key LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 241 of 1007

ENGINE - K SERIES KV6

12-3-64 REPAIRS

Refit

NOTE: Following front or rear timing belt

refitment, it is possible that, after rotating the

engine and positioning the crankshaft pulley to

the 'SAFE' position, the timing marks on the

rear timing gears may be misaligned. This

misalignment is acceptable provided that the

timing belt refitting procedure was carried out

correctly.

1.Clean camshaft gears and hubs, crankshaft

gear, tensioner and water pump pulleys.

CAUTION: If the sintered gears have been

subjected to prolonged oil contamination,

they must be soaked in a solvent bath and

then thoroughly washed in clean solvent

before refitting. Because of the porous

construction of sintered material, oil

impregnated in the gears will emerge and

contaminate the belt.

2.Fit hubs to camshaft gears and fit gears to

camshafts. Fit new bolts and tighten sufficiently

to allow gears to rotate without tipping.

3.Position timing belt to crankshaft gear.

NOTE: To prevent the timing belt from

disengaging from the crankshaft gear when

fitting, fit a suitable wedge between the belt and

oil pump belt guard.

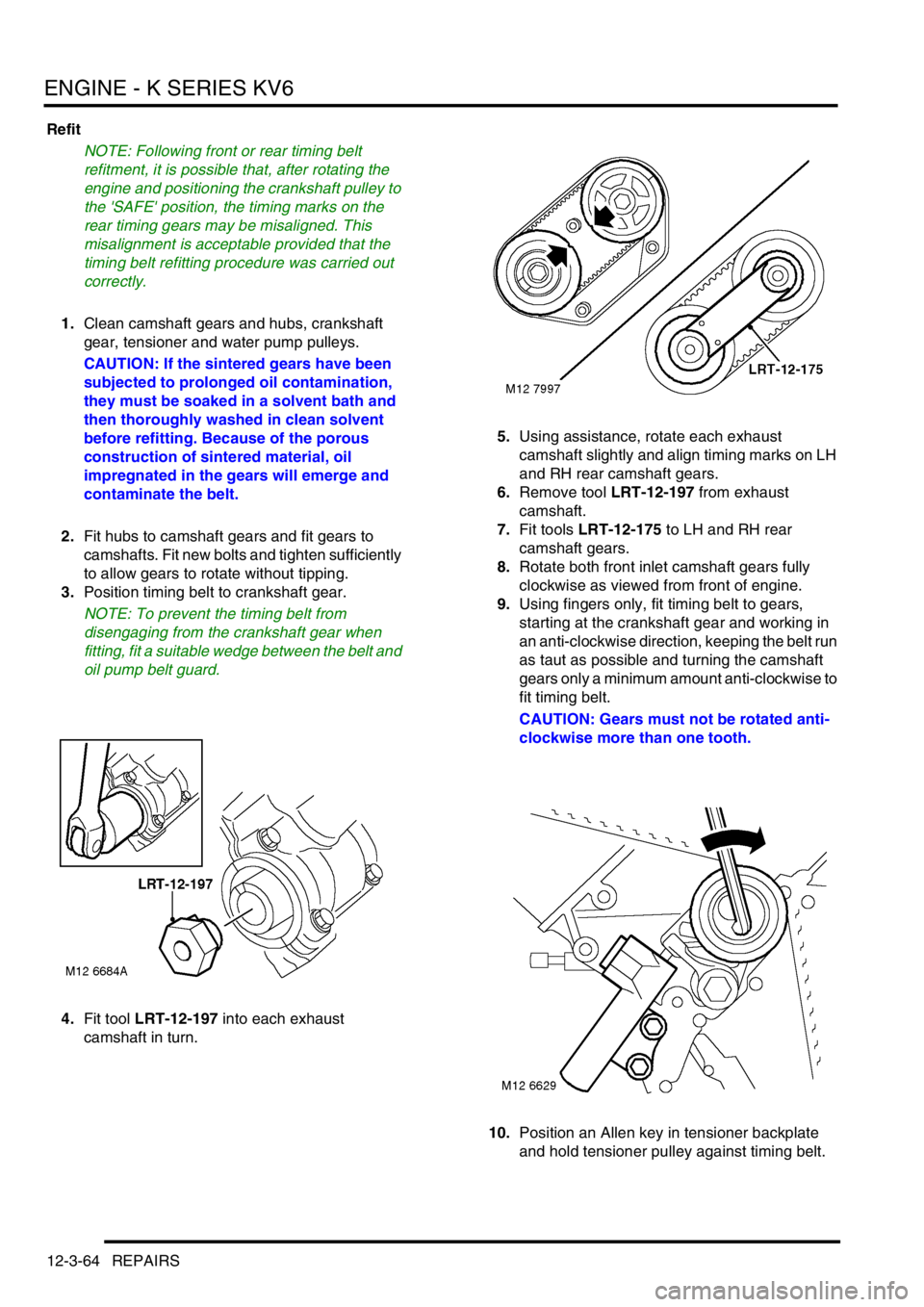

4.Fit tool LRT-12-197 into each exhaust

camshaft in turn.5.Using assistance, rotate each exhaust

camshaft slightly and align timing marks on LH

and RH rear camshaft gears.

6.Remove tool LRT-12-197 from exhaust

camshaft.

7.Fit tools LRT-12-175 to LH and RH rear

camshaft gears.

8.Rotate both front inlet camshaft gears fully

clockwise as viewed from front of engine.

9.Using fingers only, fit timing belt to gears,

starting at the crankshaft gear and working in

an anti-clockwise direction, keeping the belt run

as taut as possible and turning the camshaft

gears only a minimum amount anti-clockwise to

fit timing belt.

CAUTION: Gears must not be rotated anti-

clockwise more than one tooth.

10.Position an Allen key in tensioner backplate

and hold tensioner pulley against timing belt.

Page 290 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-113

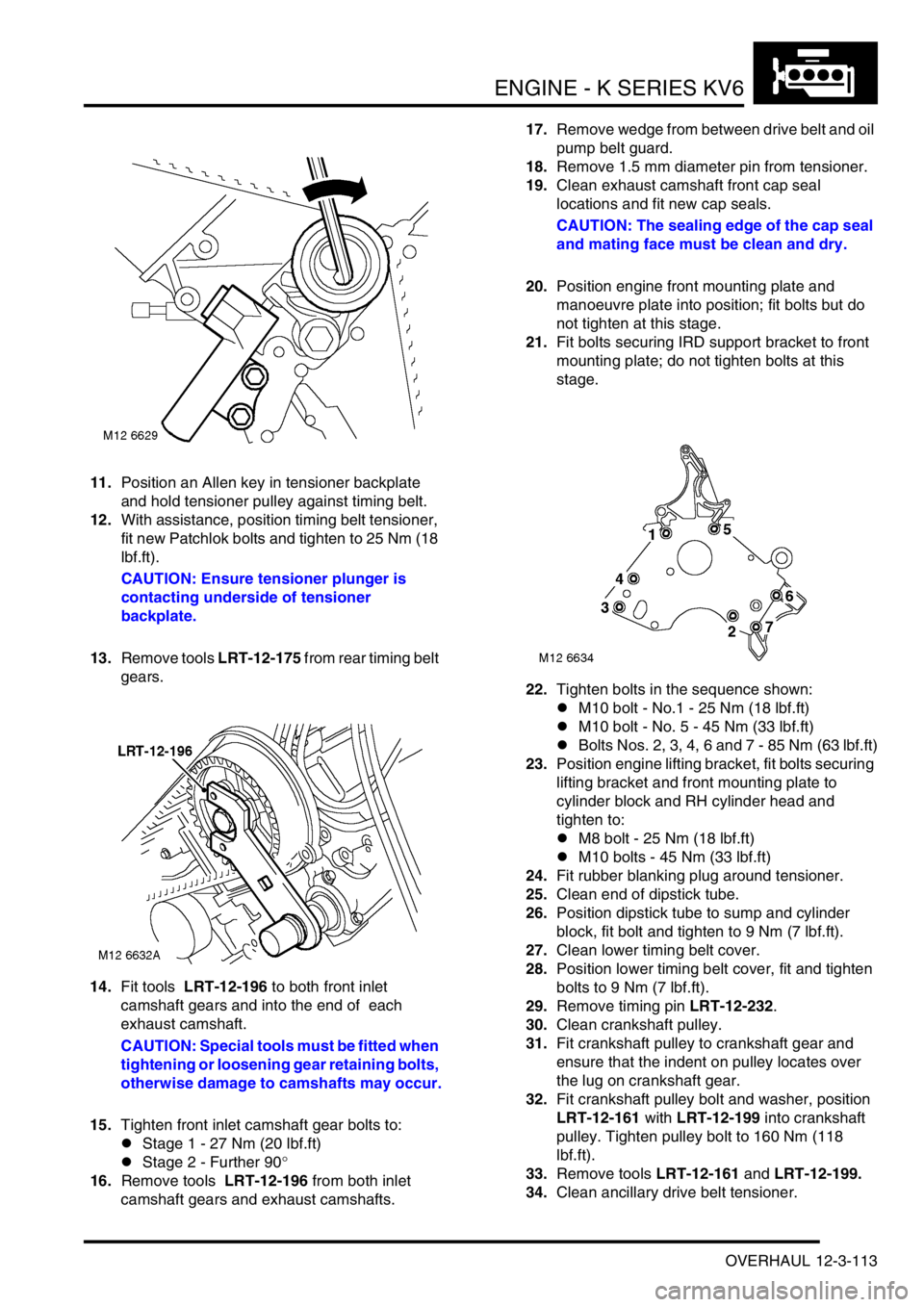

11.Position an Allen key in tensioner backplate

and hold tensioner pulley against timing belt.

12.With assistance, position timing belt tensioner,

fit new Patchlok bolts and tighten to 25 Nm (18

lbf.ft).

CAUTION: Ensure tensioner plunger is

contacting underside of tensioner

backplate.

13.Remove tools LRT-12-175 from rear timing belt

gears.

14.Fit tools LRT-12-196 to both front inlet

camshaft gears and into the end of each

exhaust camshaft.

CAUTION: Special tools must be fitted when

tightening or loosening gear retaining bolts,

otherwise damage to camshafts may occur.

15.Tighten front inlet camshaft gear bolts to:

lStage 1 - 27 Nm (20 lbf.ft)

lStage 2 - Further 90°

16.Remove tools LRT-12-196 from both inlet

camshaft gears and exhaust camshafts.17.Remove wedge from between drive belt and oil

pump belt guard.

18.Remove 1.5 mm diameter pin from tensioner.

19.Clean exhaust camshaft front cap seal

locations and fit new cap seals.

CAUTION: The sealing edge of the cap seal

and mating face must be clean and dry.

20.Position engine front mounting plate and

manoeuvre plate into position; fit bolts but do

not tighten at this stage.

21.Fit bolts securing IRD support bracket to front

mounting plate; do not tighten bolts at this

stage.

22.Tighten bolts in the sequence shown:

lM10 bolt - No.1 - 25 Nm (18 lbf.ft)

lM10 bolt - No. 5 - 45 Nm (33 lbf.ft)

lBolts Nos. 2, 3, 4, 6 and 7 - 85 Nm (63 lbf.ft)

23.Position engine lifting bracket, fit bolts securing

lifting bracket and front mounting plate to

cylinder block and RH cylinder head and

tighten to:

lM8 bolt - 25 Nm (18 lbf.ft)

lM10 bolts - 45 Nm (33 lbf.ft)

24.Fit rubber blanking plug around tensioner.

25.Clean end of dipstick tube.

26.Position dipstick tube to sump and cylinder

block, fit bolt and tighten to 9 Nm (7 lbf.ft).

27.Clean lower timing belt cover.

28.Position lower timing belt cover, fit and tighten

bolts to 9 Nm (7 lbf.ft).

29.Remove timing pin LRT-12-232.

30.Clean crankshaft pulley.

31.Fit crankshaft pulley to crankshaft gear and

ensure that the indent on pulley locates over

the lug on crankshaft gear.

32.Fit crankshaft pulley bolt and washer, position

LRT-12-161 with LRT-12-199 into crankshaft

pulley. Tighten pulley bolt to 160 Nm (118

lbf.ft).

33.Remove tools LRT-12-161 and LRT-12-199.

34.Clean ancillary drive belt tensioner.

Page 440 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-5

REPAIRS

Selector housing

$% 44.15.04

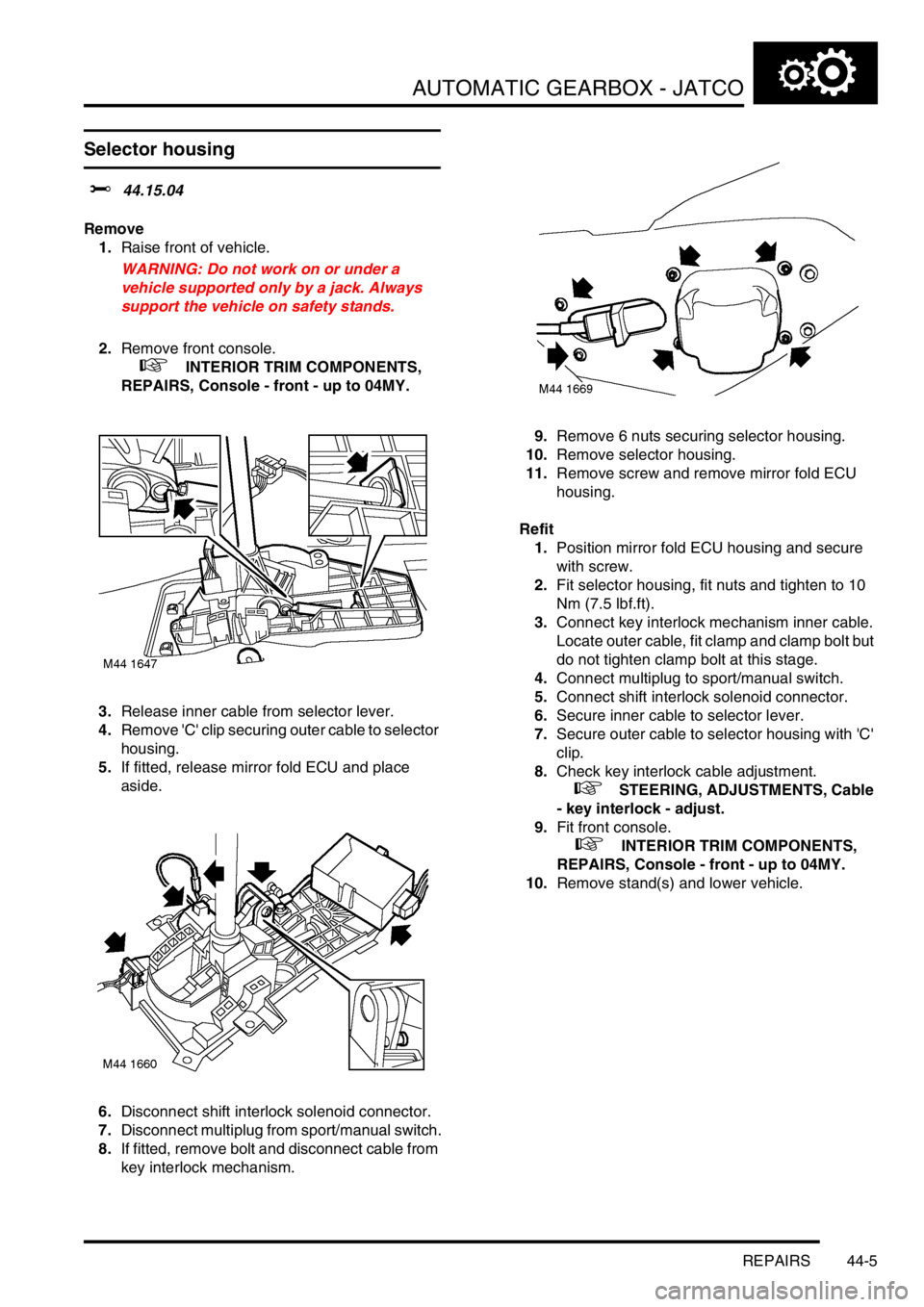

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

3.Release inner cable from selector lever.

4.Remove 'C' clip securing outer cable to selector

housing.

5.If fitted, release mirror fold ECU and place

aside.

6.Disconnect shift interlock solenoid connector.

7.Disconnect multiplug from sport/manual switch.

8.If fitted, remove bolt and disconnect cable from

key interlock mechanism.9.Remove 6 nuts securing selector housing.

10.Remove selector housing.

11.Remove screw and remove mirror fold ECU

housing.

Refit

1.Position mirror fold ECU housing and secure

with screw.

2.Fit selector housing, fit nuts and tighten to 10

Nm (7.5 lbf.ft).

3.Connect key interlock mechanism inner cable.

Locate outer cable, fit clamp and clamp bolt but

do not tighten clamp bolt at this stage.

4.Connect multiplug to sport/manual switch.

5.Connect shift interlock solenoid connector.

6.Secure inner cable to selector lever.

7.Secure outer cable to selector housing with 'C'

clip.

8.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

9.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

10.Remove stand(s) and lower vehicle.

Page 494 of 1007

STEERING

ADJUSTMENTS 57-1

STEERING ADJUST ME NTS

Power assisted steering (PAS) system -

bleed

$% 57.15.02

Check

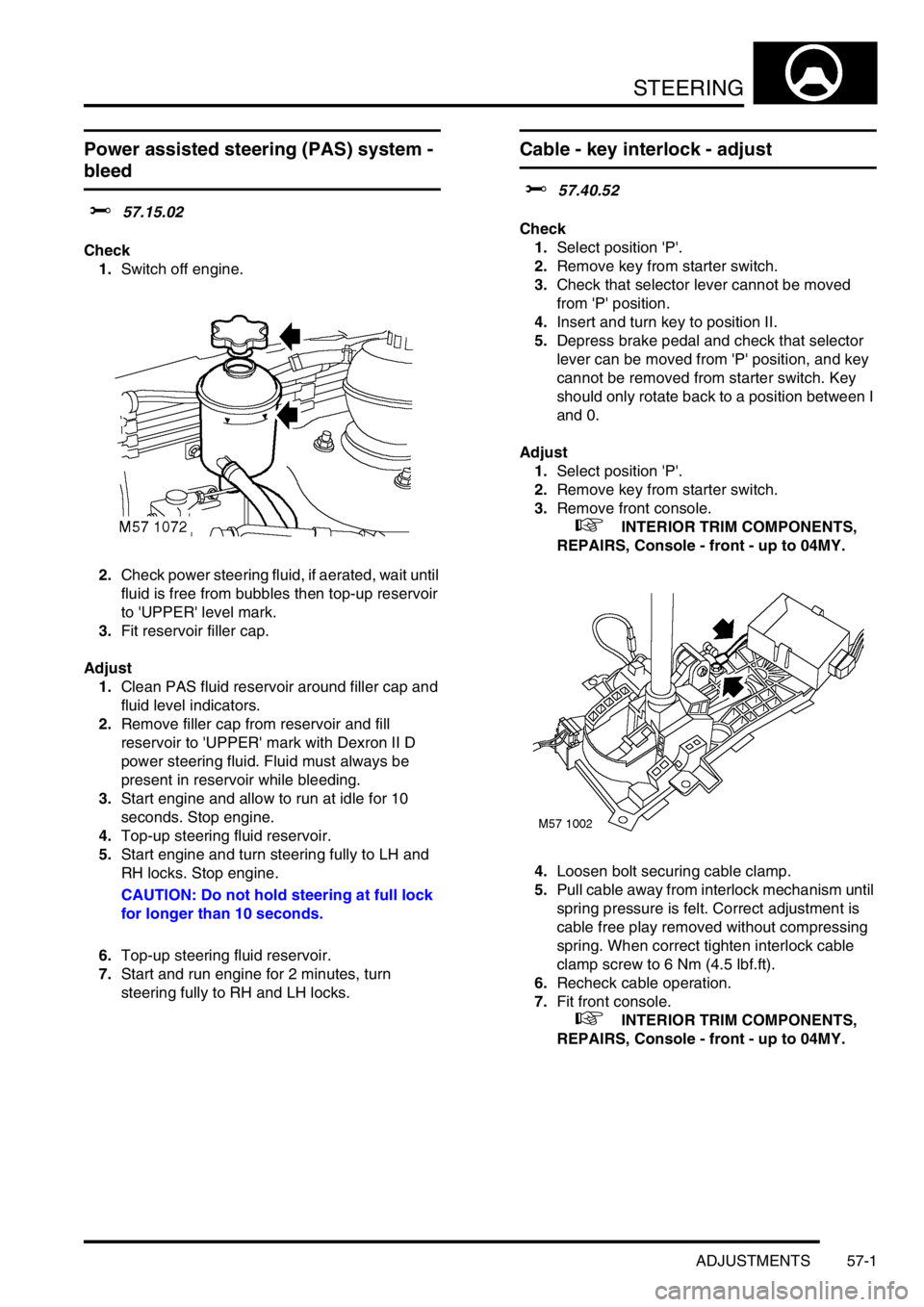

1.Switch off engine.

2.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

3.Fit reservoir filler cap.

Adjust

1.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

2.Remove filler cap from reservoir and fill

reservoir to 'UPPER' mark with Dexron II D

power steering fluid. Fluid must always be

present in reservoir while bleeding.

3.Start engine and allow to run at idle for 10

seconds. Stop engine.

4.Top-up steering fluid reservoir.

5.Start engine and turn steering fully to LH and

RH locks. Stop engine.

CAUTION: Do not hold steering at full lock

for longer than 10 seconds.

6.Top-up steering fluid reservoir.

7.Start and run engine for 2 minutes, turn

steering fully to RH and LH locks.

Cable - key interlock - adjust

$% 57.40.52

Check

1.Select position 'P'.

2.Remove key from starter switch.

3.Check that selector lever cannot be moved

from 'P' position.

4.Insert and turn key to position II.

5.Depress brake pedal and check that selector

lever can be moved from 'P' position, and key

cannot be removed from starter switch. Key

should only rotate back to a position between I

and 0.

Adjust

1.Select position 'P'.

2.Remove key from starter switch.

3.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

4.Loosen bolt securing cable clamp.

5.Pull cable away from interlock mechanism until

spring pressure is felt. Correct adjustment is

cable free play removed without compressing

spring. When correct tighten interlock cable

clamp screw to 6 Nm (4.5 lbf.ft).

6.Recheck cable operation.

7.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

Page 509 of 1007

STEERING

57-16 REPAIRS

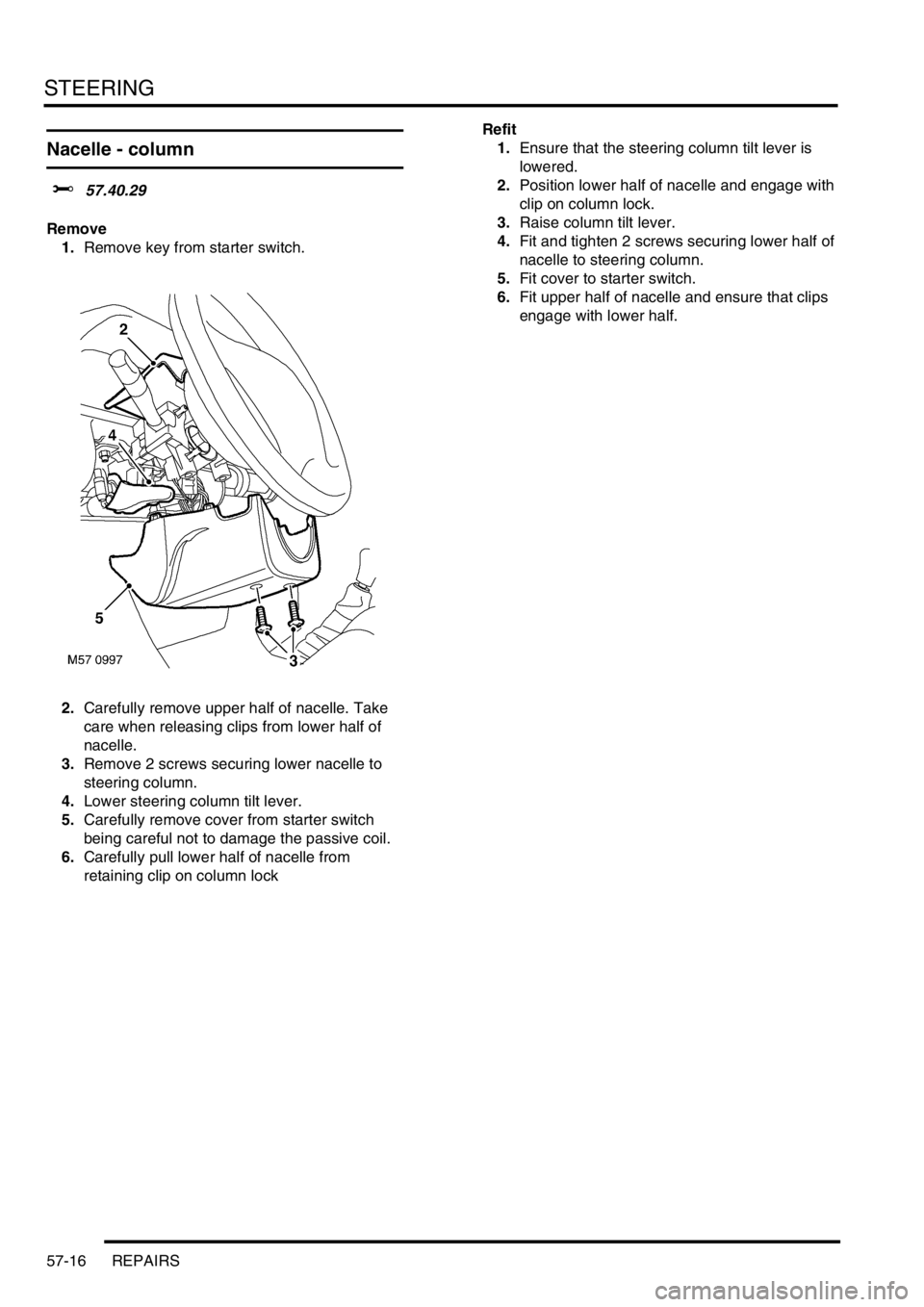

Nacelle - column

$% 57.40.29

Remove

1.Remove key from starter switch.

2.Carefully remove upper half of nacelle. Take

care when releasing clips from lower half of

nacelle.

3.Remove 2 screws securing lower nacelle to

steering column.

4.Lower steering column tilt lever.

5.Carefully remove cover from starter switch

being careful not to damage the passive coil.

6.Carefully pull lower half of nacelle from

retaining clip on column lockRefit

1.Ensure that the steering column tilt lever is

lowered.

2.Position lower half of nacelle and engage with

clip on column lock.

3.Raise column tilt lever.

4.Fit and tighten 2 screws securing lower half of

nacelle to steering column.

5.Fit cover to starter switch.

6.Fit upper half of nacelle and ensure that clips

engage with lower half.

Page 510 of 1007

STEERING

REPAIRS 57-17

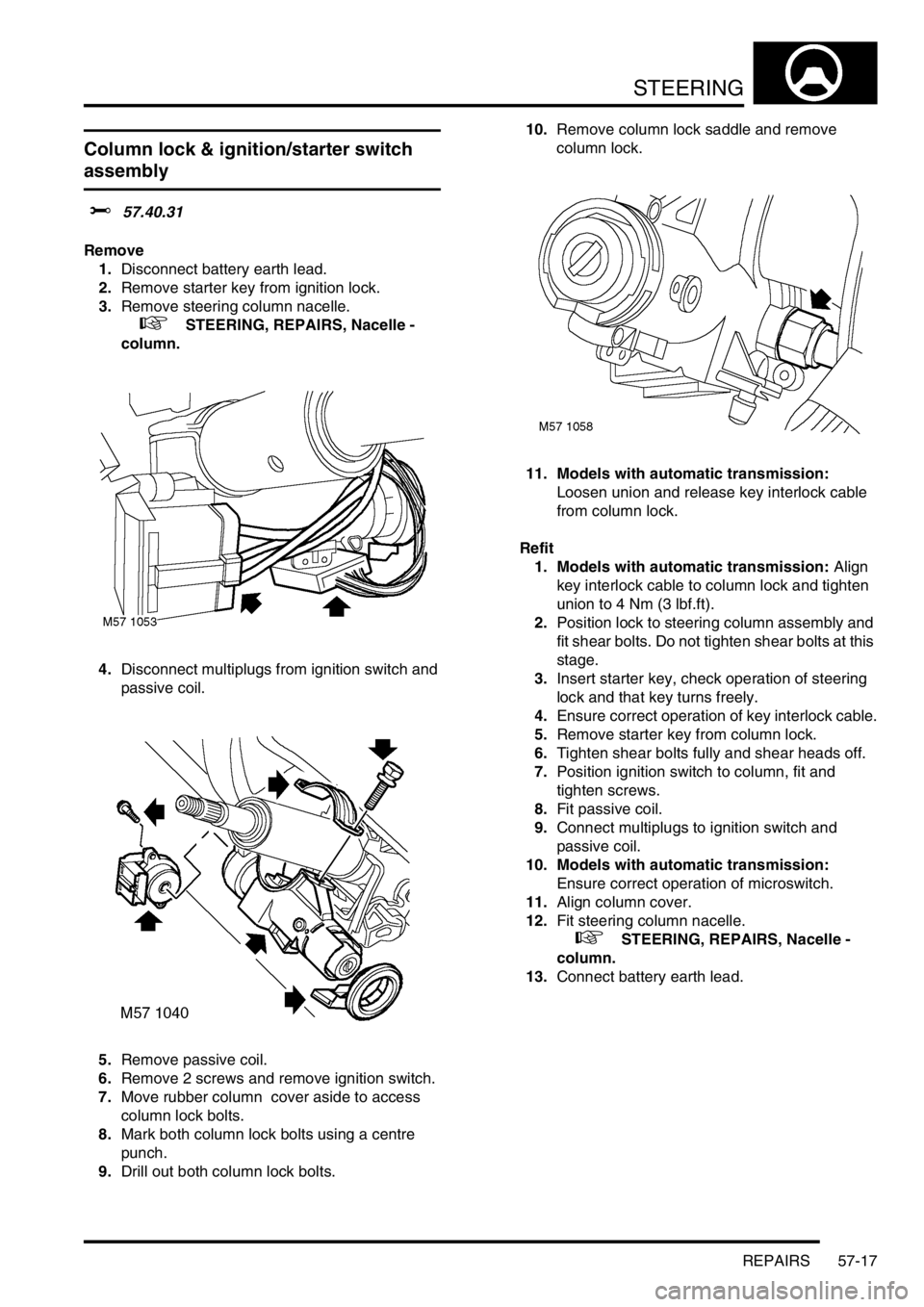

Column lock & ignition/starter switch

assembly

$% 57.40.31

Remove

1.Disconnect battery earth lead.

2.Remove starter key from ignition lock.

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

4.Disconnect multiplugs from ignition switch and

passive coil.

5.Remove passive coil.

6.Remove 2 screws and remove ignition switch.

7.Move rubber column cover aside to access

column lock bolts.

8.Mark both column lock bolts using a centre

punch.

9.Drill out both column lock bolts.10.Remove column lock saddle and remove

column lock.

11. Models with automatic transmission:

Loosen union and release key interlock cable

from column lock.

Refit

1. Models with automatic transmission: Align

key interlock cable to column lock and tighten

union to 4 Nm (3 lbf.ft).

2.Position lock to steering column assembly and

fit shear bolts. Do not tighten shear bolts at this

stage.

3.Insert starter key, check operation of steering

lock and that key turns freely.

4.Ensure correct operation of key interlock cable.

5.Remove starter key from column lock.

6.Tighten shear bolts fully and shear heads off.

7.Position ignition switch to column, fit and

tighten screws.

8.Fit passive coil.

9.Connect multiplugs to ignition switch and

passive coil.

10. Models with automatic transmission:

Ensure correct operation of microswitch.

11.Align column cover.

12.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

13.Connect battery earth lead.

Page 511 of 1007

STEERING

57-18 REPAIRS

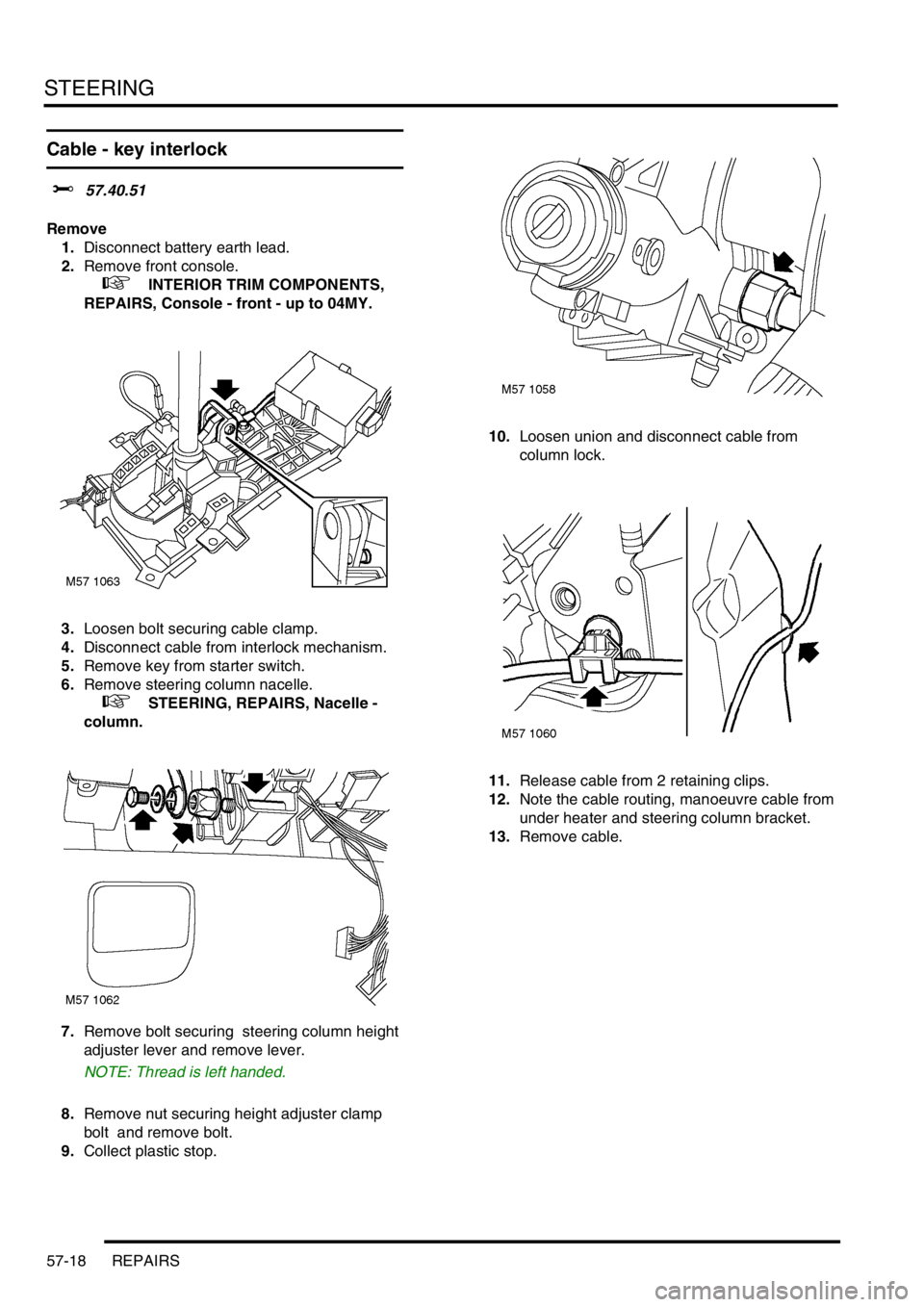

Cable - key interlock

$% 57.40.51

Remove

1.Disconnect battery earth lead.

2.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

3.Loosen bolt securing cable clamp.

4.Disconnect cable from interlock mechanism.

5.Remove key from starter switch.

6.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

7.Remove bolt securing steering column height

adjuster lever and remove lever.

NOTE: Thread is left handed.

8.Remove nut securing height adjuster clamp

bolt and remove bolt.

9.Collect plastic stop.10.Loosen union and disconnect cable from

column lock.

11.Release cable from 2 retaining clips.

12.Note the cable routing, manoeuvre cable from

under heater and steering column bracket.

13.Remove cable.

Page 512 of 1007

STEERING

REPAIRS 57-19

Refit

1.Position cable, align to heater and steering

column bracket and secure in retaining clips.

2.Align key interlock cable to column lock and

tighten union to 4 Nm (3 lbf.ft).

3.Fit height adjuster clamp bolt and tighten nut to

10 Nm (7.5 lbf.ft). Ensure bolt and plastic stop

are correctly located in slot in column bracket.

4.Fit height adjuster lever and tighten bolt 12 Nm

(9 lbf.ft). Ensure lever is in the fully up position

before tightening bolt. Hold clamp bolt nut to

prevent nut rotation.

5.Connect cable to interlock mechanism.

6.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

7.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

8.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

9.Connect battery earth lead.

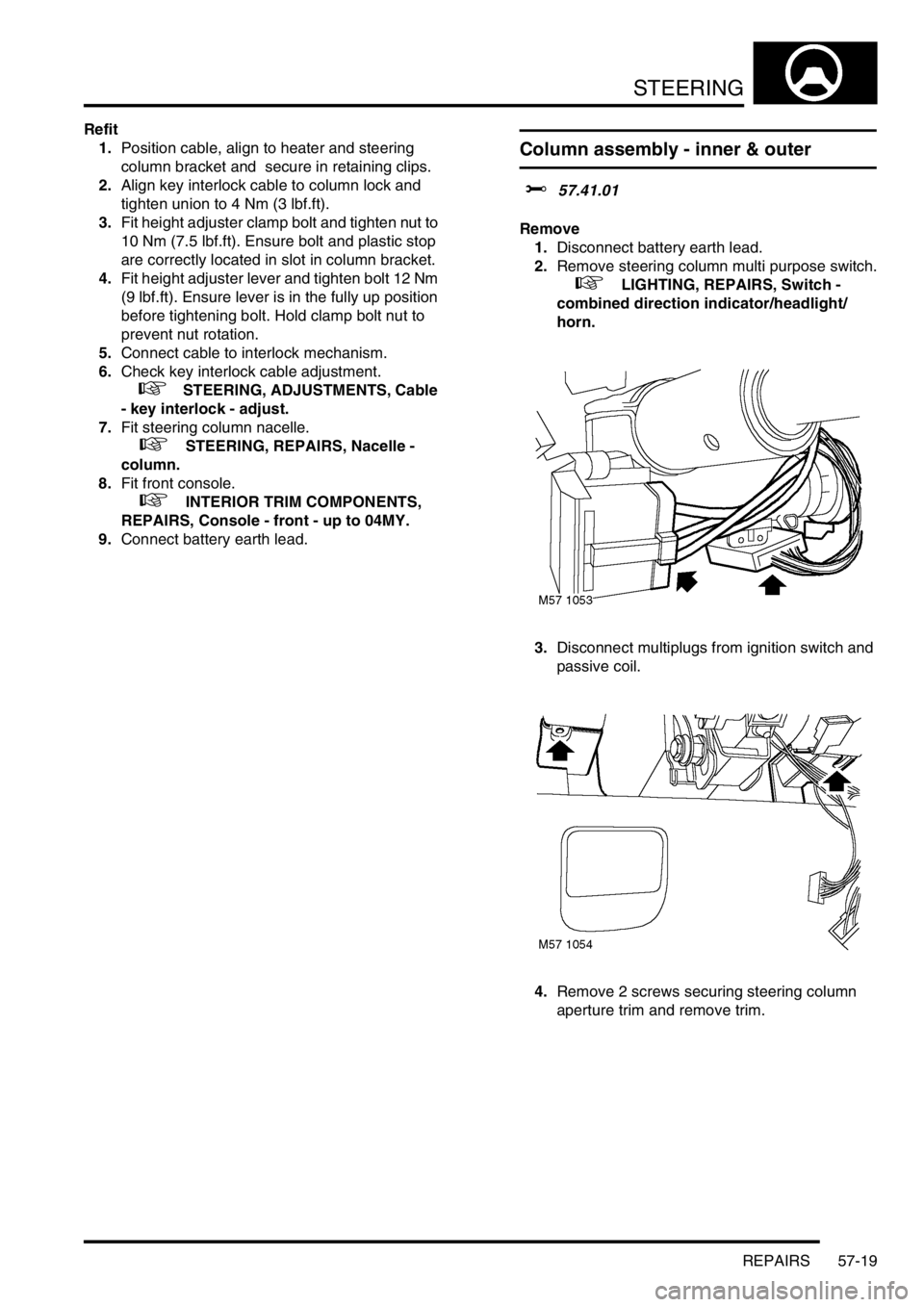

Column assembly - inner & outer

$% 57.41.01

Remove

1.Disconnect battery earth lead.

2.Remove steering column multi purpose switch.

+ LIGHTING, REPAIRS, Switch -

combined direction indicator/headlight/

horn.

3.Disconnect multiplugs from ignition switch and

passive coil.

4.Remove 2 screws securing steering column

aperture trim and remove trim.

Page 513 of 1007

STEERING

57-20 REPAIRS

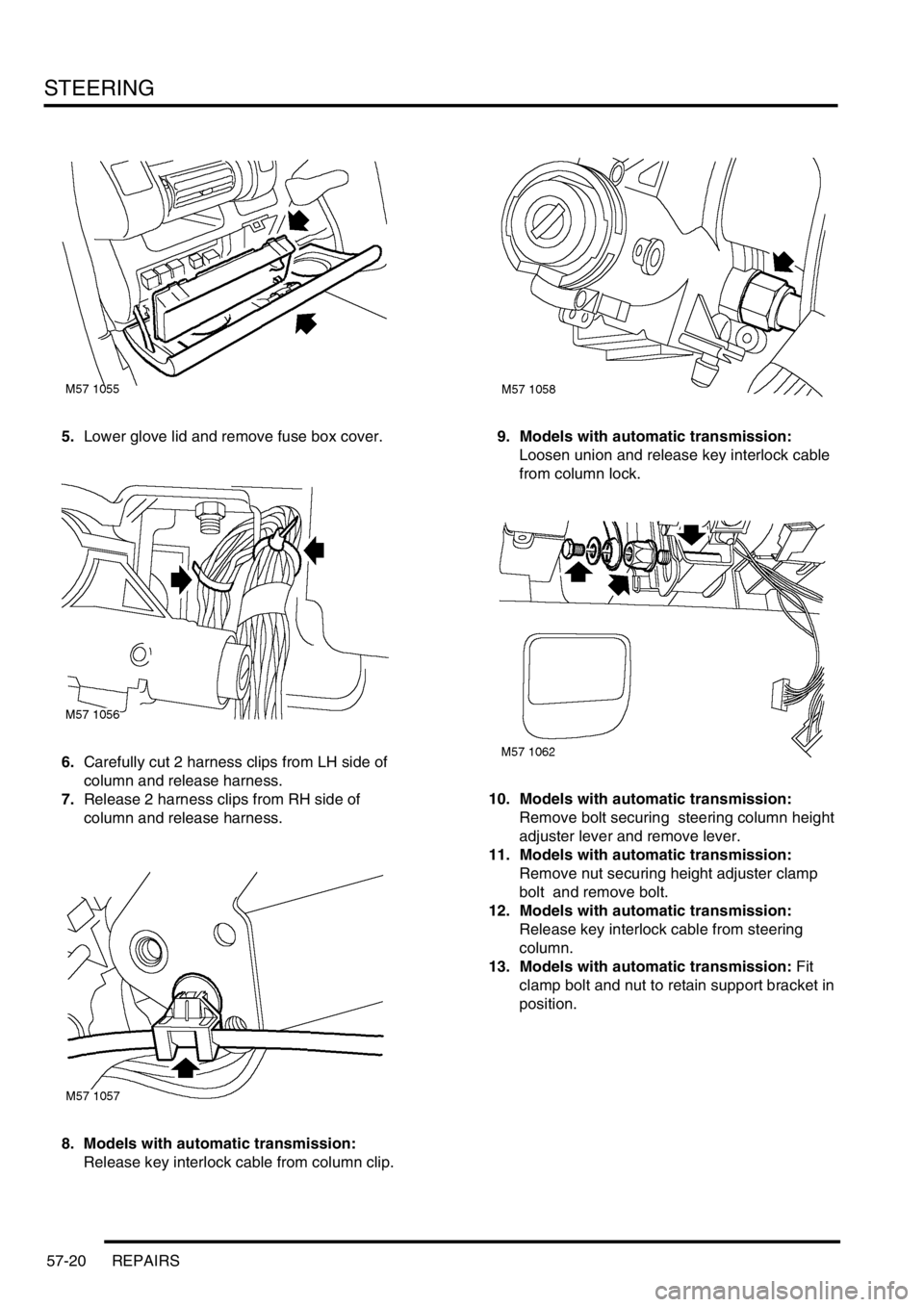

5.Lower glove lid and remove fuse box cover.

6.Carefully cut 2 harness clips from LH side of

column and release harness.

7.Release 2 harness clips from RH side of

column and release harness.

8. Models with automatic transmission:

Release key interlock cable from column clip.9. Models with automatic transmission:

Loosen union and release key interlock cable

from column lock.

10. Models with automatic transmission:

Remove bolt securing steering column height

adjuster lever and remove lever.

11. Models with automatic transmission:

Remove nut securing height adjuster clamp

bolt and remove bolt.

12. Models with automatic transmission:

Release key interlock cable from steering

column.

13. Models with automatic transmission: Fit

clamp bolt and nut to retain support bracket in

position.

Page 514 of 1007

STEERING

REPAIRS 57-21

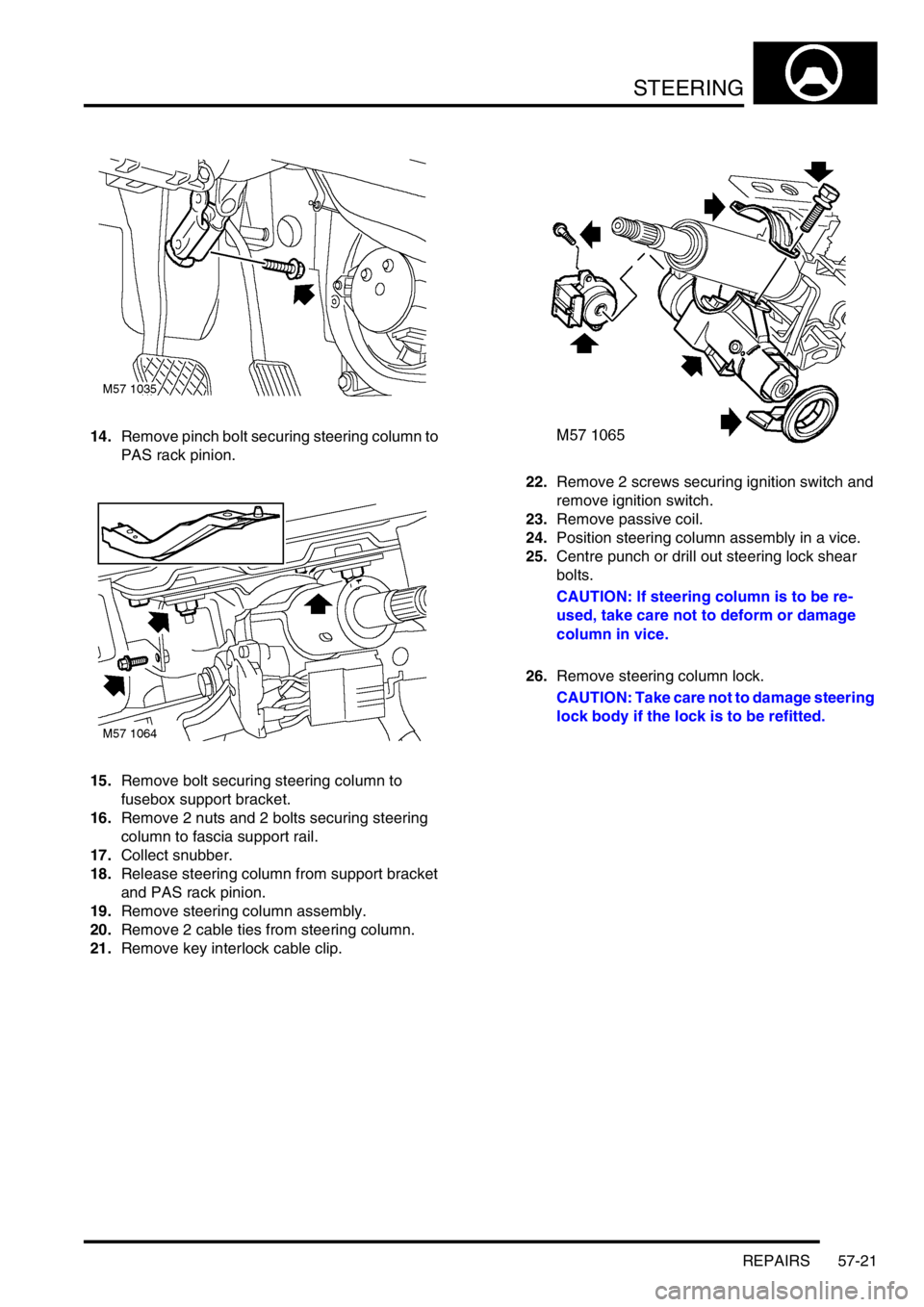

14.Remove pinch bolt securing steering column to

PAS rack pinion.

15.Remove bolt securing steering column to

fusebox support bracket.

16.Remove 2 nuts and 2 bolts securing steering

column to fascia support rail.

17.Collect snubber.

18.Release steering column from support bracket

and PAS rack pinion.

19.Remove steering column assembly.

20.Remove 2 cable ties from steering column.

21.Remove key interlock cable clip.22.Remove 2 screws securing ignition switch and

remove ignition switch.

23.Remove passive coil.

24.Position steering column assembly in a vice.

25.Centre punch or drill out steering lock shear

bolts.

CAUTION: If steering column is to be re-

used, take care not to deform or damage

column in vice.

26.Remove steering column lock.

CAUTION: Take care not to damage steering

lock body if the lock is to be refitted.