service LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2643 of 3229

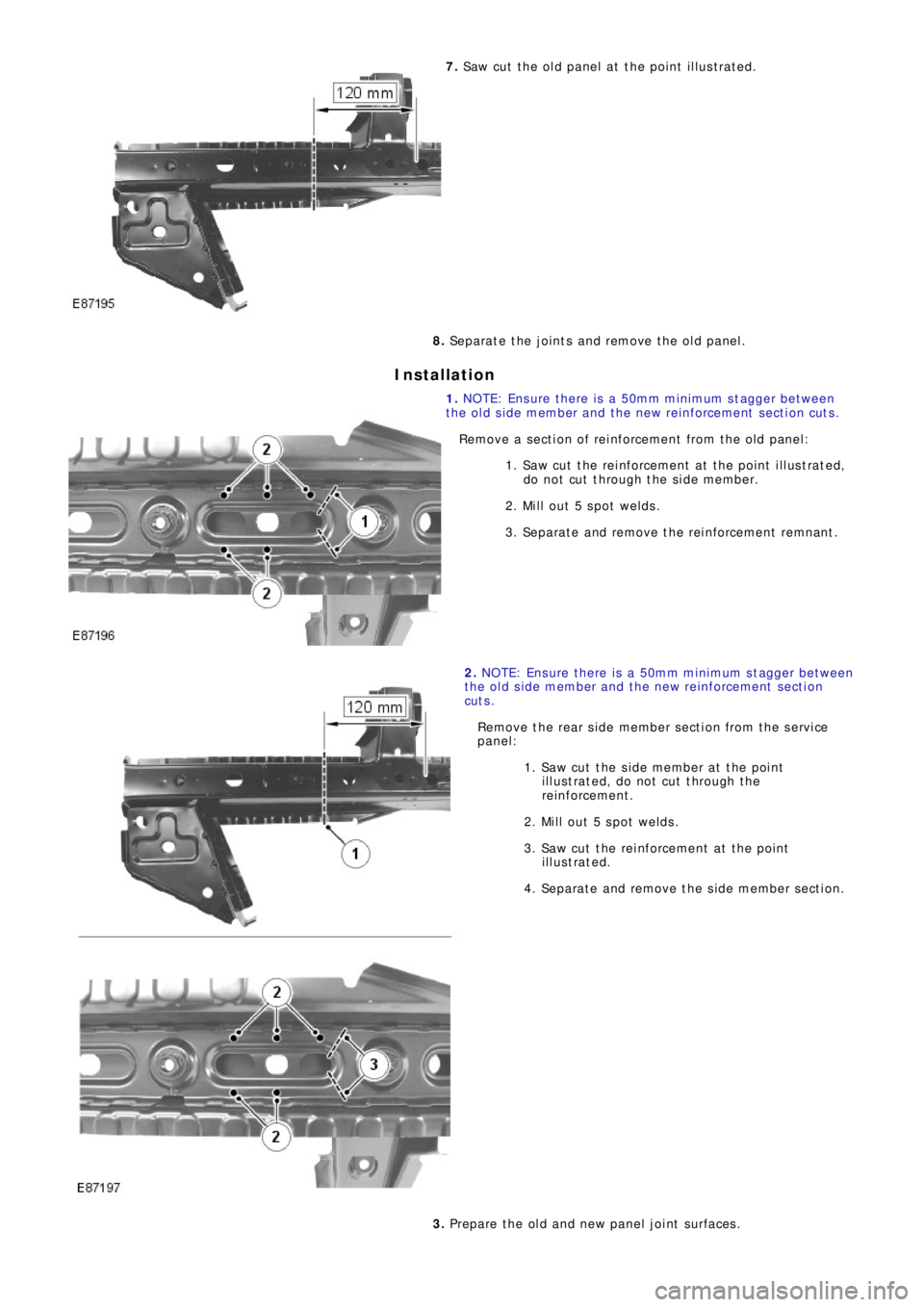

7. Saw cut the old panel at the point illustrated.

8. Separate the joints and remove the old panel.

Installation

1. NO TE: Ens ure t he re i s a 50mm mi ni mum s t a gge r be t we e n

the old side member and the new reinforcement section cuts.

Remove a section of reinforcement from the old panel:

1. Saw cut the reinforcement at the point illustrated,

do not cut through the side member.

2. Mil l out 5 s pot welds .

3. Se p a ra t e a nd re mo ve t he re i nf o rce me nt re mna nt .

2. NO TE: Ens ure t he re i s a 50mm mi ni mum s t a gge r be t we e n

the old side member and the new reinforcement section

cut s .

Remove the rear side member section from the service

panel:

1. Sa w cut t he s i de me mbe r a t t he poi nt

illustrated, do not cut through the

re i nf o rce me nt .

2. Mil l out 5 s pot welds .

3. Saw cut the reinforcement at the point

illustrated.

4. Se pa ra t e a nd re move t he s i de me mbe r s e ct i on.

3. Prepare the old and new panel joint surfaces.

Page 2646 of 3229

Publ is hed: 11-May-2011

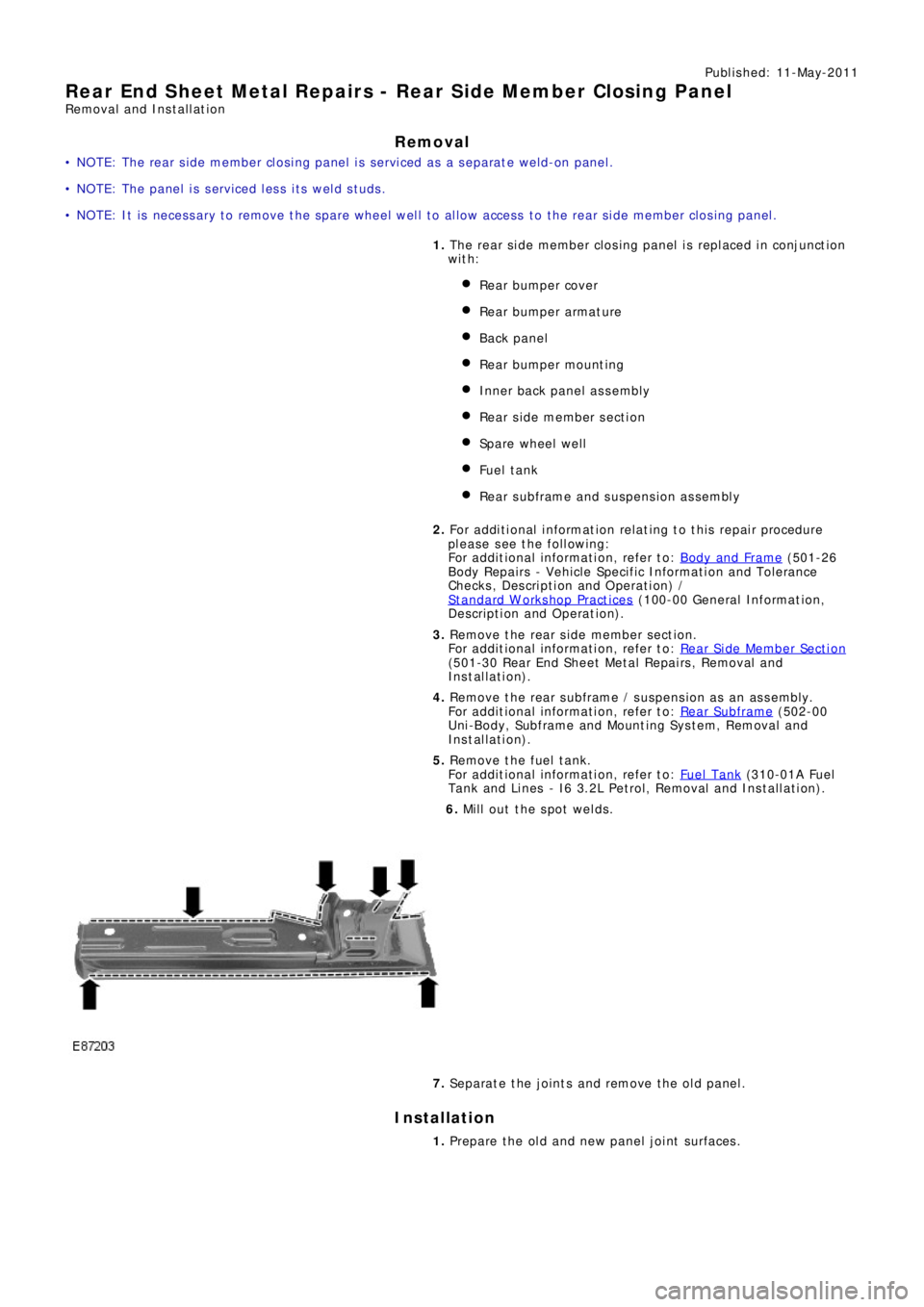

Rear End Sheet Metal Repairs - Rear Side Member Closing Panel

Removal and Installation

Removal

• NOTE: The rear side member closing panel is serviced as a separate weld-on panel.

• NOTE: The panel is serviced less its weld studs.

• NOTE: It is necessary to remove the spare wheel well to allow access to the rear side member closing panel.

1. The rear side member closing panel is replaced in conjunction

with:

Rear bumper cover

Re a r bumpe r a rma t ure

Back panel

Re a r bumpe r mo unt i ng

Inner back panel assembly

Re a r s i de me mbe r s e ct i o n

Spare wheel well

Fuel t ank

Rear subframe and suspension assembly

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he re a r s i de me mbe r s e ct i on.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : R e a r Si d e Me mb e r Se ct i o n

(501-30 Rear End Sheet Metal Repairs, Removal and

Installation).

4. Remove the rear subframe / suspension as an assembly.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Subframe

(502-00

Uni-Body, Subframe and Mounting System, Removal and

Installation).

5. Remove the fuel tank.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Fuel Tank

(310-01A Fuel

Tank and Lines - I6 3.2L Petrol, Removal and Installation).

6. Mill out the spot welds.

7. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

Page 2649 of 3229

Publ is hed: 11-May-2011

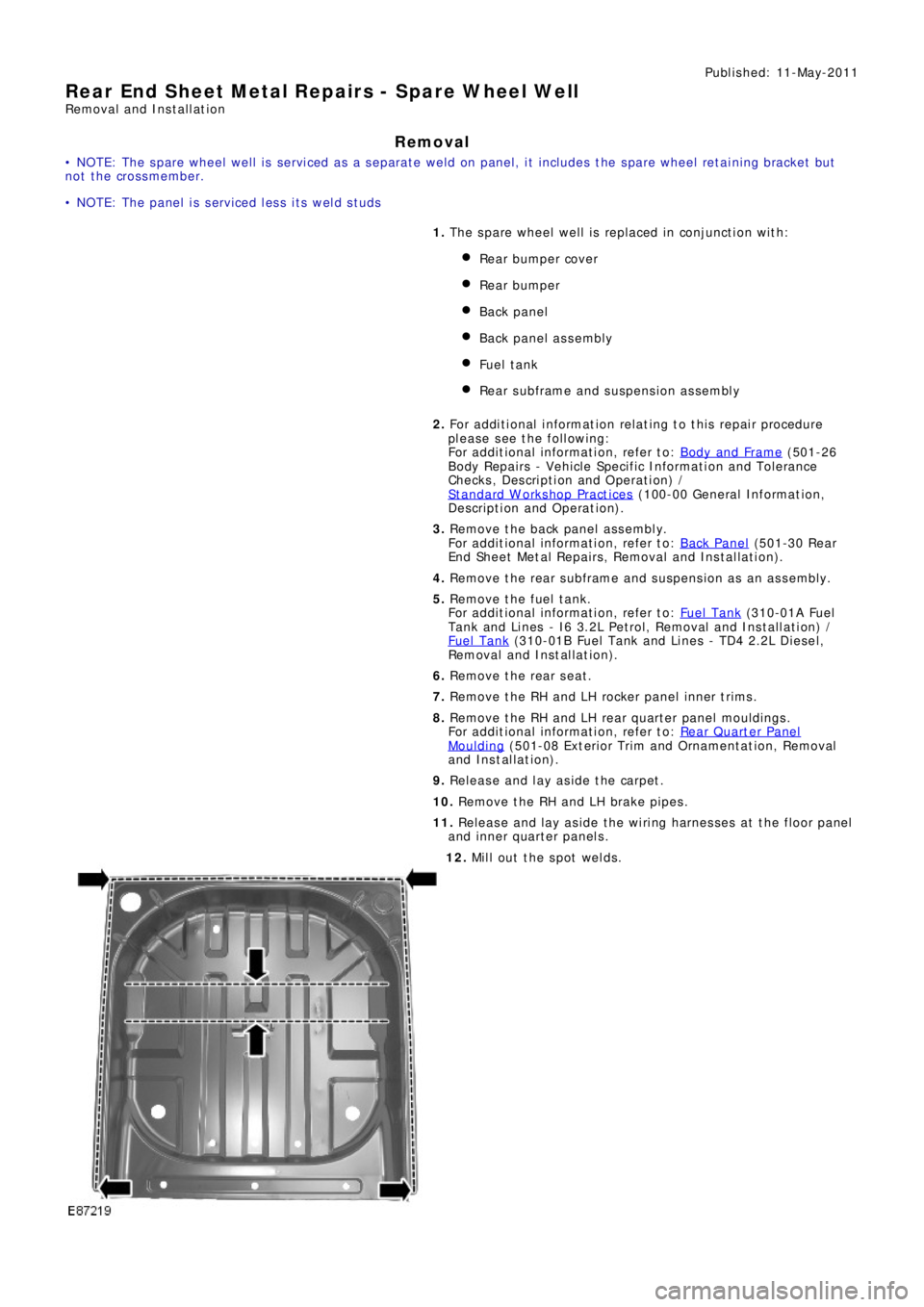

Rear End Sheet Metal Repairs - Spare Wheel Well

Removal and Installation

Removal

• NOTE: The spare wheel well is serviced as a separate weld on panel, it includes the spare wheel retaining bracket but

not the crossmember.

• NOTE: The panel is serviced less its weld studs

1. The spare wheel well is replaced in conjunction with:

Rear bumper cover

Rear bumper

Back panel

Back panel assembly

Fuel t ank

Rear subframe and suspension assembly

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the back panel assembly.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Back Panel

(501-30 Rear

End Sheet Metal Repairs, Removal and Installation).

4. Remove the rear subframe and suspension as an assembly.

5. Remove the fuel tank.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Fuel Tank

(310-01A Fuel

Tank and Lines - I6 3.2L Petrol, Removal and Installation) /

Fuel Tank

(310-01B Fuel Tank and Li nes - TD4 2.2L Di es el,

Removal and Installation).

6. Remove the rear seat.

7. Remove the RH and LH rocker panel inner trims.

8. Remove the RH and LH rear quarter panel mouldings.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Quarter Panel

Moulding (501-08 Ext eri or Trim and Ornament at i on, Removal

and Installation).

9. Release and lay aside the carpet.

10. Remove the RH and LH brake pipes.

11. Release and lay aside the wiring harnesses at the floor panel

and inner quarter panels.

12. Mill out the spot welds.

Page 2652 of 3229

Publ is hed: 11-May-2011

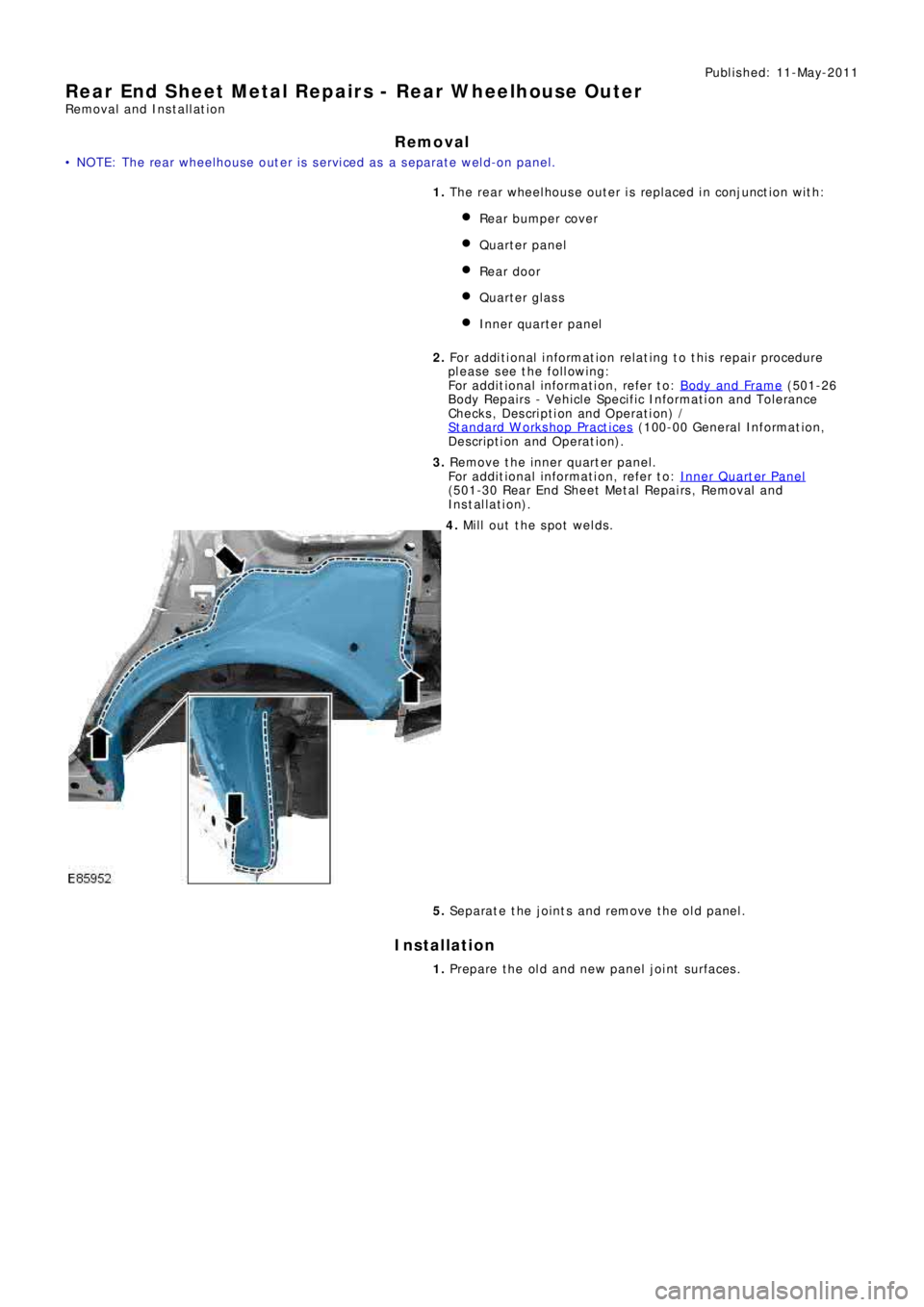

Rear End Sheet Metal Repairs - Rear Wheelhouse Outer

Removal and Installation

Removal

• NOTE: The rear wheelhouse outer is serviced as a separate weld-on panel.

1. The rear wheelhouse outer is replaced in conjunction with:

Rear bumper cover

Quarter panel

Rear door

Quarter glass

I nne r q ua rt e r p a ne l

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re mo ve t he i nne r q ua rt e r p a ne l .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Inner Quart er Panel

(501-30 Rear End Sheet Metal Repairs, Removal and

Installation).

4. Mill out the spot welds.

5. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

Page 2657 of 3229

Publ is hed: 11-May-2011

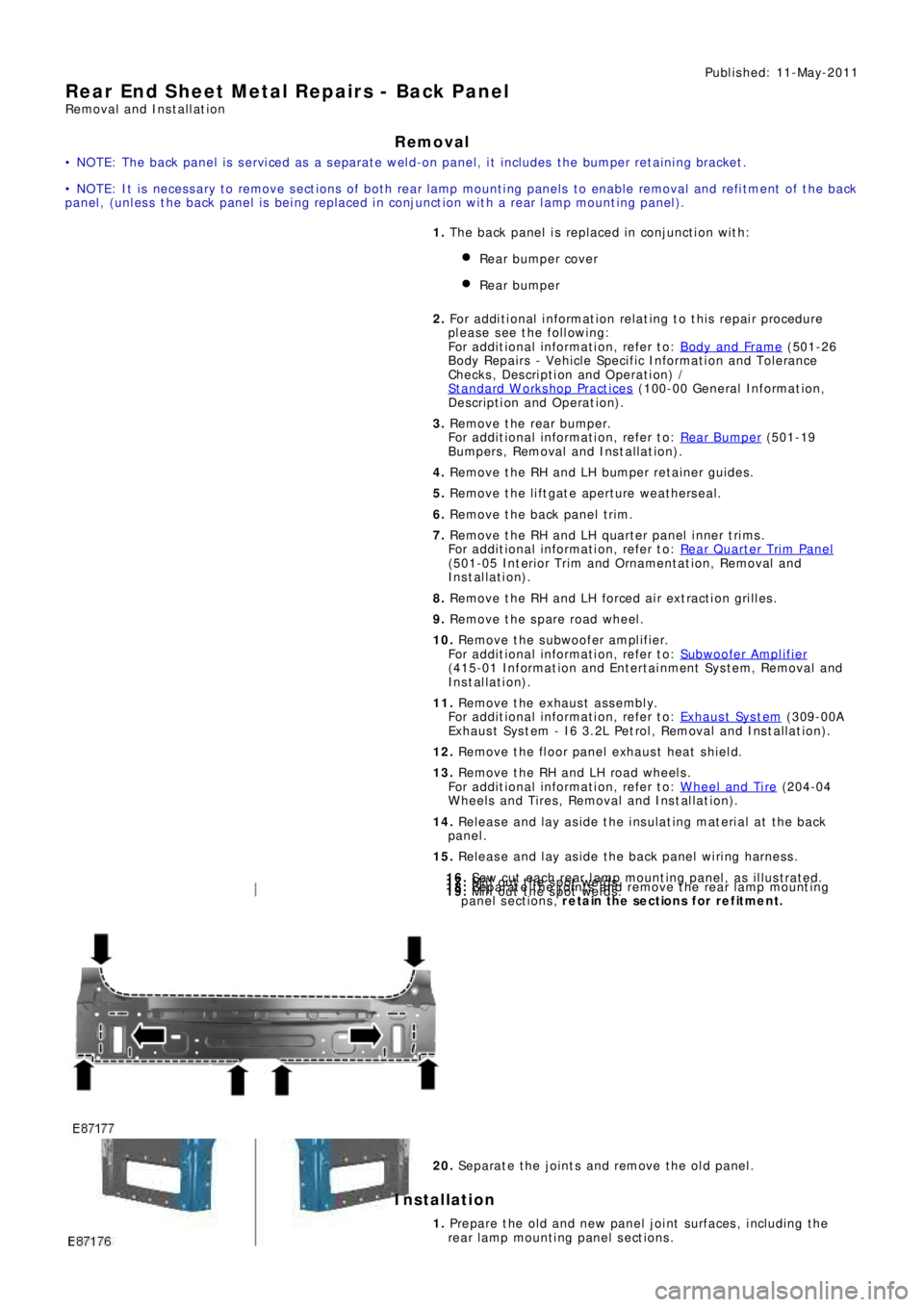

Rear End Sheet Metal Repairs - Back Panel

Removal and Installation

Removal

• NOTE: The back panel is serviced as a separate weld-on panel, it includes the bumper retaining bracket.

• NOTE: It is necessary to remove sections of both rear lamp mounting panels to enable removal and refitment of the back

panel , (unl es s t he back panel i s being replaced i n conjunct i on wit h a rear l amp mount ing panel ).

1. The back panel is replaced in conjunction with:

Rear bumper cover

Rear bumper

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he re a r bumpe r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Bumper

(501-19

Bumpe rs , Re mo va l a nd Ins t a l l a t i on).

4. Remove the RH and LH bumper retainer guides.

5. Remove the liftgate aperture weatherseal.

6. Remove the back panel trim.

7. Remove t he RH and LH quart er panel i nner t ri ms .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Quarter Trim Panel

(501-05 Int eri or Trim and Ornament at i on, Removal and

Installation).

8. Remove the RH and LH forced air extraction grilles.

9. Remove the spare road wheel.

10. Remove the subwoofer amplifier.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Subwoofer Amplifier

(415-01 Information and Entertainment System, Removal and

Installation).

11. Re move t he e xha us t a s s e mbl y.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Exhaust Syst em

(309-00A

Exhaus t Sys t em - I6 3.2L Pet rol , Removal and Ins t all at ion).

12. Remove the floor panel exhaust heat shield.

13. Remove the RH and LH road wheels.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Wheel and Tire

(204-04

Wheels and Tires, Removal and Installation).

14. Release and lay aside the insulating material at the back

panel.

15. Release and lay aside the back panel wiring harness.

16. Saw cut each rear lamp mounting panel, as illustrated.17. Mill out the spot welds.18. Separate the joints and remove the rear lamp mounting

panel sections, retain the sections for refitment.19. Mill out the spot welds.

20. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces, including the

rear l amp mount i ng panel s ect ions .

Page 2661 of 3229

Publ is hed: 11-May-2011

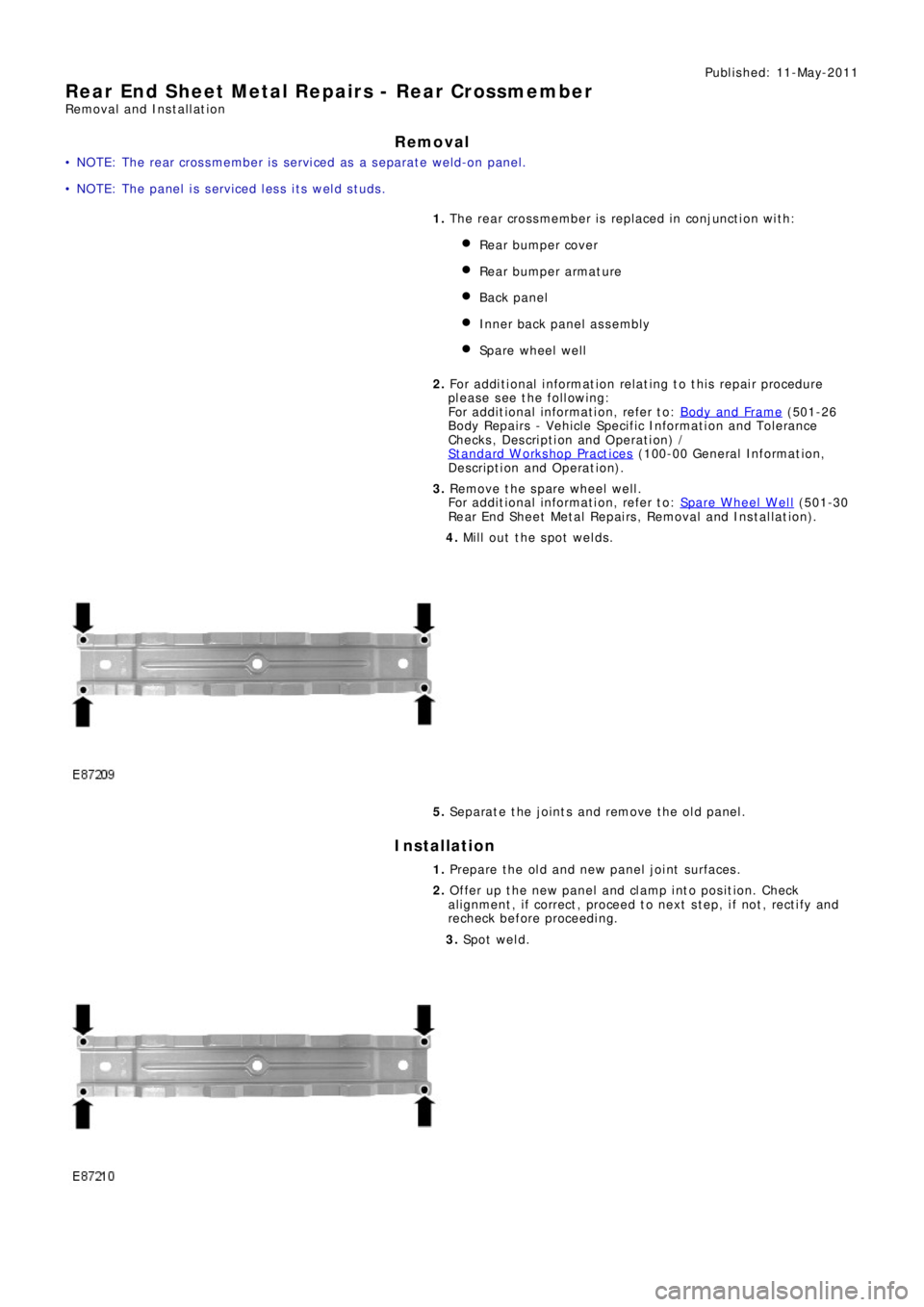

Rear End Sheet Metal Repairs - Rear Crossmember

Removal and Installation

Removal

• N O T E: T he re a r cro s s me mb e r i s s e rvi ce d a s a s e p a ra t e we l d -o n p a ne l .

• NOTE: The panel is serviced less its weld studs.

1. T he re a r cro s s me mb e r i s re p l a ce d i n co nj unct i o n wi t h:

Rear bumper cover

Re a r bumpe r a rma t ure

Back panel

Inner back panel assembly

Spare wheel well

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the spare wheel well.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Spare Wheel W ell

(501-30

Rear End Sheet Metal Repairs, Removal and Installation).

4. Mill out the spot welds.

5. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

2. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

3. Sp o t w e l d .

Page 2663 of 3229

Publ is hed: 11-May-2011

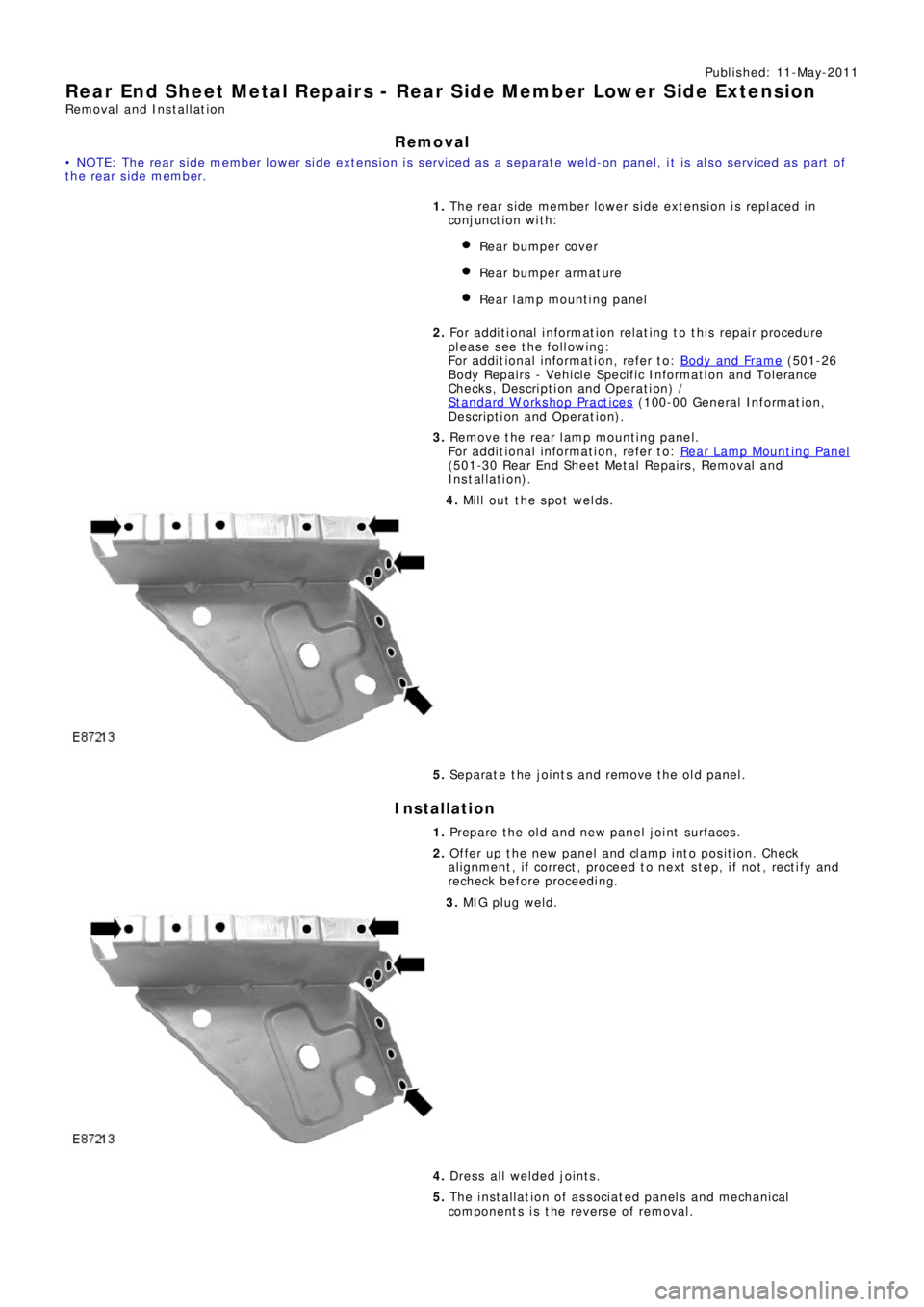

Rear End Sheet Metal Repairs - Rear Side Member Lower Side Extension

Removal and Installation

Removal

• NOTE: The rear side member lower side extension is serviced as a separate weld-on panel, it is also serviced as part of

t he re a r s i de me mbe r.

1. The rear side member lower side extension is replaced in

conjunct ion wit h:

Rear bumper cover

Re a r bumpe r a rma t ure

Rear l amp mount ing panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he re a r l a mp mount i ng pa ne l .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Lamp Mount i ng Panel

(501-30 Rear End Sheet Metal Repairs, Removal and

Installation).

4. Mill out the spot welds.

5. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

2. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

3. MIG pl ug we l d.

4. Dress all welded joints.

5. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2664 of 3229

Publ is hed: 11-May-2011

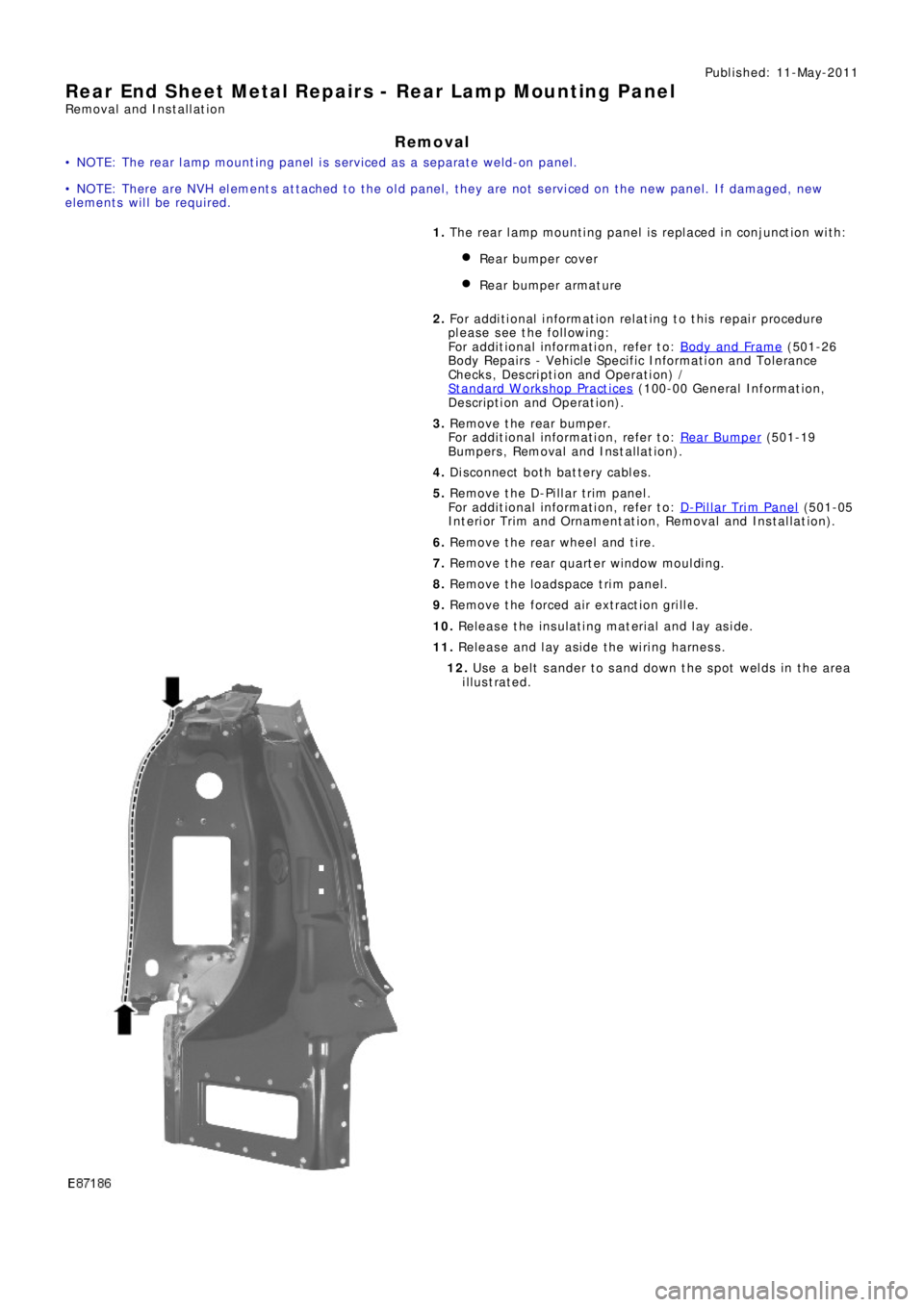

Rear End Sheet Metal Repairs - Rear Lamp Mounting Panel

Removal and Installation

Removal

• NOTE: The rear lamp mounting panel is serviced as a separate weld-on panel.

• NOTE: There are NVH elements attached to the old panel, they are not serviced on the new panel. If damaged, new

elements will be required.

1. The rear lamp mounting panel is replaced in conjunction with:

Rear bumper cover

Re a r bumpe r a rma t ure

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he re a r bumpe r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Bumper

(501-19

Bumpe rs , Re mo va l a nd Ins t a l l a t i on).

4. Disconnect both battery cables.

5. Remove the D-Pillar trim panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : D-Pillar Trim Panel

(501-05

Int erior Trim and Ornamentat ion, Removal and Installat ion).

6. Re mo ve t he re a r w he e l a nd t i re .

7. Remove t he rear quart er window moulding.

8. Remove the loadspace trim panel.

9. Remove the forced air extraction grille.

10. Release the insulating material and lay aside.

11. Release and lay aside the wiring harness.

12. Use a belt sander to sand down the spot welds in the area

illustrated.

Page 2672 of 3229

Publ is hed: 11-May-2011

Rear End Sheet Metal Repairs - Rear Wheelhouse Front Extension

Removal and Installation

Removal

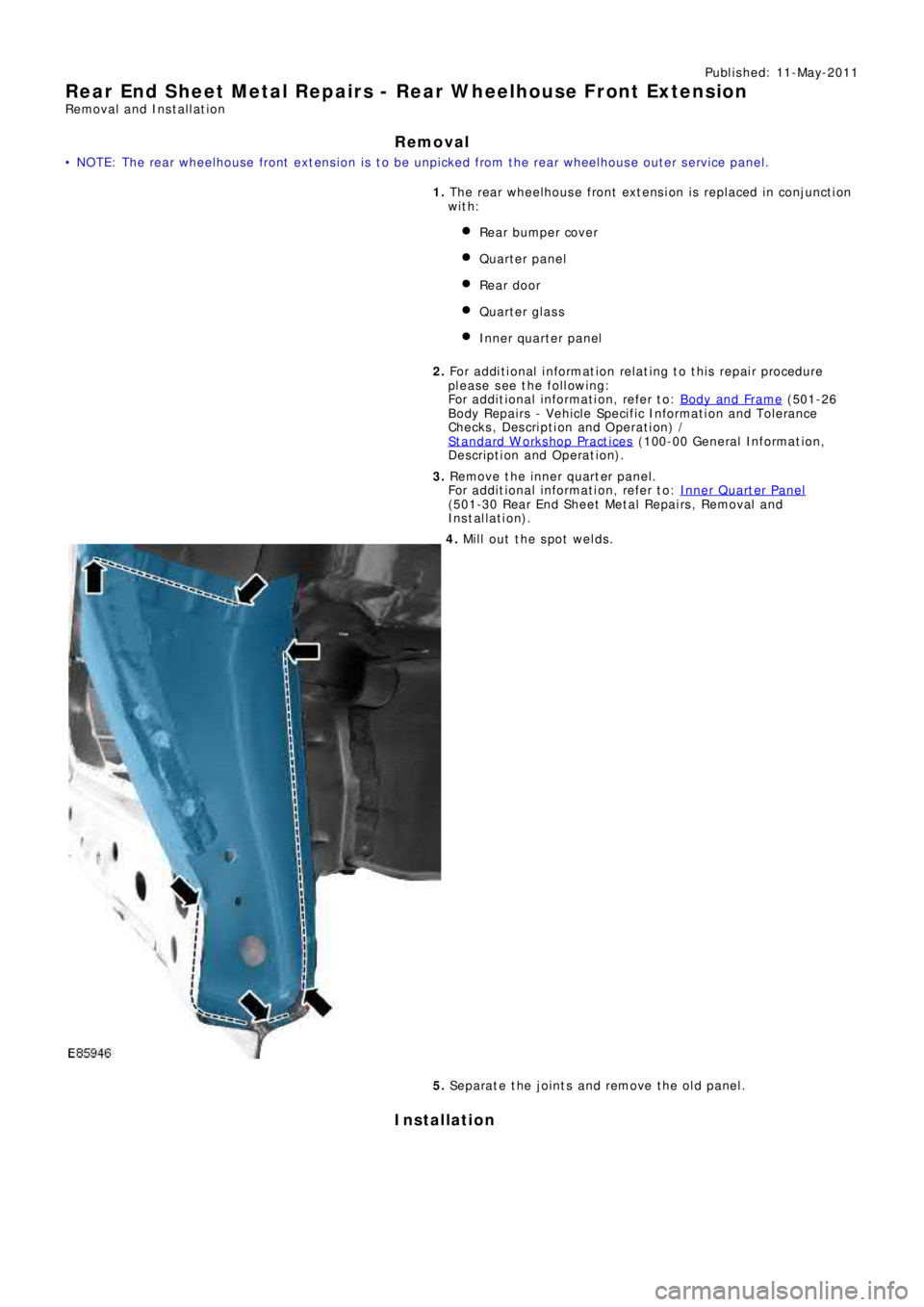

• NOTE: The rear wheelhouse front extension is to be unpicked from the rear wheelhouse outer service panel.

1. The rear wheelhouse front extension is replaced in conjunction

with:

Rear bumper cover

Quarter panel

Rear door

Quarter glass

I nne r q ua rt e r p a ne l

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re mo ve t he i nne r q ua rt e r p a ne l .

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Inner Quart er Panel

(501-30 Rear End Sheet Metal Repairs, Removal and

Installation).

4. Mill out the spot welds.

5. Separate the joints and remove the old panel.

Installation

Page 2673 of 3229

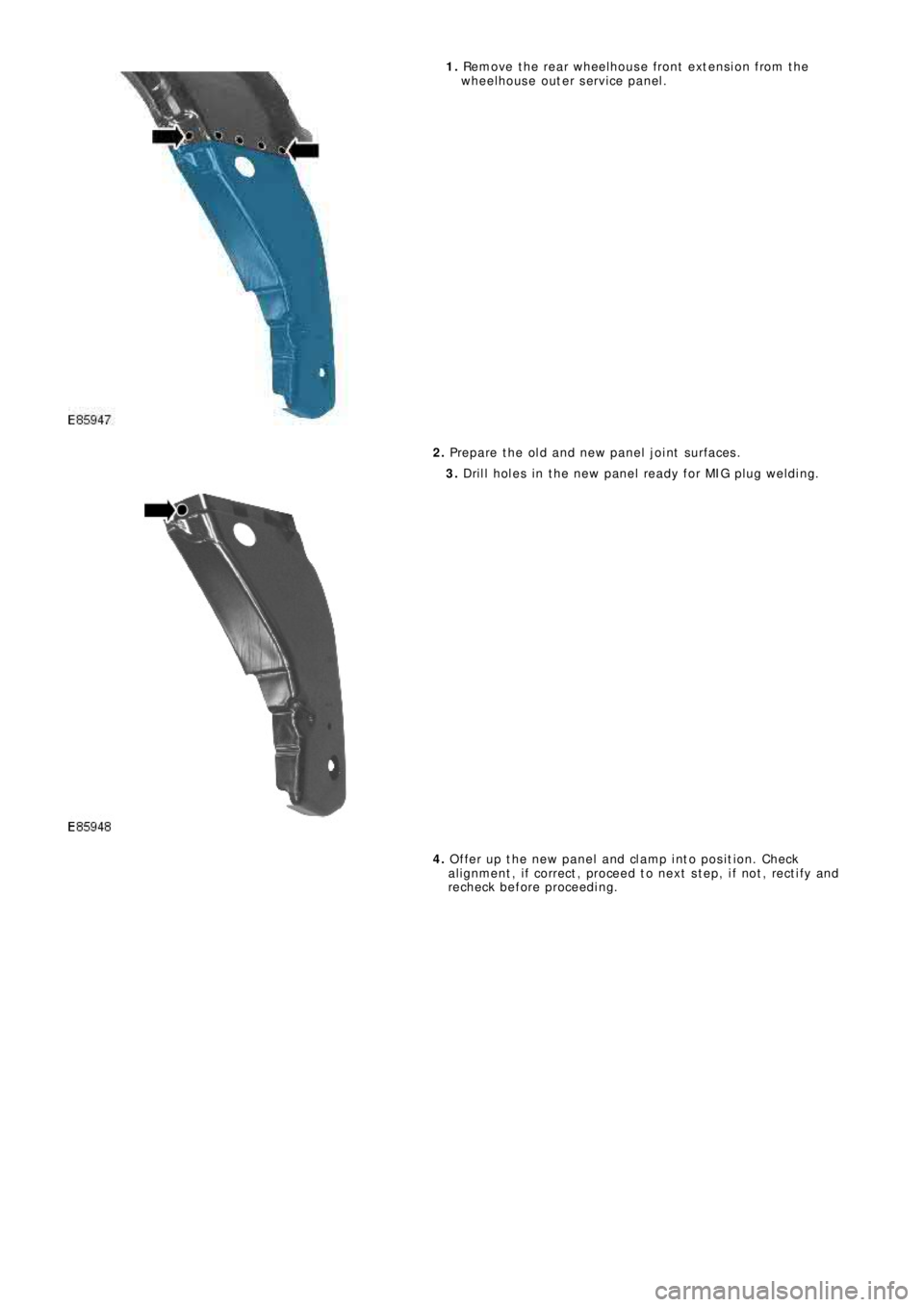

1. Remove the rear wheelhouse front extension from the

wheelhouse outer service panel.

2. Prepare the old and new panel joint surfaces.

3. Drill holes in the new panel ready for MIG plug welding.

4. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.