ignition LEXUS LS430 2003 Factory Owner's Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 105 of 4500

HINT:

This DTC is output when the VSC system detects a malfunction in the ABS system.

When DTC C1223/43 is memorized, there is no malfunction in the skid control ECU.

CIRCUIT DESCRIPTION

DTC DETECTING CONDITION DESCRIPTION

INSPECTION PROCEDURE

1.CHECK DTC (FOR ABS SYSTEM)

a. Clear the DTC (see DTC CHECK/CLEAR

).

b. Turn the ignition switch to the ON position.

c. Check that the same DTC is recorded (see DTC CHECK/CLEAR

).

OK: Go to next step

The same DTC is recorded.

NG: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

HINT:

It is suspect that the DTCs output was caused by the poor connection of the connector terminal.

OK REPAIR CIRCUIT INDICATED BY OUTPUT DTC

CIRCUIT DESCRIPTION

The steering angle sensor signal is sent to the skid control ECU through the CAN communication system. When

there is a malfunction in the communication, it will be detected by the diagnosis function.

DTC No.DTC Detecting ConditionTrouble Area

C1223/43Malfunction in ABS control systemABS control system

Page 109 of 4500

NG: Go to step 3

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

3.CHECK TERMINAL VOLTAGE (STEERING ANGLE SENSOR CONNECTOR)

a. Remove the steering wheel and the column lower cover.

b. Disconnect the steering angle sensor connector.

c. Turn the ignition switch to the ON position.

d. Measure the voltage according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

e. Measure the voltage according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

Tester ConnectionSpecified Condition

S16-1 (IG1) - S16-2 (ESS)10 to 14V

Tester ConnectionSpecified Condition

S16-3 (BAT) -S16-2 (ESS)10 to 14V

Page 113 of 4500

When U0123/62, U0124/95 or U0126/63 are output together with C1232/32, C1234/34, C1243/43, C1244/44,

C1245/45, and C1381/97 inspect and repair the trouble areas indicated by U0121/94, U0123/62, U0124/95 or

U0126/63 first.

1.CHECK SENSOR INSTALLATION (YAW RATE SENSOR)

a. Check that the yaw rate and deceleration sensor has been installed properly (see

REPLACEMENT

).

OK: Go to next step

The sensor is tightened to the specified torque.

The sensor is not tilted.

NG: INSTALL YAW RATE SENSOR CORRECTLY

OK: Go to next step

2.CHECK HARNESS AND CONNECTOR (IG TERMINAL)

a. Disconnect the yaw rate and deceleration sensor connector.

b. Turn the ignition switch to the ON position.

c. Measure the voltage according to the value (s) in the table below.

Standard:

Page 119 of 4500

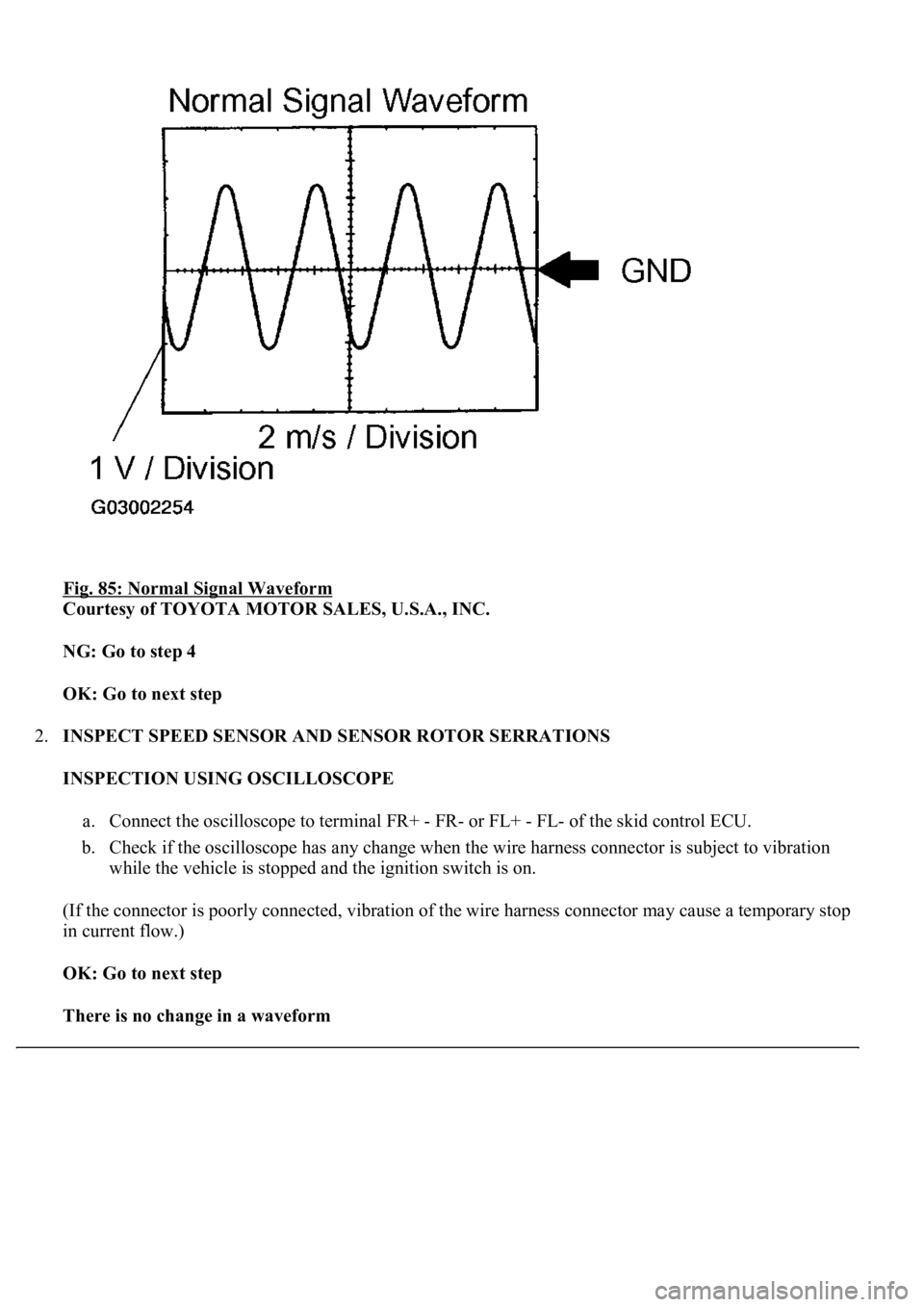

Fig. 85: Normal Signal Waveform

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: Go to step 4

OK: Go to next step

2.INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

INSPECTION USING OSCILLOSCOPE

a. Connect the oscilloscope to terminal FR+ - FR- or FL+ - FL- of the skid control ECU.

b. Check if the oscilloscope has any change when the wire harness connector is subject to vibration

while the vehicle is stopped and the ignition switch is on.

(If the connector is poorly connected, vibration of the wire harness connector may cause a temporary stop

in current flow.)

OK: Go to next step

There is no change in a waveform

Page 120 of 4500

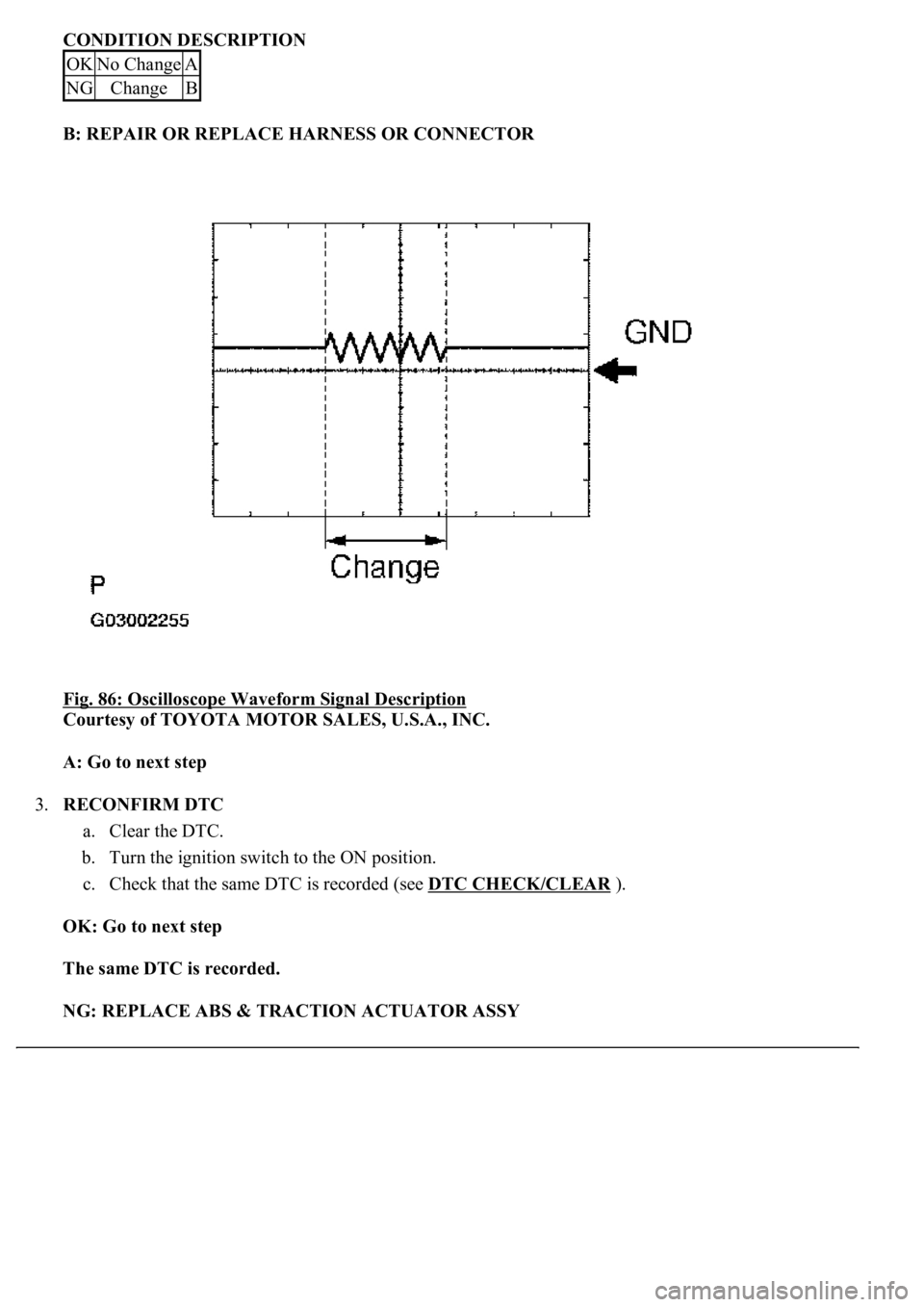

CONDITION DESCRIPTION

B: REPAIR OR REPLACE HARNESS OR CONNECTOR

Fig. 86: Oscilloscope Waveform Signal Description

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

A: Go to next step

3.RECONFIRM DTC

a. Clear the DTC.

b. Turn the ignition switch to the ON position.

c. Check that the same DTC is recorded (see DTC CHECK/CLEAR

).

OK: Go to next step

The same DTC is recorded.

NG: REPLACE ABS & TRACTION ACTUATOR ASSY

OKNo ChangeA

NGChangeB

Page 135 of 4500

OK: Go to next step

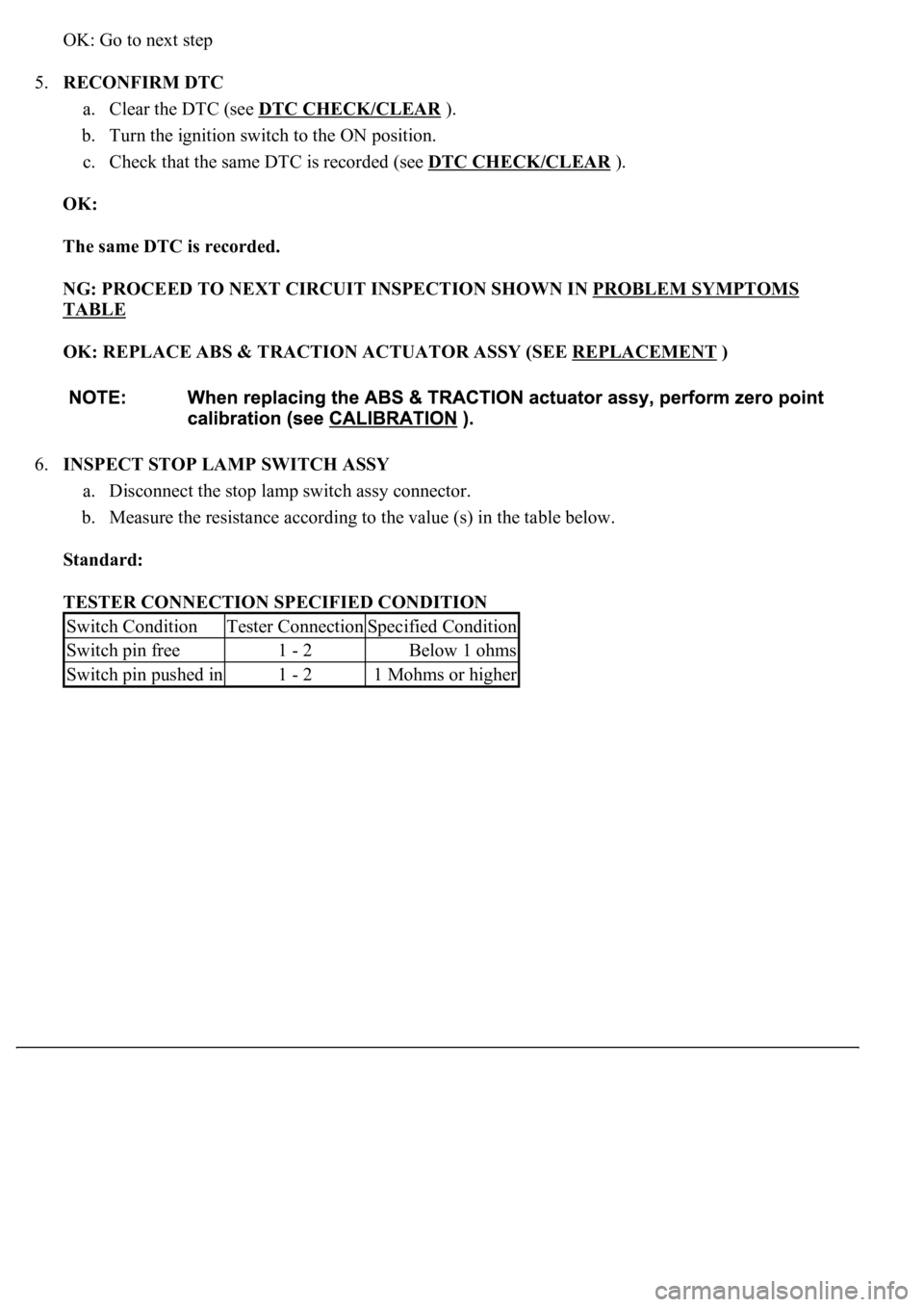

5.RECONFIRM DTC

a. Clear the DTC (see DTC CHECK/CLEAR

).

b. Turn the ignition switch to the ON position.

c. Check that the same DTC is recorded (see DTC CHECK/CLEAR

).

OK:

The same DTC is recorded.

NG: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

6.INSPECT STOP LAMP SWITCH ASSY

a. Disconnect the stop lamp switch assy connector.

b. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

Switch ConditionTester ConnectionSpecified Condition

Switch pin free1 - 2Below 1 ohms

Switch pin pushed in1 - 21 Mohms or higher

Page 140 of 4500

OK: Go to next step

9.RECONFIRM DTC

a. Clear the DTC (see DTC CHECK/CLEAR

).

b. Turn the ignition switch to the ON position.

c. Check that the same DTC is recorded (see DTC CHECK/CLEAR

).

OK:

The same DTC is recorded.

NG: PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS

TABLE

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

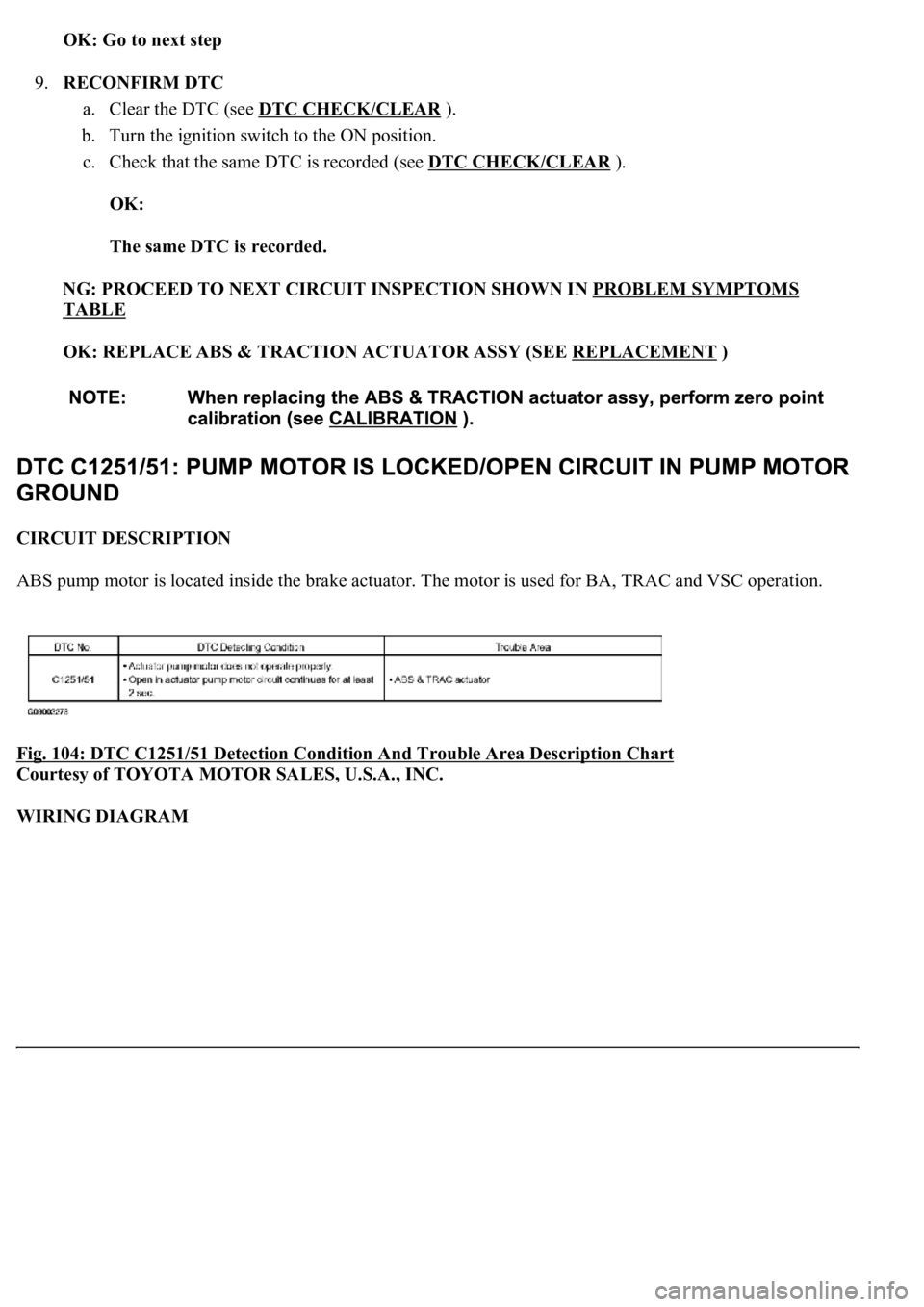

CIRCUIT DESCRIPTION

ABS pump motor is located inside the brake actuator. The motor is used for BA, TRAC and VSC operation.

Fig. 104: DTC C1251/51 Detection Condition And Trouble Area Description Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Page 145 of 4500

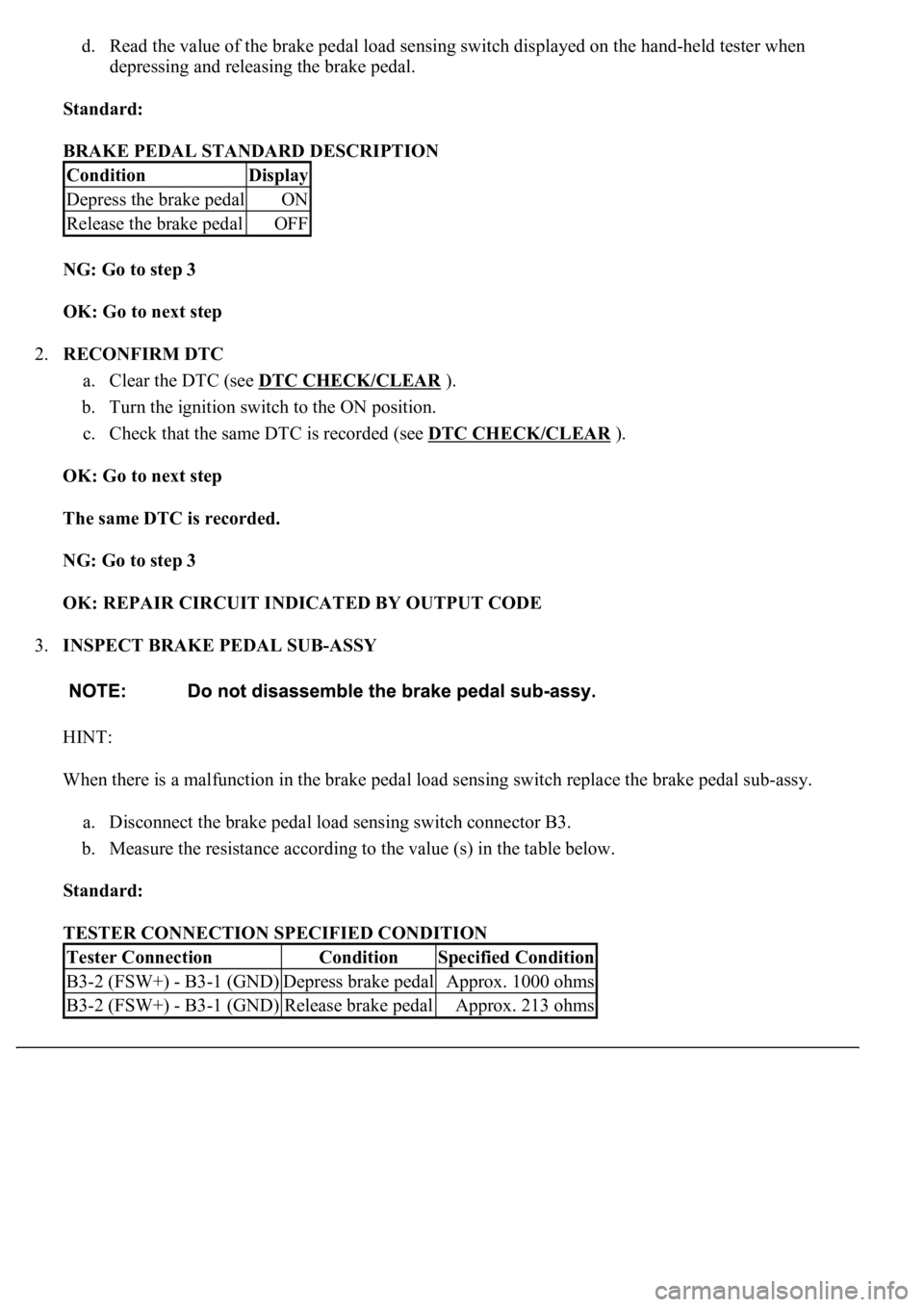

d. Read the value of the brake pedal load sensing switch displayed on the hand-held tester when

depressing and releasing the brake pedal.

Standard:

BRAKE PEDAL STANDARD DESCRIPTION

NG: Go to step 3

OK: Go to next step

2.RECONFIRM DTC

a. Clear the DTC (see DTC CHECK/CLEAR

).

b. Turn the ignition switch to the ON position.

c. Check that the same DTC is recorded (see DTC CHECK/CLEAR

).

OK: Go to next step

The same DTC is recorded.

NG: Go to step 3

OK: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

3.INSPECT BRAKE PEDAL SUB-ASSY

HINT:

When there is a malfunction in the brake pedal load sensing switch replace the brake pedal sub-assy.

a. Disconnect the brake pedal load sensing switch connector B3.

b. Measure the resistance according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

ConditionDisplay

Depress the brake pedalON

Release the brake pedalOFF

Tester ConnectionConditionSpecified Condition

B3-2 (FSW+) - B3-1 (GND)Depress brake pedalApprox. 1000 ohms

B3-2 (FSW+) - B3-1 (GND)Release brake pedalApprox. 213 ohms

Page 190 of 4500

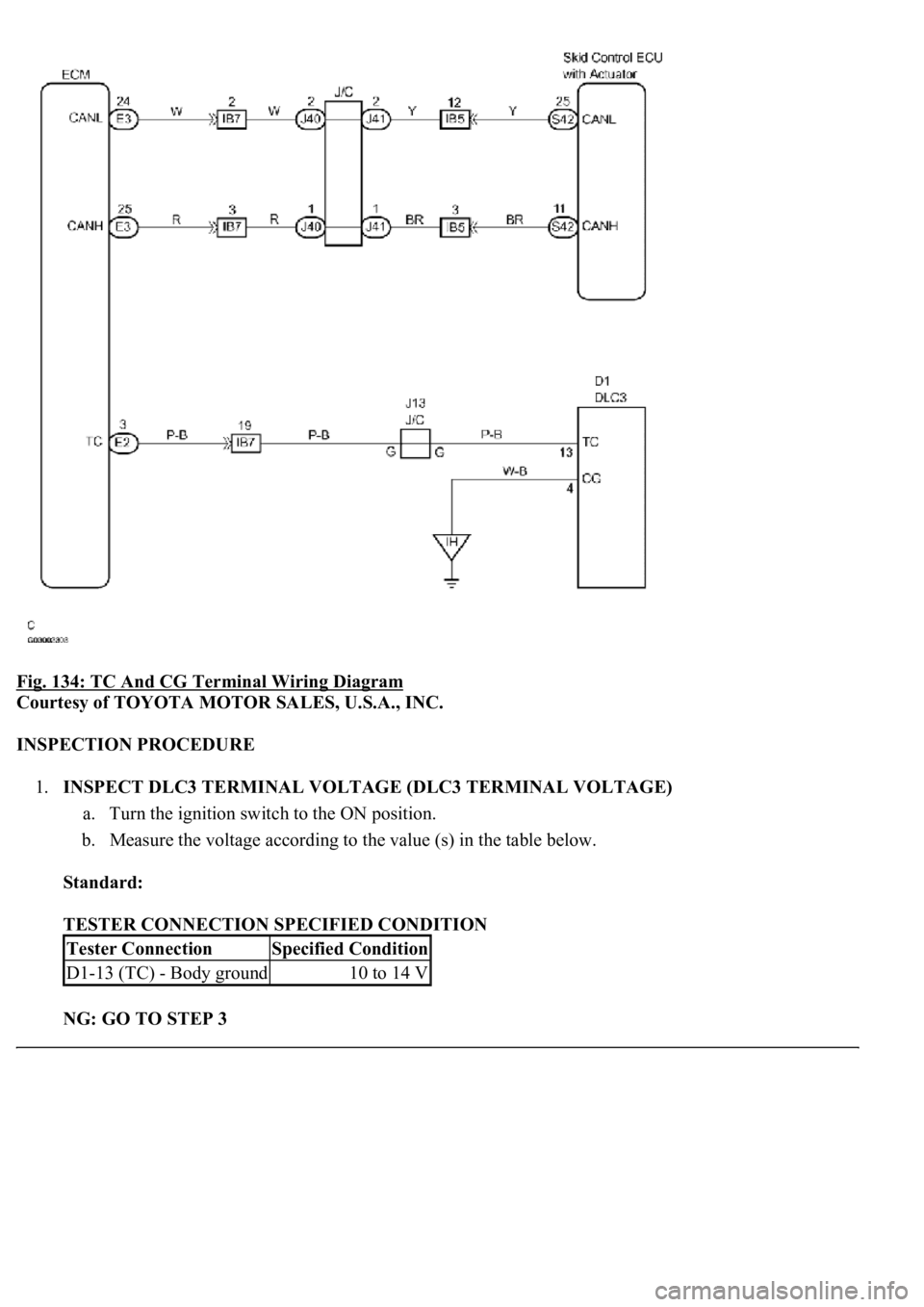

Fig. 134: TC And CG Terminal Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.INSPECT DLC3 TERMINAL VOLTAGE (DLC3 TERMINAL VOLTAGE)

a. Turn the ignition switch to the ON position.

b. Measure the voltage according to the value (s) in the table below.

Standard:

TESTER CONNECTION SPECIFIED CONDITION

NG: GO TO STEP 3

Tester ConnectionSpecified Condition

D1-13 (TC) - Body ground10 to 14 V

Page 195 of 4500

Result:

DTC OUTPUT DESCRIPTION

B: REPAIR CIRCUIT INDICATED BY OUTPUT CODE (SEE DIAGNOSTIC TROUBLE CODE

CHART )

A: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

In the sensor check mode, a malfunction of the speed sensor that cannot be detected when the vehicle is stopped

is detected while driving.

Transition to the sensor check mode can be performed by connecting terminals TS and CG of the DLC3 and

turning the ignition switch from off to the ON position.

WIRING DIAGRAM

DTC is not outputA

DTC is outputB