ird LAND ROVER FREELANDER 2001 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 419 of 1007

INTERMEDIATE REDUCTION DRIVE

41-16 REPAIRS

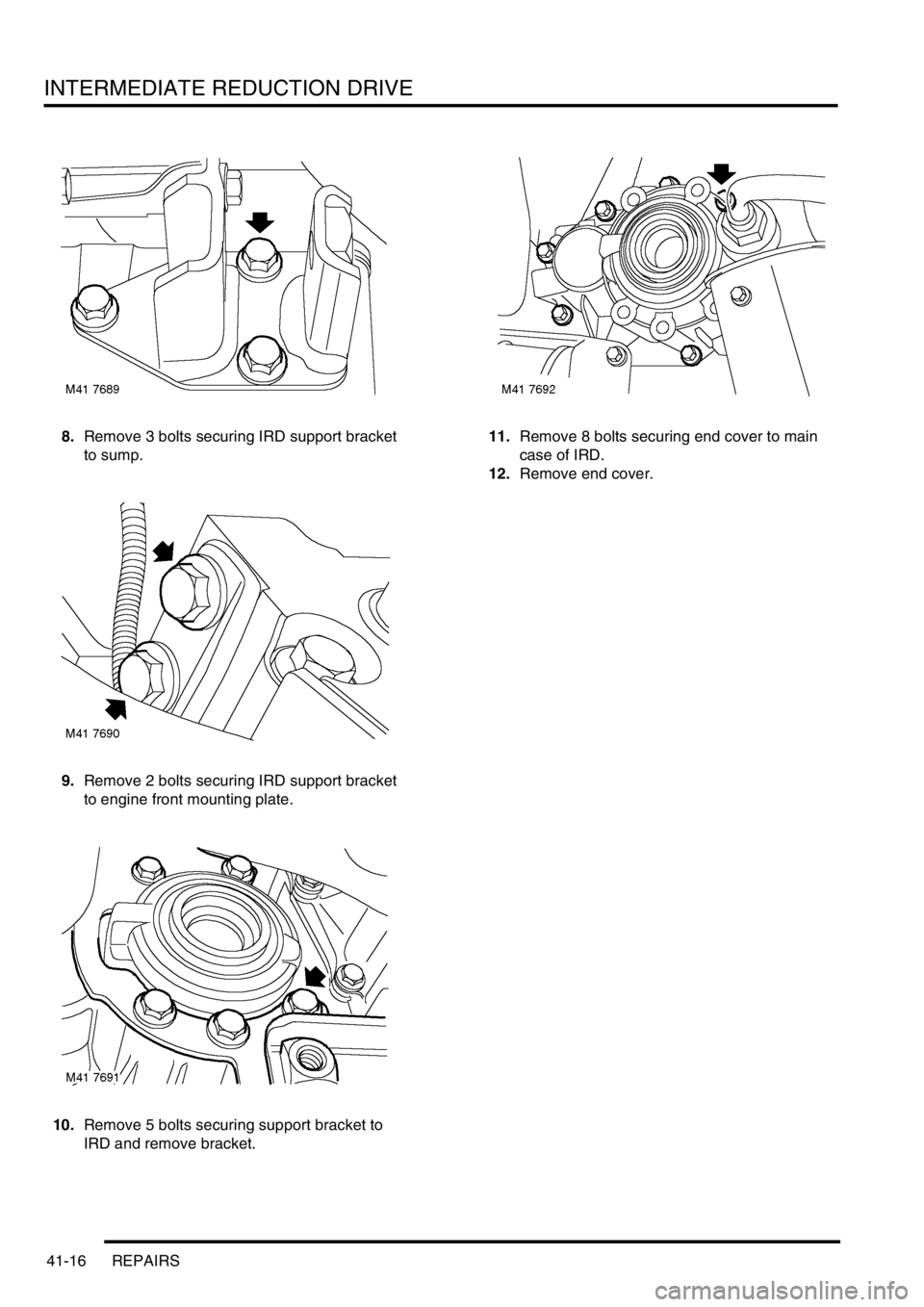

8.Remove 3 bolts securing IRD support bracket

to sump.

9.Remove 2 bolts securing IRD support bracket

to engine front mounting plate.

10.Remove 5 bolts securing support bracket to

IRD and remove bracket.11.Remove 8 bolts securing end cover to main

case of IRD.

12.Remove end cover.

Page 420 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-17

Refit

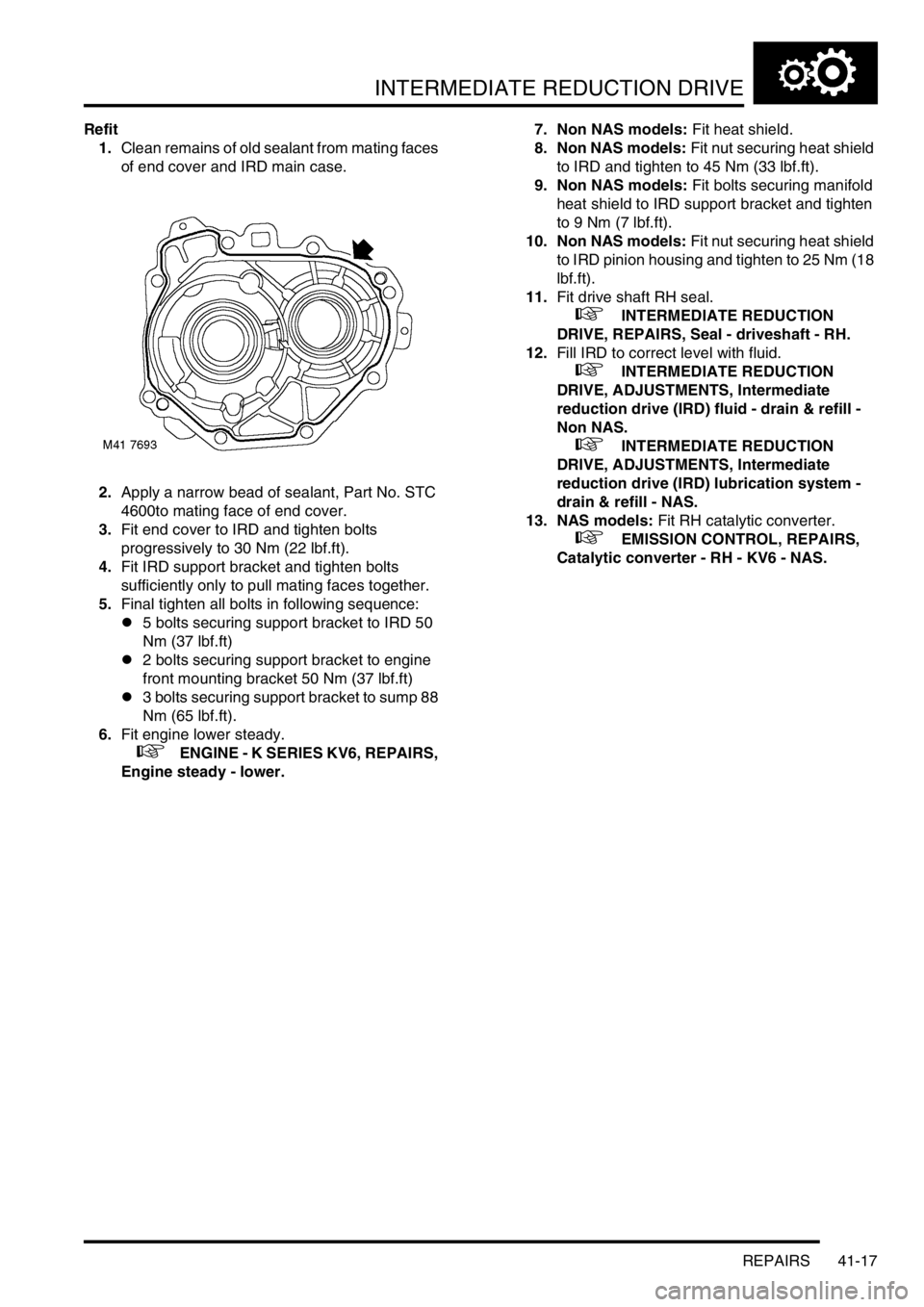

1.Clean remains of old sealant from mating faces

of end cover and IRD main case.

2.Apply a narrow bead of sealant, Part No. STC

4600to mating face of end cover.

3.Fit end cover to IRD and tighten bolts

progressively to 30 Nm (22 lbf.ft).

4.Fit IRD support bracket and tighten bolts

sufficiently only to pull mating faces together.

5.Final tighten all bolts in following sequence:

l5 bolts securing support bracket to IRD 50

Nm (37 lbf.ft)

l2 bolts securing support bracket to engine

front mounting bracket 50 Nm (37 lbf.ft)

l3 bolts securing support bracket to sump 88

Nm (65 lbf.ft).

6.Fit engine lower steady.

+ ENGINE - K SERIES KV6, REPAIRS,

Engine steady - lower.7. Non NAS models: Fit heat shield.

8. Non NAS models: Fit nut securing heat shield

to IRD and tighten to 45 Nm (33 lbf.ft).

9. Non NAS models: Fit bolts securing manifold

heat shield to IRD support bracket and tighten

to 9 Nm (7 lbf.ft).

10. Non NAS models: Fit nut securing heat shield

to IRD pinion housing and tighten to 25 Nm (18

lbf.ft).

11.Fit drive shaft RH seal.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - driveshaft - RH.

12.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

13. NAS models: Fit RH catalytic converter.

+ EMISSION CONTROL, REPAIRS,

Catalytic converter - RH - KV6 - NAS.

Page 421 of 1007

INTERMEDIATE REDUCTION DRIVE

41-18 REPAIRS

Gasket - end cover - IRD housing - K1.8

$% 41.27.05

Remove

1.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

2.Remove drive shaft RH seal.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - driveshaft - RH.

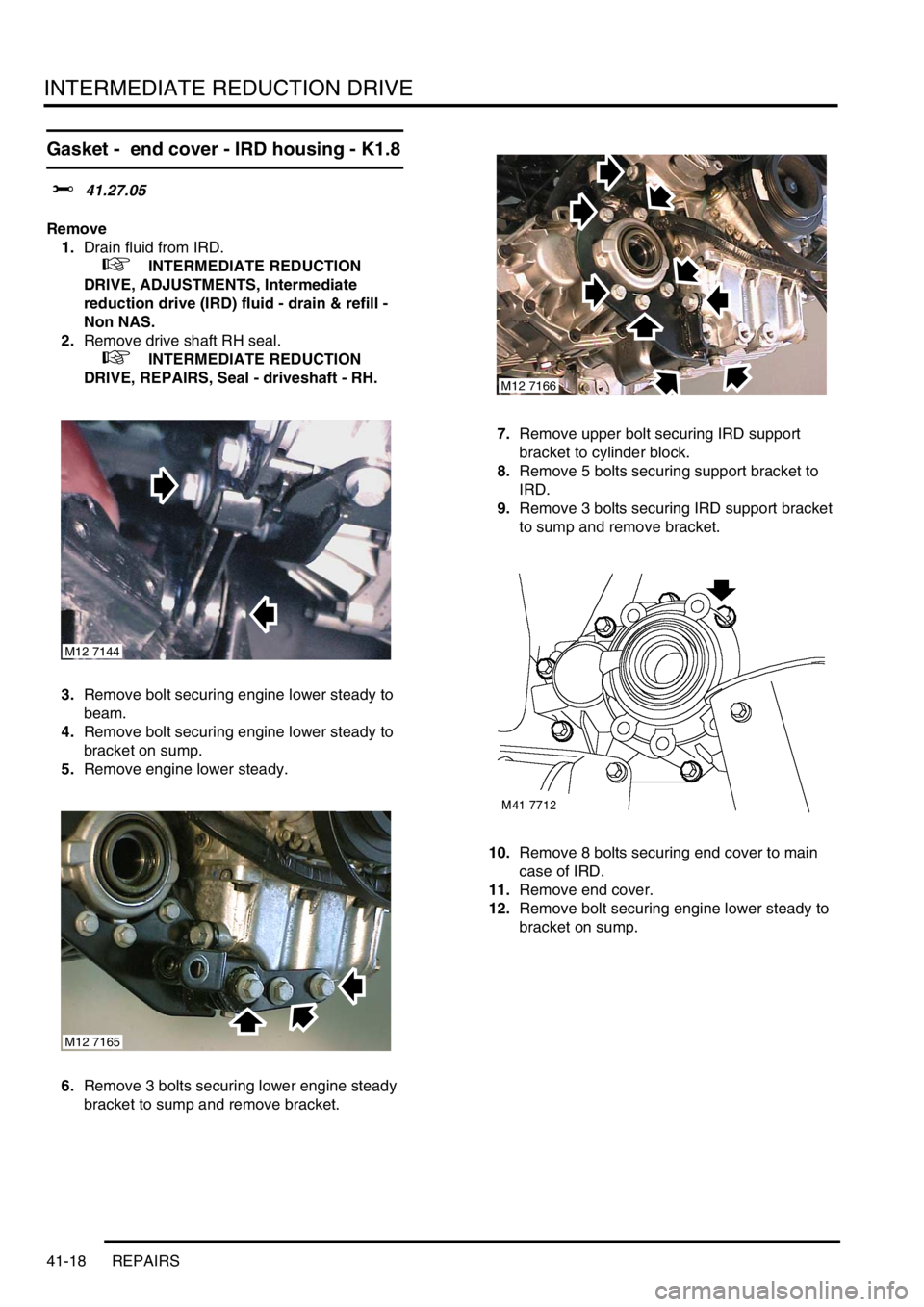

3.Remove bolt securing engine lower steady to

beam.

4.Remove bolt securing engine lower steady to

bracket on sump.

5.Remove engine lower steady.

6.Remove 3 bolts securing lower engine steady

bracket to sump and remove bracket.7.Remove upper bolt securing IRD support

bracket to cylinder block.

8.Remove 5 bolts securing support bracket to

IRD.

9.Remove 3 bolts securing IRD support bracket

to sump and remove bracket.

10.Remove 8 bolts securing end cover to main

case of IRD.

11.Remove end cover.

12.Remove bolt securing engine lower steady to

bracket on sump.

M12 7144

M12 7165

M12 7166

Page 422 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-19

Refit

1.Clean remains of old sealant from mating faces

of end cover and IRD main case.

2.Apply a narrow bead of sealant, Part No. STC

4600to mating face of end cover.

3.Fit end cover to IRD and tighten bolts

progressively to 30 Nm (22 lbf.ft).

4.Fit IRD support bracket and tighten bolts

sufficiently only to pull mating faces together.

5.Final tighten bolts securing IRD support bracket

in following sequence:

l5 bolts securing IRD support bracket to IRD

50 Nm (37 lbf.ft),

l1 bolt securing support bracket to cylinder

block 45 Nm (33 lbf.ft),

l3 bolts securing support bracket to sump 88

Nm (65 lbf.ft).

6.Position engine lower steady bracket to sump,

fit and tighten bolts to 100 Nm (74 lbf.ft).

7.Fit engine lower steady, fit bolts and tighten to

80 Nm (59 lbf.ft).

8.

9.Fit drive shaft RH seal.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - driveshaft - RH.

10.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

Seals - primary gear shaft

$% 41.29.02

Remove

1.Remove IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - K1.8.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

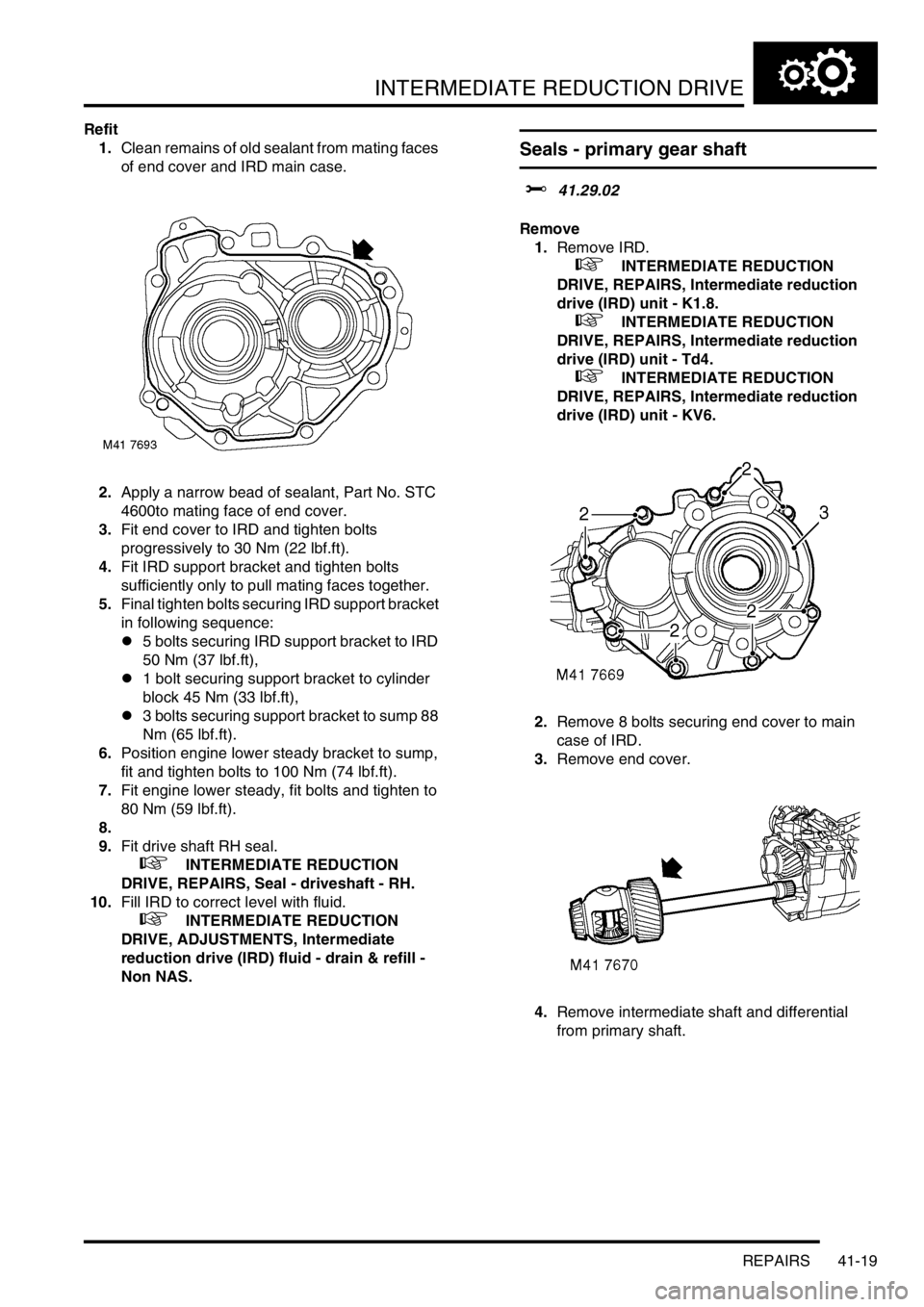

2.Remove 8 bolts securing end cover to main

case of IRD.

3.Remove end cover.

4.Remove intermediate shaft and differential

from primary shaft.

Page 423 of 1007

INTERMEDIATE REDUCTION DRIVE

41-20 REPAIRS

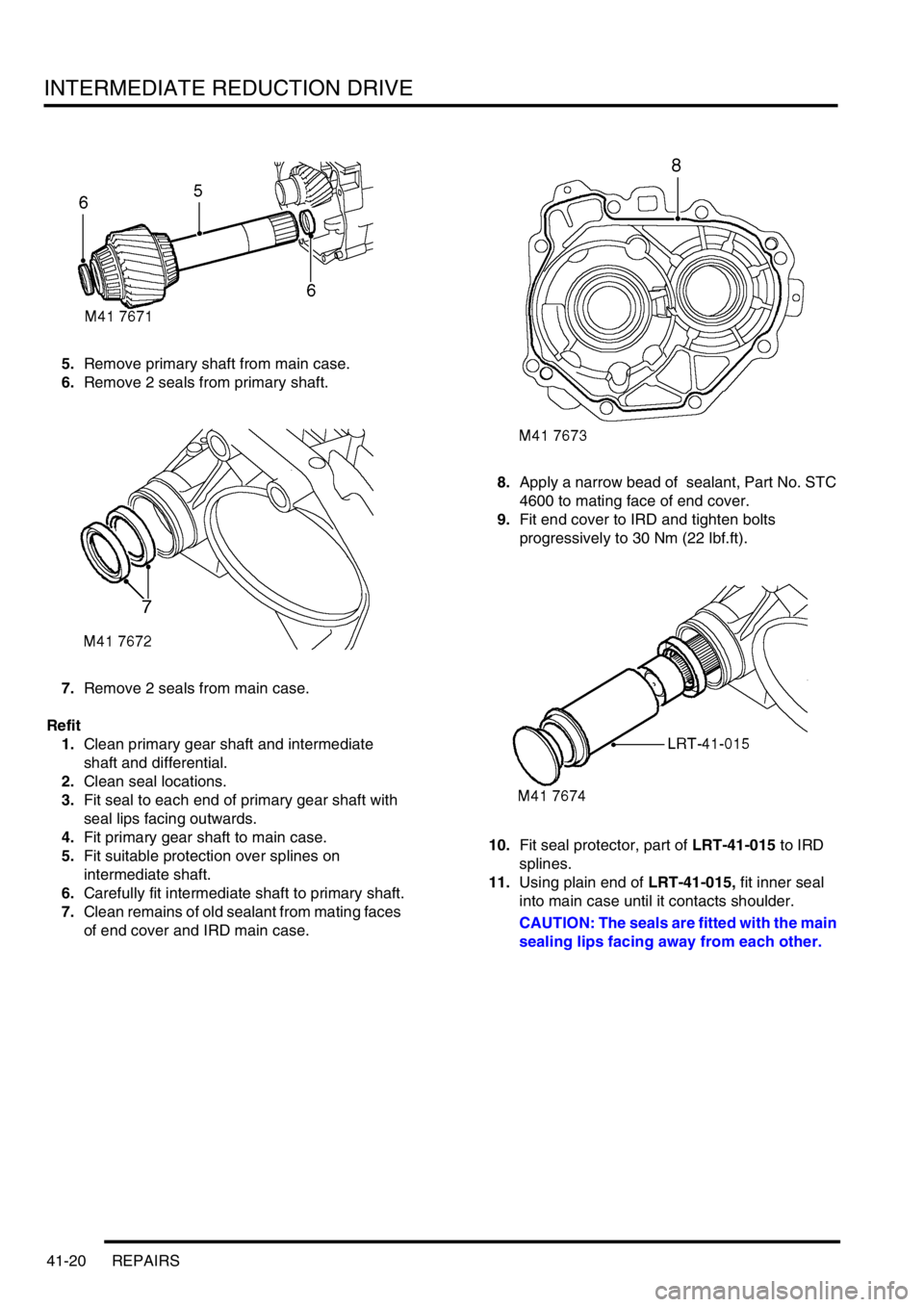

5.Remove primary shaft from main case.

6.Remove 2 seals from primary shaft.

7.Remove 2 seals from main case.

Refit

1.Clean primary gear shaft and intermediate

shaft and differential.

2.Clean seal locations.

3.Fit seal to each end of primary gear shaft with

seal lips facing outwards.

4.Fit primary gear shaft to main case.

5.Fit suitable protection over splines on

intermediate shaft.

6.Carefully fit intermediate shaft to primary shaft.

7.Clean remains of old sealant from mating faces

of end cover and IRD main case.8.Apply a narrow bead of sealant, Part No. STC

4600 to mating face of end cover.

9.Fit end cover to IRD and tighten bolts

progressively to 30 Nm (22 lbf.ft).

10.Fit seal protector, part of LRT-41-015 to IRD

splines.

11.Using plain end of LRT-41-015, fit inner seal

into main case until it contacts shoulder.

CAUTION: The seals are fitted with the main

sealing lips facing away from each other.

Page 424 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-21

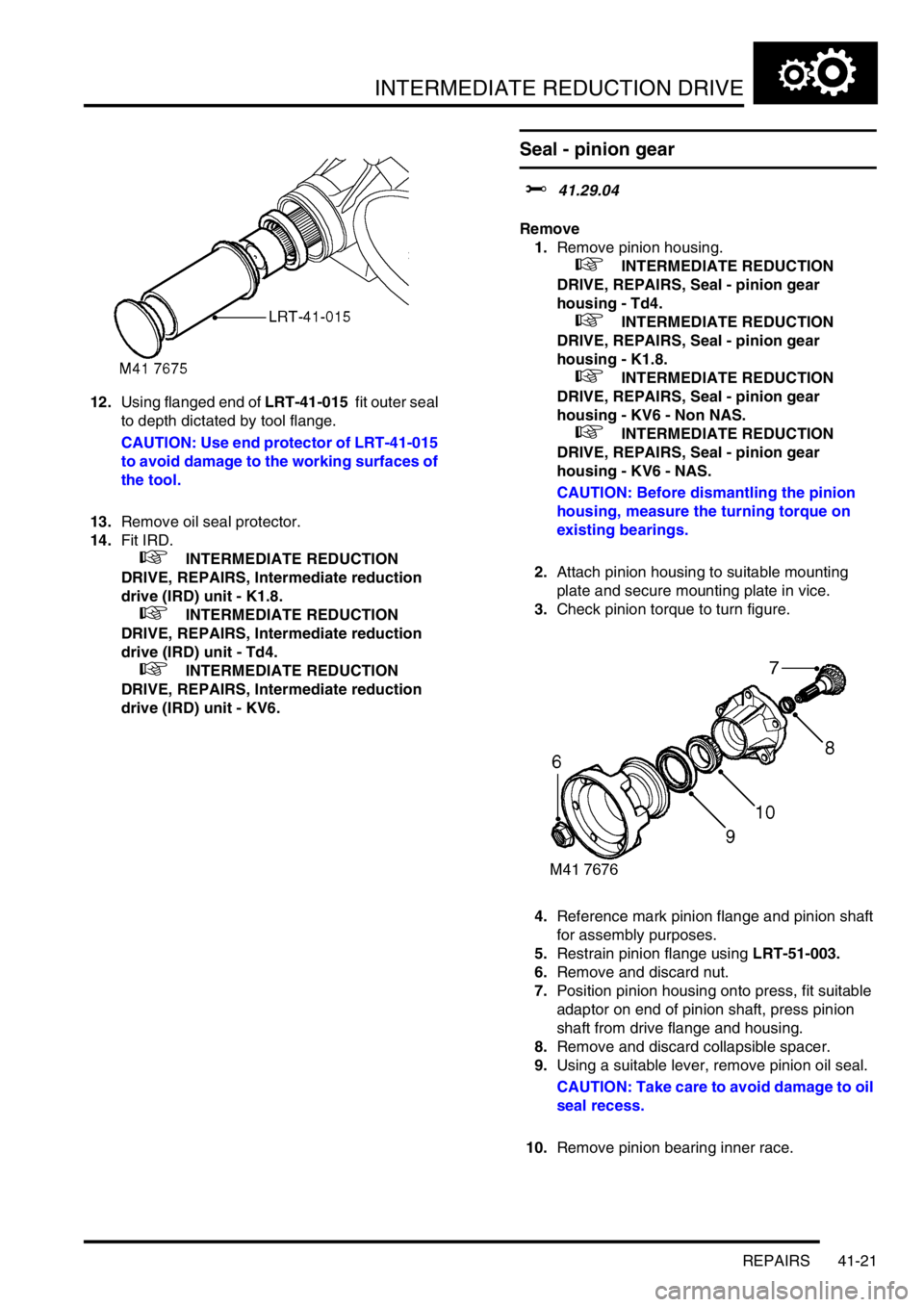

12.Using flanged end of LRT-41-015 fit outer seal

to depth dictated by tool flange.

CAUTION: Use end protector of LRT-41-015

to avoid damage to the working surfaces of

the tool.

13.Remove oil seal protector.

14.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - K1.8.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

Seal - pinion gear

$% 41.29.04

Remove

1.Remove pinion housing.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - Td4.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - K1.8.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - pinion gear

housing - KV6 - NAS.

CAUTION: Before dismantling the pinion

housing, measure the turning torque on

existing bearings.

2.Attach pinion housing to suitable mounting

plate and secure mounting plate in vice.

3.Check pinion torque to turn figure.

4.Reference mark pinion flange and pinion shaft

for assembly purposes.

5.Restrain pinion flange using LRT-51-003.

6.Remove and discard nut.

7.Position pinion housing onto press, fit suitable

adaptor on end of pinion shaft, press pinion

shaft from drive flange and housing.

8.Remove and discard collapsible spacer.

9.Using a suitable lever, remove pinion oil seal.

CAUTION: Take care to avoid damage to oil

seal recess.

10.Remove pinion bearing inner race.

Page 428 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-25

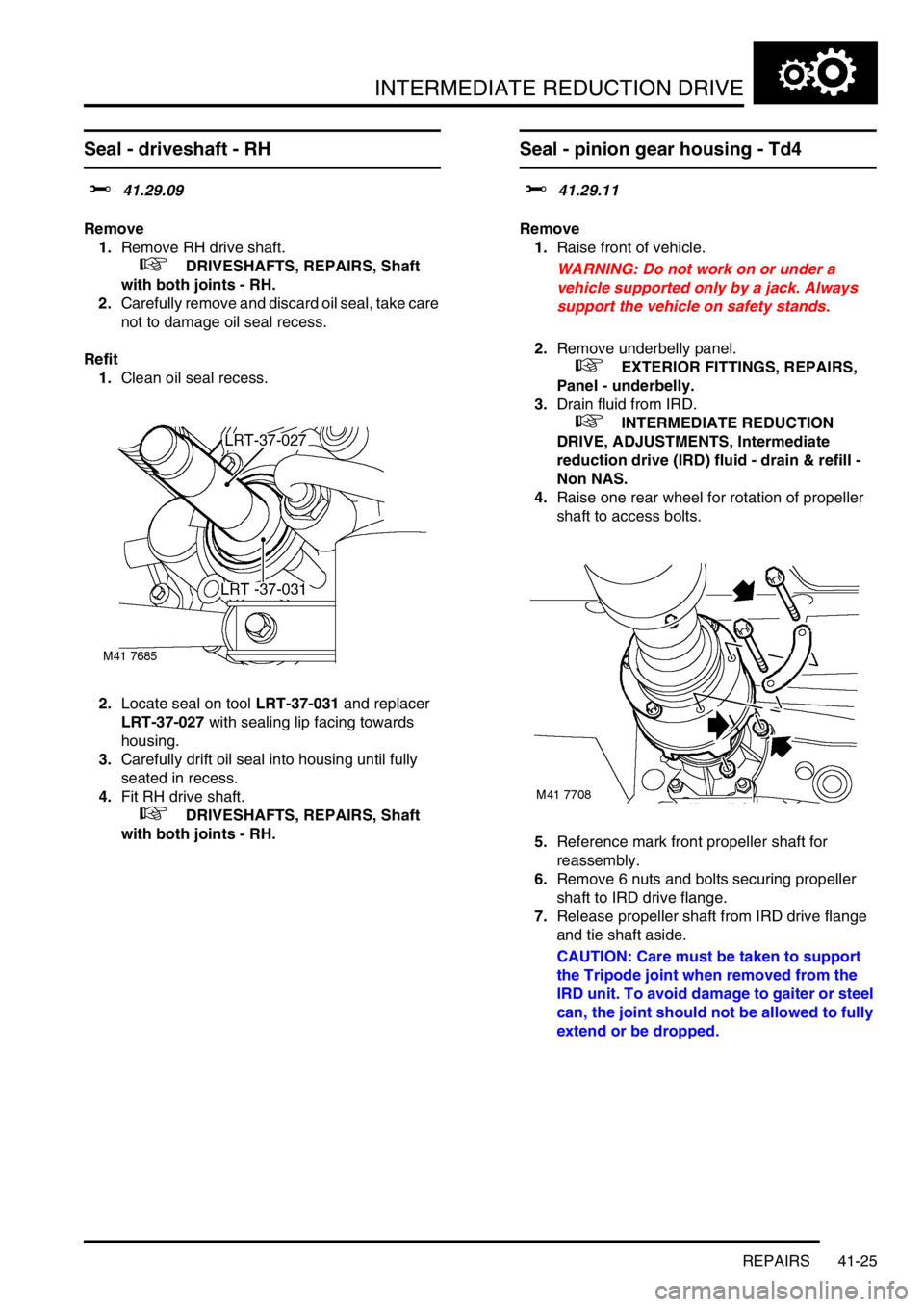

Seal - driveshaft - RH

$% 41.29.09

Remove

1.Remove RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Carefully remove and discard oil seal, take care

not to damage oil seal recess.

Refit

1.Clean oil seal recess.

2.Locate seal on tool LRT-37-031 and replacer

LRT-37-027 with sealing lip facing towards

housing.

3.Carefully drift oil seal into housing until fully

seated in recess.

4.Fit RH drive shaft.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

Seal - pinion gear housing - Td4

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.

Page 429 of 1007

INTERMEDIATE REDUCTION DRIVE

41-26 REPAIRS

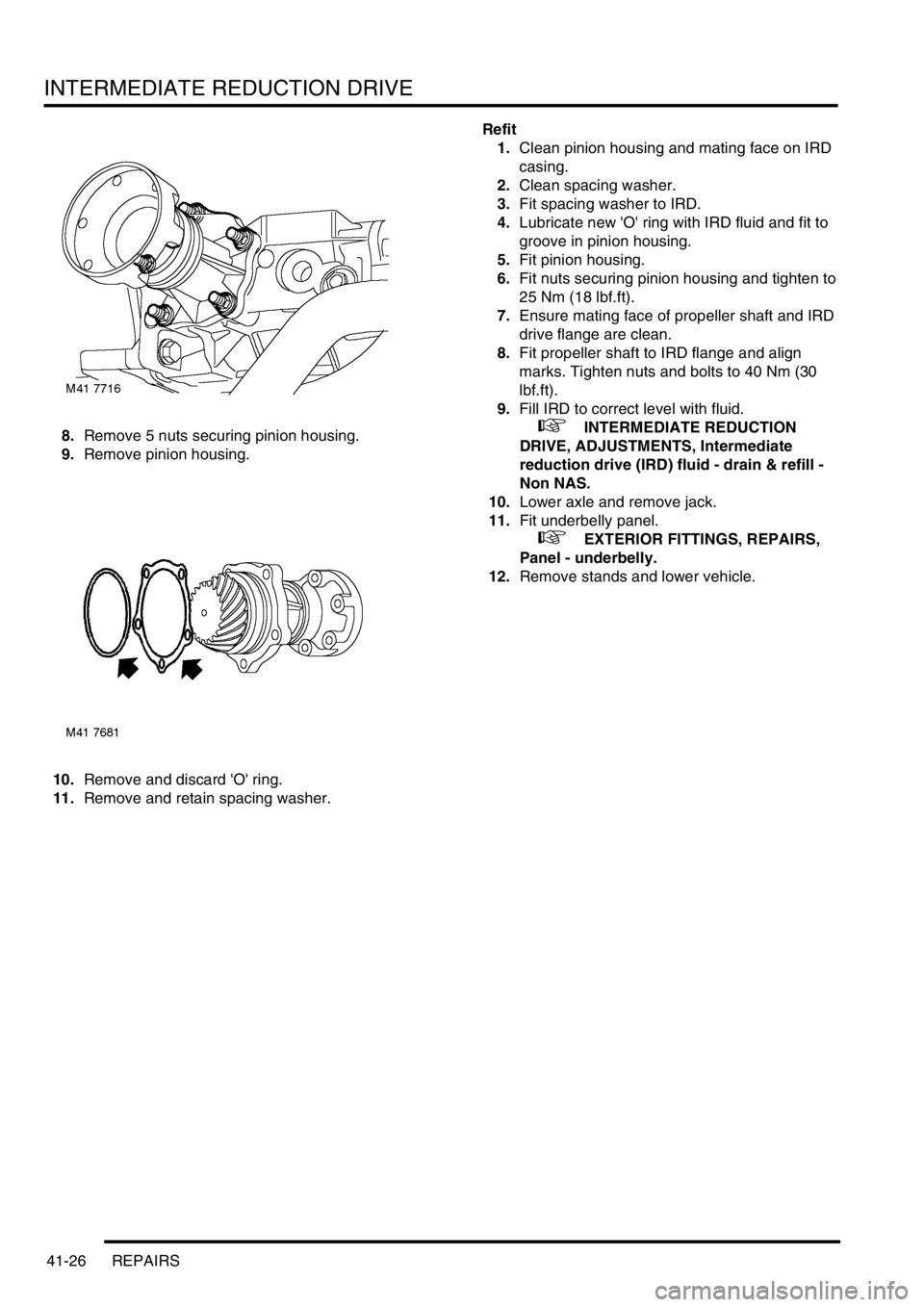

8.Remove 5 nuts securing pinion housing.

9.Remove pinion housing.

10.Remove and discard 'O' ring.

11.Remove and retain spacing washer.Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit nuts securing pinion housing and tighten to

25 Nm (18 lbf.ft).

7.Ensure mating face of propeller shaft and IRD

drive flange are clean.

8.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

9.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

10.Lower axle and remove jack.

11.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

12.Remove stands and lower vehicle.

Page 430 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-27

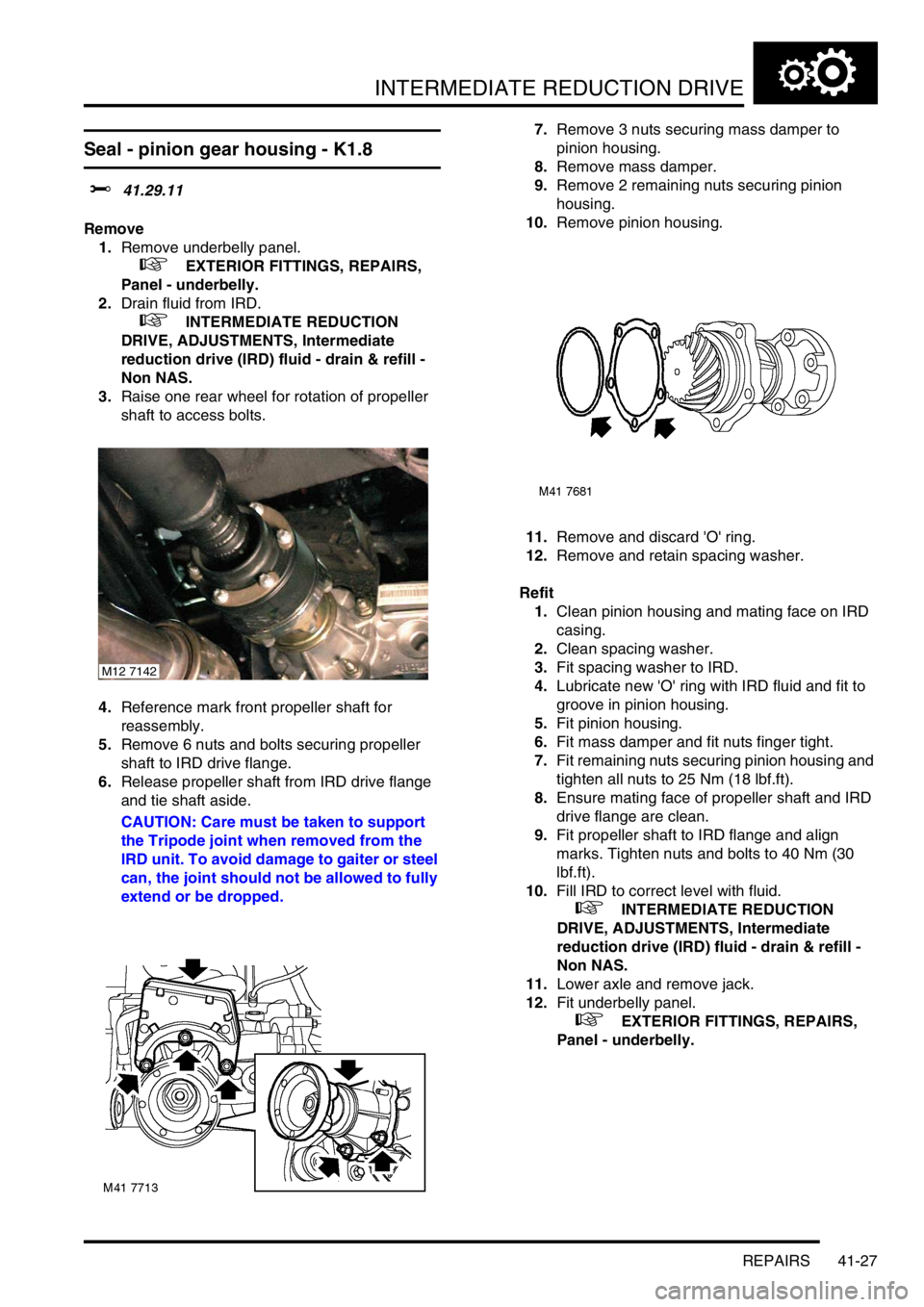

Seal - pinion gear housing - K1.8

$% 41.29.11

Remove

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

3.Raise one rear wheel for rotation of propeller

shaft to access bolts.

4.Reference mark front propeller shaft for

reassembly.

5.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

6.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.7.Remove 3 nuts securing mass damper to

pinion housing.

8.Remove mass damper.

9.Remove 2 remaining nuts securing pinion

housing.

10.Remove pinion housing.

11.Remove and discard 'O' ring.

12.Remove and retain spacing washer.

Refit

1.Clean pinion housing and mating face on IRD

casing.

2.Clean spacing washer.

3.Fit spacing washer to IRD.

4.Lubricate new 'O' ring with IRD fluid and fit to

groove in pinion housing.

5.Fit pinion housing.

6.Fit mass damper and fit nuts finger tight.

7.Fit remaining nuts securing pinion housing and

tighten all nuts to 25 Nm (18 lbf.ft).

8.Ensure mating face of propeller shaft and IRD

drive flange are clean.

9.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 40 Nm (30

lbf.ft).

10.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

11.Lower axle and remove jack.

12.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M12 7142

Page 431 of 1007

INTERMEDIATE REDUCTION DRIVE

41-28 REPAIRS

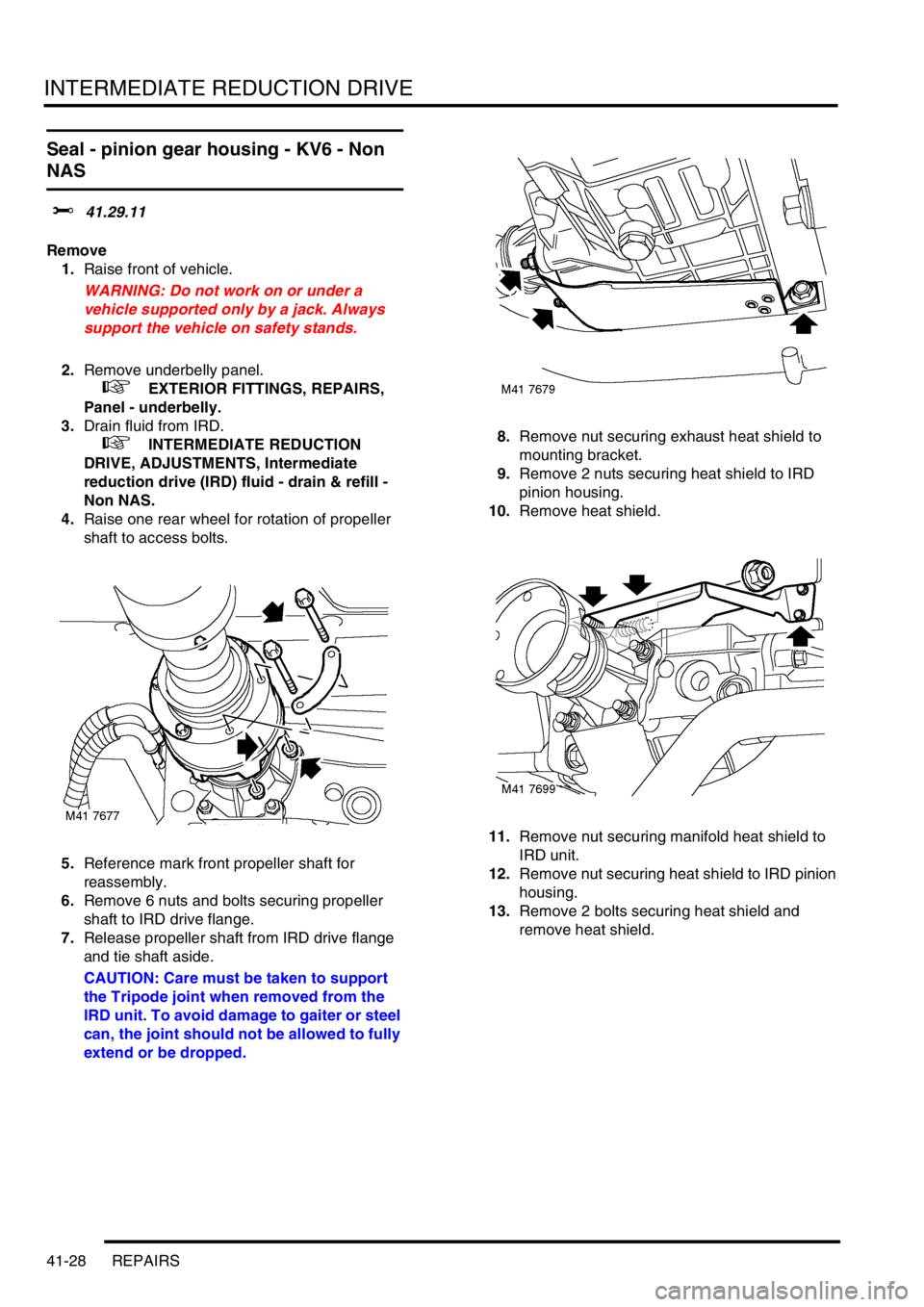

Seal - pinion gear housing - KV6 - Non

NAS

$% 41.29.11

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

4.Raise one rear wheel for rotation of propeller

shaft to access bolts.

5.Reference mark front propeller shaft for

reassembly.

6.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

7.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.8.Remove nut securing exhaust heat shield to

mounting bracket.

9.Remove 2 nuts securing heat shield to IRD

pinion housing.

10.Remove heat shield.

11.Remove nut securing manifold heat shield to

IRD unit.

12.Remove nut securing heat shield to IRD pinion

housing.

13.Remove 2 bolts securing heat shield and

remove heat shield.