light LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 14 of 1007

CONTENTS

CONTENTS 11

REAR SUSPENSION ................................................................................ 64-1

REPAIRS

Bush - trailing link............................................................................................................................ 64-1

Bearing - hub ................................................................................................................................. 64-2

Damper .......................................................................................................................................... 64-5

Trailing arm .................................................................................................................................... 64-8

Bush - trailing arm .......................................................................................................................... 64-9

Link - adjustable - transverse ......................................................................................................... 64-10

Link - transverse fixed .................................................................................................................... 64-11

Bush - link - transverse .................................................................................................................. 64-12

Sub frame ...................................................................................................................................... 64-13

BRAKES ................................................................................................... 70-1

ADJUSTMENTS

Brake bleed ..................................................................................................................................... 70-1

Cable - handbrake - check and adjust ............................................................................................ 70-2

REPAIRS

Drum - rear ...................................................................................................................................... 70-3

Disc - front....................................................................................................................................... 70-5

Hose - front - primary - LH .............................................................................................................. 70-6

Hose - rear ...................................................................................................................................... 70-7

Cylinder - master - tandem - LHD ................................................................................................... 70-8

Cylinder - master - tandem - RHD................................................................................................... 70-9

Lever assembly - handbrake........................................................................................................... 70-10

Cable - handbrake ......................................................................................................................... 70-11

Switch - handbrake warning ............................................................................................................ 70-12

Switch - stop light ............................................................................................................................ 70-13

Sensor - brake pedal position ........................................................................................................ 70-13

Shoes/pads - front - set................................................................................................................... 70-14

Brake Shoes - rear set .................................................................................................................... 70-15

Servo assembly - LHD .................................................................................................................... 70-17

Servo assembly - RHD ................................................................................................................... 70-19

Vacuum pump - Td4 - manual ........................................................................................................ 70-20

Vacuum pump - Td4 - automatic ..................................................................................................... 70-21

Vacuum - enhancer - KV6 .............................................................................................................. 70-22

Carrier assembly - calliper - front ................................................................................................... 70-23

Wheel cylinder - rear ....................................................................................................................... 70-24

Switch - low fluid level ..................................................................................................................... 70-25

Sensor & harness - front wheel - RH .............................................................................................. 70-25

Sensor & harness - front wheel - LH ............................................................................................... 70-27

Sensor & harness - rear wheel ....................................................................................................... 70-29

Modulator unit ................................................................................................................................. 70-30

Switch - hill descent - from 04MY ................................................................................................... 70-31

Switch - hill descent - up to 03MY................................................................................................... 70-32

Page 15 of 1007

CONTENTS

12 CONTENTS

RESTRAINT SYSTEMS ............................................................................ 75-1

REPAIRS

Automatic belt assembly - front - 3 door ......................................................................................... 75-1

Automatic belt assembly - front - 5 door ......................................................................................... 75-2

Seat belt - centre - rear ................................................................................................................... 75-3

Seat belt - rear - LH ........................................................................................................................ 75-4

Adjustable mounting - seat belt - 'B' pillar ....................................................................................... 75-5

Stalk - rear seat belt - LH - 3 door .................................................................................................. 75-6

Stalk - rear seat belt - LH - 5 door .................................................................................................. 75-7

Pre-tensioner - seat belt - front ....................................................................................................... 75-8

Pre-tensioner - seat belt - front - deployment - off vehicle ............................................................. 75-9

Stalk - rear seat belt - centre .......................................................................................................... 75-11

Air bag - steering wheel .................................................................................................................. 75-13

Air bag - fascia - passenger - up to 04MY ...................................................................................... 75-14

Air bag - fascia - passenger - from 04MY ....................................................................................... 75-15

Diagnostic control unit (DCU) ........................................................................................................ 75-16

Airbag - passenger - deployment - off vehicle ............................................................................... 75-17

Rotary coupler - (SRS) air bag system ........................................................................................... 75-19

Airbag module - steering wheel - deployment - off vehicle ............................................................ 75-20

Airbag module - steering wheel - deployment - in-vehicle .............................................................. 75-21

Pre-tensioner - front seatbelt - deployment - in-vehicle .................................................................. 75-23

DOORS...................................................................................................... 76-1-1

ADJUSTMENTS

Door - front or rear - adjust on striker ............................................................................................ 76-1-1

Door - front - align on hinges .......................................................................................................... 76-1-2

REPAIRS

Door assembly - front - remove for access & refit .......................................................................... 76-1-3

Door assembly - rear - remove for access & refit ........................................................................... 76-1-4

Door - tail assembly - remove for access & refit ............................................................................. 76-1-5

Glass - front door .......................................................................................................................... 76-1-6

Glass - rear door ............................................................................................................................ 76-1-7

Rubber/felt - glass channel - front door ........................................................................................ 76-1-8

Rubber/felt - glass channel - rear door .......................................................................................... 76-1-9

Glass - tail door .............................................................................................................................. 76-1-10

Quarter light - rear door .................................................................................................................. 76-1-11

Glass regulator - tail door .............................................................................................................. 76-1-12

Seal - waist inner - tail door ............................................................................................................ 76-1-13

Trim casing - front door - 3 door .................................................................................................... 76-1-14

Trim casing - front door - 5 door - up to 04MY................................................................................ 76-1-15

Trim casing - front door - 5 door - from 04MY ................................................................................ 76-1-16

Trim casing - rear door - up to 04MY .............................................................................................. 76-1-18

Trim casing - rear door - from 04MY............................................................................................... 76-1-20

Trim casing - tail door ..................................................................................................................... 76-1-22

Plastic sheet - front door - lower - 3 door........................................................................................ 76-1-23

Pocket - front door - 3 door ............................................................................................................. 76-1-23

Plastic sheet - front door - upper - 3 door ....................................................................................... 76-1-24

Plastic sheet - tail door ................................................................................................................... 76-1-24

Plastic sheet - front door - 5 door .................................................................................................. 76-1-25

Plastic sheet - rear door.................................................................................................................. 76-1-25

Latch - front door - 3 door ............................................................................................................... 76-1-26

Latch - front door - 5 door .............................................................................................................. 76-1-27

Latch - rear door ............................................................................................................................. 76-1-28

Latch - tail door ............................................................................................................................... 76-1-29

Page 23 of 1007

CONTENTS

20 CONTENTS

LIGHTING.................................................................................................. 86-2-1

ADJUSTMENTS

Headlamps - pair - align beam - up to 04MY .................................................................................. 86-2-1

Headlamps - pair - align beam - from 04MY ................................................................................... 86-2-1

REPAIRS

Headlamp assembly - up to 04MY.................................................................................................. 86-2-3

Headlamp assembly - from 04MY .................................................................................................. 86-2-4

Lamp assembly - flasher side repeater - front ................................................................................ 86-2-5

Lamp assembly - tail ....................................................................................................................... 86-2-5

Lamp assembly - number plate ...................................................................................................... 86-2-6

Lamp assembly - fog/driving - from 04MY ...................................................................................... 86-2-6

Lamp assembly - rear ..................................................................................................................... 86-2-7

Lamp assembly - centre high mounted stop (CHMSL) ................................................................... 86-2-7

Lamp assembly - glove compartment ............................................................................................. 86-2-8

Lamp assembly - load space .......................................................................................................... 86-2-8

Switch - headlamp levelling ............................................................................................................ 86-2-9

Switch - glove compartment ........................................................................................................... 86-2-9

Switch - hazard warning ................................................................................................................. 86-2-10

Switch - combined direction indicator/headlight/horn ..................................................................... 86-2-10

Switch - rear fog lamp ..................................................................................................................... 86-2-11

CONTROL UNITS ..................................................................................... 86-3-1

REPAIRS

Control unit - window lift ................................................................................................................. 86-3-1

Relay - power folding mirrors - from 02MY ..................................................................................... 86-3-1

Central Control Unit (CCU) ............................................................................................................. 86-3-2

Control Unit - power fold mirrors - up to 02MY ............................................................................... 86-3-3

SECURITY................................................................................................. 86-4-1

REPAIRS

Solenoid/motor - taildoor................................................................................................................. 86-4-1

Switch/push - horn .......................................................................................................................... 86-4-2

Horn ................................................................................................................................................ 86-4-2

Immobilisation - electronic control unit (ECU) - ............................................................................. 86-4-3

Sensor - volumetric - alarm system - 3 door ................................................................................... 86-4-3

Module (ECU) - volumetric - alarm system - 5 door - without sunroof ........................................... 86-4-5

Module (ECU) - volumetric - alarm system - 5 door - with sunroof ................................................ 86-4-7

Receiver - alarm system ................................................................................................................. 86-4-10

Coil - passive immobilisation - alarm system .................................................................................. 86-4-10

Page 24 of 1007

CONTENTS

CONTENTS 21

WINDOWS ................................................................................................ 86-5-1

REPAIRS

Motor & control unit - front door - 3 door ......................................................................................... 86-5-1

Motor & control unit - front door - 5 door ......................................................................................... 86-5-2

Switch - master window - 5 door - from 04MY ................................................................................ 86-5-2

Relay - control - tail door glass ....................................................................................................... 86-5-3

Microswitch - hardtop sensing - 3 door ........................................................................................... 86-5-4

Relay - heated front screen ........................................................................................................... 86-5-5

Switch - backlight heater ................................................................................................................. 86-5-6

IN CAR ENTERTAINMENT ...................................................................... 86-6-1

REPAIRS

Radio - up to 04MY ......................................................................................................................... 86-6-1

Radio/CD - from 04MY .................................................................................................................... 86-6-2

Speaker - rear - 3 door .................................................................................................................... 86-6-3

Speaker - rear - 5 door .................................................................................................................... 86-6-3

Speaker - front ................................................................................................................................ 86-6-4

Aerial - manual - 3 door .................................................................................................................. 86-6-4

Aerial - manual - 5 door .................................................................................................................. 86-6-5

Coaxial lead - front aerial - 3 door ................................................................................................... 86-6-6

Coaxial lead - front aerial - 5 door ................................................................................................... 86-6-7

Speaker - tweeter - front ................................................................................................................. 86-6-8

Speaker - tweeter - rear - 3 door ..................................................................................................... 86-6-9

Amplifier - power ............................................................................................................................ 86-6-10

Sub-woofer assembly .................................................................................................................... 86-6-11

Coaxial lead - extension.................................................................................................................. 86-6-12

HARNESSES ............................................................................................ 86-7-1

REPAIRS

Fuse box - passenger compartment ............................................................................................... 86-7-1

Harness - main ................................................................................................................................ 86-7-2

Harness - tailgate ............................................................................................................................ 86-7-12

Harness - interior lights - 5 door ...................................................................................................... 86-7-15

Harness - front door - 5 door ........................................................................................................... 86-7-15

Harness - rear door ......................................................................................................................... 86-7-16

DRIVER CONTROLS ................................................................................ 86-8-1

REPAIRS

Switch - remote control - audio system .......................................................................................... 86-8-1

Switch - park distance control (PDC) - from 04 MY ........................................................................ 86-8-1

Control unit (ECU) - parking aid - from 04MY ................................................................................. 86-8-2

Sensor - parking aid - rear - from 04MY ......................................................................................... 86-8-2

Sounder - parking aid - rear - from 04MY ....................................................................................... 86-8-3

Switch - handbrake warning ............................................................................................................ 86-8-3

Switch - hazard warning - from 04MY ............................................................................................. 86-8-4

Cigar lighter - front .......................................................................................................................... 86-8-4

Switch - control - exterior mirror ...................................................................................................... 86-8-5

Page 29 of 1007

INTRODUCTION

01-4

HRW Heated Rear Window

ht/HT High tension

HSLA High Strength Low Alloy

IACV Idle Air Control Valve

IAT Intake Air Temperature

ICE In-Car Entertainment

i.dia. Internal diameter

IDM Intelligent Driver Module

IF Intermediate Frequency

in Inch

in

2Square inch

in3Cubic inch

ILT Inlet Throttle

ISO International Organisation for

Standardisation

ITS Inflatable Tubular Structure

k Thousand

kg Kilogramme

kg/h Kilogrammes per hour

km Kilometre

km/h Kilometres per hour

kPa KiloPascal

KS Knock Sensor

lb(s) Pounds

lbf Pounds force

lbf.in Pounds force inches

lbf/in

2Pounds per square inch

lbf.ft Pounds force feet

λLambda

lc Low compression

LCD Liquid Crystal Display

LED Light Emitting Diode

LEV Low Emission Vehicle

LH Left-Hand

LHD Left-Hand Drive

LSM Light Switch Module

LVS Liquid Vapour Separator

mMetre

µMicro

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MFU Multi-Function Unit

MFL Multi-Function Logic

max. Maximum

MEMS Modular Engine Management

System

MIG Metal/Inert Gas

MIL Malfunction Indicator Lamp

MPa MegaPascal

MOSFET Metal Oxide Semiconductor Field

Effect Transistor

min. Minimum

- Minus (tolerance)

' Minute (angle)

mm Millimetre

mph Miles per hour MPi Multi-Point injection

MV Motorised Valve

MY Model Year

NAS North American Specification

(-) Negative (electrical)

Nm Newton metre

No. Number

NO

2Nitrogen Dioxide

NO

xOxides of Nitrogen

NTC Negative Temperature

Coefficient

NRV Non Return Valve

OBD On Board Diagnostics

OBM On Board Monitoring

o.dia. Outside diameter

OAT Organic Acid Technology

ORM Off-road Mode

ΩOhm

PAS Power Assisted Steering

PCB Printed Circuit Board

PCV Positive Crankcase Ventilation

PDC Parking Distance Control

PDOP Position Dilation Of Precision

PI Programme Information

PPS Pulse Per Second

PS Programme Service

psi Pounds per square inch

pts. Pints

% Percentage

+ Plus (tolerance) or Positive

(electrical)

±Plus or minus (tolerance)

PTC Positive Temperature Coefficient

PTFE Polytetrafluorethylene

PWM Pulse Width Modulation

RDS Radio Data Service

rRadius

:Ratio

ref Reference

REG Regionalisation

RES Rover Engineering Standards

rev/min Revolutions per minute

RF Radio Frequency

RGB Red / Green / Blue

RH Right-Hand

RHD Right-Hand Drive

ROM Read Only Memory

RON Research Octane Number

ROV Roll Over Valve

ROW Rest Of World

SAE Society of Automotive Engineers

SAI Secondary Air Injection

" Second (angle)

SLABS Self Levelling and Anti-Lock

Brake System

SLS Self Levelling Suspension

SOHC Single Overhead Camshaft

SPE Single Point Entry

Page 36 of 1007

GENERAL INFORMATION

03-5

Local issues

A number of environmental issues will be of

particular concern to residents and other neighbours

close to the site. The sensitivity of these issues will

depend on the proximity of the site and the layout

and amount of activity carried on at the site.

Noise is a major concern and therefore consideration

should be given to the time spent carrying out noisy

activities and the location of those activities that can

cause excessive noise.

Car alarm testing, panel beating, hammering and

other such noisy activities should, whenever

possible, be carried out indoors with doors and

windows shut, or as far away from houses as

possible.

Running vehicle engines may be an outside activity

which could cause nuisance to neighbours because

of both noise and smell.

Be sensitive to the time of day when these activities

are carried out and minimise the time of the noisy

operation, particularly in the early morning and late

evening.

Another local concern will be the smell from the

various materials used. Using less solvent, paint and

petrol could help prevent this annoyance.

Local residents and other business users will also be

concerned about traffic congestion, noise and

exhaust fumes, be sensitive to these concerns and

try to minimise inconvenience from deliveries,

customers and servicing operations.

Checklist

Always adhere to the following:

lidentify where the neighbours who are likely to

be affected are situated;

lminimise noise, smells and traffic nuisance;

lprevent litter by putting waste in the correct

containers;

lhave waste skips emptied regularly.Use of resource

Another environmental concern is the waste of

materials and energy that can occur in day to day

activities.

Electricity for heating, lighting and compressed air

uses resources and releases pollution during its

generation.

Fuel used for heating, running cars or vans and

mobile plant is another limited resource which

consumes large amounts of energy during its

extraction and refining processes.

Water has to be cleaned, piped to site and disposed

of, all of which creates more potential pollution;

Oil, spares, paint etc., have all produced pollution in

the process of manufacture and they become a

waste disposal problem if discarded.

Checklist

Always adhere to the following:

Electricity and heating –

lkeep doors and windows closed in the winter;

lswitch off machinery or lights when not needed;

luse energy efficient heating systems;

lswitch off computers and photocopiers when

not needed.

Fuel –

ldon't run engines unnecessarily;

lthink about whether journeys are necessary and

drive to conserve fuel.

Water –

ldon't leave taps and hose pipes running;

lmend leaks quickly, don't be wasteful.

Compressed air –

ldon't leave valves open;

lmend leaks quickly;

ldon't leave the compressor running when not

needed.

Use of environmentally damaging materials –

lcheck whether a less toxic material is available.

Handling and storage of materials –

lhave the correct facilities available for handling

liquids to prevent spillage and wastage as listed

above;

lprovide suitable locations for storage to prevent

frost damage or other deterioration.

Page 38 of 1007

GENERAL INFORMATION

03-7

General fitting instructions

Precautions against damage

To avoid damage to the vehicle when carrying out

repairs, always adhere to the following:

lAlways fit wing and seat covers before

commencing work. Avoid spilling brake fluid or

battery acid on paintwork; immediately wash off

with water if this occurs.

lDisconnect the battery earth lead before starting

work, see ELECTRICAL PRECAUTIONS.

lAlways use the recommended service tool or a

satisfactory equivalent where specified.

lProtect exposed bearing surfaces, sealing

surfaces and screw threads from damage.

Component removal

Whenever possible, clean components and

surrounding area before removal.

lBlank off openings exposed by component

removal.

lImmediately seal fuel, oil or hydraulic lines when

apertures are exposed; use plastic caps or

plugs to prevent loss of fluid and ingress of dirt.

lClose open ends of oilways exposed by

component removal with tapered hardwood

plugs or conspicuous plastic plugs.

lImmediately a component is removed, place it in

a suitable container; use a separate container

for each component and its associated parts.

lClean bench and provide marking materials,

labels, containers and locking wire before

dismantling a component.

Dismantling

Observe scrupulous cleanliness when dismantling

components, particularly when brake, fuel or

hydraulic system parts are being worked on. A

particle of dirt or a cloth fragment could cause a

serious malfunction if trapped in these systems.Use the following procedures:

lBlow out all tapped holes, crevices, oilways and

fluid passages with an air line. Ensure that any

O-rings used for sealing are correctly replaced

or renewed if disturbed during the process.

lUse marking ink to identify mating parts and

ensure correct reassembly. Do not use a centre

punch or scriber to mark parts, they could

initiate cracks or distortion in marked

components.

lWire together mating parts where necessary to

prevent accidental interchange (e.g. roller

bearing components).

lWire labels on to all parts which are to be

renewed, and to parts requiring further

inspection before being passed for reassembly;

place these parts in separate containers from

those containing parts for rebuild.

lDo not discard a part due for renewal until after

comparing it with a new part to ensure that its

correct replacement has been obtained.

Cleaning components

Always use the recommended cleaning agent or

equivalent. Ensure that adequate ventilation is

provided when volatile degreasing agents are being

used. Do not use degreasing equipment for

components containing items which could be

damaged by the use of this process.

When washing under bonnet, never direct water onto

ECM, as water ingress may occur resulting in

damage to electrical components inside.

General Inspection

All components should be inspected for wear or

damage before being reassembled.

lNever inspect a component for wear or

dimensional check unless it is absolutely clean;

a slight smear of grease can conceal an

incipient failure.

lWhen a component is to be checked

dimensionally against recommended values,

use the appropriate measuring equipment

(surface plates, micrometers, dial gauges etc.).

Ensure the measuring equipment is calibrated

and in good serviceable condition.

lReject a component if its dimensions are

outside the specified tolerances, or if it appears

to be damaged.

lA part may be refitted if its critical dimension is

exactly to its tolerance limit and it appears to be

in satisfactory condition.

lUse 'Plastigauge' 12 Type PG-1 for checking

bearing surface clearances.

Page 42 of 1007

GENERAL INFORMATION

03-11

Split pins

Always fit new split-pins of the correct size for the

hole in the bolt or stud.

Screw threads

General

Metric threads to ISO standards are used.

Damaged nuts, bolts and screws must always be

discarded. Cleaning damaged threads with a die or

tap impairs the strength and closeness of fit of the

threads and is not recommended.

Always ensure that replacement bolts are at least

equal in strength to those replaced.

Castellated nuts must not be slackened to accept a

split-pin, except in recommended cases when this

forms part of an adjustment.

Do not allow oil or grease to enter blind threaded

holes. The hydraulic action on screwing in the bolt or

stud could split the housing.

Always tighten a nut or bolt to the recommended

torque figure. Damaged or corroded threads can

affect the torque reading.

To check or re-tighten a bolt or screw to a specified

torque figure, first loosen a quarter of a turn, then

retighten to the correct torque figure.

Oil thread lightly before tightening to ensure a free

running thread, except in the case of threads treated

with sealant/lubricant, and self-locking nuts.

Page 44 of 1007

GENERAL INFORMATION

03-13

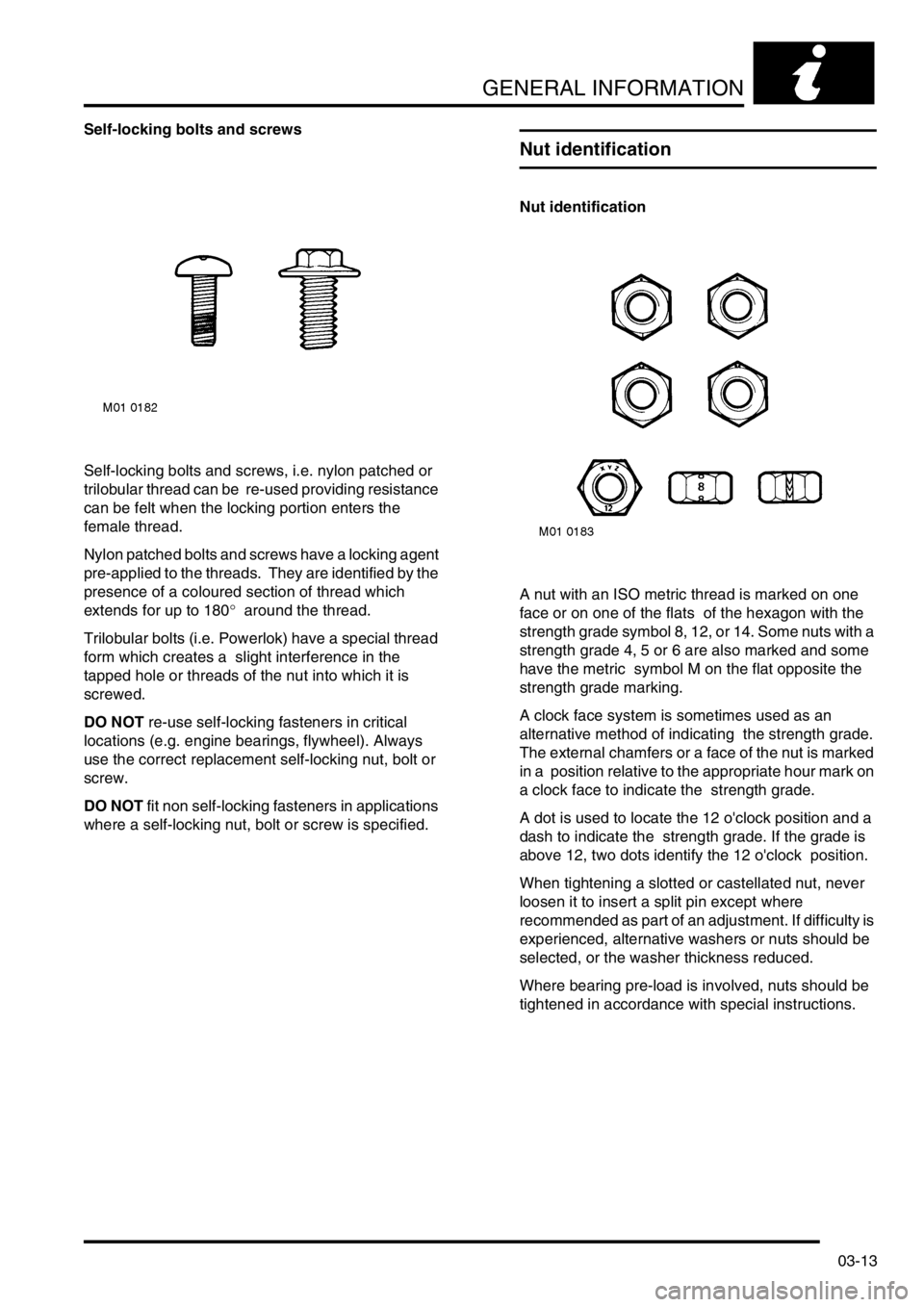

Self-locking bolts and screws

Self-locking bolts and screws, i.e. nylon patched or

trilobular thread can be re-used providing resistance

can be felt when the locking portion enters the

female thread.

Nylon patched bolts and screws have a locking agent

pre-applied to the threads. They are identified by the

presence of a coloured section of thread which

extends for up to 180° around the thread.

Trilobular bolts (i.e. Powerlok) have a special thread

form which creates a slight interference in the

tapped hole or threads of the nut into which it is

screwed.

DO NOT re-use self-locking fasteners in critical

locations (e.g. engine bearings, flywheel). Always

use the correct replacement self-locking nut, bolt or

screw.

DO NOT fit non self-locking fasteners in applications

where a self-locking nut, bolt or screw is specified.

Nut identification

Nut identification

A nut with an ISO metric thread is marked on one

face or on one of the flats of the hexagon with the

strength grade symbol 8, 12, or 14. Some nuts with a

strength grade 4, 5 or 6 are also marked and some

have the metric symbol M on the flat opposite the

strength grade marking.

A clock face system is sometimes used as an

alternative method of indicating the strength grade.

The external chamfers or a face of the nut is marked

in a position relative to the appropriate hour mark on

a clock face to indicate the strength grade.

A dot is used to locate the 12 o'clock position and a

dash to indicate the strength grade. If the grade is

above 12, two dots identify the 12 o'clock position.

When tightening a slotted or castellated nut, never

loosen it to insert a split pin except where

recommended as part of an adjustment. If difficulty is

experienced, alternative washers or nuts should be

selected, or the washer thickness reduced.

Where bearing pre-load is involved, nuts should be

tightened in accordance with special instructions.

Page 47 of 1007

GENERAL INFORMATION

03-16

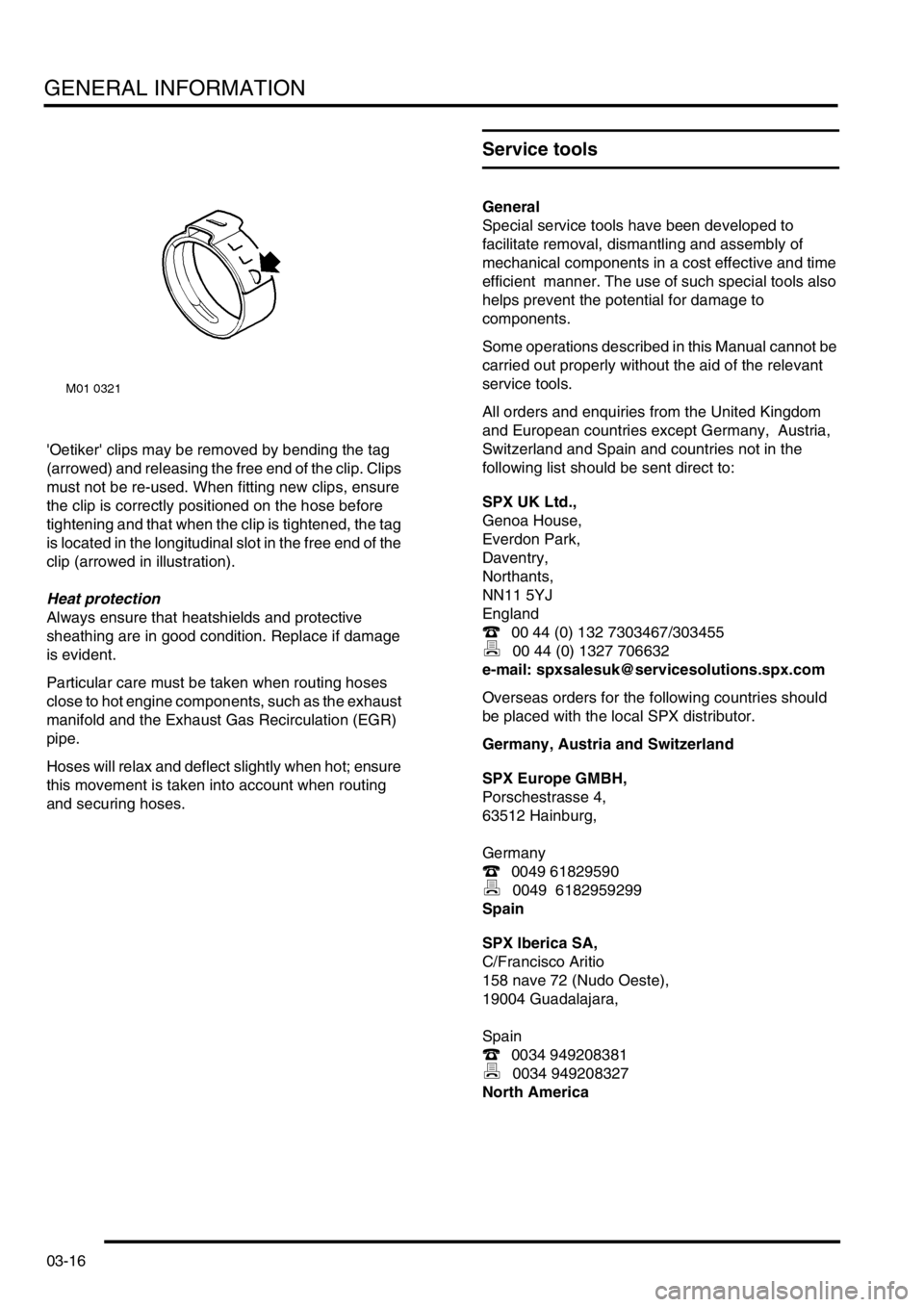

'Oetiker' clips may be removed by bending the tag

(arrowed) and releasing the free end of the clip. Clips

must not be re-used. When fitting new clips, ensure

the clip is correctly positioned on the hose before

tightening and that when the clip is tightened, the tag

is located in the longitudinal slot in the free end of the

clip (arrowed in illustration).

Heat protection

Always ensure that heatshields and protective

sheathing are in good condition. Replace if damage

is evident.

Particular care must be taken when routing hoses

close to hot engine components, such as the exhaust

manifold and the Exhaust Gas Recirculation (EGR)

pipe.

Hoses will relax and deflect slightly when hot; ensure

this movement is taken into account when routing

and securing hoses.

Service tools

General

Special service tools have been developed to

facilitate removal, dismantling and assembly of

mechanical components in a cost effective and time

efficient manner. The use of such special tools also

helps prevent the potential for damage to

components.

Some operations described in this Manual cannot be

carried out properly without the aid of the relevant

service tools.

All orders and enquiries from the United Kingdom

and European countries except Germany, Austria,

Switzerland and Spain and countries not in the

following list should be sent direct to:

SPX UK Ltd.,

Genoa House,

Everdon Park,

Daventry,

Northants,

NN11 5YJ

England

( 00 44 (0) 132 7303467/303455

) 00 44 (0) 1327 706632

e-mail: [email protected]

Overseas orders for the following countries should

be placed with the local SPX distributor.

Germany, Austria and Switzerland

SPX Europe GMBH,

Porschestrasse 4,

63512 Hainburg,

Germany

( 0049 61829590

) 0049 6182959299

Spain

SPX Iberica SA,

C/Francisco Aritio

158 nave 72 (Nudo Oeste),

19004 Guadalajara,

Spain

( 0034 949208381

) 0034 949208327

North America