key LAND ROVER FREELANDER 2001 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 865 of 1007

PAINTING

77-5-2 PAINT PROCEDURES

Paint preparation

Paint refinishing

The following process must be adhered to for paint refinishing operations.

1Seal required exterior and interior seams with an approved seam sealer

+ , , .

2Repair any damage to underbody sealers

+ , , Corrosion Prevention.

3Apply a two-pack paint refinishing system

4Apply cavity wax to all interior surfaces which have not received refinish paint

Paint repairs

Before carrying out paintwork repairs, clean the vehicle thoroughly using either a steam cleaner or high-pressure

washer.

Wash locally repaired areas using a mild water-mixable detergent and wipe them clean with solvent, immediately

before paint application.

Ensure that damaged paintwork which has led to exposed metal is abraded until the metal is clean, extending beyond

the area of the original damage. Treat the bare metal with an etch phosphate to remove all traces of rust and to provide

a key for new paint coats. Re-treat the affected area using either a separate acid-etch primer and two-pack surfacer

or an integrated etch primer/filler, and follow with a two-pack paint system. Treat those surfaces not receiving paint

using an approved cavity wax, following paint operations.

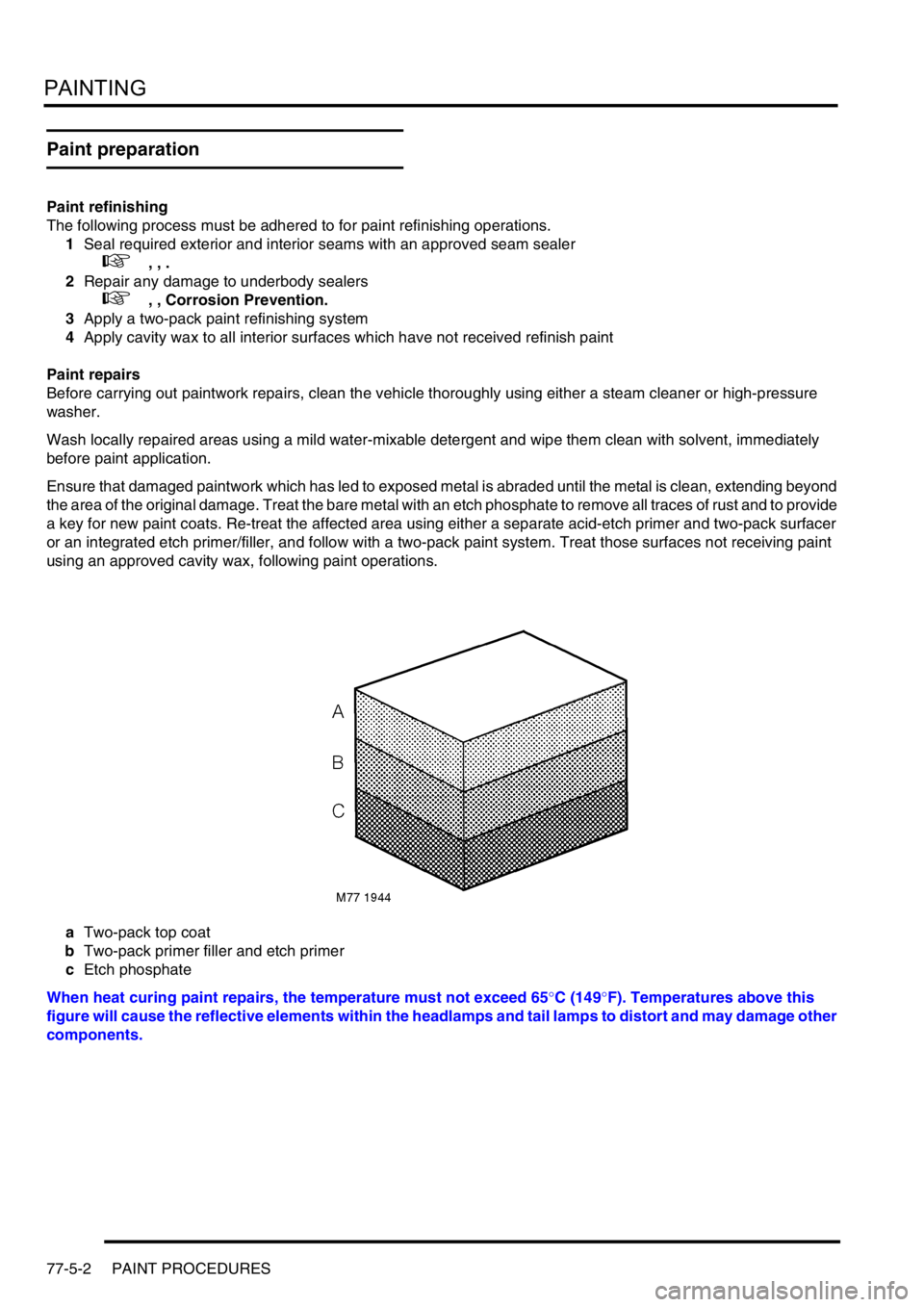

aTwo-pack top coat

bTwo-pack primer filler and etch primer

cEtch phosphate

When heat curing paint repairs, the temperature must not exceed 65°C (149°F). Temperatures above this

figure will cause the reflective elements within the headlamps and tail lamps to distort and may damage other

components.

Page 904 of 1007

AIR CONDITIONING

REPAIRS 82-17

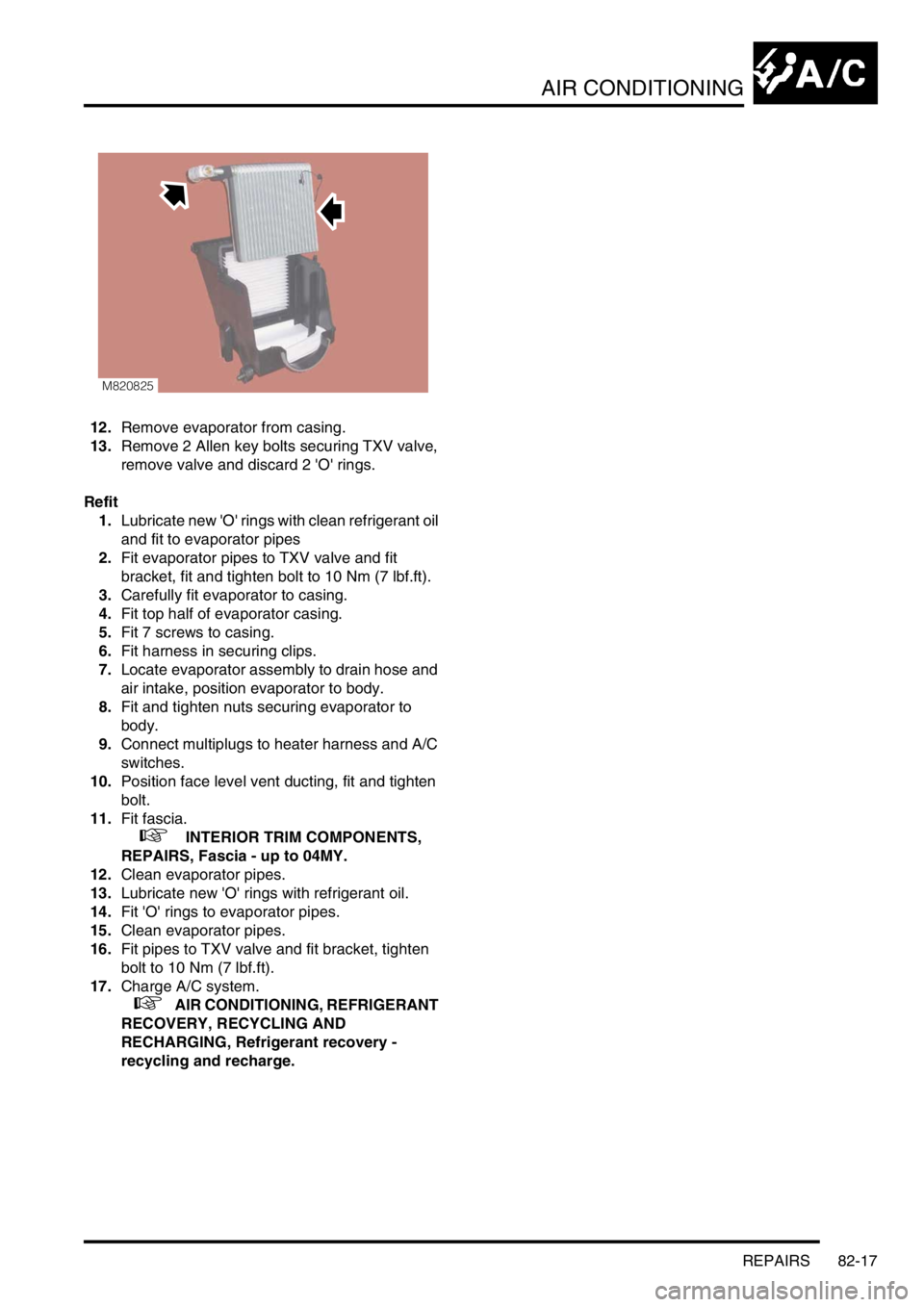

12.Remove evaporator from casing.

13.Remove 2 Allen key bolts securing TXV valve,

remove valve and discard 2 'O' rings.

Refit

1.Lubricate new 'O' rings with clean refrigerant oil

and fit to evaporator pipes

2.Fit evaporator pipes to TXV valve and fit

bracket, fit and tighten bolt to 10 Nm (7 lbf.ft).

3.Carefully fit evaporator to casing.

4.Fit top half of evaporator casing.

5.Fit 7 screws to casing.

6.Fit harness in securing clips.

7.Locate evaporator assembly to drain hose and

air intake, position evaporator to body.

8.Fit and tighten nuts securing evaporator to

body.

9.Connect multiplugs to heater harness and A/C

switches.

10.Position face level vent ducting, fit and tighten

bolt.

11.Fit fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia - up to 04MY.

12.Clean evaporator pipes.

13.Lubricate new 'O' rings with refrigerant oil.

14.Fit 'O' rings to evaporator pipes.

15.Clean evaporator pipes.

16.Fit pipes to TXV valve and fit bracket, tighten

bolt to 10 Nm (7 lbf.ft).

17.Charge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

M820825

Page 932 of 1007

LIGHTING

ADJUSTMENTS 86-2-1

LIGHTING ADJUST ME NTS

Headlamps - pair - align beam - up to

04MY

$% 86.40.17

Check

1.Align beam setting equipment to headlamp.

2.Switch on headlamps. Headlamp setting

lNon NAS models: 1.2% below horizontal

and parallel.

lNAS models: 0.4% below horizontal and

parallel.

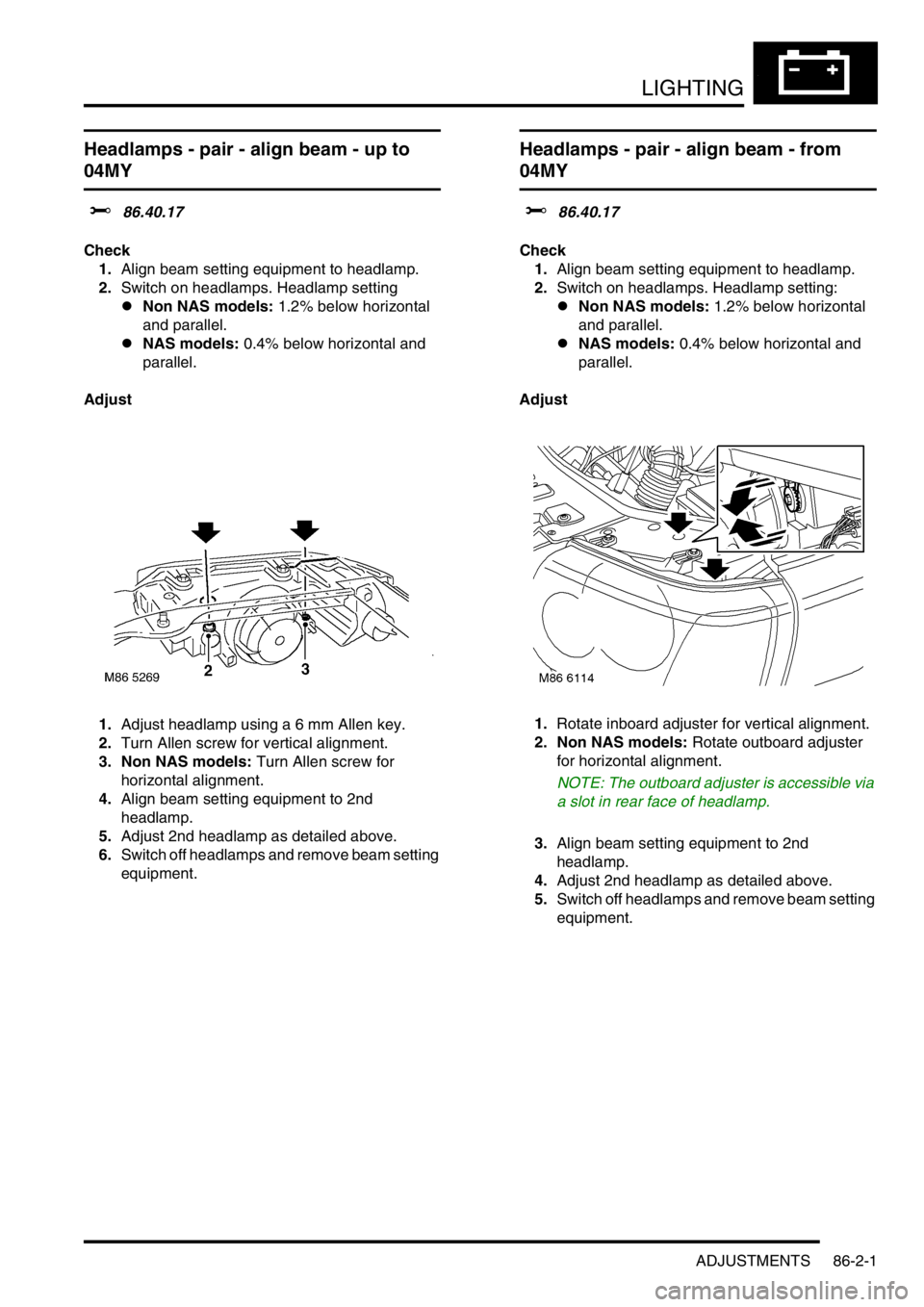

Adjust

1.Adjust headlamp using a 6 mm Allen key.

2.Turn Allen screw for vertical alignment.

3. Non NAS models: Turn Allen screw for

horizontal alignment.

4.Align beam setting equipment to 2nd

headlamp.

5.Adjust 2nd headlamp as detailed above.

6.Switch off headlamps and remove beam setting

equipment.

Headlamps - pair - align beam - from

04MY

$% 86.40.17

Check

1.Align beam setting equipment to headlamp.

2.Switch on headlamps. Headlamp setting:

lNon NAS models: 1.2% below horizontal

and parallel.

lNAS models: 0.4% below horizontal and

parallel.

Adjust

1.Rotate inboard adjuster for vertical alignment.

2. Non NAS models: Rotate outboard adjuster

for horizontal alignment.

NOTE: The outboard adjuster is accessible via

a slot in rear face of headlamp.

3.Align beam setting equipment to 2nd

headlamp.

4.Adjust 2nd headlamp as detailed above.

5.Switch off headlamps and remove beam setting

equipment.

Page 964 of 1007

IN CAR ENTERTAINMENT

REPAIRS 86-6-1

IN CAR ENTERTA INMENT REPAIRS

Radio - up to 04MY

$% 86.50.03

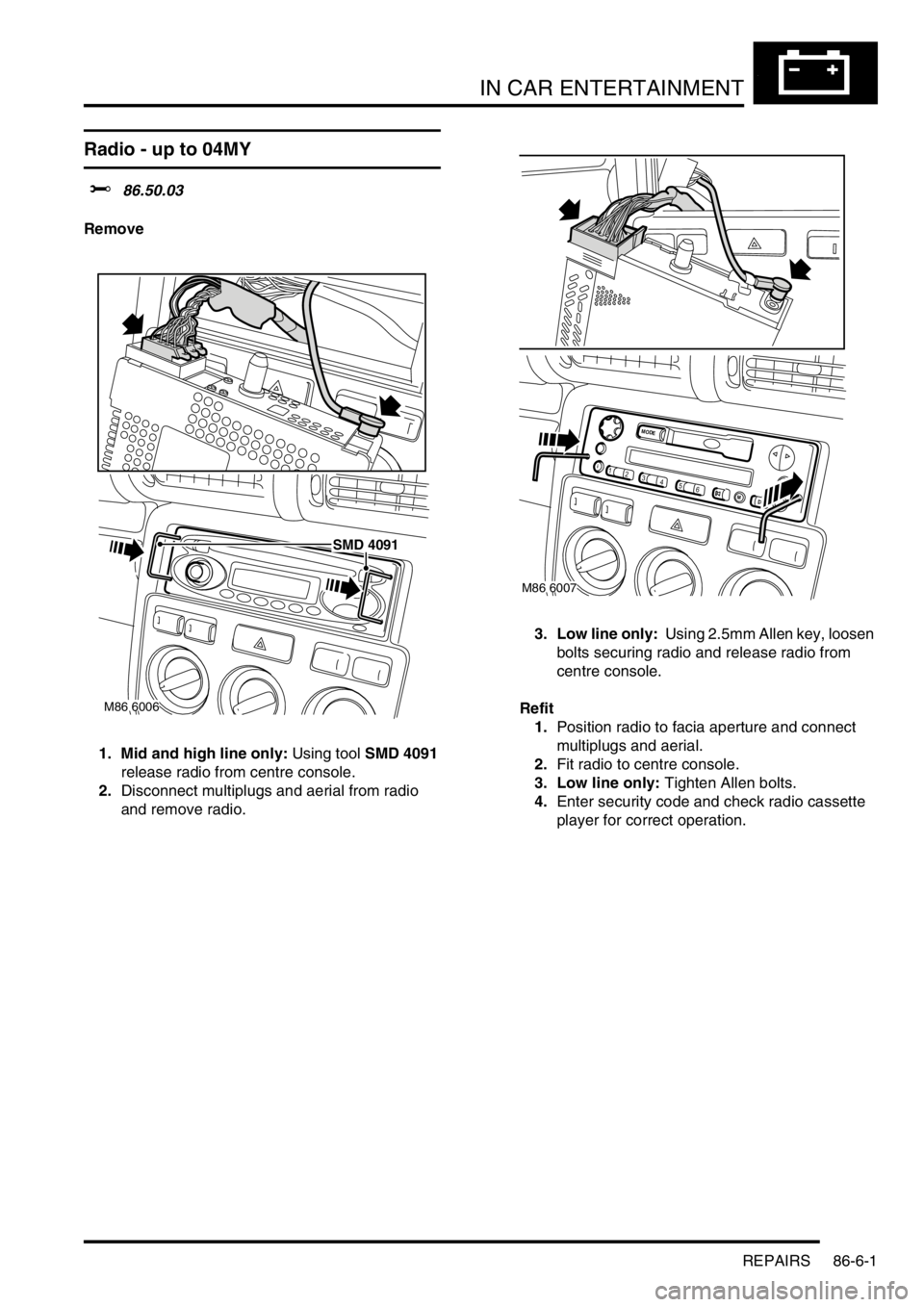

Remove

1. Mid and high line only: Using tool SMD 4091

release radio from centre console.

2.Disconnect multiplugs and aerial from radio

and remove radio.3. Low line only: Using 2.5mm Allen key, loosen

bolts securing radio and release radio from

centre console.

Refit

1.Position radio to facia aperture and connect

multiplugs and aerial.

2.Fit radio to centre console.

3. Low line only: Tighten Allen bolts.

4.Enter security code and check radio cassette

player for correct operation.

M86 6006

SMD 4091

1

23

4

5

6FM

i

M

MODE

M86 6007

Page 998 of 1007

NAVIGATION SYSTEM

REPAIRS 87-1

NAVIGATION SYST EM REPAIRS

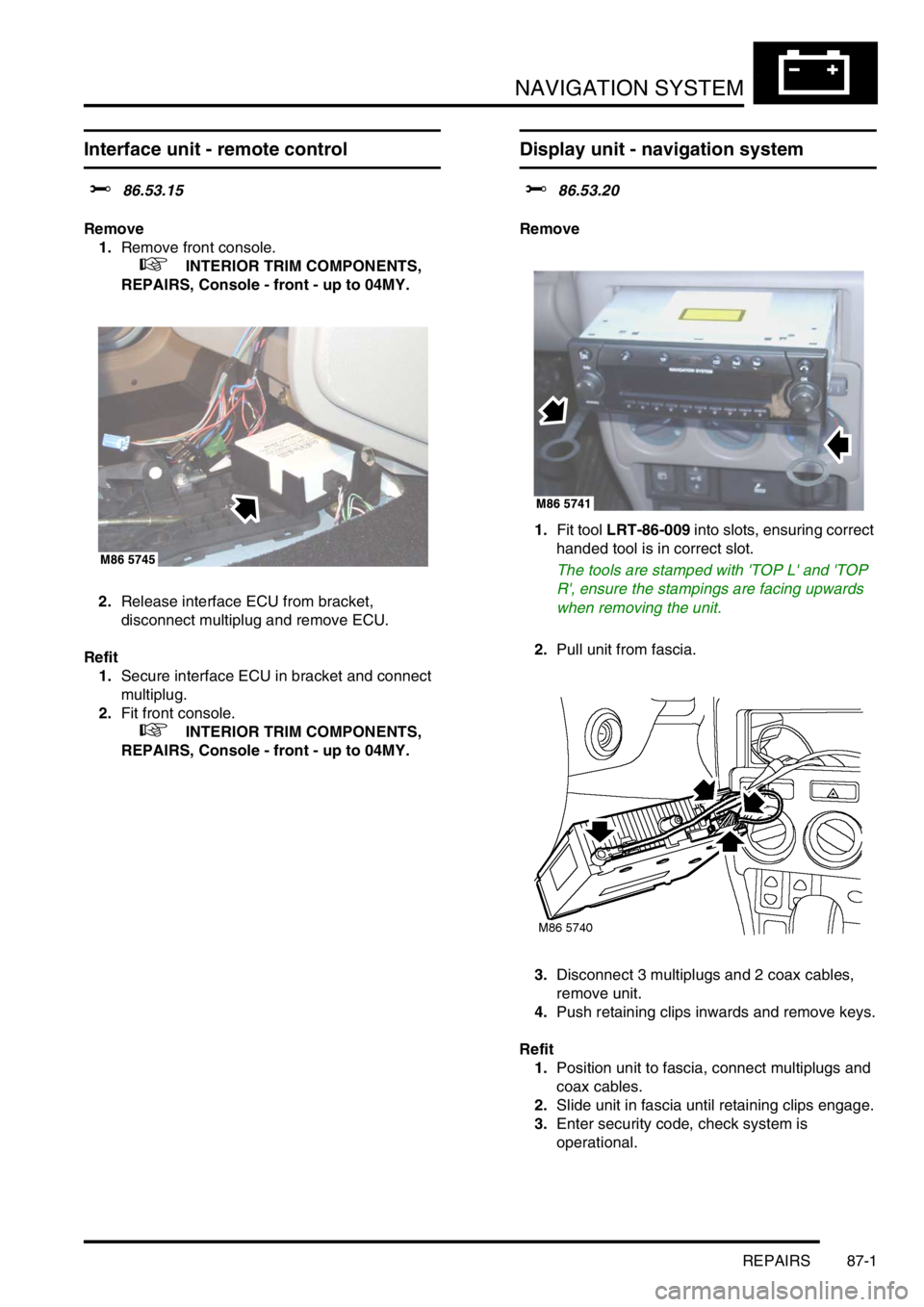

Interface unit - remote control

$% 86.53.15

Remove

1.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

2.Release interface ECU from bracket,

disconnect multiplug and remove ECU.

Refit

1.Secure interface ECU in bracket and connect

multiplug.

2.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

Display unit - navigation system

$% 86.53.20

Remove

1.Fit tool LRT-86-009 into slots, ensuring correct

handed tool is in correct slot.

The tools are stamped with 'TOP L' and 'TOP

R', ensure the stampings are facing upwards

when removing the unit.

2.Pull unit from fascia.

3.Disconnect 3 multiplugs and 2 coax cables,

remove unit.

4.Push retaining clips inwards and remove keys.

Refit

1.Position unit to fascia, connect multiplugs and

coax cables.

2.Slide unit in fascia until retaining clips engage.

3.Enter security code, check system is

operational.

M86 5745

M86 5741