fuel pump LAND ROVER FRELANDER 2 2006 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1006 of 3229

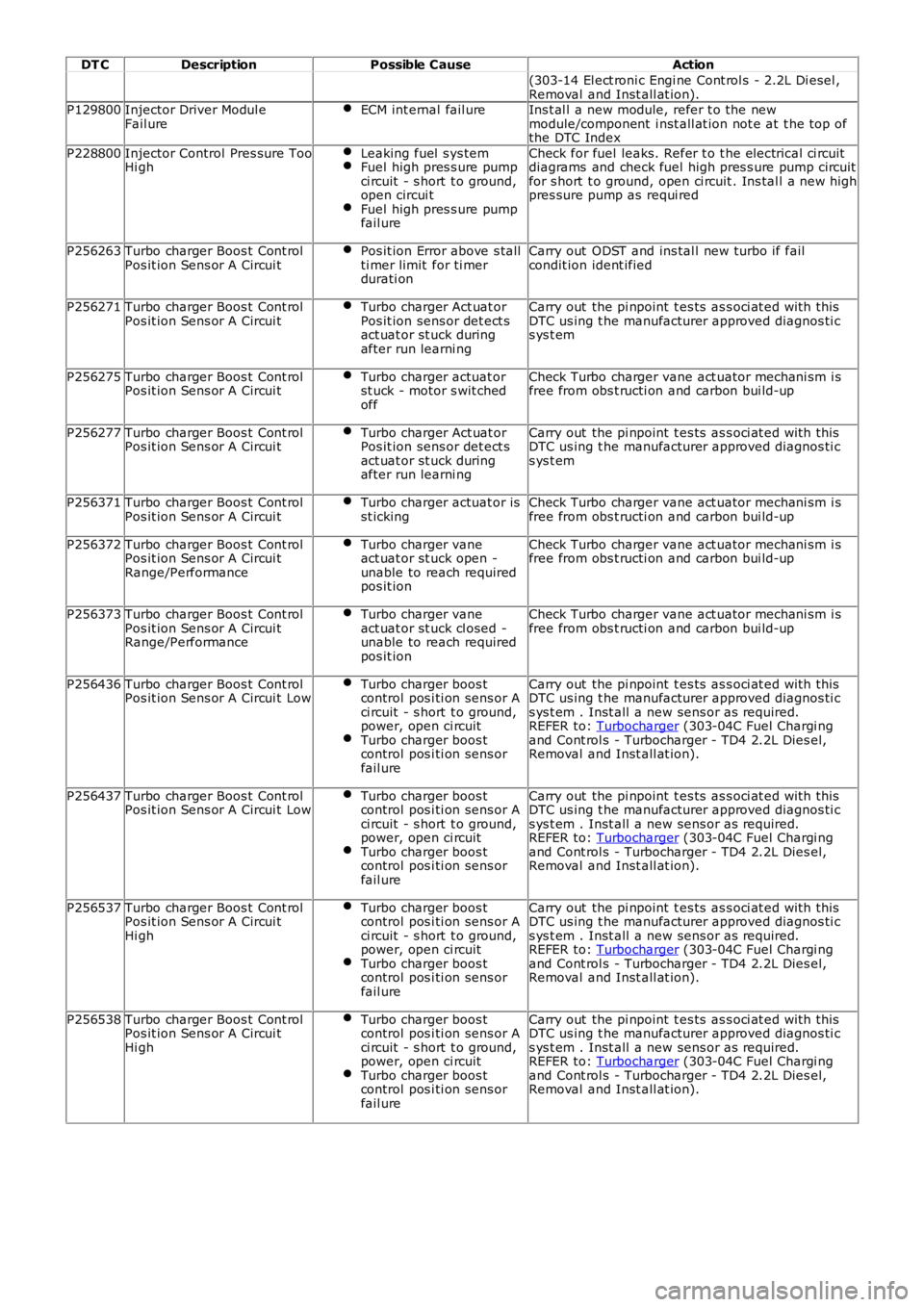

DT CDescriptionPossible CauseAction

(303-14 El ect roni c Engi ne Cont rol s - 2.2L Di esel ,Removal and Inst all at ion).P129800Injector Driver Modul eFail ureECM int ernal fail ureIns t al l a new module, refer t o the newmodule/component i nst all at ion not e at t he top ofthe DTC Index

P228800Injector Control Pres sure TooHi ghLeaking fuel s ys temFuel high pres s ure pumpci rcuit - s hort t o ground,open circui tFuel high pres s ure pumpfail ure

Check for fuel leaks. Refer t o t he electrical ci rcuitdiagrams and check fuel high pres s ure pump circuitfor s hort t o ground, open ci rcuit . Ins tal l a new highpres sure pump as requi red

P256263Turbo charger Boos t Cont rolPos it ion Sens or A Circui tPos it ion Error above s tallti mer limit for ti merdurati on

Carry out ODST and ins tal l new turbo if failcondit ion ident ified

P256271Turbo charger Boos t Cont rolPos it ion Sens or A Circui tTurbo charger Act uat orPos it ion sens or det ect sact uat or st uck duringafter run learni ng

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em

P256275Turbo charger Boos t Cont rolPos it ion Sens or A Circui tTurbo charger actuat orst uck - motor s wit chedoff

Check Turbo charger vane act uator mechani sm i sfree from obs t ructi on and carbon bui ld-up

P256277Turbo charger Boos t Cont rolPos it ion Sens or A Circui tTurbo charger Act uat orPos it ion sens or det ect sact uat or st uck duringafter run learni ng

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em

P256371Turbo charger Boos t Cont rolPos it ion Sens or A Circui tTurbo charger actuat or isst ickingCheck Turbo charger vane act uator mechani sm i sfree from obs t ructi on and carbon bui ld-up

P256372Turbo charger Boos t Cont rolPos it ion Sens or A Circui tRange/Performance

Turbo charger vaneact uat or st uck open -unable to reach requiredpos it ion

Check Turbo charger vane act uator mechani sm i sfree from obs t ructi on and carbon bui ld-up

P256373Turbo charger Boos t Cont rolPos it ion Sens or A Circui tRange/Performance

Turbo charger vaneact uat or st uck cl osed -unable to reach requiredpos it ion

Check Turbo charger vane act uator mechani sm i sfree from obs t ructi on and carbon bui ld-up

P256436Turbo charger Boos t Cont rolPos it ion Sens or A Circui t LowTurbo charger boos tcontrol pos i ti on sens or Aci rcuit - s hort t o ground,power, open ci rcuitTurbo charger boos tcontrol pos i ti on sens orfail ure

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em . Inst all a new sens or as required.REFER to: Turbocharger (303-04C Fuel Chargi ngand Cont rol s - Turbocharger - TD4 2.2L Dies el,Removal and Inst all at ion).

P256437Turbo charger Boos t Cont rolPos it ion Sens or A Circui t LowTurbo charger boos tcontrol pos i ti on sens or Aci rcuit - s hort t o ground,power, open ci rcuitTurbo charger boos tcontrol pos i ti on sens orfail ure

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em . Inst all a new sens or as required.REFER to: Turbocharger (303-04C Fuel Chargi ngand Cont rol s - Turbocharger - TD4 2.2L Dies el,Removal and Inst all at ion).

P256537Turbo charger Boos t Cont rolPos it ion Sens or A Circui tHi gh

Turbo charger boos tcontrol pos i ti on sens or Aci rcuit - s hort t o ground,power, open ci rcuitTurbo charger boos tcontrol pos i ti on sens orfail ure

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em . Inst all a new sens or as required.REFER to: Turbocharger (303-04C Fuel Chargi ngand Cont rol s - Turbocharger - TD4 2.2L Dies el,Removal and Inst all at ion).

P256538Turbo charger Boos t Cont rolPos it ion Sens or A Circui tHi gh

Turbo charger boos tcontrol pos i ti on sens or Aci rcuit - s hort t o ground,power, open ci rcuitTurbo charger boos tcontrol pos i ti on sens orfail ure

Carry out the pi npoint t es ts as s oci at ed wi th thisDTC us ing t he manufacturer approved diagnos ti cs ys t em . Inst all a new sens or as required.REFER to: Turbocharger (303-04C Fuel Chargi ngand Cont rol s - Turbocharger - TD4 2.2L Dies el,Removal and Inst all at ion).

Page 1013 of 3229

8.

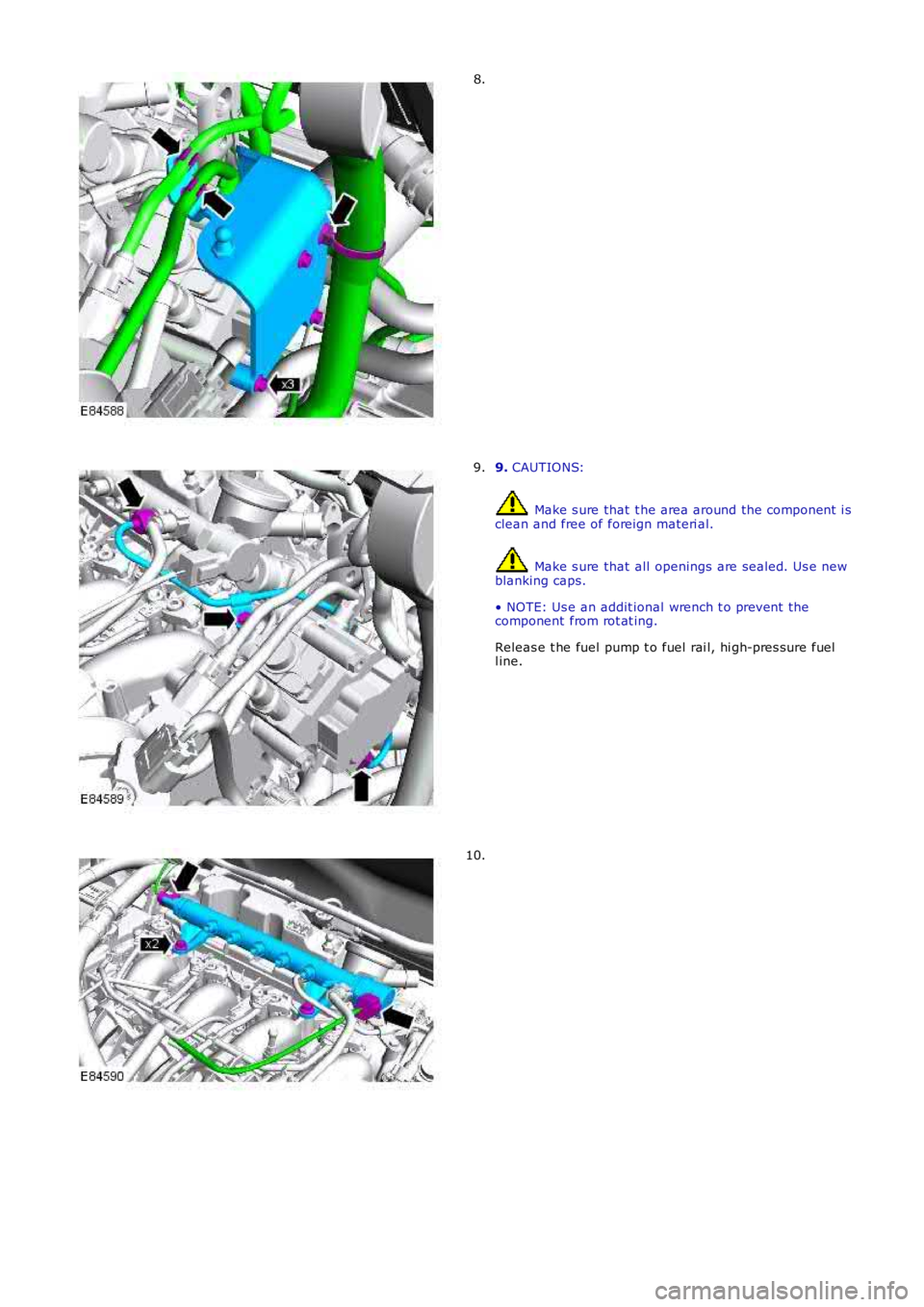

9. CAUTIONS:

Make s ure that t he area around the component i sclean and free of foreign materi al.

Make s ure that all openings are sealed. Us e newblanking caps.

• NOTE: Us e an addit ional wrench t o prevent thecomponent from rot at ing.

Releas e t he fuel pump t o fuel rai l, hi gh-pres sure fuell ine.

9.

10.

Page 1014 of 3229

Stage 1:

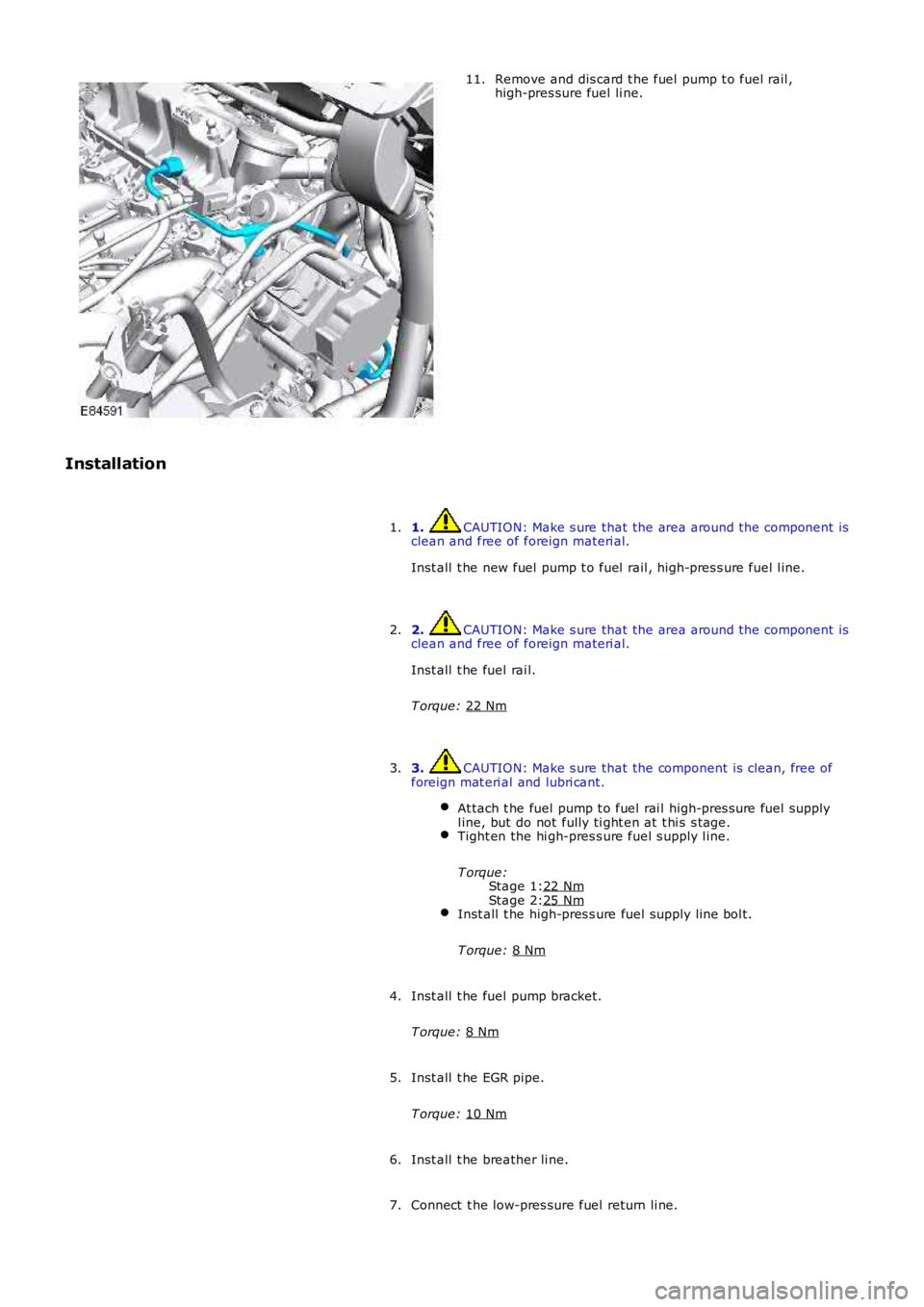

Stage 2: Remove and dis card t he fuel pump t o fuel rail ,

high-pres sure fuel li ne.

11.

Installation 1. CAUTION: Make s ure that the area around t he component is

clean and free of foreign materi al.

Inst all t he new fuel pump t o fuel rail , hi gh-pres s ure fuel l ine.

1.

2. CAUTION: Make s ure that the area around t he component is

clean and free of foreign materi al.

Inst all t he fuel rai l.

T orque: 22 Nm 2.

3. CAUTION: Make s ure that the component is clean, free of

foreign mat eri al and lubri cant.

At tach t he fuel pump t o fuel rai l high-pres s ure fuel supply

l ine, but do not fully ti ght en at t hi s s tage. Tight en the hi gh-pres s ure fuel s upply l ine.

T orque: 22 Nm 25 Nm

Inst all t he high-pres s ure fuel supply line bol t.

T orque: 8 Nm 3.

Inst all t he fuel pump bracket.

T orque: 8 Nm 4.

Inst all t he EGR pipe.

T orque: 10 Nm 5.

Inst all t he breather li ne.

6.

Connect t he low-pres sure fuel return li ne.

7.

Page 1016 of 3229

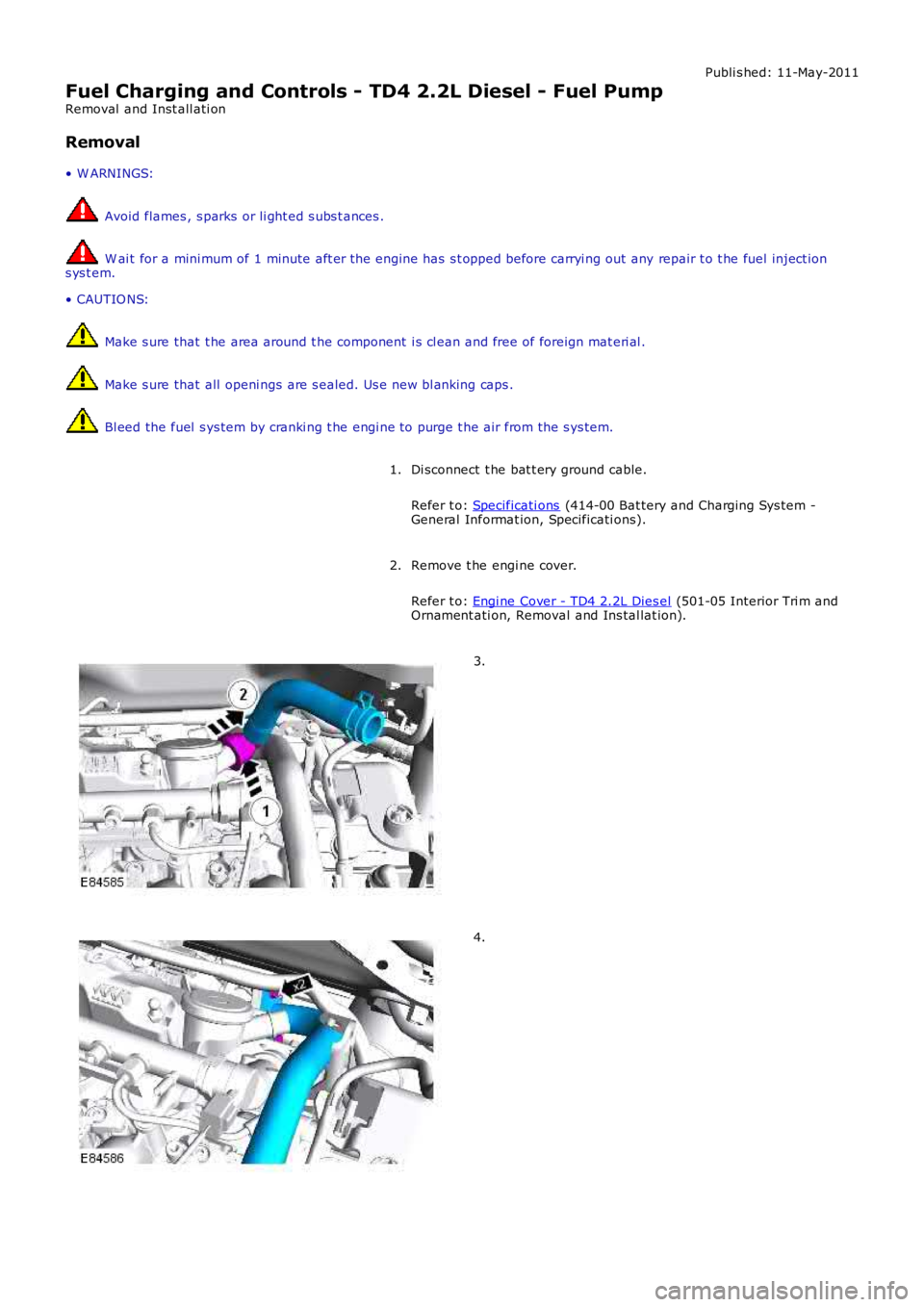

Publi s hed: 11-May-2011

Fuel Charging and Controls - TD4 2.2L Diesel - Fuel Pump

Removal and Inst all ati on

Removal

• W ARNINGS:

Avoid flames , s parks or li ght ed s ubs t ances .

W ai t for a mini mum of 1 minute aft er the engine has s t opped before carryi ng out any repair t o t he fuel inject ions ys t em.

• CAUTIO NS:

Make s ure that t he area around t he component i s cl ean and free of foreign mat eri al .

Make s ure that all openi ngs are s ealed. Us e new bl anking caps .

Bl eed the fuel s ys tem by cranki ng t he engi ne to purge t he air from the s ys tem.

Di sconnect t he bat t ery ground cable.

Refer t o: Specificati ons (414-00 Bat tery and Charging Sys tem -General Informat ion, Specificati ons).

1.

Remove t he engi ne cover.

Refer t o: Engi ne Cover - TD4 2.2L Dies el (501-05 Interior Tri m andOrnament ati on, Removal and Ins tal lat ion).

2.

3.

4.

Page 1018 of 3229

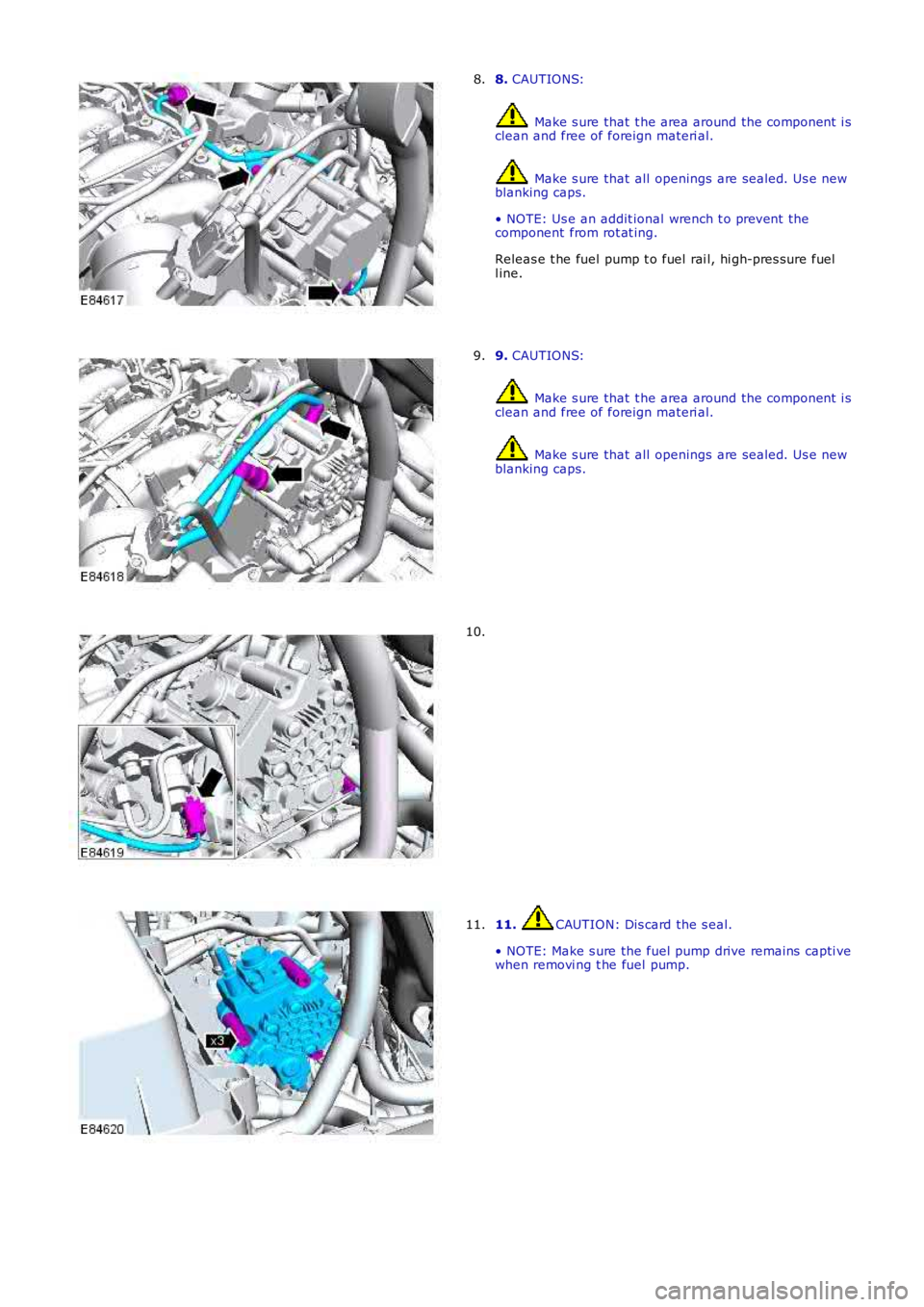

8. CAUTIONS:

Make s ure that t he area around the component i sclean and free of foreign materi al.

Make s ure that all openings are sealed. Us e newblanking caps.

• NOTE: Us e an addit ional wrench t o prevent thecomponent from rot at ing.

Releas e t he fuel pump t o fuel rai l, hi gh-pres sure fuell ine.

8.

9. CAUTIONS:

Make s ure that t he area around the component i sclean and free of foreign materi al.

Make s ure that all openings are sealed. Us e newblanking caps.

9.

10.

11. CAUTION: Dis card the s eal.

• NOTE: Make s ure the fuel pump drive remains capti vewhen removi ng t he fuel pump.

11.

Page 1019 of 3229

Stage 1:

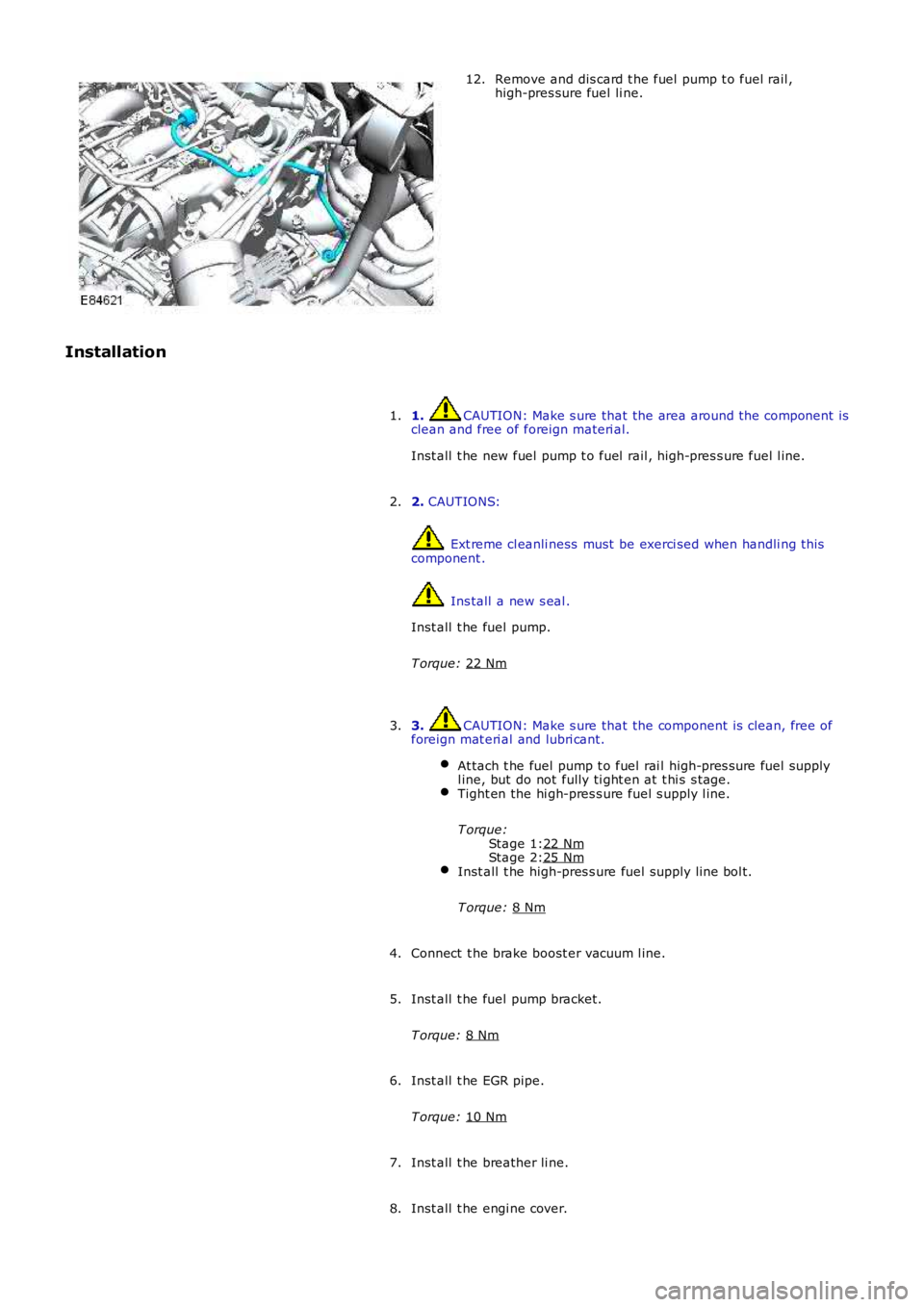

Stage 2: Remove and dis card t he fuel pump t o fuel rail ,

high-pres sure fuel li ne.

12.

Installation 1. CAUTION: Make s ure that the area around t he component is

clean and free of foreign materi al.

Inst all t he new fuel pump t o fuel rail , hi gh-pres s ure fuel l ine.

1.

2. CAUTIONS: Ext reme cl eanli ness must be exerci sed when handli ng t hi s

component . Ins tall a new s eal .

Inst all t he fuel pump.

T orque: 22 Nm 2.

3. CAUTION: Make s ure that the component is clean, free of

foreign mat eri al and lubri cant.

At tach t he fuel pump t o fuel rai l high-pres s ure fuel supply

l ine, but do not fully ti ght en at t hi s s tage. Tight en the hi gh-pres s ure fuel s upply l ine.

T orque: 22 Nm 25 Nm

Inst all t he high-pres s ure fuel supply line bol t.

T orque: 8 Nm 3.

Connect t he brake boost er vacuum l ine.

4.

Inst all t he fuel pump bracket.

T orque: 8 Nm 5.

Inst all t he EGR pipe.

T orque: 10 Nm 6.

Inst all t he breather li ne.

7.

Inst all t he engi ne cover.

8.

Page 1078 of 3229

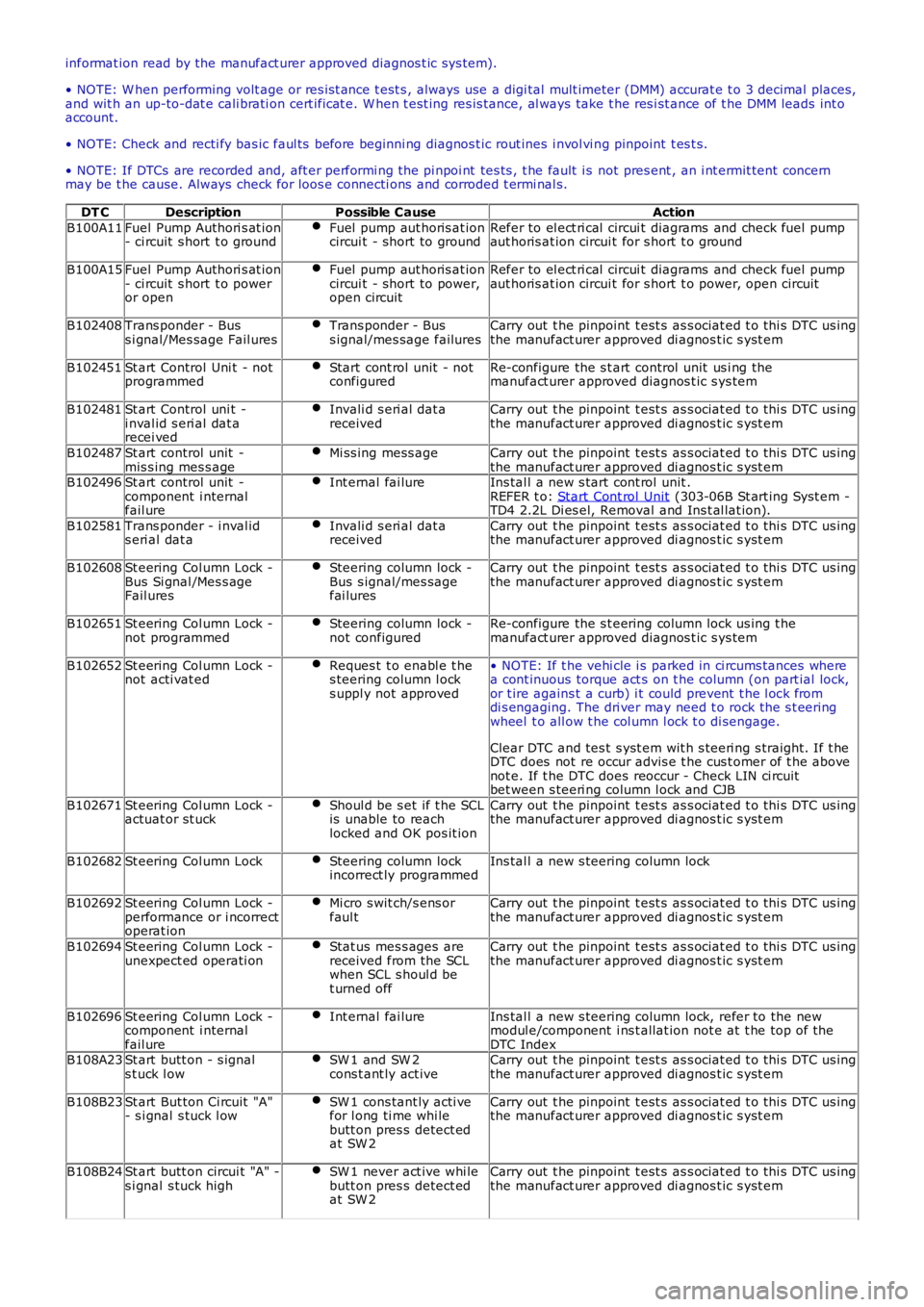

informat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o 3 decimal places,and wit h an up-to-dat e cali brati on cert ificat e. W hen t est ing res is tance, al ways take t he res i st ance of t he DMM leads int oaccount.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , t he fault i s not pres ent , an i nt ermit tent concernmay be t he cause. Always check for loos e connecti ons and corroded t ermi nal s.

DT CDescriptionPossible CauseAction

B100A11Fuel Pump Authori s at ion- ci rcuit s hort t o groundFuel pump aut horis at ioncircui t - short to groundRefer to el ect ri cal circui t diagrams and check fuel pumpaut horis at ion circui t for s hort t o ground

B100A15Fuel Pump Authori s at ion- ci rcuit s hort t o poweror open

Fuel pump aut horis at ioncircui t - short to power,open circuit

Refer to el ect ri cal circui t diagrams and check fuel pumpaut horis at ion circui t for s hort t o power, open circuit

B102408Trans ponder - Buss i gnal/Mes sage Fail uresTrans ponder - Buss ignal/mes sage failuresCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102451St art Control Uni t - notprogrammedStart cont rol unit - notconfiguredRe-configure the s t art control unit us i ng themanufact urer approved diagnos t ic s ys tem

B102481St art Control uni t -i nval id s eri al dat arecei ved

Invali d s eri al dat areceivedCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102487St art control unit -mis s ing mes s ageMi ss ing mess ageCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst emB102496St art control unit -component i nternalfail ure

Int ernal fai lureIns tal l a new s tart cont rol unit .REFER t o: Start Cont rol Unit (303-06B St art ing Syst em -TD4 2.2L Di es el, Removal and Ins t al lat ion).

B102581Trans ponder - i nval ids eri al dat aInvali d s eri al dat areceivedCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102608St eering Col umn Lock -Bus Si gnal /Mes s ageFail ures

Steering column lock -Bus s ignal/mes sagefai lures

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102651St eering Col umn Lock -not programmedSteering column lock -not configuredRe-configure the s t eering column lock us ing t hemanufact urer approved diagnos t ic s ys tem

B102652St eering Col umn Lock -not acti vat edReques t t o enabl e t hes teering column l ocks uppl y not approved

• NOTE: If t he vehi cle i s parked in ci rcums tances wherea cont inuous torque act s on t he column (on part ial lock,or t ire agains t a curb) i t could prevent t he l ock fromdi s engaging. The dri ver may need t o rock the s t eeringwheel t o all ow t he col umn l ock t o di sengage.

Clear DTC and tes t s yst em wit h s teeri ng s traight. If t heDTC does not re occur advis e t he cus t omer of t he abovenot e. If t he DTC does reoccur - Check LIN ci rcuitbet ween s teeri ng column l ock and CJB

B102671St eering Col umn Lock -actuat or st uckShoul d be s et if t he SCLis unable to reachlocked and OK pos it ion

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102682St eering Col umn LockSteering column lockincorrect ly programmedIns tal l a new s teering column lock

B102692St eering Col umn Lock -performance or i ncorrectoperat ion

Mi cro s wit ch/s ens orfaul tCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102694St eering Col umn Lock -unexpect ed operati onStat us mes s ages arereceived from the SCLwhen SCL s houl d bet urned off

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B102696St eering Col umn Lock -component i nternalfail ure

Int ernal fai lureIns tal l a new s teering column lock, refer to the newmodul e/component i ns t allat ion not e at t he top of t heDTC IndexB108A23St art butt on - s ignals t uck l owSW 1 and SW 2cons t ant ly act iveCarry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108B23St art But ton Ci rcuit "A"- s i gnal s tuck l owSW 1 cons tant ly acti vefor l ong ti me whi lebutt on pres s detect edat SW 2

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

B108B24St art butt on circui t "A" -s i gnal s tuck highSW 1 never act ive whi lebutt on pres s detect edat SW 2

Carry out t he pinpoint t est s as s ociat ed t o t hi s DTC us ingthe manufact urer approved di agnos t ic s yst em

Page 1101 of 3229

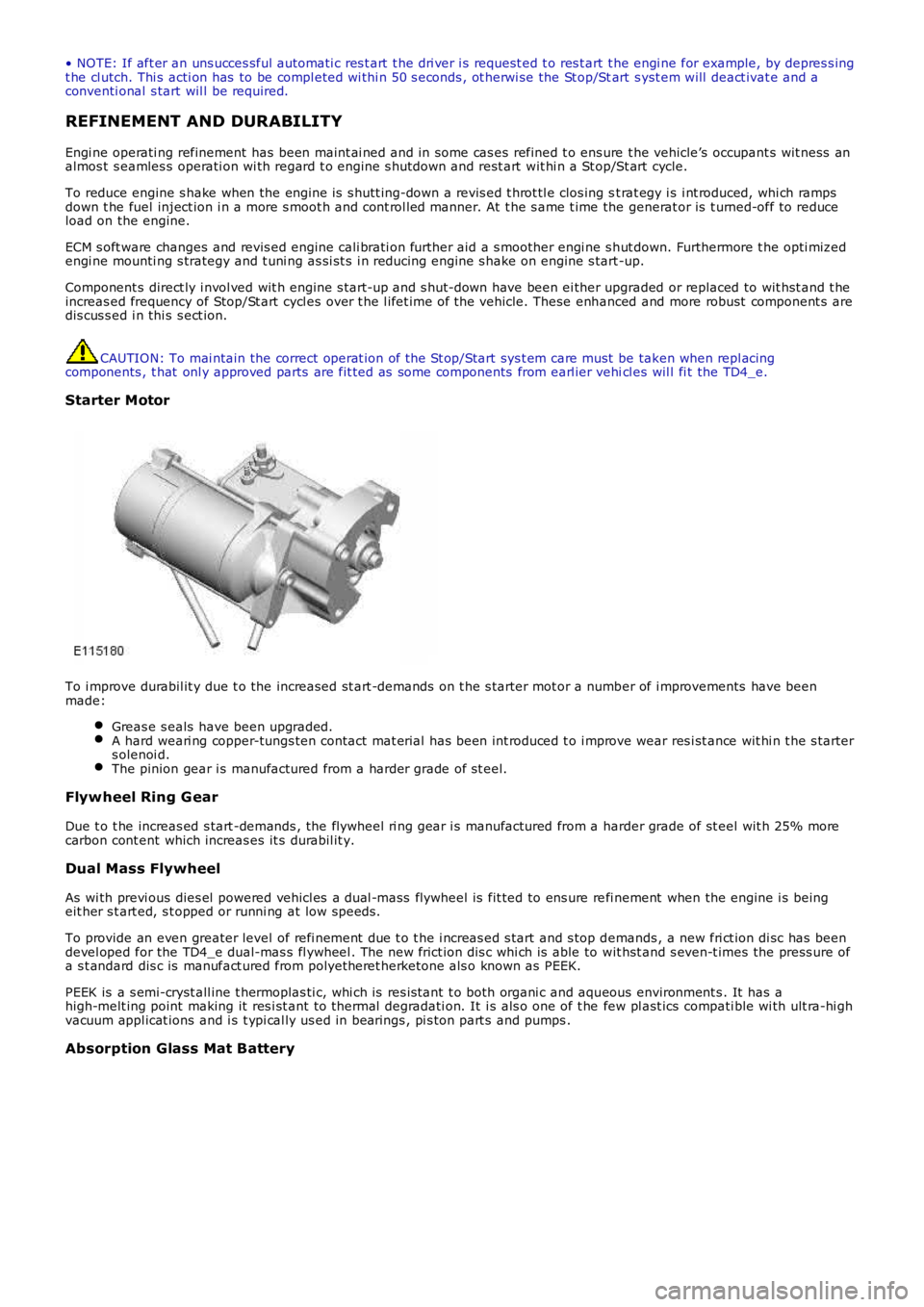

• NOTE: If aft er an uns ucces sful aut omati c res t art t he dri ver i s request ed t o res t art t he engi ne for example, by depres s ingt he cl utch. Thi s acti on has to be compl eted wi thi n 50 s econds , ot herwi se the St op/Start s yst em will deact ivat e and aconventi onal s tart wil l be required.

REFINEMENT AND DURABILITY

Engi ne operati ng refinement has been maint ai ned and in some cas es refined t o ens ure t he vehicle’s occupant s wit ness analmos t s eamles s operati on wi th regard t o engine s hutdown and rest art wit hi n a St op/St art cycle.

To reduce engine s hake when the engine is s hutt ing-down a revis ed t hrot tl e clos ing st rat egy i s i nt roduced, whi ch rampsdown t he fuel inject ion i n a more s moot h and cont rol led manner. At t he s ame t ime the generat or is t urned-off to reduceload on the engine.

ECM s oft ware changes and revis ed engine cali brati on further aid a s moother engi ne s hut down. Furthermore t he opti mizedengi ne mounti ng s trategy and t uni ng as si st s i n reducing engine s hake on engine s tart-up.

Component s direct ly i nvol ved wit h engine s tart-up and s hut-down have been ei ther upgraded or replaced to wit hst and t heincreas ed frequency of Stop/St art cycl es over t he l ifet ime of the vehicle. These enhanced and more robust component s aredis cus s ed i n thi s s ect ion.

CAUTION: To mai ntain the correct operat ion of t he St op/Start sys t em care must be taken when repl acingcomponents , t hat onl y approved parts are fit ted as some components from earl ier vehicl es wil l fi t the TD4_e.

Starter Motor

To i mprove durabil it y due t o the increased st art -demands on t he s tarter mot or a number of i mprovements have beenmade:

Greas e s eals have been upgraded.A hard weari ng copper-tungs ten contact mat erial has been int roduced t o i mprove wear res i st ance wit hi n t he s tarters olenoi d.The pinion gear i s manufactured from a harder grade of st eel.

Flywheel Ring G ear

Due t o t he increas ed s tart -demands , the flywheel ri ng gear i s manufactured from a harder grade of st eel wit h 25% morecarbon cont ent which increas es it s durabil it y.

Dual Mass Flywheel

As wi th previ ous dies el powered vehicl es a dual -mass flywheel is fit ted to ens ure refi nement when the engine i s beingeit her s t art ed, s t opped or runni ng at low speeds.

To provide an even greater level of refi nement due t o t he i ncreas ed s tart and s top demands , a new fri ct ion di sc has beendevel oped for the TD4_e dual-mas s fl ywheel . The new frict ion dis c whi ch is able to wit hst and s even-t imes the press ure ofa s t andard dis c is manufact ured from polyetheret herketone als o known as PEEK.

PEEK is a s emi-cryst all ine t hermoplas ti c, whi ch is res is tant t o both organi c and aqueous environment s . It has ahigh-melt ing point making it res i st ant to thermal degradati on. It i s als o one of t he few pl ast ics compati ble wi th ult ra-hi ghvacuum appl icat ions and i s t ypi cal ly us ed in bearings , pi s ton part s and pumps .

Absorption Glass Mat Battery

Page 1104 of 3229

25-Fuel fired heat er (i f fi tt ed)

26-Auxili ary coolant pump **

* Vehicles wit hout fuel fired heat er.

** Vehicles wi th fuel fi red heater.

INTELLIGENT TECHNOLOGY

New and revi s ed components as di s cus s ed in this secti on have been developed t o ensure t hat al l vehicl e s ys t ems operatevirtuall y uninterrupt ed in a Stop/St art cycl e.

Voltage Quality Module

Duri ng an engine St op/Start cycle t he VQM (volt age qual it y module) mai ntains t he vehicle’s el ect ri cal s yst ems by s upplyinga s upport volt age around the vehicle's electroni c components during an engine res tart. This al lows crucial vehicle s ys temst o cont inue unint errupt ed when t here i s a s udden draw of amps from the bat tery.

The vehi cl e’s s t art er mot or cons umes 2kW of el ect ri cal power and can draw s everal hundred amps of current from thebatt ery during cranking. Thi s s udden draw of current causes a momentary volt age drop around al l t he vehicle ci rcuit s. Manyof the vehicle's electroni c s ys t ems are des i gned t o operat e at a nomi nal 12 volt s , so thi s s udden drop in bat tery volt agewit hout the VQM ins t al led woul d temporaril y i nt errupt servi ces such as :

audi o s yst emcel lul ar phonenavi gat ion sys temmes s age Cent er.

Once the engi ne is runni ng a s ignal from t he ECM triggers a relay wit hi n t he VQM t o bypass the converter s t age andvolt age control is gi ven back t o t he vehi cl e's normal charging sys tem. The VQM is specified t o boost vol tage for ones econd, alt hough i n many s it uati ons i t can s upply a volt age boos t for up t o 5 seconds .

The VQM is effecti vel y a DC (direct current) converter, which convert s a variable DC input vol tage from as l ow as 6V up t oa s t abl e 12V DC out put ± 0.5V.

Rated at a nominal 180W , it can s uppl y up t o 15 amps of load at 12 vol ts . The VQM can t olerat e i ns t ant aneous s pikes upt o 300 W at ts , enough to maintai n uninterrupt ed power t o vehicle s ys tems during engine cranking.

VQM fault s are trans mi tt ed via a diagnost ic l ink t o t he CJB where they are hel d; the fault codes can be di agnos ed us ingLand Rover approved diagnos t ic equipment .

Battery Monitoring System

Mounted on t he batt ery negat ive t ermi nal t he BMS (batt ery moni toring s yst em) module is i ntegral wi th t he batt erynegat ive cable.

Batt ery healt h s t at us i s a fundamental fact or in t he correct operat ion of t he Stop/St art s ys tem. Computat ion of t he batt erys tat us is performed by t he BMS module and will i nit iate a ‘St op Inhi bit or’ or ‘Start Ini ti at or’ i n a St op/Start cycle if t hebatt ery cannot meet t he requi red demand. For addit ional informati on refer to the ‘Stop Inhi bit ors , Start Init iat ors and St art

Page 1107 of 3229

To ens ure t he vehi cl e’s braki ng s ys t em i s never compromi sed, a brake vacuum s ens or is int roduced on Stop/St art vehiclest o monit or vacuum reserves in t he brake s ervo. The vacuum sens or is mount ed in the vacuum pipe and hardwi red to t heECM. In the event of brake vacuum decreas ing below a s et threshold during a Stop/St art cycl e t he ECM wi ll s end a s ignalt o eit her:

Rest art t he engine and consequentl y replenis h vacuum reserves .Inhi bi t t he engi ne s hut ti ng down if vacuum res erves are not s uffi ci ent.

An example of vacuum res erves deplet ing, is by t he dri ver repeat edly pres s ing t he brake pedal when the engine iss hut down duri ng a St art/Stop cycle. This acti on wil l init iat e an engine res tart when vacuum reserves decreas e below thes et thres hold.

If a fault develops wi th the brake vacuum s ensor a DTC wil l be logged in the CJB.

Auxiliary Coolant Pump

Duri ng a St op/Start cycle when the engine i s s hutdown and consequent ly the engine-driven coolant pump is st ati onary, thedesi red s et cabi n t emperature cannot be mai ntai ned for a prol onged period, especially in col d ambient t emperatures . Tocount eract this , an auxil iary el ect ri c cool ant -pump has been integrat ed i nt o t he cool ing s ys tem to maint ain t he cool antfl ow t hrough t he cabi n’s heat er core. Thi s s upporti ng ci rculat ion t herefore prol ongs t he s et temperat ure set ti ng in the cabinand accordi ngl y prevents an early engine res tart.

Dependi ng on vehi cl e clas s ifi cat ion the auxil iary coolant pump i s eit her:

Hardwi red di rectl y to the ECM.Or if t he vehicle i s fit ted wi th a FFBH (fuel fi red boos ter heat er), t he FFBH coolant pump i s uti li zed and act ivatedvia t he FFBH.

The functi onal it y of bot h t ypes of auxil iary coolant pump i s t he s ame wi th regards the Stop/St art s ys tem.

To dis guis e t he acti vat ion s ound of the auxil iary pump, t he pump i s acti vat ed at the same ti me as t he engine s huts down.

Remote Handset

To all ow t he dri ver eas e of use, a revis ed remot e handset releas e has been introduced. Thi s all ows t he driver t o ins t ant lyrel eas e t he remote hands et from t he s tart cont rol module when t he engine i s s hut down in a Stop/Start cycle.

The vehi cl e reverts t o t he conventi onal remote hands et releas e when not in a Stop/Start cycle, that i s by pres s ing t heignit ion St art /St op butt on before rel eas i ng the remote hands et.

Stall Recovery

In the event of an engi ne s tal l, t he Stop/St art s ys tem ent ers a unique ‘s t al l recovery’ mode. This feature aut omat ical lyatt empts to res tart the engine as soon as t he driver full y depres ses t he clut ch pedal; t he natural react ion of t he dri verwhen experiencing a s t alled engi ne si tuat ion.

Once the cl utch s ensor detects the ‘bot t om of t ravel’ threshold, refer to ‘Linear Clut ch Sens or’, t he s t arter mot or isact ivat ed to res tart the engine. The warni ng indicat ors normal ly as s oci ated wi th an engi ne s tal l, for example the i gni ti onand low oil pres s ure i ndi cat ors i n t he ins t rument clus ter wil l be s uppress ed s o wi ll not il lumi nat e. The Eco indicator does