door lock LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 638 of 1007

DOORS

REPAIRS 76-1-33

Handle - exterior - tail door

$% 76.58.05

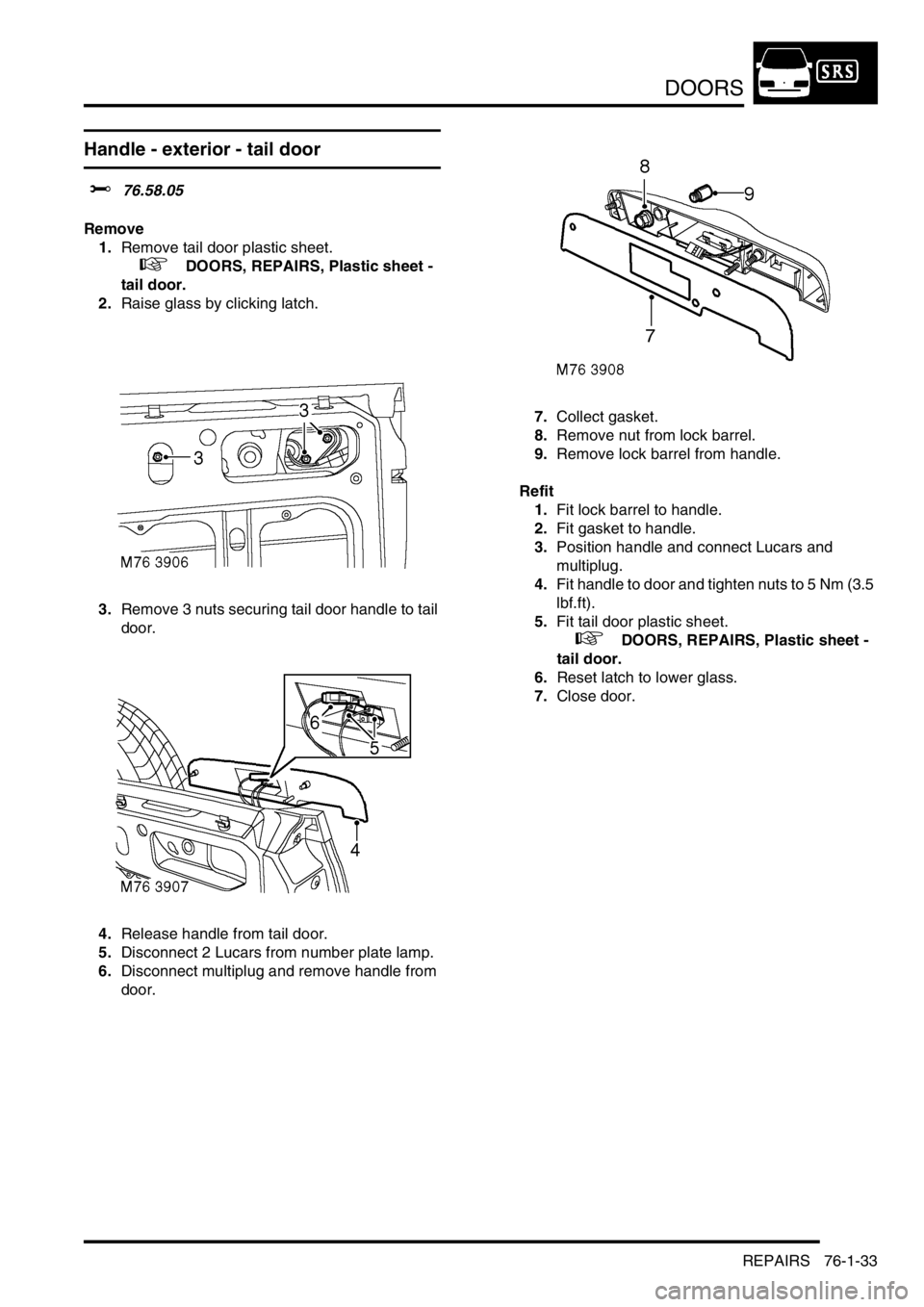

Remove

1.Remove tail door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

tail door.

2.Raise glass by clicking latch.

3.Remove 3 nuts securing tail door handle to tail

door.

4.Release handle from tail door.

5.Disconnect 2 Lucars from number plate lamp.

6.Disconnect multiplug and remove handle from

door.7.Collect gasket.

8.Remove nut from lock barrel.

9.Remove lock barrel from handle.

Refit

1.Fit lock barrel to handle.

2.Fit gasket to handle.

3.Position handle and connect Lucars and

multiplug.

4.Fit handle to door and tighten nuts to 5 Nm (3.5

lbf.ft).

5.Fit tail door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

tail door.

6.Reset latch to lower glass.

7.Close door.

Page 639 of 1007

DOORS

76-1-34 REPAIRS

Handle - exterior - front door

$% 76.58.07

Remove

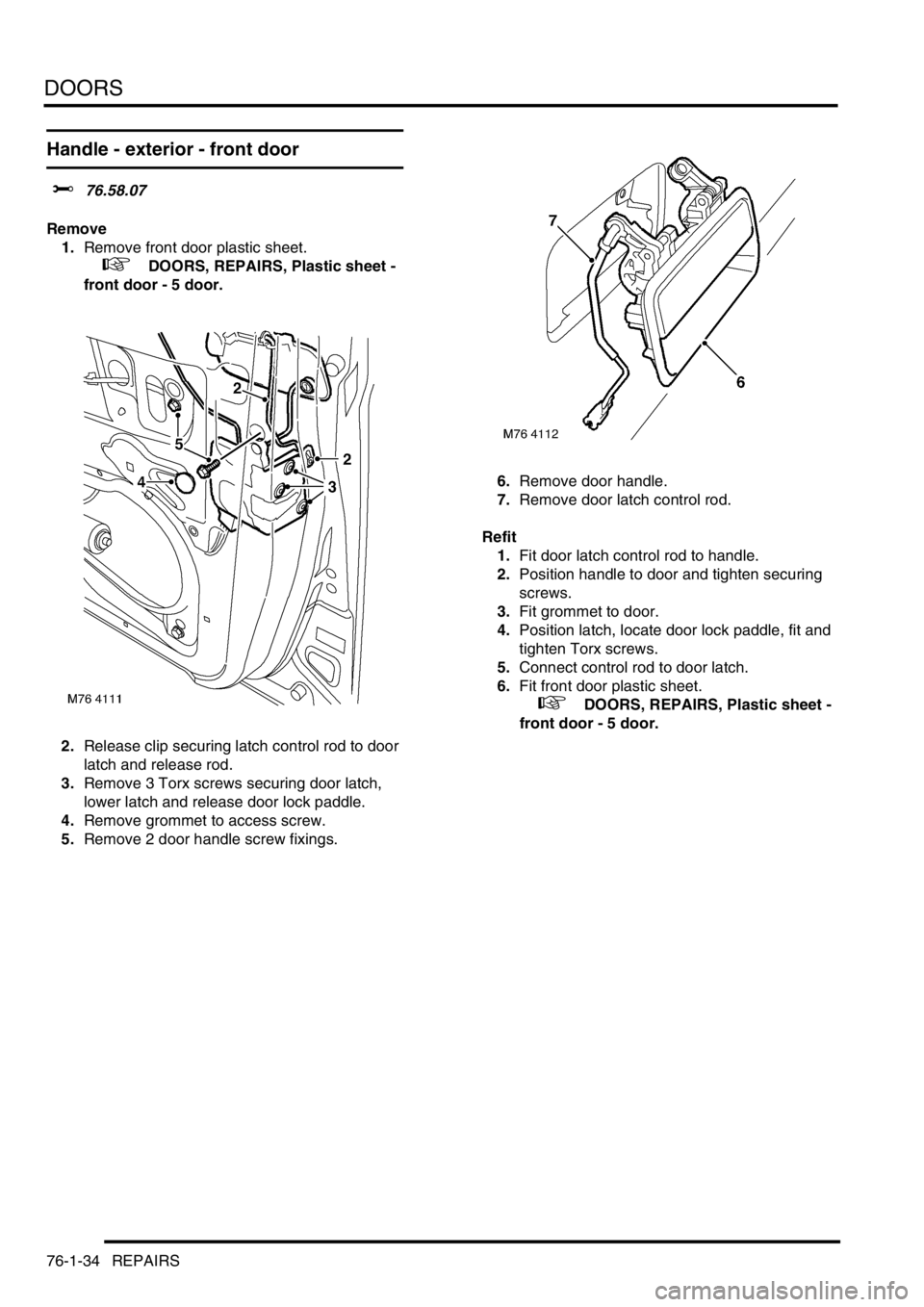

1.Remove front door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

front door - 5 door.

2.Release clip securing latch control rod to door

latch and release rod.

3.Remove 3 Torx screws securing door latch,

lower latch and release door lock paddle.

4.Remove grommet to access screw.

5.Remove 2 door handle screw fixings.6.Remove door handle.

7.Remove door latch control rod.

Refit

1.Fit door latch control rod to handle.

2.Position handle to door and tighten securing

screws.

3.Fit grommet to door.

4.Position latch, locate door lock paddle, fit and

tighten Torx screws.

5.Connect control rod to door latch.

6.Fit front door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

front door - 5 door.

Page 693 of 1007

SCREENS

76-4-2 REPAIRS

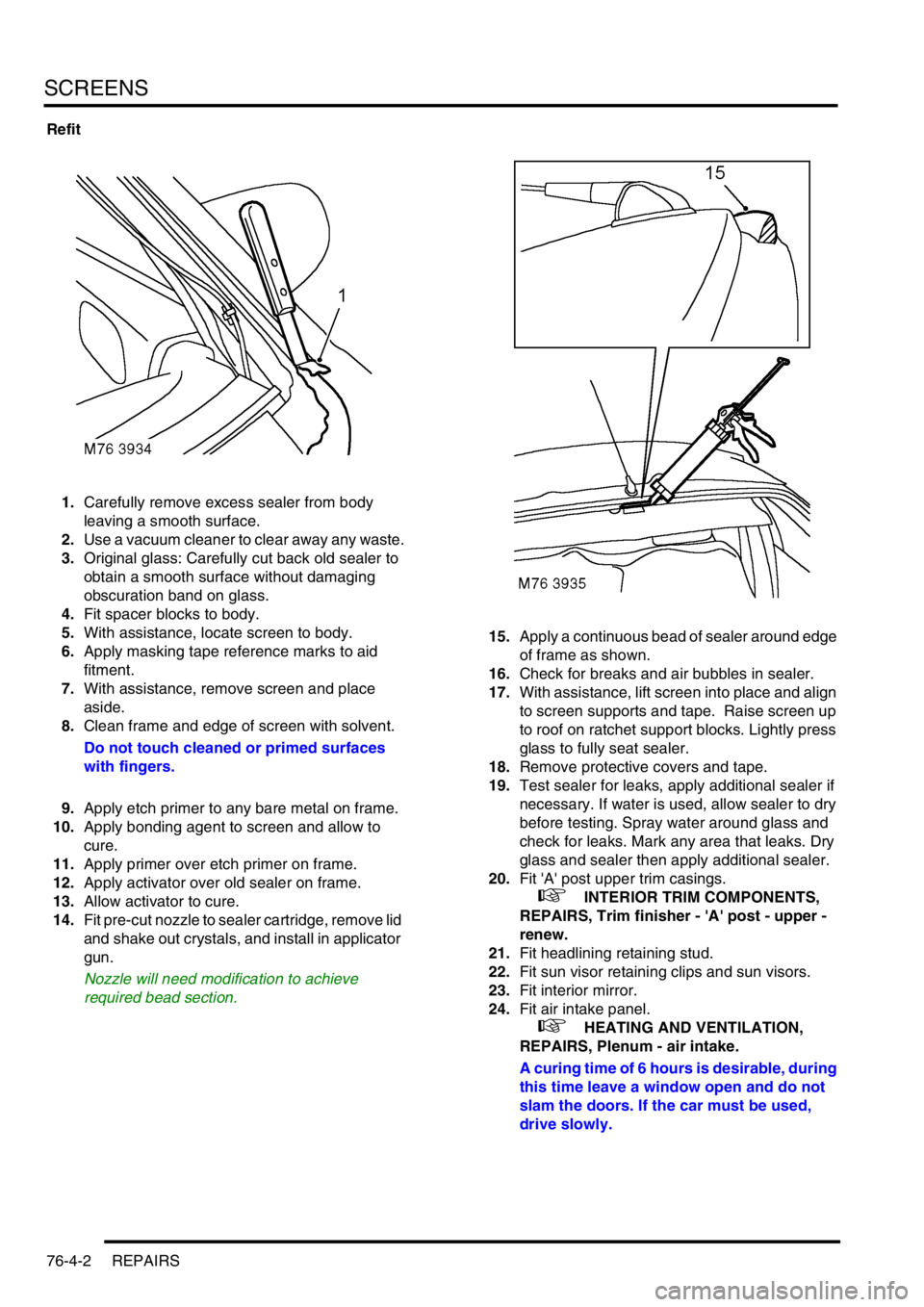

Refit

1.Carefully remove excess sealer from body

leaving a smooth surface.

2.Use a vacuum cleaner to clear away any waste.

3.Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4.Fit spacer blocks to body.

5.With assistance, locate screen to body.

6.Apply masking tape reference marks to aid

fitment.

7.With assistance, remove screen and place

aside.

8.Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9.Apply etch primer to any bare metal on frame.

10.Apply bonding agent to screen and allow to

cure.

11.Apply primer over etch primer on frame.

12.Apply activator over old sealer on frame.

13.Allow activator to cure.

14.Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals, and install in applicator

gun.

Nozzle will need modification to achieve

required bead section.15.Apply a continuous bead of sealer around edge

of frame as shown.

16.Check for breaks and air bubbles in sealer.

17.With assistance, lift screen into place and align

to screen supports and tape. Raise screen up

to roof on ratchet support blocks. Lightly press

glass to fully seat sealer.

18.Remove protective covers and tape.

19.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

20.Fit 'A' post upper trim casings.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim finisher - 'A' post - upper -

renew.

21.Fit headlining retaining stud.

22.Fit sun visor retaining clips and sun visors.

23.Fit interior mirror.

24.Fit air intake panel.

+ HEATING AND VENTILATION,

REPAIRS, Plenum - air intake.

A curing time of 6 hours is desirable, during

this time leave a window open and do not

slam the doors. If the car must be used,

drive slowly.

Page 694 of 1007

SCREENS

REPAIRS 76-4-3

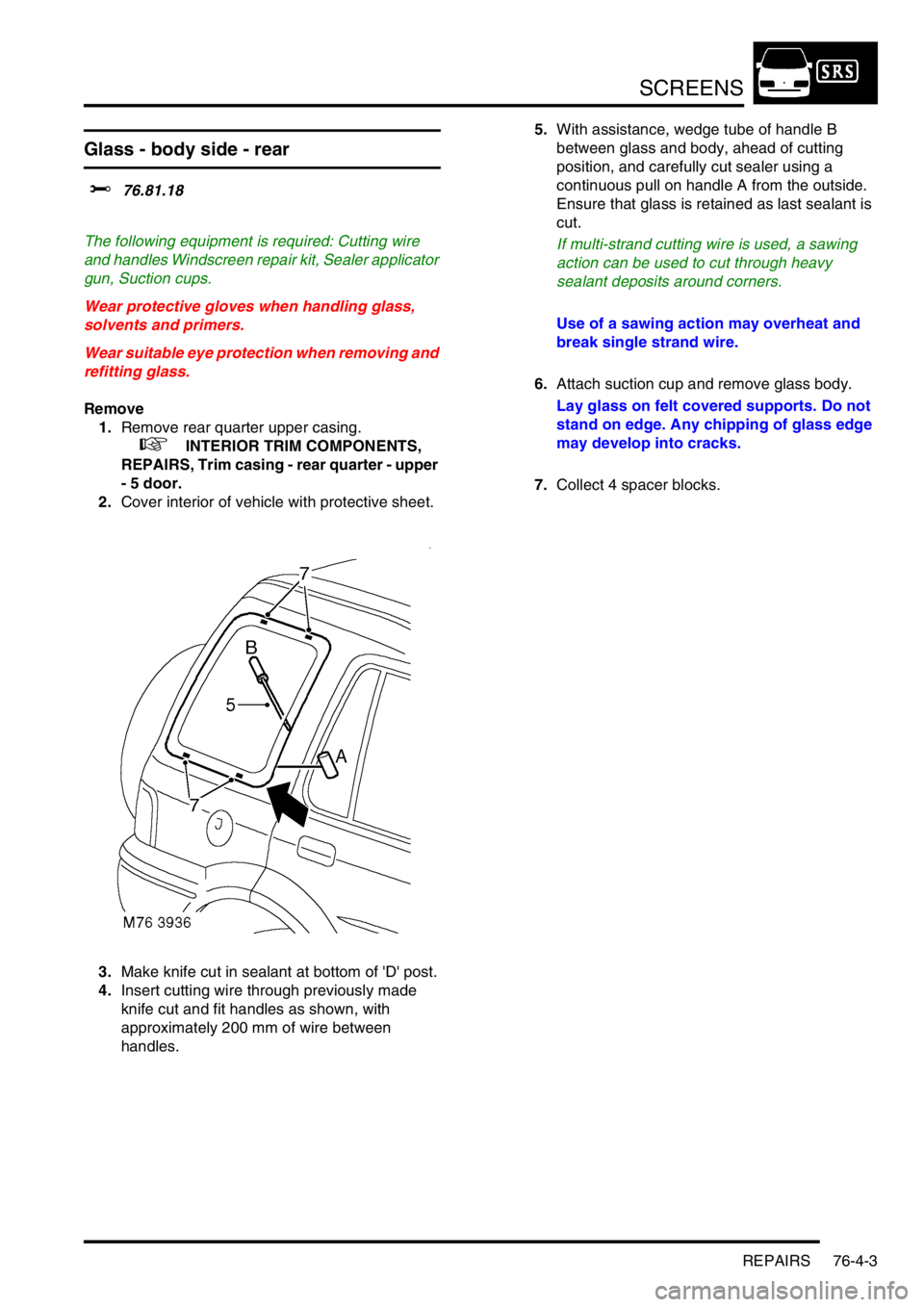

Glass - body side - rear

$% 76.81.18

The following equipment is required: Cutting wire

and handles Windscreen repair kit, Sealer applicator

gun, Suction cups.

Wear protective gloves when handling glass,

solvents and primers.

Wear suitable eye protection when removing and

refitting glass.

Remove

1.Remove rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

2.Cover interior of vehicle with protective sheet.

3.Make knife cut in sealant at bottom of 'D' post.

4.Insert cutting wire through previously made

knife cut and fit handles as shown, with

approximately 200 mm of wire between

handles. 5.With assistance, wedge tube of handle B

between glass and body, ahead of cutting

position, and carefully cut sealer using a

continuous pull on handle A from the outside.

Ensure that glass is retained as last sealant is

cut.

If multi-strand cutting wire is used, a sawing

action can be used to cut through heavy

sealant deposits around corners.

Use of a sawing action may overheat and

break single strand wire.

6.Attach suction cup and remove glass body.

Lay glass on felt covered supports. Do not

stand on edge. Any chipping of glass edge

may develop into cracks.

7.Collect 4 spacer blocks.

Page 695 of 1007

SCREENS

76-4-4 REPAIRS

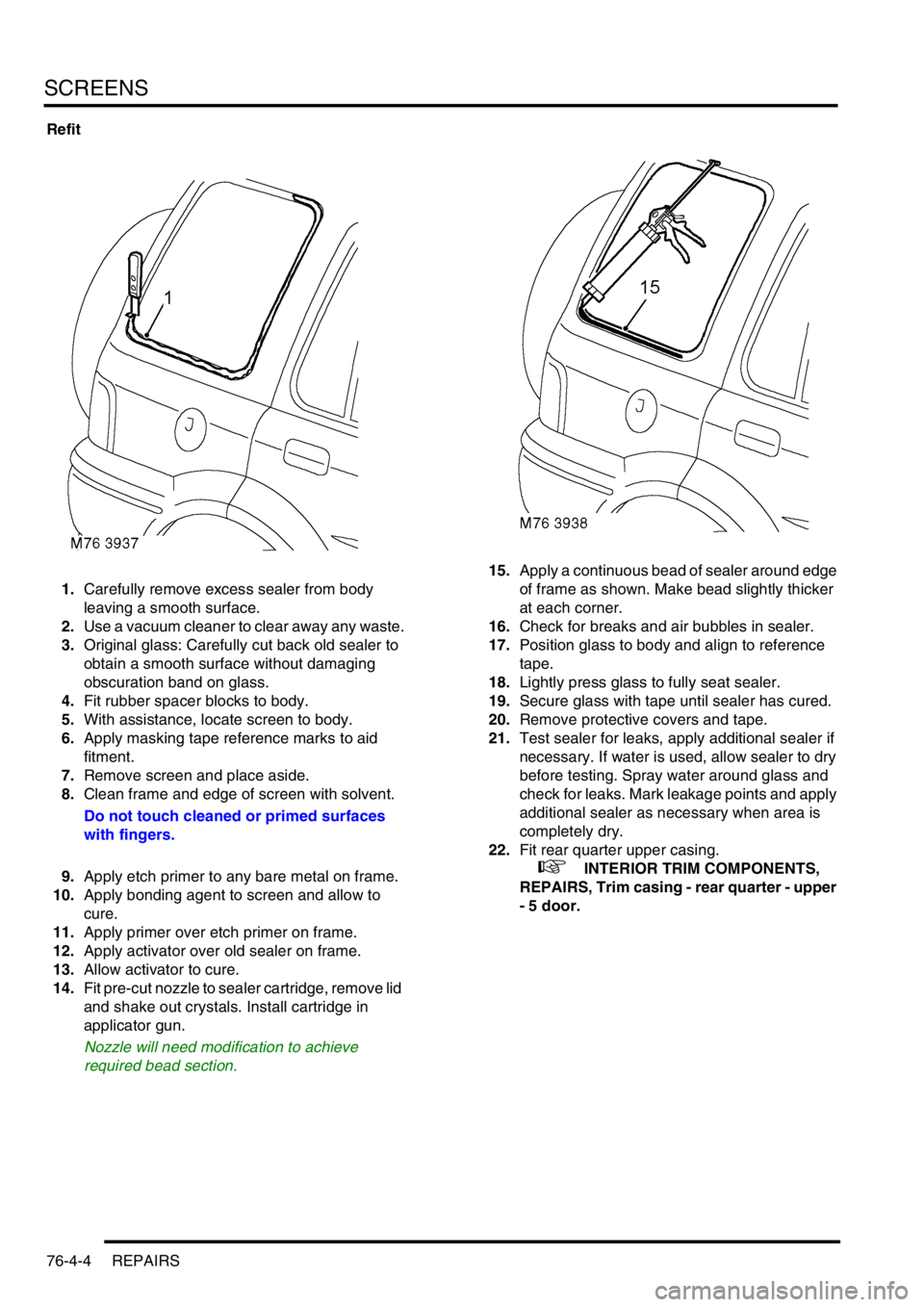

Refit

1.Carefully remove excess sealer from body

leaving a smooth surface.

2.Use a vacuum cleaner to clear away any waste.

3.Original glass: Carefully cut back old sealer to

obtain a smooth surface without damaging

obscuration band on glass.

4.Fit rubber spacer blocks to body.

5.With assistance, locate screen to body.

6.Apply masking tape reference marks to aid

fitment.

7.Remove screen and place aside.

8.Clean frame and edge of screen with solvent.

Do not touch cleaned or primed surfaces

with fingers.

9.Apply etch primer to any bare metal on frame.

10.Apply bonding agent to screen and allow to

cure.

11.Apply primer over etch primer on frame.

12.Apply activator over old sealer on frame.

13.Allow activator to cure.

14.Fit pre-cut nozzle to sealer cartridge, remove lid

and shake out crystals. Install cartridge in

applicator gun.

Nozzle will need modification to achieve

required bead section.15.Apply a continuous bead of sealer around edge

of frame as shown. Make bead slightly thicker

at each corner.

16.Check for breaks and air bubbles in sealer.

17.Position glass to body and align to reference

tape.

18.Lightly press glass to fully seat sealer.

19.Secure glass with tape until sealer has cured.

20.Remove protective covers and tape.

21.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark leakage points and apply

additional sealer as necessary when area is

completely dry.

22.Fit rear quarter upper casing.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Trim casing - rear quarter - upper

- 5 door.

Page 711 of 1007

SEATS

76-5-16 REPAIRS

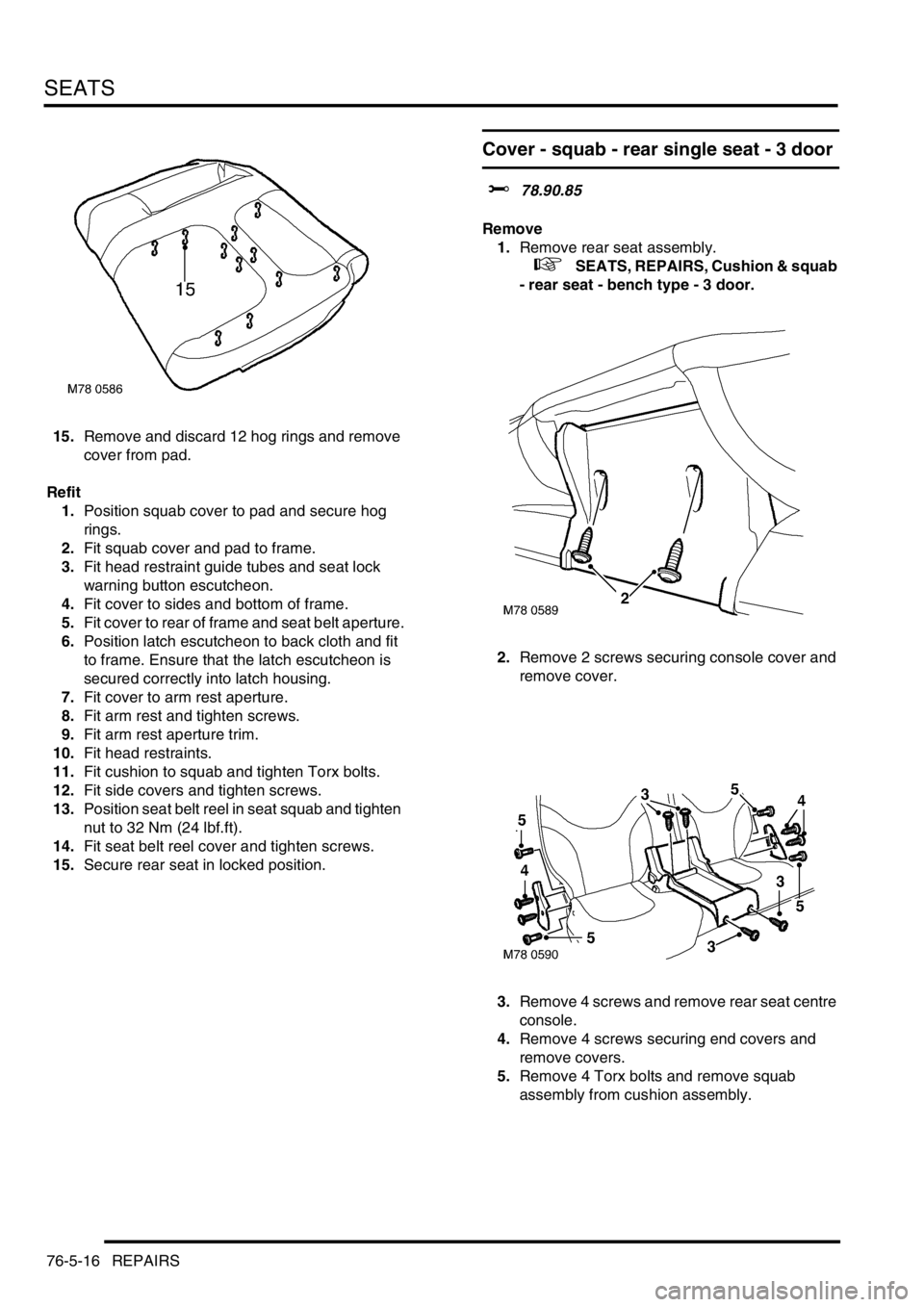

15.Remove and discard 12 hog rings and remove

cover from pad.

Refit

1.Position squab cover to pad and secure hog

rings.

2.Fit squab cover and pad to frame.

3.Fit head restraint guide tubes and seat lock

warning button escutcheon.

4.Fit cover to sides and bottom of frame.

5.Fit cover to rear of frame and seat belt aperture.

6.Position latch escutcheon to back cloth and fit

to frame. Ensure that the latch escutcheon is

secured correctly into latch housing.

7.Fit cover to arm rest aperture.

8.Fit arm rest and tighten screws.

9.Fit arm rest aperture trim.

10.Fit head restraints.

11.Fit cushion to squab and tighten Torx bolts.

12.Fit side covers and tighten screws.

13.Position seat belt reel in seat squab and tighten

nut to 32 Nm (24 lbf.ft).

14.Fit seat belt reel cover and tighten screws.

15.Secure rear seat in locked position.

Cover - squab - rear single seat - 3 door

$% 78.90.85

Remove

1.Remove rear seat assembly.

+ SEATS, REPAIRS, Cushion & squab

- rear seat - bench type - 3 door.

2.Remove 2 screws securing console cover and

remove cover.

3.Remove 4 screws and remove rear seat centre

console.

4.Remove 4 screws securing end covers and

remove covers.

5.Remove 4 Torx bolts and remove squab

assembly from cushion assembly.

Page 728 of 1007

HOOD

REPAIRS 76-7-3

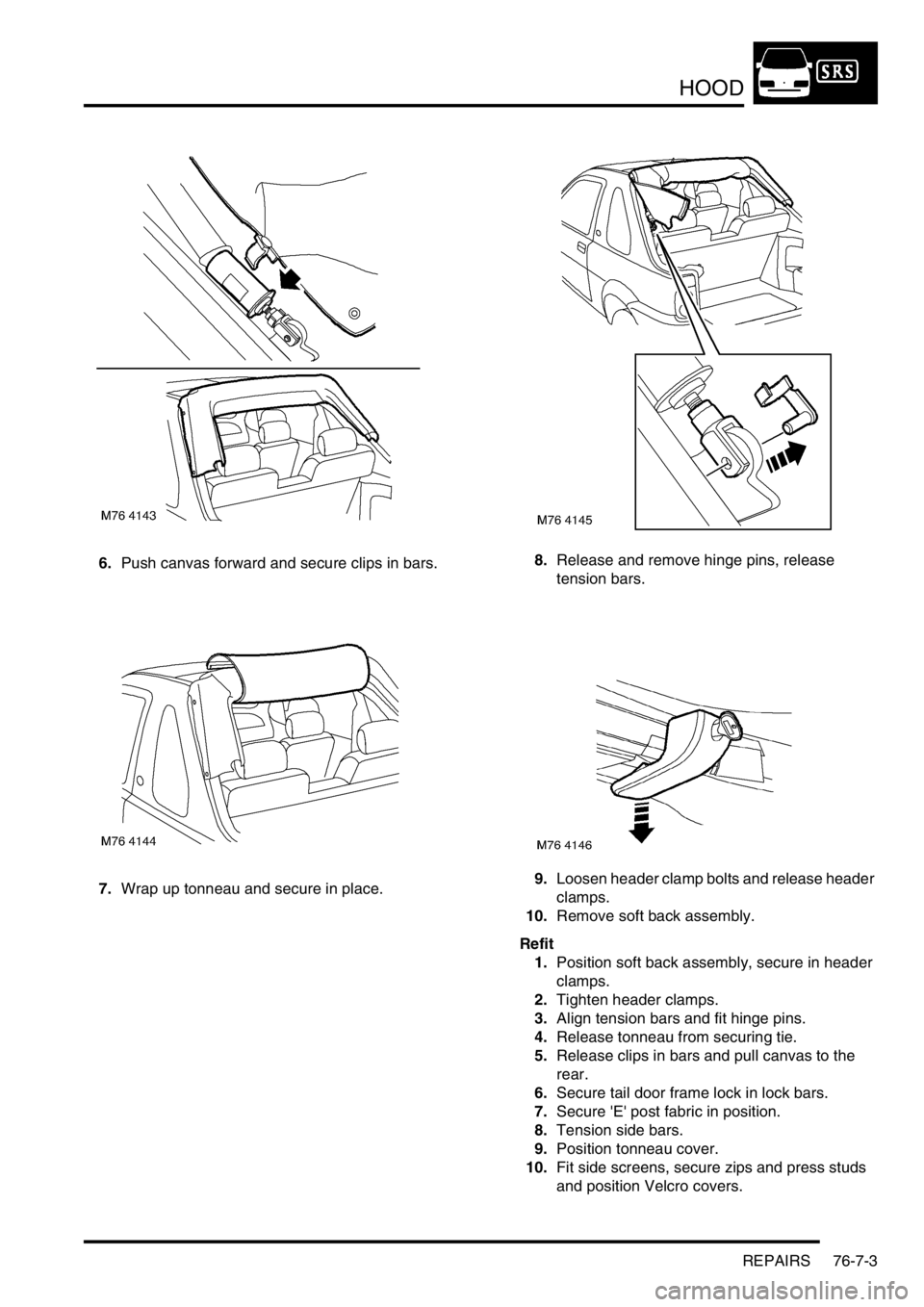

6.Push canvas forward and secure clips in bars.

7.Wrap up tonneau and secure in place.8.Release and remove hinge pins, release

tension bars.

9.Loosen header clamp bolts and release header

clamps.

10.Remove soft back assembly.

Refit

1.Position soft back assembly, secure in header

clamps.

2.Tighten header clamps.

3.Align tension bars and fit hinge pins.

4.Release tonneau from securing tie.

5.Release clips in bars and pull canvas to the

rear.

6.Secure tail door frame lock in lock bars.

7.Secure 'E' post fabric in position.

8.Tension side bars.

9.Position tonneau cover.

10.Fit side screens, secure zips and press studs

and position Velcro covers.

Page 818 of 1007

PANEL REPAIRS

TIMES 77-2-63

TIME S

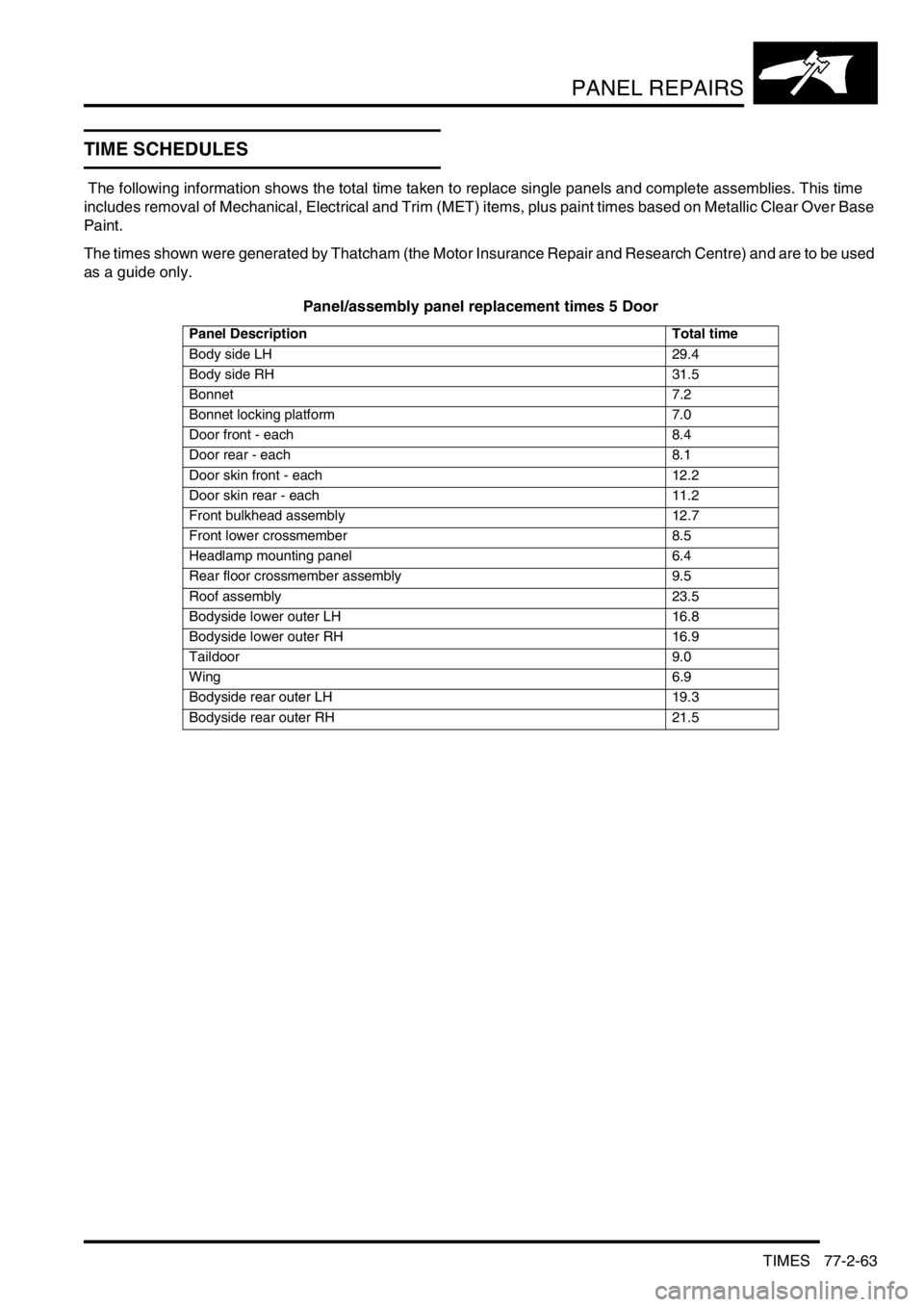

TIME SCHEDULES

The following information shows the total time taken to replace single panels and complete assemblies. This time

includes removal of Mechanical, Electrical and Trim (MET) items, plus paint times based on Metallic Clear Over Base

Paint.

The times shown were generated by Thatcham (the Motor Insurance Repair and Research Centre) and are to be used

as a guide only.

Panel/assembly panel replacement times 5 Door

Panel Description Total time

Body side LH 29.4

Body side RH 31.5

Bonnet 7.2

Bonnet locking platform 7.0

Door front - each 8.4

Door rear - each 8.1

Door skin front - each 12.2

Door skin rear - each 11.2

Front bulkhead assembly 12.7

Front lower crossmember 8.5

Headlamp mounting panel 6.4

Rear floor crossmember assembly 9.5

Roof assembly 23.5

Bodyside lower outer LH 16.8

Bodyside lower outer RH 16.9

Taildoor 9.0

Wing6.9

Bodyside rear outer LH 19.3

Bodyside rear outer RH 21.5

Page 819 of 1007

PANEL REPAIRS

77-2-64 TIMES

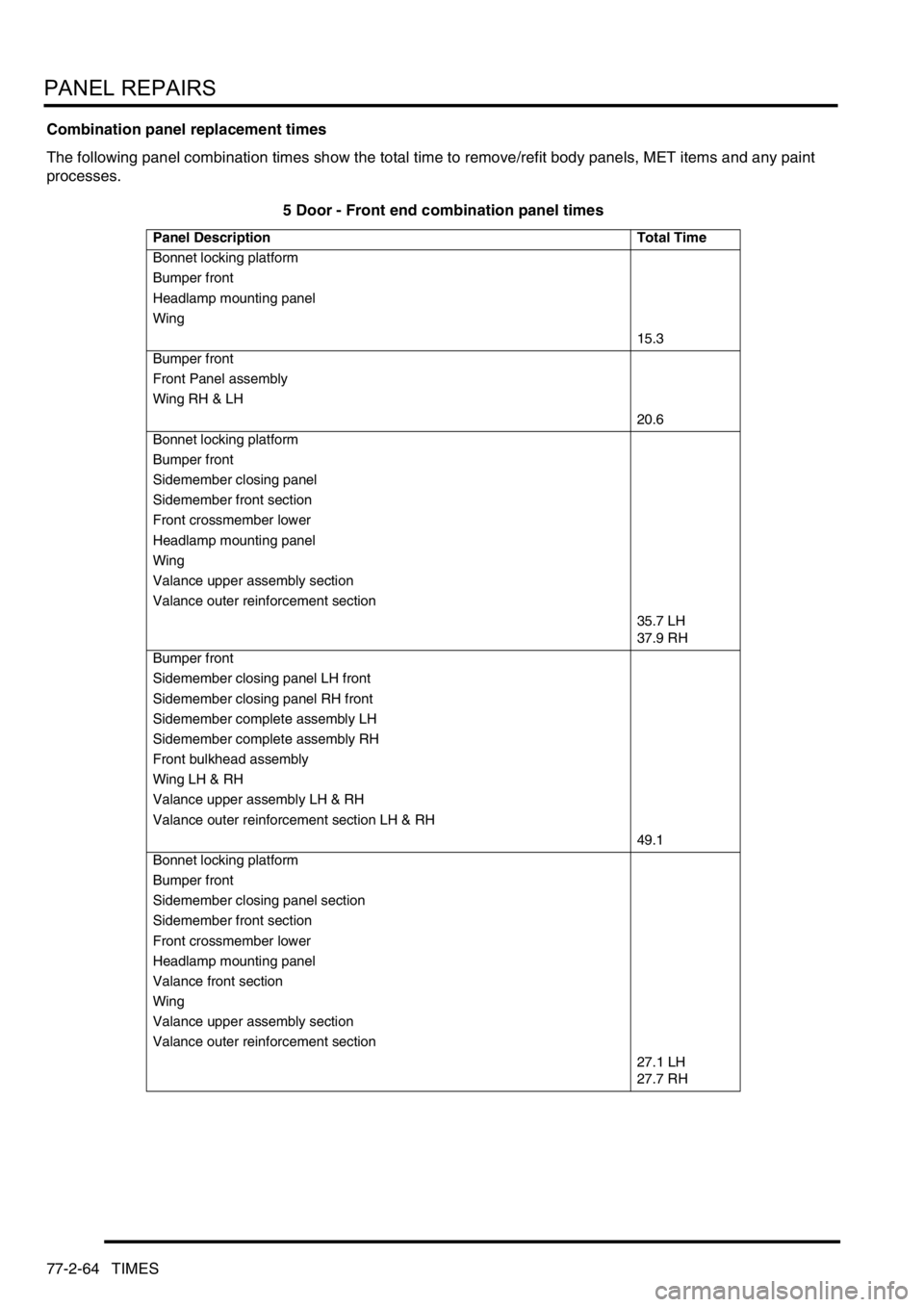

Combination panel replacement times

The following panel combination times show the total time to remove/refit body panels, MET items and any paint

processes.

5 Door - Front end combination panel times

Panel Description Total Time

Bonnet locking platform

Bumper front

Headlamp mounting panel

Wing

15.3

Bumper front

Front Panel assembly

Wing RH & LH

20.6

Bonnet locking platform

Bumper front

Sidemember closing panel

Sidemember front section

Front crossmember lower

Headlamp mounting panel

Wing

Valance upper assembly section

Valance outer reinforcement section

35.7 LH

37.9 RH

Bumper front

Sidemember closing panel LH front

Sidemember closing panel RH front

Sidemember complete assembly LH

Sidemember complete assembly RH

Front bulkhead assembly

Wing LH & RH

Valance upper assembly LH & RH

Valance outer reinforcement section LH & RH

49.1

Bonnet locking platform

Bumper front

Sidemember closing panel section

Sidemember front section

Front crossmember lower

Headlamp mounting panel

Valance front section

Wing

Valance upper assembly section

Valance outer reinforcement section

27.1 LH

27.7 RH

Page 851 of 1007

CORROSION PREVENTION AND SEALING

77-4-20 SEALING

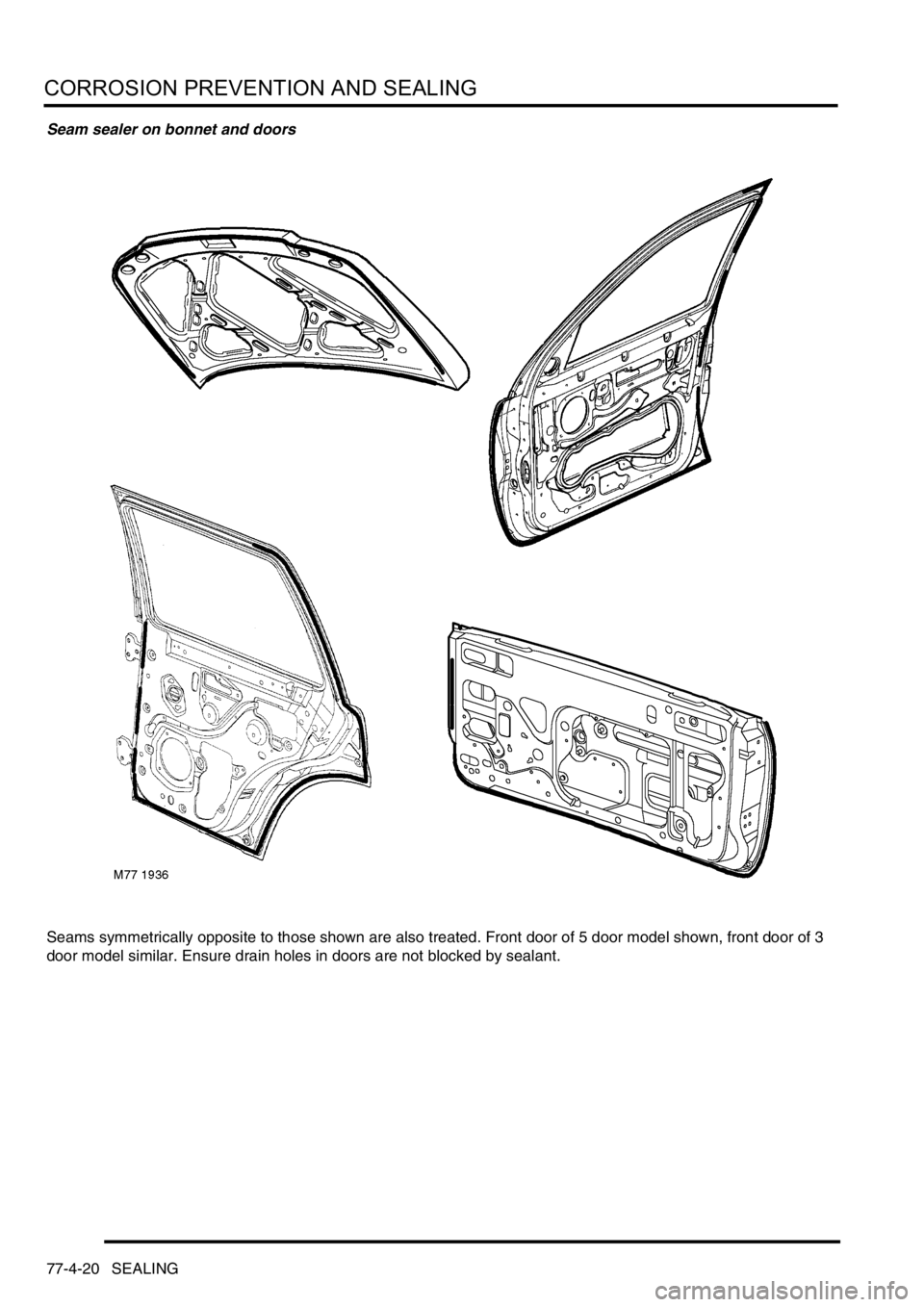

Seam sealer on bonnet and doors

Seams symmetrically opposite to those shown are also treated. Front door of 5 door model shown, front door of 3

door model similar. Ensure drain holes in doors are not blocked by sealant.