ird LAND ROVER FREELANDER 2001 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 462 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-27

21.Fit new circlip to LH drive shaft.

22.With assistance, fit LH drive shaft to gearbox,

keep shaft square to prevent damage to oil seal

in gearbox.

23.Fit IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

24.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - Td4.

25.Fit fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - Td4.

26.Fit intake ducting assembly.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Ducting - intake assembly.

27.Connect battery earth lead.

28.Untie and close bonnet.

Fluid pan - reseal

$% 44.24.05

Remove

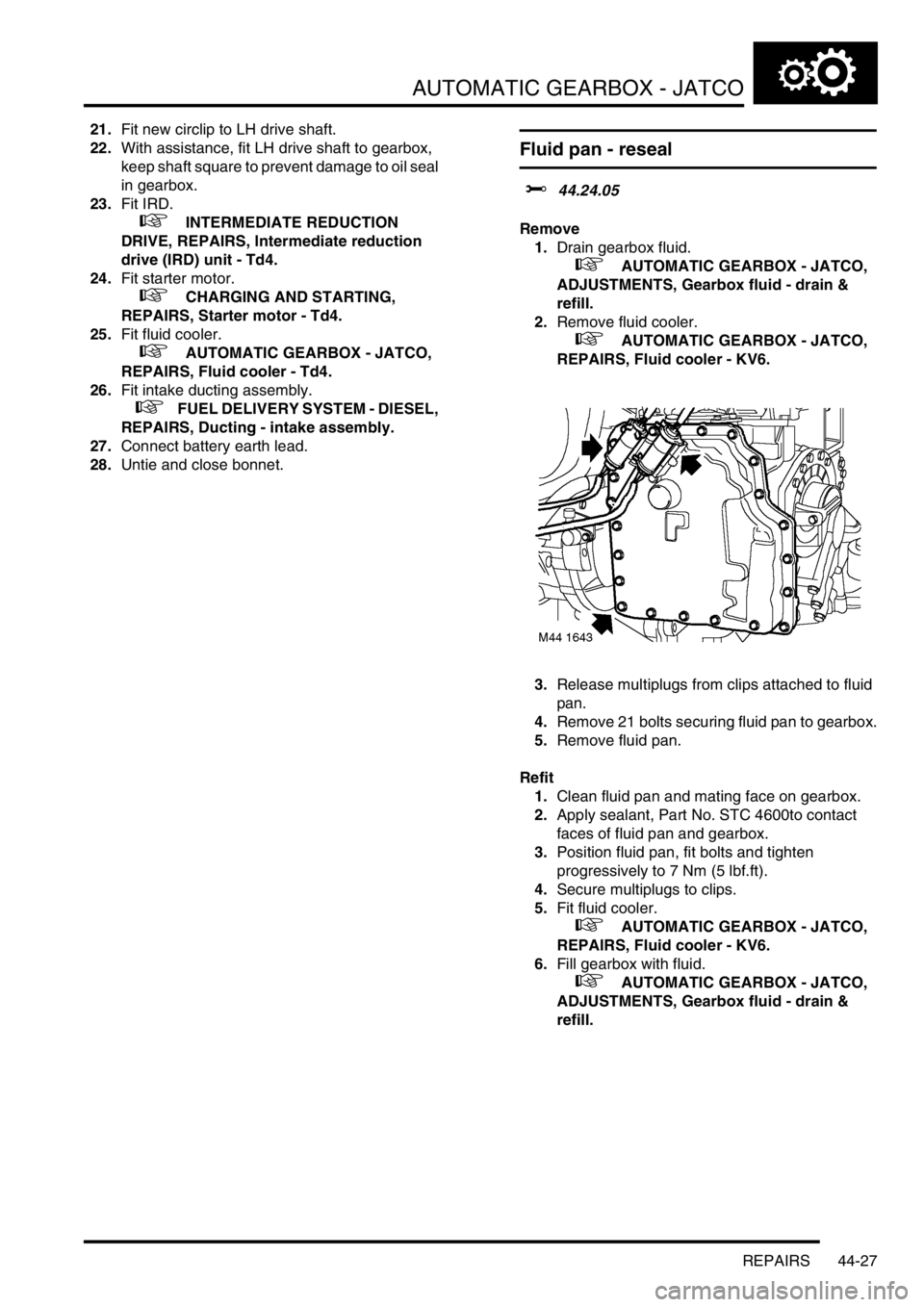

1.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

2.Remove fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - KV6.

3.Release multiplugs from clips attached to fluid

pan.

4.Remove 21 bolts securing fluid pan to gearbox.

5.Remove fluid pan.

Refit

1.Clean fluid pan and mating face on gearbox.

2.Apply sealant, Part No. STC 4600to contact

faces of fluid pan and gearbox.

3.Position fluid pan, fit bolts and tighten

progressively to 7 Nm (5 lbf.ft).

4.Secure multiplugs to clips.

5.Fit fluid cooler.

+ AUTOMATIC GEARBOX - JATCO,

REPAIRS, Fluid cooler - KV6.

6.Fill gearbox with fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

Page 476 of 1007

DRIVESHAFTS

REPAIRS 47-9

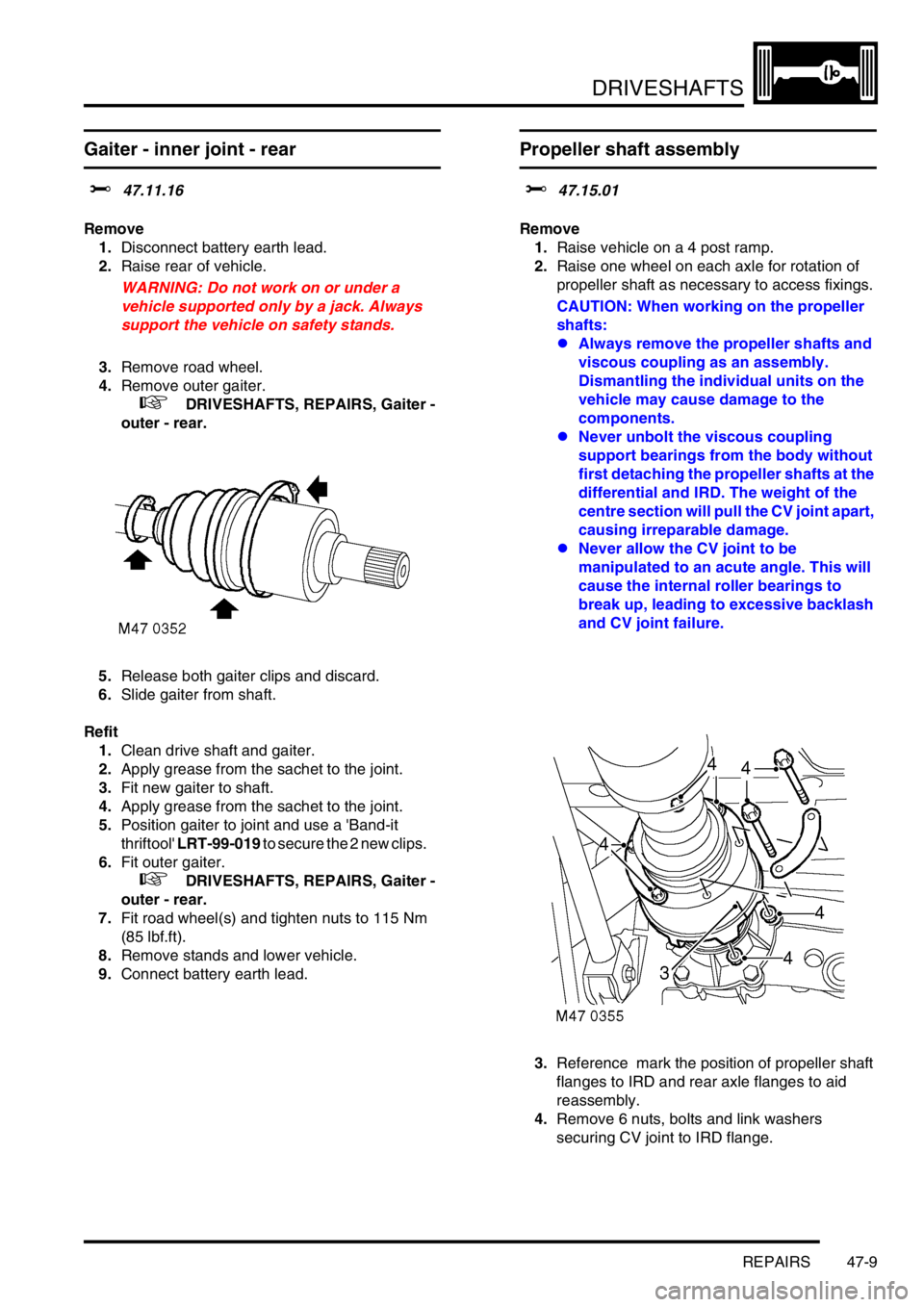

Gaiter - inner joint - rear

$% 47.11.16

Remove

1.Disconnect battery earth lead.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove road wheel.

4.Remove outer gaiter.

+ DRIVESHAFTS, REPAIRS, Gaiter -

outer - rear.

5.Release both gaiter clips and discard.

6.Slide gaiter from shaft.

Refit

1.Clean drive shaft and gaiter.

2.Apply grease from the sachet to the joint.

3.Fit new gaiter to shaft.

4.Apply grease from the sachet to the joint.

5.Position gaiter to joint and use a 'Band-it

thriftool' LRT-99-019 to secure the 2 new clips.

6.Fit outer gaiter.

+ DRIVESHAFTS, REPAIRS, Gaiter -

outer - rear.

7.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

8.Remove stands and lower vehicle.

9.Connect battery earth lead.

Propeller shaft assembly

$% 47.15.01

Remove

1.Raise vehicle on a 4 post ramp.

2.Raise one wheel on each axle for rotation of

propeller shaft as necessary to access fixings.

CAUTION: When working on the propeller

shafts:

lAlways remove the propeller shafts and

viscous coupling as an assembly.

Dismantling the individual units on the

vehicle may cause damage to the

components.

lNever unbolt the viscous coupling

support bearings from the body without

first detaching the propeller shafts at the

differential and IRD. The weight of the

centre section will pull the CV joint apart,

causing irreparable damage.

lNever allow the CV joint to be

manipulated to an acute angle. This will

cause the internal roller bearings to

break up, leading to excessive backlash

and CV joint failure.

3.Reference mark the position of propeller shaft

flanges to IRD and rear axle flanges to aid

reassembly.

4.Remove 6 nuts, bolts and link washers

securing CV joint to IRD flange.

Page 477 of 1007

DRIVESHAFTS

47-10 REPAIRS

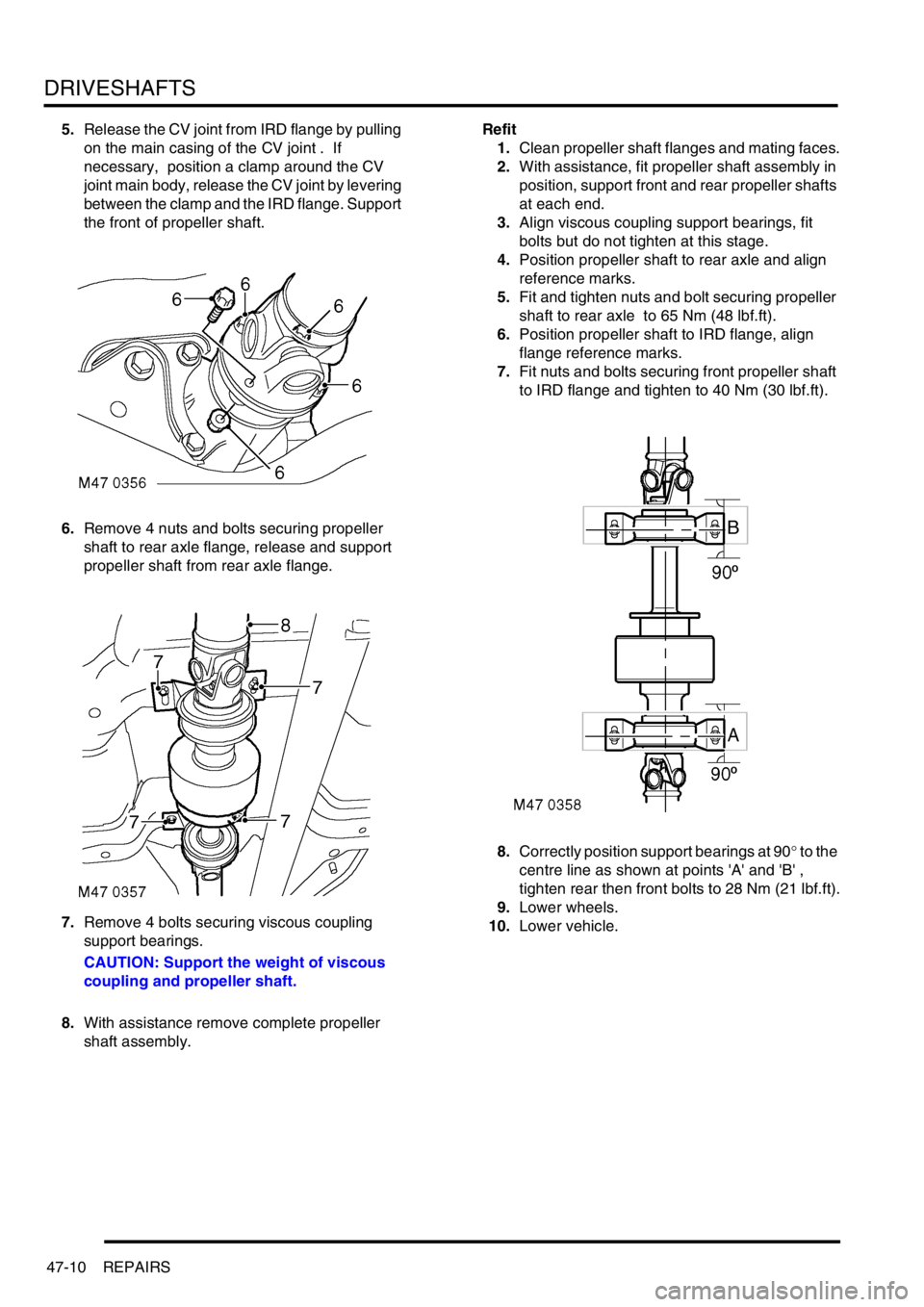

5.Release the CV joint from IRD flange by pulling

on the main casing of the CV joint . If

necessary, position a clamp around the CV

joint main body, release the CV joint by levering

between the clamp and the IRD flange. Support

the front of propeller shaft.

6.Remove 4 nuts and bolts securing propeller

shaft to rear axle flange, release and support

propeller shaft from rear axle flange.

7.Remove 4 bolts securing viscous coupling

support bearings.

CAUTION: Support the weight of viscous

coupling and propeller shaft.

8.With assistance remove complete propeller

shaft assembly.Refit

1.Clean propeller shaft flanges and mating faces.

2.With assistance, fit propeller shaft assembly in

position, support front and rear propeller shafts

at each end.

3.Align viscous coupling support bearings, fit

bolts but do not tighten at this stage.

4.Position propeller shaft to rear axle and align

reference marks.

5.Fit and tighten nuts and bolt securing propeller

shaft to rear axle to 65 Nm (48 lbf.ft).

6.Position propeller shaft to IRD flange, align

flange reference marks.

7.Fit nuts and bolts securing front propeller shaft

to IRD flange and tighten to 40 Nm (30 lbf.ft).

8.Correctly position support bearings at 90° to the

centre line as shown at points 'A' and 'B' ,

tighten rear then front bolts to 28 Nm (21 lbf.ft).

9.Lower wheels.

10.Lower vehicle.

Page 480 of 1007

DRIVESHAFTS

REPAIRS 47-13

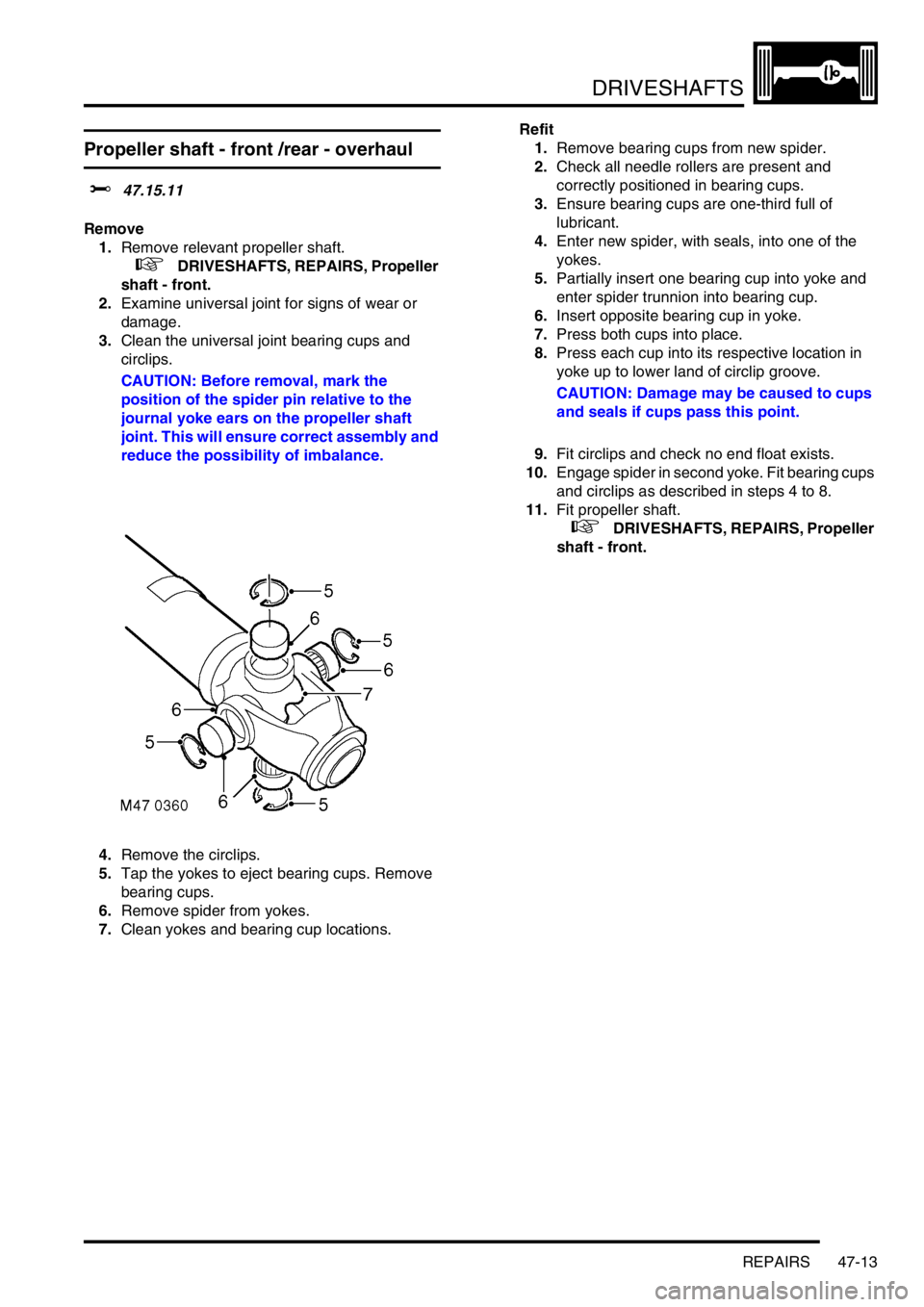

Propeller shaft - front /rear - overhaul

$% 47.15.11

Remove

1.Remove relevant propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft - front.

2.Examine universal joint for signs of wear or

damage.

3.Clean the universal joint bearing cups and

circlips.

CAUTION: Before removal, mark the

position of the spider pin relative to the

journal yoke ears on the propeller shaft

joint. This will ensure correct assembly and

reduce the possibility of imbalance.

4.Remove the circlips.

5.Tap the yokes to eject bearing cups. Remove

bearing cups.

6.Remove spider from yokes.

7.Clean yokes and bearing cup locations.Refit

1.Remove bearing cups from new spider.

2.Check all needle rollers are present and

correctly positioned in bearing cups.

3.Ensure bearing cups are one-third full of

lubricant.

4.Enter new spider, with seals, into one of the

yokes.

5.Partially insert one bearing cup into yoke and

enter spider trunnion into bearing cup.

6.Insert opposite bearing cup in yoke.

7.Press both cups into place.

8.Press each cup into its respective location in

yoke up to lower land of circlip groove.

CAUTION: Damage may be caused to cups

and seals if cups pass this point.

9.Fit circlips and check no end float exists.

10.Engage spider in second yoke. Fit bearing cups

and circlips as described in steps 4 to 8.

11.Fit propeller shaft.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft - front.

Page 499 of 1007

STEERING

57-6 REPAIRS

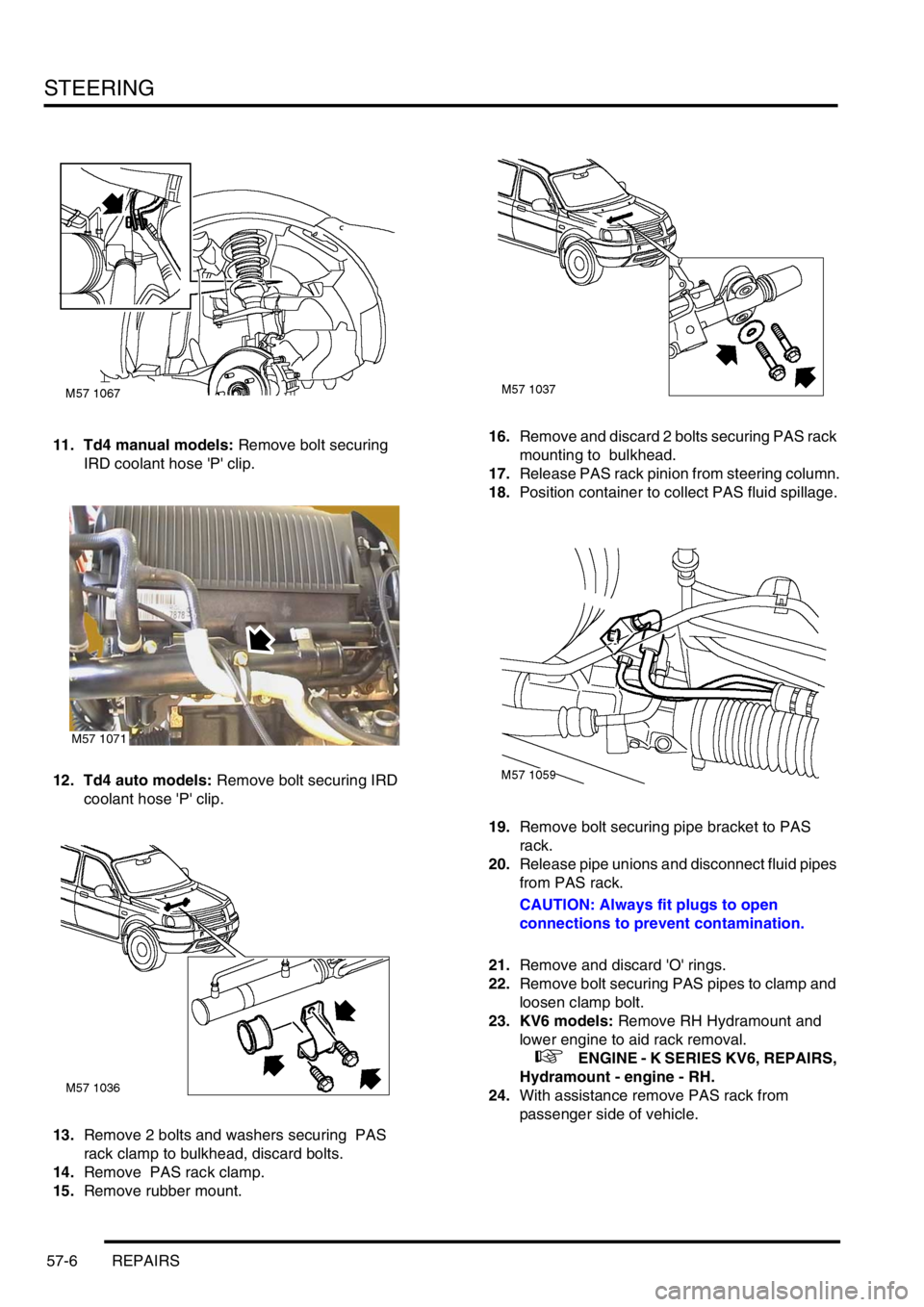

11. Td4 manual models: Remove bolt securing

IRD coolant hose 'P' clip.

12. Td4 auto models: Remove bolt securing IRD

coolant hose 'P' clip.

13.Remove 2 bolts and washers securing PAS

rack clamp to bulkhead, discard bolts.

14.Remove PAS rack clamp.

15.Remove rubber mount.16.Remove and discard 2 bolts securing PAS rack

mounting to bulkhead.

17.Release PAS rack pinion from steering column.

18.Position container to collect PAS fluid spillage.

19.Remove bolt securing pipe bracket to PAS

rack.

20.Release pipe unions and disconnect fluid pipes

from PAS rack.

CAUTION: Always fit plugs to open

connections to prevent contamination.

21.Remove and discard 'O' rings.

22.Remove bolt securing PAS pipes to clamp and

loosen clamp bolt.

23. KV6 models: Remove RH Hydramount and

lower engine to aid rack removal.

+ ENGINE - K SERIES KV6, REPAIRS,

Hydramount - engine - RH.

24.With assistance remove PAS rack from

passenger side of vehicle.

M57 1071

Page 500 of 1007

STEERING

REPAIRS 57-7

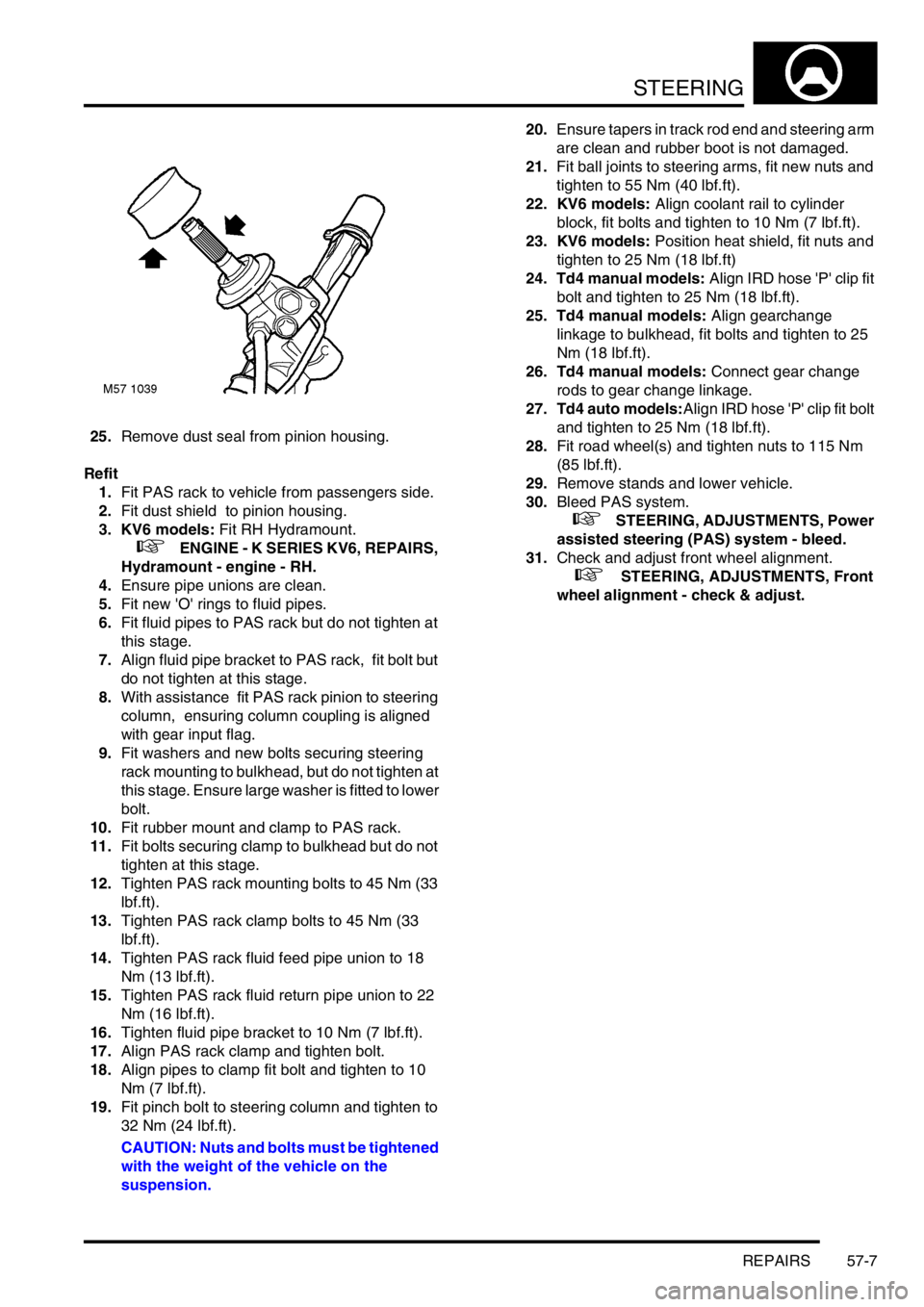

25.Remove dust seal from pinion housing.

Refit

1.Fit PAS rack to vehicle from passengers side.

2.Fit dust shield to pinion housing.

3. KV6 models: Fit RH Hydramount.

+ ENGINE - K SERIES KV6, REPAIRS,

Hydramount - engine - RH.

4.Ensure pipe unions are clean.

5.Fit new 'O' rings to fluid pipes.

6.Fit fluid pipes to PAS rack but do not tighten at

this stage.

7.Align fluid pipe bracket to PAS rack, fit bolt but

do not tighten at this stage.

8.With assistance fit PAS rack pinion to steering

column, ensuring column coupling is aligned

with gear input flag.

9.Fit washers and new bolts securing steering

rack mounting to bulkhead, but do not tighten at

this stage. Ensure large washer is fitted to lower

bolt.

10.Fit rubber mount and clamp to PAS rack.

11.Fit bolts securing clamp to bulkhead but do not

tighten at this stage.

12.Tighten PAS rack mounting bolts to 45 Nm (33

lbf.ft).

13.Tighten PAS rack clamp bolts to 45 Nm (33

lbf.ft).

14.Tighten PAS rack fluid feed pipe union to 18

Nm (13 lbf.ft).

15.Tighten PAS rack fluid return pipe union to 22

Nm (16 lbf.ft).

16.Tighten fluid pipe bracket to 10 Nm (7 lbf.ft).

17.Align PAS rack clamp and tighten bolt.

18.Align pipes to clamp fit bolt and tighten to 10

Nm (7 lbf.ft).

19.Fit pinch bolt to steering column and tighten to

32 Nm (24 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with the weight of the vehicle on the

suspension.20.Ensure tapers in track rod end and steering arm

are clean and rubber boot is not damaged.

21.Fit ball joints to steering arms, fit new nuts and

tighten to 55 Nm (40 lbf.ft).

22. KV6 models: Align coolant rail to cylinder

block, fit bolts and tighten to 10 Nm (7 lbf.ft).

23. KV6 models: Position heat shield, fit nuts and

tighten to 25 Nm (18 lbf.ft)

24. Td4 manual models: Align IRD hose 'P' clip fit

bolt and tighten to 25 Nm (18 lbf.ft).

25. Td4 manual models: Align gearchange

linkage to bulkhead, fit bolts and tighten to 25

Nm (18 lbf.ft).

26. Td4 manual models: Connect gear change

rods to gear change linkage.

27. Td4 auto models:Align IRD hose 'P' clip fit bolt

and tighten to 25 Nm (18 lbf.ft).

28.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

29.Remove stands and lower vehicle.

30.Bleed PAS system.

+ STEERING, ADJUSTMENTS, Power

assisted steering (PAS) system - bleed.

31.Check and adjust front wheel alignment.

+ STEERING, ADJUSTMENTS, Front

wheel alignment - check & adjust.