fuse LAND ROVER FRELANDER 2 2006 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 1927 of 3229

The s ys t em operat es by t he AFS cont rol module recei vi ng inputs from t he engine cont rol module for engine runni ng s ignal ,t he ABS module for st eeri ng angl e and vehi cle s peed and a reverse gear i nput from the trans mi ss i on.

The AFS cont rol module proces s es thes e s ignals and provi des an output t o the headlamp leveling motors to adjus t theheadl amp hori zont al ai m according t o vehicle speed and s teering angle.

• NOTE: In market s wit h Dayt ime Running Lamps (DRL), t he AFS s yst em will not operate when the DRL are act ive.

The AFS cont rol module is connect ed on the hi gh s peed CAN bus to receive i nformat ion from other vehicle s ys tems . Thecont rol module is connect ed to the AFS power module on a dedi cat ed Local Interconnect Net work (LIN) bus . The AFScont rol module cal culat es, us ing input dat a from other s ys t ems , the requi red pos it ion of t he hori zont al adjus t ment of t heproject or modul es. The pos it ion i nformat ion is t hen output on t he LIN bus to t he AFS power module l ocat ed on eachheadl amp as sembl y. Thi s module t hen outputs the appropriate s ignal s t o power the AFS s t epper mot ors i n t he headl ampt o the appropriat e posi ti on.

The hori zont al pos it ion of t he project or modul es is dependant on a number of input vari abl es . The pos it ion i s determinedby vehi cle s peed and s teeri ng angl e. W hen reverse gear i s elected, the projector modules are moved t o t he st rai ght aheadposi ti on t o avoi d glare t o other road us ers .

The angl es of each projector module di ffer to gi ve the correct spread of light , for example, when turning l eft , the l eft handproject or modul e wi ll have a great er s wi vel ling angl e than t he right hand projector module.

In the event of a fai lure of the AFS sys tem, a warning indicator in the ins trument cl us t er flas hes t o warn the driver. TheAFS warni ng indicator i lluminates when t he i gni ti on s wit ch is i n power mode 6 and will flas h cont inuousl y unti l the faul t isrect ifi ed.

Illumi nati on of the AFS warning i ndi cat or does not neces s aril y mean t hat there is a fault wit h the AFS sys tem. The faultmay be caus ed by a fai lure of anot her sys tem s uch as st eeri ng angl e s ens or or the vehicle s peed s i gnal mi ss i ng,preventi ng the AFS s ys tem operati ng correctl y.

HEADLAMP LEVELING

Headl amp l evel ing provides for the adjus t ment of the vert ical aim of the headlamps to minimi ze glare to other road us erswhen t he vehi cl e att it ude changes due t o vehi cle l oadi ng.

Two t ypes of headlamp l evel ing are avai lable dependant on the t ype of headlamps fit ted to the vehicle:

Manual headlamp l evel ing - Hal ogen headlamps only (ROW vehicles only)Automat ic headlamp level ing - Xenon headlamps only.

Manual Headlamp Leveling - ROW Halogen Headlamps Only

Manual headlamp l evel li ng is only avai lable on RO W vehicles wit h halogen headl amps .

• NOTE: Headlamp l evel ling is not avai lable on NAS vehicles wi th hal ogen headlamps .

The manual s ys tem compris es t he fol lowing components :

Two headlamp l evel ling motorsHeadl amp l evel ing rheos tat rotary cont rol .

W hen t he i gni ti on is i n i gni ti on power mode 6, power i s s uppli ed t o t he li ght control modul e via t he i gni ti on rel ay in t heBJB and a fuse in t he CJB. Power i s als o s uppl ied vi a the ignit ion relay i n the BJB to t he headlamp l evel ing mot or in eachheadl amp as sembl y.

Movement of t he leveli ng rot ary control produces a variable volt age output, whi ch is s ens ed by the motors. The mot orsreact to the suppli ed vol tage and move the headlamp t o t he reques ted pos it ion whi ch rel at es t o t he suppli ed volt age fromt he leveling rotary cont rol . The headlamps can onl y be lowered from t heir unladen posi ti on t o compens ate for changes invehi cl e at ti tude due t o l oading.

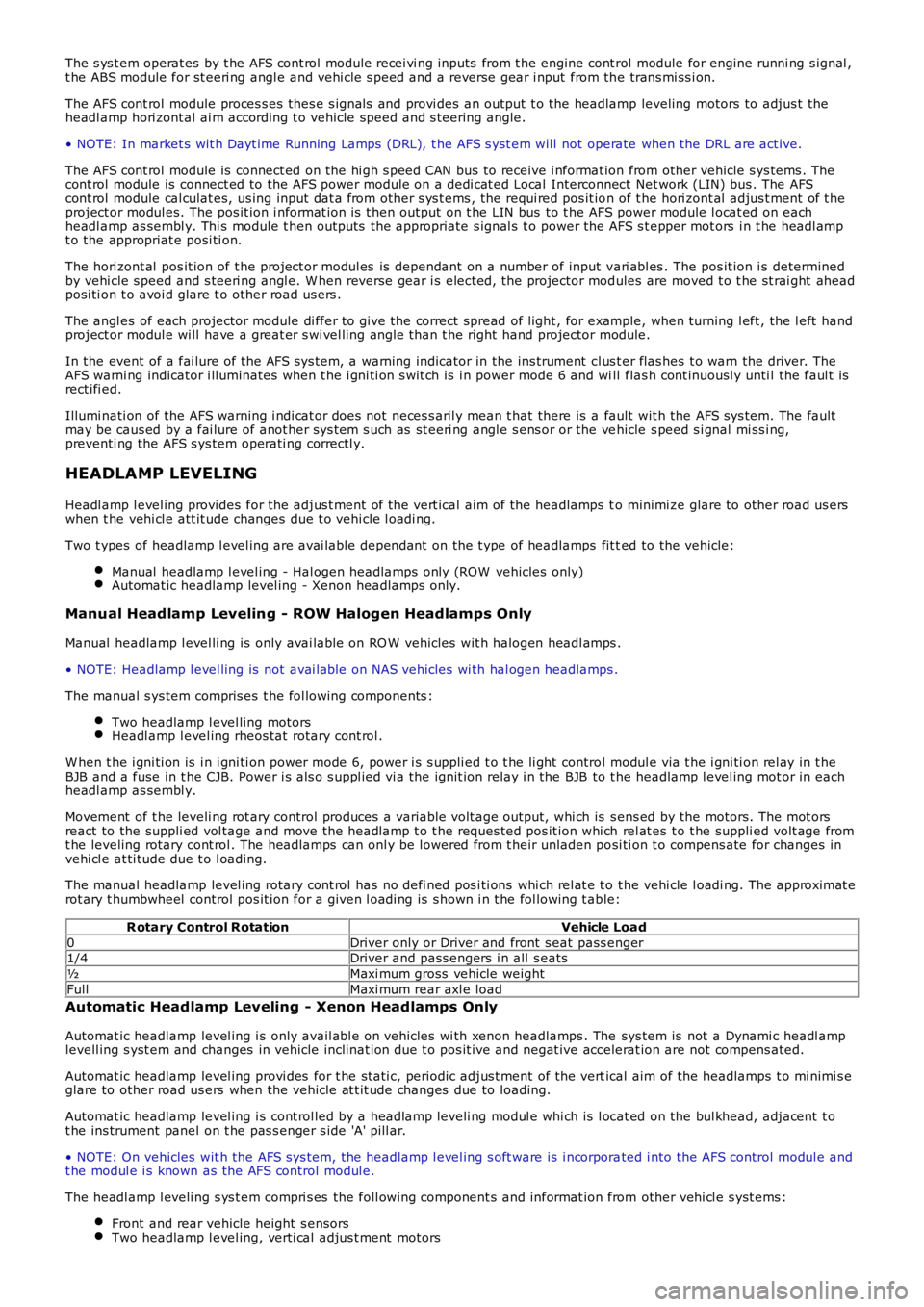

The manual headlamp level ing rotary cont rol has no defi ned pos i ti ons whi ch rel at e t o t he vehi cle l oadi ng. The approximat erot ary t humbwheel control pos it ion for a given l oadi ng is s hown i n t he fol lowing t able:

R otary Control RotationVehicle Load

0Driver only or Driver and front s eat pass enger1/4Driver and pass engers i n all s eats

½Maxi mum gross vehicle weight

FullMaxi mum rear axl e load

Automatic Headlamp Leveling - Xenon Headlamps Only

Automat ic headlamp level ing i s only avail abl e on vehicles wi th xenon headlamps . The sys tem is not a Dynami c headl amplevell ing s yst em and changes in vehicle inclinat ion due t o pos it ive and negat ive accelerat ion are not compens ated.

Automat ic headlamp level ing provi des for t he st ati c, periodic adjus t ment of the vertical aim of the headlamps t o mi nimi s eglare to other road us ers when the vehicle at t it ude changes due to loading.

Automat ic headlamp level ing i s cont rol led by a headlamp leveli ng modul e whi ch is l ocat ed on the bul khead, adjacent t ot he ins trument panel on t he pas s enger s ide 'A' pill ar.

• NOTE: On vehicles wit h the AFS sys tem, the headlamp l evel ing s oft ware is i ncorporated i nto the AFS control modul e andt he modul e i s known as the AFS control modul e.

The headl amp l eveli ng s ys t em compri s es the foll owing component s and informat ion from other vehi cl e s yst ems :

Front and rear vehicle height s ensorsTwo headlamp l evel ing, verti cal adjus t ment motors

Page 1933 of 3229

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

• NOTE: Pri or to ins tall ati on/replacement of the Headlamp Ass embly carry out all relevant i nternal vis ual and mechanicalchecks for correct cable l ocat ion and t erminati on including: checks for corroded, bent or backed out pi ns or terminals ,incorrect ly i nserted connect ors and harnes s damage due t o chaffi ng or incorrect routing.

• NOTE: If the control modul e has been removed and rei nst all ed, carry out a DTC code clear, cycl e t he ignit ion st ate to off,t hen on. This will erase any DTCs that have been l ogged during t he module ins tall ation procedure

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.

REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Headlamp Cont rol Modul e (HCM) (100-00 General Informati on,Des cript ion and Operat ion).

Symptom Chart

SymptomPossible CausesActionLow beam lamp(s )i noperat iveBulb fail ureFus e(s ) blownCi rcuit faul tLight ing control s wi tchfaul tLeft -hand s t eeringcolumn mult ifuncti ons wit ch faul t

Check t he bulb and fuse condit ion (s ee vis ual i nspecti on). Check theheadlamp ci rcuit s . Check t he li ght ing control swit ch funct ion. Check theleft -hand s t eering column mult ifunct ion s wi tch operat ion. Refer to theel ect ri cal guides . Check for DTCs indicati ng a headl amp or rel atedci rcuit faul t.Hi gh beam lamp(s )i noperat ive

Low beam lamp(s )dimIncorrect bul b rat ingTouri st l ever s et in thewrong pos i ti onCi rcuit faul tLight ing control s wi tchfaul tLeft -hand s t eeringcolumn mult ifuncti ons wit ch faul t

Check t he bulb condi ti on and rat ing. Check the t ouris t l ever i s s etcorrectl y. Check the headlamp ci rcuit s . Check t he li ght ing control swit chfunct ion. Check the l eft -hand s teering column mult ifuncti on s wit chfunct ion. Refer t o t he electrical gui des .

Hi gh beam lamp(s )dim

Low beam lamp(s )s tuck onCi rcuit faul tLight ing control s wi tchfaul tLeft -hand s t eeringcolumn mult ifuncti ons wit ch faul tHeadlamp ti merfunct ion faul t

Check t he headl amp circui ts . Check t he l ighti ng cont rol s wit ch functi on.Check t he left-hand st eeri ng col umn mul ti funct ion swi tch operat ion.Check t he headl amp t imer funct ion. Refer to the el ect ri cal guides .Check for DTCs i ndicat ing a headl amp circui t fault

Hi gh beam lamp(s )s tuck on

Headlamp l ow/hi ghbeam s wi tchingfunct ion i noperat ive

Ci rcuit faul tLeft -hand s t eeringcolumn mult ifuncti ons wit ch faul tXenon lamp s hut termechani s m fault

Check t he headl amp circui ts . Check t he l eft-hand s teeri ng col umnmult ifunct ion s wit ch operati on. Check t he xenon l amp s hutt ermechanis m operati on. Refer t o t he electrical gui des . Check for DTCsindicati ng a headl amp circui t fault

W arning l amp(s )i noperat iveFus e(s ) blownLight ing control s wi tchfaul tLeft -hand s t eeringcolumn mult ifuncti ons wit ch inoperat iveCi rcuit faul tInst rument clus t erfaul t

Check t he fus e(s ) (s ee vi s ual i ns pecti on). Check t he li ghti ng cont rolswi tch funct ion. Check t he l eft -hand s teeri ng column mul ti functi onswi tch funct ion. Check t he warni ng lamp circuit s . Refer to the el ect ri calgui des . Check for DTCs indicat ing an i nst rument clus ter or CAN s ys temfault .

Headlamp W et -InternalCondens ati onW at er Ingres sCheck for out st anding Techni cal Service Bull eti ns (TSBs ) rel at ing to'Headl amp Internal Condens ati on'. Carry out the i nst ruct ions in theservi ce bullet in to det ermi ne if t he faul t is relat ed to condens at ion orwater ingres s .

Page 1949 of 3229

Publi s hed: 11-May-2011

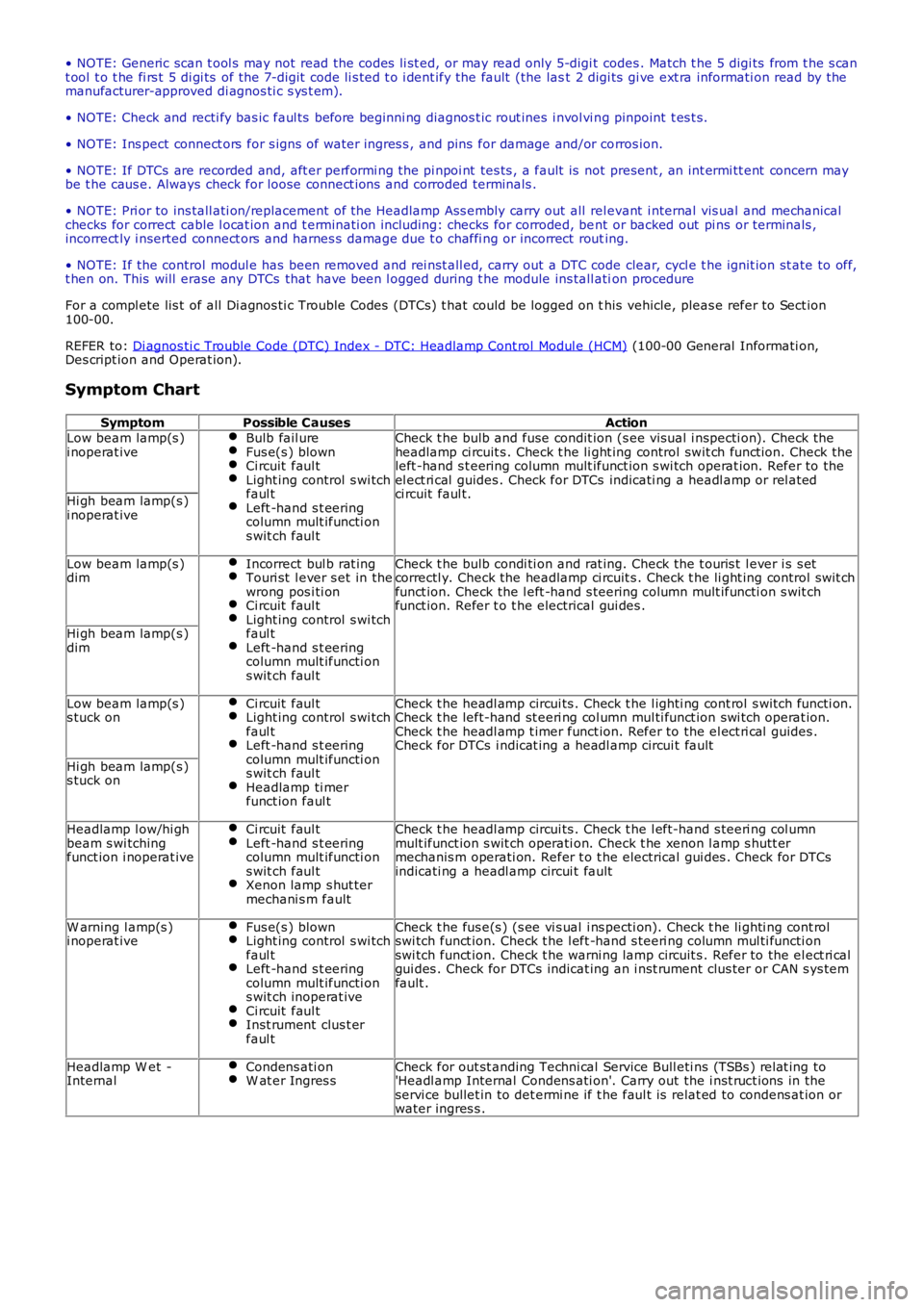

Exterior Lighting - Trailer Module

Removal and Inst all ati on

Removal

• NOTE: The t rail er modul e i s fi tt ed wi th a replaceble fuse.

Remove t he LH rear quart er trim panel .

Refer t o: Rear Quarter Tri m Panel (501-05 Int erior Tri m andOrnament ati on, Removal and Ins tal lat ion).

1.

Remove the trai ler module.2.

3. NOTE: Do not dis ass embl e further if t he componenti s removed for acces s onl y.

Remove t he fus e.

3.

Installation

To i nst all , revers e t he removal procedure.1.

Us ing t he Land Rover approved diagnost ic sys tem, cali brat e a newmodule.2.

Page 1960 of 3229

Publi s hed: 11-May-2011

Daytime Running Lamps (DRL) - Daytime Running Lamps (DRL)

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the dayt ime running l amps sys t em, refer t o t he rel evant Des cript ion and Operat ion s ecti on int he works hop manual .REFER to: Dayti me Running Lamps (DRL) (417-04 Dayt ime Running Lamps (DRL), Des cri pt ion and Operati on).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.2.

Visual Inspection

Electrical

Fuses (refer to the el ect ri cal guide)BulbsSwit chesElectrical connect orsW iri ng harnes s

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he relevantDi agnos ti c s ect ion and DTC Index.4.

Page 1969 of 3229

Publi shed: 06-Jul-2011

Module Communications Network - Communications Network

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Communi cat ions Net work, refer to t he relevant Des cript ion and O perati on sect ion i n theworks hop manual .REFER to: Communi cat ions Network (418-00 Modul e Communi cat ions Network, Des cri pti on and Operati on).

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage and sys tem integrit y.2.

Visual InspectionElectrical

Fuses (refer to elect rical guide)W iri ng harnes sCorrect engagement of el ect ri cal connectorsLoose or corroded connect ionsRouti ng of fi bre opt ic harnes sesCorrect engagement of opt ical connect orsCorrect pl acement of opti cal connectors (ring order)Correct as s embly of opti cal connect ors (backout , etc)Damage t o fibre (chafi ng, abras ion, kinking, cut s , etc)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.4.

For a compl ete lis t of all di agnos ti c troubl e codes that coul d be l ogged on t his vehicle, pleas e refer to s ect ion 100-00.REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Body Cont rol Module (BCM) (100-00 General Informat ion,Des cript ion and Operat ion).

Page 1989 of 3229

Secure t he engi ne harnes s to the fus ebox.

5.

Inst all and s ecure t he bat t ery l ead to t he fusebox and ins t al l the

s mall bat tery lead cover.

T orque: 10 Nm 6.

Connect t he two electrical connect ors t o t he BJB.

7.

Secure t he 3 eart h point s and s ecure t he harness cl ips t o t he vehi cl e

body.

T orque: 10 Nm 8.

Secure t he batt ery l ead to the bat tery terminal clamp.

T orque: 25 Nm 9.

Inst all t he fus e box cover.

10.

Inst all t he harness cover to the s us pens ion turret.

11.

Feed harness under t he air cleaner duct and s ecure the duct t o the

grommet.

12.

Secure headl amp and bumper harness cl ips .

13.

Connect t he height sens or elect rical connect or and s ecure t he

harnes s wit h t he cli ps .

14.

Inst all headl amp mount ing plat e.

T orque: 10 Nm 15.

Connect t he s ide repeat er el ect ri cal connector.

16.

Connect t he heat ed was her jet electrical connect ion and s ecure t he

harnes s t o the vehicl e body.

17.

Connect t he ABS s ens or and s ecure t he harness to t he vehicle body.

18.

Secure t he was her pipe to the harnes s and s ecure t he harness to the

body.

19.

Connect t he cras h s ens or electrical connect ors .

20.

Connect t he the bonnet lock electrical connect or

21.

Secure t he harness to the body and t hen secure the bonnet releas e

cabl e t o t he harness .

22.

Secure t he was her pipe to the was her bot tl e.

23.

Inst all t he washer bott le and connect t he elect rical connecti ons .

T orque: 10 Nm 24.

Page 2008 of 3229

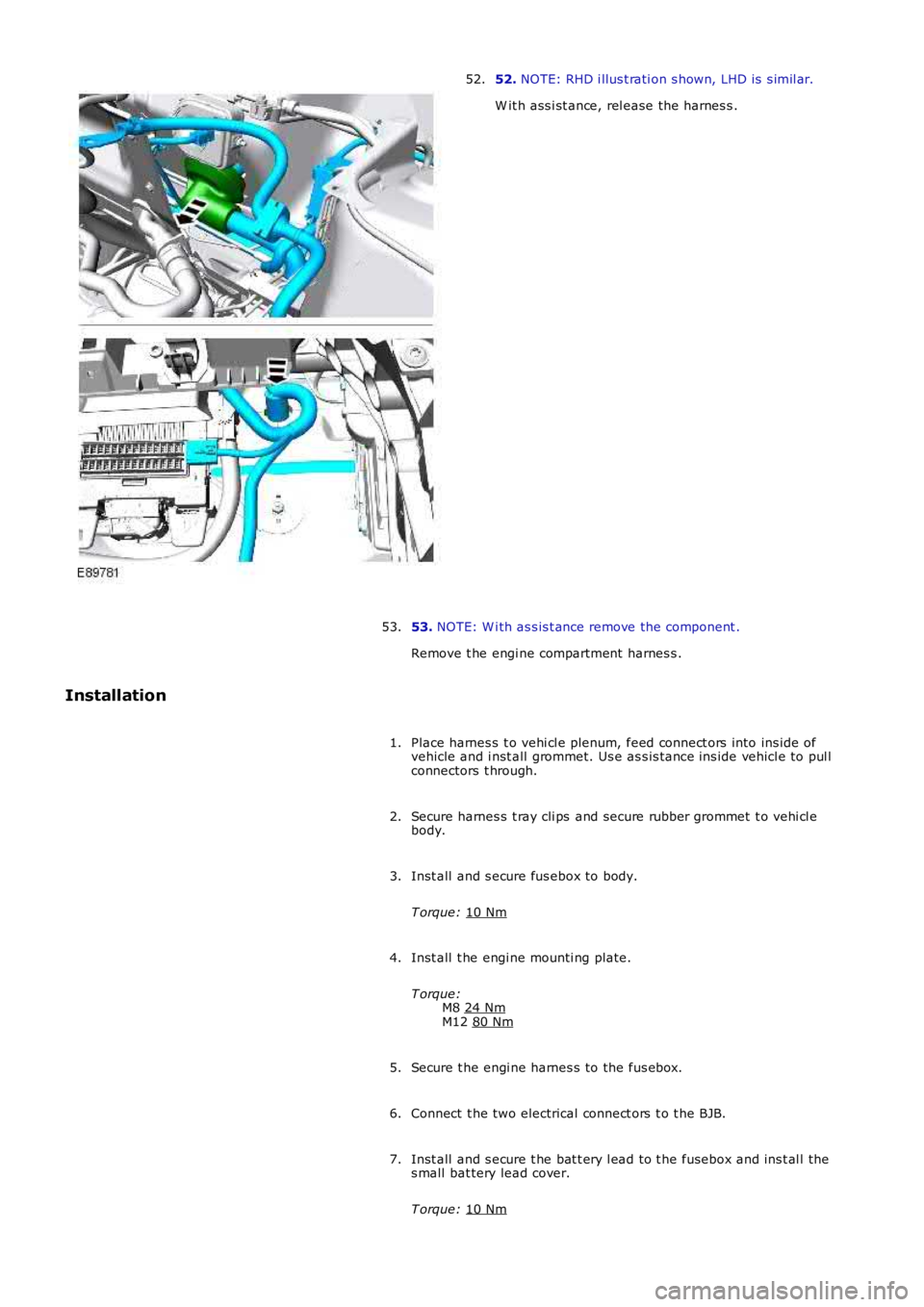

52.

NOTE: RHD i llus t rati on s hown, LHD is s imil ar.

W it h ass i st ance, rel ease the harnes s .

52.

53. NOTE: W i th as s is t ance remove the component .

Remove t he engi ne compartment harnes s .

53.

Installation Place harnes s t o vehi cl e plenum, feed connect ors into ins ide of

vehicle and i nst all grommet. Us e as s is tance ins ide vehicl e to pul l

connectors t hrough.

1.

Secure harnes s t ray cli ps and secure rubber grommet t o vehi cl e

body.

2.

Inst all and s ecure fus ebox to body.

T orque: 10 Nm 3.

Inst all t he engi ne mounti ng plate.

T orque: M8 24 Nm M12

80 Nm 4.

Secure t he engi ne harnes s to the fus ebox.

5.

Connect t he two electrical connect ors t o t he BJB.

6.

Inst all and s ecure t he bat t ery l ead to t he fusebox and ins t al l the

s mall bat tery lead cover.

T orque: 10 Nm 7.

Page 2075 of 3229

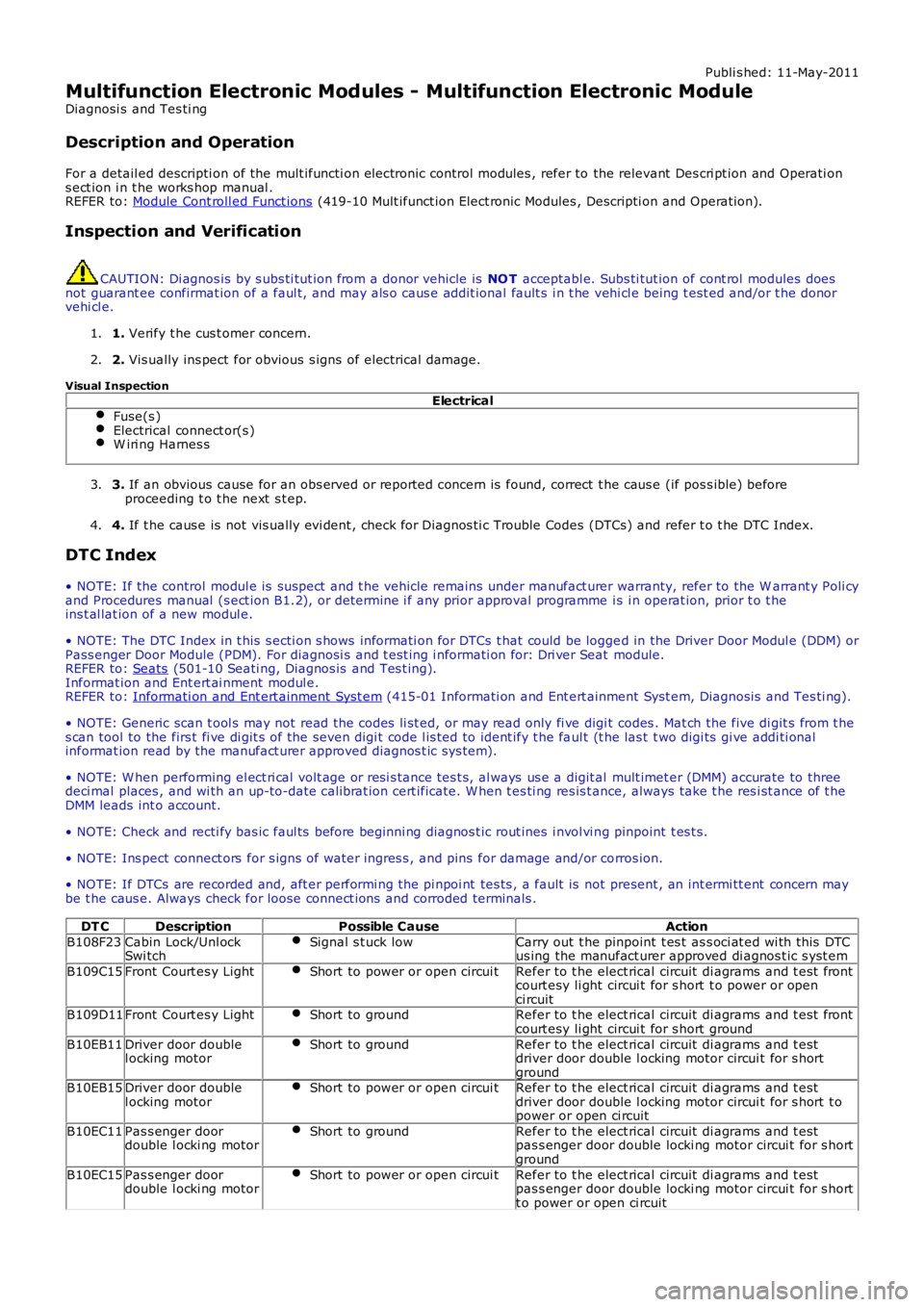

Publi s hed: 11-May-2011

Multifunction Electronic Modules - Multifunction Electronic Module

Diagnosi s and Tes ti ng

Description and Operation

For a detail ed descripti on of the mult ifuncti on electronic cont rol modules , refer to the relevant Des cri pt ion and Operati on

s ect ion i n t he works hop manual .

REFER to: Module Cont roll ed Funct ions (419-10 Mult ifunct ion Elect ronic Modules , Descripti on and Operat ion).

Inspection and Verification CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is

NO T acceptabl e. Subs ti tut ion of cont rol modules does

not guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he v ehi cl e being t est ed and/or t he donor

vehi cl e.

1. Verify t he cus t omer concern.

1.

2. Vis ually ins pect for obvious s igns of electrical damage.

2.

Visual Inspection Electrical

Fuse(s ) Electrical connect or(s )

W iri ng Harnes s

3.

If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) before

proceeding t o t he next s t ep.

3.

4. If t he caus e is not vis ually evi dent , check for Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.

4.

DTC Index

• NOTE: If the control modul e is sus pect and t he vehicle remains under manufact urer warranty, refer to the W arrant y Poli cy

and Procedures manual (s ect ion B1.2), or determine i f any prior approval programme i s i n operat ion, prior t o t he

ins t al lat ion of a new modul e.

• NOTE: The DTC Index in t his s ecti on s hows informati on for DTCs t hat could be logge d in the Driver Door Modul e (DDM) or

Pass enger Door Module (PDM). For diagnosi s and t est ing i nformati on for: Dri ver Seat module.

REFER to: Seats (501-10 Seati ng, Diagnos is and Tes t ing).

Informat ion and Ent ert ai nment modul e.

REFER to: Informati on and Ent ert ainment Syst em (415-01 Informati on and Ent ert ainment Syst em, Diagnos is and Tes ti ng).

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digi t codes . Mat ch the five di git s from t he

s can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he fa ul t (t he las t t wo digi ts gi ve addi ti onal

informat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to three

deci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t a nce, always take t he res i st ance of t he

DMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi n g pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or co rros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is no t present , an int ermi tt ent concern may

be t he caus e. Always check for loose connect ions and corroded terminals .

DT C Description Possible Cause Action

B108F23 Cabin Lock/Unl ock

Swi tch Signal s t uck low Carry out t he pinpoint t es t as s oci at ed wi th this DTC

us ing the manufact urer approved di agnos t ic s yst em

B109C15 Front Court es y Light Short to power or open circui t Refer to t he elect rical circuit di agrams and t est front

court esy li ght circui t for s hort t o power or open

ci rcuit

B109D11 Front Court es y Light Short to ground Refer to t he elect rical circuit di agrams and t est front

court esy li ght circui t for s hort ground

B10EB11 Driver door double

l ocking motor Short to ground Refer to t he elect rical circuit di agrams and t est

driver door double l ocking motor circui t for s hort

ground

B10EB15 Driver door double

l ocking motor Short to power or open circui t Refer to t he elect rical circuit di agrams and t est

driver door double l ocking motor circui t for s hort t o

power or open ci rcuit

B10EC11 Pas s enger door

double l ocki ng motor Short to ground Refer to t he elect rical circuit di agrams and t est

pas s enger door double locki ng motor circui t for s hort

ground

B10EC15 Pas s enger door

double l ocki ng motor Short to power or open circui t Refer to t he elect rical circuit di agrams and t est

pas s enger door double locki ng motor circui t for s hort

t o power or open ci rcuit

Page 2189 of 3229

Publi shed: 26-Jul-2011

Seating - Heater Mats

Diagnosi s and Tes ti ng

Principles of Operation

Heated s eats incorporate heat er elements in t he cushi on and the backres t of the s eat. Each cus hion heat er el ement has at hermal sens or, whi ch suppli es a feedback temperat ure si gnal t o t he rel at ed s eat heat er modul e. The backres t heat erelement s do not have a thermal sens or, and are regulat ed at the s ame temperat ure as the cus hi on heat er elements .

For a detail ed descripti on of the seat heater mat , refer t o t he rel evant Des cript ion and Operat ion s ecti on in the workshopmanual. REFER to: Seats (501-10, Descripti on and Operat ion).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.2.

Visual inspectionMechanicalElectrical

Seat heat er swi tches condi ti on and ins tal lati onFusesHarnes s es and connect orsSeat heat er modul eSeat heat er swi tchesSeat heat er mat

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Chart.4.

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o thewarranty poli cy and procedures manual (s ect ion B1.2), or det ermine i f any prior approval programme is i n operati on, priort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

DTC Index

For a compl ete lis t of all di agnos ti c troubl e codes that coul d be l ogged on t his vehicle, pleas e refer to s ect ion 100-00.

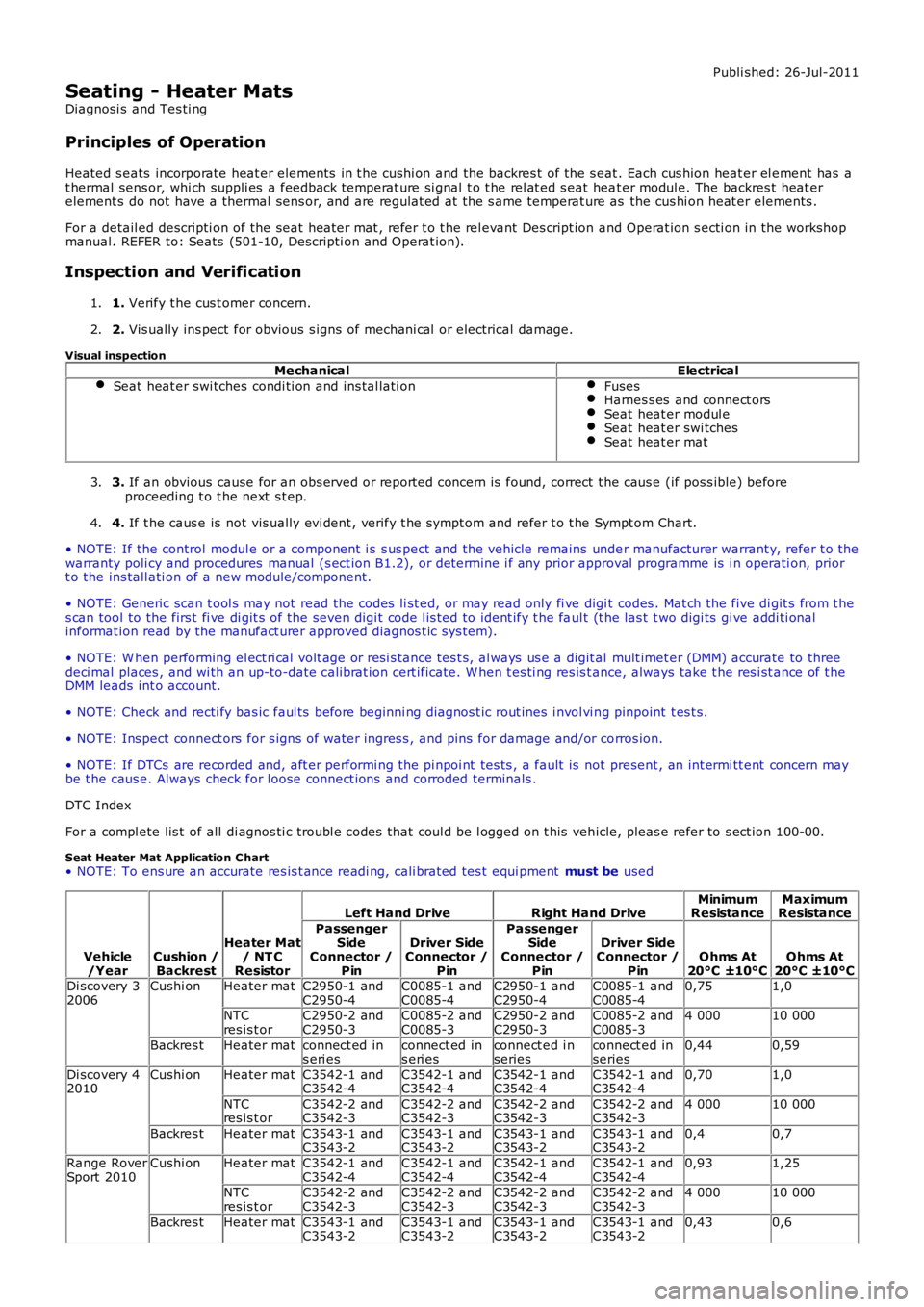

Seat Heater Mat Application C hart• NOTE: To ens ure an accurate res is t ance readi ng, cali brated tes t equi pment must be used

Vehicle/YearCushion /Backrest

Heater Mat/ NT CResistor

Left Hand DriveRight Hand DriveMinimumResistanceMaximumResistance

PassengerSideConnector /Pin

Driver SideConnector /Pin

PassengerSideConnector /Pin

Driver SideConnector /PinOhms At20°C ±10°COhms At20°C ±10°CDi scovery 32006Cushi onHeater matC2950-1 andC2950-4C0085-1 andC0085-4C2950-1 andC2950-4C0085-1 andC0085-40,751,0

NTCres is t orC2950-2 andC2950-3C0085-2 andC0085-3C2950-2 andC2950-3C0085-2 andC0085-34 00010 000

Backres tHeater matconnect ed ins eri esconnect ed ins eri esconnect ed i nseriesconnect ed inseries0,440,59

Di scovery 42010Cushi onHeater matC3542-1 andC3542-4C3542-1 andC3542-4C3542-1 andC3542-4C3542-1 andC3542-40,701,0

NTCres is t orC3542-2 andC3542-3C3542-2 andC3542-3C3542-2 andC3542-3C3542-2 andC3542-34 00010 000

Backres tHeater matC3543-1 andC3543-2C3543-1 andC3543-2C3543-1 andC3543-2C3543-1 andC3543-20,40,7

Range RoverSport 2010Cushi onHeater matC3542-1 andC3542-4C3542-1 andC3542-4C3542-1 andC3542-4C3542-1 andC3542-40,931,25

NTCres is t orC3542-2 andC3542-3C3542-2 andC3542-3C3542-2 andC3542-3C3542-2 andC3542-34 00010 000

Backres tHeater matC3543-1 andC3543-2C3543-1 andC3543-2C3543-1 andC3543-2C3543-1 andC3543-20,430,6

Page 2373 of 3229

1

1

1

1

1

1

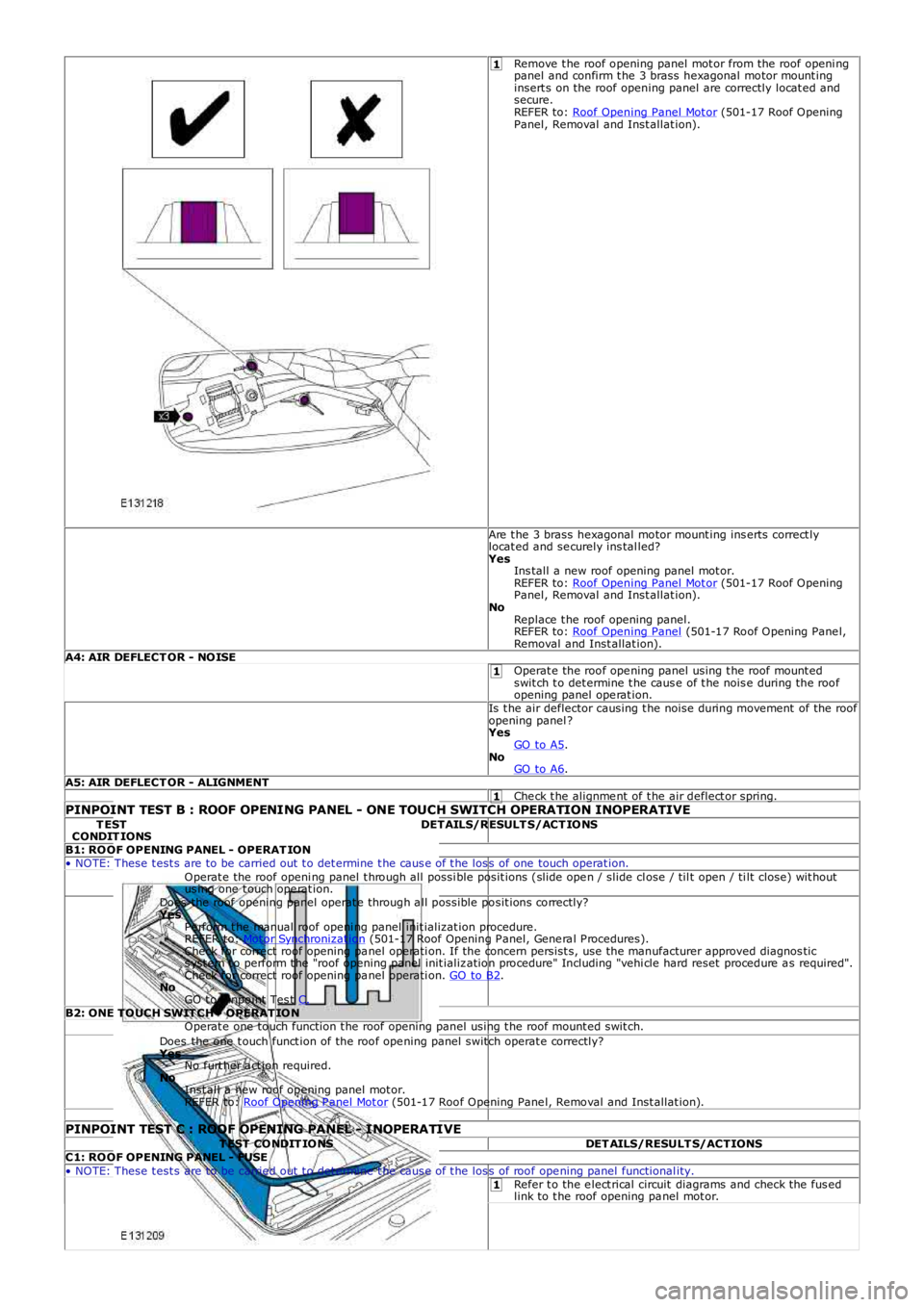

Remove t he roof opening panel mot or from the roof openi ngpanel and confirm t he 3 brass hexagonal motor mount inginsert s on the roof opening panel are correctly locat ed andsecure.REFER to: Roof Opening Panel Mot or (501-17 Roof OpeningPanel, Removal and Inst allat ion).

Are t he 3 brass hexagonal motor mount ing ins erts correct lylocat ed and se curely ins tal led?YesIns tall a new roof opening panel mot or.REFER to: Roof Opening Panel Mot or (501-17 Roof OpeningPanel, Removal and Inst allat ion).NoReplace t he roof opening panel.REFER to: Roof Opening Panel (501-17 Roof Opening Pane l,Removal and Inst allat ion).A4: AIR DEFLECT OR - NOISEOperat e the roof ope ning panel using t he roof mount edswit ch t o det ermine t he caus e of t he nois e during the roofopening panel ope rat ion.Is t he air deflector causing t he noise during movement of the roofopening panel ?YesGO to A5.NoGO to A6.A5: AIR DEFLECT OR - ALIGNMENTChe ck t he alignme nt of t he air deflect or spring.PINPOINT TEST B : ROOF OPENING PANEL - ONE TOUCH SWITCH OPERATION INOPERATIVET ESTCONDIT IONSDETAILS/RESULT S/ACT IONS

B1: ROOF OPENING PANEL - OPERAT ION• NOTE: These t est s are to be carried out t o det ermine t he caus e of t he los s of one touch operat ion.Operat e the roof openi ng panel t hrough all possi ble posit ions (slide ope n / slide close / til t open / ti lt close) wit houtus ing one t ouch ope rat ion.Does the roof opening panel operat e through a ll possible posit ions correctly?YesPe rform t he manual roof openi ng panel init ializat ion procedure.REFER to: Mot or Synchronizat ion (501-17 Roof Opening P anel, Gene ra l P rocedures).Check for correct roof opening pa nel operati on. If the concern persist s, use t he manufacturer approved diagnos tics yst em t o perform t he "roof opening panel init ializ ation procedure" Including "vehi cle hard reset procedure a s required".Check for correct roof opening pa nel operati on. GO to B2.NoGO t o Pinpoint Tes t C.B2: ONE TOUCH SWIT CH - OPERAT IONOperat e one touch function t he roof opening panel using t he roof mount ed swit ch.Does the one t ouch funct ion of the roof ope ning panel switch operat e correctly?YesNo furt her a ct ion required.NoInst all a new roof opening panel mot or.REFER to: Roof Opening P anel Mot or (501-17 Roof Opening Pane l, Removal and Inst allat ion).

PINPOINT TEST C : ROOF OPENING PANEL - INOPERATIVET EST CONDIT IONSDET AILS/RESULT S/ACTIONSC1: ROOF OPENING PANEL - FUSE• NOTE: These t est s are to be carried out t o det ermine t he caus e of t he los s of roof ope ning panel functional ity.Refer t o the e lect rical circuit diagrams and check the fus edlink to t he roof opening pa nel mot or.