ECU LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 996 of 1007

DRIVER CONTROLS

REPAIRS 86-8-5

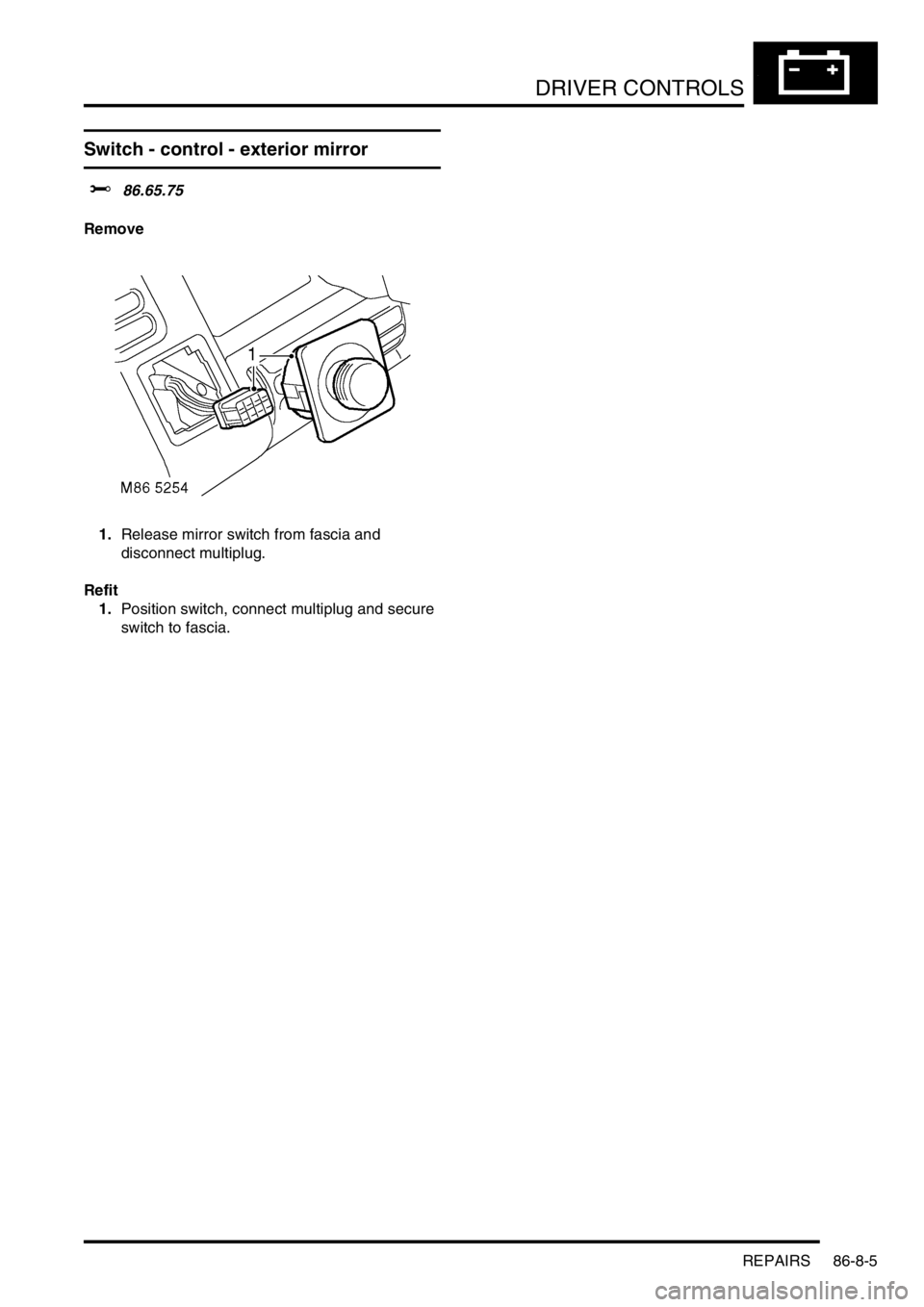

Switch - control - exterior mirror

$% 86.65.75

Remove

1.Release mirror switch from fascia and

disconnect multiplug.

Refit

1.Position switch, connect multiplug and secure

switch to fascia.

Page 998 of 1007

NAVIGATION SYSTEM

REPAIRS 87-1

NAVIGATION SYST EM REPAIRS

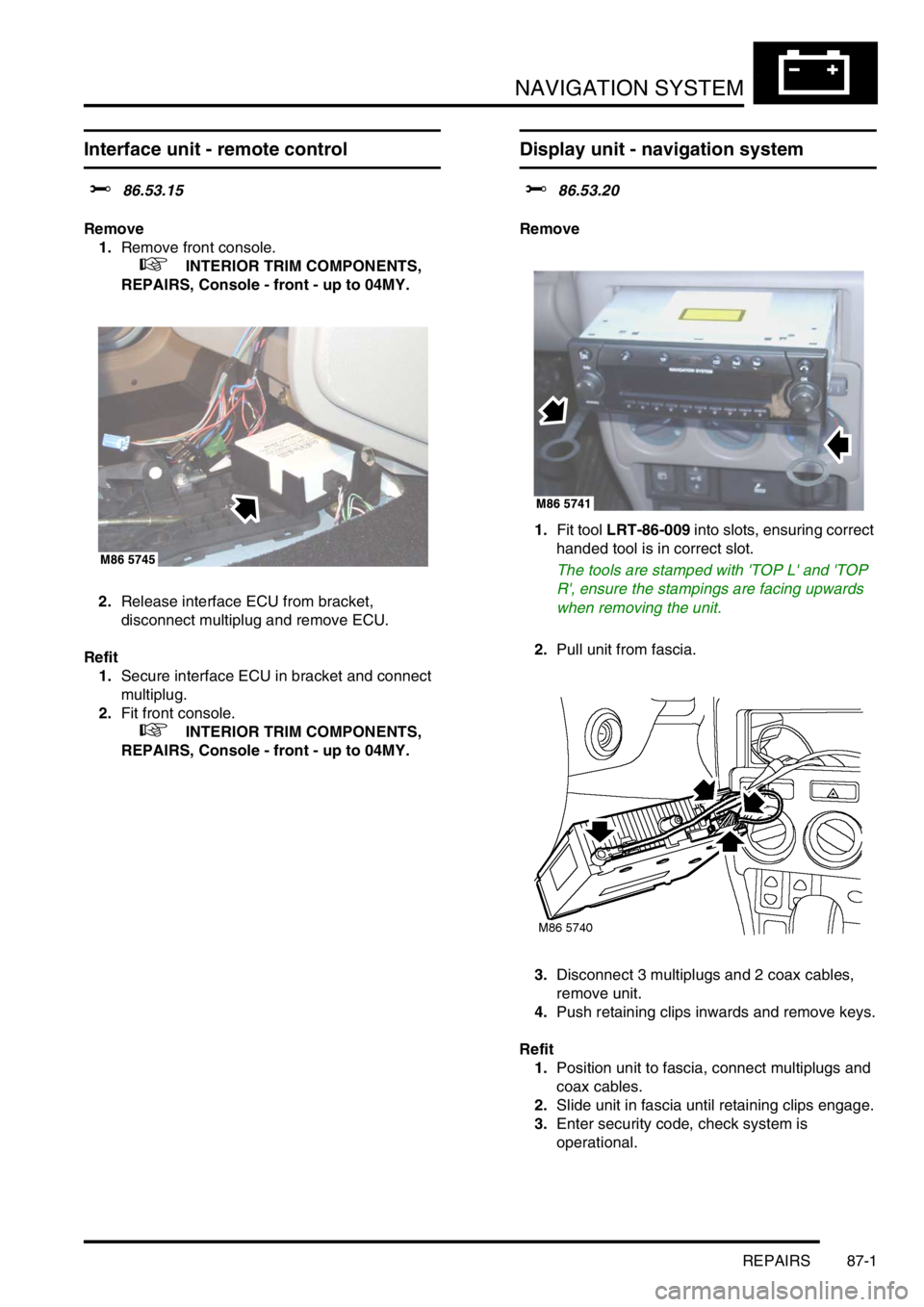

Interface unit - remote control

$% 86.53.15

Remove

1.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

2.Release interface ECU from bracket,

disconnect multiplug and remove ECU.

Refit

1.Secure interface ECU in bracket and connect

multiplug.

2.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

Display unit - navigation system

$% 86.53.20

Remove

1.Fit tool LRT-86-009 into slots, ensuring correct

handed tool is in correct slot.

The tools are stamped with 'TOP L' and 'TOP

R', ensure the stampings are facing upwards

when removing the unit.

2.Pull unit from fascia.

3.Disconnect 3 multiplugs and 2 coax cables,

remove unit.

4.Push retaining clips inwards and remove keys.

Refit

1.Position unit to fascia, connect multiplugs and

coax cables.

2.Slide unit in fascia until retaining clips engage.

3.Enter security code, check system is

operational.

M86 5745

M86 5741

Page 1000 of 1007

INSTRUMENTS

REPAIRS 88-1

INS TRUMENTS REPAIRS

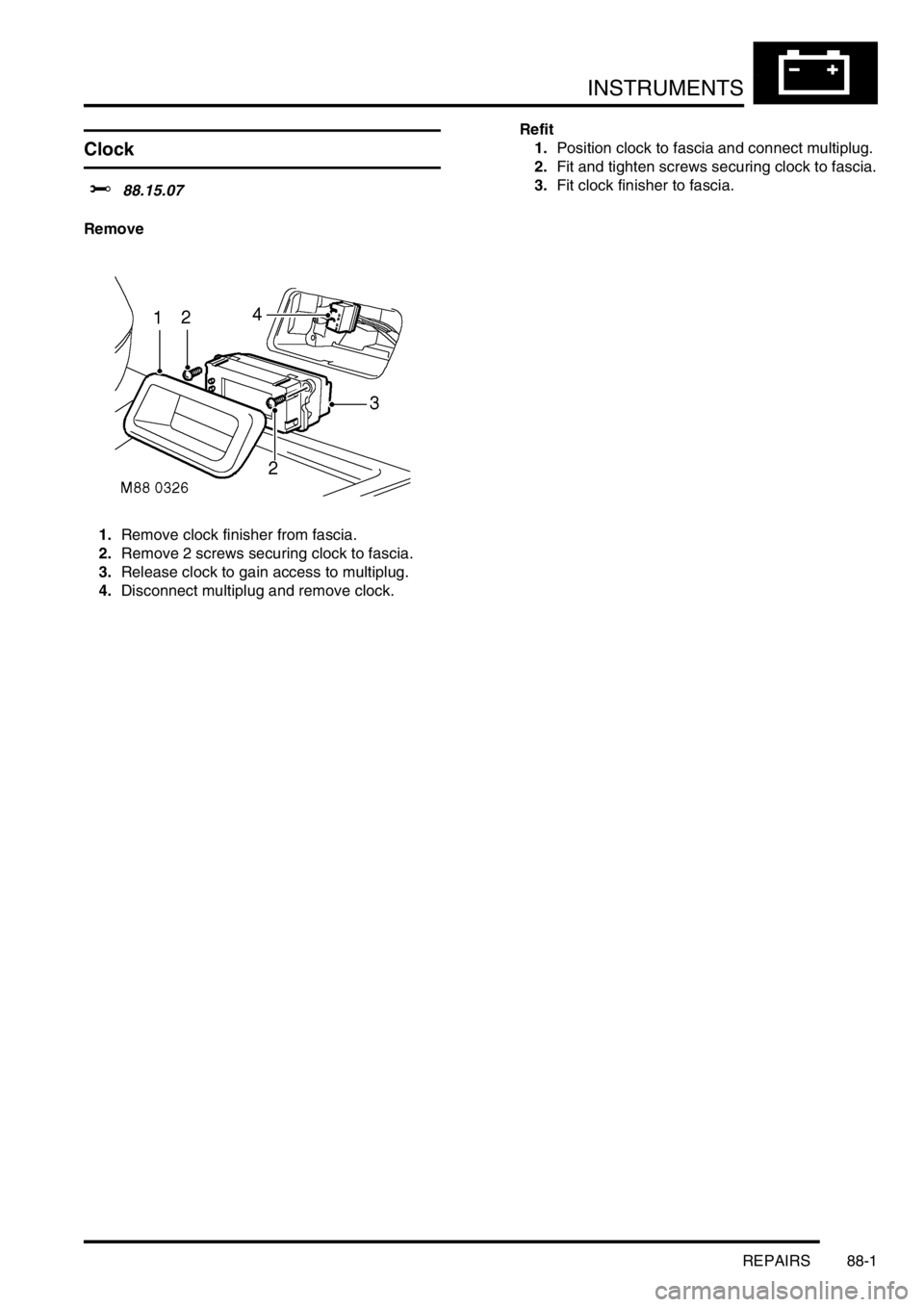

Clock

$% 88.15.07

Remove

1.Remove clock finisher from fascia.

2.Remove 2 screws securing clock to fascia.

3.Release clock to gain access to multiplug.

4.Disconnect multiplug and remove clock.Refit

1.Position clock to fascia and connect multiplug.

2.Fit and tighten screws securing clock to fascia.

3.Fit clock finisher to fascia.

Page 1001 of 1007

INSTRUMENTS

88-2 REPAIRS

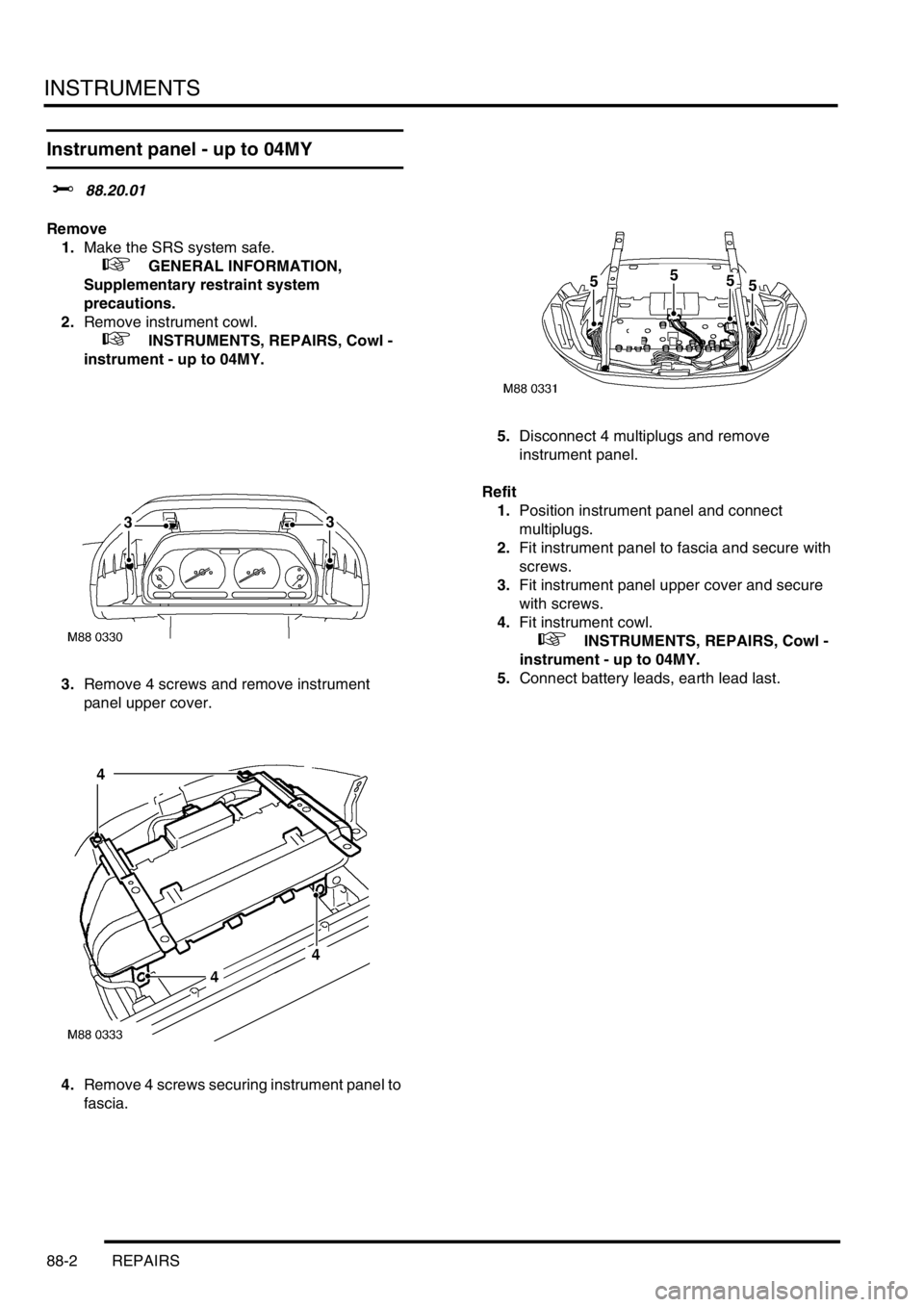

Instrument panel - up to 04MY

$% 88.20.01

Remove

1.Make the SRS system safe.

+ GENERAL INFORMATION,

Supplementary restraint system

precautions.

2.Remove instrument cowl.

+ INSTRUMENTS, REPAIRS, Cowl -

instrument - up to 04MY.

3.Remove 4 screws and remove instrument

panel upper cover.

4.Remove 4 screws securing instrument panel to

fascia.5.Disconnect 4 multiplugs and remove

instrument panel.

Refit

1.Position instrument panel and connect

multiplugs.

2.Fit instrument panel to fascia and secure with

screws.

3.Fit instrument panel upper cover and secure

with screws.

4.Fit instrument cowl.

+ INSTRUMENTS, REPAIRS, Cowl -

instrument - up to 04MY.

5.Connect battery leads, earth lead last.

Page 1002 of 1007

INSTRUMENTS

REPAIRS 88-3

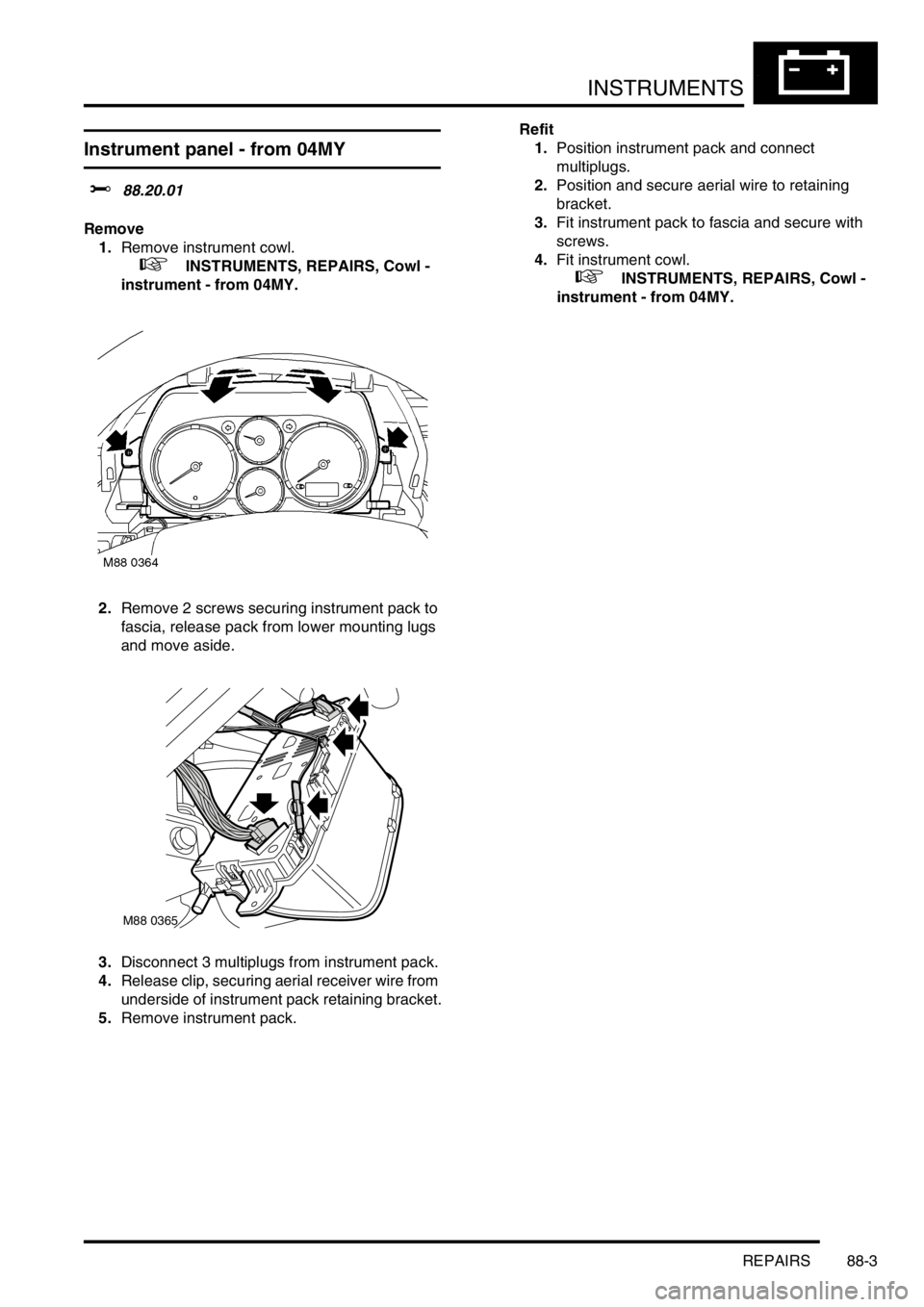

Instrument panel - from 04MY

$% 88.20.01

Remove

1.Remove instrument cowl.

+ INSTRUMENTS, REPAIRS, Cowl -

instrument - from 04MY.

2.Remove 2 screws securing instrument pack to

fascia, release pack from lower mounting lugs

and move aside.

3.Disconnect 3 multiplugs from instrument pack.

4.Release clip, securing aerial receiver wire from

underside of instrument pack retaining bracket.

5.Remove instrument pack.Refit

1.Position instrument pack and connect

multiplugs.

2.Position and secure aerial wire to retaining

bracket.

3.Fit instrument pack to fascia and secure with

screws.

4.Fit instrument cowl.

+ INSTRUMENTS, REPAIRS, Cowl -

instrument - from 04MY.

M88 0365

Page 1004 of 1007

INSTRUMENTS

REPAIRS 88-5

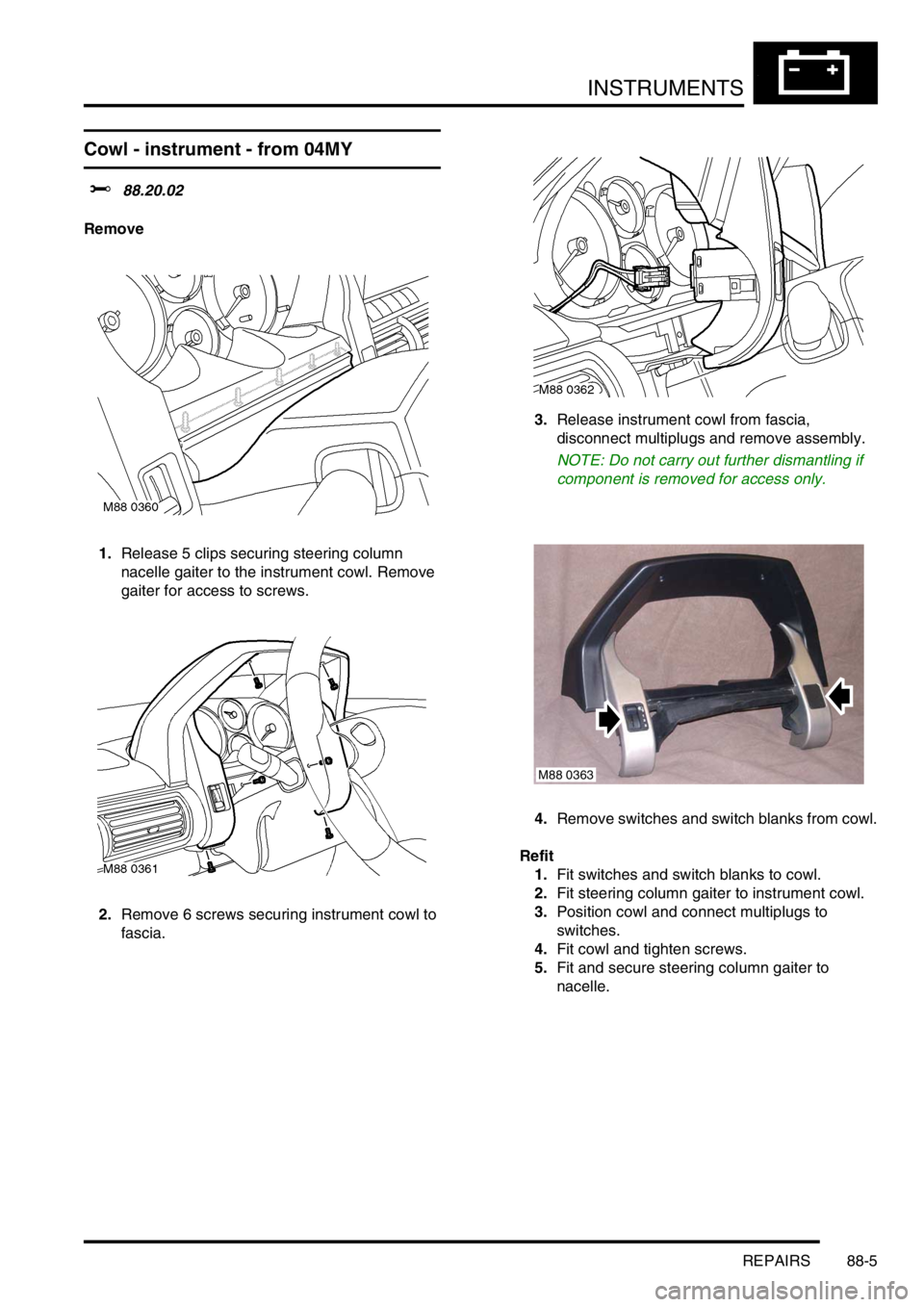

Cowl - instrument - from 04MY

$% 88.20.02

Remove

1.Release 5 clips securing steering column

nacelle gaiter to the instrument cowl. Remove

gaiter for access to screws.

2.Remove 6 screws securing instrument cowl to

fascia.3.Release instrument cowl from fascia,

disconnect multiplugs and remove assembly.

NOTE: Do not carry out further dismantling if

component is removed for access only.

4.Remove switches and switch blanks from cowl.

Refit

1.Fit switches and switch blanks to cowl.

2.Fit steering column gaiter to instrument cowl.

3.Position cowl and connect multiplugs to

switches.

4.Fit cowl and tighten screws.

5.Fit and secure steering column gaiter to

nacelle.

M88 0363

Page 1005 of 1007

INSTRUMENTS

88-6 REPAIRS

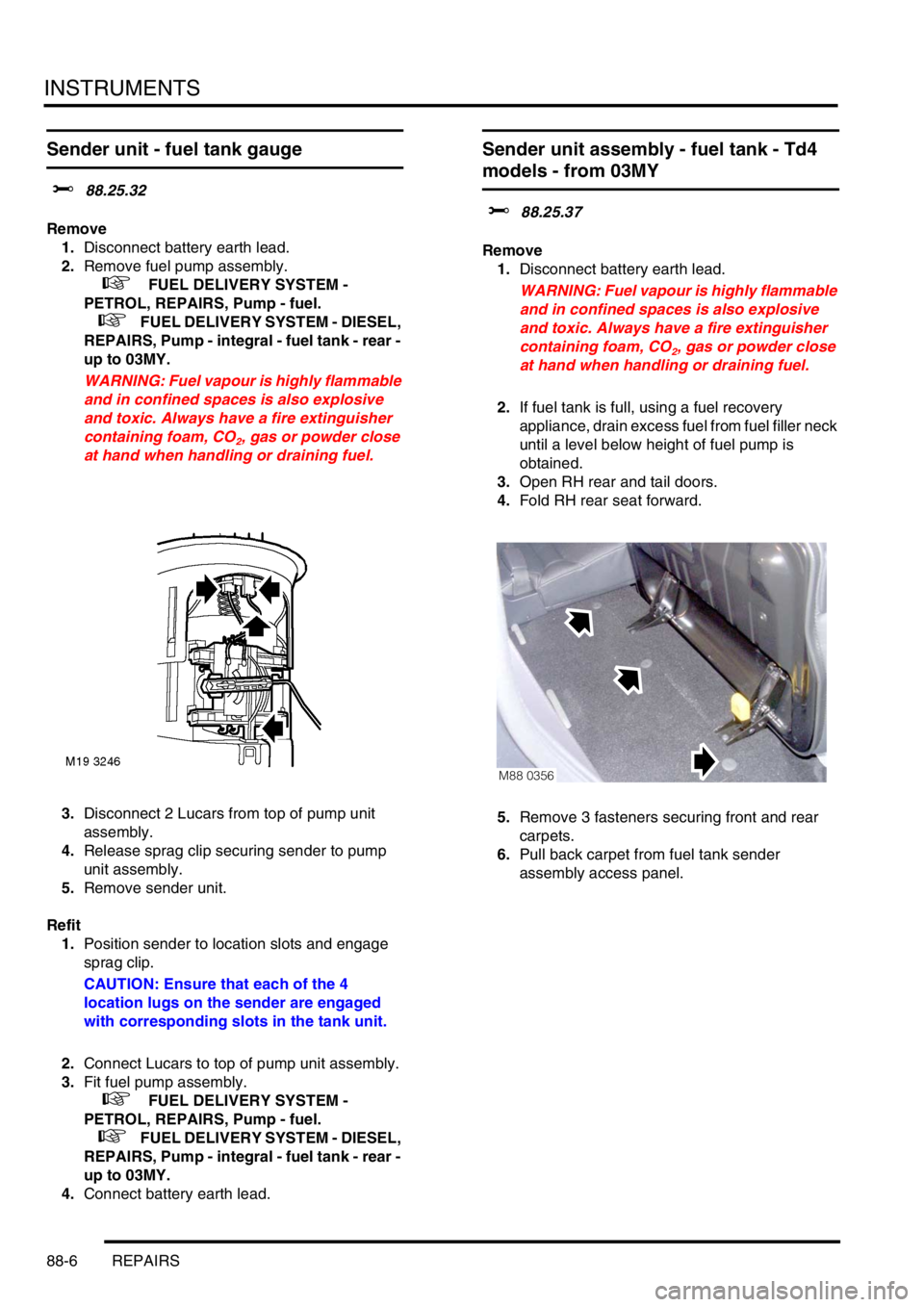

Sender unit - fuel tank gauge

$% 88.25.32

Remove

1.Disconnect battery earth lead.

2.Remove fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Pump - integral - fuel tank - rear -

up to 03MY.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

3.Disconnect 2 Lucars from top of pump unit

assembly.

4.Release sprag clip securing sender to pump

unit assembly.

5.Remove sender unit.

Refit

1.Position sender to location slots and engage

sprag clip.

CAUTION: Ensure that each of the 4

location lugs on the sender are engaged

with corresponding slots in the tank unit.

2.Connect Lucars to top of pump unit assembly.

3.Fit fuel pump assembly.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Pump - fuel.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Pump - integral - fuel tank - rear -

up to 03MY.

4.Connect battery earth lead.

Sender unit assembly - fuel tank - Td4

models - from 03MY

$% 88.25.37

Remove

1.Disconnect battery earth lead.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

2.If fuel tank is full, using a fuel recovery

appliance, drain excess fuel from fuel filler neck

until a level below height of fuel pump is

obtained.

3.Open RH rear and tail doors.

4.Fold RH rear seat forward.

5.Remove 3 fasteners securing front and rear

carpets.

6.Pull back carpet from fuel tank sender

assembly access panel.

M88 0356

Page 1006 of 1007

INSTRUMENTS

REPAIRS 88-7

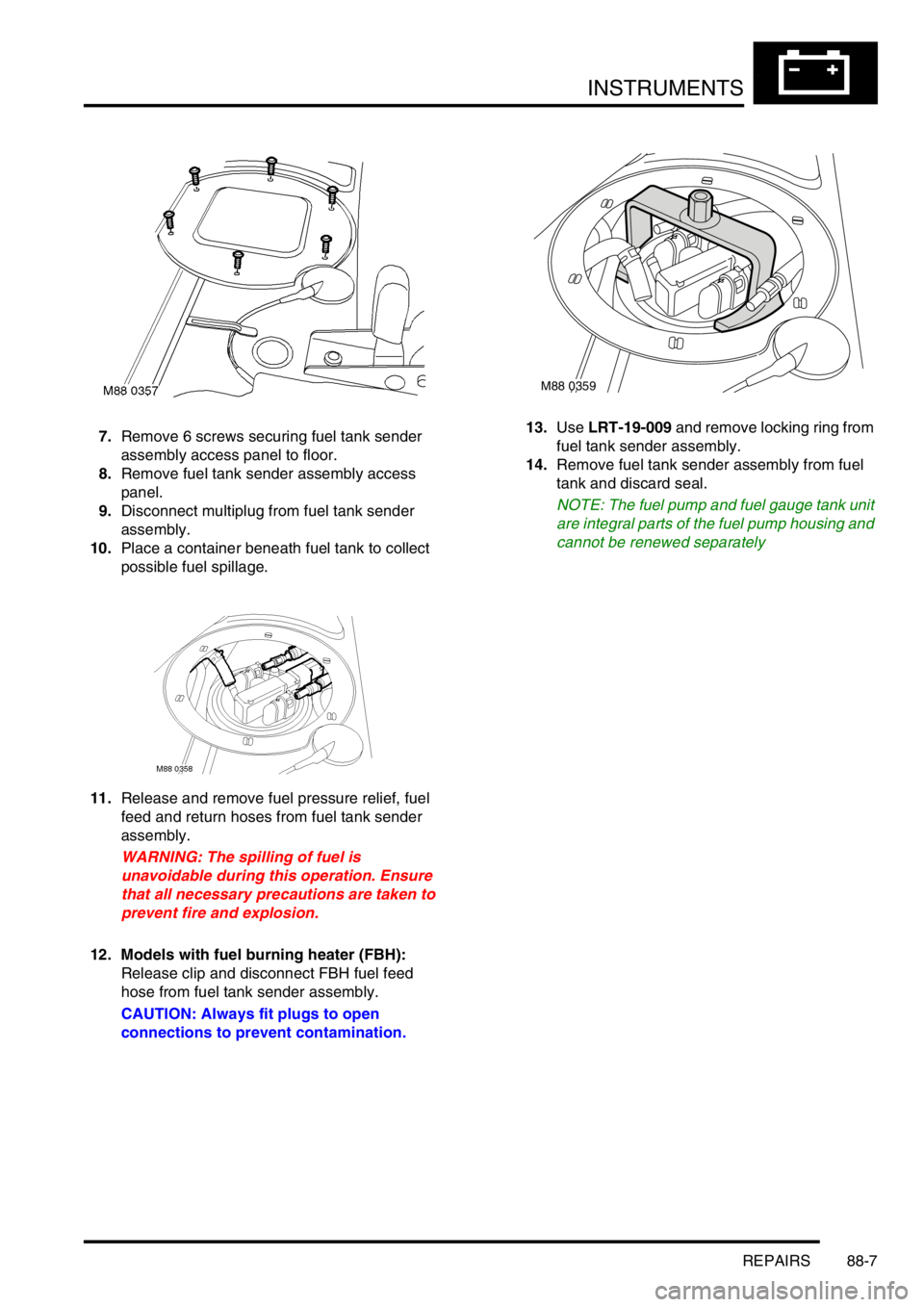

7.Remove 6 screws securing fuel tank sender

assembly access panel to floor.

8.Remove fuel tank sender assembly access

panel.

9.Disconnect multiplug from fuel tank sender

assembly.

10.Place a container beneath fuel tank to collect

possible fuel spillage.

11.Release and remove fuel pressure relief, fuel

feed and return hoses from fuel tank sender

assembly.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

12. Models with fuel burning heater (FBH):

Release clip and disconnect FBH fuel feed

hose from fuel tank sender assembly.

CAUTION: Always fit plugs to open

connections to prevent contamination.13.Use LRT-19-009 and remove locking ring from

fuel tank sender assembly.

14.Remove fuel tank sender assembly from fuel

tank and discard seal.

NOTE: The fuel pump and fuel gauge tank unit

are integral parts of the fuel pump housing and

cannot be renewed separately

M88 0359

Page 1007 of 1007

INSTRUMENTS

88-8 REPAIRS

Refit

1.Clean fuel tank sender assembly and mating

face.

2.Fit new fuel tank sender assembly seal to fuel

tank.

3.Fit fuel tank sender assembly to fuel tank.

4.Using LRT-19-009 fit and secure fuel tank

sender assembly locking ring to fuel tank.

5. Models with FBH: Connect FBH hose to fuel

tank sender assembly and secure with clip.

6.Fit and secure pressure relief, fuel feed and

return hoses to fuel tank sender assembly.

7.Remove container from beneath fuel tank.

8.Connect multiplug to fuel tank sender

assembly.

9.Fit fuel tank sender assembly access panel and

secure with screws.

10.Position carpet to floor and secure with

fasteners.

11.Reposition rear seat.

12.Close rear and tail doors.

13.Connect battery earth lead.