrying airbag modules and seat

belt pre-tensioner units.

WARNING: Never attach anything to an airbag

cover or any trim component covering an airbag

module. Do not allow anything to rest on top of

an airbag module.

WARNING: Always keep components cool, dry

and free from contamination.

Page 55 of 1007

GENERAL INFORMATION

03-24

SRS Harnesses and Connectors

CAUTION: Always observe the following

precautions with regards to SRS system

electrical wiring:

lNever attempt to modify, splice or repair

SRS wiring.

lNever install electronic equipment (such as

a mobile telephone, two-way radio or in-car

entertainment system) in such a way that it

could generate electrical interference in the

airbag harness. Seek specialist advice when

installing such equipment.

NOTE: SRS system wiring can be identified by a

special yellow outer sleeve protecting the wires

(black with yellow stripe protective coverings are

sometimes used).

WARNING: Always ensure SRS wiring is routed

correctly. Be careful to avoid trapping or

pinching the SRS wiring. Do not leave the

connectors hanging loose or allow SRS

components to hang from their harnesses. Look

for possible points of chafing.CAUTION: Ensure all SRS harness connectors

are mated correctly and securely fastened. Do

not leave the connectors hanging loose.

Rotary Coupler

CAUTION: Always follow the procedure for fitting

and checking the rotary coupler as instructed in

the SRS repairs section. Comply with all safety

and installation procedures to ensure the system

functions correctly. Observe the following

precautions:

lDo not install a rotary coupler if it is

suspected to be defective.

lDo not attempt to service, modify or repair a

rotary coupler.

lDo not cut, splice or modify the wires

attached to the rotary coupler.

lAlways ensure the rotary coupler

connectors are mated correctly and securely

fastened.

lAlways ensure the battery is disconnected

before working on the rotary coupler.

lDo not unlock and rotate the rotary coupler

when it is removed from the vehicle.

lDo not turn the road wheels when the rotary

coupler is removed from the vehicle.

lAlways ensure the rotary coupler is removed

and installed in its centred position and with

the front road wheels in the straight ahead

position - refer to the SRS repair section for

the correct removal and installation

procedure.

lIf a new rotary coupler is being installed,

ensure the locking tab holding the coupler's

rotational position is not broken; units with a

broken locking tab should not be used.

Page 60 of 1007

GENERAL INFORMATION

03-29

Air conditioning system precautions

General

The air conditioning system contains fluids and

components which could be potentially hazardous to

the service engineer or the environment if not

serviced and handled correctly. The following

guidelines are intended to alert the service engineer

to potential sources of danger and emphasise the

importance of ensuring the integrity of the Air

Conditioning operating conditions and components

fitted to the vehicle.

Where necessary, additional specific precautions are

detailed in the relevant sections of this Manual which

should be referred to prior to commencing repair

operations.

The refrigerant used in the air conditioning system is

HFC-134a (Hydrofluorocarbon) R134a. Always

adhere to the following precautions:

WARNING: Servicing must only be carried out by

personnel familiar with both the vehicle system

and the charging and testing equipment. All

operations must be carried out in a well

ventilated area away from open flame and heat

sources.

WARNING: Do not allow a refrigerant container to

be heated by direct flame or to be placed near

any heating appliance. A refrigerant container

must not be heated above 50

°C.

Do not leave a container of refrigerant without its

cap fitted. Do not transport a container of

refrigerant that is unrestrained, especially in the

boot of a car.

WARNING: Do not smoke or weld in areas where

R134a is in use. Inhalation of concentrations of

vapour can cause dizziness, disorientation,

incoordination, narcosis, nausea or vomiting.

R134a is odourless and colourless. Do not

handle or discharge in an enclosed area, or any

area where the vapour and liquid can come in

contact with a naked flame or hot metal. R134a is

not flammable but can cause a highly toxic gas.

WARNING: Do not allow fluids other than R134a

or compressor lubricant to enter the air

conditioning system. Spontaneous combustion

may occur.WARNING: R134a is a hazardous liquid and when

handled incorrectly can cause serious injury.

Suitable protective clothing, consisting of face

protection, heat proof gloves, rubber boots and

rubber apron or waterproof overalls, must be

worn when carrying out operations on the air

conditioning system.

WARNING: Due to its low evaporating

temperature, R134a must be handled with care.

R134a splashed on any part of the body will

cause immediate freezing of that area. Also,

refrigerant cylinders and replenishment trolleys

when discharging will freeze skin to them if

contact is made.

WARNING: Under no circumstances should

refrigerant hoses be disconnected without first

discharging the system.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

WARNING: Refrigerant must always be recycled

before re-use to ensure that the purity of the

refrigerant is high enough for safe use in the air

conditioning system.

Recycling should always be carried out with

equipment which is design certified by

Underwriter Laboratory Inc. for compliance with

SAE J1991. Other equipment may not recycle

refrigerant to the required level of purity.

A R134a Refrigerant Recovery Recycling

Recharging Station must not be used with any

other type of refrigerant.

Refrigerant R134a from domestic and

commercial sources must not be used in motor

vehicle air conditioning systems.

Page 61 of 1007

GENERAL INFORMATION

03-30

Remedial actions

If an accident involving R134a should occur, conduct

the following remedial actions:

lIf liquid R134a enters the eye, do not rub it.

Gently run large quantities of eye wash over

affected eye to raise the temperature. If an eye

wash is not available, cool clean water may be

used to flush the eye. After rinsing, cover the

eye with a clean pad and seek immediate

medical attention.

lIf liquid R134a is splashed onto the skin, run

large quantities of water over the affected area

to raise the temperature. Implement the same

action if the skin comes in contact with

discharging cylinders. Wrap the contaminated

body parts in blankets (or similar materials) and

seek immediate medical attention.

lIf the debilitating effects of inhalation of R134a

vapour is suspected, seek fresh air. If the

affected person is unconscious, move them

away from the contaminated area to fresh air

and apply artificial respiration and/or oxygen

and seek immediate medical attention.

Service precautions

Observe the following precautions when handling

components used in the air conditioning system:

lAir conditioning units must not be lifted by their

hoses, pipes or capillary lines.

lHoses and lines must not be subjected to any

twist or stress - the efficiency of the system will

be impaired by kinks or restrictions. Ensure that

hoses are correctly positioned before tightening

couplings, and ensure that all clips and supports

are utilised.

lFlexible hoses should not be positioned close to

the exhaust manifold (less than 100mm) unless

protected by heat shielding.

lCompleted assemblies must be checked for

refrigeration lines touching metal panels. Any

direct contact of components and panels may

transmit noise and so must be eliminated.

lThe appropriate torque wrench must be used

when tightening refrigerant connections to the

stipulated value. An additional spanner must be

used to hold the union to prevent twisting of the

pipe when tightening connections.

lBefore connecting any hose or pipe, ensure that

refrigerant oil is applied to the seat of the new

'O' ring seals, BUT NOT to the threads of the

connection.

lAll protective plugs must remain in place to seal

the component until immediately prior to

connection.

lEnsure components are at room temperature

before uncapping, to prevent condensation of

moisture from the air that enters it.

lComponents must not remain uncapped for

longer than 15 minutes. In the event of a delay,

the caps must be fitted.

lWhen disconnecting, immediately cap all air

conditioning pipes to prevent ingress of dirt and

moisture into the system.

lThe modulator (receiver/drier) contains

desiccant which absorbs moisture. It must be

positively sealed at all times. A modulator that

has been left uncapped must not be used, fit a

new unit.

lThe modulator should be the last component

connected to the system to ensure optimum

dehydration and maximum moisture protection

of the system.

lWhenever the refrigerant system is opened, the

modulator must be renewed immediately before

evacuating and recharging the system.

lUse alcohol and a clean lint-free cloth to clean

dirty connections.

lEnsure that all new parts fitted are marked for

use with R134a.

Page 70 of 1007

GENERAL DATA

04-7

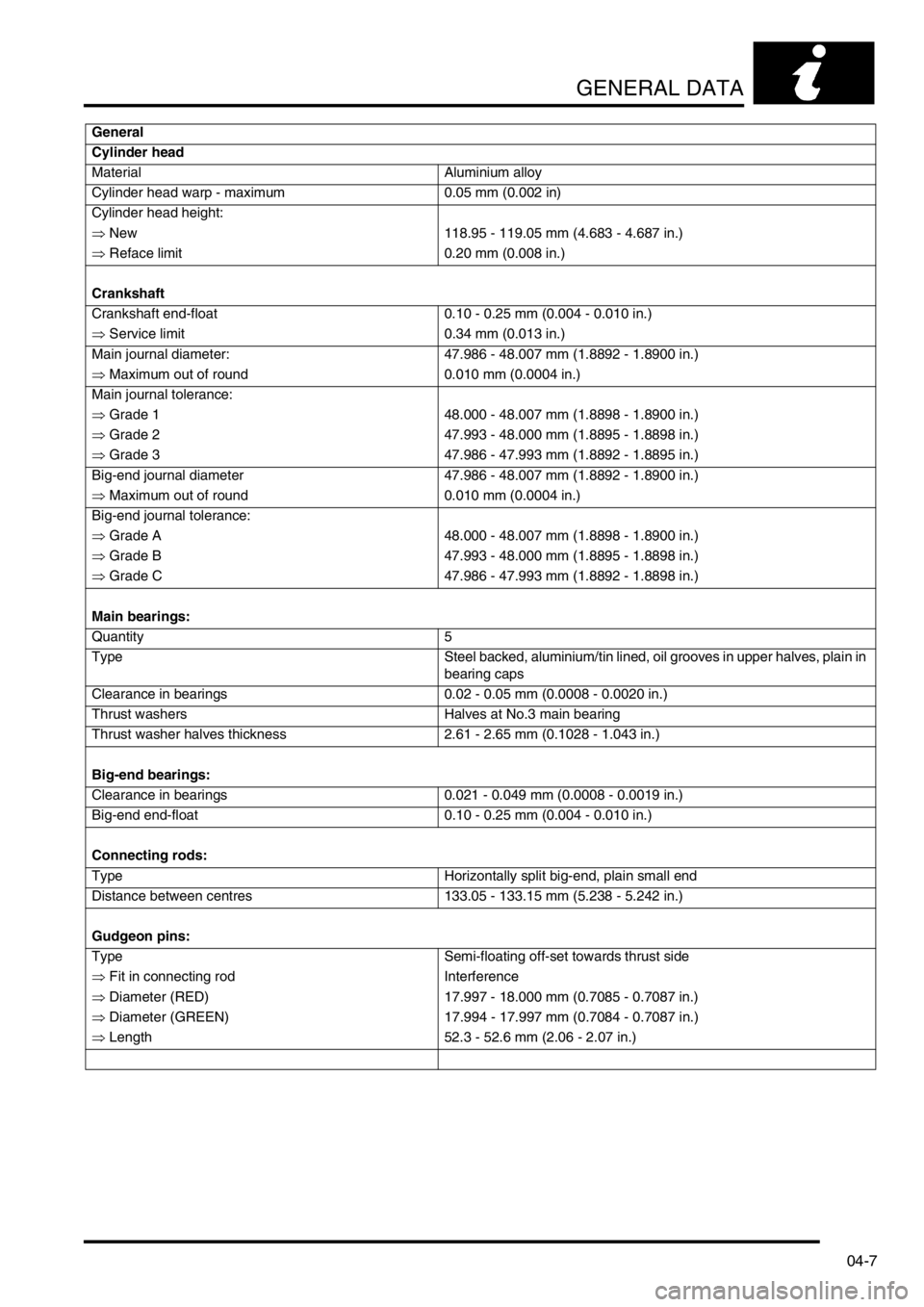

Cylinder head

Material Aluminium alloy

Cylinder head warp - maximum 0.05 mm (0.002 in)

Cylinder head height:

⇒ New 118.95 - 119.05 mm (4.683 - 4.687 in.)

⇒ Reface limit 0.20 mm (0.008 in.)

Crankshaft

Crankshaft end-float 0.10 - 0.25 mm (0.004 - 0.010 in.)

⇒ Service limit 0.34 mm (0.013 in.)

Main journal diameter: 47.986 - 48.007 mm (1.8892 - 1.8900 in.)

⇒ Maximum out of round 0.010 mm (0.0004 in.)

Main journal tolerance:

⇒ Grade 1 48.000 - 48.007 mm (1.8898 - 1.8900 in.)

⇒ Grade 2 47.993 - 48.000 mm (1.8895 - 1.8898 in.)

⇒ Grade 3 47.986 - 47.993 mm (1.8892 - 1.8895 in.)

Big-end journal diameter 47.986 - 48.007 mm (1.8892 - 1.8900 in.)

⇒ Maximum out of round 0.010 mm (0.0004 in.)

Big-end journal tolerance:

⇒ Grade A 48.000 - 48.007 mm (1.8898 - 1.8900 in.)

⇒ Grade B 47.993 - 48.000 mm (1.8895 - 1.8898 in.)

⇒ Grade C 47.986 - 47.993 mm (1.8892 - 1.8898 in.)

Main bearings:

Quantity 5

Type Steel backed, aluminium/tin lined, oil grooves in upper halves, plain in

bearing caps

Clearance in bearings 0.02 - 0.05 mm (0.0008 - 0.0020 in.)

Thrust washers Halves at No.3 main bearing

Thrust washer halves thickness 2.61 - 2.65 mm (0.1028 - 1.043 in.)

Big-end bearings:

Clearance in bearings 0.021 - 0.049 mm (0.0008 - 0.0019 in.)

Big-end end-float 0.10 - 0.25 mm (0.004 - 0.010 in.)

Connecting rods:

Type Horizontally split big-end, plain small end

Distance between centres 133.05 - 133.15 mm (5.238 - 5.242 in.)

Gudgeon pins:

Type Semi-floating off-set towards thrust side

⇒ Fit in connecting rod Interference

⇒ Diameter (RED) 17.997 - 18.000 mm (0.7085 - 0.7087 in.)

⇒ Diameter (GREEN) 17.994 - 17.997 mm (0.7084 - 0.7087 in.)

⇒ Length 52.3 - 52.6 mm (2.06 - 2.07 in.) General