fuel pump LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 793 of 3229

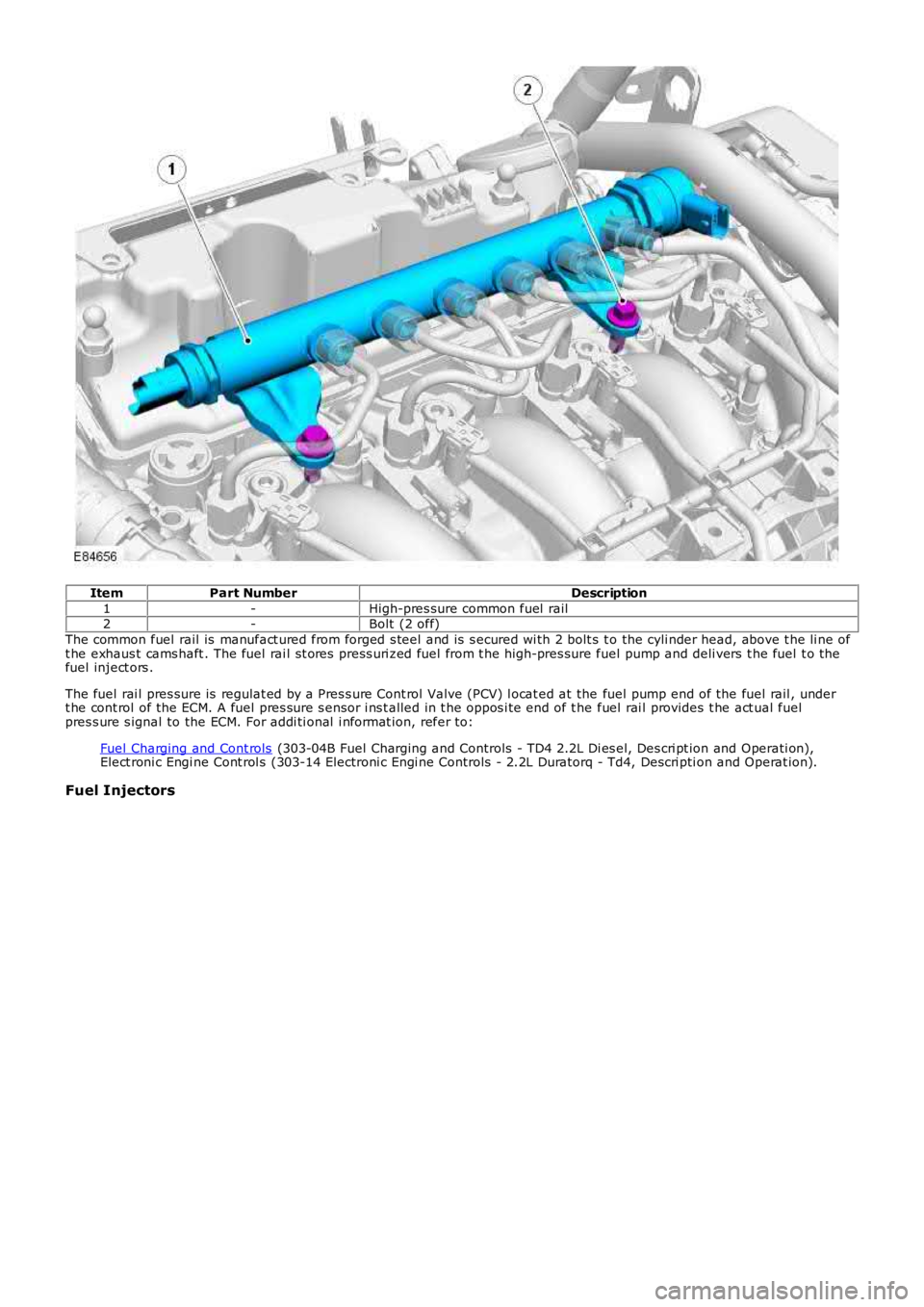

ItemPart NumberDescription

1-High-pres sure common fuel rail2-Bolt (2 off)

The common fuel rail is manufact ured from forged s teel and is s ecured wi th 2 bolt s to the cyli nder head, above t he li ne oft he exhaus t cams haft . The fuel rai l st ores press uri zed fuel from t he high-pres sure fuel pump and deli vers t he fuel t o thefuel inject ors .

The fuel rai l pres sure is regulat ed by a Pres s ure Cont rol Valve (PCV) l ocat ed at the fuel pump end of the fuel rail , undert he cont rol of the ECM. A fuel pres sure s ensor i ns t alled in t he oppos i te end of t he fuel rai l provides t he act ual fuelpres s ure s ignal to the ECM. For addi ti onal i nformat ion, refer to:

Fuel Charging and Cont rols (303-04B Fuel Charging and Controls - TD4 2.2L Di es el, Des cri pt ion and Operati on),Elect roni c Engi ne Cont rol s (303-14 Electroni c Engi ne Controls - 2.2L Duratorq - Td4, Descri pti on and Operat ion).

Fuel Injectors

Page 799 of 3229

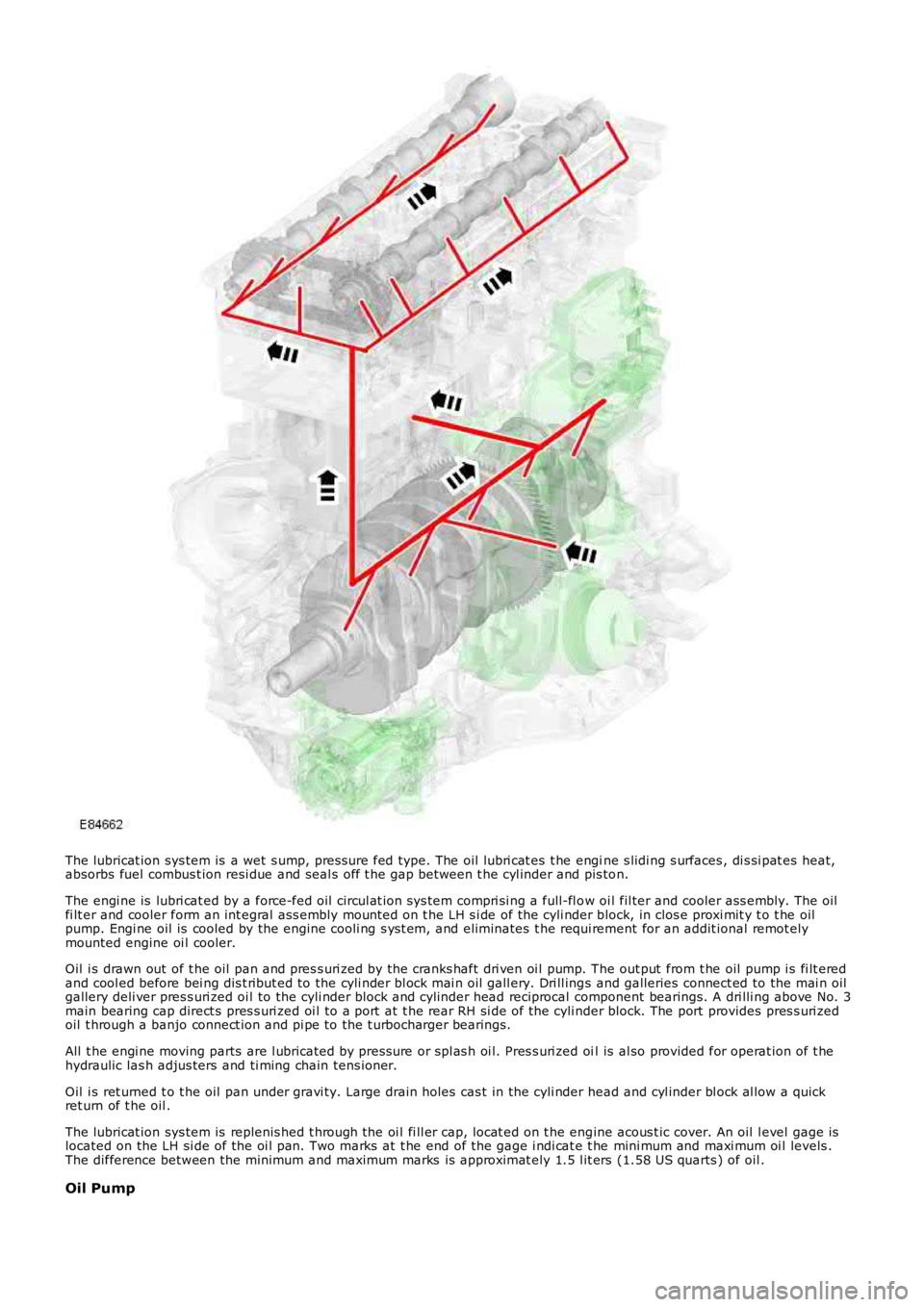

The lubricat ion sys tem is a wet s ump, pres sure fed type. The oil lubri cat es t he engine s lidi ng s urfaces , di s si pat es heat,absorbs fuel combus t ion resi due and seal s off t he gap between t he cyl inder and pis ton.

The engi ne is lubri cat ed by a force-fed oil circul at ion sys tem compri si ng a full-fl ow oi l fil ter and cooler ass embly. The oilfi lt er and cooler form an int egral ass embly mount ed on t he LH s i de of the cyli nder block, in clos e proxi mit y t o t he oilpump. Engi ne oil is cooled by the engine cooli ng s ys t em, and eliminates t he requi rement for an addit ional remot elymounted engine oi l cooler.

Oil i s drawn out of t he oil pan and pres s uri zed by the cranks haft dri ven oi l pump. The out put from t he oil pump i s fi lt eredand cool ed before bei ng dis t ribut ed to the cyli nder bl ock mai n oil gall ery. Dri ll ings and galleries connect ed to the mai n oilgallery deli ver pres s uri zed oi l to the cyli nder block and cyl inder head reciprocal component bearings. A dri lli ng above No. 3main bearing cap direct s pres s uri zed oi l to a port at t he rear RH si de of the cyli nder block. The port provides pres s uri zedoil t hrough a banjo connect ion and pi pe to the t urbocharger bearings.

All t he engi ne moving parts are l ubricated by press ure or spl as h oi l. Pres s uri zed oil is al so provided for operat ion of t hehydraulic las h adjus ters and ti ming chain tens ioner.

Oil i s ret urned t o t he oil pan under gravi ty. Large drain holes cas t in the cyli nder head and cyl inder bl ock al low a quickret urn of t he oil .

The lubricat ion sys tem is replenis hed t hrough the oi l fi ll er cap, locat ed on t he engine acous t ic cover. An oil l evel gage islocated on the LH si de of the oi l pan. Two marks at t he end of the gage i ndi cat e t he mini mum and maxi mum oi l levels .The difference between the minimum and maximum marks is approximat ely 1.5 l it ers (1.58 US quarts ) of oil .

Oil Pump

Page 802 of 3229

Publi s hed: 11-May-2011

Engine - TD4 2.2L Diesel - Engine

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the 2.2L Dies el engi ne, refer t o the relevant Descri pti on and Operat ion s ect ion in t heworks hop manual .REFER to: Engine (303-01B Engine - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

1. Verify t he cus t omer concern. Concerns have been s eparated i nto Leaks and Noise Vibration and Harshness(NVH) for ease of us e.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual Inspection

MechanicalIntake air s ys tem leaks/damageFuel l eaksCoolant levelCoolant leaks.REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Di es el, Di agnos is and Tes t ing).Oi l levelOi l leaksVis i bl y damaged or worn partsLoose or mis s ing nuts or bol ts

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he concern is not vis uall y evi dent , verify t he s ymptom and refer t o t he Symptom Chart .4.

Symptom Charts

Symptom C hart, LeaksSymptomPossible CauseAction

External coolant leaksDamaged hos e(s )Damaged expans iont ankDamaged radi atorLeaki ngs eals /gas ket sCracked/damagedcas ings

For cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Internal cool ant leaks . Note: T hismay be indicated by theproduction of w hite smoke fromthe exhaust

Leaki ngs eals /gas ket sCracked/damagedcas ings

Check for cros s contami nat ion of cooli ng sys t em andengine oi l. Check for exhaus t gases bei ng emit tedt hrough header t ank. For addi ti onal cooling sys temchecks .REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine overheatsInsuffi ci ent coolantInsuffi ci ent engineoi lCooli ng s ys t empres s ure cap faultThermos t at notopeningCoolant pump failureCooli ng fan fail ure

Check for correct coolant/engi ne oil l evels . For cool ings ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).

Engine t akes t oo l ong to reachoperat ing t emperatureThermos t at st uckopenFor cool ing s ys tem checks.REFER t o: Engi ne Cool ing (303-03B Engine Cooli ng - TD42.2L Dies el, Di agnos is and Tes ti ng).External oil l eaksGas ket sSealsHos esOi l fi lt erOi l coolerDamaged/Cracked

Cl ean and confirm t he area of t he l eak. Vis uall y check t hecondit ion of oil carryi ng component s. Check the crankcaseventi lat ion s ys tem.REFER t o: Engi ne Emis s ion Cont rol (303-08B EngineEmis si on Control - TD4 2.2L Di es el, Di agnos is andTes ti ng).

Page 803 of 3229

SymptomPossible CauseAction

cas ingsCrankcaseventi lat ion s yst emPi st on ring blow-by

Carry out a compres s ion tes t, GO to Pinpoint Test A.

Internal oil l eaks (leaks int o cool antor combus t ion chamber) Note: T hismay be indicated by theproduction of blue smoke from theexhaust

Gas ket sSealsHos esDamaged/Crackedcas ingsW orn valve gui desW orn cyli nderbores /pi s tonsBroken pi st on rings

Check for t races of oil in the coolant. Check for evidenceof oi l i n t he combus t ion chambers (depos it s on t he glowpl ugs , et c). Confirm oi l cons umpti on and vehi cl e us agewit h the owner/driver. Carry out an oil consumpt ion t es t,GO t o Pinpoint Test B.

• NOTE: As t he checks s ugges ted here are open to i nterpretat ion, they s hould be us ed as a gui de only. Descripti ons ofnois es, et c, are i n general t erms, s o depend on a degree of experi ence on t he part of t he t echnician.

Symptom C hart, NVHSymptomPossible CauseAction

Ratt le/ti cki ng from t op ofengineVal ve gear noi seCamshaft bearing nois eCamshaft chain noi s eTens ioner nois eVacuum pump noi s eHigh pres s ure fuel pumpnoi s eInject or leaki ng

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check t he functi on of the hydrauli c t appet s and condit ionof cams haft l obes and beari ngs. Check the cams haft chainsand tens ioners , vacuum pump and high pres s ure fuel pump.Carry out i njector l eak t es t

Squeaking/Creaking/Squealfrom front of engineAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel t

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).

W hi ne/Slap/Growl fromfront of engi neAcces sory dri ve bel tAcces sory dri ve bel ttens ionerDri ven component s onaccess ory dri ve bel tTimi ng bel t nois eTimi ng bel t t ens ionernoi s e

Check t he acces sory dri ve belt and dri ven components .REFER t o: Acces s ory Drive (303-05B Acces sory Drive - TD42.2L Di es el, Di agnos is and Tes t ing).Check t he t imi ng bel t and t ens ioners for nois e/damage

Knock from l ower half ofengine (oft en wors e wi th acold engine)

Engi ne oil level/pres surelowPis ton s l apPis ton pi n nois eConnecti ng rod beari ngnoi s e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

Knock/Rumble from lowerhalf of engine (oft en wors eon overrun)

Engi ne oil level/pres surelowMain beari ng nois e

Check t he engi ne oil l evel and pres s ure, GO t o Pi npoint Tes tC. . Check for debri s i n the engi ne oil, check condit ion ofengi ne components

W hi ne/W hi st leInt ake ai r s ys t em l eaksDamaged turbocharger(when nois e emanat ingfrom rear of engine)

Check for loose/damaged intake ai r sys tem components .Check for excess i ve turbocharger shaft fl oat Note: a smallamount of turbocharger shaft float is normal/acceptable.Check for general damage t o t urbocharger

Mi sfire/Rough runningElect roni c engi ne cont rol sFuel charging andcont rolsInt ake ai r s ys t em l eaksExhaus t gas recirculat ion(EGR) s yst emBurnt/s ti cki ng val vesW orn val ve guidesW orn cyl inderbores/pis t onsBroken pis ton ri ngsDamaged/Cracked cas ings

For el ect ronic engine controls .REFER t o: Electroni c Engine Controls (303-14B ElectronicEngi ne Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).For fuel charging and cont rols sys tems tes ts .REFER t o: Fuel Chargi ng and Cont rol s (303-04B Fuel Chargingand Cont rol s - TD4 2.2L Dies el , Diagnosi s and Test ing).Check i nt ake air s yst em for damage/leaks . For EGR s ys temtes ts .REFER t o: Engi ne Emi ss ion Cont rol (303-08B Engi ne Emis s ionCont rol - TD4 2.2L Dies el, Diagnos is and Tes ti ng).Check for damaged engine component s . Carry out acompress i on tes t, GO t o Pinpoint Test A.

Pinpoint Tests

• NOTE: W here reference is made to 's uit abl e equi pment', this refers t o s tandard workshop equipment . Refer to theoperati ng ins t ructi ons for your own equipment when performing any t es t s .

PINPOINT TEST A : CHECK THE CYLINDER COMPRESSIONS

W ARNING: Only compres s ion t es ters abl e t o read the hi gher compres si on pres s ures found i n dies el engi nes shouldbe us ed. Fai lure to foll ow t his i ns t ructi on may resul t in personal injury.

Page 839 of 3229

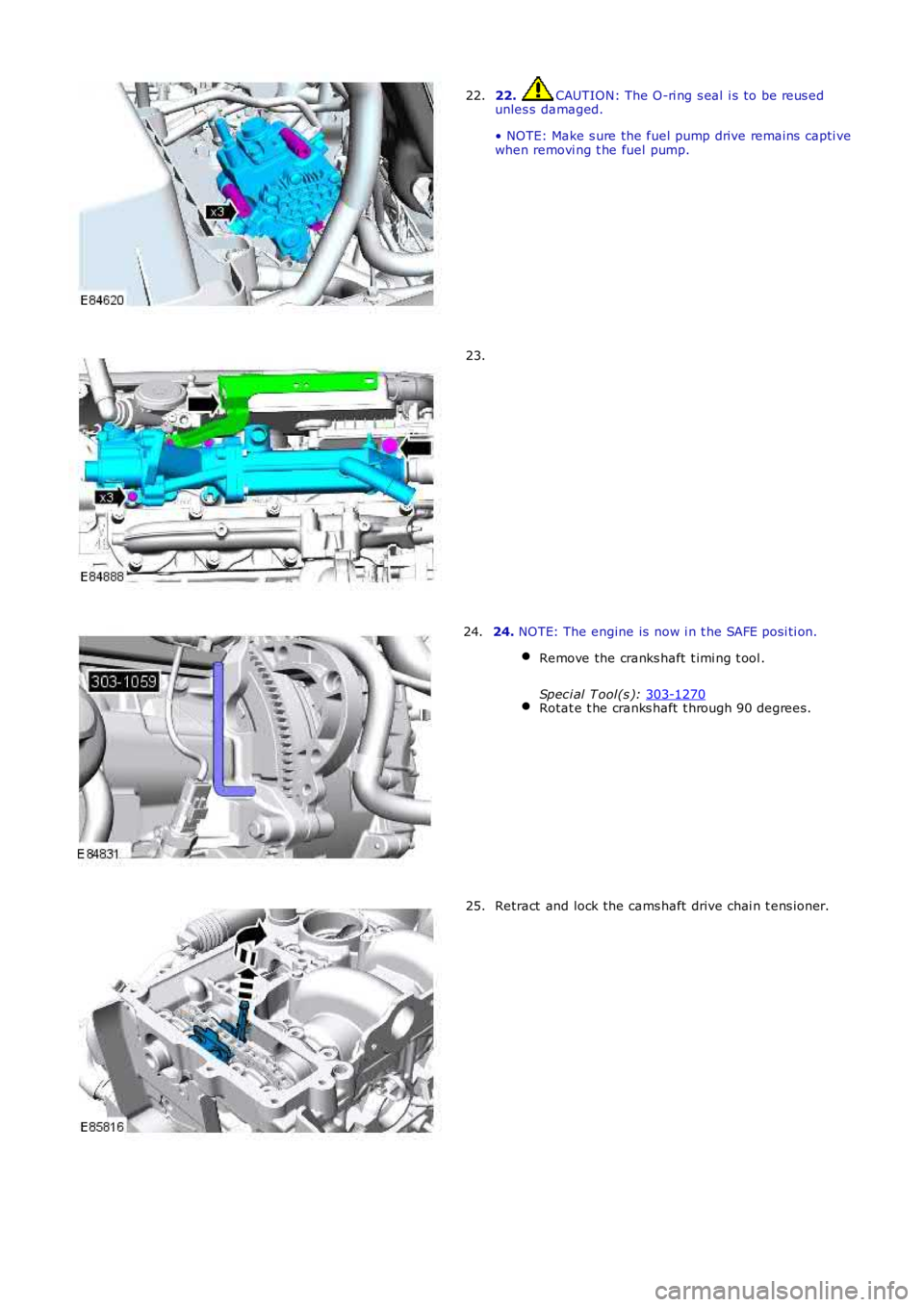

22. CAUTION: The O-ri ng s eal i s to be reus ed

unles s damaged.

• NOTE: Make s ure the fuel pump drive remains capti ve

when removi ng t he fuel pump.

22. 23.

24.

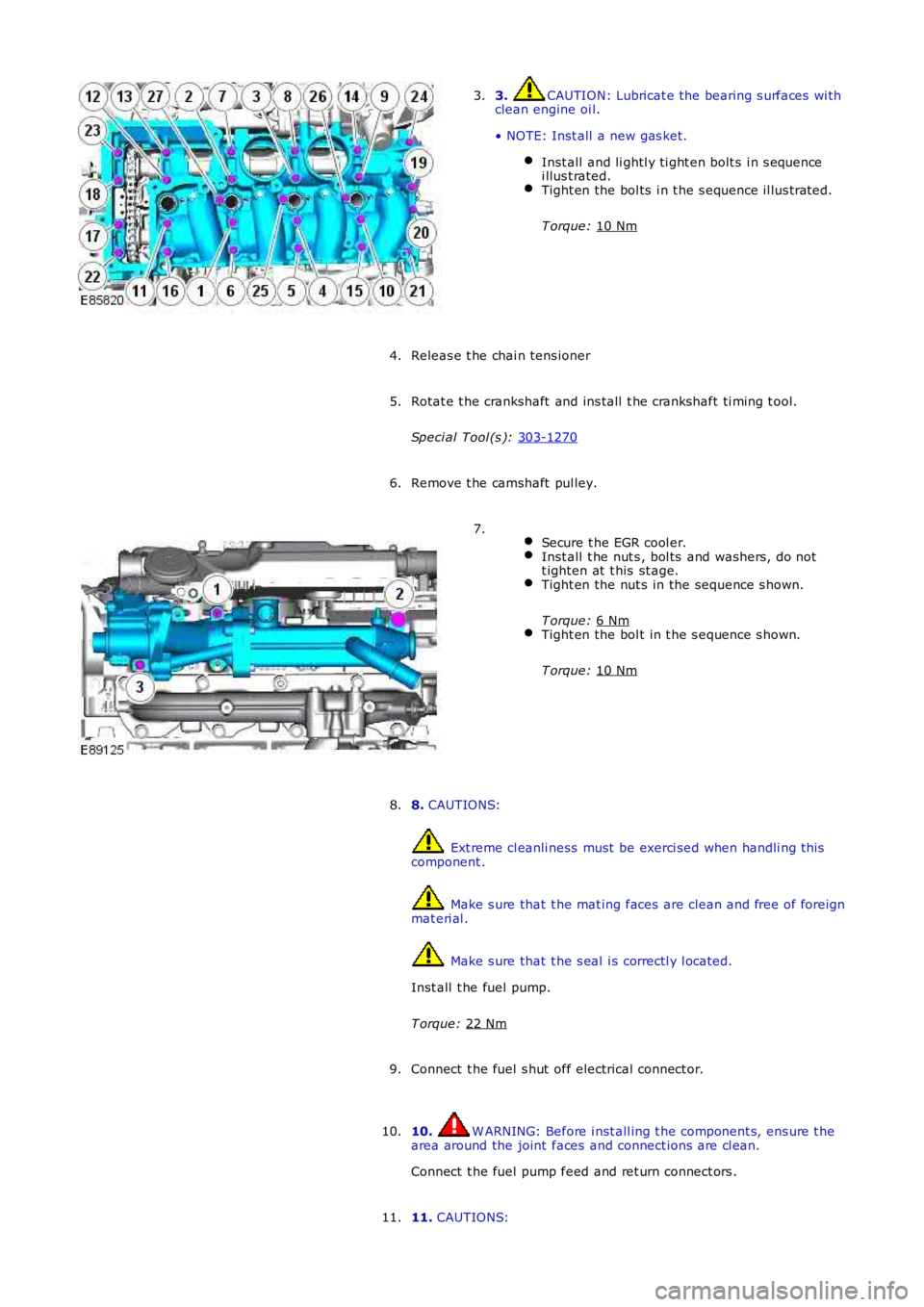

NOTE: The engine is now i n t he SAFE pos i ti on.

Remove the cranks haft t imi ng t ool .

Spec i al T ool(s ): 303-1270 Rotat e t he cranks haft t hrough 90 degrees .24.

Retract and lock the cams haft drive chai n t ens i oner.

25.

Page 841 of 3229

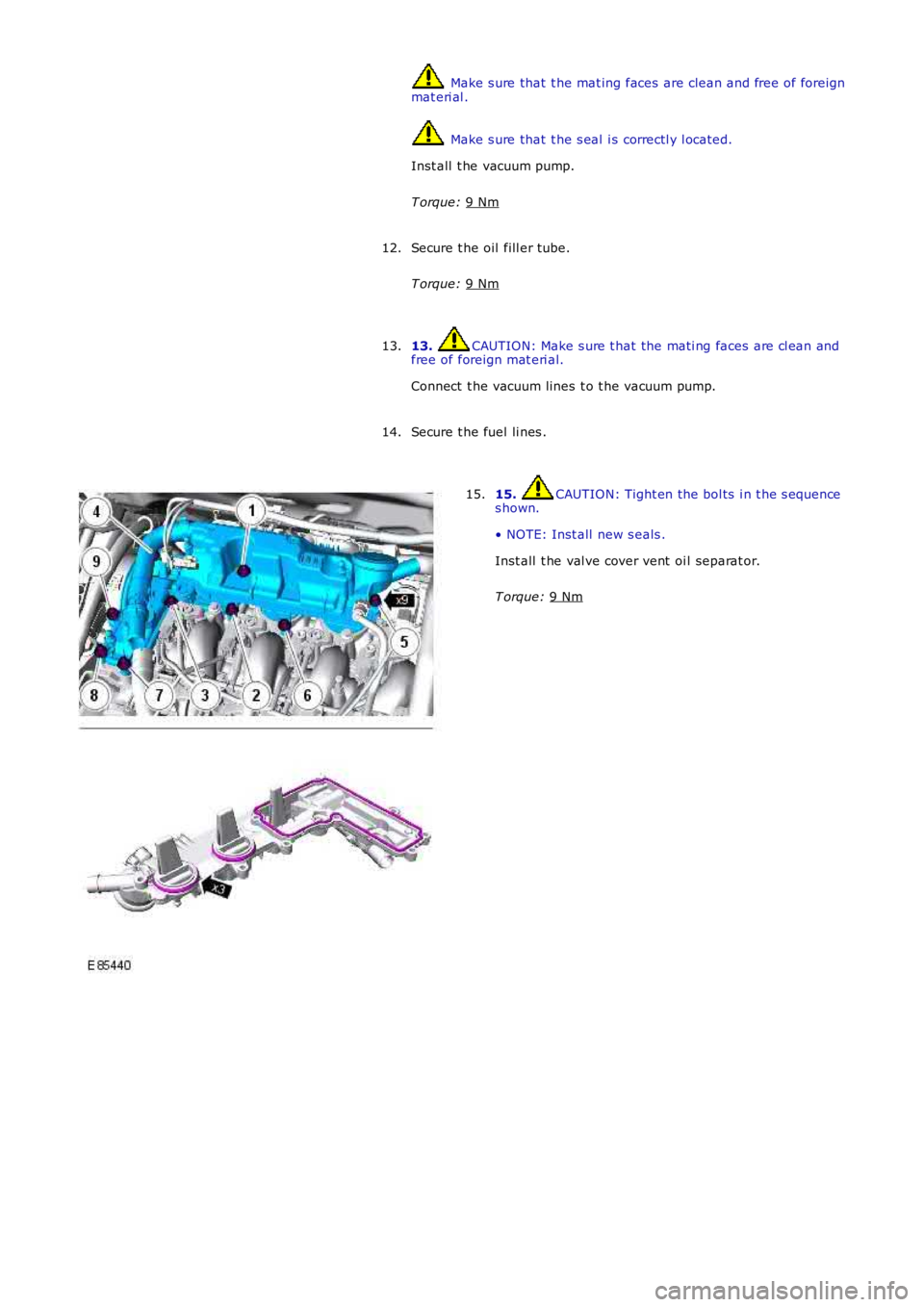

3. CAUTION: Lubricat e the bearing s urfaces wi th

clean engine oi l.

• NOTE: Inst all a new gas ket. Inst all and li ghtl y ti ght en bolt s i n s equence

i llus t rated. Tight en the bol ts i n t he s equence il lus trated.

T orque: 10 Nm 3.

Releas e t he chai n tens ioner

4.

Rotat e t he crankshaft and ins tall t he crankshaft ti ming t ool.

Speci al Tool (s ): 303-1270 5.

Remove t he camshaft pul ley.

6.

Secure t he EGR cool er. Inst all t he nut s , bol ts and washers, do not

t ighten at t his st age. Tight en the nut s in the sequence s hown.

T orque: 6 Nm Tight en the bol t in t he s equence s hown.

T orque: 10 Nm 7.

8. CAUTIONS: Ext reme cl eanli ness must be exerci sed when handli ng t hi s

component . Make s ure that t he mat ing faces are clean and free of foreign

mat eri al . Make s ure that t he s eal i s correctl y l ocated.

Inst all t he fuel pump.

T orque: 22 Nm 8.

Connect t he fuel s hut off electrical connect or.

9.

10. W ARNING: Before i nst all ing t he component s, ens ure t he

area around the joint faces and connect ions are cl ean.

Connect t he fuel pump feed and ret urn connect ors .

10.

11. CAUTIONS:

11.

Page 842 of 3229

Make s ure that t he mat ing faces are clean and free of foreign

mat eri al . Make s ure that t he s eal i s correctl y l ocated.

Inst all t he vacuum pump.

T orque: 9 Nm Secure t he oil fill er tube.

T orque: 9 Nm 12.

13. CAUTION: Make s ure t hat the mati ng faces are cl ean and

free of foreign mat eri al.

Connect t he vacuum lines t o t he vacuum pump.

13.

Secure t he fuel li nes .

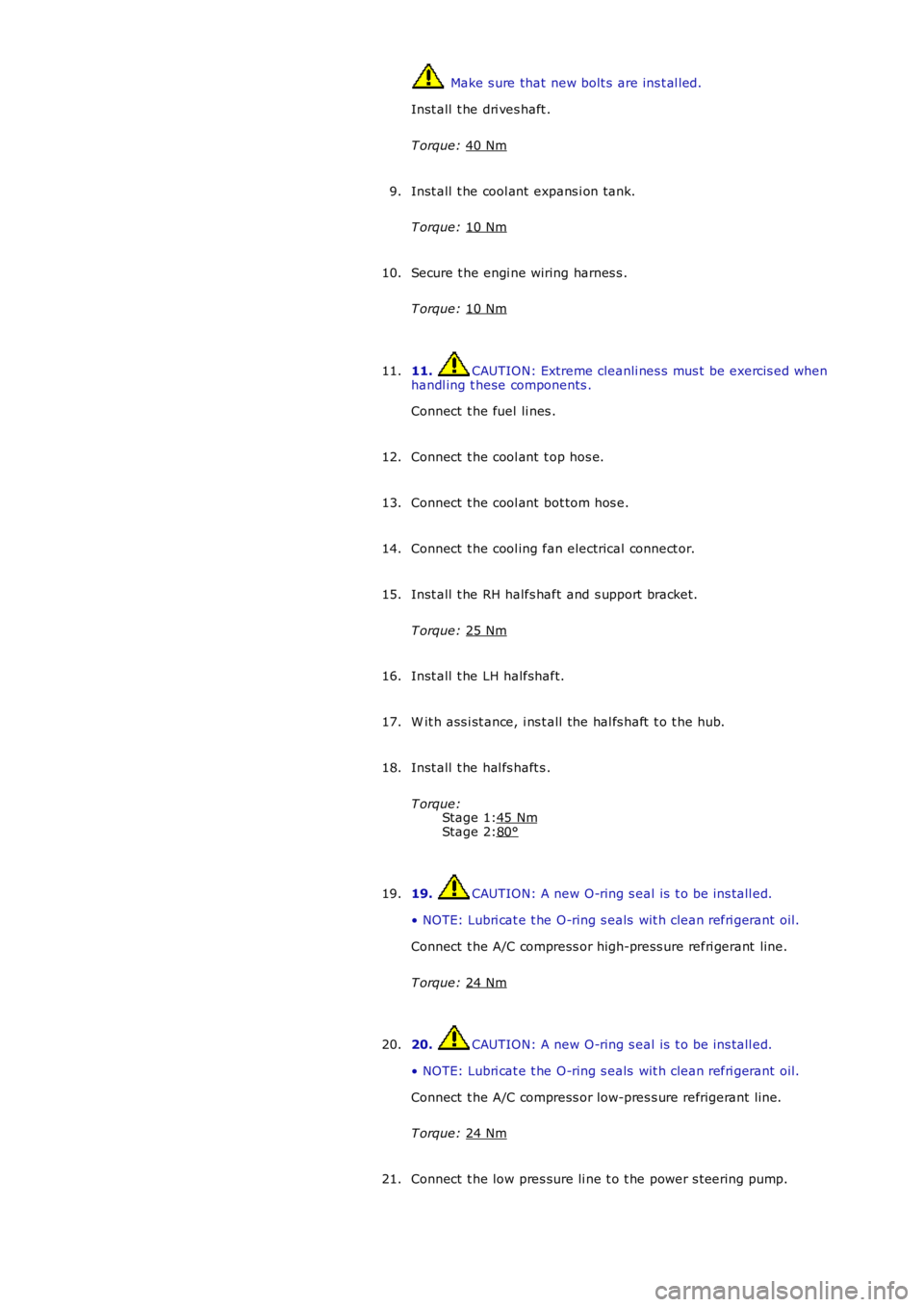

14. 15. CAUTION: Tight en the bol ts i n t he s equence

s hown.

• NOTE: Inst all new s eals .

Inst all t he val ve cover vent oi l separat or.

T orque: 9 Nm 15.

Page 905 of 3229

Stage 1:

Stage 2: Make s ure that new bolt s are ins t al led.

Inst all t he dri ves haft .

T orque: 40 Nm Inst all t he cool ant expans i on tank.

T orque: 10 Nm 9.

Secure t he engi ne wiring harnes s .

T orque: 10 Nm 10.

11. CAUTION: Extreme cleanli nes s mus t be exercis ed when

handl ing t hese components .

Connect t he fuel li nes .

11.

Connect t he cool ant t op hos e.

12.

Connect t he cool ant bot tom hos e.

13.

Connect t he cool ing fan electrical connect or.

14.

Inst all t he RH halfs haft and s upport bracket.

T orque: 25 Nm 15.

Inst all t he LH halfshaft.

16.

W it h ass i st ance, i ns t all the hal fs haft t o t he hub.

17.

Inst all t he hal fs haft s .

T orque: 45 Nm 80°18.

19. CAUTION: A new O-ring s eal is t o be ins tall ed.

• NOTE: Lubri cat e t he O-ring s eals wit h clean refri gerant oil.

Connect t he A/C compress or high-press ure refri gerant line.

T orque: 24 Nm 19.

20. CAUTION: A new O-ring s eal is t o be ins tall ed.

• NOTE: Lubri cat e t he O-ring s eals wit h clean refri gerant oil.

Connect t he A/C compress or low-pres s ure refrigerant li ne.

T orque: 24 Nm 20.

Connect t he low pres sure li ne t o t he power s t eering pump.

21.

Page 939 of 3229

5-Engine coolant pump

6-Exhaus t Gas Recircul at ion (EGR) valve cool er

7-Heat er connect ion hos es8-Cl imat e cont rol s yst em heat er matrix

9-Thermal control modul e

10-Auxil iary coolant pump (col d cli mate vehi cl es )11-Fuel Fi red Boos ter Heater (FFBH) - (cold cli mate vehi cl e)

OVERVIEW

The main requirement of t he TD4 di es el engi ne cool ing s ys tem is t o regul ate t he engines operati ng t emperature, wit hi n anopti mum range for all ambi ent and operat ing condit ions. Addit ional functi ons of t he cool ing s ys tem are to provi de heat ingt o the cl imat e cont rol s ys tem, and cooling for the EGR s ys t em, engi ne lubri cat ion sys tem, and t rans mi ss i on lubri cat ions ys t em (automat ic t rans mis s ion model s only).

The cool ing s ys tem pipes and hoses feature qui ck rel eas e coupl ings t o all ow eas y acces s to the sys tem.

On cold cl imat e market vehicles , the cooli ng s ys t em i s modified t o i ncorporate a FFBH and auxi liary cool ing pump. TheFFBH provides auxili ary heati ng t o t he vehi cl e cabi n.For addit ional informat ion, refer t o: Fuel Fired Boost er Heat er (412-02B Auxi liary Cli mate Cont rol , Des cri pti on andOperat ion).

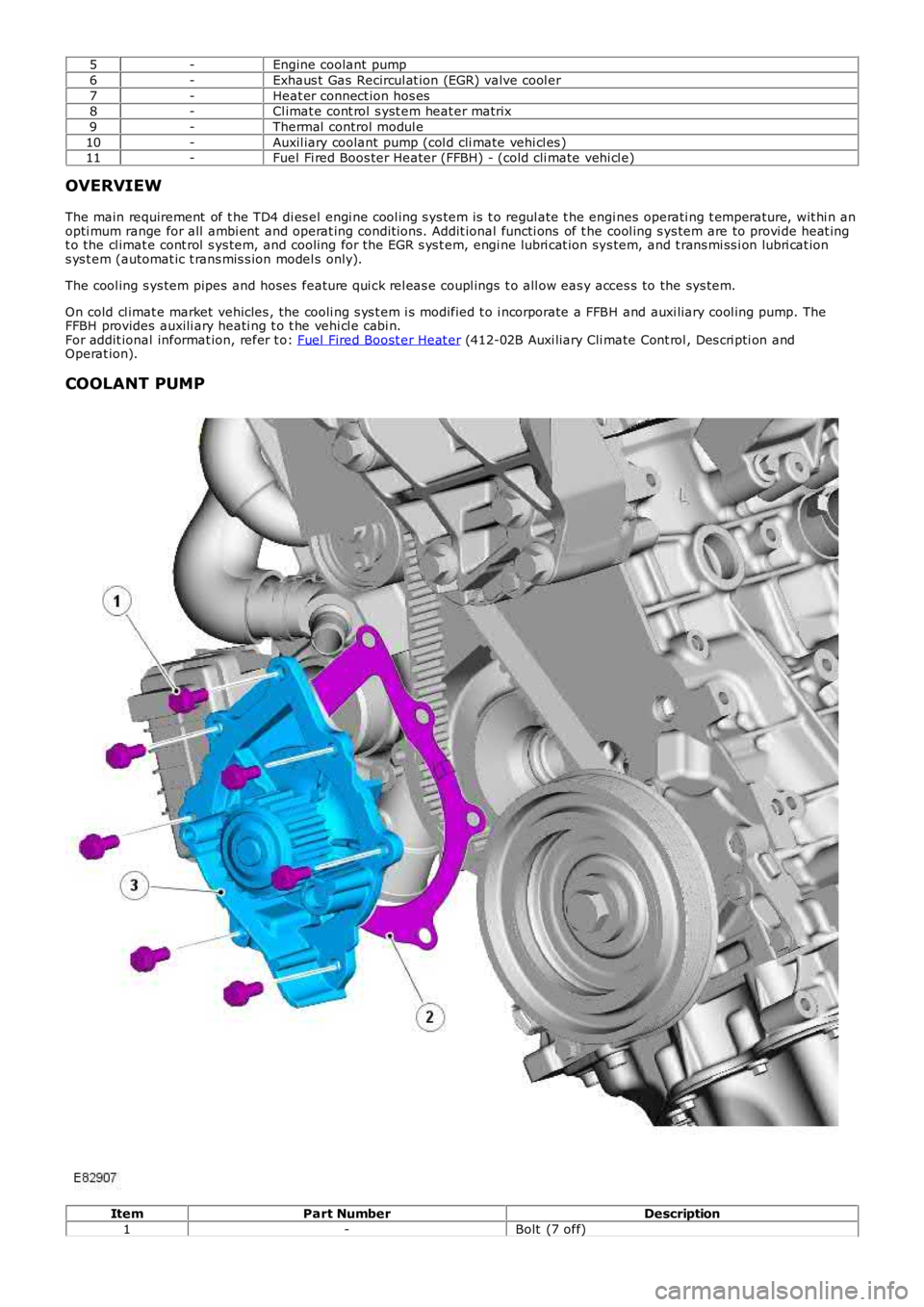

COOLANT PUMP

ItemPart NumberDescription

1-Bolt (7 off)

Page 946 of 3229

Entrained gases i n t he cool ing s ys tem escape t hrough the t hermal control modul e degas l ine t o t he cool ant res ervoir.

The increas ing coolant temperature is felt at t he t hermos tat , and is regi s tered on the ins trument cl us t er coolantt emperature gage vi a t he ECM and ECT s ens or s i gnal.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

Engine Normal Operating Temperature

W i th the coolant t emperature increas ing, at 83°C (181°F) t he t hermos tat reacts and commences openi ng. The by-pas svalve is progres s ively clos ed. Hot coolant ret urning from t he engi ne t o t he thermal control modul e i s now all owed to pas st hrough the t op hos e connecti on to the radiator. The fl ow of hot coolant t o t he radiat or now forces cold cool ant wi thi n t heradi at or and bot t om hos e t o fl ow t o t he thermal cont rol module.

Duri ng the thermos t at opening period t here i s an i nit ial temperat ure di fferenti al of t he coolant at bot h s ides of t het hermos tat . The thermos t at react s t o t he t emperature different ial and part iall y closes , whi le t he by-pas s val ve opensfurther. The thermos t at and by-pas s valve conti nue to oscil lat e whil e t he cool ant t emperat ure i ncreas es .

At a coolant temperat ure of 91°C (196°F) t he thermost at is full y opened and t he by-pas s valve i s ful ly clos ed. The returncool ant from t he engi ne is now ful ly circul ated t hrough t he radiat or and bot tom hose. Coolant flows t hrough the radiat orfrom the RH tank t o t he LH t ank, and i s cool ed by air pass i ng through the mat ri x. Ent rai ned gas es i n the radiat or es capet hrough the connect ed degas l ine t o t he cool ant res ervoir.

The increas ed cool ant volume created by heat expans ion caus es the coolant level to ri se through t he connecti ng res ervoirhose, and i nt o t he res ervoi r.

The t emperature of the cooli ng s ys t em i s cons t ant ly moni tored by t he ECM via the ECT s ens or s i gnal. The ECM uses t heECT s ignal to control operati on of the cooling fans , and to adjus t engine fueling. The ECM al so operates t he fans i nres ponse to input s from the aut omati c t ransmis s ion oil t emperat ure s ensor, Air Condit ioning (A/C) s ys tem cont rol s wit ch,and t he A/C pres sure s ens or. For addit ional i nformati on, refer to: El ect ronic Engine Cont rols - 2.2L Di es el (303-14Electroni c Engine Controls - 2.2L Dies el, Des cript ion and Operat ion).For addit ional informat ion, refer t o: Air Condit ioning (412-01 Cli mat e Cont rol , Descripti on and Operat ion).

The cool ing fan s peed is als o infl uenced by vehicle road s peed. The ECM adjus t s the speed of t he cool ing fans tocompens ate for t he ram air effect , us ing t he CAN bus road speed s ignal received from the Ant i-Lock Brake Sys tem (ABS)module.

W hen t he engine i s s hut down, t he coolant t emperature and volume decreas e. The thermos t at st art s t o clos e as t hecool ant t emperat ure decreas es to 89°C (192°F), and is fully cl osed at 81°C (178°F). The coolant level wit hin t he res ervoi rdecreas es as coolant is drawn from the res ervoi r to replenis h the s ys tem.

Followi ng engi ne s hut down when the coolant pump i s s tat ionary, the ECM may cont inue t o operat e t he cool ing fans for apre-det ermined peri od to maint ai n engine cooling.