wheel LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 48 of 1007

GENERAL INFORMATION

03-17

SPX Corporation,

665, Eisenhower Drive,

Owatonna,

MN 55060,

USA

( 0018 772979110

) 0018 005787375

Australia

SPX Australia,

28, Clayton Road,

Notting Hill,

Victoria 3168,

Australia

( 00 (61) 00395446222

) 00 (61) 0395445222

e-mail: [email protected]

Japan and East Asia

Jatek Ltd.,

5 - 53, Minawacho 2-chome,

Kohoku-ku,

Yokohama,

Kanagawa 223-0051,

Japan

( 0081 455627700

) 0081 455627800

Rolling road testing

General

IMPORTANT: Use a four wheel rolling road for

brake testing if possible.

The front and rear wheels cannot be driven

independently due to the viscous coupling. This

eliminates the need for differential lock by

progressively applying more torque to the rear

wheels if the front wheels start to slip.

DO NOT attempt to drive individual wheels with

vehicle supported on floor jacks or stands.

Four wheel rolling road

Provided that front and rear rollers are rotating at

identical speeds and that normal workshop safety

standards are applied, there is no speed restriction

during testing, except any that may apply to the tyres.

Before testing a vehicle with anti-lock brakes on a

four wheel rolling road, disconnect the ABS

modulator. The ABS function will not work, the ABS

warning light will illuminate. Normal braking will be

available.

Two wheel rolling road

ABS will not function on a two wheel rolling road. The

ABS light will illuminate during testing. Normal

braking will be available.

If brake testing on a two wheel rolling road is

necessary, the following precautions should be

taken:

lpropeller shaft to the rear axle is removed/

disconnected;

lneutral selected in gearbox;

lhill descent control not selected.

When checking brakes, run engine at idle speed to

maintain servo vacuum.

Page 52 of 1007

GENERAL INFORMATION

03-21

It should be noted that these precautions are not

restricted to operations performed when servicing

the SRS system, the same care should be exercised

when working on ancillary systems and components

located in the vicinity of SRS components; these

include but are not limited to:

lSteering system – steering wheel airbag,

rotary coupler.

lFront fascia – passenger front airbag (where

fitted); SRS DCU behind centre console, on

transmission tunnel under the HeVAC system.

lFront seats – seat belt pre-tensioners, integral

with seat belt buckle assembly.

lElectrical system – SRS harnesses, link leads

and connectors.

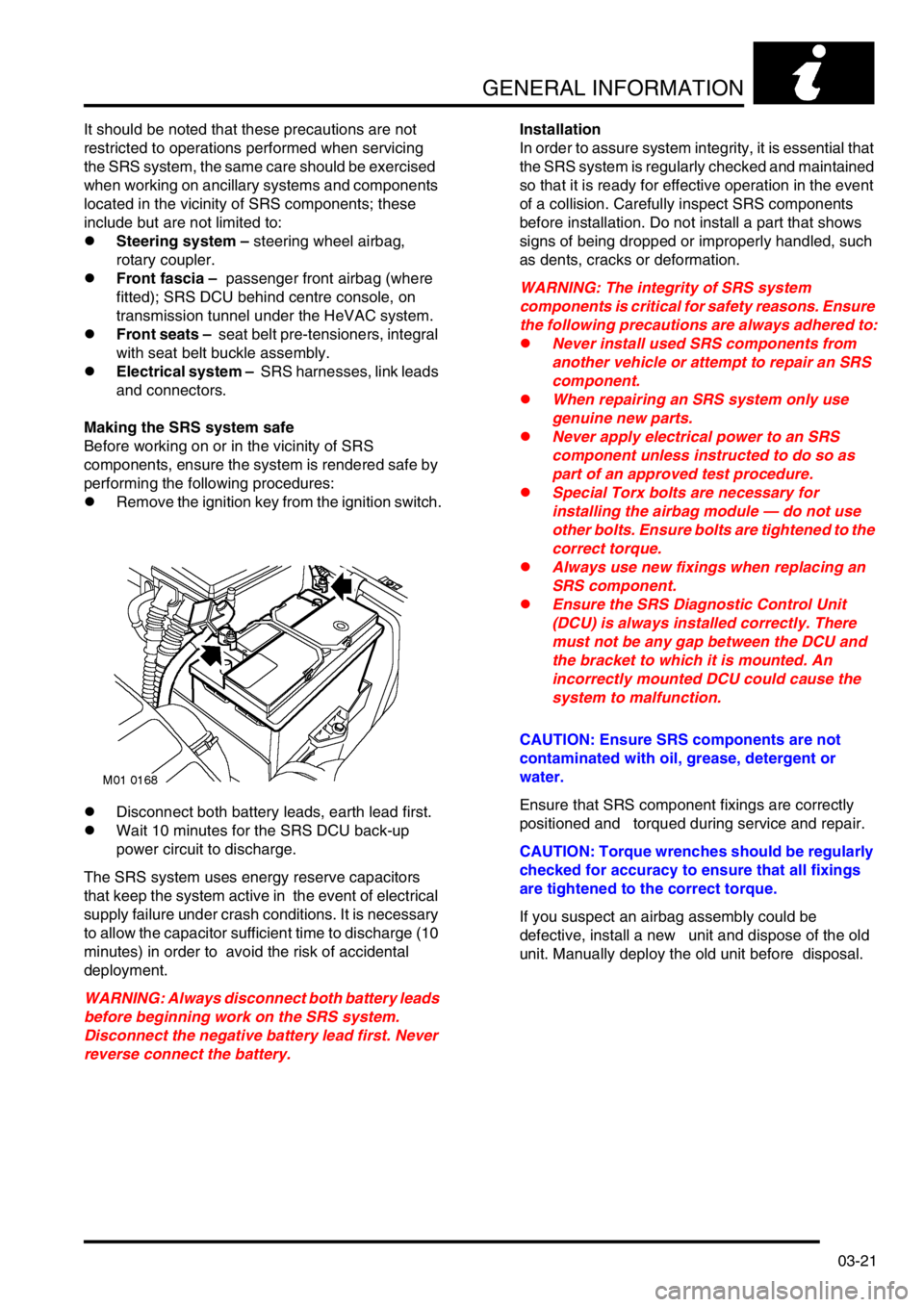

Making the SRS system safe

Before working on or in the vicinity of SRS

components, ensure the system is rendered safe by

performing the following procedures:

lRemove the ignition key from the ignition switch.

lDisconnect both battery leads, earth lead first.

lWait 10 minutes for the SRS DCU back-up

power circuit to discharge.

The SRS system uses energy reserve capacitors

that keep the system active in the event of electrical

supply failure under crash conditions. It is necessary

to allow the capacitor sufficient time to discharge (10

minutes) in order to avoid the risk of accidental

deployment.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.Installation

In order to assure system integrity, it is essential that

the SRS system is regularly checked and maintained

so that it is ready for effective operation in the event

of a collision. Carefully inspect SRS components

before installation. Do not install a part that shows

signs of being dropped or improperly handled, such

as dents, cracks or deformation.

WARNING: The integrity of SRS system

components is critical for safety reasons. Ensure

the following precautions are always adhered to:

lNever install used SRS components from

another vehicle or attempt to repair an SRS

component.

lWhen repairing an SRS system only use

genuine new parts.

lNever apply electrical power to an SRS

component unless instructed to do so as

part of an approved test procedure.

lSpecial Torx bolts are necessary for

installing the airbag module — do not use

other bolts. Ensure bolts are tightened to the

correct torque.

lAlways use new fixings when replacing an

SRS component.

lEnsure the SRS Diagnostic Control Unit

(DCU) is always installed correctly. There

must not be any gap between the DCU and

the bracket to which it is mounted. An

incorrectly mounted DCU could cause the

system to malfunction.

CAUTION: Ensure SRS components are not

contaminated with oil, grease, detergent or

water.

Ensure that SRS component fixings are correctly

positioned and torqued during service and repair.

CAUTION: Torque wrenches should be regularly

checked for accuracy to ensure that all fixings

are tightened to the correct torque.

If you suspect an airbag assembly could be

defective, install a new unit and dispose of the old

unit. Manually deploy the old unit before disposal.

Page 55 of 1007

GENERAL INFORMATION

03-24

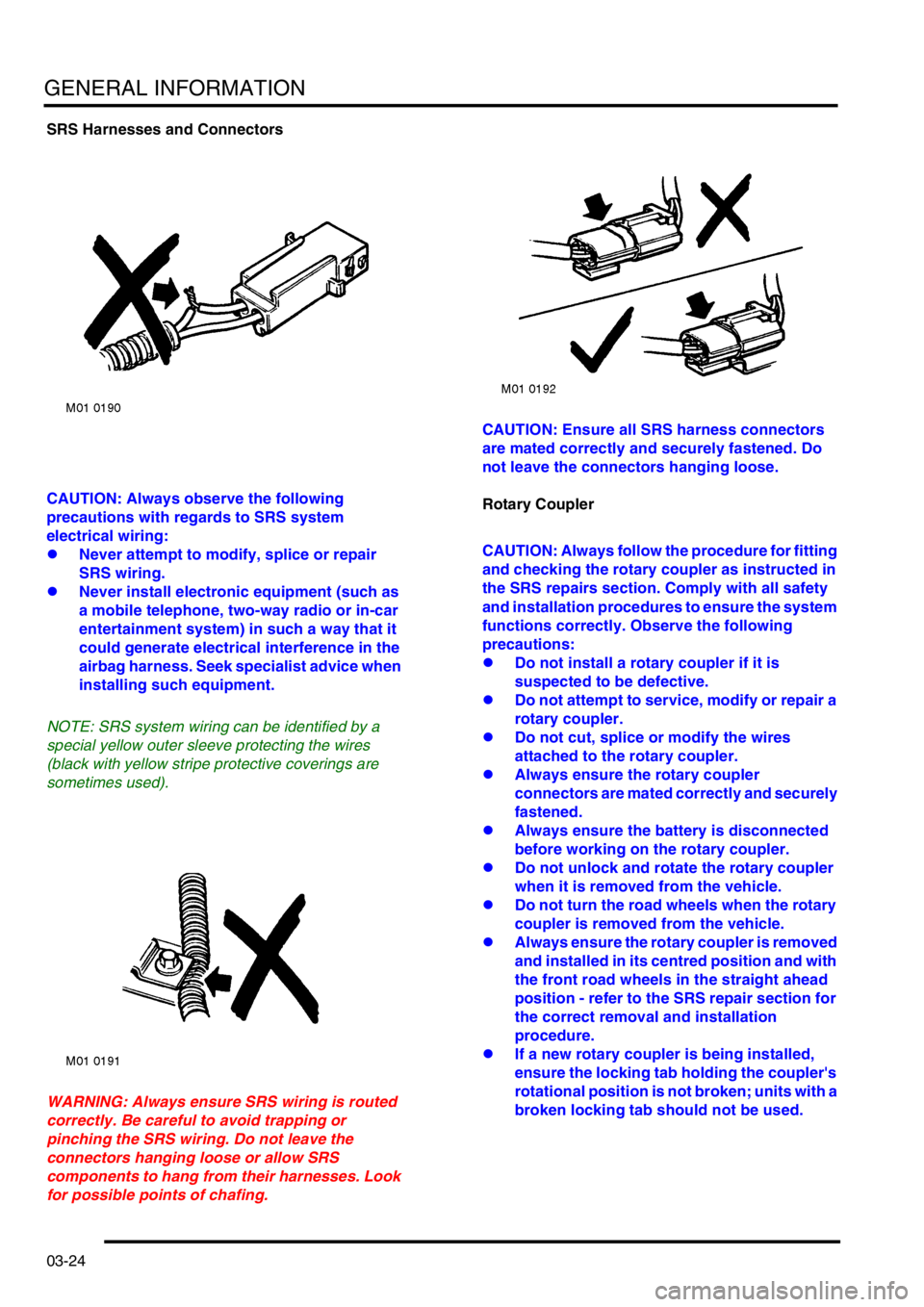

SRS Harnesses and Connectors

CAUTION: Always observe the following

precautions with regards to SRS system

electrical wiring:

lNever attempt to modify, splice or repair

SRS wiring.

lNever install electronic equipment (such as

a mobile telephone, two-way radio or in-car

entertainment system) in such a way that it

could generate electrical interference in the

airbag harness. Seek specialist advice when

installing such equipment.

NOTE: SRS system wiring can be identified by a

special yellow outer sleeve protecting the wires

(black with yellow stripe protective coverings are

sometimes used).

WARNING: Always ensure SRS wiring is routed

correctly. Be careful to avoid trapping or

pinching the SRS wiring. Do not leave the

connectors hanging loose or allow SRS

components to hang from their harnesses. Look

for possible points of chafing.CAUTION: Ensure all SRS harness connectors

are mated correctly and securely fastened. Do

not leave the connectors hanging loose.

Rotary Coupler

CAUTION: Always follow the procedure for fitting

and checking the rotary coupler as instructed in

the SRS repairs section. Comply with all safety

and installation procedures to ensure the system

functions correctly. Observe the following

precautions:

lDo not install a rotary coupler if it is

suspected to be defective.

lDo not attempt to service, modify or repair a

rotary coupler.

lDo not cut, splice or modify the wires

attached to the rotary coupler.

lAlways ensure the rotary coupler

connectors are mated correctly and securely

fastened.

lAlways ensure the battery is disconnected

before working on the rotary coupler.

lDo not unlock and rotate the rotary coupler

when it is removed from the vehicle.

lDo not turn the road wheels when the rotary

coupler is removed from the vehicle.

lAlways ensure the rotary coupler is removed

and installed in its centred position and with

the front road wheels in the straight ahead

position - refer to the SRS repair section for

the correct removal and installation

procedure.

lIf a new rotary coupler is being installed,

ensure the locking tab holding the coupler's

rotational position is not broken; units with a

broken locking tab should not be used.

Page 57 of 1007

GENERAL INFORMATION

03-26

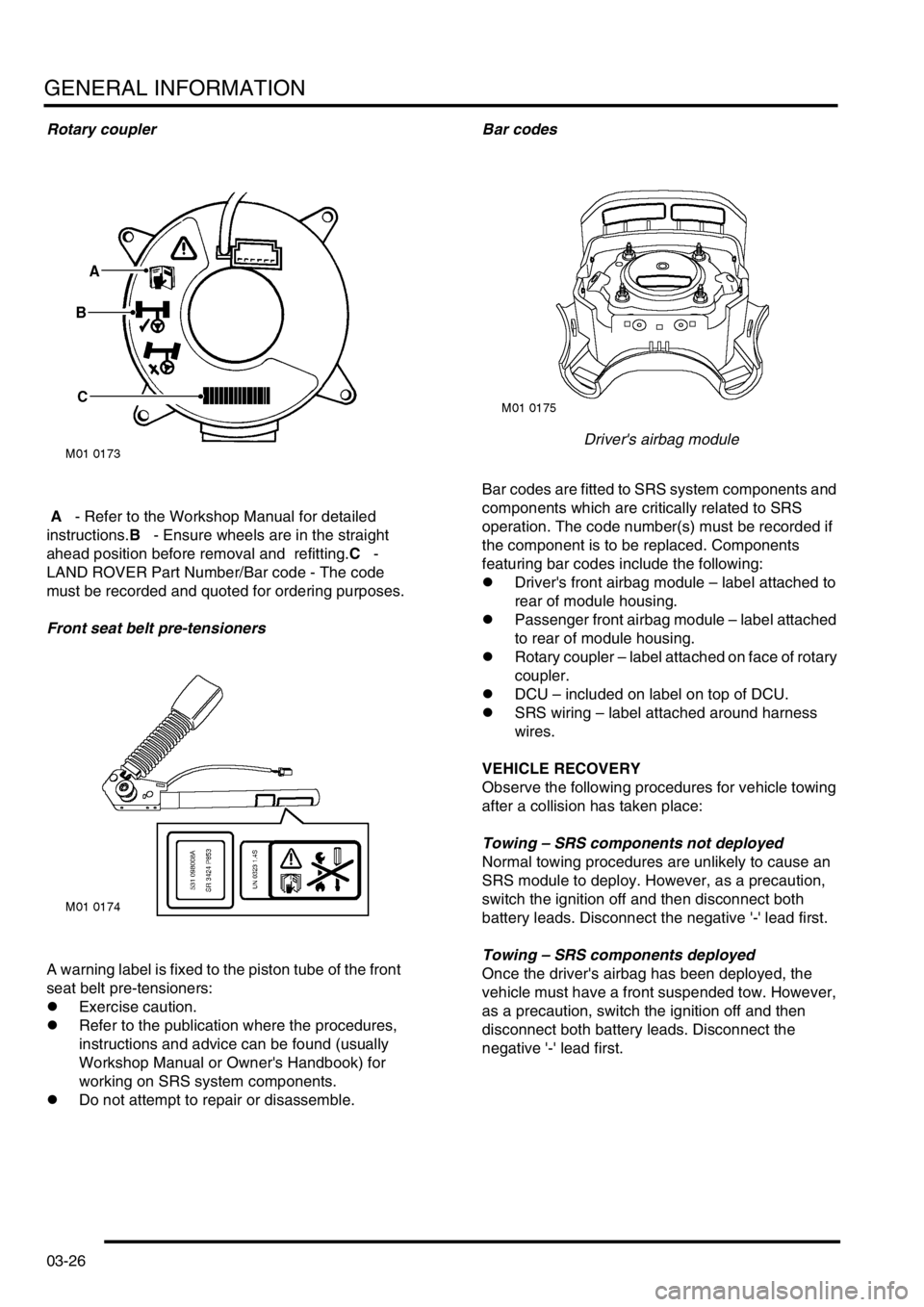

Rotary coupler

A - Refer to the Workshop Manual for detailed

instructions.B - Ensure wheels are in the straight

ahead position before removal and refitting.C -

LAND ROVER Part Number/Bar code - The code

must be recorded and quoted for ordering purposes.

Front seat belt pre-tensioners

A warning label is fixed to the piston tube of the front

seat belt pre-tensioners:

lExercise caution.

lRefer to the publication where the procedures,

instructions and advice can be found (usually

Workshop Manual or Owner's Handbook) for

working on SRS system components.

lDo not attempt to repair or disassemble.Bar codes

Driver's airbag module

Bar codes are fitted to SRS system components and

components which are critically related to SRS

operation. The code number(s) must be recorded if

the component is to be replaced. Components

featuring bar codes include the following:

lDriver's front airbag module – label attached to

rear of module housing.

lPassenger front airbag module – label attached

to rear of module housing.

lRotary coupler – label attached on face of rotary

coupler.

lDCU – included on label on top of DCU.

lSRS wiring – label attached around harness

wires.

VEHICLE RECOVERY

Observe the following procedures for vehicle towing

after a collision has taken place:

Towing – SRS components not deployed

Normal towing procedures are unlikely to cause an

SRS module to deploy. However, as a precaution,

switch the ignition off and then disconnect both

battery leads. Disconnect the negative '-' lead first.

Towing – SRS components deployed

Once the driver's airbag has been deployed, the

vehicle must have a front suspended tow. However,

as a precaution, switch the ignition off and then

disconnect both battery leads. Disconnect the

negative '-' lead first.

Page 59 of 1007

GENERAL INFORMATION

03-28

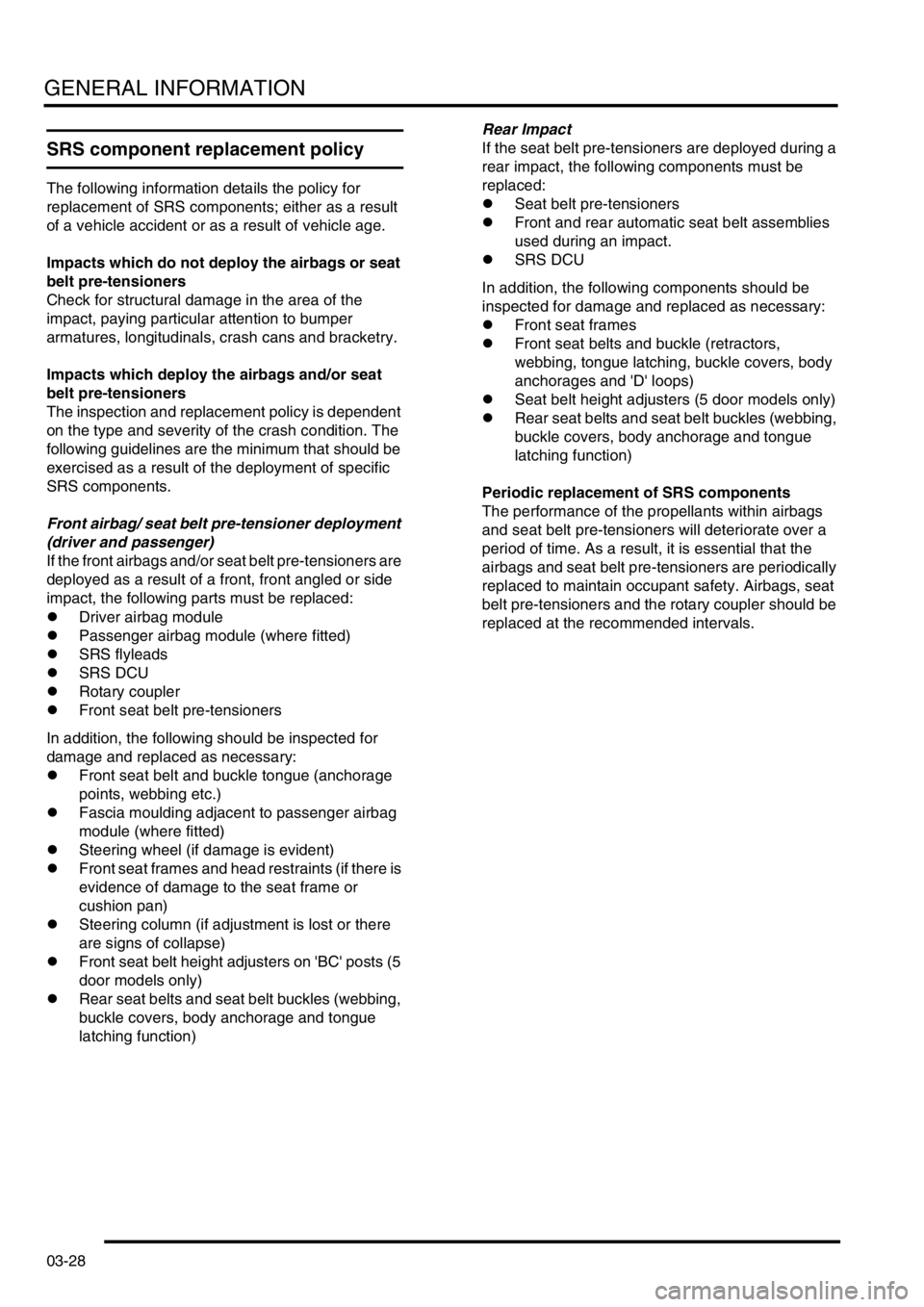

SRS component replacement policy

The following information details the policy for

replacement of SRS components; either as a result

of a vehicle accident or as a result of vehicle age.

Impacts which do not deploy the airbags or seat

belt pre-tensioners

Check for structural damage in the area of the

impact, paying particular attention to bumper

armatures, longitudinals, crash cans and bracketry.

Impacts which deploy the airbags and/or seat

belt pre-tensioners

The inspection and replacement policy is dependent

on the type and severity of the crash condition. The

following guidelines are the minimum that should be

exercised as a result of the deployment of specific

SRS components.

Front airbag/ seat belt pre-tensioner deployment

(driver and passenger)

If the front airbags and/or seat belt pre-tensioners are

deployed as a result of a front, front angled or side

impact, the following parts must be replaced:

lDriver airbag module

lPassenger airbag module (where fitted)

lSRS flyleads

lSRS DCU

lRotary coupler

lFront seat belt pre-tensioners

In addition, the following should be inspected for

damage and replaced as necessary:

lFront seat belt and buckle tongue (anchorage

points, webbing etc.)

lFascia moulding adjacent to passenger airbag

module (where fitted)

lSteering wheel (if damage is evident)

lFront seat frames and head restraints (if there is

evidence of damage to the seat frame or

cushion pan)

lSteering column (if adjustment is lost or there

are signs of collapse)

lFront seat belt height adjusters on 'BC' posts (5

door models only)

lRear seat belts and seat belt buckles (webbing,

buckle covers, body anchorage and tongue

latching function)Rear Impact

If the seat belt pre-tensioners are deployed during a

rear impact, the following components must be

replaced:

lSeat belt pre-tensioners

lFront and rear automatic seat belt assemblies

used during an impact.

lSRS DCU

In addition, the following components should be

inspected for damage and replaced as necessary:

lFront seat frames

lFront seat belts and buckle (retractors,

webbing, tongue latching, buckle covers, body

anchorages and 'D' loops)

lSeat belt height adjusters (5 door models only)

lRear seat belts and seat belt buckles (webbing,

buckle covers, body anchorage and tongue

latching function)

Periodic replacement of SRS components

The performance of the propellants within airbags

and seat belt pre-tensioners will deteriorate over a

period of time. As a result, it is essential that the

airbags and seat belt pre-tensioners are periodically

replaced to maintain occupant safety. Airbags, seat

belt pre-tensioners and the rotary coupler should be

replaced at the recommended intervals.

Page 73 of 1007

GENERAL DATA

04-10

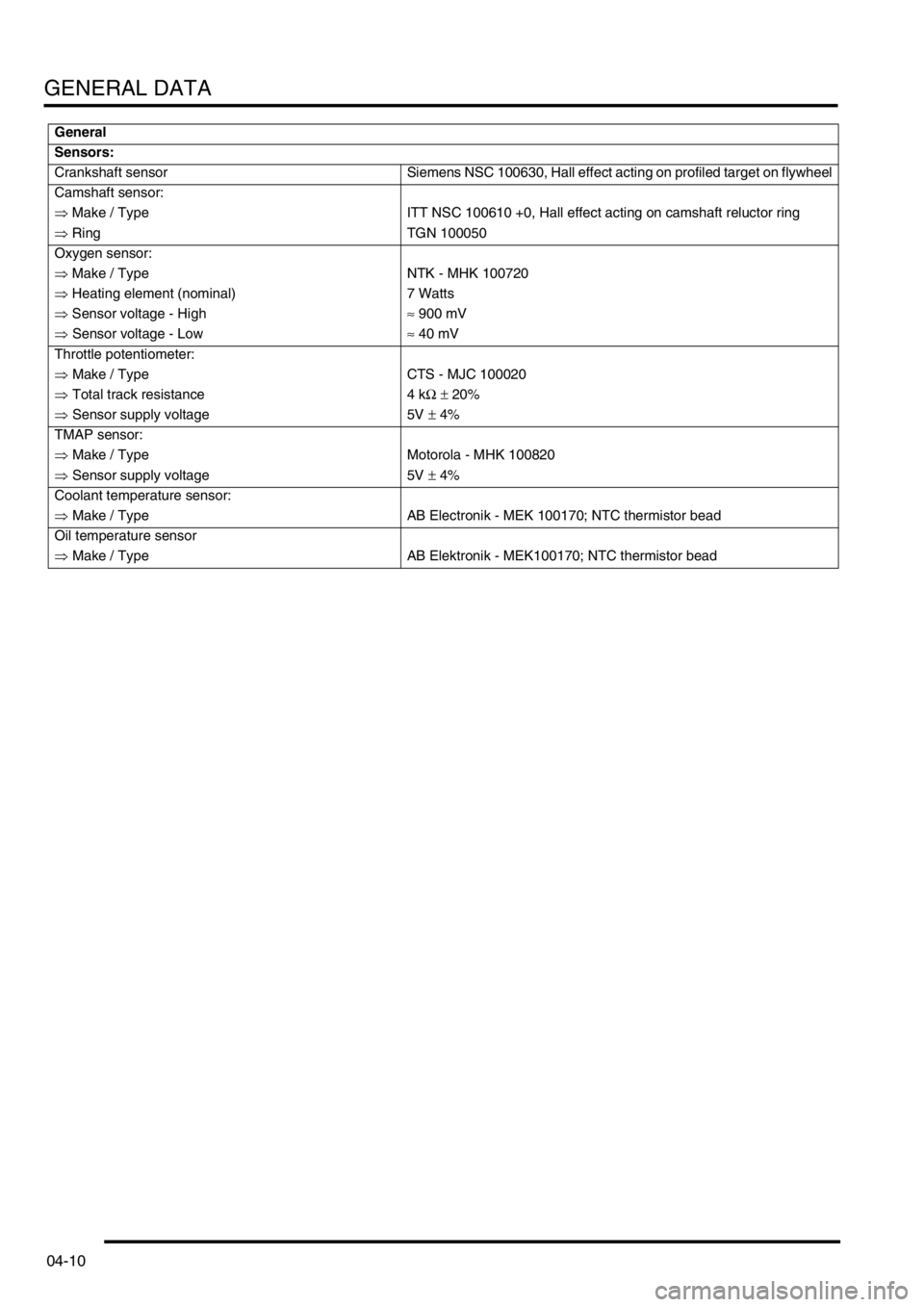

Sensors:

Crankshaft sensor Siemens NSC 100630, Hall effect acting on profiled target on flywheel

Camshaft sensor:

⇒ Make / Type ITT NSC 100610 +0, Hall effect acting on camshaft reluctor ring

⇒ Ring TGN 100050

Oxygen sensor:

⇒ Make / Type NTK - MHK 100720

⇒ Heating element (nominal) 7 Watts

⇒ Sensor voltage - High≈ 900 mV

⇒ Sensor voltage - Low≈ 40 mV

Throttle potentiometer:

⇒ Make / Type CTS - MJC 100020

⇒ Total track resistance 4 kΩ ± 20%

⇒ Sensor supply voltage 5V ± 4%

TMAP sensor:

⇒ Make / Type Motorola - MHK 100820

⇒ Sensor supply voltage 5V ± 4%

Coolant temperature sensor:

⇒ Make / Type AB Electronik - MEK 100170; NTC thermistor bead

Oil temperature sensor

⇒ Make / Type AB Elektronik - MEK100170; NTC thermistor bead General

Page 79 of 1007

GENERAL DATA

04-16

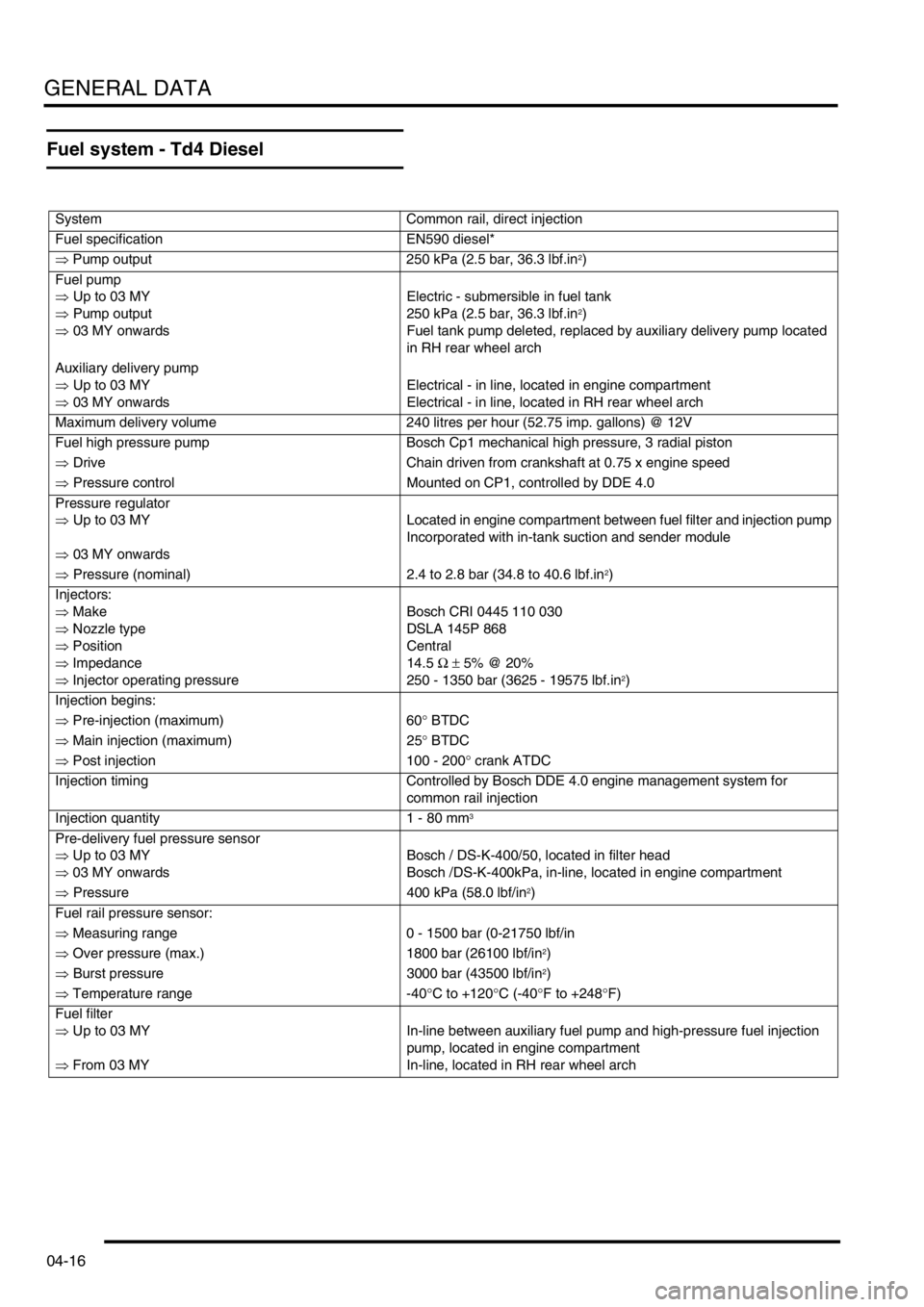

Fuel system - Td4 Diesel

System Common rail, direct injection

Fuel specification EN590 diesel*

⇒ Pump output 250 kPa (2.5 bar, 36.3 lbf.in

2)

Fuel pump

⇒ Up to 03 MY

⇒ Pump output

⇒ 03 MY onwardsElectric - submersible in fuel tank

250 kPa (2.5 bar, 36.3 lbf.in

2)

Fuel tank pump deleted, replaced by auxiliary delivery pump located

in RH rear wheel arch

Auxiliary delivery pump

⇒ Up to 03 MY

⇒ 03 MY onwardsElectrical - in line, located in engine compartment

Electrical - in line, located in RH rear wheel arch

Maximum delivery volume 240 litres per hour (52.75 imp. gallons) @ 12V

Fuel high pressure pump Bosch Cp1 mechanical high pressure, 3 radial piston

⇒ Drive Chain driven from crankshaft at 0.75 x engine speed

⇒ Pressure control Mounted on CP1, controlled by DDE 4.0

Pressure regulator

⇒ Up to 03 MY

⇒ 03 MY onwardsLocated in engine compartment between fuel filter and injection pump

Incorporated with in-tank suction and sender module

⇒ Pressure (nominal) 2.4 to 2.8 bar (34.8 to 40.6 lbf.in

2)

Injectors:

⇒ Make

⇒ Nozzle type

⇒ Position

⇒ Impedance

⇒ Injector operating pressureBosch CRI 0445 110 030

DSLA 145P 868

Central

14.5 Ω ± 5% @ 20%

250 - 1350 bar (3625 - 19575 lbf.in

2)

Injection begins:

⇒ Pre-injection (maximum) 60° BTDC

⇒ Main injection (maximum) 25° BTDC

⇒ Post injection 100 - 200° crank ATDC

Injection timing Controlled by Bosch DDE 4.0 engine management system for

common rail injection

Injection quantity 1 - 80 mm

3

Pre-delivery fuel pressure sensor

⇒ Up to 03 MY

⇒ 03 MY onwardsBosch / DS-K-400/50, located in filter head

Bosch /DS-K-400kPa, in-line, located in engine compartment

⇒ Pressure 400 kPa (58.0 lbf/in

2)

Fuel rail pressure sensor:

⇒ Measuring range 0 - 1500 bar (0-21750 lbf/in

⇒ Over pressure (max.) 1800 bar (26100 lbf/in

2)

⇒ Burst pressure 3000 bar (43500 lbf/in

2)

⇒ Temperature range -40°C to +120°C (-40°F to +248°F)

Fuel filter

⇒ Up to 03 MY

⇒ From 03 MYIn-line between auxiliary fuel pump and high-pressure fuel injection

pump, located in engine compartment

In-line, located in RH rear wheel arch

Page 90 of 1007

GENERAL DATA

04-27

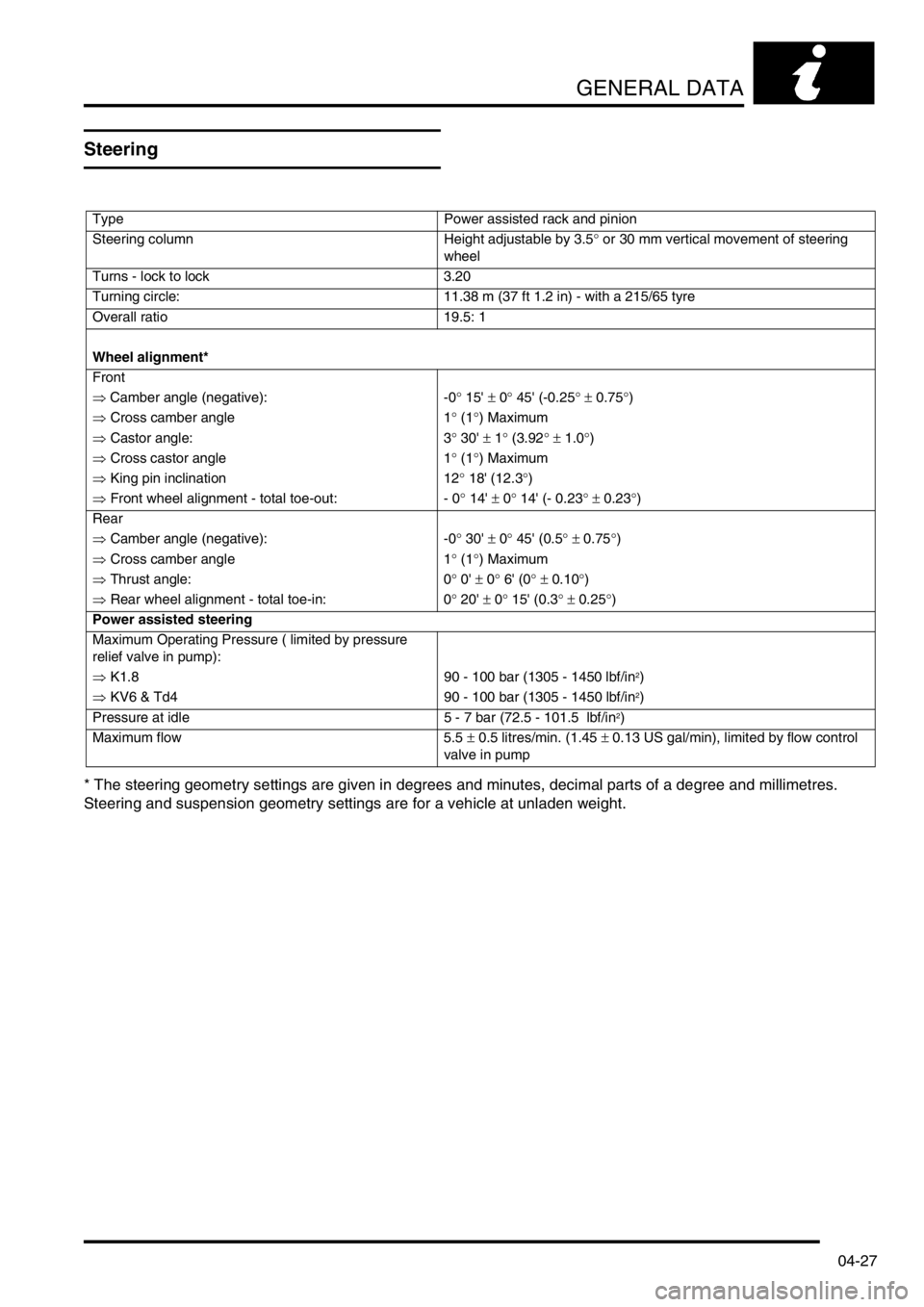

Steering

* The steering geometry settings are given in degrees and minutes, decimal parts of a degree and millimetres.

Steering and suspension geometry settings are for a vehicle at unladen weight.

Type Power assisted rack and pinion

Steering column Height adjustable by 3.5° or 30 mm vertical movement of steering

wheel

Turns - lock to lock 3.20

Turning circle: 11.38 m (37 ft 1.2 in) - with a 215/65 tyre

Overall ratio 19.5: 1

Wheel alignment*

Front

⇒ Camber angle (negative): -0° 15' ± 0° 45' (-0.25° ± 0.75°)

⇒ Cross camber angle 1° (1°) Maximum

⇒ Castor angle: 3° 30' ± 1° (3.92° ± 1.0°)

⇒ Cross castor angle 1° (1°) Maximum

⇒ King pin inclination 12° 18' (12.3°)

⇒ Front wheel alignment - total toe-out: - 0° 14' ± 0° 14' (- 0.23° ± 0.23°)

Rear

⇒ Camber angle (negative): -0° 30' ± 0° 45' (0.5° ± 0.75°)

⇒ Cross camber angle 1° (1°) Maximum

⇒ Thrust angle: 0° 0' ± 0° 6' (0° ± 0.10°)

⇒ Rear wheel alignment - total toe-in: 0° 20' ± 0° 15' (0.3° ± 0.25°)

Power assisted steering

Maximum Operating Pressure ( limited by pressure

relief valve in pump):

⇒ K1.8 90 - 100 bar (1305 - 1450 lbf/in

2)

⇒ KV6 & Td4 90 - 100 bar (1305 - 1450 lbf/in

2)

Pressure at idle 5 - 7 bar (72.5 - 101.5 lbf/in

2)

Maximum flow 5.5 ± 0.5 litres/min. (1.45 ± 0.13 US gal/min), limited by flow control

valve in pump

Page 91 of 1007

GENERAL DATA

04-28

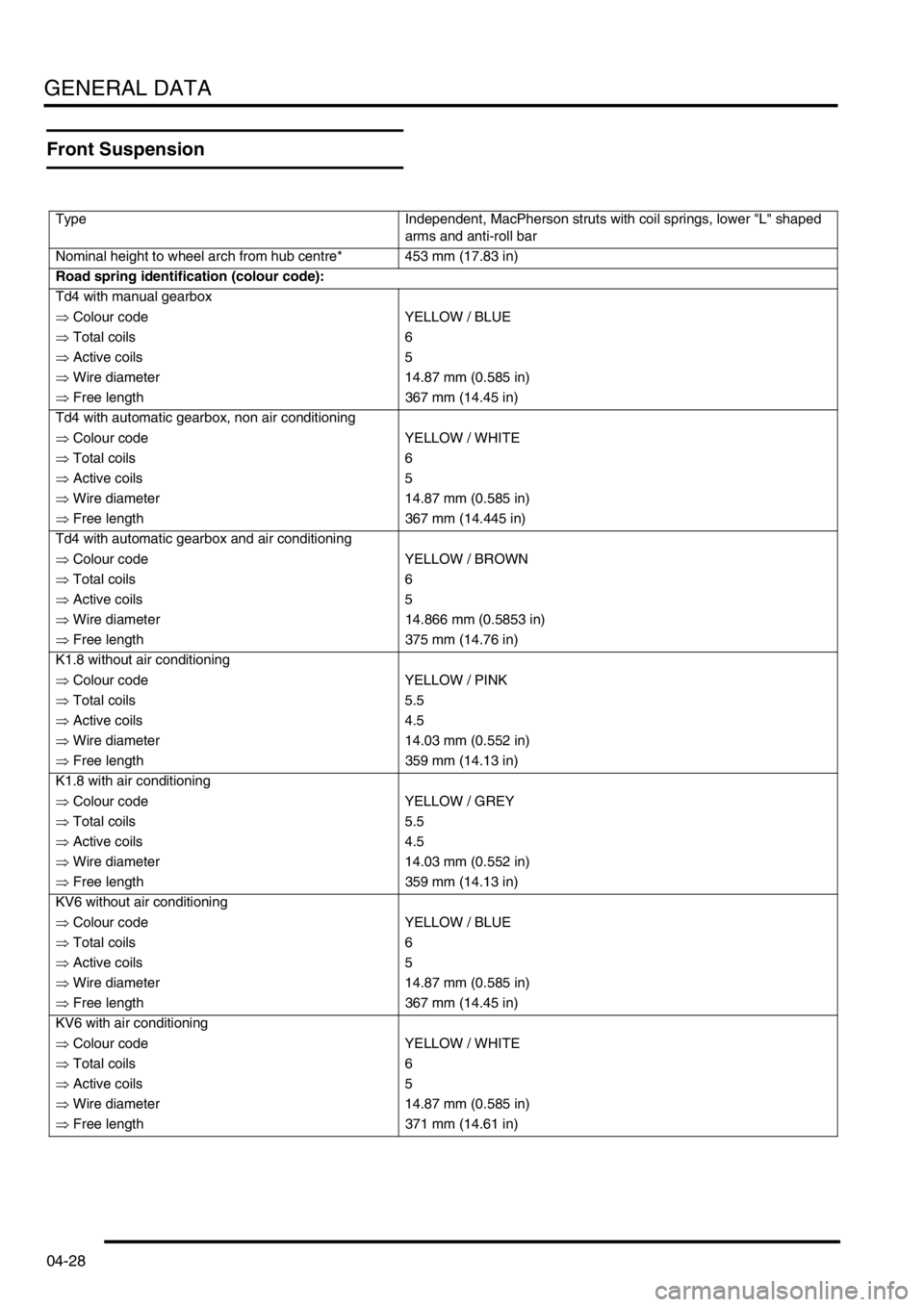

Front Suspension

Type Independent, MacPherson struts with coil springs, lower "L" shaped

arms and anti-roll bar

Nominal height to wheel arch from hub centre* 453 mm (17.83 in)

Road spring identification (colour code):

Td4 with manual gearbox

⇒ Colour code YELLOW / BLUE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.45 in)

Td4 with automatic gearbox, non air conditioning

⇒ Colour code YELLOW / WHITE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.445 in)

Td4 with automatic gearbox and air conditioning

⇒ Colour code YELLOW / BROWN

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.866 mm (0.5853 in)

⇒ Free length 375 mm (14.76 in)

K1.8 without air conditioning

⇒ Colour code YELLOW / PINK

⇒ Total coils 5.5

⇒ Active coils 4.5

⇒ Wire diameter 14.03 mm (0.552 in)

⇒ Free length 359 mm (14.13 in)

K1.8 with air conditioning

⇒ Colour code YELLOW / GREY

⇒ Total coils 5.5

⇒ Active coils 4.5

⇒ Wire diameter 14.03 mm (0.552 in)

⇒ Free length 359 mm (14.13 in)

KV6 without air conditioning

⇒ Colour code YELLOW / BLUE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.45 in)

KV6 with air conditioning

⇒ Colour code YELLOW / WHITE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 371 mm (14.61 in)

Page 93 of 1007

GENERAL DATA

04-30

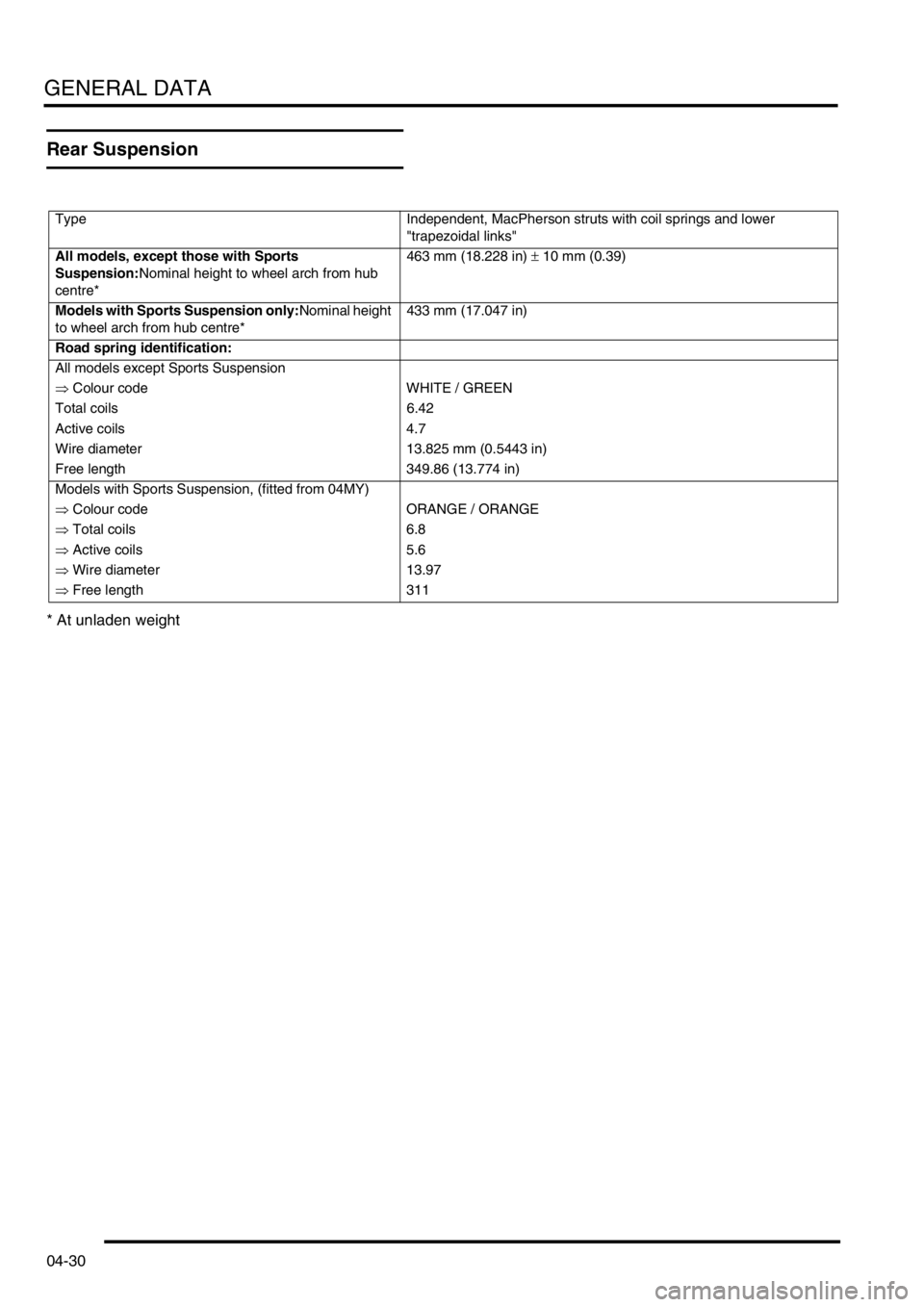

Rear Suspension

* At unladen weight

Type Independent, MacPherson struts with coil springs and lower

"trapezoidal links"

All models, except those with Sports

Suspension:Nominal height to wheel arch from hub

centre*463 mm (18.228 in) ± 10 mm (0.39)

Models with Sports Suspension only:Nominal height

to wheel arch from hub centre*433 mm (17.047 in)

Road spring identification:

All models except Sports Suspension

⇒ Colour code WHITE / GREEN

Total coils 6.42

Active coils 4.7

Wire diameter 13.825 mm (0.5443 in)

Free length 349.86 (13.774 in)

Models with Sports Suspension, (fitted from 04MY)

⇒ Colour code ORANGE / ORANGE

⇒ Total coils 6.8

⇒ Active coils 5.6

⇒ Wire diameter 13.97

⇒ Free length 311