ECU LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 560 of 1007

BRAKES

REPAIRS 70-11

Cable - handbrake

$% 70.35.25

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel(s).

3.Release rear ash tray, disconnect connector

from cigar lighter and remove ash tray.

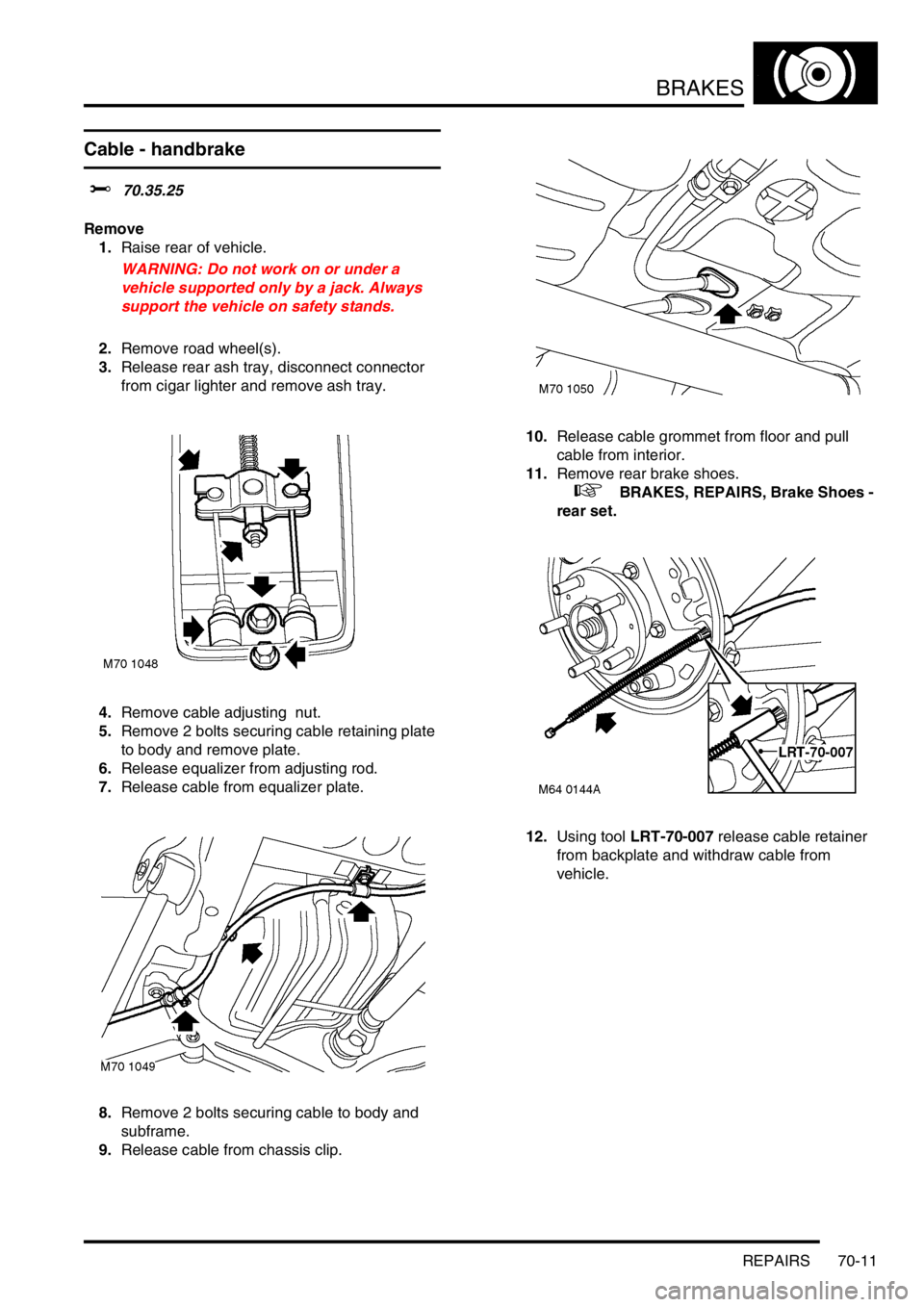

4.Remove cable adjusting nut.

5.Remove 2 bolts securing cable retaining plate

to body and remove plate.

6.Release equalizer from adjusting rod.

7.Release cable from equalizer plate.

8.Remove 2 bolts securing cable to body and

subframe.

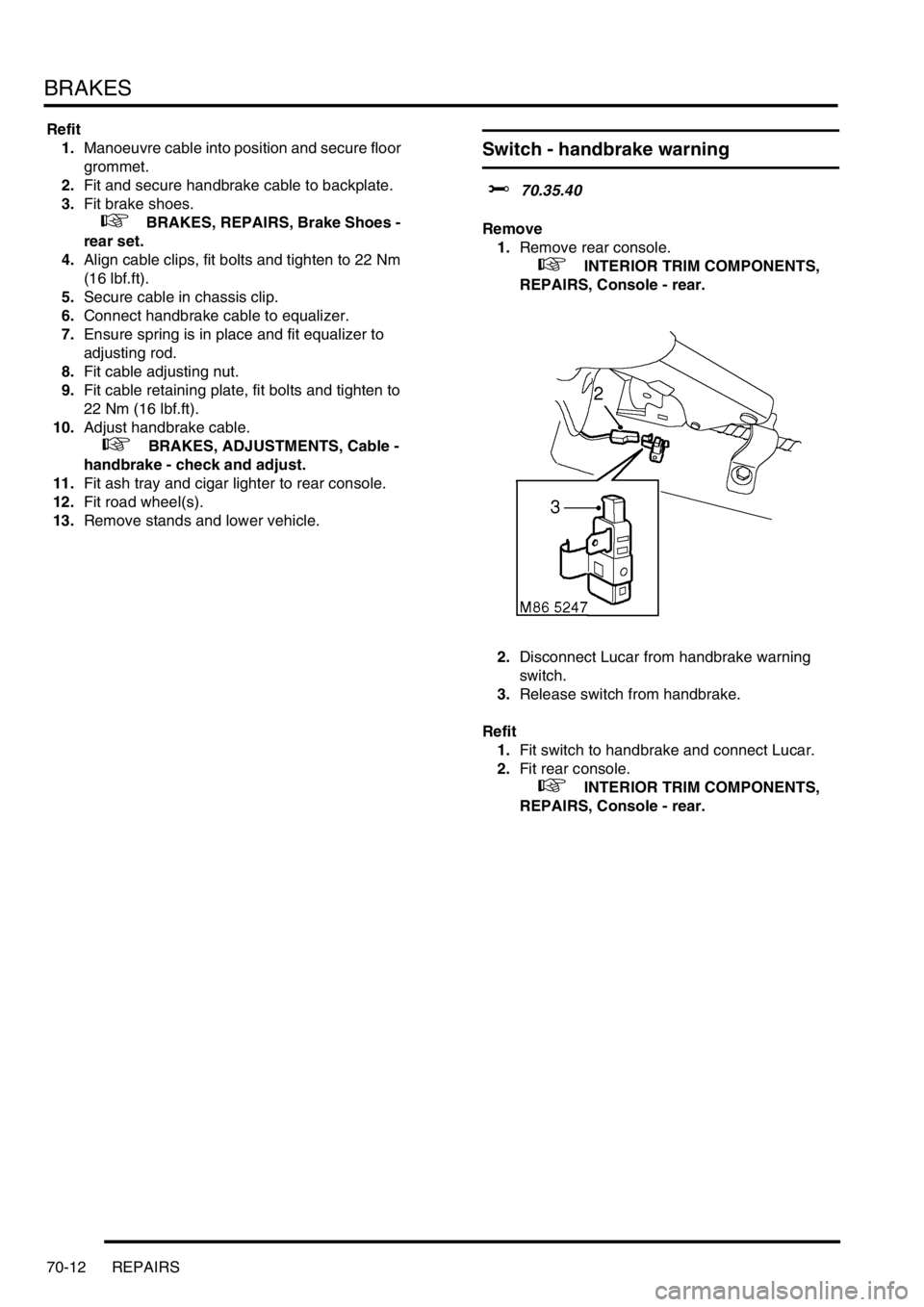

9.Release cable from chassis clip.10.Release cable grommet from floor and pull

cable from interior.

11.Remove rear brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

12.Using tool LRT-70-007 release cable retainer

from backplate and withdraw cable from

vehicle.

Page 561 of 1007

BRAKES

70-12 REPAIRS

Refit

1.Manoeuvre cable into position and secure floor

grommet.

2.Fit and secure handbrake cable to backplate.

3.Fit brake shoes.

+ BRAKES, REPAIRS, Brake Shoes -

rear set.

4.Align cable clips, fit bolts and tighten to 22 Nm

(16 lbf.ft).

5.Secure cable in chassis clip.

6.Connect handbrake cable to equalizer.

7.Ensure spring is in place and fit equalizer to

adjusting rod.

8.Fit cable adjusting nut.

9.Fit cable retaining plate, fit bolts and tighten to

22 Nm (16 lbf.ft).

10.Adjust handbrake cable.

+ BRAKES, ADJUSTMENTS, Cable -

handbrake - check and adjust.

11.Fit ash tray and cigar lighter to rear console.

12.Fit road wheel(s).

13.Remove stands and lower vehicle.

Switch - handbrake warning

$% 70.35.40

Remove

1.Remove rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

2.Disconnect Lucar from handbrake warning

switch.

3.Release switch from handbrake.

Refit

1.Fit switch to handbrake and connect Lucar.

2.Fit rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

Page 562 of 1007

BRAKES

REPAIRS 70-13

Switch - stop light

$% 70.35.42

Remove

1.Disconnect brake light switch multiplug.

2.Release bayonet fitting on brake light switch

and remove switch.

Refit

1.Position switch and secure bayonet fitting.

2.Connect brake light switch multiplug.

3.Depress and hold brake pedal.

4.Reset switch by pulling plunger fully out.

5.Release brake pedal slowly to set switch

adjustment.

Sensor - brake pedal position

$% 70.35.44

Remove

1.Release bayonet fitting on brake light switch

and remove switch.

2.Release sensor from mounting bracket.

3.Disconnect sensor multiplug and remove

sensor.

4.Remove sensor mounting from bracket.

Refit

1.Position sensor to mounting bracket and

connect multiplug.

2.Position switch and secure bayonet fitting.

3.Hold brake pedal depressed and push sensor

fully into bracket, release pedal slowly to set

sensor position.

Page 566 of 1007

BRAKES

REPAIRS 70-17

14.Check wheel cylinder pistons for freedom of

movement.

15.Check brake adjuster threads, nut and

handbrake linkage for wear. Renew if

necessary.

16.Check condition of return springs and renew if

necessary.

17.Ensure brake adjuster is fully off.

Refit

1.Position adjuster and expander to brake shoes

and fit return springs.

2.Smear brake shoe contact points with Molykote

111 grease.

3.Remove elastic band from wheel cylinder.

4.Manoeuvre brake shoes around rear hub and

locate to abutment and wheel cylinder.

5.Fit brake shoe retaining pins and secure with

clips.

6.Connect hand brake cable to brake shoe lever.

7.Fit brake drum.

+ BRAKES, REPAIRS, Drum - rear.

8.Apply brake pedal a min. of 30 times to ensure

full adjustment of rear brake shoes after

refitting.

9.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

10.Remove stands and lower vehicle.

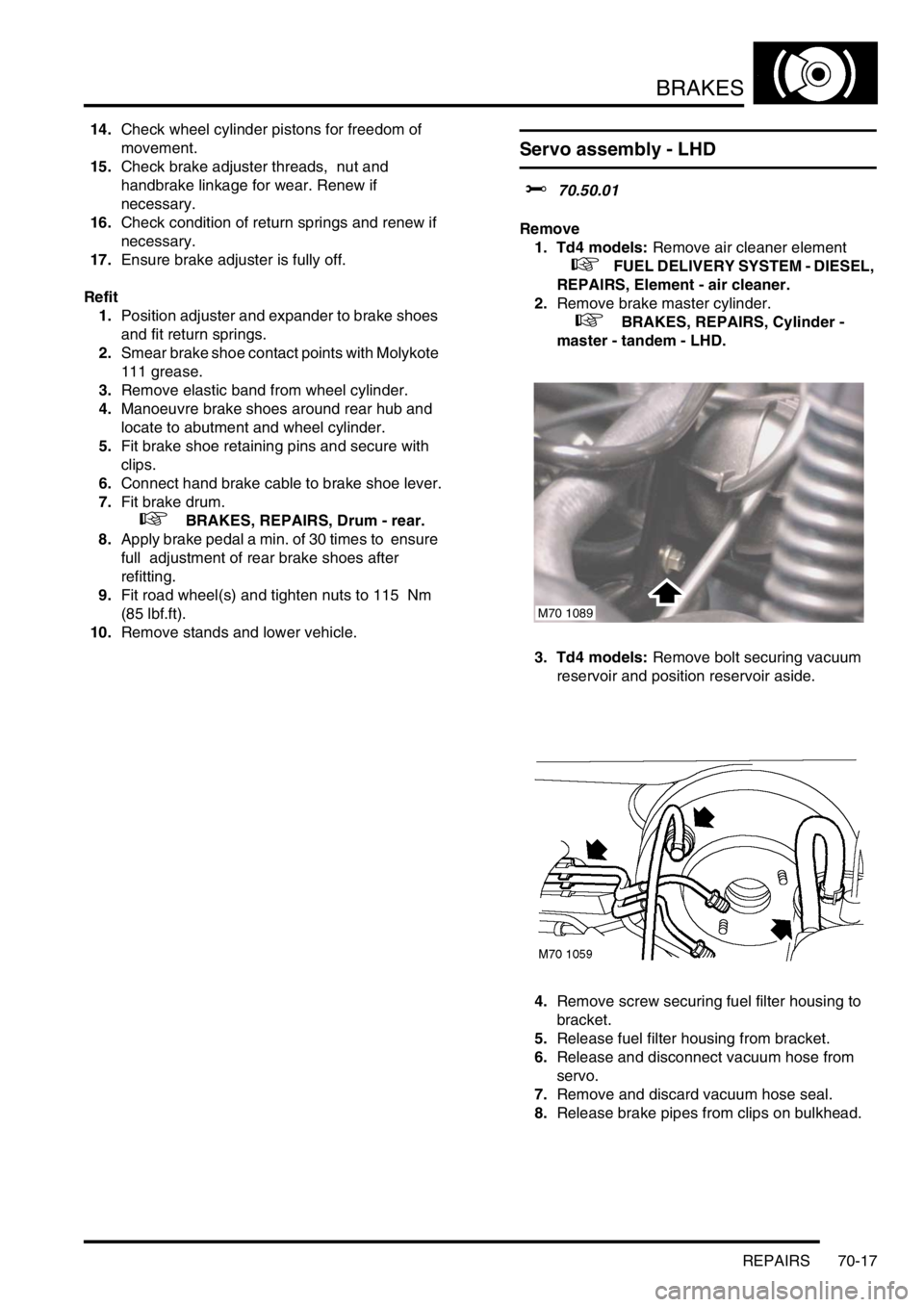

Servo assembly - LHD

$% 70.50.01

Remove

1. Td4 models: Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

2.Remove brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - LHD.

3. Td4 models: Remove bolt securing vacuum

reservoir and position reservoir aside.

4.Remove screw securing fuel filter housing to

bracket.

5.Release fuel filter housing from bracket.

6.Release and disconnect vacuum hose from

servo.

7.Remove and discard vacuum hose seal.

8.Release brake pipes from clips on bulkhead.

M70 1089

Page 567 of 1007

BRAKES

70-18 REPAIRS

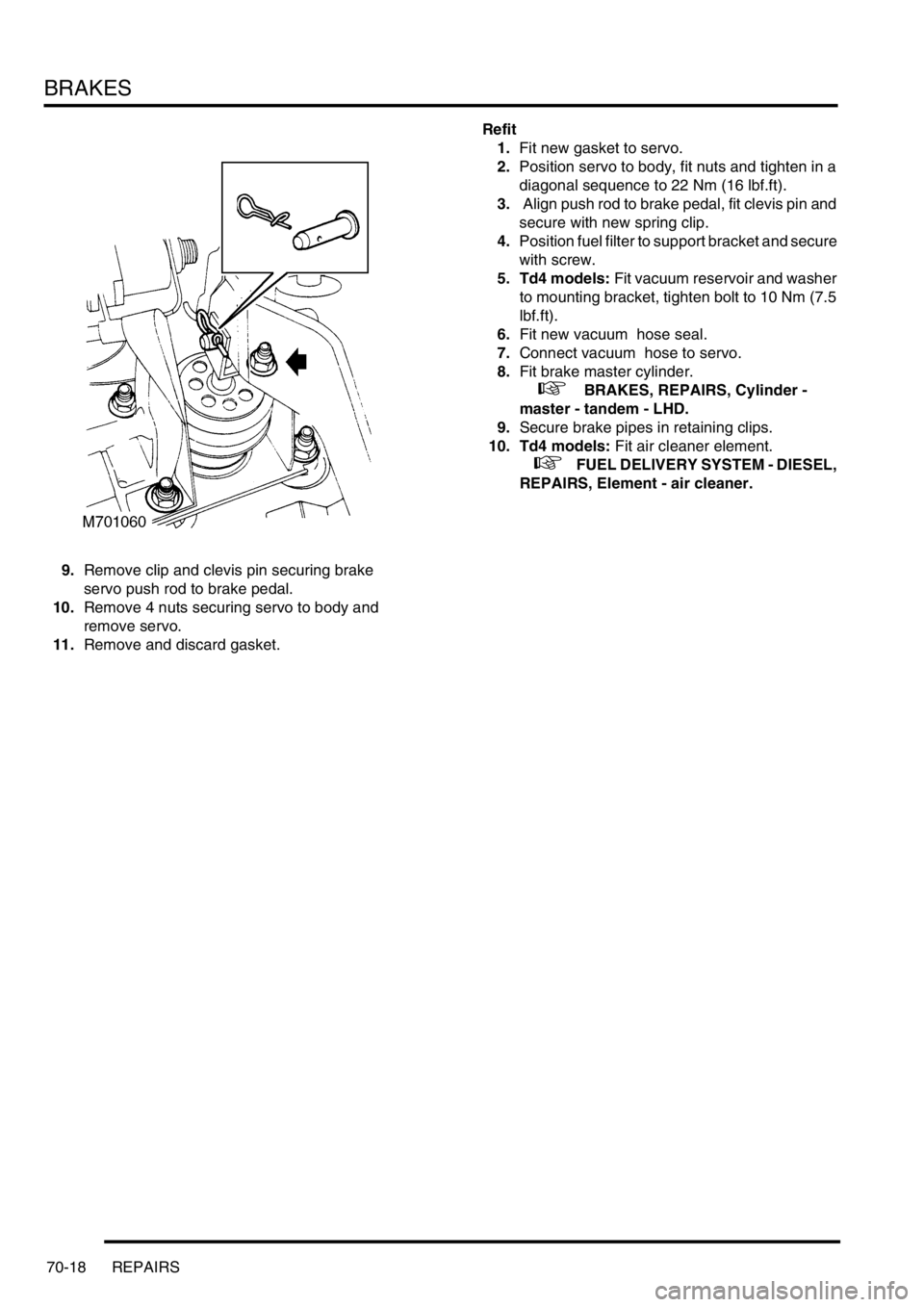

9.Remove clip and clevis pin securing brake

servo push rod to brake pedal.

10.Remove 4 nuts securing servo to body and

remove servo.

11.Remove and discard gasket.Refit

1.Fit new gasket to servo.

2.Position servo to body, fit nuts and tighten in a

diagonal sequence to 22 Nm (16 lbf.ft).

3. Align push rod to brake pedal, fit clevis pin and

secure with new spring clip.

4.Position fuel filter to support bracket and secure

with screw.

5. Td4 models: Fit vacuum reservoir and washer

to mounting bracket, tighten bolt to 10 Nm (7.5

lbf.ft).

6.Fit new vacuum hose seal.

7.Connect vacuum hose to servo.

8.Fit brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - LHD.

9.Secure brake pipes in retaining clips.

10. Td4 models: Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

Page 568 of 1007

BRAKES

REPAIRS 70-19

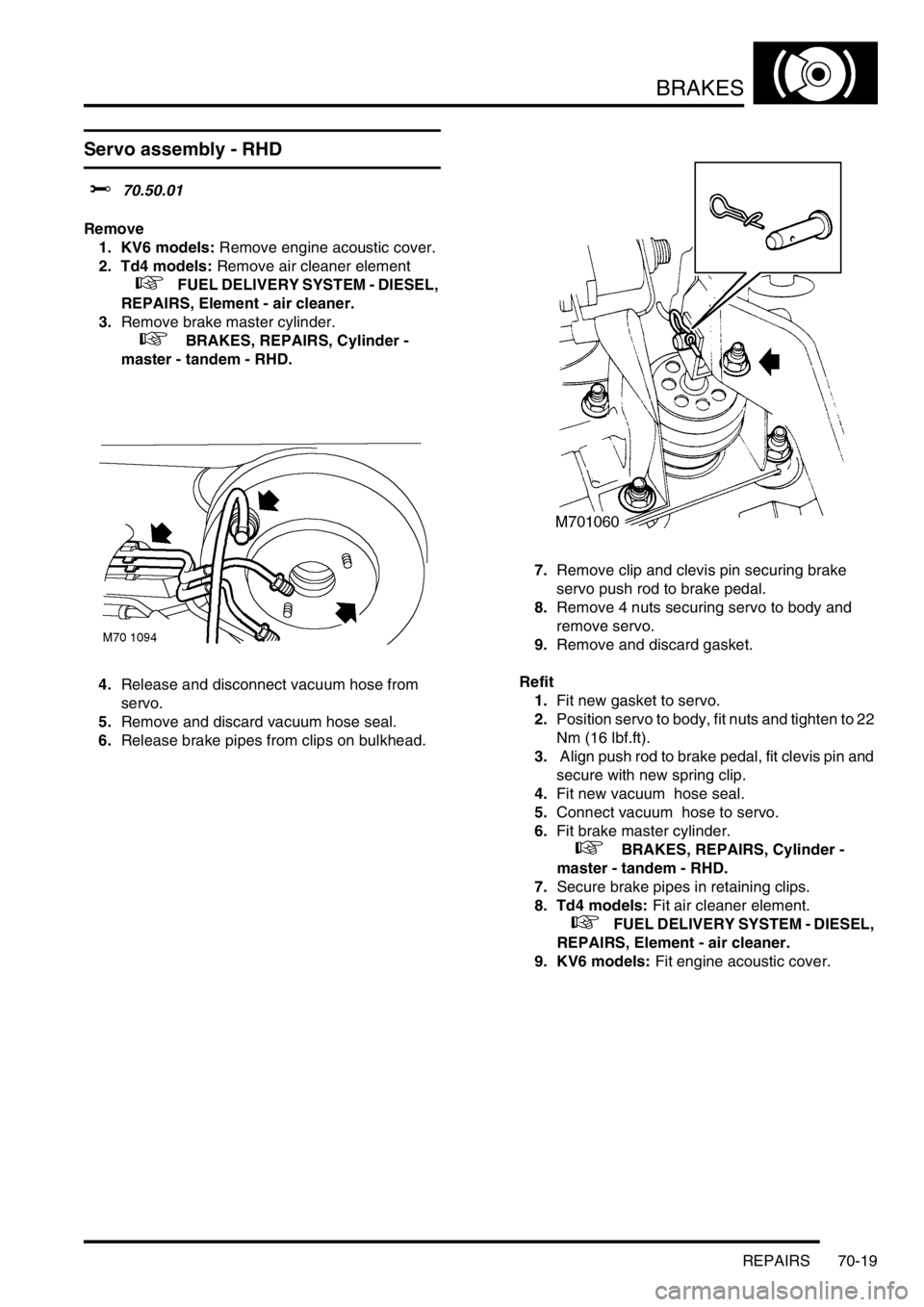

Servo assembly - RHD

$% 70.50.01

Remove

1. KV6 models: Remove engine acoustic cover.

2. Td4 models: Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Remove brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - RHD.

4.Release and disconnect vacuum hose from

servo.

5.Remove and discard vacuum hose seal.

6.Release brake pipes from clips on bulkhead.7.Remove clip and clevis pin securing brake

servo push rod to brake pedal.

8.Remove 4 nuts securing servo to body and

remove servo.

9.Remove and discard gasket.

Refit

1.Fit new gasket to servo.

2.Position servo to body, fit nuts and tighten to 22

Nm (16 lbf.ft).

3. Align push rod to brake pedal, fit clevis pin and

secure with new spring clip.

4.Fit new vacuum hose seal.

5.Connect vacuum hose to servo.

6.Fit brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - RHD.

7.Secure brake pipes in retaining clips.

8. Td4 models: Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

9. KV6 models: Fit engine acoustic cover.

Page 569 of 1007

BRAKES

70-20 REPAIRS

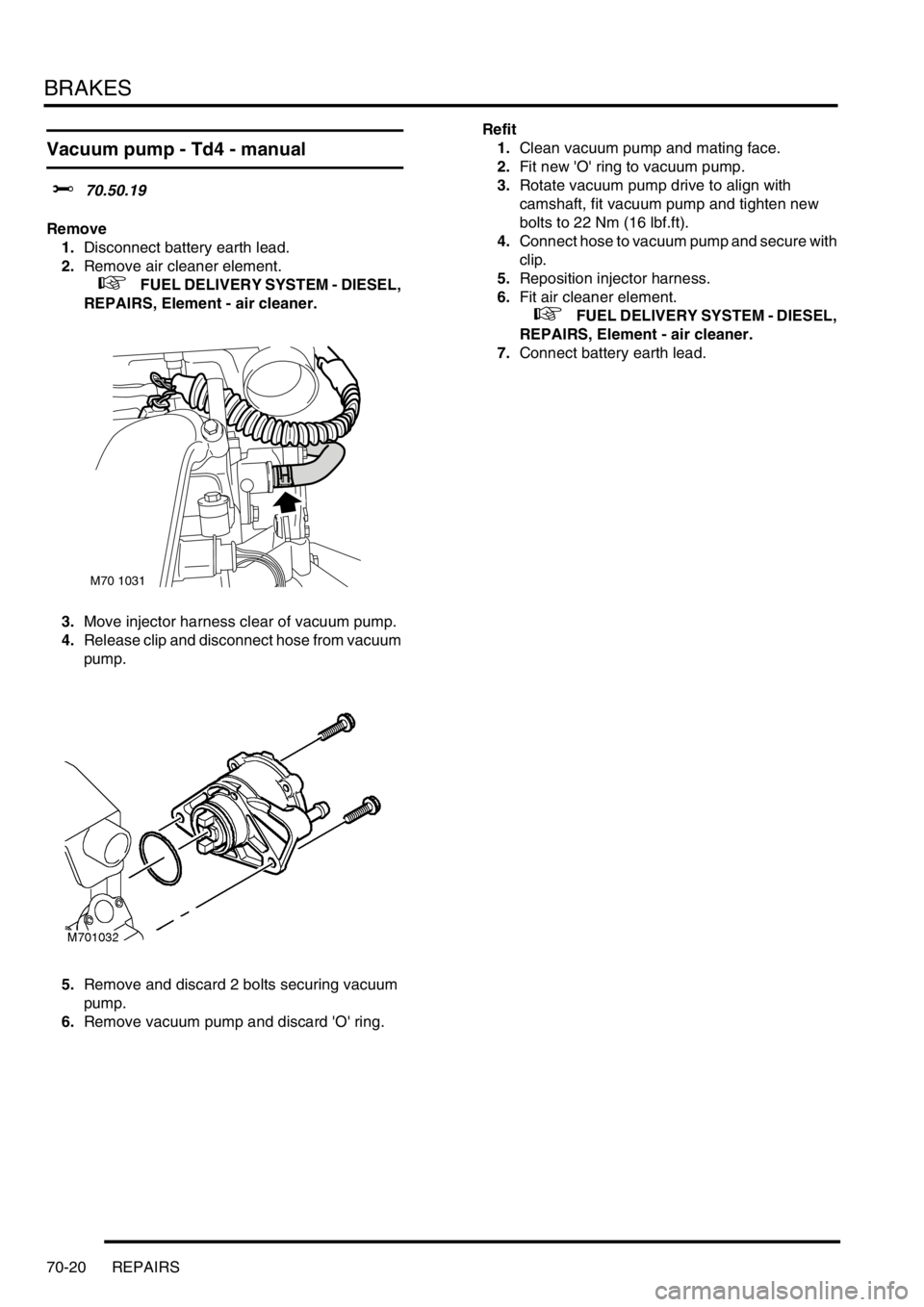

Vacuum pump - Td4 - manual

$% 70.50.19

Remove

1.Disconnect battery earth lead.

2.Remove air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

3.Move injector harness clear of vacuum pump.

4.Release clip and disconnect hose from vacuum

pump.

5.Remove and discard 2 bolts securing vacuum

pump.

6.Remove vacuum pump and discard 'O' ring.Refit

1.Clean vacuum pump and mating face.

2.Fit new 'O' ring to vacuum pump.

3.Rotate vacuum pump drive to align with

camshaft, fit vacuum pump and tighten new

bolts to 22 Nm (16 lbf.ft).

4.Connect hose to vacuum pump and secure with

clip.

5.Reposition injector harness.

6.Fit air cleaner element.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

7.Connect battery earth lead.

M70 1031

Page 570 of 1007

BRAKES

REPAIRS 70-21

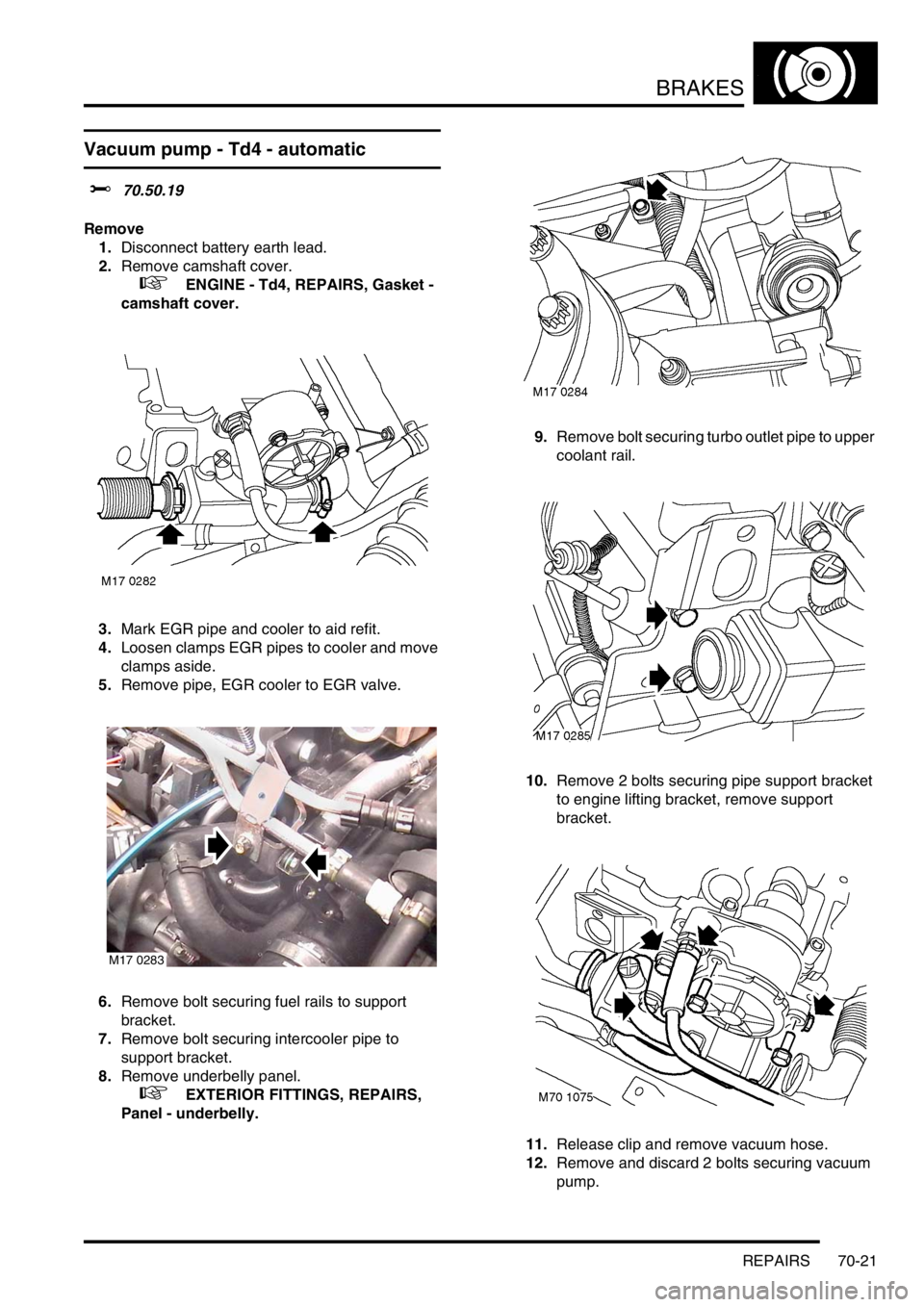

Vacuum pump - Td4 - automatic

$% 70.50.19

Remove

1.Disconnect battery earth lead.

2.Remove camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

3.Mark EGR pipe and cooler to aid refit.

4.Loosen clamps EGR pipes to cooler and move

clamps aside.

5.Remove pipe, EGR cooler to EGR valve.

6.Remove bolt securing fuel rails to support

bracket.

7.Remove bolt securing intercooler pipe to

support bracket.

8.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.9.Remove bolt securing turbo outlet pipe to upper

coolant rail.

10.Remove 2 bolts securing pipe support bracket

to engine lifting bracket, remove support

bracket.

11.Release clip and remove vacuum hose.

12.Remove and discard 2 bolts securing vacuum

pump.

M17 0283

Page 571 of 1007

BRAKES

70-22 REPAIRS

13.Remove 3 bolts securing EGR cooler to

cylinder head and lifting bracket.

14.Move EGR cooler aside for access to vacuum

pump.

15.Remove vacuum pump and discard 'O' ring.

Refit

1.Clean vacuum pump and mating face.

2.Fit new seal to vacuum pump, fit vacuum pump

and tighten new bolts to 22 Nm (16 lbf.ft).

3.Position EGR cooler to mounting, fit bolts and

tighten to 25 Nm (18 lbf.ft).

4.Position pipe support bracket to engine lifting

bracket, fit and tighten bolts to 25 Nm (18 lbf.ft).

5.Fit vacuum hose and tighten clip.

6.Fit bolt securing turbocharger pipe to coolant

rail and tighten to 25 Nm (18 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Fit bolt securing turbocharger intercooler pipe

to support bracket and tighten to 10 Nm (7.5

lbf.ft).

9.Fit bolt securing fuel rails to support bracket

and tighten to 10 Nm (7.5 lbf.ft).

10.Align EGR pipe to cooler, fit clamp but do not

fully tighten until camshaft cover is refitted.

11.Fit EGR pipe clamp and tighten screw.

12.Fit camshaft cover.

+ ENGINE - Td4, REPAIRS, Gasket -

camshaft cover.

13.Connect battery earth lead.

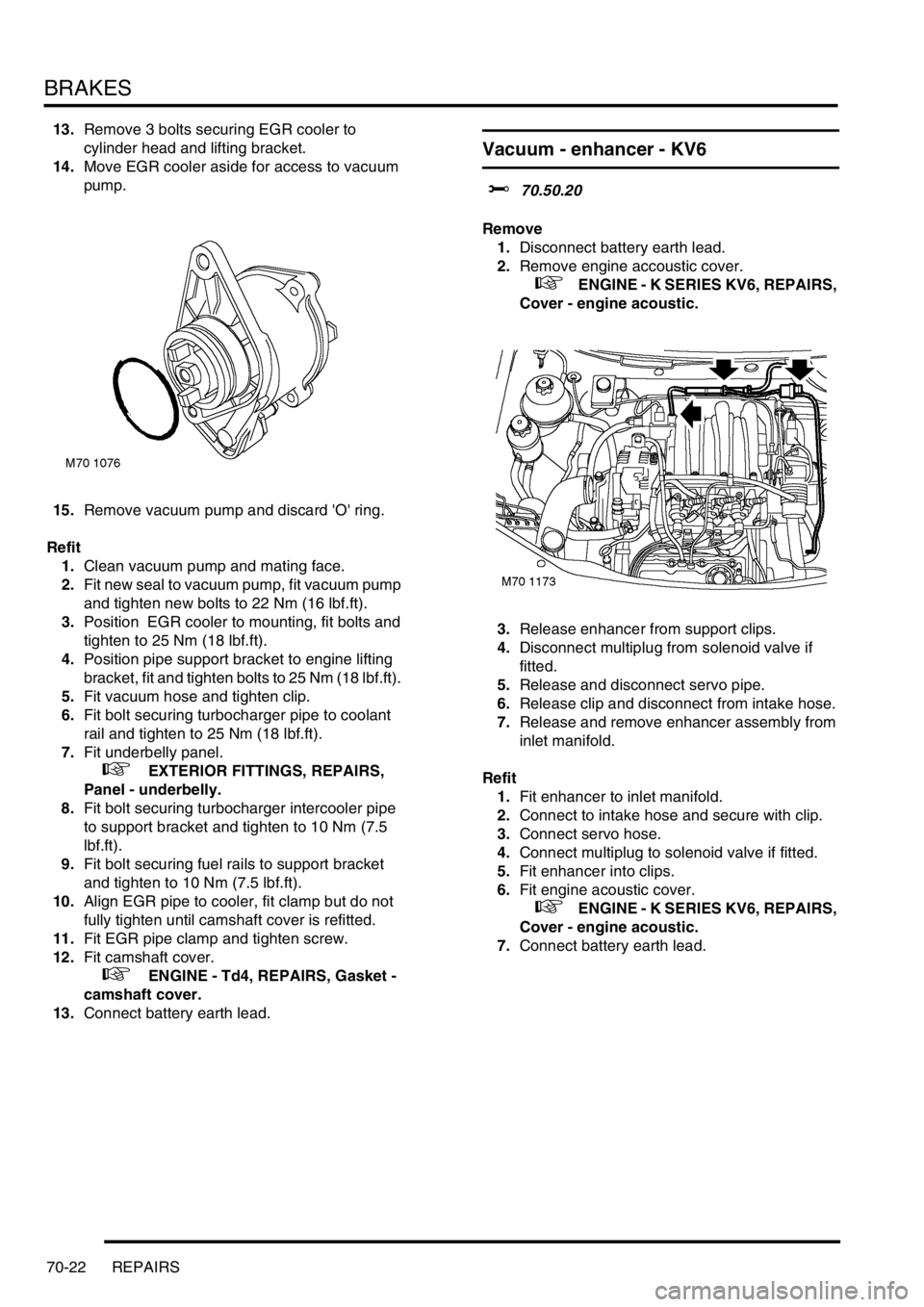

Vacuum - enhancer - KV6

$% 70.50.20

Remove

1.Disconnect battery earth lead.

2.Remove engine accoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Release enhancer from support clips.

4.Disconnect multiplug from solenoid valve if

fitted.

5.Release and disconnect servo pipe.

6.Release clip and disconnect from intake hose.

7.Release and remove enhancer assembly from

inlet manifold.

Refit

1.Fit enhancer to inlet manifold.

2.Connect to intake hose and secure with clip.

3.Connect servo hose.

4.Connect multiplug to solenoid valve if fitted.

5.Fit enhancer into clips.

6.Fit engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

7.Connect battery earth lead.

Page 572 of 1007

BRAKES

REPAIRS 70-23

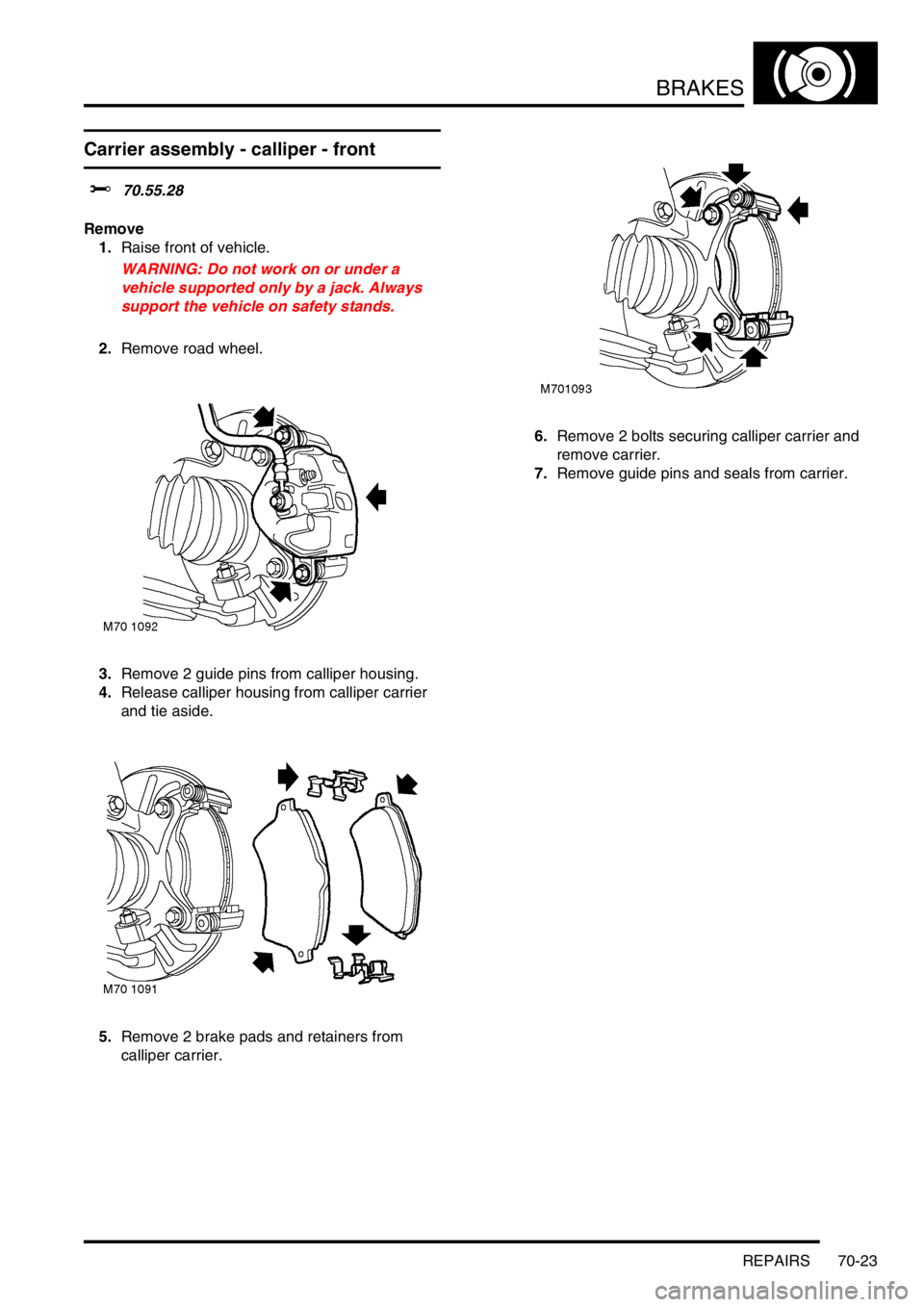

Carrier assembly - calliper - front

$% 70.55.28

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove road wheel.

3.Remove 2 guide pins from calliper housing.

4.Release calliper housing from calliper carrier

and tie aside.

5.Remove 2 brake pads and retainers from

calliper carrier.6.Remove 2 bolts securing calliper carrier and

remove carrier.

7.Remove guide pins and seals from carrier.