recommended oil LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 818 of 4500

PRECAUTION

1. The automatic transmission is composed of highly precision-finished parts which need careful inspection

before reassembly because even a small nick could cause fluid leakage or affect performance. The

instructions here are organized so that you work on only one component group at a time. This will help

avoid confusion from similar-looking parts of different sub-assemblies being on your workbench at the

same time. The component groups should be inspected and repaired from the converter housing side.

Inspect, repair and reassemble as much as possible before proceeding to the next component group. If a

defect is found in a certain component group during reassembly, inspect and repair this group

immediately. If a component group cannot be assembled because parts are being ordered, be sure to keep

all parts of the group in a separate container while proceeding with disassembly, inspection, repair and

reassembly of other component groups. Recommended ATF: ATF WS

2. All disassembled parts should be washed clean and any fluid passages and holes should be blown through

with compressed air.

3. Dry all parts with compressed air. Never use shop rags.

4. When using compressed air, be careful not to not aim at yourself to prevent accidentally spraying ATF or

kerosene on your face.

5. Only recommended automatic transaxle fluid or kerosene should be used for cleaning.

6. After cleaning, the parts should be arranged in the correct order for efficient inspection, repairs, and

reassembly.

7. When disassembling a valve body, be sure to match each valve together with the corresponding spring.

8. New discs for the brakes and clutches that are to be used for replacement must be soaked in ATF for at

least 15 minutes before reassembly.

9. All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with

ATF prior to reassembly.

10. All gaskets and rubber O-rings should be replaced.

11. Do not apply adhesive cements to gaskets or similar parts.

12. Make sure that the ends of a snap ring are not aligned with one of the cutouts and are installed in the

groove correctly.

13. When replacing a worn bushing, the sub-assembly containing the bushing must also be replaced.

14. Check thrust bearings and races for wear or damage. Replace them as necessary.

15. Use petroleum jelly to keep parts in place.

16. When working with FIPG material, perform the following: Using a razor blade and a gasket scraper,

remove all the old packing (FIPG) material from the gasket surface.

Thoroughly clean all components to remove any loose material.

Page 3498 of 4500

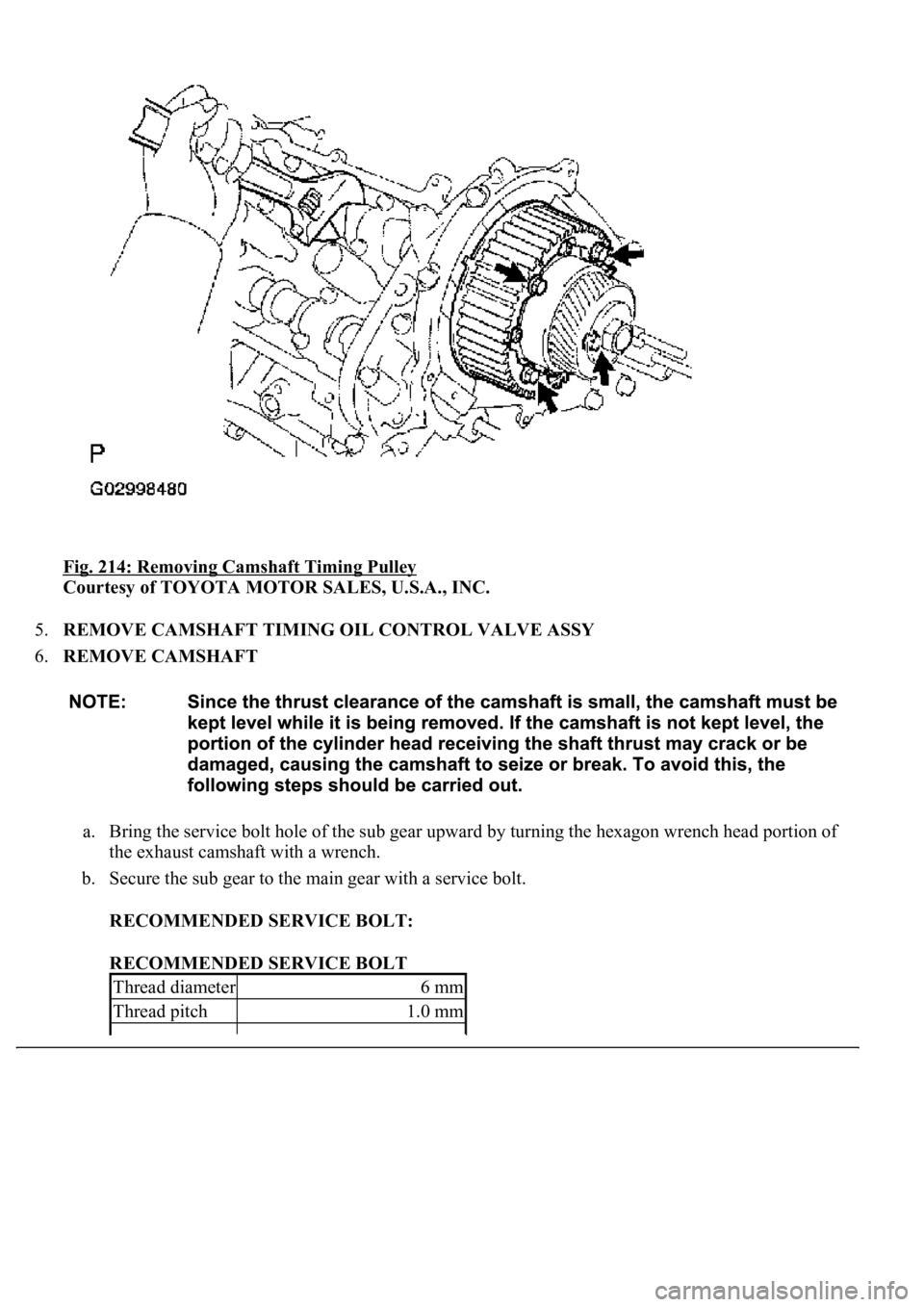

Fig. 214: Removing Camshaft Timing Pulley

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

5.REMOVE CAMSHAFT TIMING OIL CONTROL VALVE ASSY

6.REMOVE CAMSHAFT

a. Bring the service bolt hole of the sub gear upward by turning the hexagon wrench head portion of

the exhaust camshaft with a wrench.

b. Secure the sub gear to the main gear with a service bolt.

RECOMMENDED SERVICE BOLT:

RECOMMENDED SERVICE BOLT

Thread diameter6 mm

Thread pitch1.0 mm