fuse LAND ROVER FRELANDER 2 2006 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2374 of 3229

1

2

1

1

2

1

1

1

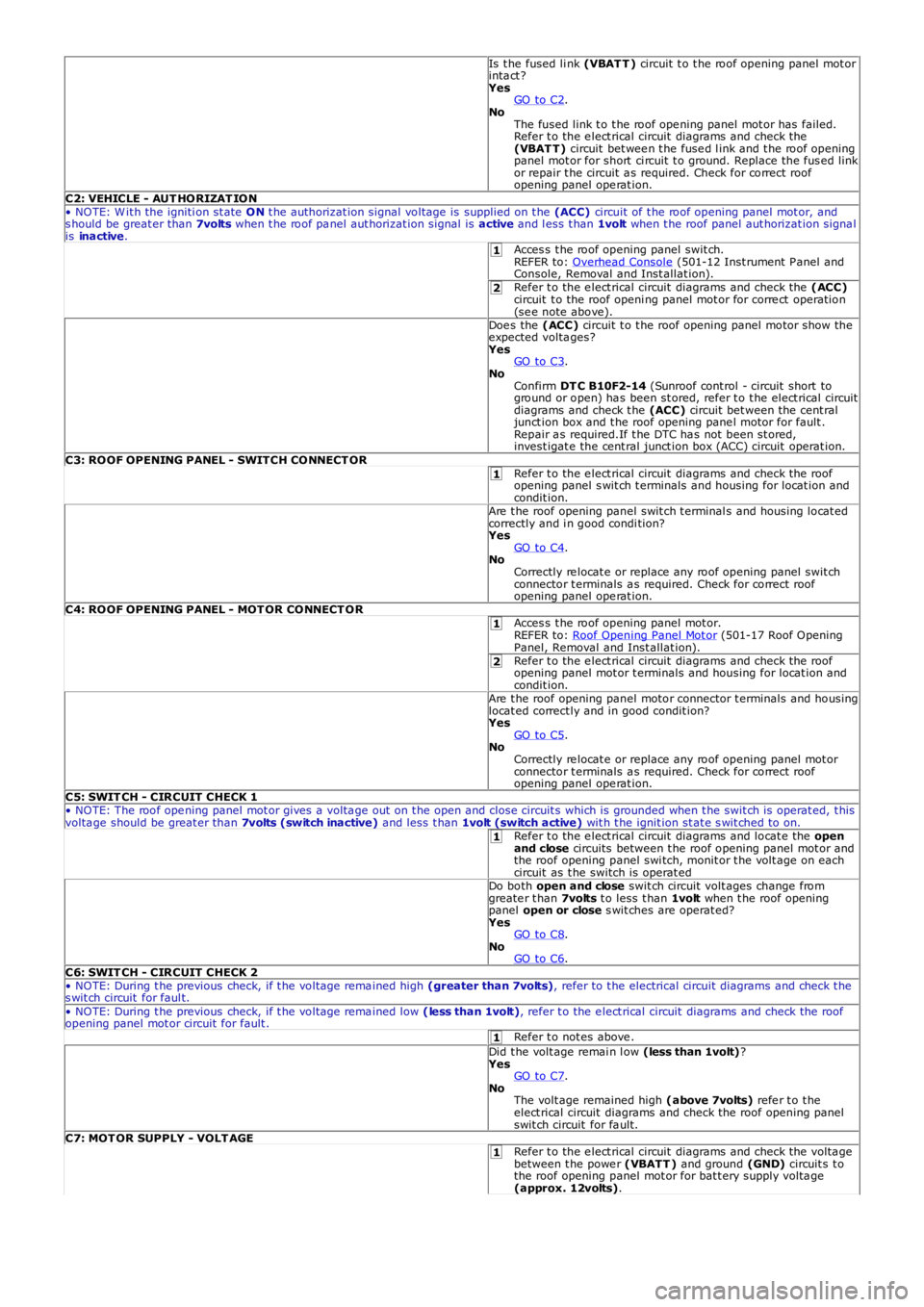

Is t he fused li nk (VBAT T ) circuit t o t he roof opening panel mot orinta ct ?YesGO to C2.NoThe fused link t o t he roof ope ning panel mot or has failed.Refer t o the e lect rical circuit diagrams and check the(VBAT T) circuit bet wee n t he fuse d l ink and t he roof openingpanel mot or for short ci rcuit t o ground. Replace the fus ed linkor repair t he circuit a s required. Check for correct roofopening panel ope rat ion.C2: VEHICLE - AUT HORIZAT ION• NOTE: W it h the igniti on st ate ON t he authorizat ion signal voltage is supplied on t he (ACC) circuit of t he roof opening panel mot or, ands hould be great er than 7volts when t he roof pa nel aut horizat ion signal is active and l ess t han 1volt when t he roof panel aut horizat ion signa lis inactive.Acces s t he roof opening panel swit ch.REFER to: Overhead Console (501-12 Inst rument P anel andConsole, Removal and Inst allat ion).Refer t o the e lect rical circuit diagrams and check the (ACC)circuit t o the roof openi ng panel mot or for corre ct operation(se e note above).Doe s the (ACC) circuit t o t he roof opening panel motor show theexpected volta ges?YesGO to C3.NoConfirm DT C B10F2-14 (Sunroof cont rol - circuit short toground or open) ha s been st ored, refer t o t he elect rical circuitdiagrams and check t he (ACC) circuit bet ween the cent raljunct ion box and t he roof opening pane l motor for fault .Repair a s required.If t he DTC ha s not been st ored,invest igat e the cent ral junct ion box (ACC) circuit operat ion.C3: ROOF OPENING PANEL - SWITCH CONNECT ORRefer t o the e lect rical circuit diagrams and check the roofopening panel s wit ch t erminals and housing for locat ion andcondit ion.Are t he roof opening panel swit ch t erminal s and housing locat edcorrectly and i n good condi tion?YesGO to C4.NoCorrectly re locat e or replace any roof opening panel swit chconnector t erminals a s required. Check for correct roofopening panel ope rat ion.C4: ROOF OPENING PANEL - MOT OR CONNECT ORAcces s t he roof opening panel mot or.REFER to: Roof Opening Panel Mot or (501-17 Roof OpeningPanel, Removal and Inst allat ion).Refer t o the e lect rical circuit diagrams and check the roofopening panel mot or t erminals and housing for locat ion andcondit ion.Are t he roof opening panel motor connector t erminals and housinglocat ed correct ly and in good condit ion?YesGO to C5.NoCorrectly re locat e or replace any roof opening panel mot orconnector t erminals a s required. Check for correct roofopening panel ope rat ion.C5: SWIT CH - CIRCUIT CHECK 1• NOTE: The roof ope ning panel mot or gives a volta ge out on t he open and close circuit s which is grounded when t he swit ch is operat ed, t hisvolta ge should be great er than 7volts (switch inactive) and less t han 1volt (switch active) wit h t he ignit ion st at e s wit ched to on.Refer t o the e lect rical circuit diagrams and locat e the openand close circuits between t he roof opening panel mot or andthe roof opening panel swi tch, monit or t he volt age on eachcircuit as t he switch is operat edDo both open and close swit ch circuit volt ages change fromgreate r t han 7volts t o less t han 1volt when t he roof openingpanel open or close s wit ches are operat ed?YesGO to C8.NoGO to C6.C6: SWIT CH - CIRCUIT CHECK 2• NOTE: During t he previous check, if t he voltage rema ined high (greater than 7volts), refer to t he electrical circuit diagrams and check t hes wit ch circuit for faul t.• NOTE: During t he previous check, if t he voltage rema ined low (less than 1volt), refer t o the e lect rical circuit diagrams and check the roofopening panel mot or circuit for fault .Refer t o not es above .Did t he volt age remai n l ow (less than 1volt)?YesGO to C7.NoThe volt age remained high (above 7volts) refe r t o t heelect rical circuit diagrams and check the roof opening panelswit ch circuit for fa ult.C7: MOT OR SUPPLY - VOLT AGERefer t o the e lect rical circuit diagrams and check the volta gebetween t he powe r (VBATT ) and ground (GND) circuit s t othe roof opening panel mot or for bat t ery supply volta ge(approx. 12volts).

Page 2452 of 3229

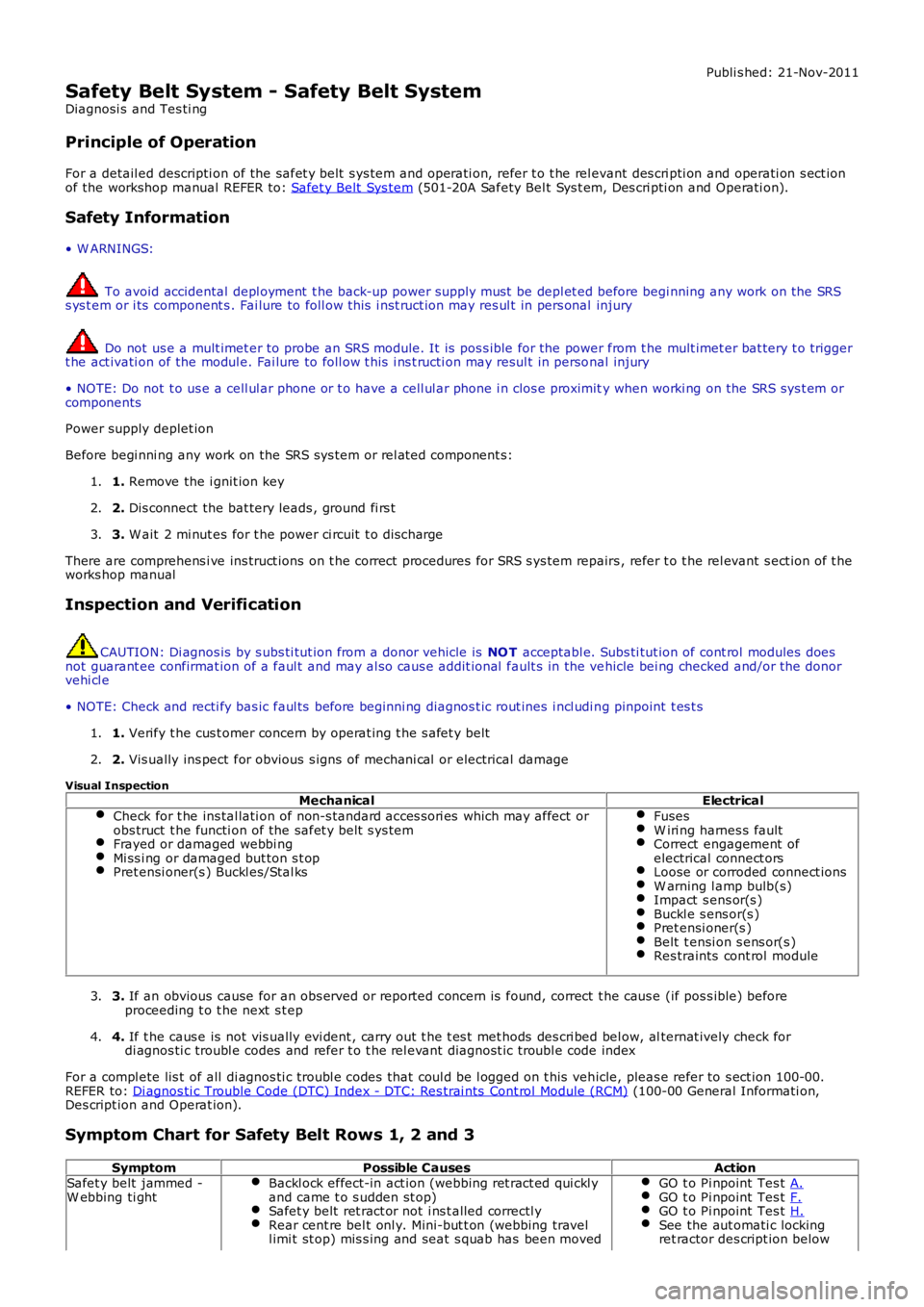

Publi s hed: 21-Nov-2011

Safety Belt System - Safety Belt System

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the safet y belt s ys tem and operati on, refer t o t he relevant des cri pti on and operati on s ect ionof the workshop manual REFER to: Safet y Belt Sys tem (501-20A Safety Bel t Sys t em, Des cri pti on and Operati on).

Safety Information

• W ARNINGS:

To avoid accidental depl oyment t he back-up power supply must be depl et ed before begi nning any work on the SRSs ys t em or i ts component s . Fai lure to foll ow t his i nst ruct ion may res ul t in pers onal injury

Do not us e a mult imet er to probe an SRS module. It is pos s ible for the power from the mult imet er bat tery t o triggert he act ivati on of the modul e. Fai lure to foll ow t his i ns t ructi on may resul t in personal injury

• NOTE: Do not t o us e a cell ul ar phone or t o have a cell ul ar phone i n clos e proximity when worki ng on the SRS sys t em orcomponents

Power supply deplet ion

Before begi nni ng any work on the SRS sys tem or rel at ed component s:

1. Remove the i gnit ion key1.

2. Dis connect the bat tery leads , ground fi rs t2.

3. W ait 2 mi nut es for t he power ci rcuit t o dis charge3.

There are comprehens i ve ins truct ions on t he correct procedures for SRS s ys tem repairs , refer t o t he rel evant s ect ion of t heworks hop manual

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t and may al so caus e addit ional fault s in the vehicle bei ng checked and/or the donorvehi cl e

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i ncl udi ng pinpoint t es t s

1. Verify t he cus t omer concern by operat ing t he s afet y belt1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage2.

Visual InspectionMechanicalElectrical

Check for t he ins tal lati on of non-s tandard acces s ori es which may affect orobs truct t he functi on of the safet y belt s ys temFrayed or damaged webbi ngMi ss i ng or damaged but ton s t opPret ensi oner(s ) Buckl es/Stal ks

FusesW iri ng harnes s faultCorrect engagement ofelectrical connect orsLoose or corroded connect ionsW arning l amp bulb(s)Impact s ens or(s )Buckl e s ens or(s )Pret ensi oner(s )Belt t ensi on s ens or(s )Res traints cont rol module

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , carry out t he t es t met hods des cri bed bel ow, alternat ively check fordi agnos ti c troubl e codes and refer t o t he rel evant diagnost ic troubl e code index4.

For a compl ete lis t of all di agnos ti c troubl e codes that coul d be l ogged on t his vehicle, pleas e refer to s ect ion 100-00.REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Res trai nts Cont rol Module (RCM) (100-00 General Informati on,Des cript ion and Operat ion).

Symptom Chart for Safety Belt Rows 1, 2 and 3

SymptomPossible CausesActionSafet y belt jammed -W ebbing ti ghtBackl ock effect-in act ion (webbing ret ract ed qui ckl yand came t o s udden st op)Safet y belt ret ract or not i ns t alled correctl yRear cent re bel t onl y. Mini-but t on (webbing travell imi t st op) mis s ing and seat s quab has been moved

GO t o Pi npoint Tes t A.GO t o Pi npoint Tes t F.GO t o Pi npoint Tes t H.See the aut omati c lockingret ractor des cript ion below

Page 2486 of 3229

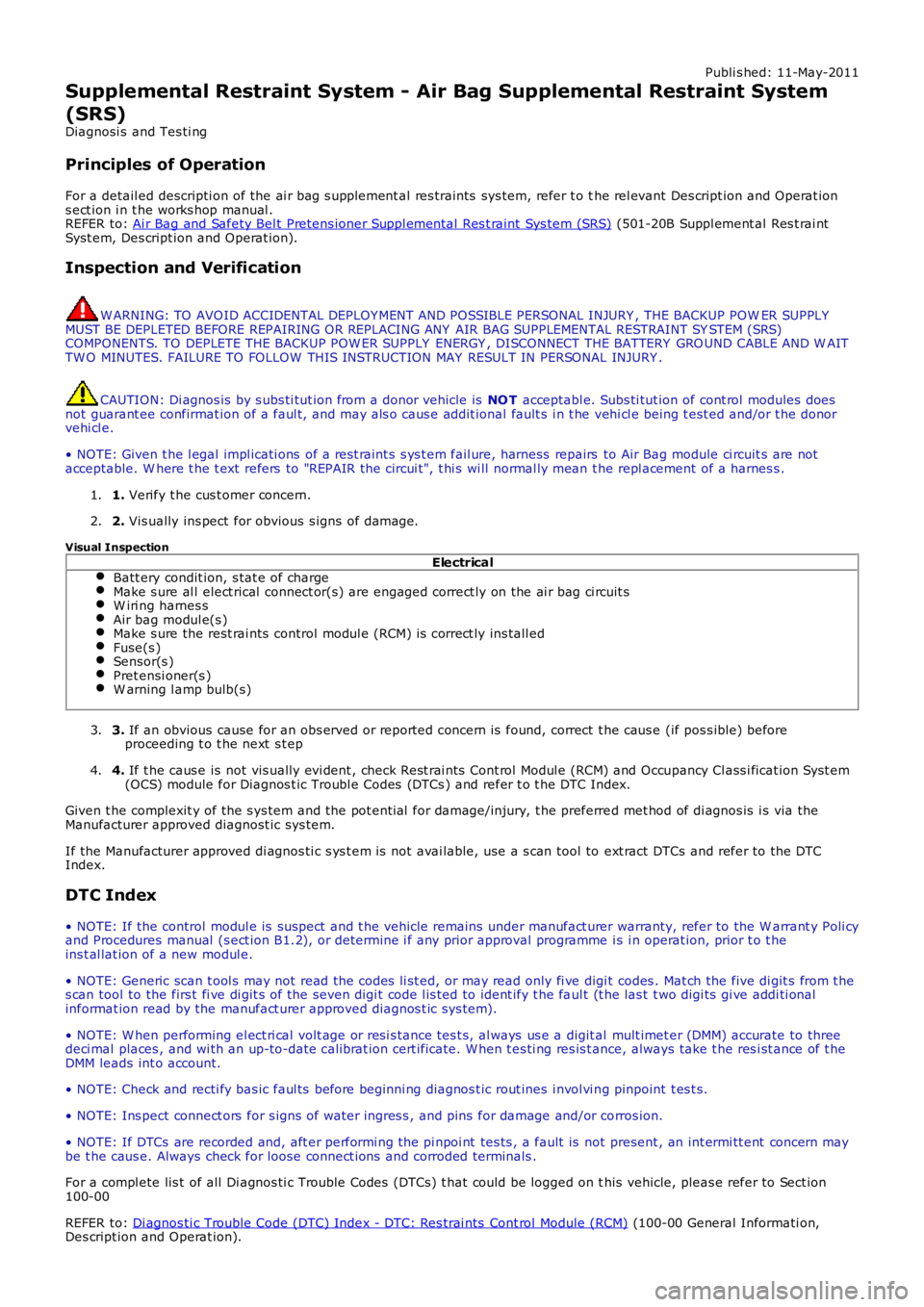

Publi s hed: 11-May-2011

Supplemental Restraint System - Air Bag Supplemental Restraint System

(SRS)

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the ai r bag s upplement al res traints sys tem, refer t o the rel evant Des cript ion and Operat ions ect ion i n t he works hop manual .REFER to: Ai r Bag and Safety Bel t Pretens ioner Suppl ement al Res t raint Sys tem (SRS) (501-20B Suppl ement al Res t rai ntSyst em, Des cript ion and Operat ion).

Inspection and Verification

W ARNING: TO AVOID ACCIDENTAL DEPLOY MENT AND POSSIBLE PERSONAL INJURY , THE BACKUP POWER SUPPLYMUST BE DEPLETED BEFORE REPAIRING OR REPLACING ANY AIR BAG SUPPLEMENTAL RESTRAINT SYSTEM (SRS)COMPONENTS. TO DEPLETE THE BACKUP POW ER SUPPLY ENERGY , DISCONNECT THE BATTERY GRO UND CABLE AND W AITTW O MINUTES. FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN PERSONAL INJURY .

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Given t he l egal impl icati ons of a res t raint s s ys t em fail ure, harness repairs to Air Bag module ci rcuit s are notacceptable. W here t he t ext refers to "REPAIR the circui t", t hi s wi ll normal ly mean the repl acement of a harnes s .

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage.2.

Visual Inspection

ElectricalBatt ery condit ion, s tat e of chargeMake s ure al l elect rical connect or(s) are engaged correct ly on the ai r bag ci rcuit sW iri ng harnes sAir bag modul e(s )Make s ure the rest rai nts control modul e (RCM) is correct ly ins tall edFuse(s )Sensor(s )Pret ensi oner(s )W arning l amp bulb(s)

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check Rest rai nts Cont rol Modul e (RCM) and Occupancy Cl ass i ficat ion Syst em(OCS) module for Diagnos t ic Troubl e Codes (DTCs ) and refer t o t he DTC Index.4.

Given t he complexit y of the s ys tem and the pot enti al for damage/injury, t he preferred met hod of di agnos is i s via theManufacturer approved diagnost ic sys tem.

If the Manufacturer approved di agnos ti c s ys t em i s not avai lable, use a s can tool to ext ract DTCs and refer to the DTCIndex.

DTC Index

• NOTE: If the control modul e is sus pect and t he vehicle remains under manufact urer warranty, refer to the W arrant y Poli cyand Procedures manual (s ect ion B1.2), or determine i f any prior approval programme is i n operat ion, prior t o t heins t al lat ion of a new modul e.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing el ect ri cal volt age or resi s tance tes t s, al ways us e a digit al mult imet er (DMM) accurate to threedeci mal places , and wi th an up-to-date cali brat ion cert ificate. W hen t es ti ng res is t ance, always take t he res i st ance of t heDMM leads int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00

REFER to: Di agnos ti c Trouble Code (DTC) Index - DTC: Res trai nts Cont rol Module (RCM) (100-00 General Informati on,Des cript ion and Operat ion).

Page 2725 of 3229

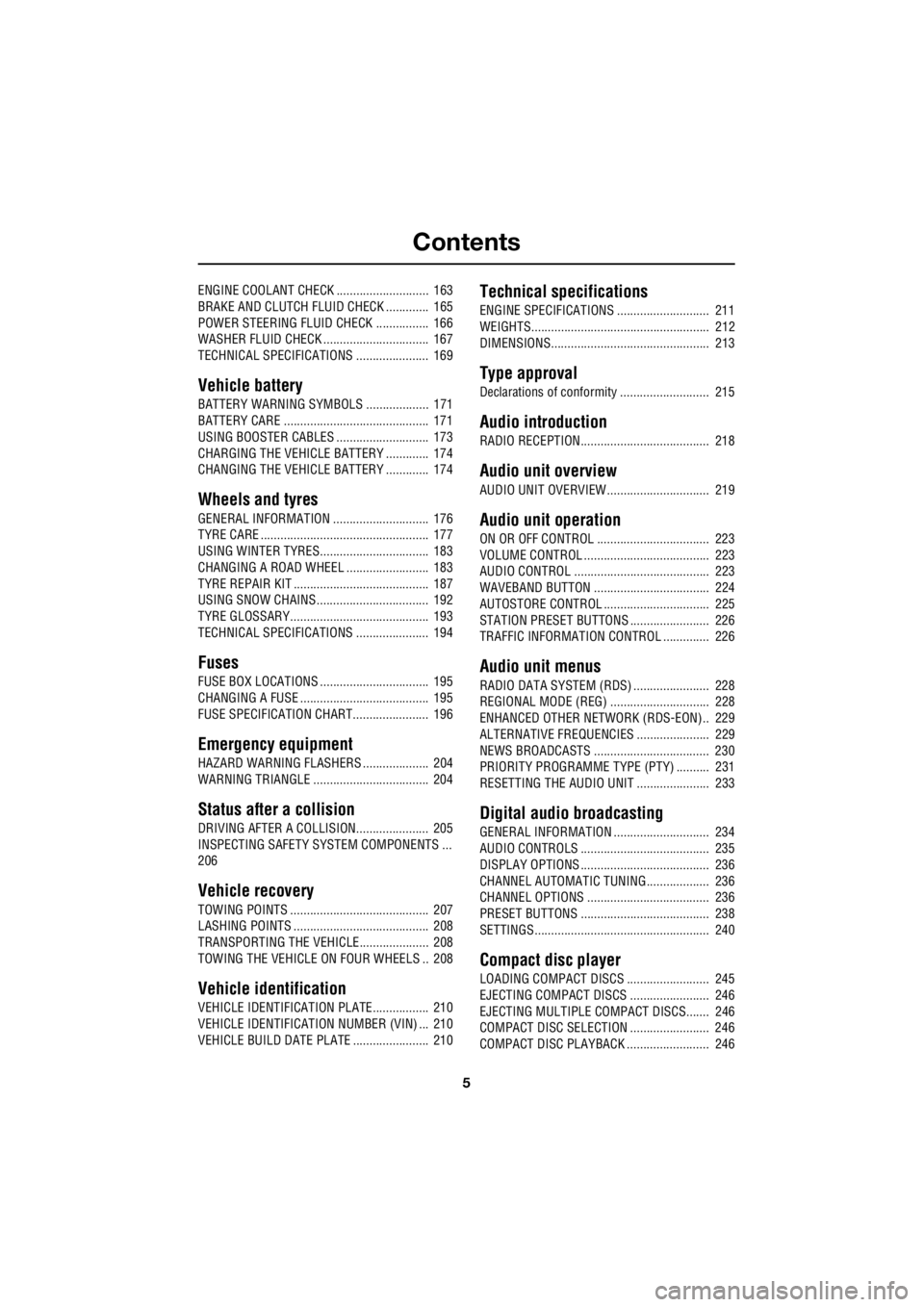

Contents

5

R

ENGINE COOLANT CHECK ............................ 163

BRAKE AND CLUTCH FLUID CHECK ............. 165

POWER STEERING FLUID CHECK ................ 166

WASHER FLUID CHECK ................................ 167

TECHNICAL SPECIFICATIONS ...................... 169

Vehicle battery

BATTERY WARNING SYMBOLS ................... 171

BATTERY CARE ............................................ 171

USING BOOSTER CABLES ............................ 173

CHARGING THE VE HICLE BATTERY ............. 174

CHANGING THE VE HICLE BATTERY ............. 174

Wheels and tyres

GENERAL INFORMATION ............................. 176

TYRE CARE ................................................... 177

USING WINTER TYRES................................. 183

CHANGING A ROAD WHEEL ......................... 183

TYRE REPAIR KIT ......................................... 187

USING SNOW CHAINS.................................. 192

TYRE GLOSSARY.......................................... 193

TECHNICAL SPECIFICATIONS ...................... 194

Fuses

FUSE BOX LOCATIONS ................................. 195

CHANGING A FUSE ....................................... 195

FUSE SPECIFICATION CHART....................... 196

Emergency equipment

HAZARD WARNING FLASHERS .................... 204

WARNING TRIANGLE ................................... 204

Status after a collision

DRIVING AFTER A COLLISION...................... 205

INSPECTING SAFETY SYSTEM COMPONENTS ...

206

Vehicle recovery

TOWING POINTS .......................................... 207

LASHING POINTS ......................................... 208

TRANSPORTING THE VEHICLE..................... 208

TOWING THE VEHICLE ON FOUR WHEELS .. 208

Vehicle identification

VEHICLE IDENTIFICATION PLATE................. 210

VEHICLE IDENTIFI CATION NUMBER (VIN) ... 210

VEHICLE BUILD DATE PLATE ....................... 210

Technical specifications

ENGINE SPECIFICATIONS ............................ 211

WEIGHTS...................................................... 212

DIMENSIONS................................................ 213

Type approval

Declarations of conformity ........................... 215

Audio introduction

RADIO RECEPTION....................................... 218

Audio unit overview

AUDIO UNIT OVERVIEW............................... 219

Audio unit operation

ON OR OFF CONTROL .................................. 223

VOLUME CONTROL ...................................... 223

AUDIO CONTROL ......................................... 223

WAVEBAND BUTTON ................................... 224

AUTOSTORE CONTROL ................................ 225

STATION PRESET BUTTONS ........................ 226

TRAFFIC INFORMATION CONTROL .............. 226

Audio unit menus

RADIO DATA SYSTEM (RDS) ....................... 228

REGIONAL MODE (REG) .............................. 228

ENHANCED OTHER NETWORK (RDS-EON).. 229

ALTERNATIVE FREQUENCIES ...................... 229

NEWS BROADCASTS ................................... 230

PRIORITY PROGRAMME TYPE (PTY) .......... 231

RESETTING THE AUDIO UNIT ...................... 233

Digital audio broadcasting

GENERAL INFORMATION ............................. 234

AUDIO CONTROLS ....................................... 235

DISPLAY OPTIONS ....................................... 236

CHANNEL AUTOMATIC TUNING................... 236

CHANNEL OPTIONS ..................................... 236

PRESET BUTTONS ....................................... 238

SETTINGS..................................................... 240

Compact disc player

LOADING COMPACT DISCS ......................... 245

EJECTING COMPACT DISCS ........................ 246

EJECTING MULTIPLE CO MPACT DISCS....... 246

COMPACT DISC SELECTION ........................ 246

COMPACT DISC PLAYBACK ......................... 246

Page 2915 of 3229

195

Fuses

R

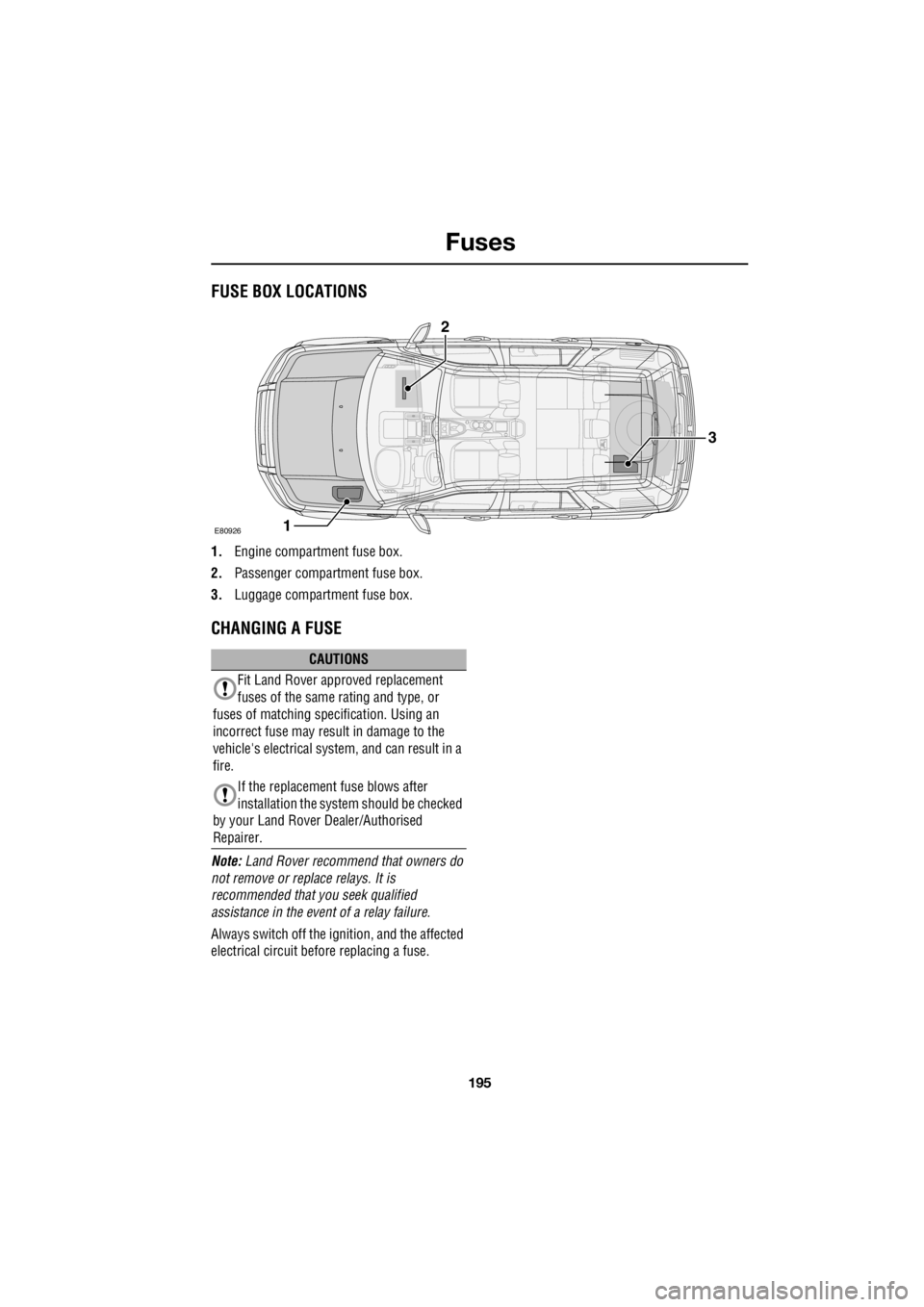

FusesFUSE BOX LOCATIONS

1. Engine compartment fuse box.

2. Passenger compartment fuse box.

3. Luggage compartment fuse box.

CHANGING A FUSE

Note: Land Rover recommend that owners do

not remove or repl ace relays. It is

recommended that you seek qualified

assistance in the event of a relay failure.

Always switch off the i gnition, and the affected

electrical circuit before replacing a fuse.

E80926

3

1

2

CAUTIONS

Fit Land Rover approved replacement

fuses of the same rating and type, or

fuses of matching spec ification. Using an

incorrect fuse may result in damage to the

vehicle's electrical system, and can result in a

fire.

If the replacement fuse blows after

installation the syst em should be checked

by your Land Rover Dealer/Authorised

Repairer.

Page 2916 of 3229

Fuses

196

L

FUSE SPECIFICATION CHART

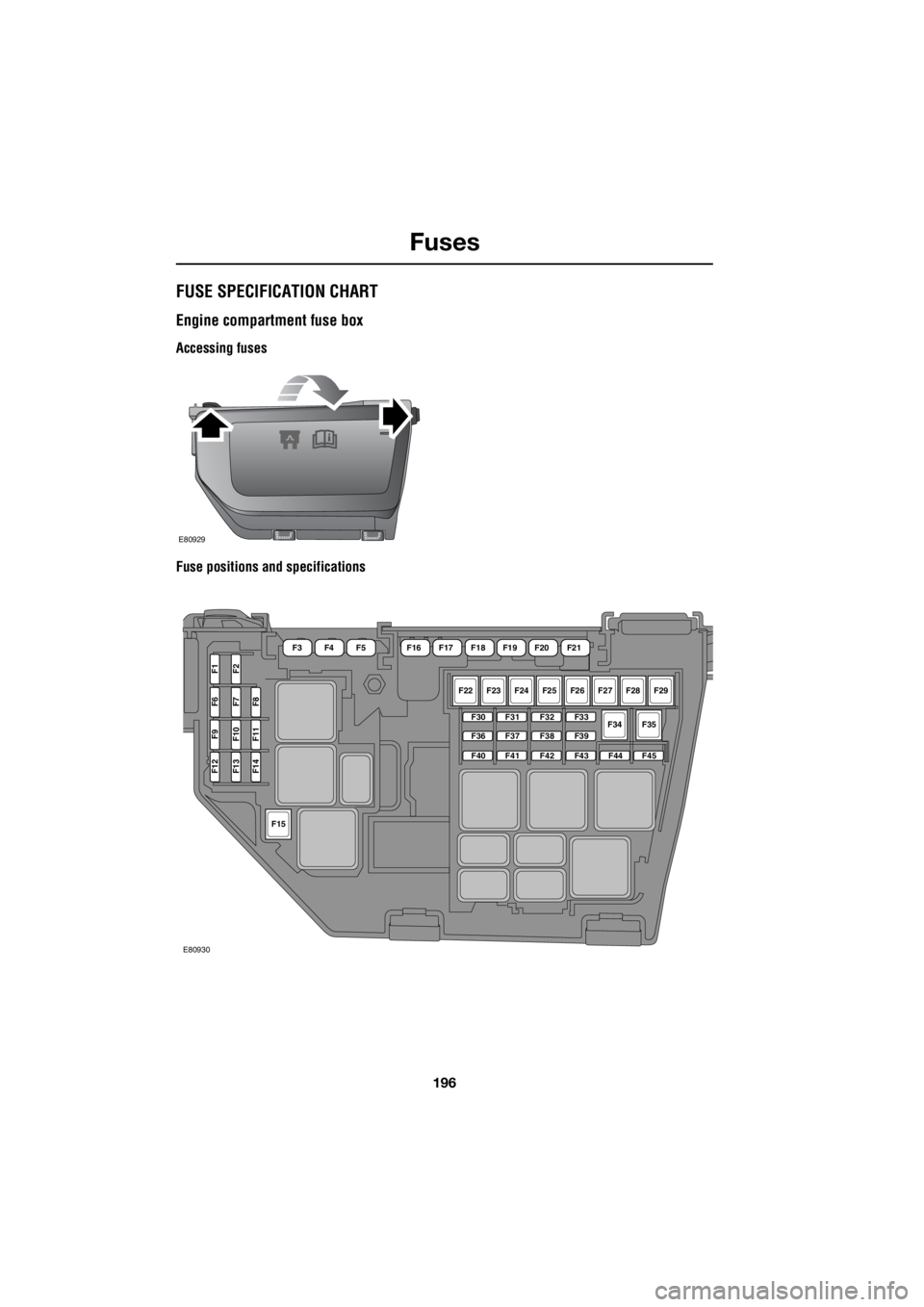

Engine compartment fuse box

Accessing fuses

Fuse positions and specifications

E80929

F22F23F24F25F26F27F28F29

F34F35F30

F36

F40

F31

F37

F41

F32

F38

F42

F33

F39

F43F44F45

F15

F12F13F14

F9F10F11

F6F7F8

F1F2

F16F17F18F19F20F21F3F4F5

E80930

Page 2917 of 3229

197

Fuses

R

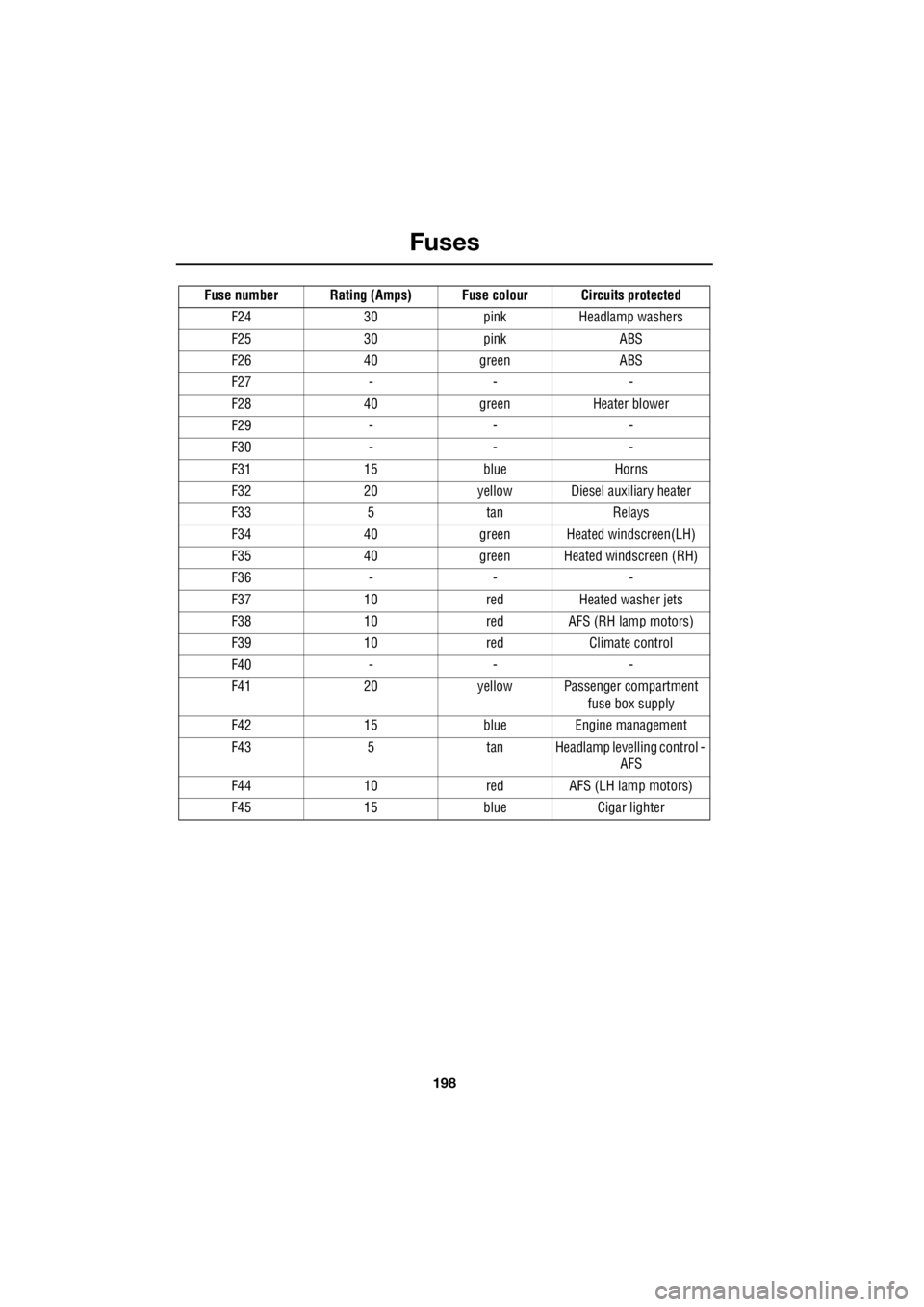

Fuse number Rating (Amps) Fuse colour Circuits protected F1 5 tan Glow plugs

F2 15 blue Automatic transmission

F3 80 - Cooling fans

F4 60 - Glow plugs

F5 - - -

F6 (Diesel) 10 red Engine management F6 (Petrol) 15 blue Engine management F7 5 tan Relays

F8 (Diesel) 10 red Engine management F8 (Petrol) 15 blue Engine management

F9 (Diesel) 10 red Engine management

F9 (Petrol) 15 blue Engine management

F10 (Petrol) 10 red Engine management

F11 (Diesel) 10 red Engine management

F11 (Petrol) 10 red Engine management

F12 (Diesel) 10 red Engine management

F12 (Petrol) 20 yell ow Engine management

F13 15 blue Air Conditioning

F14 (Diesel) 15 blue Engine management

F15 40 green Starter motor

F16 (Diesel) 100 - Diesel PTC heater F17 60 - Passenger compartment fuse box supply

F18 60 - Passenger compartment fuse box supply

F19 60 - Luggage compartment fuse box supply

F20 60 - Luggage compartment fuse box supply

F21 60 - Luggage compartment fuse box supply - Audio unit

F22 30 pink Windscreen wipers

F23 - - -

Page 2918 of 3229

Fuses

198

L

F24 30 pink Headlamp washers

F25 30 pink ABS

F26 40 green ABS

F27 - - -

F28 40 green Heater blower

F29 - - -

F30 - - -

F31 15 blue Horns

F32 20 yellow Diesel auxiliary heater

F33 5 tan Relays

F34 40 green Heated windscreen(LH)

F35 40 green Heated windscreen (RH)

F36 - - -

F37 10 red Heated washer jets

F38 10 red AFS (RH lamp motors)

F39 10 red Climate control

F40 - - -

F41 20 yellow Passenger compartment fuse box supply

F42 15 blue Engine management

F43 5 tan Headlamp levelling control - AFS

F44 10 red AFS (LH lamp motors)

F45 15 blue Cigar lighter

Fuse number Rating (Amps) Fuse colour Circuits protected

Page 2919 of 3229

199

Fuses

R

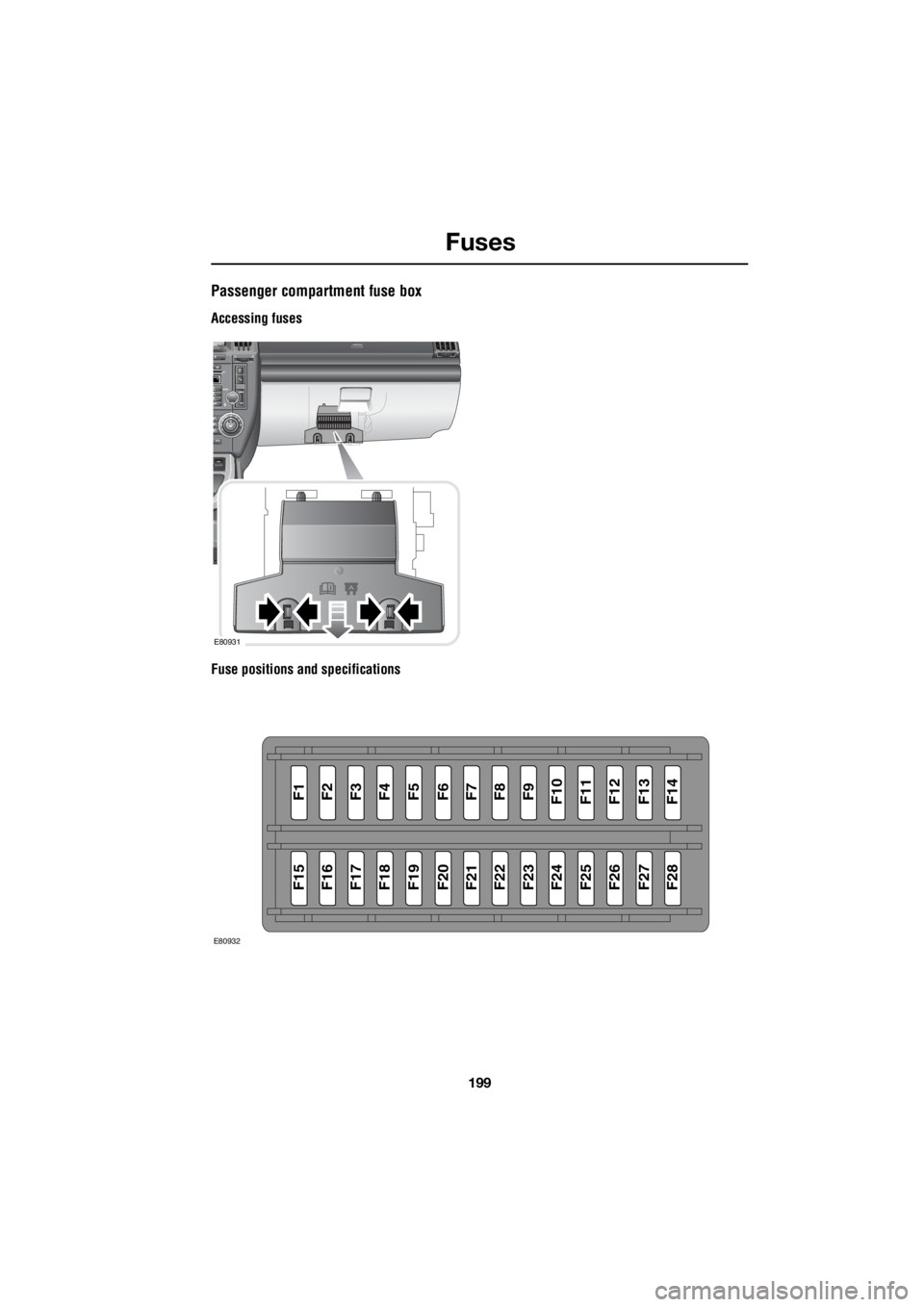

Passenger compartment fuse box

Accessing fuses

Fuse positions and specifications

E80931

F1F2F3F4F5F6F7F8F9F10F11F12F13F14

F15F16F17F18F19F20F21F22F23F24F25F26F27F28

E80932

Page 2920 of 3229

Fuses

200

L

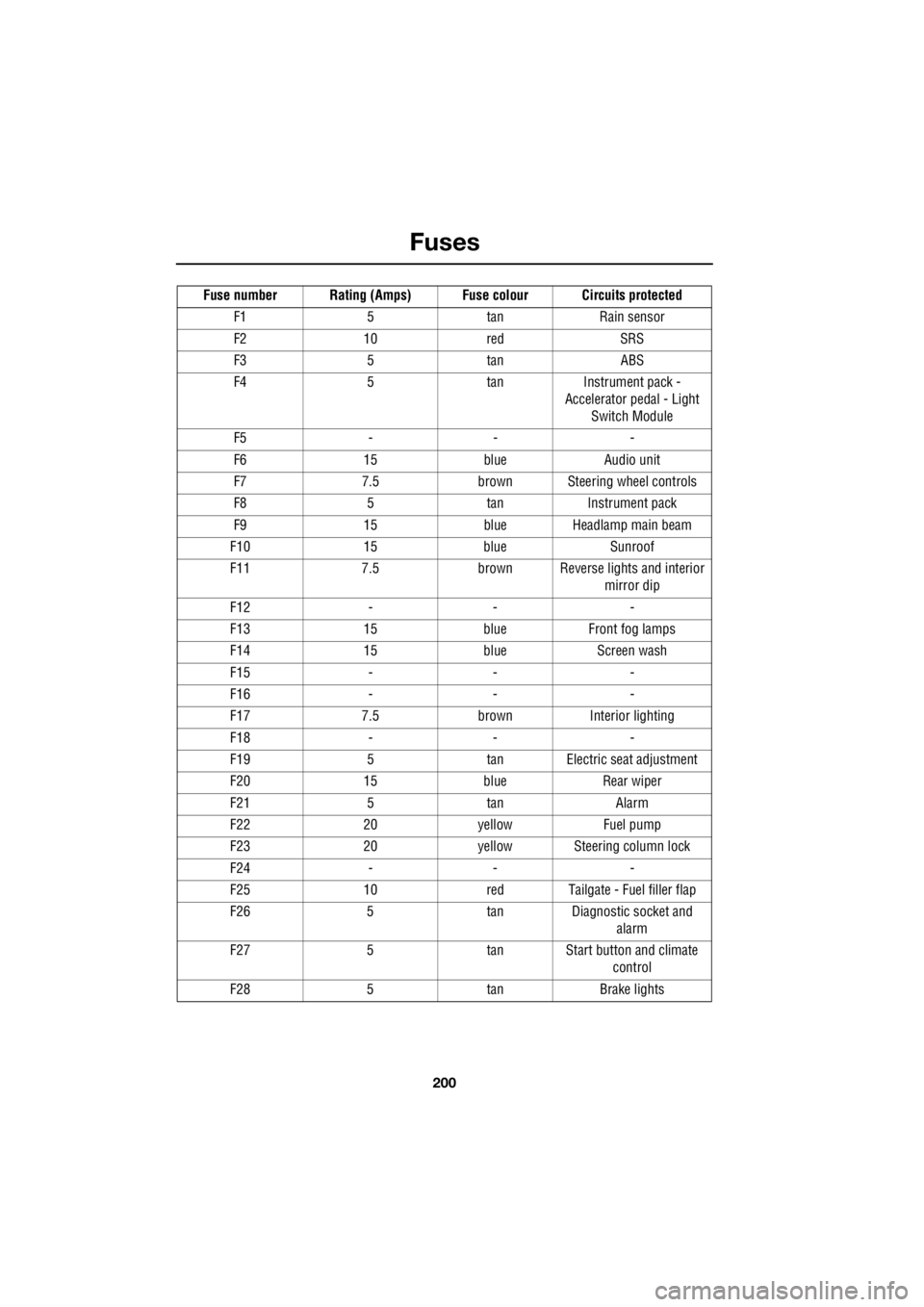

Fuse number Rating (Amps) Fuse co lour Circuits protected

F1 5 tan Rain sensor

F2 10 red SRS

F3 5 tan ABS

F4 5 tan Instrument pack - Accelerator pedal - Light

Switch Module

F5 - - -

F6 15 blue Audio unit

F7 7.5 brown Steering wheel controls

F8 5 tan Instrument pack

F9 15 blue Headlamp main beam

F10 15 blue Sunroof

F11 7.5 brown Reverse lights and interior mirror dip

F12 - - -

F13 15 blue Front fog lamps

F14 15 blue Screen wash

F15 - - -

F16 - - -

F17 7.5 brown Interior lighting

F18 - - -

F19 5 tan Electric seat adjustment

F20 15 blue Rear wiper

F21 5 tan Alarm

F22 20 yellow Fuel pump

F23 20 yellow Steering column lock

F24 - - -

F25 10 red Tailgate - Fuel filler flap

F26 5 tan Diagnostic socket and alarm

F27 5 tan Start button and climate control

F28 5 tan Brake lights