oil level LEXUS LS430 2003 Factory User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 3285 of 4500

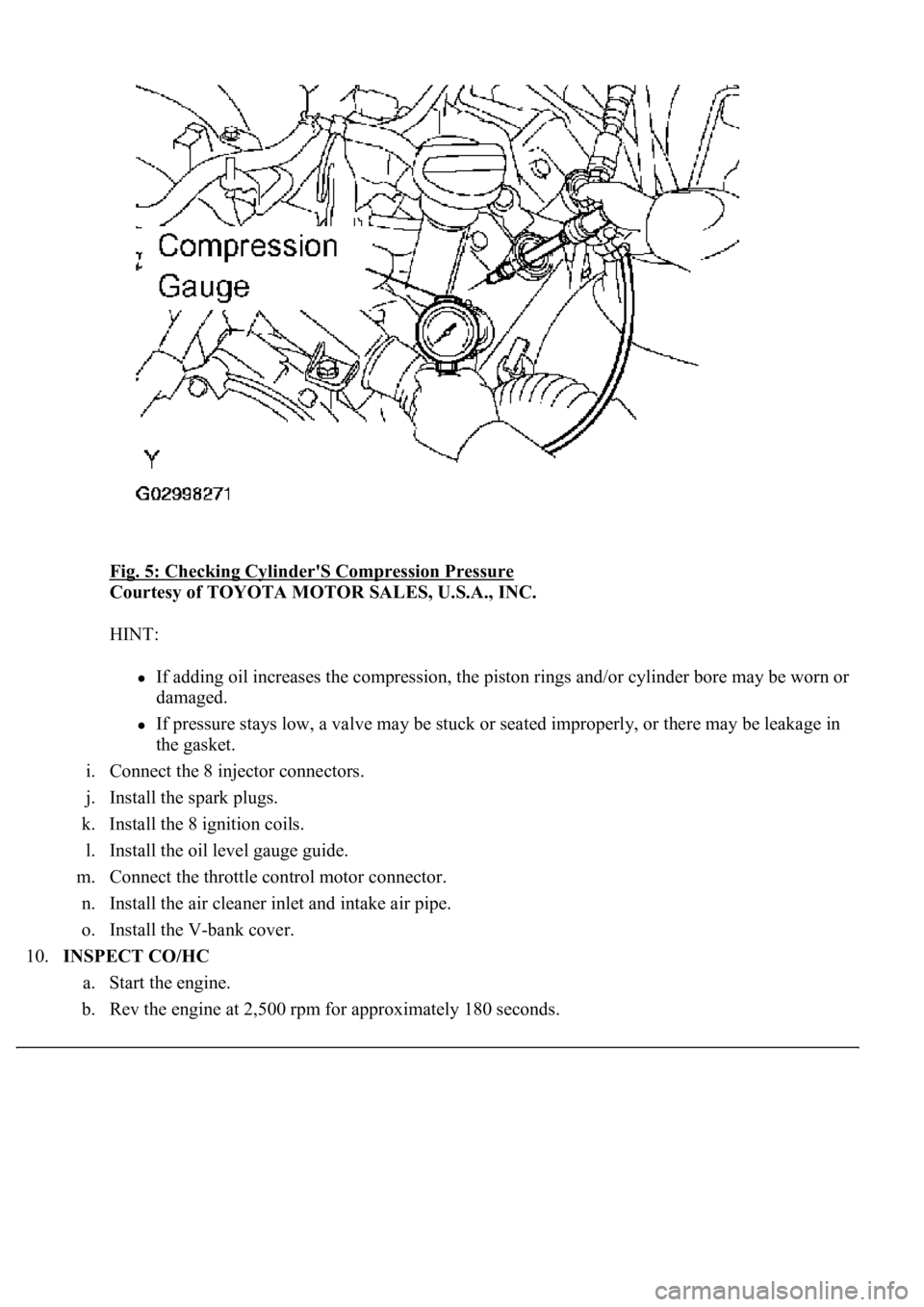

Fig. 5: Checking Cylinder'S Compression Pressure

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

If adding oil increases the compression, the piston rings and/or cylinder bore may be worn or

damaged.

If pressure stays low, a valve may be stuck or seated improperly, or there may be leakage in

the gasket.

i. Connect the 8 injector connectors.

j. Install the spark plugs.

k. Install the 8 ignition coils.

l. Install the oil level gauge guide.

m. Connect the throttle control motor connector.

n. Install the air cleaner inlet and intake air pipe.

o. Install the V-bank cover.

10.INSPECT CO/HC

a. Start the engine.

b. Rev the engine at 2,500 rpm for approximately 180 seconds.

Page 3318 of 4500

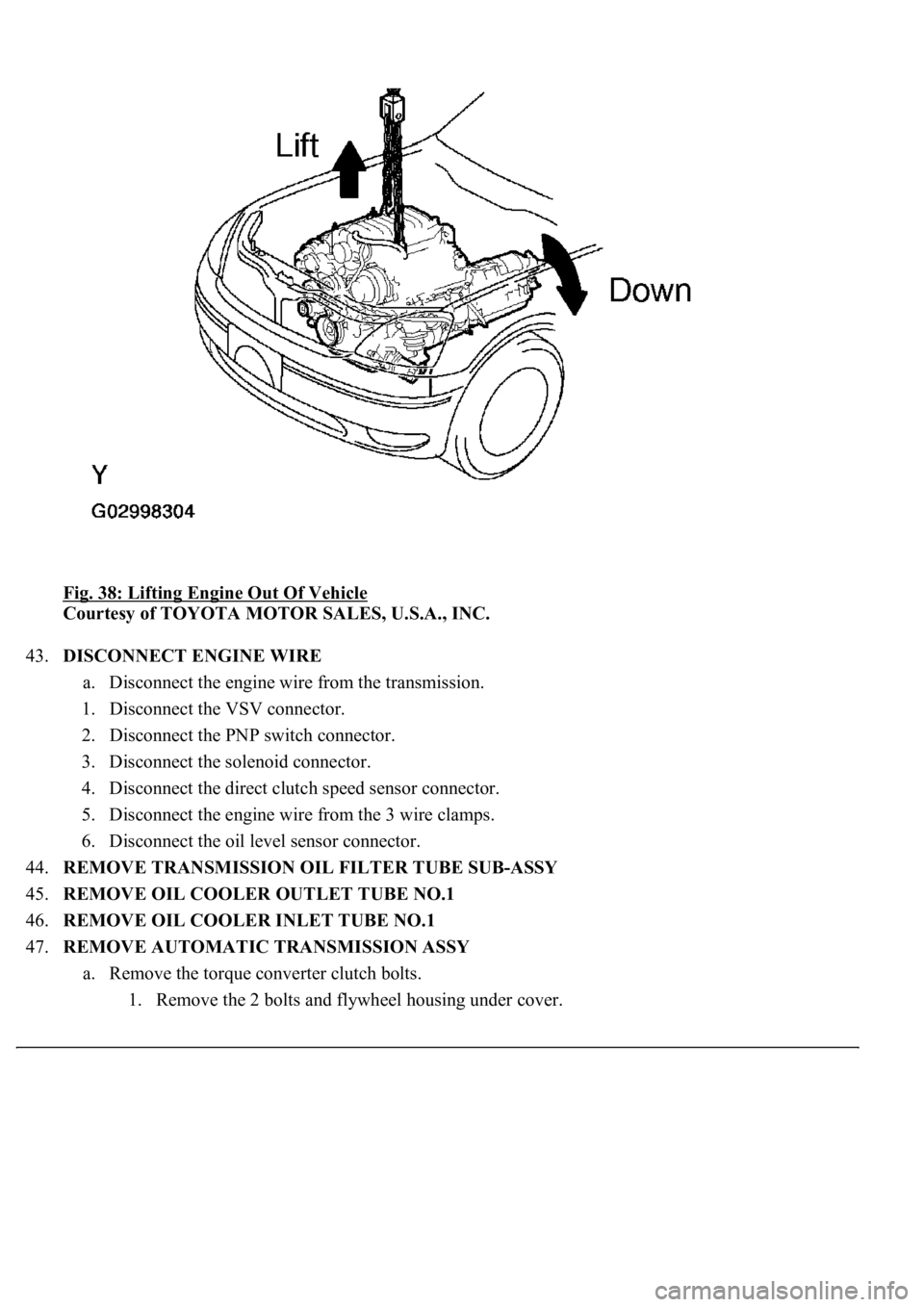

Fig. 38: Lifting Engine Out Of Vehicle

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

43.DISCONNECT ENGINE WIRE

a. Disconnect the engine wire from the transmission.

1. Disconnect the VSV connector.

2. Disconnect the PNP switch connector.

3. Disconnect the solenoid connector.

4. Disconnect the direct clutch speed sensor connector.

5. Disconnect the engine wire from the 3 wire clamps.

6. Disconnect the oil level sensor connector.

44.REMOVE TRANSMISSION OIL FILTER TUBE SUB-ASSY

45.REMOVE OIL COOLER OUTLET TUBE NO.1

46.REMOVE OIL COOLER INLET TUBE NO.1

47.REMOVE AUTOMATIC TRANSMISSION ASSY

a. Remove the torque converter clutch bolts.

1. Remove the 2 bolts and fl

ywheel housing under cover.

Page 3327 of 4500

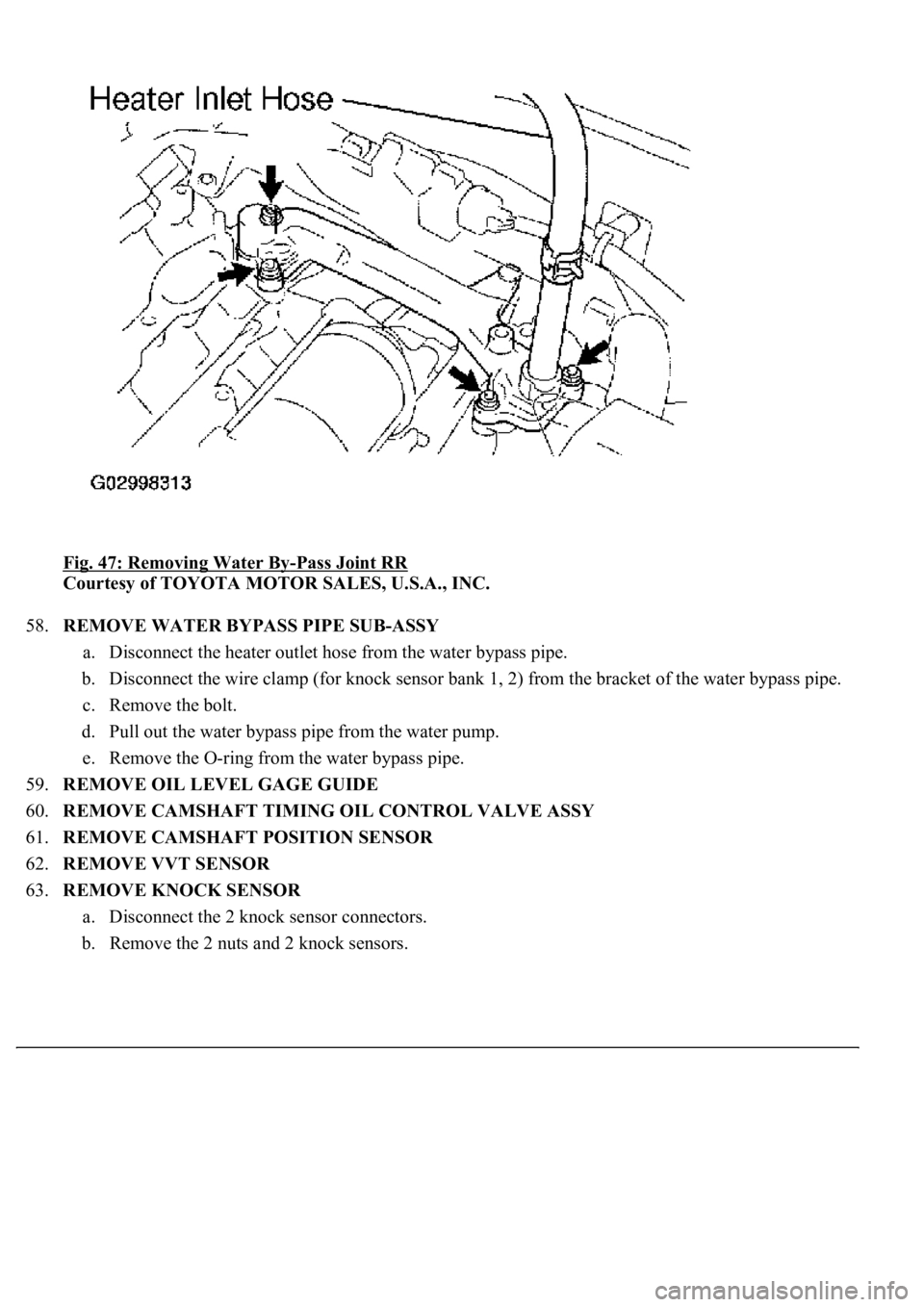

Fig. 47: Removing Water By-Pass Joint RR

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

58.REMOVE WATER BYPASS PIPE SUB-ASSY

a. Disconnect the heater outlet hose from the water bypass pipe.

b. Disconnect the wire clamp (for knock sensor bank 1, 2) from the bracket of the water bypass pipe.

c. Remove the bolt.

d. Pull out the water bypass pipe from the water pump.

e. Remove the O-ring from the water bypass pipe.

59.REMOVE OIL LEVEL GAGE GUIDE

60.REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSY

61.REMOVE CAMSHAFT POSITION SENSOR

62.REMOVE VVT SENSOR

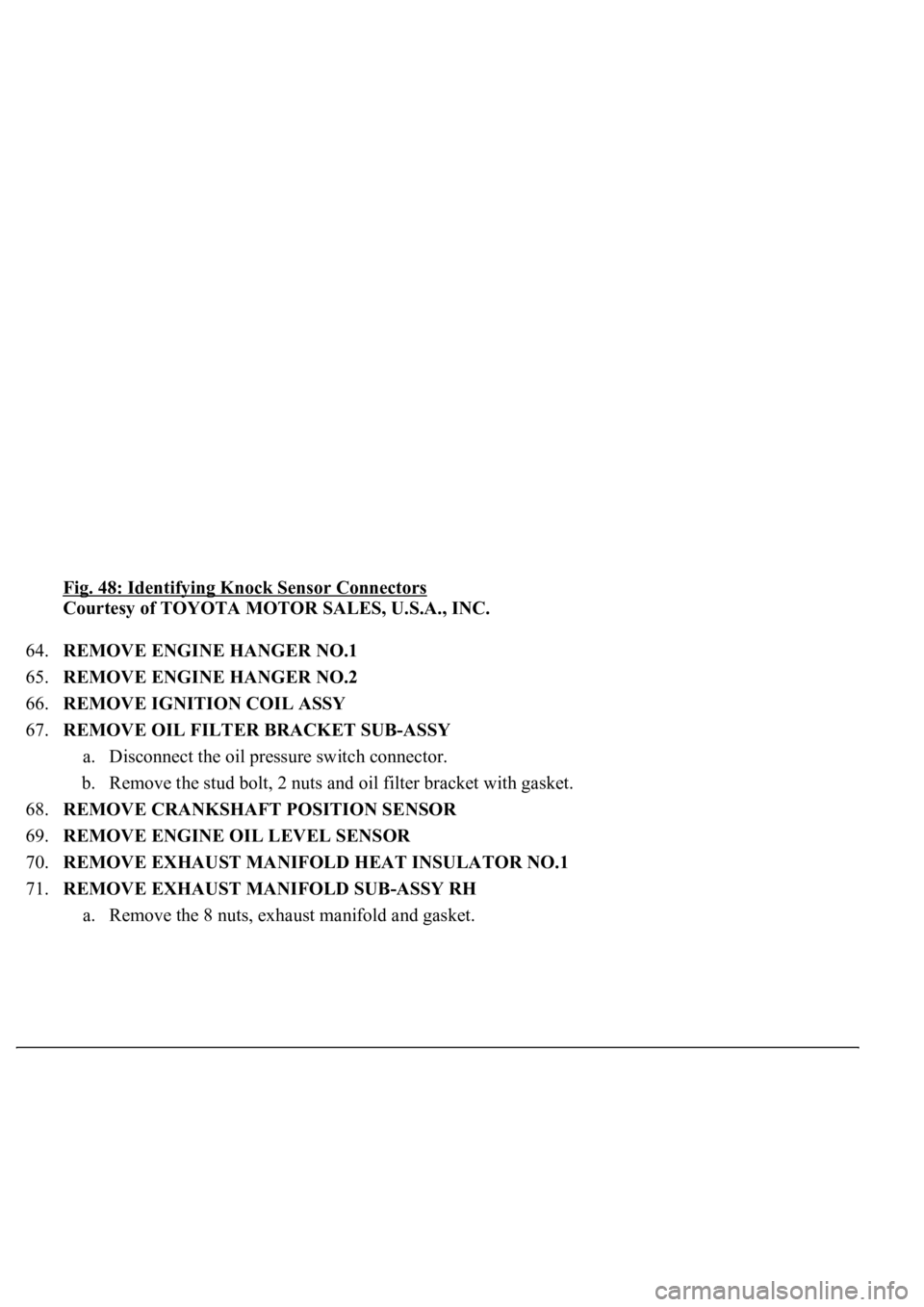

63.REMOVE KNOCK SENSOR

a. Disconnect the 2 knock sensor connectors.

b. Remove the 2 nuts and 2 knock sensors.

Page 3328 of 4500

Fig. 48: Identifying Knock Sensor Connectors

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

64.REMOVE ENGINE HANGER NO.1

65.REMOVE ENGINE HANGER NO.2

66.REMOVE IGNITION COIL ASSY

67.REMOVE OIL FILTER BRACKET SUB-ASSY

a. Disconnect the oil pressure switch connector.

b. Remove the stud bolt, 2 nuts and oil filter bracket with gasket.

68.REMOVE CRANKSHAFT POSITION SENSOR

69.REMOVE ENGINE OIL LEVEL SENSOR

70.REMOVE EXHAUST MANIFOLD HEAT INSULATOR NO.1

71.REMOVE EXHAUST MANIFOLD SUB-ASSY RH

a. Remove the 8 nuts, exhaust manifold and

gasket.

Page 3338 of 4500

Fig. 58: Installing Exhaust Manifold

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

85.INSTALL EXHAUST MANIFOLD HEAT INSULATOR NO.1

86.INSTALL ENGINE OIL LEVEL SENSOR

87.INSTALL CRANKSHAFT POSITION SENSOR (See REPLACEMENT

)

88.INSTALL OIL FILTER BRACKET SUB-ASSY

Torque: 18 N.m (184 kgf.cm, 13 ft.lbf)

89.INSTALL IGNITION COIL ASSY

Torque: 7.5 N.m (77 kgf.cm, 66 in.lbf)

90.INSTALL ENGINE HANGER NO.2

Torque: 37 N.m (377 kgf.cm, 27 ft.lbf)

91.INSTALL ENGINE HANGER NO. 1

Torque: 37 N.m (377 kgf.cm, 27 ft.lbf)

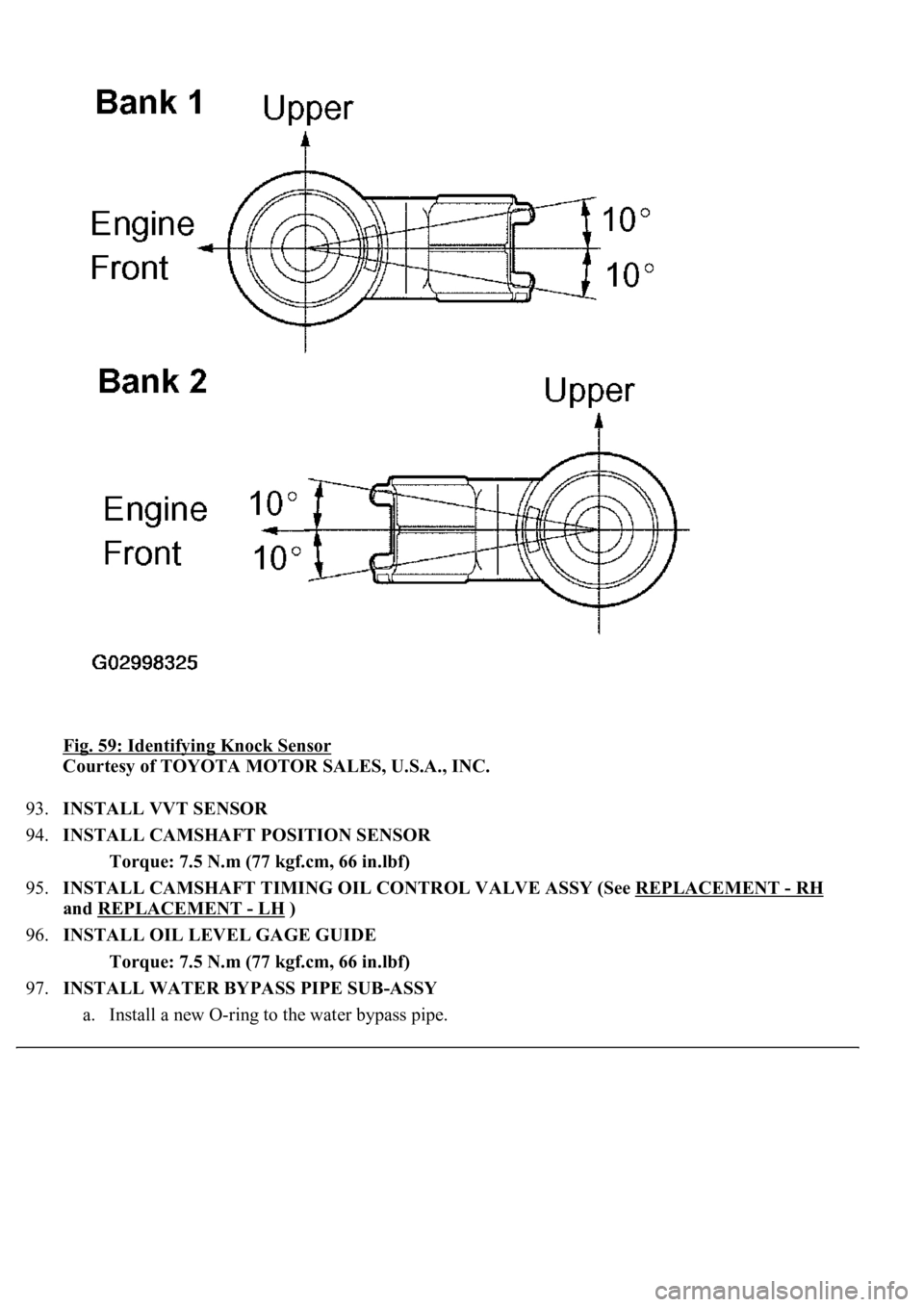

92.INSTALL KNOCK SENSOR

a. Install the 2 knock sensors with the 2 nuts, as shown in the illustration.

Torque: 20 N.m (204 kgf.cm, 15 ft.lbf)

b. Connect the 2 knock sensor connectors.

Page 3339 of 4500

Fig. 59: Identifying Knock Sensor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

93.INSTALL VVT SENSOR

94.INSTALL CAMSHAFT POSITION SENSOR

Torque: 7.5 N.m (77 kgf.cm, 66 in.lbf)

95.INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSY (See REPLACEMENT

- RH

and REPLACEMENT

- LH )

96.INSTALL OIL LEVEL GAGE GUIDE

Torque: 7.5 N.m (77 kgf.cm, 66 in.lbf)

97.INSTALL WATER BYPASS PIPE SUB-ASSY

a. Install a new O-rin

g to the water bypass pipe.

Page 3352 of 4500

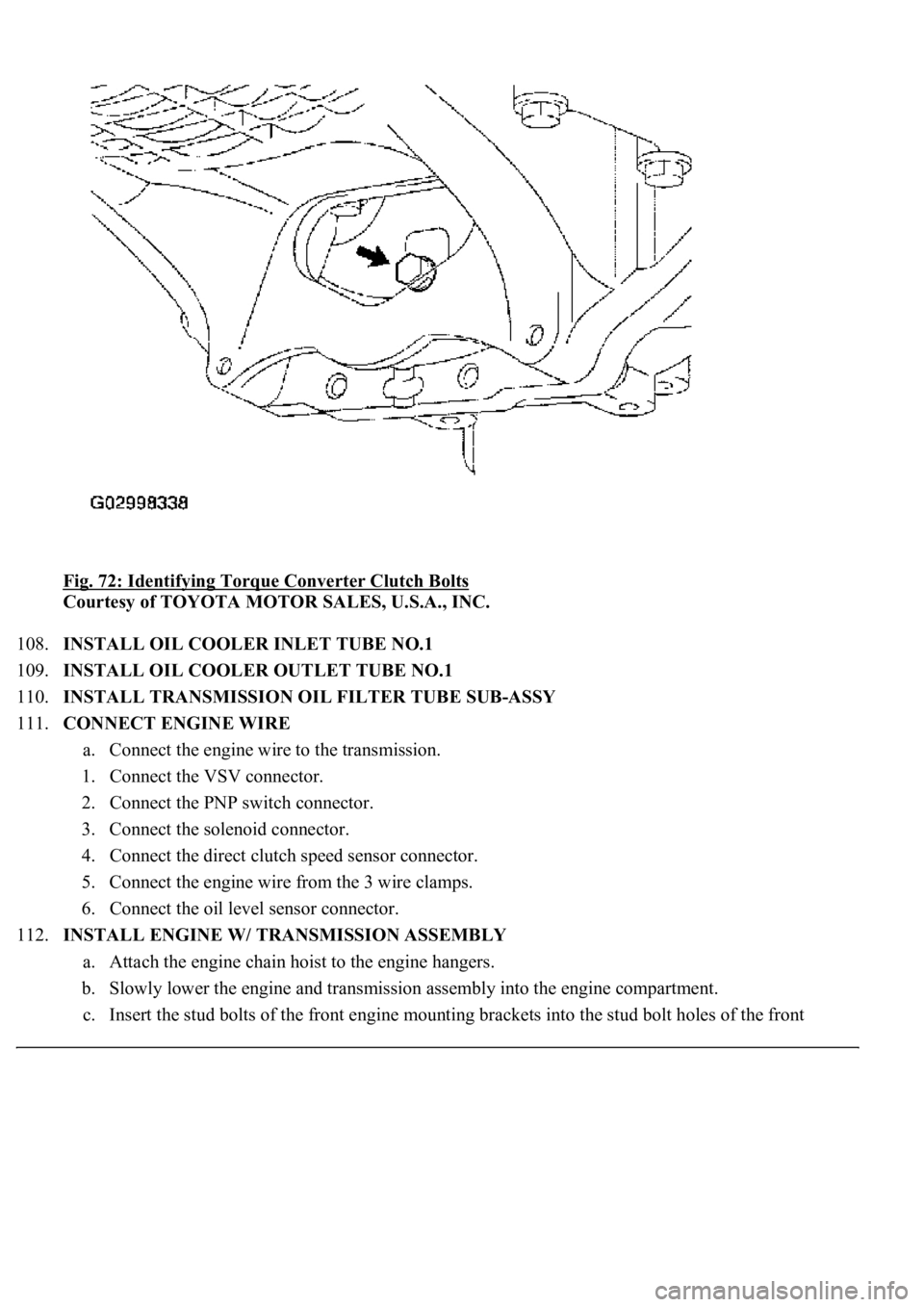

Fig. 72: Identifying Torque Converter Clutch Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

108.INSTALL OIL COOLER INLET TUBE NO.1

109.INSTALL OIL COOLER OUTLET TUBE NO.1

110.INSTALL TRANSMISSION OIL FILTER TUBE SUB-ASSY

111.CONNECT ENGINE WIRE

a. Connect the engine wire to the transmission.

1. Connect the VSV connector.

2. Connect the PNP switch connector.

3. Connect the solenoid connector.

4. Connect the direct clutch speed sensor connector.

5. Connect the engine wire from the 3 wire clamps.

6. Connect the oil level sensor connector.

112.INSTALL ENGINE W/ TRANSMISSION ASSEMBLY

a. Attach the engine chain hoist to the engine hangers.

b. Slowly lower the engine and transmission assembly into the engine compartment.

c. Insert the stud bolts of the front en

gine mounting brackets into the stud bolt holes of the front

Page 3766 of 4500

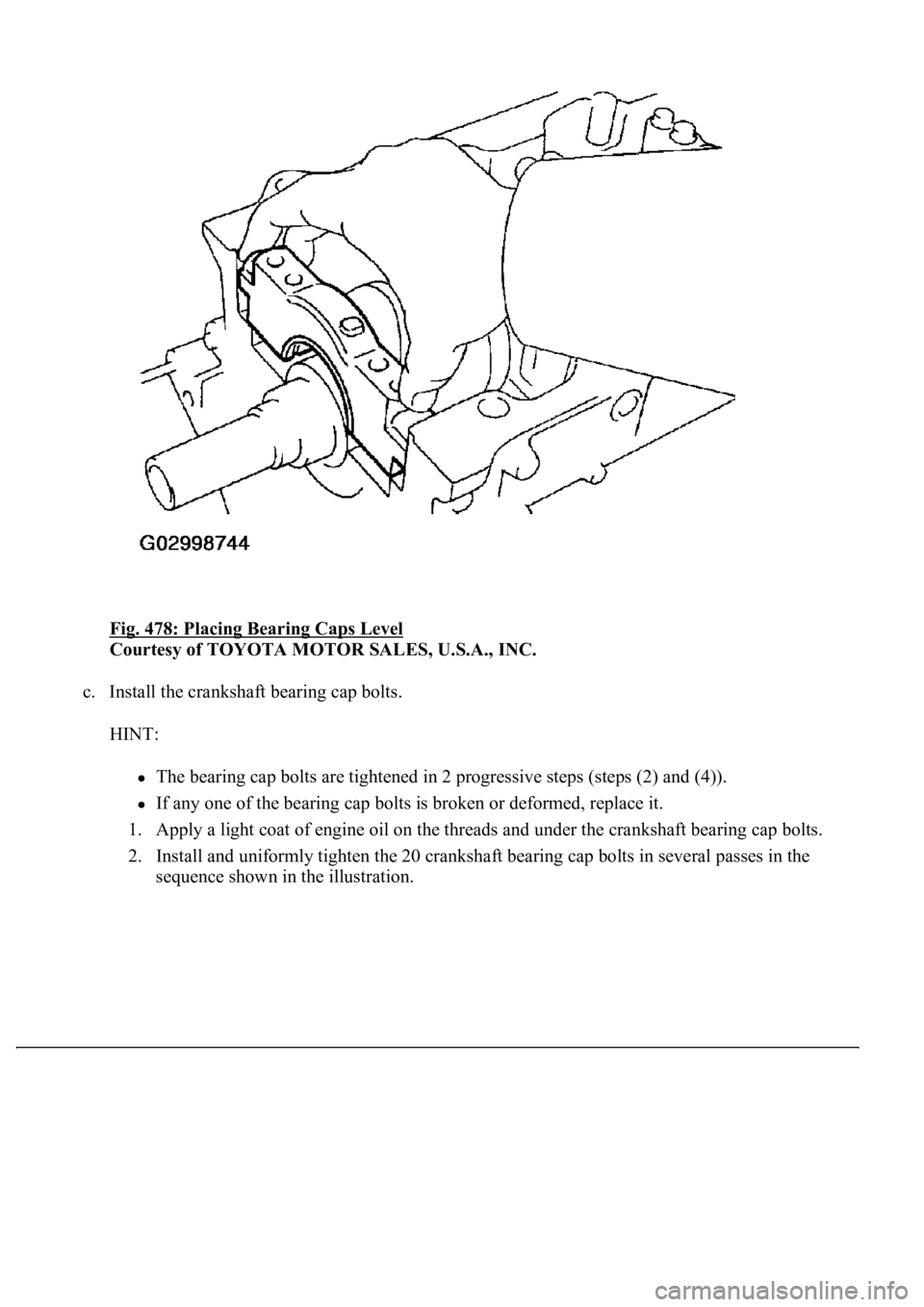

Fig. 478: Placing Bearing Caps Level

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Install the crankshaft bearing cap bolts.

HINT:

The bearing cap bolts are tightened in 2 progressive steps (steps (2) and (4)).

If any one of the bearing cap bolts is broken or deformed, replace it.

1. Apply a light coat of engine oil on the threads and under the crankshaft bearing cap bolts.

2. Install and uniformly tighten the 20 crankshaft bearing cap bolts in several passes in the

sequence shown in the illustration.

Page 4339 of 4500

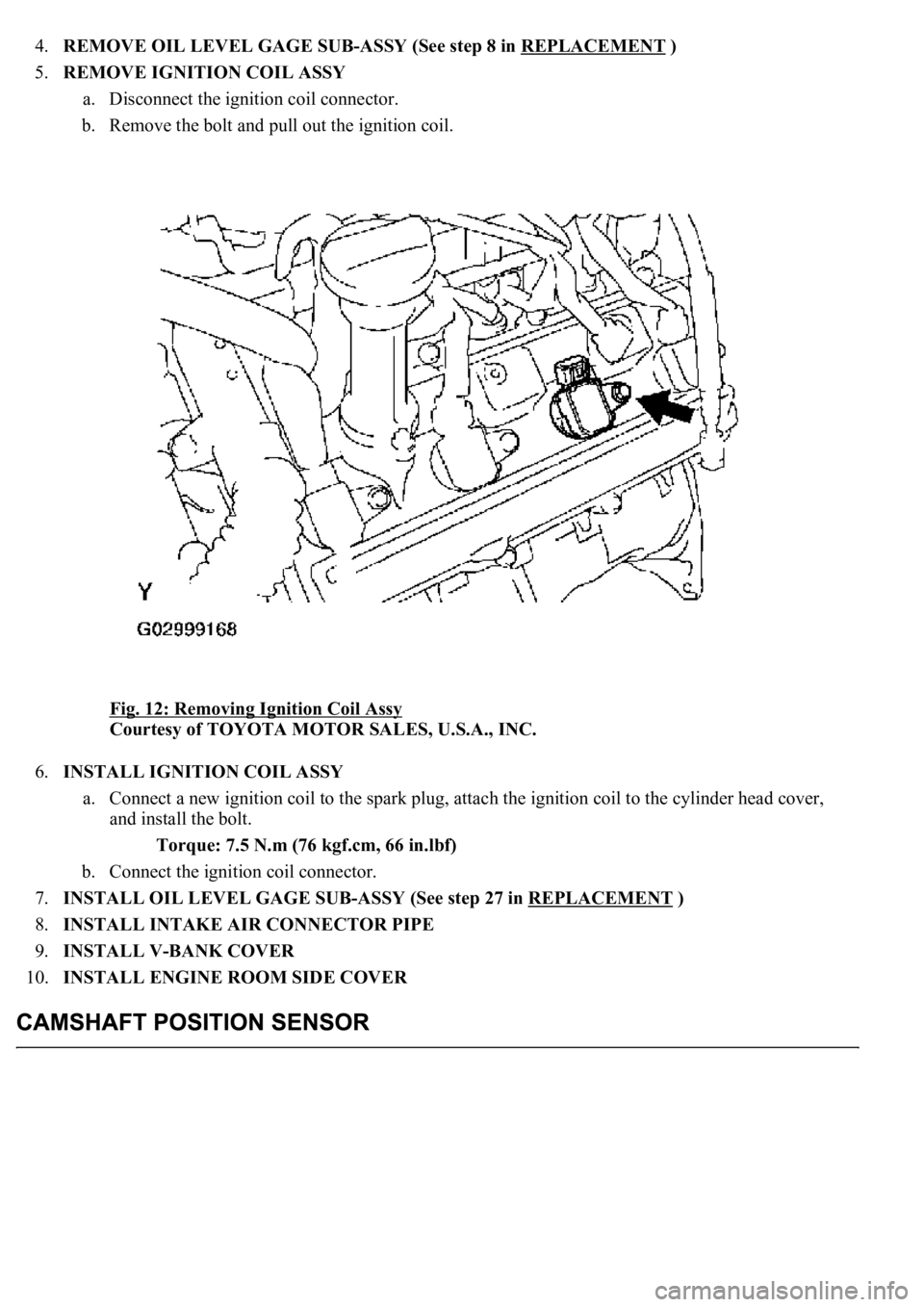

4.REMOVE OIL LEVEL GAGE SUB-ASSY (See step 8 in REPLACEMENT )

5.REMOVE IGNITION COIL ASSY

a. Disconnect the ignition coil connector.

b. Remove the bolt and pull out the ignition coil.

Fig. 12: Removing Ignition Coil Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

6.INSTALL IGNITION COIL ASSY

a. Connect a new ignition coil to the spark plug, attach the ignition coil to the cylinder head cover,

and install the bolt.

Torque: 7.5 N.m (76 kgf.cm, 66 in.lbf)

b. Connect the ignition coil connector.

7.INSTALL OIL LEVEL GAGE SUB-ASSY (See step 27 in REPLACEMENT

)

8.INSTALL INTAKE AIR CONNECTOR PIPE

9.INSTALL V-BANK COVER

10.INSTALL ENGINE ROOM SIDE COVER