key LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 13 of 1007

CONTENTS

10 CONTENTS

REAR AXLE & FINAL DRIVE ................................................................... 51-1

REPAIRS

Differential assembly ..................................................................................................................... 51-1

Cover - rear - differential ................................................................................................................. 51-2

Bush - differential mounting - front ................................................................................................. 51-3

Bush - differential mounting - rear ................................................................................................. 51-4

Oil seal - pinion .............................................................................................................................. 51-5

Oil seal - differential housing ......................................................................................................... 51-6

STEERING ................................................................................................ 57-1

ADJUSTMENTS

Power assisted steering (PAS) system - bleed............................................................................... 57-1

Cable - key interlock - adjust .......................................................................................................... 57-1

Front wheel alignment - check & adjust .......................................................................................... 57-2

Alignment - rear wheel - check & adjust ......................................................................................... 57-3

Power steering - pressure test ........................................................................................................ 57-4

REPAIRS

Power steering rack ........................................................................................................................ 57-5

Gaiter - PAS rack ............................................................................................................................ 57-8

Oil cooler - Td4 & K1.8 models ....................................................................................................... 57-9

Oil cooler - KV6 models .................................................................................................................. 57-10

Drive belt - K1.8 .............................................................................................................................. 57-11

Pump - steering - KV6 .................................................................................................................... 57-12

Pump - steering - K1.8 .................................................................................................................... 57-14

Pump - steering - Td4 ..................................................................................................................... 57-15

Nacelle - column ............................................................................................................................. 57-16

Column lock & ignition/starter switch assembly .............................................................................. 57-17

Cable - key interlock ....................................................................................................................... 57-18

Column assembly - inner & outer ................................................................................................... 57-19

Ball joint - track rod ......................................................................................................................... 57-23

Track rod......................................................................................................................................... 57-24

Steering wheel ................................................................................................................................ 57-25

FRONT SUSPENSION .............................................................................. 60-1

REPAIRS

Anti roll bar...................................................................................................................................... 60-1

Ball joint link - anti roll bar .............................................................................................................. 60-2

Mounting rubbers - anti roll bar - set .............................................................................................. 60-2

Bearing - hub ................................................................................................................................. 60-3

Damper .......................................................................................................................................... 60-7

Lower arm assembly ...................................................................................................................... 60-10

Rear beam ..................................................................................................................................... 60-13

Bush - lower arm - front .................................................................................................................. 60-15

Bush - lower arm - rear ................................................................................................................... 60-16

Page 20 of 1007

CONTENTS

CONTENTS 17

BODY SEALING MATERIALS ................................................................. 77-3-1

MATERIALS AND APPLICATIONS

........................................................................................................................................................ 77-3-1

APPROVED MATERIALS

........................................................................................................................................................ 77-3-3

APPLICATION EQUIPMENT

Application Equipment .................................................................................................................... 77-3-5

CORROSION PREVENTION AND SEALING .......................................... 77-4-1

CORROSION PREVENTION

Cavity wax treatment areas and injection holes - 3 door ................................................................ 77-4-1

Key to Figure, cavity wax treatment areas and injection holes - 3 door .......................................... 77-4-2

Sill cavity wax injection holes - 5 door ............................................................................................ 77-4-3

Door cavity wax treatment areas and injection hole - 5 door .......................................................... 77-4-4

Corrosion Prevention ...................................................................................................................... 77-4-5

SEALING

Underbody sealer treatment areas ................................................................................................. 77-4-7

Underbody sealer............................................................................................................................ 77-4-8

INTERNAL SEALING

Expanding foam acoustic seals ...................................................................................................... 77-4-27

Expanding foam acoustic seals ...................................................................................................... 77-4-28

LEAK DETECTION

Water Leaks .................................................................................................................................... 77-4-31

PAINTING ................................................................................................. 77-5-1

PANEL PROCEDURES

Panel Preparation ........................................................................................................................... 77-5-1

PAINT PROCEDURES

Paint preparation............................................................................................................................. 77-5-2

Page 28 of 1007

INTRODUCTION

01-3

Abbreviations and Symbols

A Amperes

AAP Ambient Air Pressure

AAT Ambient Air Temperature

ABDC After Bottom Dead Centre

ABS Anti-Lock Brake System

ABS / TC Anti-lock Brake System / Traction

Control

ac Alternating current

A/C Air Conditioning

ACE Active Cornering Enhancement

ACEA Association of Constructors of

European Automobiles

AFR Air Fuel Ratio

AP Ambient Pressure

ASC Anti-shunt Control

ATC Air Temperature Control

ATDC After Top Dead Centre

AUX Auxiliary

AVC Automatic Volume Control

BBDC Before Bottom Dead Centre

BBUS Battery Backed Up Sounder

BCU Body Control Unit

BDC Bottom Dead Centre

bhp Brake Horse Power

BP Boost Pressure

BPP Brake Pedal Position

BS British Standard

BTDC Before Top Dead Centre

BWD Backward

C Celsius

CAN Controller Area Network

CD Compact Disc

CDC Centre Differential Control

CDL Central Door Locking

CD - ROM Compact Disc - Read Only

Memory

CFC Chlorofluorocarbon

CHMSL Centre High Mounted Stop Lamp

CKP Crankshaft Position

CLV Calculated Load Value

cm Centimetre

cm

2Square centimetre

cm3Cubic centimetre

CMP Camshaft Position

CPP Clutch Pedal Position

CO Carbon Monoxide

CO

2Carbon Dioxide

COB Clear Over Base

CR Common Rail

CVS Canister Vent Solenoid

dB Decibels

DDM Driver's Door Module

deg. Degree, angle or temperature

DI Direct Injection

dia. DiameterDIN Deutsche Industrie Normen

(German Industrial Standards)

dc Direct current

DCV Directional Control Valve

DOHC Double Overhead Camshaft

DSP Digital Signal Processing

DTI Dial Test Indicator

DMF Dual Mass Flywheel

DVD Digital Versatile Disc

EACV Electronic Air Control Valve

EAT Electronic Automatic

Transmission

EBD Electronic Brake pressure

Distribution

ECD European Community Directive

ECM Engine Control Module

ECT Engine Coolant Temperature

ECU Electronic Control Unit

EDC Electronic Diesel Control

EEPROM Electronic Erasable

Programmable Read Only

Memory

EGR Exhaust Gas Recirculation

EKA Emergency Key Access

ELR Emergency Locking Retractor

EN European Norm

EOBD European On Board Diagnostics

EON Enhanced Other Network

ERL Electrical Reference Library

ETC Electronic Traction Control

EUI Electronic Unit Injector

EVAP Evaporative Emission

EVR Electronic Vacuum Regulator

F Fahrenheit

ft. Feet

FBH Fuel Burning Heater

FET Field Effect Transistor

FIP Fuel Injection Pump

FTC Fast Throttle Control

FWD Forward

> Greater than

g Gramme or Gravity

gal. Gallons

GMT Greenwich Mean Time

GPS Global Positioning System

hHour

hc High compression

HC Hydro Carbons

HDC Hill Descent Control

HDOP Height Dilation Of Precision

HDPE High Density Polyethylene

HFS Heated Front Screen

Hg Mercury

HO

2S Heated Oxygen Sensor

HMW High Molecular Weight

Page 41 of 1007

GENERAL INFORMATION

03-10

Joints and joint faces

General

Fit joints dry unless specified otherwise.

lAlways use the correct gaskets as specified.

lWhen joining compound is used, apply in a thin

uniform film to metal surfaces; take care to

prevent joining compound from entering

oilways, pipes or blind tapped holes.

lIf gaskets and/or joining compound is

recommended for use; remove all traces of old

joining material prior to reassembly. Do not use

a tool which will damage the joint faces and

smooth out any scratches or burrs using an oil

stone. Do not allow dirt or joining material to

enter any tapped holes or enclosed parts.

lPrior to reassembly, blow through any pipes,

channels or crevices with compressed air.

Locking devices

General

Always replace locking devices with one of the same

design.

Tab Washers

Always release locking tabs and fit new locking

washers, do not re-use locking tabs. Ensure the new

tab washer is the same design as that replaced.

Locking Nuts

Always use a backing spanner when loosening or

tightening locking nuts, brake and fuel pipe unions.

Roll Pins

Always fit new roll pins of an interference fit in the

hole.

Circlips

Always fit new circlips of the correct size for the

groove.

Locking wire

Always fit locking wire of the correct type. Arrange

wire so that its tension tends to tighten the bolt heads

or nuts to which it is fitted.

Keys and Keyways

Remove burrs from edges of keyways with a fine file

and clean thoroughly before attempting to refit key.

Clean and inspect key closely; keys are suitable for

refitting only if indistinguishable from new, as any

indentation may indicate the onset of wear.

Page 52 of 1007

GENERAL INFORMATION

03-21

It should be noted that these precautions are not

restricted to operations performed when servicing

the SRS system, the same care should be exercised

when working on ancillary systems and components

located in the vicinity of SRS components; these

include but are not limited to:

lSteering system – steering wheel airbag,

rotary coupler.

lFront fascia – passenger front airbag (where

fitted); SRS DCU behind centre console, on

transmission tunnel under the HeVAC system.

lFront seats – seat belt pre-tensioners, integral

with seat belt buckle assembly.

lElectrical system – SRS harnesses, link leads

and connectors.

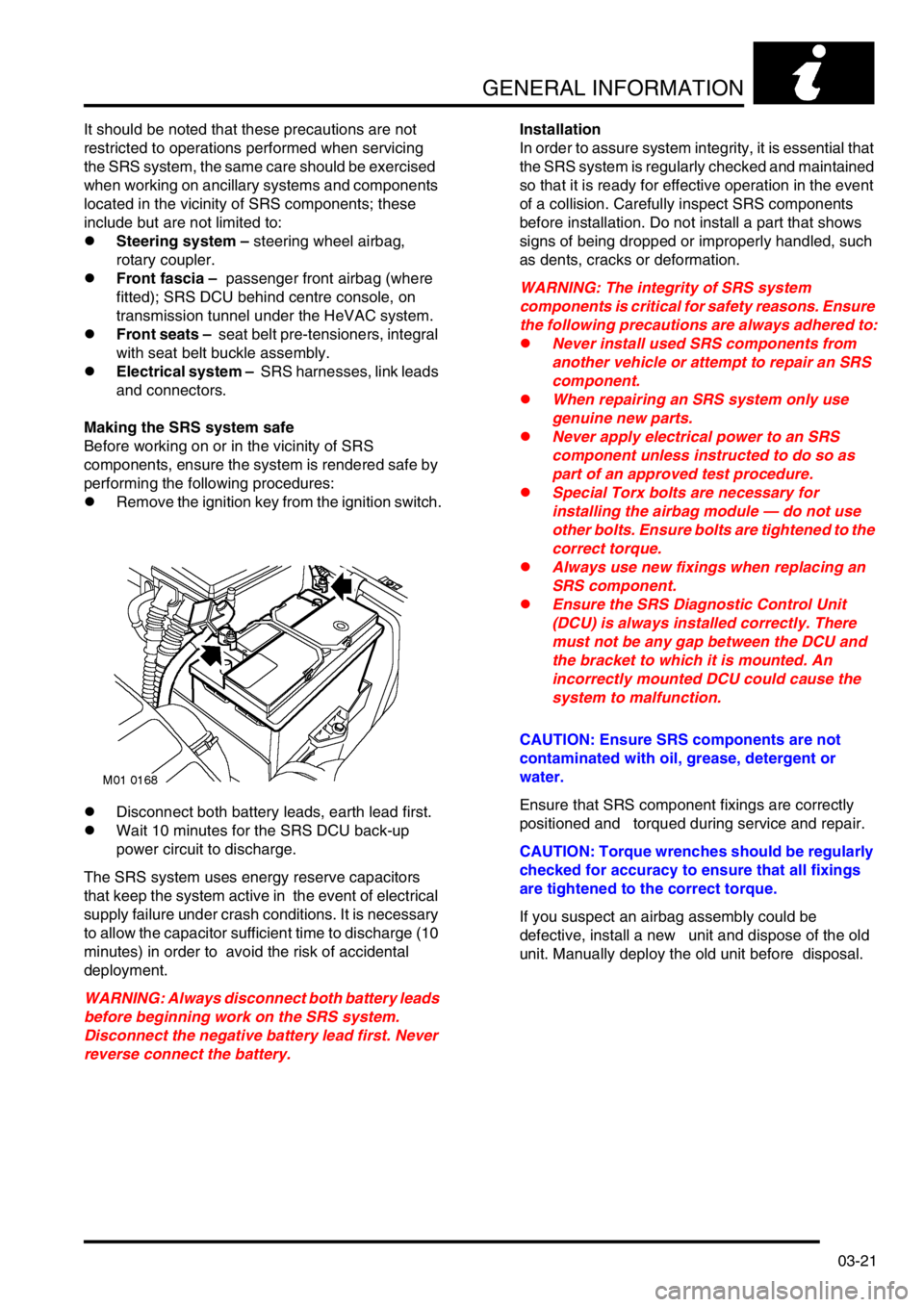

Making the SRS system safe

Before working on or in the vicinity of SRS

components, ensure the system is rendered safe by

performing the following procedures:

lRemove the ignition key from the ignition switch.

lDisconnect both battery leads, earth lead first.

lWait 10 minutes for the SRS DCU back-up

power circuit to discharge.

The SRS system uses energy reserve capacitors

that keep the system active in the event of electrical

supply failure under crash conditions. It is necessary

to allow the capacitor sufficient time to discharge (10

minutes) in order to avoid the risk of accidental

deployment.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.Installation

In order to assure system integrity, it is essential that

the SRS system is regularly checked and maintained

so that it is ready for effective operation in the event

of a collision. Carefully inspect SRS components

before installation. Do not install a part that shows

signs of being dropped or improperly handled, such

as dents, cracks or deformation.

WARNING: The integrity of SRS system

components is critical for safety reasons. Ensure

the following precautions are always adhered to:

lNever install used SRS components from

another vehicle or attempt to repair an SRS

component.

lWhen repairing an SRS system only use

genuine new parts.

lNever apply electrical power to an SRS

component unless instructed to do so as

part of an approved test procedure.

lSpecial Torx bolts are necessary for

installing the airbag module — do not use

other bolts. Ensure bolts are tightened to the

correct torque.

lAlways use new fixings when replacing an

SRS component.

lEnsure the SRS Diagnostic Control Unit

(DCU) is always installed correctly. There

must not be any gap between the DCU and

the bracket to which it is mounted. An

incorrectly mounted DCU could cause the

system to malfunction.

CAUTION: Ensure SRS components are not

contaminated with oil, grease, detergent or

water.

Ensure that SRS component fixings are correctly

positioned and torqued during service and repair.

CAUTION: Torque wrenches should be regularly

checked for accuracy to ensure that all fixings

are tightened to the correct torque.

If you suspect an airbag assembly could be

defective, install a new unit and dispose of the old

unit. Manually deploy the old unit before disposal.

Page 105 of 1007

TORQUE WRENCH SETTINGS

06-2

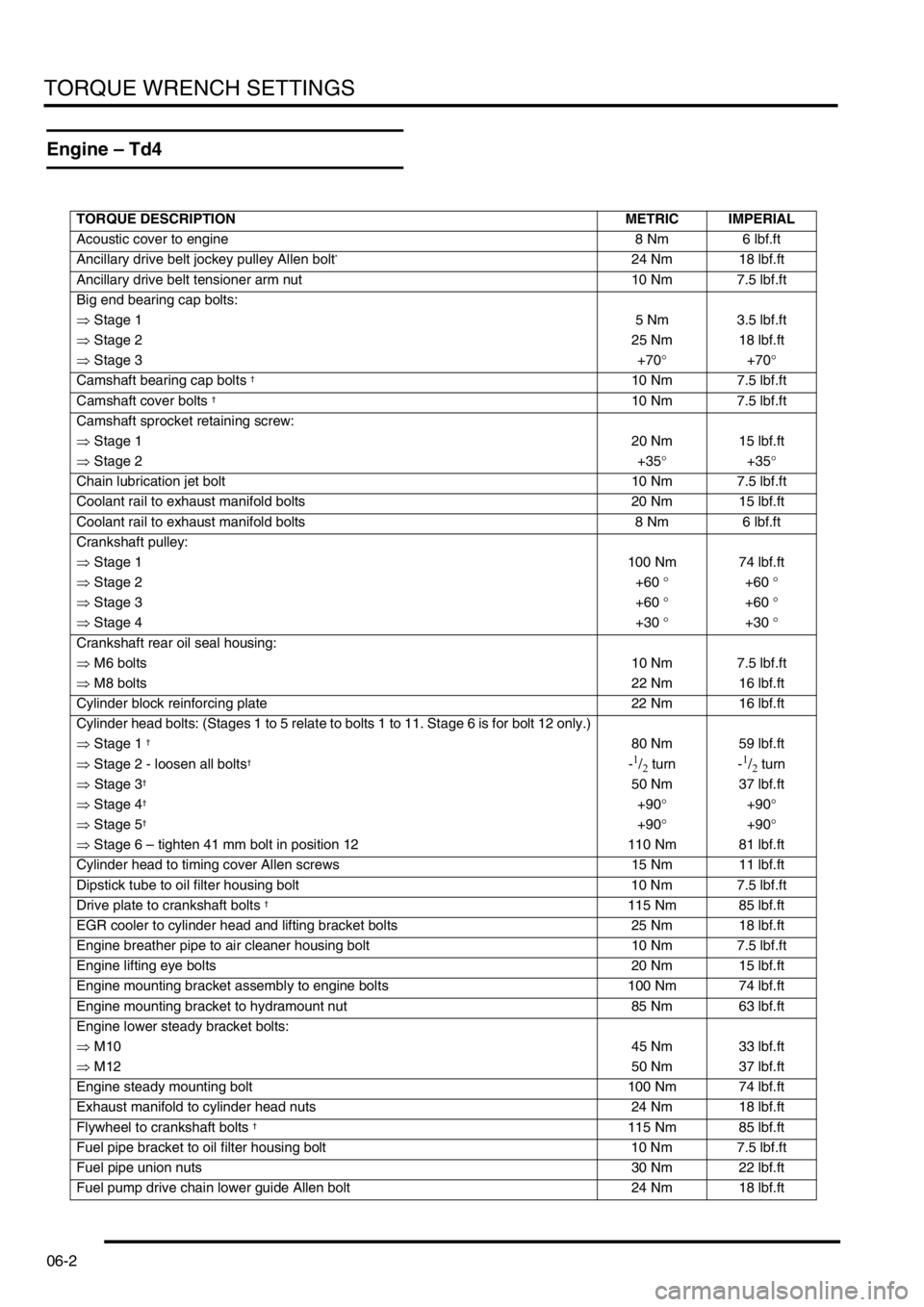

Engine – Td4

TORQUE DESCRIPTION METRIC IMPERIAL

Acoustic cover to engine 8 Nm 6 lbf.ft

Ancillary drive belt jockey pulley Allen bolt

*24 Nm 18 lbf.ft

Ancillary drive belt tensioner arm nut 10 Nm 7.5 lbf.ft

Big end bearing cap bolts:

⇒ Stage 15 Nm 3.5 lbf.ft

⇒ Stage 225 Nm 18 lbf.ft

⇒ Stage 3+70°+70°

Camshaft bearing cap bolts

† 10 Nm 7.5 lbf.ft

Camshaft cover bolts

† 10 Nm 7.5 lbf.ft

Camshaft sprocket retaining screw:

⇒ Stage 120 Nm 15 lbf.ft

⇒ Stage 2+35°+35°

Chain lubrication jet bolt 10 Nm 7.5 lbf.ft

Coolant rail to exhaust manifold bolts 20 Nm 15 lbf.ft

Coolant rail to exhaust manifold bolts 8 Nm 6 lbf.ft

Crankshaft pulley:

⇒ Stage 1100 Nm 74 lbf.ft

⇒ Stage 2+60 °+60 °

⇒ Stage 3+60 °+60 °

⇒ Stage 4+30 °+30 °

Crankshaft rear oil seal housing:

⇒ M6 bolts10 Nm 7.5 lbf.ft

⇒ M8 bolts22 Nm 16 lbf.ft

Cylinder block reinforcing plate 22 Nm 16 lbf.ft

Cylinder head bolts: (Stages 1 to 5 relate to bolts 1 to 11. Stage 6 is for bolt 12 only.)

⇒ Stage 1

†80 Nm 59 lbf.ft

⇒ Stage 2 - loosen all bolts

†-1/2 turn -1/2 turn

⇒ Stage 3

†50 Nm 37 lbf.ft

⇒ Stage 4

†+90°+90°

⇒ Stage 5

†+90°+90°

⇒ Stage 6 – tighten 41 mm bolt in position 12 110 Nm 81 lbf.ft

Cylinder head to timing cover Allen screws 15 Nm 11 lbf.ft

Dipstick tube to oil filter housing bolt 10 Nm 7.5 lbf.ft

Drive plate to crankshaft bolts

† 115 Nm 85 lbf.ft

EGR cooler to cylinder head and lifting bracket bolts 25 Nm 18 lbf.ft

Engine breather pipe to air cleaner housing bolt 10 Nm 7.5 lbf.ft

Engine lifting eye bolts 20 Nm 15 lbf.ft

Engine mounting bracket assembly to engine bolts 100 Nm 74 lbf.ft

Engine mounting bracket to hydramount nut 85 Nm 63 lbf.ft

Engine lower steady bracket bolts:

⇒ M1045 Nm 33 lbf.ft

⇒ M1250 Nm 37 lbf.ft

Engine steady mounting bolt 100 Nm 74 lbf.ft

Exhaust manifold to cylinder head nuts 24 Nm 18 lbf.ft

Flywheel to crankshaft bolts

† 115 Nm 85 lbf.ft

Fuel pipe bracket to oil filter housing bolt 10 Nm 7.5 lbf.ft

Fuel pipe union nuts 30 Nm 22 lbf.ft

Fuel pump drive chain lower guide Allen bolt 24 Nm 18 lbf.ft

Page 128 of 1007

TORQUE WRENCH SETTINGS

06-25

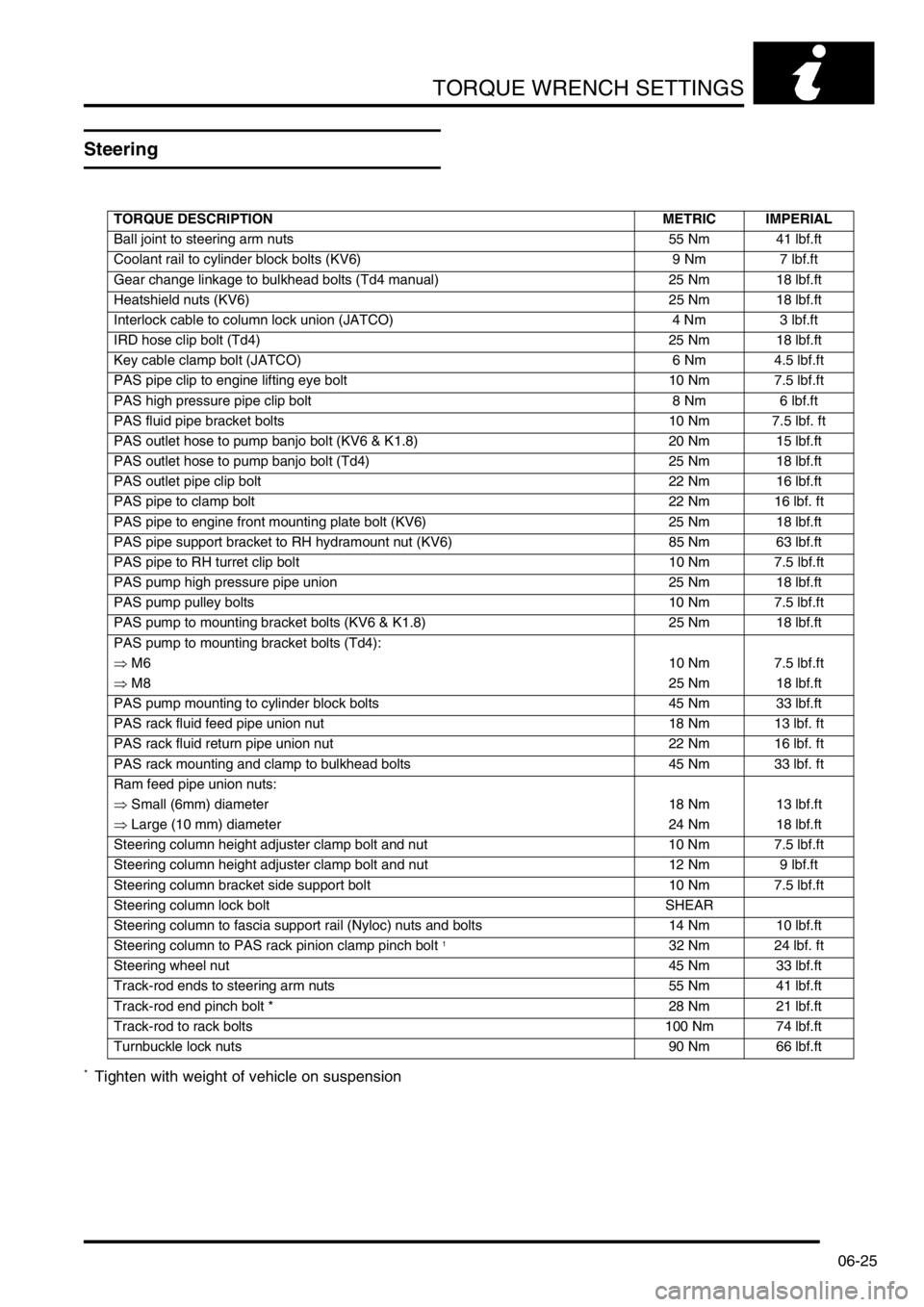

Steering

* Tighten with weight of vehicle on suspension

TORQUE DESCRIPTION METRIC IMPERIAL

Ball joint to steering arm nuts 55 Nm 41 lbf.ft

Coolant rail to cylinder block bolts (KV6) 9 Nm 7 lbf.ft

Gear change linkage to bulkhead bolts (Td4 manual) 25 Nm 18 lbf.ft

Heatshield nuts (KV6) 25 Nm 18 lbf.ft

Interlock cable to column lock union (JATCO) 4 Nm 3 lbf.ft

IRD hose clip bolt (Td4) 25 Nm 18 lbf.ft

Key cable clamp bolt (JATCO) 6 Nm 4.5 lbf.ft

PAS pipe clip to engine lifting eye bolt 10 Nm 7.5 lbf.ft

PAS high pressure pipe clip bolt 8 Nm 6 lbf.ft

PAS fluid pipe bracket bolts 10 Nm 7.5 lbf. ft

PAS outlet hose to pump banjo bolt (KV6 & K1.8) 20 Nm 15 lbf.ft

PAS outlet hose to pump banjo bolt (Td4) 25 Nm 18 lbf.ft

PAS outlet pipe clip bolt 22 Nm 16 lbf.ft

PAS pipe to clamp bolt 22 Nm 16 lbf. ft

PAS pipe to engine front mounting plate bolt (KV6) 25 Nm 18 lbf.ft

PAS pipe support bracket to RH hydramount nut (KV6) 85 Nm 63 lbf.ft

PAS pipe to RH turret clip bolt 10 Nm 7.5 lbf.ft

PAS pump high pressure pipe union 25 Nm 18 lbf.ft

PAS pump pulley bolts 10 Nm 7.5 lbf.ft

PAS pump to mounting bracket bolts (KV6 & K1.8) 25 Nm 18 lbf.ft

PAS pump to mounting bracket bolts (Td4):

⇒ M610 Nm 7.5 lbf.ft

⇒ M825 Nm 18 lbf.ft

PAS pump mounting to cylinder block bolts 45 Nm 33 lbf.ft

PAS rack fluid feed pipe union nut 18 Nm 13 lbf. ft

PAS rack fluid return pipe union nut 22 Nm 16 lbf. ft

PAS rack mounting and clamp to bulkhead bolts 45 Nm 33 lbf. ft

Ram feed pipe union nuts:

⇒ Small (6mm) diameter 18 Nm 13 lbf.ft

⇒ Large (10 mm) diameter 24 Nm 18 lbf.ft

Steering column height adjuster clamp bolt and nut 10 Nm 7.5 lbf.ft

Steering column height adjuster clamp bolt and nut 12 Nm 9 lbf.ft

Steering column bracket side support bolt 10 Nm 7.5 lbf.ft

Steering column lock bolt SHEAR

Steering column to fascia support rail (Nyloc) nuts and bolts 14 Nm 10 lbf.ft

Steering column to PAS rack pinion clamp pinch bolt

132 Nm 24 lbf. ft

Steering wheel nut 45 Nm 33 lbf.ft

Track-rod ends to steering arm nuts 55 Nm 41 lbf.ft

Track-rod end pinch bolt * 28 Nm 21 lbf.ft

Track-rod to rack bolts 100 Nm 74 lbf.ft

Turnbuckle lock nuts 90 Nm 66 lbf.ft

Page 141 of 1007

LIFTING AND TOWING

08-2

Raising the front of a vehicle

Position the cup of the hydraulic arm under the

centre of the front body crossmember assembly.

Use jack to raise front road wheels to enable safety

stands to be installed under the front end of each

longitudinal member.

Carefully lower jack until vehicle sits securely on

safety stands.

Before working on the underside of a vehicle re-

check the stability of the vehicle on the stands.

Use the reverse procedure when removing a vehicle

from stands.

NOTE: For some repair operations it may be

necessary to use a jack to support the engine under

the sump. In this case, a block of wood should be

used on the jack to protect the sump.

Raising the rear of a vehicle

Position cup of hydraulic arm under the centre of the

rear subframe crossmember at the position

identified by the embossed arrows.

Use jack to raise rear road wheels to enable safety

stands to be installed under the rear ends of the

body longitudinal members.

Carefully lower jack until vehicle sits securely on

safety stands.

Before working on the underside of a vehicle, re-

check the stability of the vehicle on the stands.

Use the reverse procedure when removing a vehicle

from stands.

Wheel-free lift

Locate the lifting pads under the ends of the body

longitudinal members. Raise the ramp to support the

weight of the vehicle, ensure the vehicle is secure on

the lifting pads, then raise the ramp to the required

height.

Towing

General

The vehicle has permanent four wheel drive. The

following instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes

lTurn ignition key to position '1' to release

steering lock and then to position 'II' to enable

the brake lights, wipers and direction indicators

to be operated, if necessary.

l Select neutral in gearbox and ensure HDC (hill

descent control) is deselected.

lSecure tow rope, chain or cable to towing eye.

lRelease the parking brake.

CAUTION: The brake servo and power assisted

steering system will not be functional without the

engine running. Greater pedal pressure will be

required to apply the brakes and the steering

system will require greater effort to turn the front

road wheels. The vehicle tow connection should

only be used under normal road conditions,

'snatch' recovery should be avoided.

Suspended tow by breakdown vehicle

Mark propeller shaft drive flanges and mating flanges

with identification lines to enable the propeller shaft

to be refitted in its original position.

Remove the propeller shaft fixings then remove the

shaft from the vehicle.

CAUTION: To prevent vehicle damage, rear

propeller shaft MUST BE removed.

Page 142 of 1007

LIFTING AND TOWING

08-3

If the front of the vehicle is to be trailed, turn ignition

key to position 'I' to release steering lock.

WARNING: Do not turn the starter switch to

position '0' or remove the ignition key while the

vehicle is being towed.

CAUTION: If it is considered unsafe to turn the

starter switch to position '1' due to accident

damage or an electrical fault; disconnect the

battery before turning the ignition switch.

CAUTION: The steering wheel and/or linkage

must be secured in a straight ahead position. DO

NOT use the steering lock mechanism for this

purpose.

CAUTION: Under no circumstances should the

vehicle be towed or recovered by means of

lashing to the rear subframe. Serious damage to

the subframe and body could result.

CAUTION: Only use the rear towing eye for

towing another vehicle.

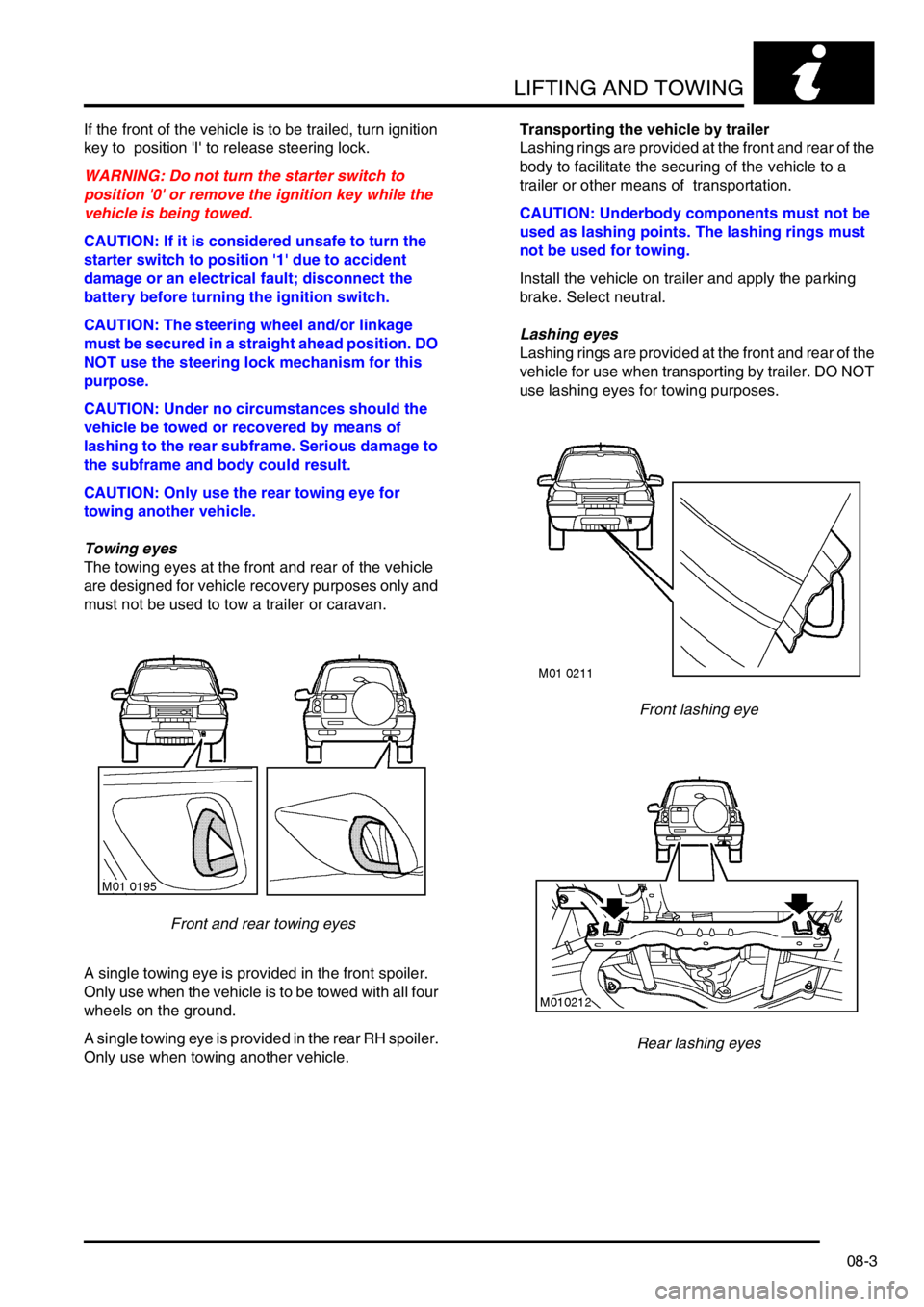

Towing eyes

The towing eyes at the front and rear of the vehicle

are designed for vehicle recovery purposes only and

must not be used to tow a trailer or caravan.

Front and rear towing eyes

A single towing eye is provided in the front spoiler.

Only use when the vehicle is to be towed with all four

wheels on the ground.

A single towing eye is provided in the rear RH spoiler.

Only use when towing another vehicle.Transporting the vehicle by trailer

Lashing rings are provided at the front and rear of the

body to facilitate the securing of the vehicle to a

trailer or other means of transportation.

CAUTION: Underbody components must not be

used as lashing points. The lashing rings must

not be used for towing.

Install the vehicle on trailer and apply the parking

brake. Select neutral.

Lashing eyes

Lashing rings are provided at the front and rear of the

vehicle for use when transporting by trailer. DO NOT

use lashing eyes for towing purposes.

Front lashing eye

Rear lashing eyes

Page 153 of 1007

MAINTENANCE

10-6 MAINTENANCE

Alarm Handset Battery

Replace

1.Insert the blade of a small, flat bladed

screwdriver into the slot at the keyring end of

the handset and carefully prise the two halves

of the handset apart.

2.Slide the battery out of the clip taking care not

to touch the circuit board or the battery

contacts.

3.Press and hold each button in turn for at least 5

seconds to drain any residual power from the

handset.

4.Fit the replacement battery (Land Rover

STC4080 or Panasonic CR2032) ensuring the

correct polarity is maintained (+) side facing

upwards. Avoid touching the flat surfaces of the

battery.

5.Press the 2 halves of the handset together,

making sure the two halves click into place

correctly.

6.Check the operation of the handset.

Road Wheels

Remove

1.Loosen wheel nuts. Raise vehicle for wheel

free condition and remove the wheel nuts.

2.Mark the wheel to stud relationship to ensure

that the wheels are refitted in the same

orientation.

Refit

1.Apply a thin coat of anti-seize compound to

wheel hub centre.

2.Refit wheels to original hub position.

NOTE: When refitting road wheel nuts, do not

overtighten using powered tools. Ensure the

wheel nuts are correctly torqued in the correct

sequence.

3.Tighten wheel nuts to 115 Nm (85 lbf.ft).