low beam LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 74 of 3229

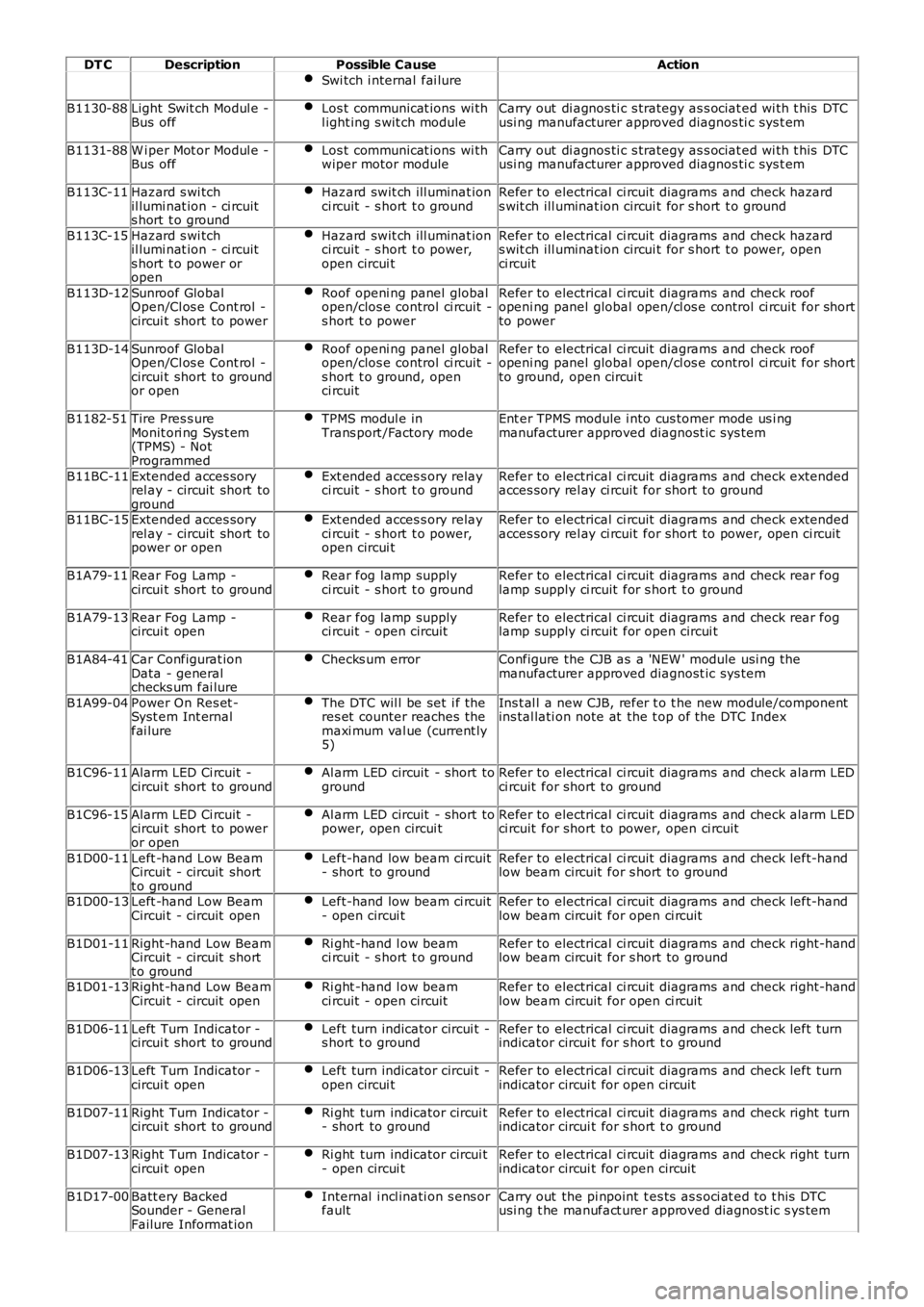

DT CDescriptionPossible CauseAction

Swi tch i nternal fai lure

B1130-88Light Swit ch Modul e -Bus offLos t communicat ions wi thl ight ing s wit ch moduleCarry out di agnos ti c s trategy as s ociat ed wi th t his DTCusi ng manufacturer approved diagnos ti c sys t em

B1131-88W i per Mot or Modul e -Bus offLos t communicat ions wi thwiper motor moduleCarry out di agnos ti c s trategy as s ociat ed wi th t his DTCusi ng manufacturer approved diagnos ti c sys t em

B113C-11Hazard s wi tchil lumi nat ion - ci rcuits hort t o ground

Hazard swit ch ill uminat ionci rcuit - s hort t o groundRefer to electrical ci rcuit diagrams and check hazards wit ch ill uminat ion circui t for s hort t o ground

B113C-15Hazard s wi tchil lumi nat ion - ci rcuits hort t o power oropen

Hazard swit ch ill uminat ionci rcuit - s hort t o power,open circui t

Refer to electrical ci rcuit diagrams and check hazards wit ch ill uminat ion circui t for s hort t o power, openci rcuit

B113D-12Sunroof GlobalOpen/Cl os e Cont rol -circui t short to power

Roof openi ng panel globalopen/clos e control ci rcuit -s hort t o power

Refer to electrical ci rcuit diagrams and check roofopeni ng panel global open/cl os e control ci rcuit for shortto power

B113D-14Sunroof GlobalOpen/Cl os e Cont rol -circui t short to groundor open

Roof openi ng panel globalopen/clos e control ci rcuit -s hort t o ground, openci rcuit

Refer to electrical ci rcuit diagrams and check roofopeni ng panel global open/cl os e control ci rcuit for shortto ground, open circui t

B1182-51Tire Pres s ureMonit ori ng Sys t em(TPMS) - NotProgrammed

TPMS modul e inTrans port /Factory modeEnt er TPMS module i nto cus tomer mode us i ngmanufacturer approved diagnost ic sys tem

B11BC-11Extended acces soryrel ay - circuit short toground

Ext ended acces s ory relayci rcuit - s hort t o groundRefer to electrical ci rcuit diagrams and check extendedacces sory rel ay ci rcuit for short to ground

B11BC-15Extended acces soryrel ay - circuit short topower or open

Ext ended acces s ory relayci rcuit - s hort t o power,open circui t

Refer to electrical ci rcuit diagrams and check extendedacces sory rel ay ci rcuit for short to power, open ci rcuit

B1A79-11Rear Fog Lamp -circui t short to groundRear fog lamp supplyci rcuit - s hort t o groundRefer to electrical ci rcuit diagrams and check rear foglamp supply ci rcuit for s hort t o ground

B1A79-13Rear Fog Lamp -circui t openRear fog lamp supplyci rcuit - open circuitRefer to electrical ci rcuit diagrams and check rear foglamp supply ci rcuit for open circui t

B1A84-41Car Configurat ionData - generalchecks um fai lure

Checks um errorConfigure the CJB as a 'NEW ' module usi ng t hemanufacturer approved diagnost ic sys tem

B1A99-04Power On Res et -Syst em Int ernalfai lure

The DTC wil l be set i f theres et counter reaches themaxi mum val ue (current ly5)

Ins t al l a new CJB, refer t o t he new module/componentins tal lati on note at the t op of the DTC Index

B1C96-11Alarm LED Ci rcuit -circui t short to groundAl arm LED circuit - short togroundRefer to electrical ci rcuit diagrams and check alarm LEDci rcuit for short to ground

B1C96-15Alarm LED Ci rcuit -circui t short to poweror open

Al arm LED circuit - short topower, open circui tRefer to electrical ci rcuit diagrams and check alarm LEDci rcuit for short to power, open ci rcuit

B1D00-11Left -hand Low BeamCircui t - circuit shortt o ground

Left-hand low beam ci rcuit- short to groundRefer to electrical ci rcuit diagrams and check left-handlow beam circuit for s hort to ground

B1D00-13Left -hand Low BeamCircui t - circuit openLeft-hand low beam ci rcuit- open circui tRefer to electrical ci rcuit diagrams and check left-handlow beam circuit for open ci rcuit

B1D01-11Right -hand Low BeamCircui t - circuit shortt o ground

Ri ght -hand l ow beamci rcuit - s hort t o groundRefer to electrical ci rcuit diagrams and check right-handlow beam circuit for s hort to ground

B1D01-13Right -hand Low BeamCircui t - circuit openRi ght -hand l ow beamci rcuit - open circuitRefer to electrical ci rcuit diagrams and check right-handlow beam circuit for open ci rcuit

B1D06-11Left Turn Indicator -circui t short to groundLeft turn indicator circui t -s hort t o groundRefer to electrical ci rcuit diagrams and check left turnindicator circui t for s hort t o ground

B1D06-13Left Turn Indicator -circui t openLeft turn indicator circui t -open circui tRefer to electrical ci rcuit diagrams and check left turnindicator circui t for open circuit

B1D07-11Right Turn Indicator -circui t short to groundRi ght turn indicator circui t- short to groundRefer to electrical ci rcuit diagrams and check right turnindicator circui t for s hort t o ground

B1D07-13Right Turn Indicator -circui t openRi ght turn indicator circui t- open circui tRefer to electrical ci rcuit diagrams and check right turnindicator circui t for open circuit

B1D17-00Batt ery BackedSounder - GeneralFailure Informat ion

Internal i ncl inati on s ens orfaultCarry out the pi npoint t es ts as s oci at ed t o t his DTCusi ng t he manufact urer approved diagnost ic s ys tem

Page 571 of 3229

Publi s hed: 11-May-2011

Steering Column - Steering Column

Des cript ion and Operat ion

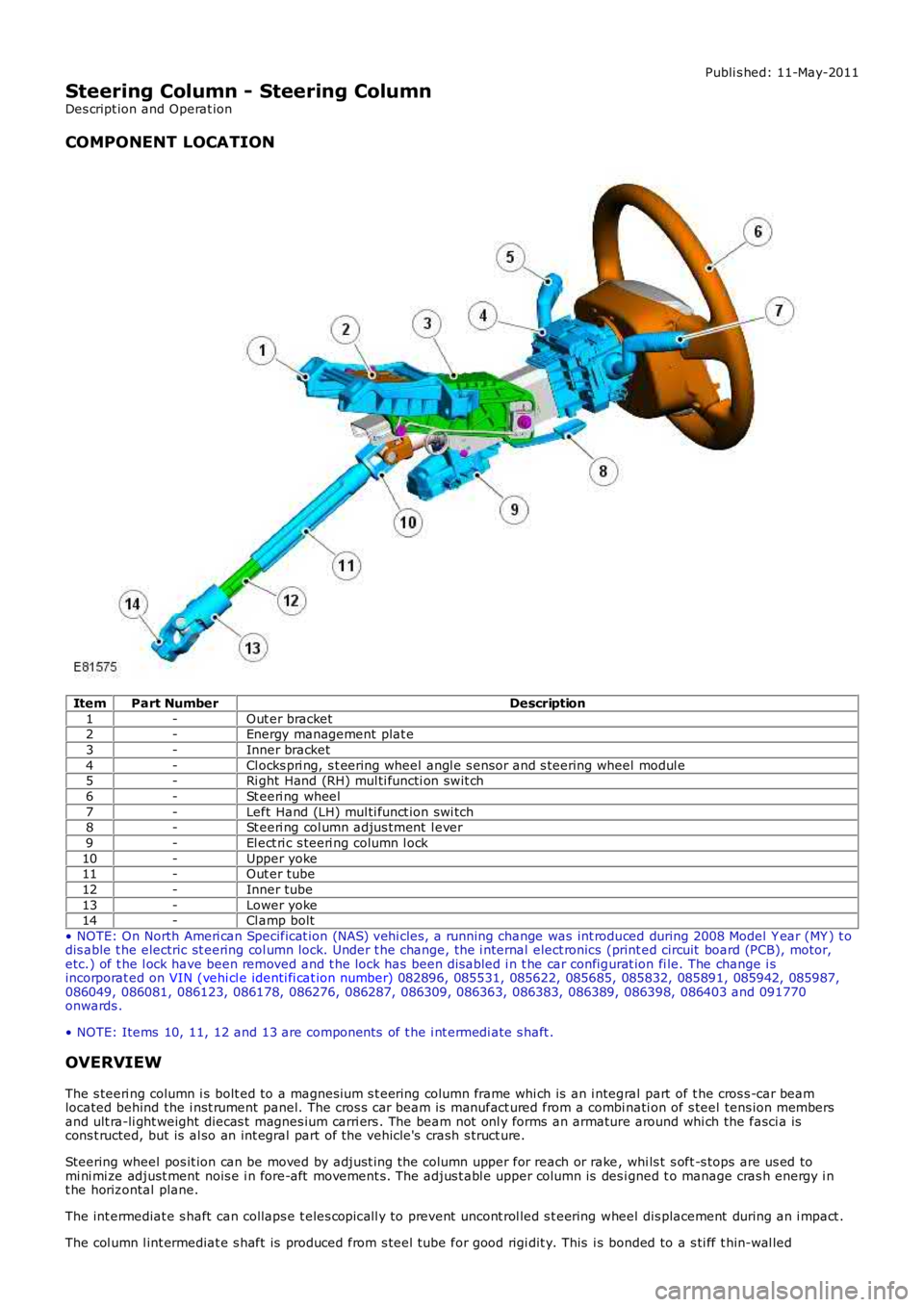

COMPONENT LOCATION

ItemPart NumberDescription

1-Out er bracket2-Energy management plat e

3-Inner bracket

4-Cl ocks pri ng, s t eering wheel angl e s ensor and s teering wheel modul e5-Ri ght Hand (RH) mul ti functi on swit ch

6-St eeri ng wheel

7-Left Hand (LH) mul ti funct ion swi tch8-St eeri ng col umn adjus tment l ever

9-El ect ri c s teeri ng column l ock

10-Upper yoke11-Out er tube

12-Inner tube

13-Lower yoke14-Cl amp bolt

• NOTE: On North Ameri can Specificat ion (NAS) vehi cles , a running change was int roduced during 2008 Model Y ear (MY ) t odis able t he electric st eering col umn lock. Under t he change, the i nternal elect ronics (print ed circuit board (PCB), motor,etc.) of t he l ock have been removed and t he lock has been dis abled i n t he car configurat ion fi le. The change i sincorporat ed on VIN (vehi cl e identi fi cat ion number) 082896, 085531, 085622, 085685, 085832, 085891, 085942, 085987,086049, 086081, 086123, 086178, 086276, 086287, 086309, 086363, 086383, 086389, 086398, 086403 and 091770onwards .

• NOTE: Items 10, 11, 12 and 13 are components of t he i nt ermedi ate s haft .

OVERVIEW

The s teeri ng column i s bolt ed to a magnesi um s t eering column frame whi ch is an i ntegral part of t he cros s -car beamlocated behind the i nst rument panel. The cros s car beam is manufact ured from a combinati on of s teel tens ion membersand ult ra-li ght weight diecas t magnes ium carri ers . The beam not onl y forms an armature around whi ch the fasci a iscons t ructed, but is al so an int egral part of the vehicle's crash s truct ure.

Steering wheel pos it ion can be moved by adjust ing the column upper for reach or rake, whi ls t s oft -s tops are us ed tomi ni mi ze adjust ment nois e i n fore-aft movement s. The adjus t abl e upper column is des igned t o manage cras h energy i nt he horizontal plane.

The int ermediat e s haft can collaps e t eles copicall y to prevent uncont rol led s t eering wheel dis placement during an i mpact .

The col umn l int ermediat e s haft is produced from s teel tube for good rigi dit y. This is bonded to a s ti ff t hin-wal led

Page 585 of 3229

Publi s hed: 11-May-2011

Steering Column Switches - Steering Column Switches

Des cript ion and Operat ion

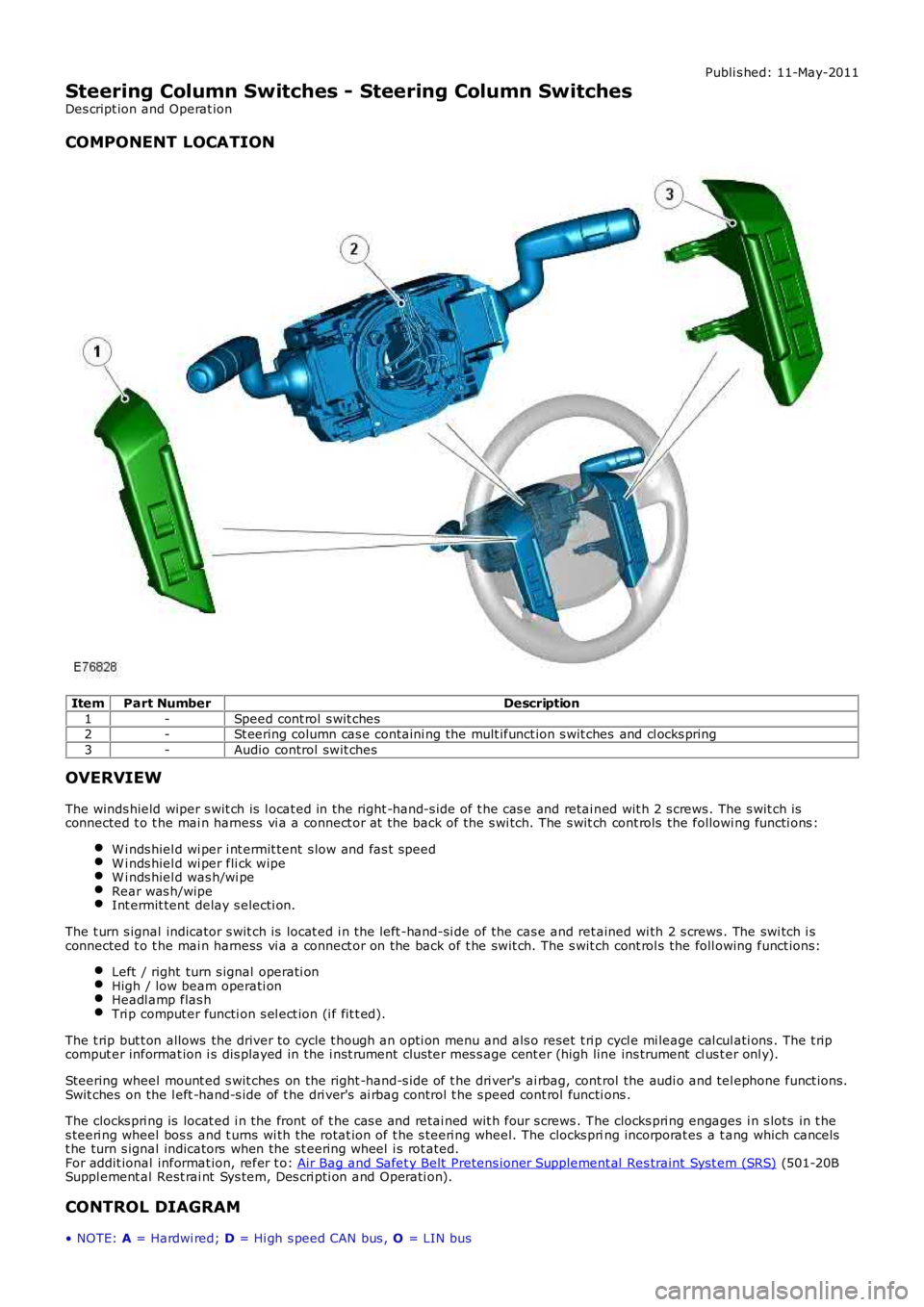

COMPONENT LOCATION

ItemPart NumberDescription

1-Speed cont rol s wit ches2-St eering column cas e containi ng the mult ifunct ion s wit ches and cl ocks pring

3-Audio control swit ches

OVERVIEW

The winds hield wiper s wit ch is l ocat ed in the right -hand-s ide of t he cas e and retai ned wit h 2 s crews . The s wit ch isconnected t o t he mai n harness vi a a connect or at the back of the s wi tch. The s wit ch cont rols the followi ng functi ons :

W i nds hiel d wi per i nt ermit tent s low and fas t speedW i nds hiel d wi per fli ck wipeW i nds hiel d was h/wi peRear was h/wipeInt ermit tent delay s electi on.

The t urn s ignal indicator s wit ch is locat ed i n t he left -hand-si de of the cas e and ret ained wi th 2 s crews . The swi tch i sconnected t o t he mai n harness vi a a connect or on the back of t he swit ch. The s wit ch cont rol s the foll owing funct ions:

Left / right turn s ignal operati onHigh / low beam operati onHeadl amp flas hTri p comput er functi on s el ect ion (i f fit t ed).

The t rip but t on allows the driver to cycle t hough an opti on menu and als o reset t ri p cycl e mi leage cal cul ati ons . The t ripcomput er informat ion i s dis played in the i nst rument clus ter mes s age cent er (high line ins trument cl us t er onl y).

Steering wheel mount ed s wit ches on the right -hand-s ide of t he dri ver's ai rbag, cont rol the audi o and tel ephone funct ions.Swit ches on the l eft -hand-s ide of t he dri ver's ai rbag control t he s peed cont rol functi ons .

The clocks pri ng is locat ed i n the front of t he cas e and retai ned wit h four s crews . The clocks pri ng engages i n s lots in t hes teeri ng wheel bos s and t urns wi th the rotat ion of t he s teeri ng wheel. The clocks pring incorporat es a t ang which cancelst he turn s ignal indicators when the st eering wheel i s rot ated.For addit ional informat ion, refer t o: Air Bag and Safet y Belt Pretens ioner Supplement al Res traint Syst em (SRS) (501-20BSuppl ement al Rest rai nt Sys tem, Des cri pti on and Operati on).

CONTROL DIAGRAM

• NOTE: A = Hardwi red; D = Hi gh s peed CAN bus , O = LIN bus

Page 587 of 3229

11-Int egrated audio modul e

12-Int egrated control modul e

PRINCIPLES OF OPERATION

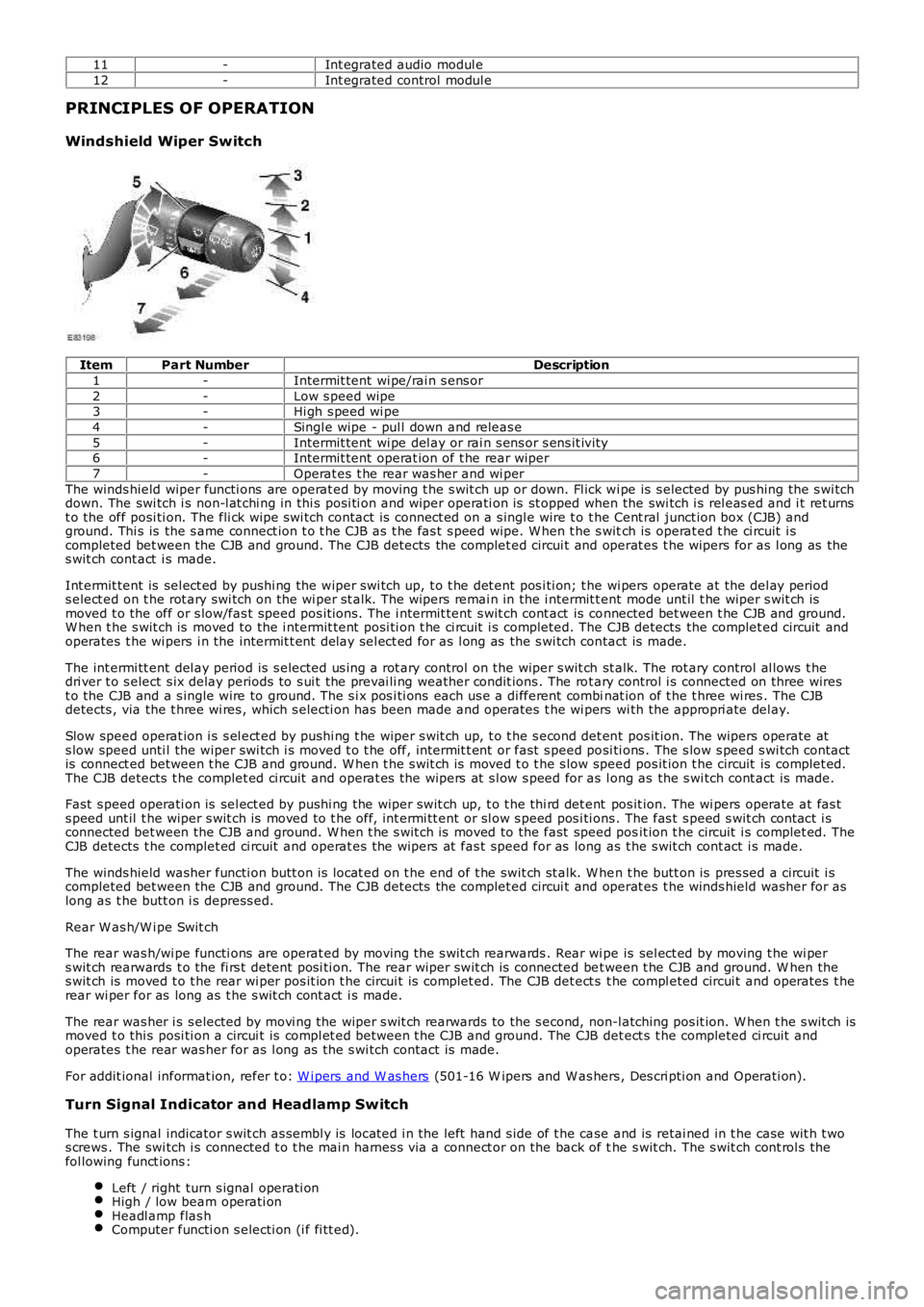

Windshield Wiper Switch

ItemPart NumberDescription

1-Intermit tent wi pe/rai n s ens or

2-Low s peed wipe3-Hi gh s peed wi pe

4-Singl e wipe - pul l down and releas e

5-Intermit tent wi pe del ay or rai n s ens or s ens it ivi ty6-Intermit tent operat ion of t he rear wiper

7-Operat es t he rear was her and wi per

The winds hield wiper functi ons are operat ed by moving t he s wit ch up or down. Fl ick wi pe is s elected by pus hing the s wi tchdown. The swi tch i s non-l at chi ng in thi s posi ti on and wiper operati on is st opped when the swi tch i s rel eas ed and i t ret urnst o the off posi ti on. The fli ck wipe s wi tch contact is connect ed on a s ingl e wire t o t he Cent ral junct ion box (CJB) andground. Thi s is the s ame connect ion t o t he CJB as t he fas t s peed wipe. W hen t he s witch is operat ed t he ci rcuit i scompleted bet ween the CJB and ground. The CJB detects the complet ed circui t and operat es t he wipers for as l ong as thes wit ch cont act i s made.

Int ermit tent is sel ect ed by pushi ng the wiper swi tch up, t o t he det ent pos i ti on; t he wi pers operate at the del ay periods elect ed on t he rot ary swi tch on the wi per st alk. The wipers remai n in the i ntermit tent mode unt il t he wiper s wit ch ismoved t o the off or s low/fas t speed pos it ions. The i ntermit tent s wit ch cont act is connected bet ween t he CJB and ground.W hen t he s wit ch is moved to the i ntermit tent posi ti on t he ci rcuit i s completed. The CJB detects the complet ed circuit andoperates t he wi pers i n the intermit t ent delay sel ect ed for as l ong as the s wi tch contact is made.

The int ermi tt ent del ay period is s elected us i ng a rot ary control on the wiper s wit ch st alk. The rot ary control al lows t hedri ver t o s elect s ix delay periods to s ui t the prevai li ng weather condit ions . The rot ary control i s connected on three wirest o the CJB and a s ingle wire to ground. The s i x pos i ti ons each us e a di fferent combinat ion of t he t hree wi res . The CJBdetects , via the t hree wi res , which s electi on has been made and operates t he wi pers wi th the appropri ate del ay.

Slow speed operat ion i s s el ect ed by pus hi ng t he wiper s wit ch up, t o t he s econd det ent pos it ion. The wipers operate ats low speed unti l the wiper swi tch i s moved t o t he off, intermit t ent or fast s peed posi ti ons . The s low s peed s wi tch contactis connect ed between t he CJB and ground. W hen t he s wit ch is moved t o t he s low speed pos it ion t he circuit is complet ed.The CJB detects t he complet ed ci rcuit and operat es the wipers at s l ow s peed for as long as the s wi tch cont act is made.

Fast s peed operati on is sel ect ed by pushi ng the wiper swit ch up, t o t he thi rd det ent pos it ion. The wi pers operate at fas ts peed unt il t he wiper s wit ch is moved to t he off, int ermi tt ent or sl ow s peed pos i ti ons . The fas t s peed s wit ch cont act i sconnected bet ween the CJB and ground. W hen t he s wit ch is moved to the fast speed posit ion t he circuit i s complet ed. TheCJB detects t he complet ed ci rcuit and operat es the wipers at fas t speed for as long as t he s wit ch cont act i s made.

The winds hield washer functi on butt on is locat ed on t he end of t he swit ch st alk. W hen t he butt on is pres sed a circuit i scompleted bet ween the CJB and ground. The CJB detects the complet ed circui t and operat es t he winds hield washer for aslong as t he butt on i s depress ed.

Rear W as h/W i pe Swit ch

The rear was h/wi pe functi ons are operat ed by moving t he s wit ch rearwards . Rear wi pe is sel ect ed by moving t he wi pers wit ch rearwards t o the fi rs t detent posi ti on. The rear wiper swit ch is connected bet ween t he CJB and ground. W hen thes wit ch is moved t o t he rear wi per pos it ion t he circui t is complet ed. The CJB det ect s t he compl eted circui t and operates t herear wi per for as long as t he s wit ch cont act i s made.

The rear was her i s s elected by movi ng the wiper s wit ch rearwards to the s econd, non-l atching pos it ion. W hen t he s wit ch ismoved t o thi s posi ti on a circui t is compl et ed between t he CJB and ground. The CJB det ect s t he completed ci rcuit andoperates t he rear was her for as l ong as the s wi tch contact is made.

For addit ional informat ion, refer t o: W i pers and W as hers (501-16 W ipers and W as hers , Des cri pti on and Operati on).

Turn Signal Indicator and Headlamp Switch

The t urn s ignal indicator s wit ch as sembl y is locat ed i n the left hand s ide of t he case and is retai ned in t he case wit h t wos crews . The swi tch i s connected t o t he mai n harnes s via a connect or on the back of the s wit ch. The s wit ch cont rol s thefol lowing funct ions :

Left / right turn s ignal operati onHigh / low beam operati onHeadl amp flas hComputer functi on s electi on (i f fi tt ed).

Page 588 of 3229

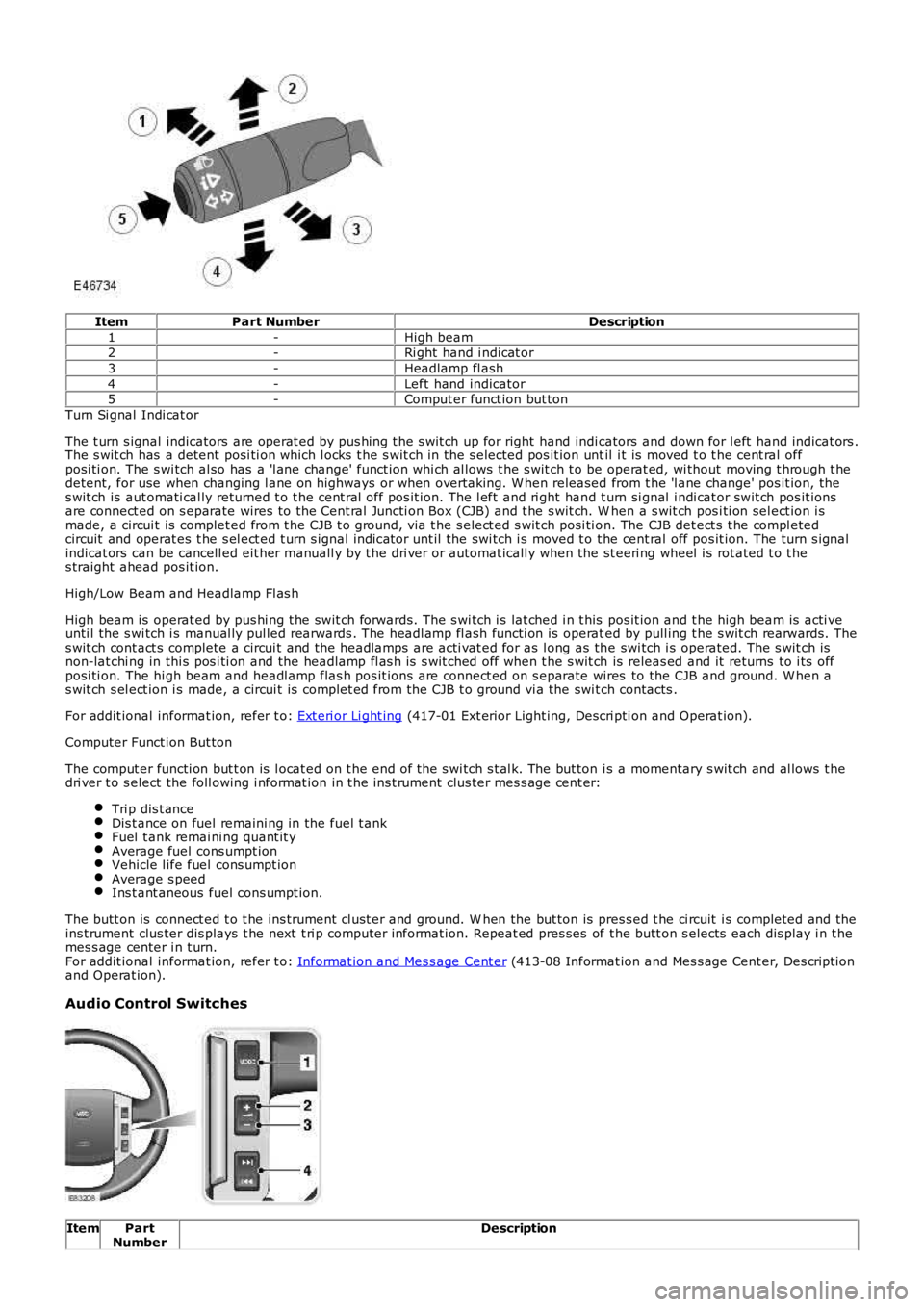

ItemPart NumberDescription

1-High beam2-Ri ght hand i ndicat or

3-Headlamp fl ash

4-Left hand indicator5-Comput er funct ion but ton

Turn Si gnal Indi cat or

The t urn s ignal indicators are operat ed by pus hing t he s wit ch up for right hand indicators and down for l eft hand indicat ors .The s wit ch has a detent posi ti on which l ocks t he s wit ch in the s elected pos it ion until i t is moved t o t he cent ral offposi ti on. The s wi tch al so has a 'l ane change' funct ion whi ch al lows t he s wit ch t o be operat ed, wi thout moving t hrough t hedetent, for use when changing l ane on highways or when overtaking. W hen released from t he 'l ane change' pos it ion, thes wit ch is aut omati cal ly returned t o t he cent ral off pos it ion. The l eft and ri ght hand t urn si gnal i ndi cat or swit ch pos it ionsare connect ed on s eparate wires to the Cent ral Juncti on Box (CJB) and t he s wit ch. W hen a s wit ch pos i ti on sel ect ion i smade, a circui t is complet ed from t he CJB t o ground, vi a t he s elect ed s wit ch posi ti on. The CJB det ect s t he compl etedcircuit and operat es t he s el ect ed t urn s ignal indicator unt il the swi tch i s moved t o t he cent ral off pos it ion. The turn s ignalindicat ors can be cancell ed eit her manuall y by t he dri ver or automat icall y when t he st eeri ng wheel i s rot ated t o t hes traight ahead pos it ion.

High/Low Beam and Headlamp Fl as h

High beam is operat ed by pus hi ng t he swit ch forwards. The s wi tch i s lat ched i n t his pos it ion and t he high beam is acti veunti l the s wi tch i s manual ly pul led rearwards . The headl amp fl ash functi on is operated by pull ing t he s wit ch rearwards. Thes wit ch cont act s complete a circui t and the headlamps are acti vat ed for as l ong as the swi tch i s operated. The s wit ch isnon-lat chi ng in thi s pos i ti on and the headlamp fl as h is s wit ched off when t he s wit ch is releas ed and it returns to i ts offposi ti on. The hi gh beam and headl amp flas h pos it ions are connect ed on s eparate wires to the CJB and ground. W hen as wit ch s el ect ion i s made, a circui t is complet ed from the CJB t o ground vi a the swi tch contacts .

For addit ional informat ion, refer t o: Ext eri or Li ght ing (417-01 Ext erior Light ing, Descri pti on and Operat ion).

Computer Funct ion But ton

The comput er functi on but t on is l ocat ed on t he end of the s wi tch s t al k. The but ton is a momentary s wit ch and al lows t hedri ver t o s elect the foll owing i nformat ion in t he ins t rument clus ter mes s age cent er:

Tri p dis t anceDis t ance on fuel remaini ng in the fuel t ankFuel t ank remai ni ng quant it yAverage fuel cons umpt ionVehicle l ife fuel cons umpt ionAverage s peedIns t ant aneous fuel cons umpt ion.

The butt on is connect ed t o t he ins trument cl ust er and ground. W hen the but ton is pres s ed t he ci rcuit i s completed and theins t rument clus ter dis plays t he next t ri p computer informat ion. Repeat ed pres ses of t he butt on s elects each dis play i n t hemes s age center i n t urn.For addit ional informat ion, refer t o: Informat ion and Mes s age Cent er (413-08 Informat ion and Mes s age Cent er, Des cript ionand Operat ion).

Audio Control Switches

ItemPartNumberDescription

Page 773 of 3229

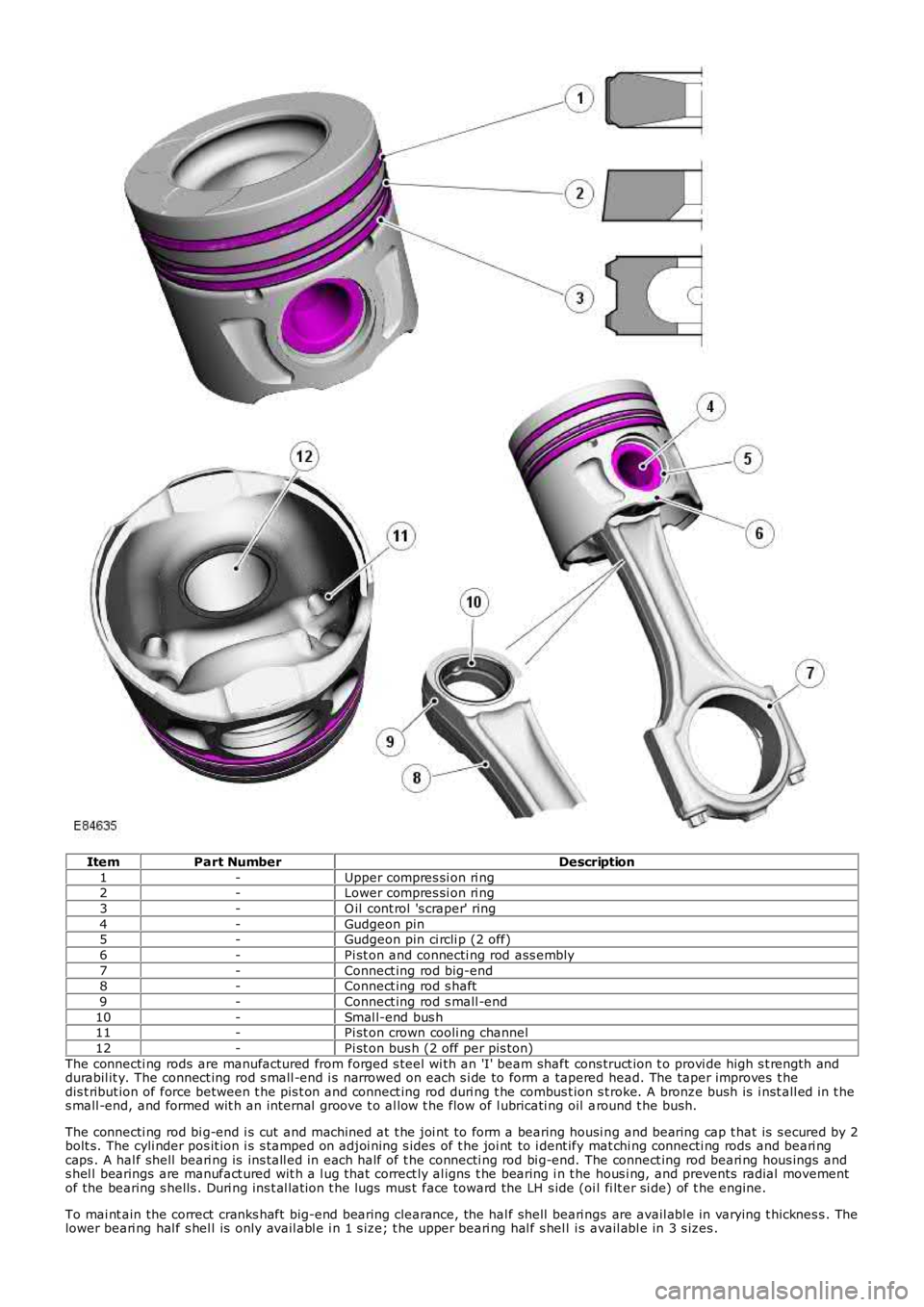

ItemPart NumberDescription

1-Upper compres si on ri ng2-Lower compres si on ri ng

3-O il cont rol 's craper' ring

4-Gudgeon pin5-Gudgeon pin ci rcli p (2 off)

6-Pi st on and connecti ng rod ass embly

7-Connect ing rod big-end8-Connect ing rod s haft

9-Connect ing rod s mall -end

10-Smal l-end bus h11-Pi st on crown cooli ng channel

12-Pi st on bus h (2 off per pis ton)

The connecti ng rods are manufactured from forged s teel wi th an 'I' beam shaft cons truct ion t o provi de high s t rength anddurabil it y. The connect ing rod s mall -end i s narrowed on each s i de to form a tapered head. The taper improves t hedis t ribut ion of force between t he pis t on and connect ing rod duri ng t he combus t ion s troke. A bronze bush is i nst all ed in t hes mall -end, and formed wit h an internal groove t o al low t he flow of l ubricati ng oil around t he bush.

The connecti ng rod bi g-end i s cut and machined at t he joi nt to form a bearing housi ng and bearing cap t hat is s ecured by 2bolt s. The cyli nder pos it ion i s s tamped on adjoi ning s ides of t he joi nt to i dent ify mat chi ng connecti ng rods and beari ngcaps . A hal f shell beari ng is ins tall ed in each half of t he connecti ng rod bi g-end. The connect ing rod beari ng hous ings ands hel l bearings are manufact ured wit h a l ug that correct ly al igns t he bearing i n t he hous i ng, and prevents radial movementof the bearing s hells . Duri ng ins t al lat ion t he lugs mus t face toward the LH s ide (oil fi lt er si de) of t he engine.

To mai nt ain the correct cranks haft big-end bearing clearance, the hal f shell beari ngs are avail abl e in varying t hicknes s . Thelower beari ng hal f s hel l is only avail abl e i n 1 s ize; t he upper beari ng hal f s hel l is avail abl e in 3 s izes .

Page 1634 of 3229

OVERVIEW

The air dis t ri but ion and fil tering s ys tem cont rols the di st ributi on and qual it y of air s uppl ied i nto t he front and rear of t hecabi n. The sys tem cons is t s of:

Air ductsAir regi s ters and vent sA cabin ai r fi lt er.

AIR DUCTS

The air ducts di st ri bute ai r from t he heater as sembl y to the various regi st ers and vents in t he i ns t rument panel and t o t herear of t he vehi cl e.

The face l evel /s ide window duct and t he wi nds hiel d duct form part of t he ins trument panel as sembl y.

Each front footwell duct is a s nap fit into the s i de of the heater as s embly and s ecured t o the cross car beam by a s ingles crew. The front footwel l ducts als o provide a locati on for t he foot well lamps .

The rear cabi n ducts are als o a snap fit i nto the heater as s embly. Each duct runs underneath t he carpet and is secured t ot he fl oor of t he vehi cl e by a si ngl e s crew l ocat ed beneat h t he front seat .

AIR REGISTERS AND VENTS

The air regi s ters allow the vehicle occupant s t o cont rol t he fl ow and di recti on of ai r from t he air ducts . The ins t rumentpanel contains 4 air regi st ers ; 1 mount ed on eit her end of t he i ns t rument panel and 2 mount ed central ly.

The air vents are fixed outl et s . The ins trument panel cont ains 4 ai r vent s ; 1 mounted on ei ther end of t he ins trumentpanel and 2 mount ed along t he t op edge, below the wi ndshi el d.

CABIN AIR FILTER

The cabi n air fil ter is locat ed behind t he RH s i de of the i nst rument panel and is housed wit hin t he heater as sembl y. Thefi lt er removes odors and fine part icl es , i ncludi ng pol len, from t he air ent ering the heater as s embly.

Page 1769 of 3229

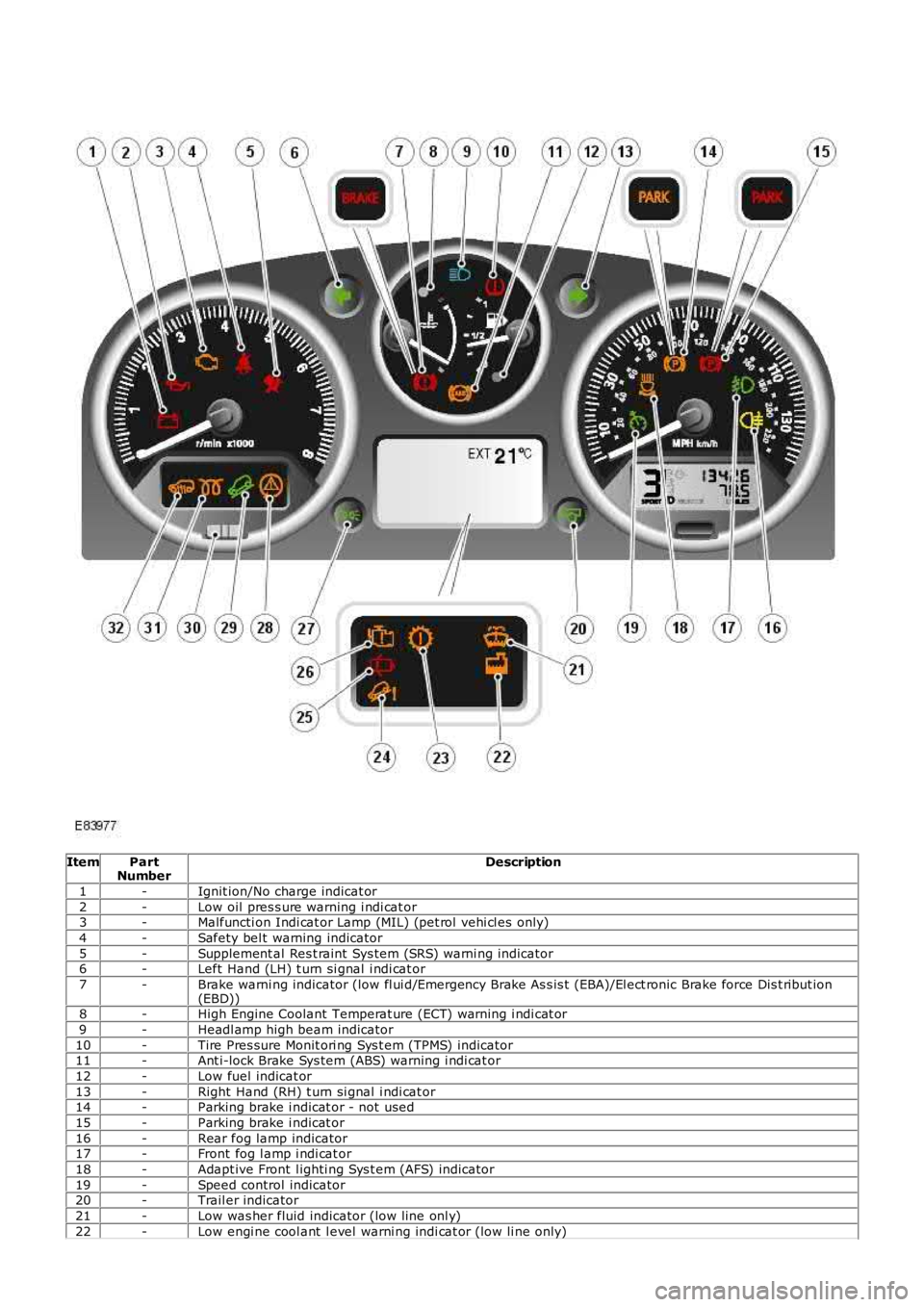

ItemPartNumberDescription

1-Ignit ion/No charge indicat or

2-Low oil pres s ure warning i ndi cat or3-Malfuncti on Indi cat or Lamp (MIL) (pet rol vehi cl es only)

4-Safety bel t warning indicator

5-Supplement al Res t raint Sys tem (SRS) warni ng indicator6-Left Hand (LH) t urn si gnal i ndi cat or

7-Brake warni ng indicator (low fl ui d/Emergency Brake As s is t (EBA)/El ect ronic Brake force Dis t ribut ion(EBD))8-High Engine Coolant Temperat ure (ECT) warning i ndi cat or

9-Headl amp high beam indicator

10-Tire Pres sure Monit ori ng Sys t em (TPMS) indicator11-Ant i-lock Brake Sys tem (ABS) warning i ndi cat or

12-Low fuel indicat or

13-Right Hand (RH) t urn si gnal i ndi cat or14-Parking brake i ndicat or - not used

15-Parking brake i ndicat or

16-Rear fog lamp indicator17-Front fog l amp i ndi cat or

18-Adapt ive Front l ighti ng Sys t em (AFS) indicator

19-Speed control indicator20-Trail er indicator

21-Low was her fluid indicator (low line onl y)

22-Low engi ne cool ant l evel warni ng indi cat or (low li ne only)

Page 1771 of 3229

Vehicle i n power mode 6 (all vehi cles except NAS vehicles )Vehicle i n power mode 6 for 75 s econds (NAS vehicl es onl y)Vehicle s peed is greater t han 6 mph (10 kph)Dri vers s afet y belt not s ecured in i ts buckleLarge pas senger det ect ed i n front pas s enger s eat wit h an uns ecured safety bel t.

The warni ng indicator wi ll flas h at a frequency of 2 Hz while accompani ed by a chime from the i nst rument clus ter for 10s econds. Thi s is foll owed by a 10 s econd period where the warning i ndicat or is permanent ly ill uminat ed and the s ounder i ss il ent . Thi s 10 s econd cycle wi ll be repeat ed for a maxi mum of 190 seconds or any of t he condit ions l is t ed above cease toexis t.

Supplemental Restraint System Warning Indicator

The Suppl ement al Rest rai nt Sys tem (SRS) warning i ndi cat or is i lluminated on recei pt of a medium s peed CAN bus si gnalfrom the CJB. The si gnal originat es in t he RCM whi ch monit ors t he condi ti on of the SRS and ill uminat es the red warni ngindicat or accordingly.

The SRS warni ng indicator i s il lumi nat ed by t he RCM for a 6 s econd bul b check when the vehicle firs t ent ers power mode 6.If a fault is detect ed wit h t he indicator, the ins trument cl us t er returns a medi um speed CAN bus s ignal vi a t he CJB to theRCM and a Diagnos t ic Troubl e Code (DTC) i s s tored in the RCM's memory. The mes s age 'SrS' wi ll als o be di spl ayed i n t heodometer.For addit ional informat ion, refer t o: Informat ion and Mes s age Cent er (413-08 Informat ion and Mes s age Cent er, Des cript ionand Operat ion).

Left and Right Hand Turn Signal Indicators

The green l eft and right hand turn s ignal i ndicat ors are i ll uminated on recei pt of medium speed CAN bus s i gnals from t heCJB. The CJB provi des a CAN bus s ignal wit h one of t he foll owing values :

0 - LH st eeri ng col umn mul ti -funct ion s wit ch in the central pos it ion1 - LH st eeri ng col umn mul ti -funct ion s wit ch in the LH turn posi ti on2 - LH st eeri ng col umn mul ti -funct ion s wit ch in the RH turn pos it ion3 - Hazard fl as hers reques t ed.

If the vehicle is i n power mode 6 t he ins trument cl ust er wil l fl as h the appropri ate turn s ignal i ndicat or if a medium speedCAN bus s ignal is recei ved wit h a value of 1 or 2. Medi um s peed CAN bus s ignals wi th a value of 3 wi ll acti vat e both theLH and RH turn s ignal i ndicat ors si mult aneous ly i rrespecti ve of power mode.

W hen acti vat ed, the l eft and right hand turn s ignal indicators wil l be accompanied by 'ti ck t ock' chimes from t he ins trumentclus ter s ounder.

Brake Warning Indicator

EBA and EBD warnings are trans mi tt ed t o t he CJB from t he ABS module over t he high s peed CAN bus . Thes e s ignals arerel ayed t o t he i ns t rument clus ter on t he medium s peed CAN bus and wil l act ivate the brake warning i ndicat or when t hevehi cl e i s in power mode 6. If an EBA warni ng is request ed, the i ndi cat or wil l ill uminat e in an amber color. If an EBDwarni ng is reques t ed, t he indi cat or will i ll uminate in a red color.

Low brake flui d level warnings are als o t rans mit t ed to the i nst rument clus t er from the CJB on the medi um s peed CAN bus .The s ignal origi nat es in the ABS modul e which recei ves a hardwired input from the brake flui d level s ens or. If a l ow brakefl uid warning i s reques ted, the indicator wil l il lumi nat e i n a red col or when the vehicle is i n power mode 6.

The brake warni ng indi cat or i s als o s ubject t o a 3 second bul b check when the vehicle firs t ent ers power mode 6. Theindicat or wi ll i lluminate in a amber color for 1.5 s econds t hen a red col or for 1.5 s econds .

High Eng ine Coolant Temperature Warning Ind icator

The red hi gh Engine Coolant Temperature (ECT) warning i ndi cat or is control led by the engine t emperat ure gage s oft ware(see above).

Headlamp High Beam Indicator

The blue headlamp hi gh beam i ndi cat or is i ll uminated on recei pt of a medium s peed CAN bus si gnal from the CJB. Thes ignal origi nat es in the l ight s wit ch module and i s t ransmit ted t o t he CJB over t he LIN bus. The i nst rument clus t er will onlyil lumi nat e t he headl amp high beam indicator when t he vehicle i s in power mode 6 and t he LH s teeri ng column mul ti -functi on s wit ch is moved t o t he high beam pos i ti on.

Tire Pressure Monitoring System Indicator

The Tire Pres s ure Moni tori ng Syst em (TPMS) indicator i s cont rol led by t he ins t rument clus ter on receipt of medium s peedCAN bus s ignals from t he CJB. The s ignal ori gi nates i n t he TPMS module. The indicator i s il lumi nat ed in an amber col or fora 3 second bulb check by the TPMS modul e when t he vehi cl e enters power mode 6. If t he indicator remains i lluminated orfl ashes after t he engi ne is st art ed or when dri vi ng, the TPMS has developed a faul t. The t ire pres s ures s houl d bemonit ored manuall y unti l the fault is recti fi ed.For addit ional informat ion, refer t o: W heels and Ti res (204-04 W heels and Tires , Des cript ion and Operat ion).

Anti-lock Brake System Warning Indicator

The Anti -l ock Brake Sys t em (ABS) warning i ndicat or is controll ed by the ABS module whi ch trans mi ts a high s peed CAN busmes s age to t he CJB. The CJB relays t he mes sage t o t he i ns t rument clus ter over the medi um s peed CAN bus . The warningindicat or i s il lumi nat ed i n an amber col or for 3 s econds for a bulb check by the ABS modul e when t he vehi cl e enters powermode 6. If the warning i ndi cat or remains ill uminat ed or ill uminat es when drivi ng, an ABS fault has occurred and t he ABSfuncti on wil l not be avai lable.

Duri ng the bul b check, if t he warni ng indicator comes on for 0.5 s econd, t hen goes off for 0.5 second and is then

Page 1821 of 3229

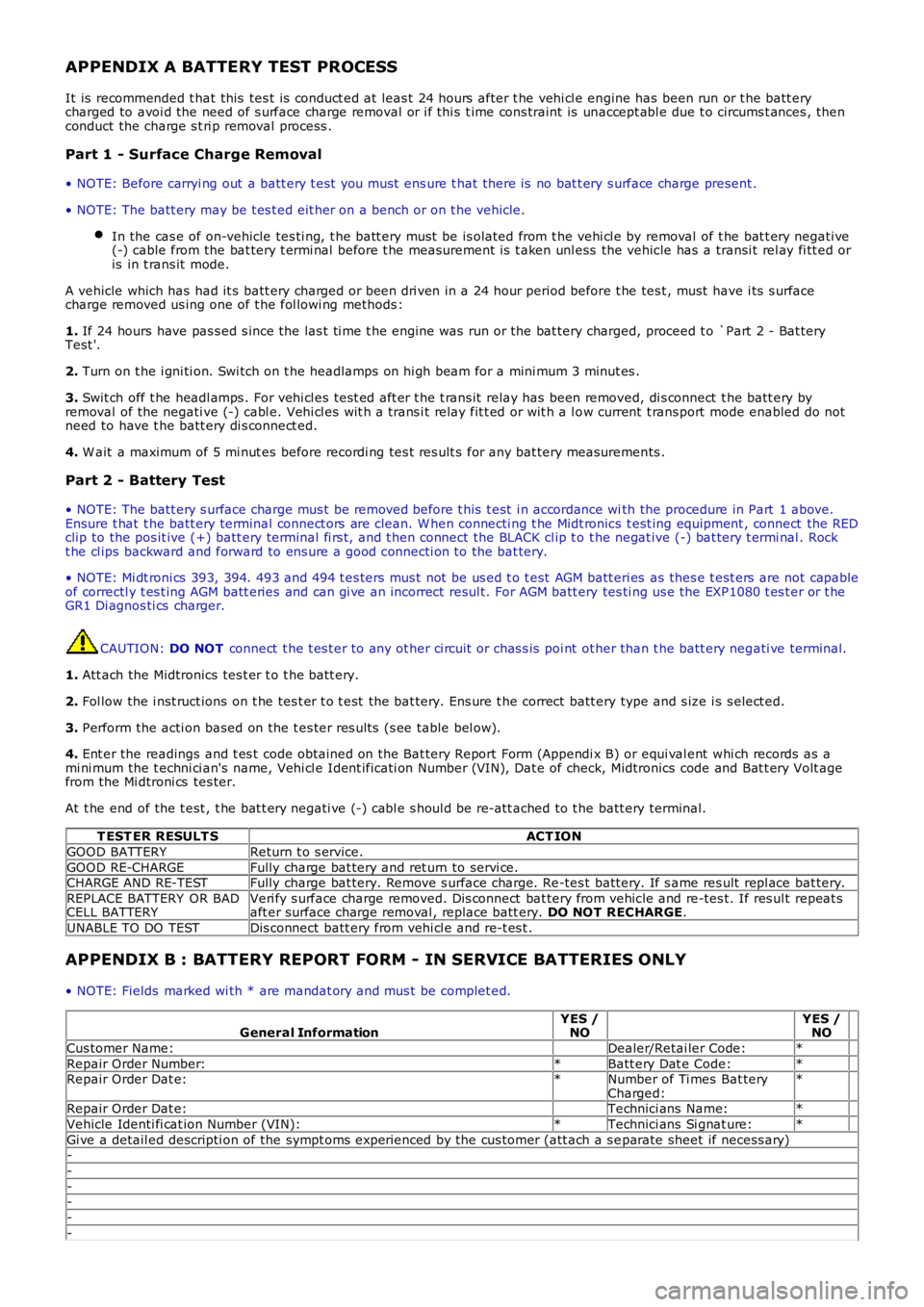

APPENDIX A BATTERY TEST PROCESS

It is recommended t hat this tes t is conduct ed at leas t 24 hours after t he vehi cl e engine has been run or t he batt erycharged to avoi d the need of s urface charge removal or i f thi s t ime cons traint is unaccept abl e due t o circums t ances , thenconduct the charge s t ri p removal process .

Part 1 - Surface Charge Removal

• NOTE: Before carryi ng out a batt ery t est you must ens ure t hat there is no bat t ery s urface charge present .

• NOTE: The batt ery may be t es t ed eit her on a bench or on t he vehicle.

In the cas e of on-vehicle tes ti ng, t he batt ery must be is olated from t he vehi cl e by removal of t he bat t ery negati ve(-) cable from the bat tery t ermi nal before t he measurement is t aken unl ess the vehicle has a transi t rel ay fi tt ed oris in t rans it mode.

A vehicle which has had it s batt ery charged or been dri ven in a 24 hour period before t he tes t , must have i ts s urfacecharge removed us ing one of t he fol lowi ng methods :

1. If 24 hours have pas s ed s ince the las t ti me t he engine was run or the bat tery charged, proceed t o `Part 2 - Bat teryTest '.

2. Turn on t he i gni ti on. Swi tch on t he headlamps on hi gh beam for a mini mum 3 minut es .

3. Swit ch off t he headl amps . For vehi cl es tes t ed aft er t he t rans it relay has been removed, di s connect t he batt ery byremoval of the negati ve (-) cabl e. Vehi cl es wit h a trans i t relay fit t ed or wit h a l ow current t rans port mode enabled do notneed to have t he batt ery di s connect ed.

4. W ait a maximum of 5 mi nut es before recordi ng tes t res ult s for any bat tery measurements .

Part 2 - Battery Test

• NOTE: The batt ery s urface charge mus t be removed before t his t est i n accordance with the procedure in Part 1 above.Ensure t hat t he batt ery terminal connect ors are clean. W hen connecti ng t he Midt ronics t est ing equipment , connect the REDclip to the pos it ive (+) batt ery terminal fi rs t, and t hen connect the BLACK cl ip t o t he negat ive (-) bat tery t ermi nal . Rockt he cl ips backward and forward to ens ure a good connecti on to the bat tery.

• NOTE: Mi dt roni cs 393, 394. 493 and 494 t es ters mus t not be us ed t o t est AGM batt eri es as thes e t est ers are not capableof correctl y t es t ing AGM batt eries and can gi ve an incorrect resul t. For AGM batt ery tes ti ng us e the EXP1080 t es t er or t heGR1 Di agnos ti cs charger.

CAUTION: DO NOT connect t he t es t er to any ot her ci rcuit or chas s is poi nt ot her than t he batt ery negati ve terminal.

1. Att ach the Midtronics tes t er t o t he batt ery.

2. Fol low the i nst ruct ions on t he tes t er t o t est the bat tery. Ens ure t he correct batt ery type and s ize i s s elect ed.

3. Perform the acti on based on the t es ter res ult s (s ee table bel ow).

4. Ent er the readings and t es t code obtained on the Bat tery Report Form (Appendi x B) or equi val ent whi ch records as ami ni mum the t echni ci an's name, Vehi cl e Ident ificati on Number (VIN), Dat e of check, Midtronics code and Bat t ery Volt agefrom the Mi dtroni cs tes ter.

At t he end of the t est , t he bat t ery negati ve (-) cabl e s houl d be re-att ached to t he batt ery terminal.

T EST ER RESULT SACT ION

GOOD BATTERYReturn t o s ervice.

GOOD RE-CHARGEFully charge bat tery and ret urn to servi ce.CHARGE AND RE-TESTFully charge bat tery. Remove s urface charge. Re-tes t batt ery. If s ame res ult repl ace bat tery.

REPLACE BATTERY OR BADCELL BATTERYVeri fy s urface charge removed. Dis connect bat tery from vehicle and re-tes t. If res ult repeat saft er surface charge removal , replace batt ery. DO NOT RECHARGE.

UNABLE TO DO TESTDis connect batt ery from vehi cl e and re-t es t .

APPENDIX B : BATTERY REPORT FORM - IN SERVICE BATTERIES ONLY

• NOTE: Fields marked wi th * are mandat ory and mus t be complet ed.

General InformationYES /NO YES /NO

Cus tomer Name: Dealer/Retai ler Code:*

Repair Order Number:*Batt ery Dat e Code:* Repair Order Dat e:*Number of Ti mes Bat teryCharged:*

Repair Order Dat e: Technici ans Name:*

Vehicle Identi fi cat ion Number (VIN):*Technici ans Si gnat ure:*

Gi ve a detail ed descripti on of the sympt oms experienced by the cus tomer (att ach a s eparate sheet if necess ary)-

-

--

-

-