Rear LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 1 of 4500

LS430 SPECIFICATIONS INDEX

SystemSpecification/Procedure

Air Conditioning

ServiceSERVICE DATA

TorqueTORQUE SPECIFICATION

Axle Nut/Hub Nut

Front69 N.m (700 kgf.cm, 51 ft.lbf)

Rear290 N.m (2,960 kgf.cm, 214 ft.lbf)

BatteryNA

Brakes

Bleeding

SequenceBLEEDING

Disc BrakesSERVICE DATA

TorqueTORQUE SPECIFICATION

Charging

GeneratorSERVICE DATA

TorqueTORQUE SPECIFICATION

Drive Belts

AdjustmentREPLACEMENT

Belt RoutingDRIVE BELT

Engine Cooling

General Service

SpecificationsSERVICE DATA

Radiator Cap

PressureStandard Value

93 to 123 kPa (0.95 to 1.25 kgf/cm

2 , 13.5 to 17.8 psi)

Minimum Standard Value

78 kPa (0.8 kgf/cm

2 , 11.4 psi)

Thermostat R & ITHERMOSTAT

Water Pump R &

IWATER PUMP

Engine Mechanical

CompressionSERVICE DATA

Oil Pressureat idle, 29 kPa (0.3 kgf.cm2 , 43 psi) or more

at 3,000 rpm, 294 to 588 kPa (3.0 to 6.0 kgf.cm

2 , 43 to 85 psi)

OverhaulSERVICE DATA

TorqueTORQUE SPECIFICATION

Page 2 of 4500

Fluid SpecificationsSee FLUIDS under MAINTENANCE tab.

Flywheel/Flex Plate

(Drive Plate) TorqueStep1: 49 N.m (500 kgf.cm, 36 ft lbs)

Step2: Turn 90°

Fuel System

Pressure

Specification304 to 343 kPa (3.1 to 3.5 kgf/cm2 , 44 to 50 psi)

Fuel Pressure Test

ProcedureON-VEHICLE INSPECTION

Fuel Filter

LocationCOMPONENTS

Ignition

Firing Order &

Cylinder

IdentificationFIRING ORDER & CYLINDER IDENTIFICATION

Spark Plug

TypeND SK20R11

NGK 1FR6A11

GapStandard electrode gap: 1.0 - 1.1 mm (0.039 - 0.043 in.)

Maximum electrode gap: 1.3 mm (0.051 in.)

Torque7.5 N.m (76 kgf.cm, 66 ft.lbf)

Starting

StarterSERVICE DATA

TorqueTORQUE SPECIFICATION

Wheel Alignment

Front

Adjustment

SpecificationsSERVICE DATA

TorqueTORQUE SPECIFICATION

Rear

Adjustment

SpecificationsSERVICE DATA

TorqueTORQUE SPECIFICATION

Wheel & Tire

Wheel Lug Nut

Torque103 N.m (1,050 kgf.cm 76 ft.lbf)

Page 8 of 4500

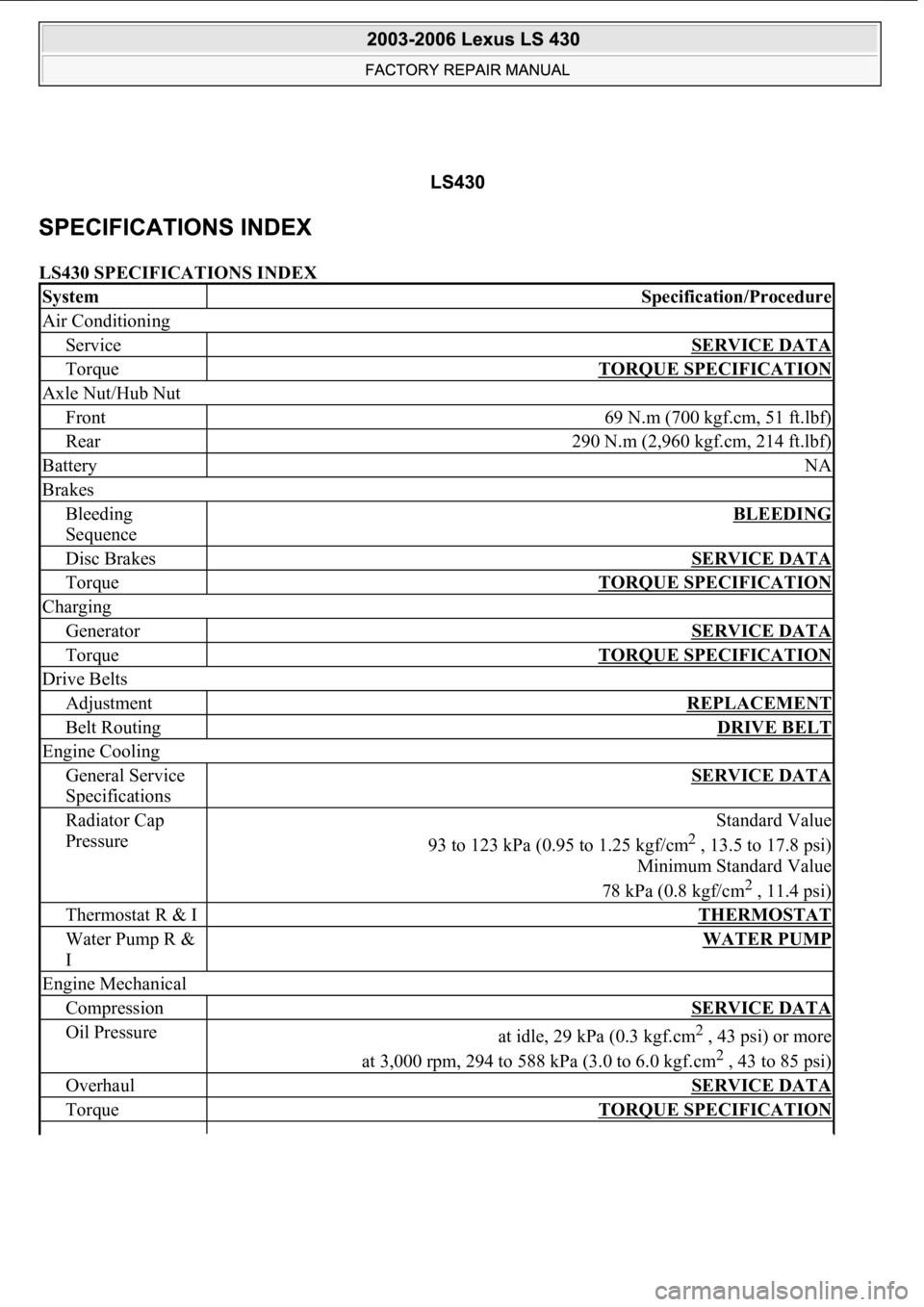

Fig. 4: ABS & TRACTION Actuator System Description

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Operation description

The skid control ECU detects wheel lock condition by receiving vehicle speed signals from each

<005600530048004800470003005600480051005600520055000f00030044005100470003005600480051004700560003004600520051005700550052004f00030056004c004a00510044004f005600030057005200030057004b0048000300530058005000

53000300500052005700520055000300440051004700030056[olenoid valve. The pump motor and

solenoid valve avoid wheel lock by controlling the oil pressure of each wheel cylinder.

The ABS warning lamp comes on when the ABS system is malfunctioning.

b. EBD (Electronic Brake force Distribution)

The EBD control utilizes ABS, realizing proper brake force distribution between front and rear

wheels in accordance with driving conditions.

In addition, during cornering braking, it also controls the brake forces of the right and left wheels,

helping to maintain vehicle behavior.

Page 9 of 4500

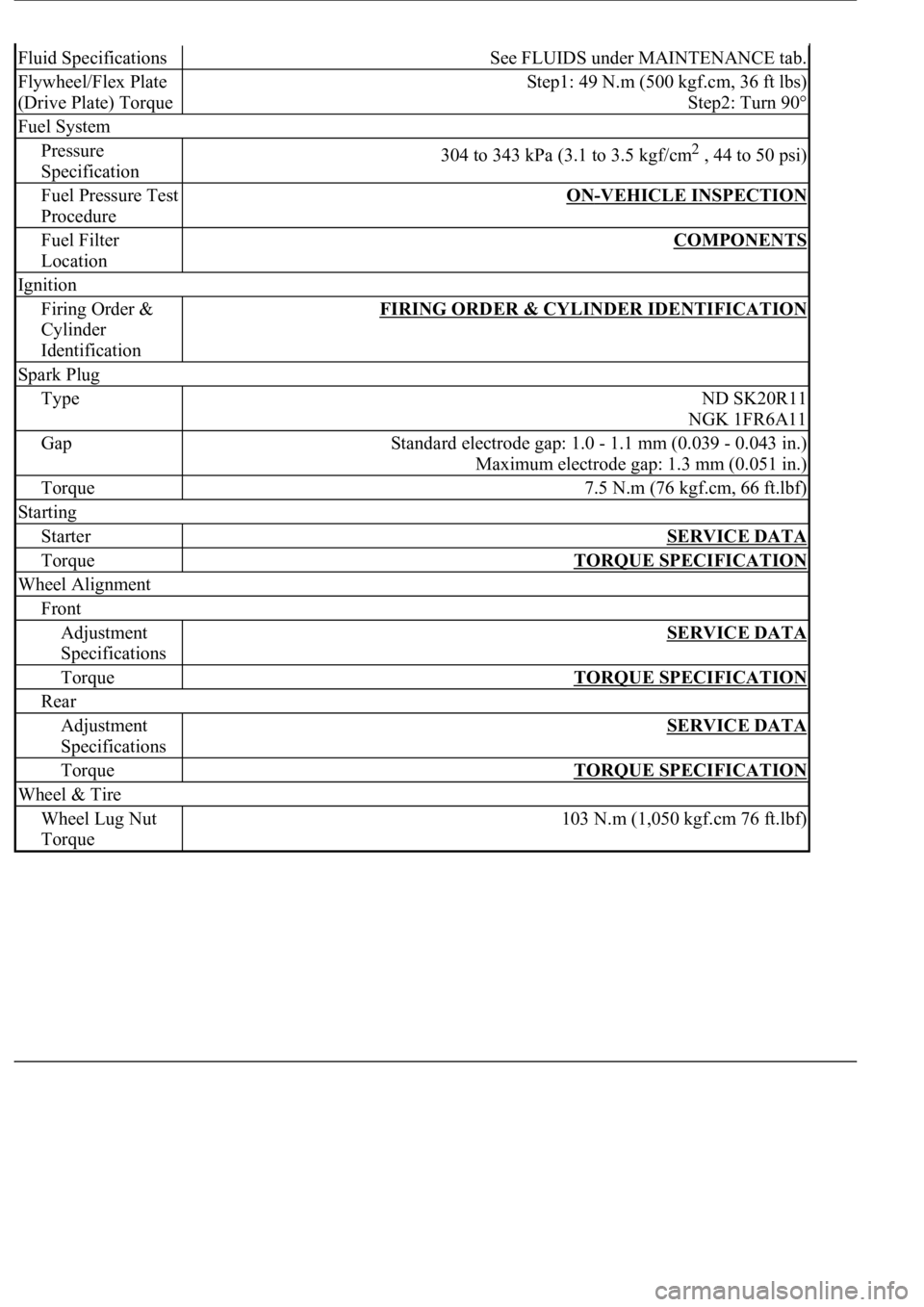

Fig. 5: ABS & TRACTION Actuator - Electronic Brake Force Distribution

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Operation description

The skid control ECU receives the speed signal from each speed sensor to detect the slip condition

<0052004900030057004b00480003005a004b00480048004f0056000300440051004700030056004800510047005600030057004b00480003004600520051005700550052004f00030056004c004a00510044004f00030057005200030057004b0048000300

560052004f004800510052004c004700110003[

The solenoid valve controls the oil pressure of each wheel cylinder and splits the control power

properly between the front and rear wheels and the right and rear wheels.

Both of the ABS warning lamp and the brake warning lamp come on to indicate a malfunction in

the EBD system.

c. BA (Brake Assist)

The primary purpose of the brake assist system is to provide an auxiliary brake force to assist the

driver who cannot generate a large enough brake force during emergency braking, thus helping to

maximize the vehicle's brake performance.

Page 11 of 4500

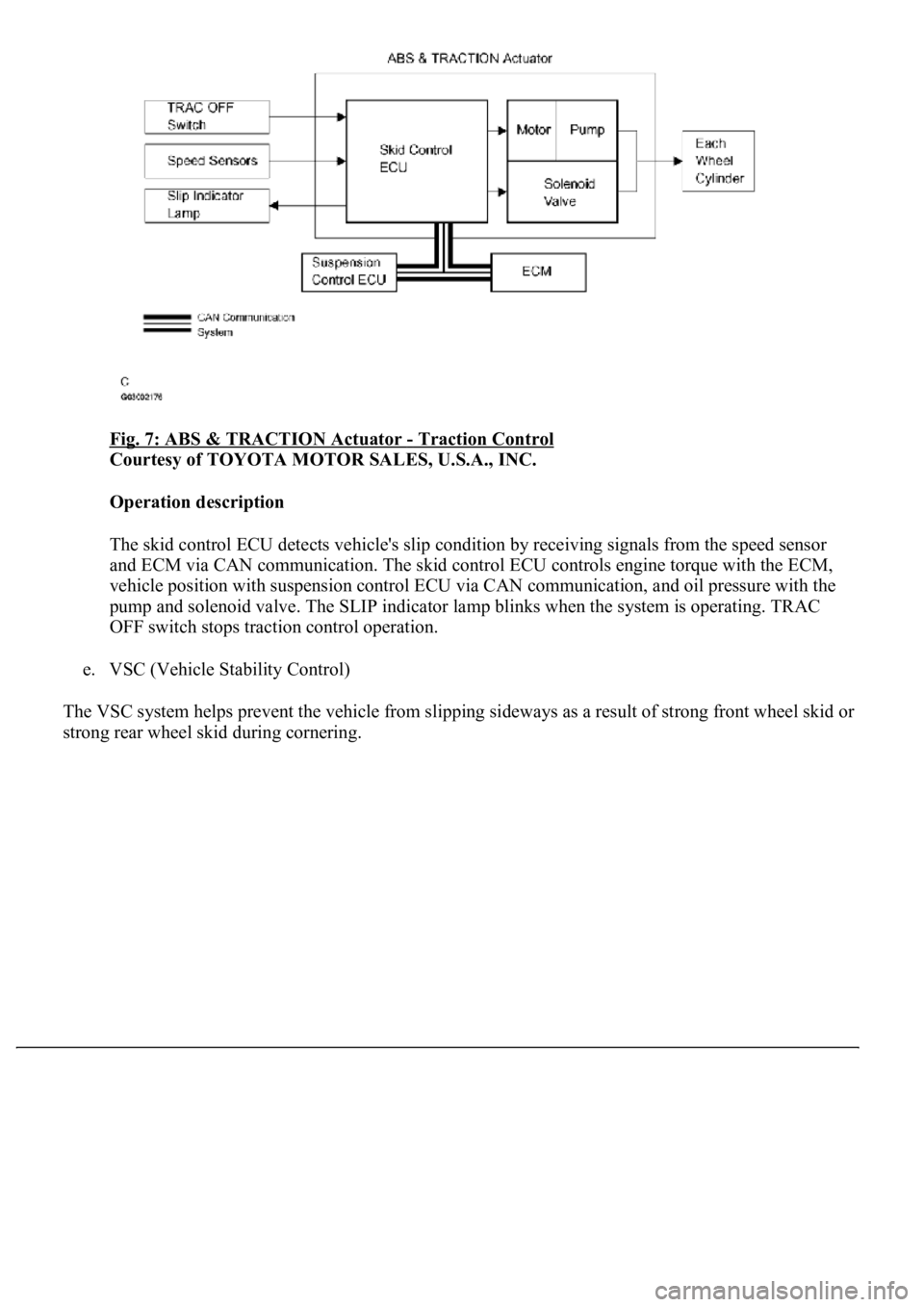

Fig. 7: ABS & TRACTION Actuator - Traction Control

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Operation description

The skid control ECU detects vehicle's slip condition by receiving signals from the speed sensor

<004400510047000300280026003000030059004c004400030026002400310003004600520050005000580051004c004600440057004c00520051001100030037004b004800030056004e004c00470003004600520051005700550052004f00030028002600

380003004600520051005700550052004f0056000300480051[gine torque with the ECM,

vehicle position with suspension control ECU via CAN communication, and oil pressure with the

pump and solenoid valve. The SLIP indicator lamp blinks when the system is operating. TRAC

OFF switch stops traction control operation.

e. VSC (Vehicle Stability Control)

The VSC system helps prevent the vehicle from slipping sideways as a result of strong front wheel skid or

stron

g rear wheel skid during cornering.

Page 39 of 4500

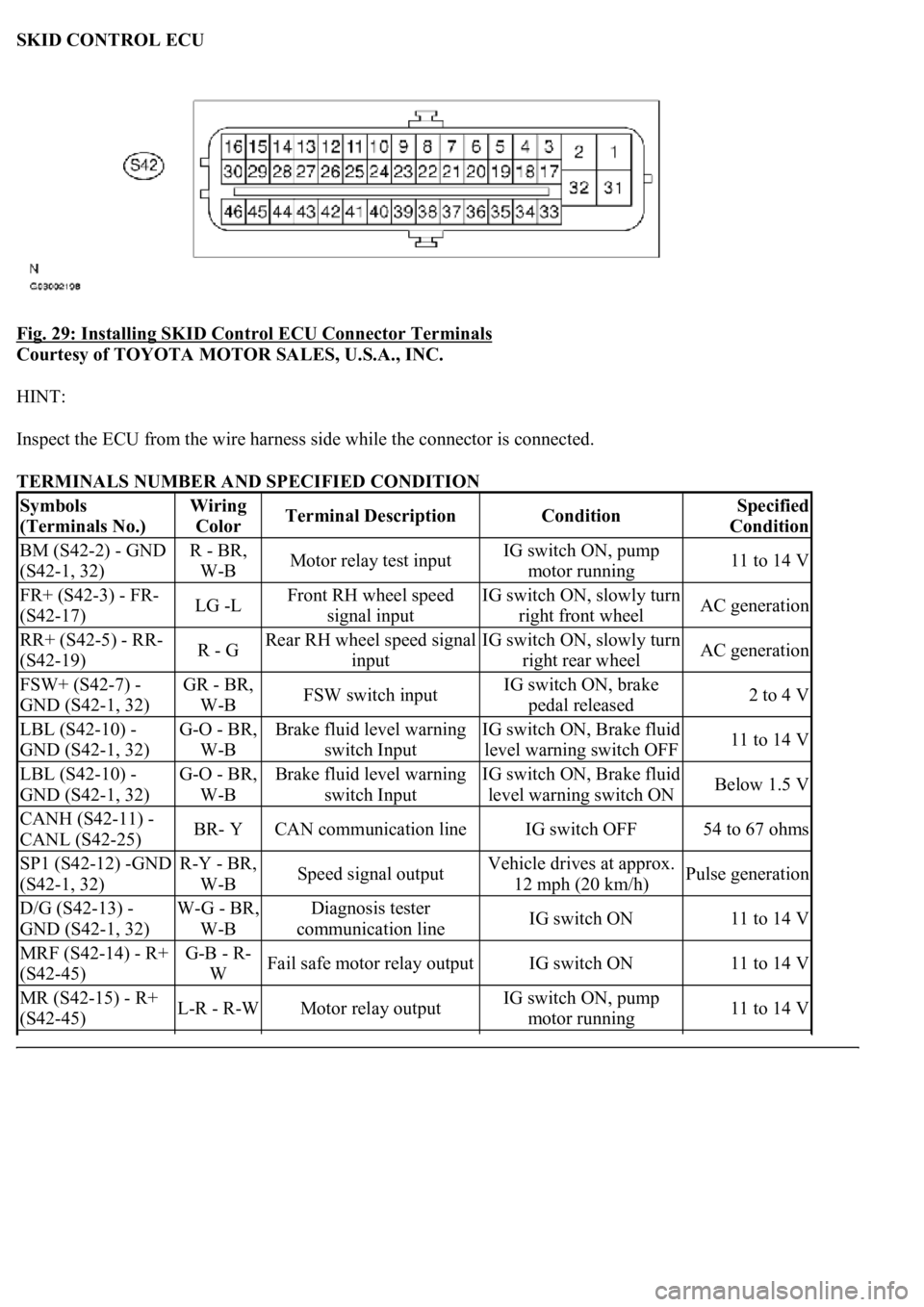

SKID CONTROL ECU

Fig. 29: Installing SKID Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

Inspect the ECU from the wire harness side while the connector is connected.

TERMINALS NUMBER AND SPECIFIED CONDITION

Symbols

(Terminals No.)Wiring

ColorTerminal DescriptionConditionSpecified

Condition

BM (S42-2) - GND

(S42-1, 32)R - BR,

W-BMotor relay test inputIG switch ON, pump

motor running11 to 14 V

FR+ (S42-3) - FR-

(S42-17)LG -LFront RH wheel speed

signal inputIG switch ON, slowly turn

right front wheelAC generation

RR+ (S42-5) - RR-

(S42-19)R - GRear RH wheel speed signal

inputIG switch ON, slowly turn

right rear wheelAC generation

FSW+ (S42-7) -

GND (S42-1, 32)GR - BR,

W-BFSW switch inputIG switch ON, brake

pedal released2 to 4 V

LBL (S42-10) -

GND (S42-1, 32)G-O - BR,

W-BBrake fluid level warning

switch InputIG switch ON, Brake fluid

level warning switch OFF11 to 14 V

LBL (S42-10) -

GND (S42-1, 32)G-O - BR,

W-BBrake fluid level warning

switch InputIG switch ON, Brake fluid

level warning switch ONBelow 1.5 V

CANH (S42-11) -

CANL (S42-25)BR- YCAN communication lineIG switch OFF54 to 67 ohms

SP1 (S42-12) -GND

(S42-1, 32)R-Y - BR,

W-BSpeed signal outputVehicle drives at approx.

12 mph (20 km/h)Pulse generation

D/G (S42-13) -

GND (S42-1, 32)W-G - BR,

W-BDiagnosis tester

communication lineIG switch ON11 to 14 V

MRF (S42-14) - R+

(S42-45)G-B - R-

WFail safe motor relay outputIG switch ON11 to 14 V

MR (S42-15) - R+

(S42-45)L-R - R-WMotor relay outputIG switch ON, pump

motor running11 to 14 V

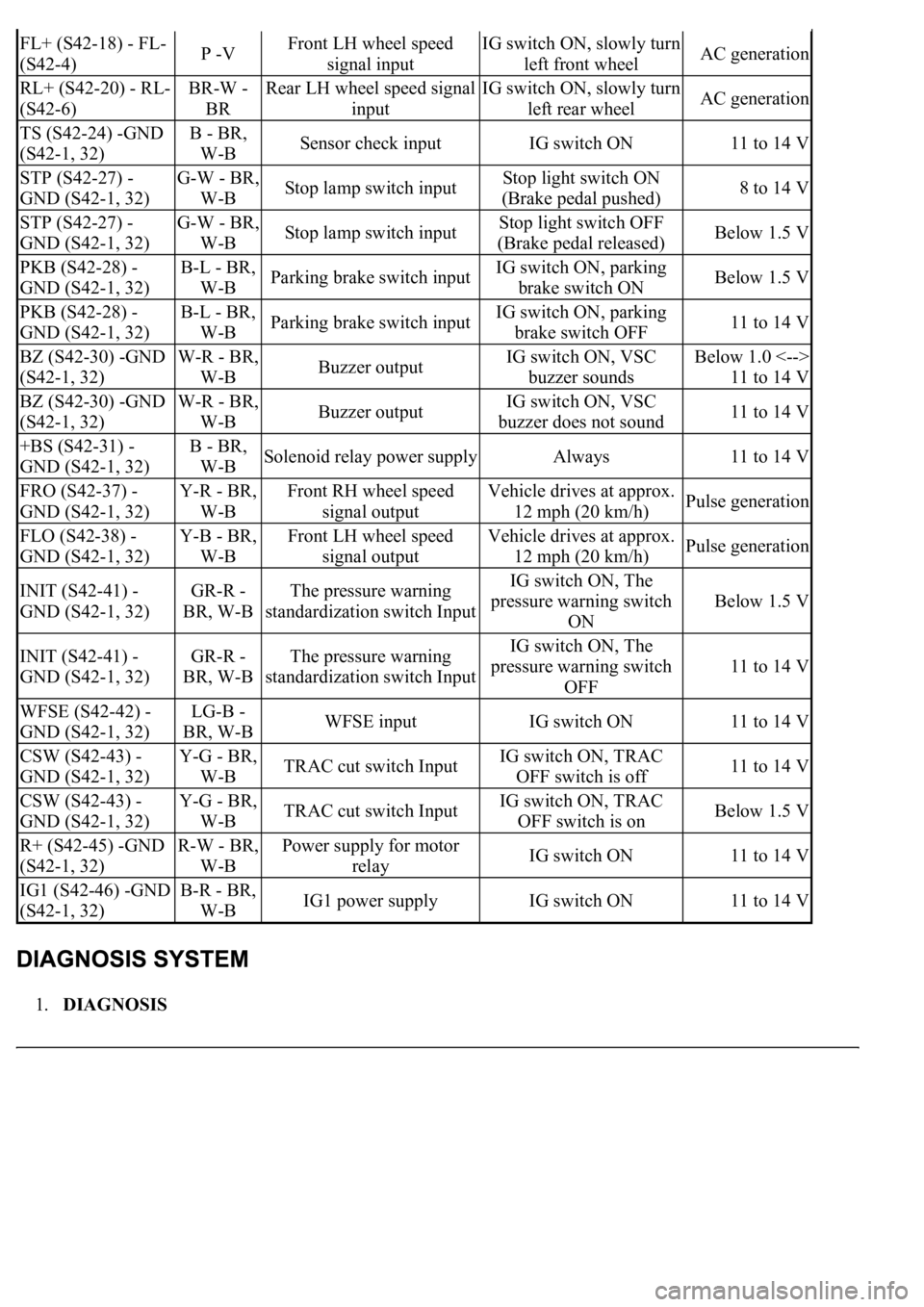

Page 40 of 4500

1.DIAGNOSIS

FL+ (S42-18) - FL-

(S42-4)P -VFront LH wheel speed

signal inputIG switch ON, slowly turn

left front wheelAC generation

RL+ (S42-20) - RL-

(S42-6)BR-W -

BRRear LH wheel speed signal

inputIG switch ON, slowly turn

left rear wheelAC generation

TS (S42-24) -GND

(S42-1, 32)B - BR,

W-BSensor check inputIG switch ON11 to 14 V

STP (S42-27) -

GND (S42-1, 32)G-W - BR,

W-BStop lamp switch inputStop light switch ON

(Brake pedal pushed)8 to 14 V

STP (S42-27) -

GND (S42-1, 32)G-W - BR,

W-BStop lamp switch inputStop light switch OFF

(Brake pedal released)Below 1.5 V

PKB (S42-28) -

GND (S42-1, 32)B-L - BR,

W-BParking brake switch inputIG switch ON, parking

brake switch ONBelow 1.5 V

PKB (S42-28) -

GND (S42-1, 32)B-L - BR,

W-BParking brake switch inputIG switch ON, parking

brake switch OFF11 to 14 V

BZ (S42-30) -GND

(S42-1, 32)W-R - BR,

W-BBuzzer outputIG switch ON, VSC

buzzer soundsBelow 1.0 <-->

11 to 14 V

BZ (S42-30) -GND

(S42-1, 32)W-R - BR,

W-BBuzzer outputIG switch ON, VSC

buzzer does not sound11 to 14 V

+BS (S42-31) -

GND (S42-1, 32)B - BR,

W-BSolenoid relay power supplyAlways11 to 14 V

FRO (S42-37) -

GND (S42-1, 32)Y-R - BR,

W-BFront RH wheel speed

signal outputVehicle drives at approx.

12 mph (20 km/h)Pulse generation

FLO (S42-38) -

GND (S42-1, 32)Y-B - BR,

W-BFront LH wheel speed

signal outputVehicle drives at approx.

12 mph (20 km/h)Pulse generation

INIT (S42-41) -

GND (S42-1, 32)GR-R -

BR, W-BThe pressure warning

standardization switch InputIG switch ON, The

pressure warning switch

ON

Below 1.5 V

INIT (S42-41) -

GND (S42-1, 32)GR-R -

BR, W-BThe pressure warning

standardization switch InputIG switch ON, The

pressure warning switch

OFF

11 to 14 V

WFSE (S42-42) -

GND (S42-1, 32)LG-B -

BR, W-BWFSE inputIG switch ON11 to 14 V

CSW (S42-43) -

GND (S42-1, 32)Y-G - BR,

W-BTRAC cut switch InputIG switch ON, TRAC

OFF switch is off11 to 14 V

CSW (S42-43) -

GND (S42-1, 32)Y-G - BR,

W-BTRAC cut switch InputIG switch ON, TRAC

OFF switch is onBelow 1.5 V

R+ (S42-45) -GND

(S42-1, 32)R-W - BR,

W-BPower supply for motor

relayIG switch ON11 to 14 V

IG1 (S42-46) -GND

(S42-1, 32)B-R - BR,

W-BIG1 power supplyIG switch ON11 to 14 V

Page 55 of 4500

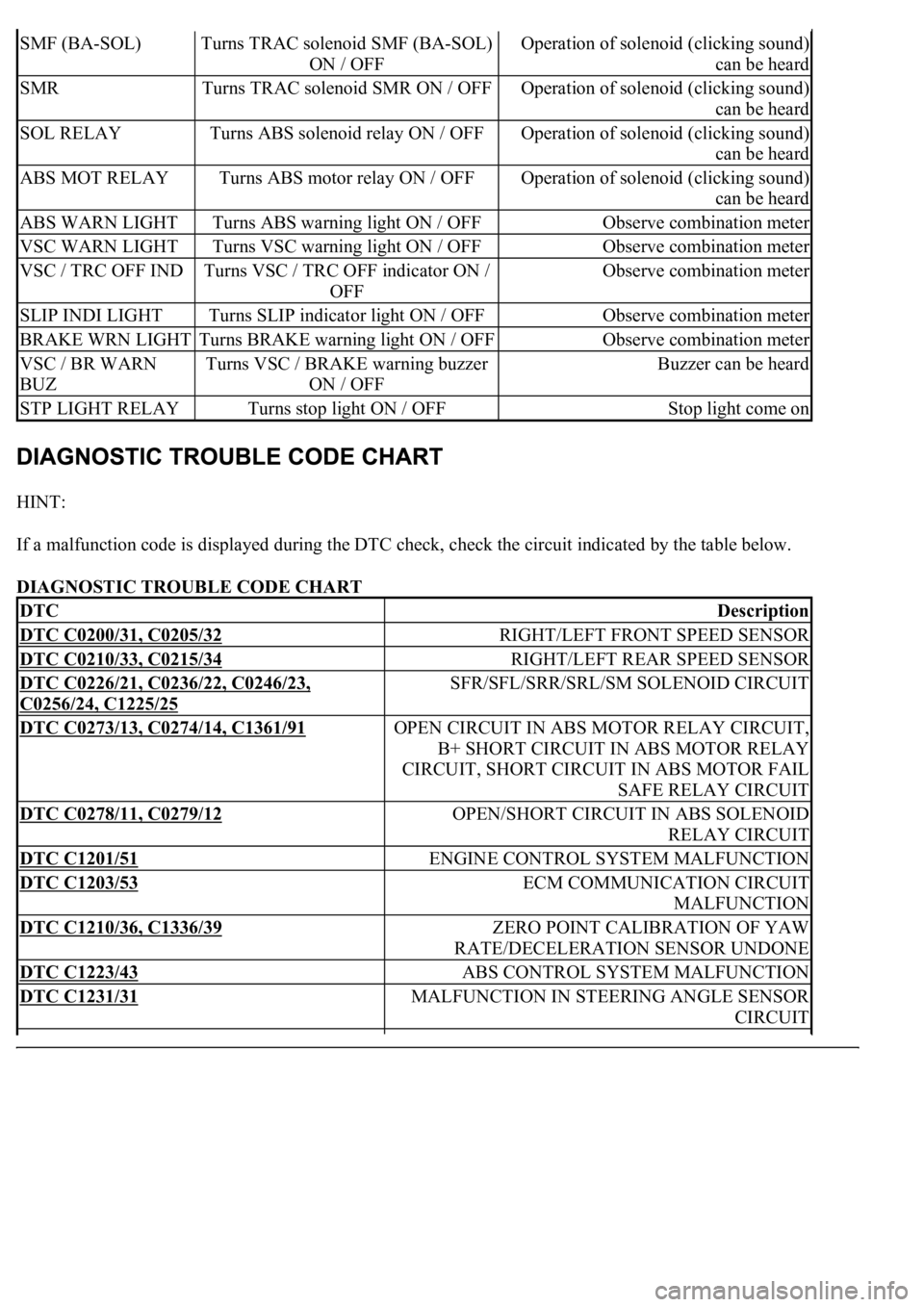

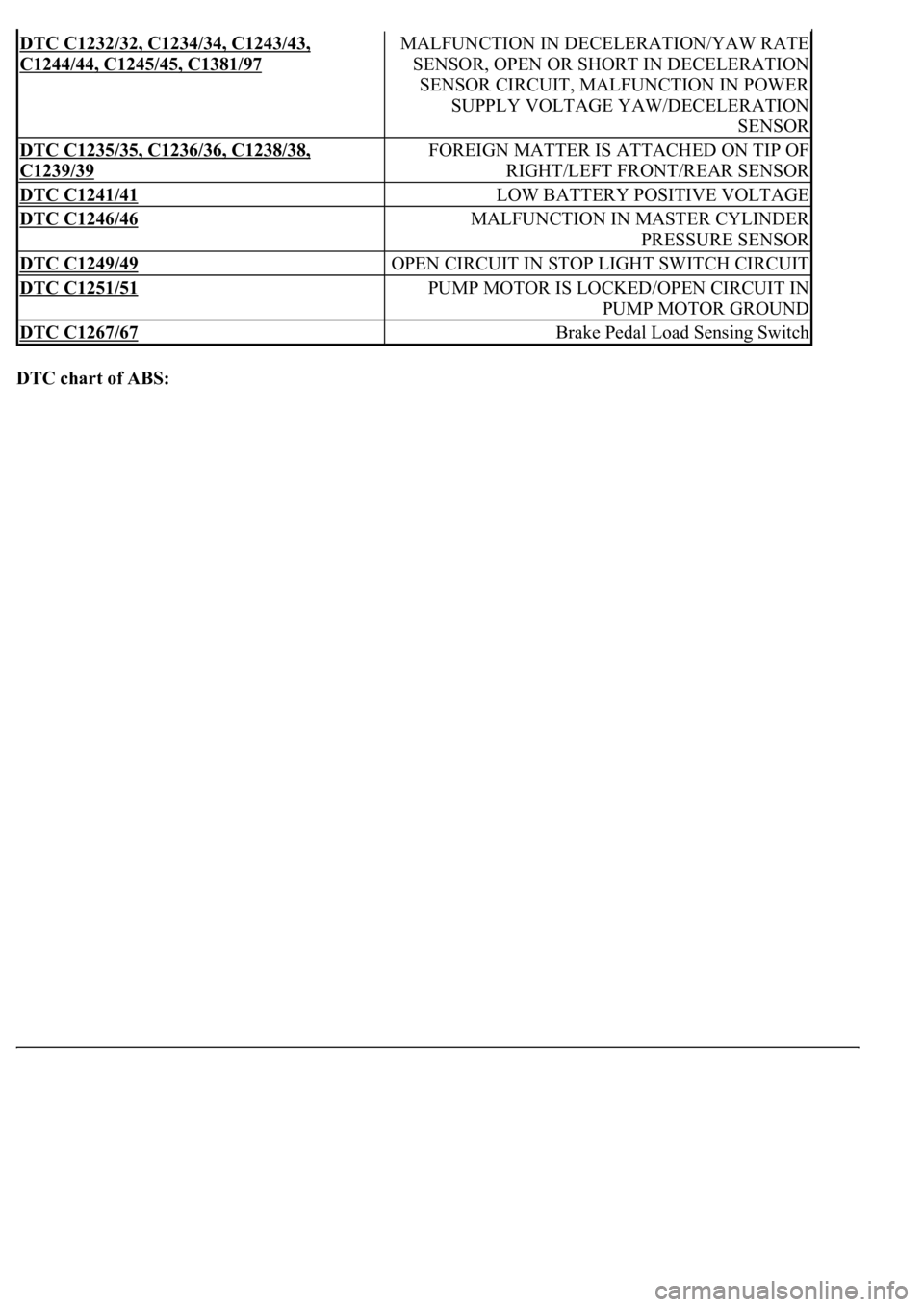

HINT:

If a malfunction code is displayed during the DTC check, check the circuit indicated by the table below.

DIAGNOSTIC TROUBLE CODE CHART

SMF (BA-SOL)Turns TRAC solenoid SMF (BA-SOL)

ON / OFFOperation of solenoid (clicking sound)

can be heard

SMRTurns TRAC solenoid SMR ON / OFFOperation of solenoid (clicking sound)

can be heard

SOL RELAYTurns ABS solenoid relay ON / OFFOperation of solenoid (clicking sound)

can be heard

ABS MOT RELAYTurns ABS motor relay ON / OFFOperation of solenoid (clicking sound)

can be heard

ABS WARN LIGHTTurns ABS warning light ON / OFFObserve combination meter

VSC WARN LIGHTTurns VSC warning light ON / OFFObserve combination meter

VSC / TRC OFF INDTurns VSC / TRC OFF indicator ON /

OFFObserve combination meter

SLIP INDI LIGHTTurns SLIP indicator light ON / OFFObserve combination meter

BRAKE WRN LIGHTTurns BRAKE warning light ON / OFFObserve combination meter

VSC / BR WARN

BUZTurns VSC / BRAKE warning buzzer

ON / OFFBuzzer can be heard

STP LIGHT RELAYTurns stop light ON / OFFStop light come on

DTCDescription

DTC C0200/31, C0205/32RIGHT/LEFT FRONT SPEED SENSOR

DTC C0210/33, C0215/34RIGHT/LEFT REAR SPEED SENSOR

DTC C0226/21, C0236/22, C0246/23,

C0256/24, C1225/25

SFR/SFL/SRR/SRL/SM SOLENOID CIRCUIT

DTC C0273/13, C0274/14, C1361/91OPEN CIRCUIT IN ABS MOTOR RELAY CIRCUIT,

B+ SHORT CIRCUIT IN ABS MOTOR RELAY

CIRCUIT, SHORT CIRCUIT IN ABS MOTOR FAIL

SAFE RELAY CIRCUIT

DTC C0278/11, C0279/12OPEN/SHORT CIRCUIT IN ABS SOLENOID

RELAY CIRCUIT

DTC C1201/51ENGINE CONTROL SYSTEM MALFUNCTION

DTC C1203/53ECM COMMUNICATION CIRCUIT

MALFUNCTION

DTC C1210/36, C1336/39ZERO POINT CALIBRATION OF YAW

RATE/DECELERATION SENSOR UNDONE

DTC C1223/43ABS CONTROL SYSTEM MALFUNCTION

DTC C1231/31MALFUNCTION IN STEERING ANGLE SENSOR

CIRCUIT

Page 56 of 4500

DTC chart of ABS:

DTC C1232/32, C1234/34, C1243/43,

C1244/44, C1245/45, C1381/97

MALFUNCTION IN DECELERATION/YAW RATE

SENSOR, OPEN OR SHORT IN DECELERATION

SENSOR CIRCUIT, MALFUNCTION IN POWER

SUPPLY VOLTAGE YAW/DECELERATION

SENSOR

DTC C1235/35, C1236/36, C1238/38,

C1239/39

FOREIGN MATTER IS ATTACHED ON TIP OF

RIGHT/LEFT FRONT/REAR SENSOR

DTC C1241/41LOW BATTERY POSITIVE VOLTAGE

DTC C1246/46MALFUNCTION IN MASTER CYLINDER

PRESSURE SENSOR

DTC C1249/49OPEN CIRCUIT IN STOP LIGHT SWITCH CIRCUIT

DTC C1251/51PUMP MOTOR IS LOCKED/OPEN CIRCUIT IN

PUMP MOTOR GROUND

DTC C1267/67Brake Pedal Load Sensing Switch

Page 60 of 4500

CIRCUIT DESCRIPTION

The speed sensor detects wheel speed and sends the appropriate signals to the ECU. These signals are used to

control the ABS control system. The front and rear rotors have 48 serrations respectively.

When the rotors rotate, the magnetic field emitted by the permanent magnet in the speed sensor generates an

AC voltage. Since the frequency of this AC voltage changes in direct proportion to the speed of the rotor, the

frequenc

y is used by the ECU to detect the speed of each wheel.