wheel alignment LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 2 of 4500

Fluid SpecificationsSee FLUIDS under MAINTENANCE tab.

Flywheel/Flex Plate

(Drive Plate) TorqueStep1: 49 N.m (500 kgf.cm, 36 ft lbs)

Step2: Turn 90°

Fuel System

Pressure

Specification304 to 343 kPa (3.1 to 3.5 kgf/cm2 , 44 to 50 psi)

Fuel Pressure Test

ProcedureON-VEHICLE INSPECTION

Fuel Filter

LocationCOMPONENTS

Ignition

Firing Order &

Cylinder

IdentificationFIRING ORDER & CYLINDER IDENTIFICATION

Spark Plug

TypeND SK20R11

NGK 1FR6A11

GapStandard electrode gap: 1.0 - 1.1 mm (0.039 - 0.043 in.)

Maximum electrode gap: 1.3 mm (0.051 in.)

Torque7.5 N.m (76 kgf.cm, 66 ft.lbf)

Starting

StarterSERVICE DATA

TorqueTORQUE SPECIFICATION

Wheel Alignment

Front

Adjustment

SpecificationsSERVICE DATA

TorqueTORQUE SPECIFICATION

Rear

Adjustment

SpecificationsSERVICE DATA

TorqueTORQUE SPECIFICATION

Wheel & Tire

Wheel Lug Nut

Torque103 N.m (1,050 kgf.cm 76 ft.lbf)

Page 20 of 4500

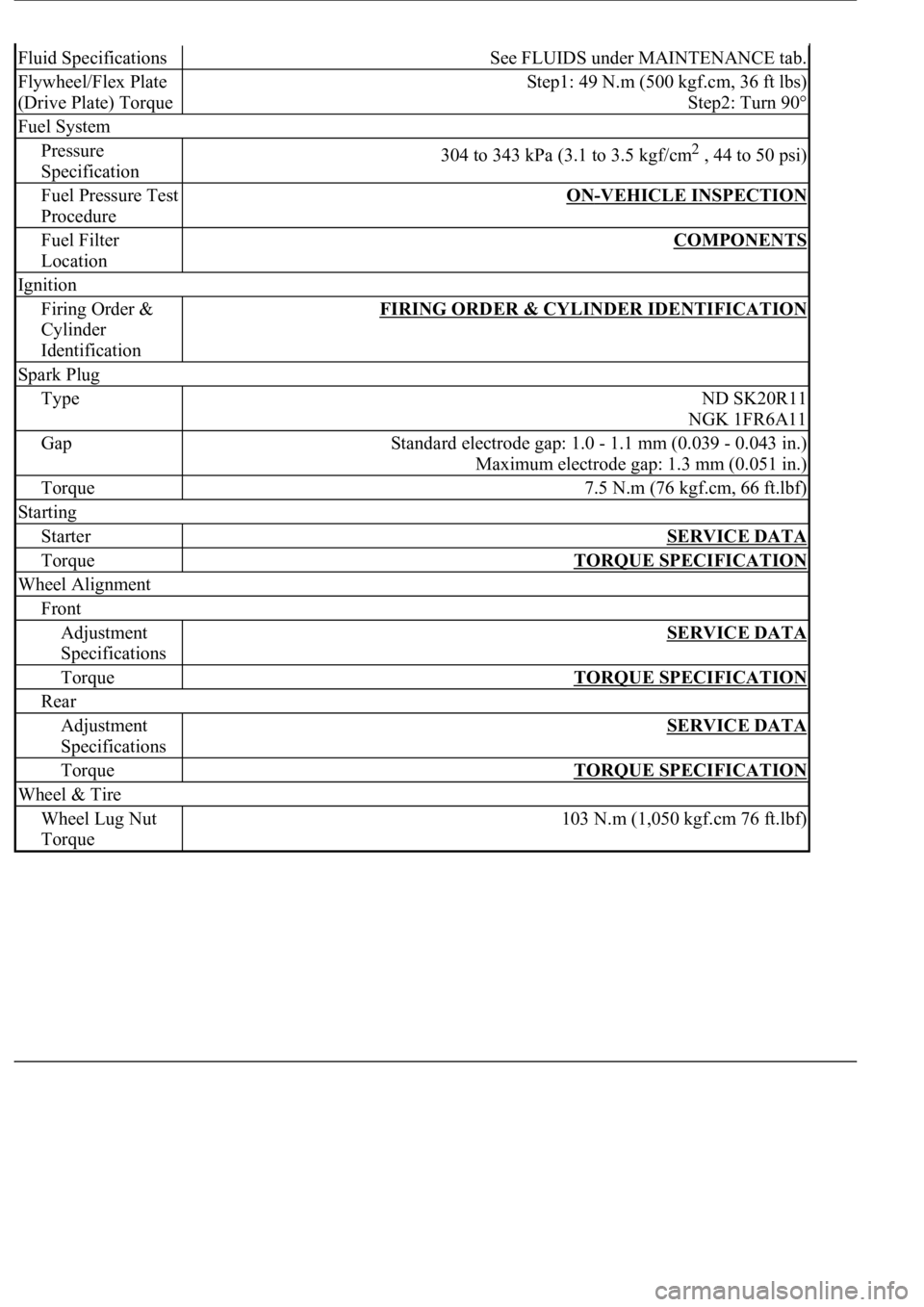

Fig. 13: Inspecting Connector And/Or Wire Harness

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

1.DESCRIPTION

a. After replacin

g the VSC relevant components or performing "Front wheel alignment adjustment",

Page 1100 of 4500

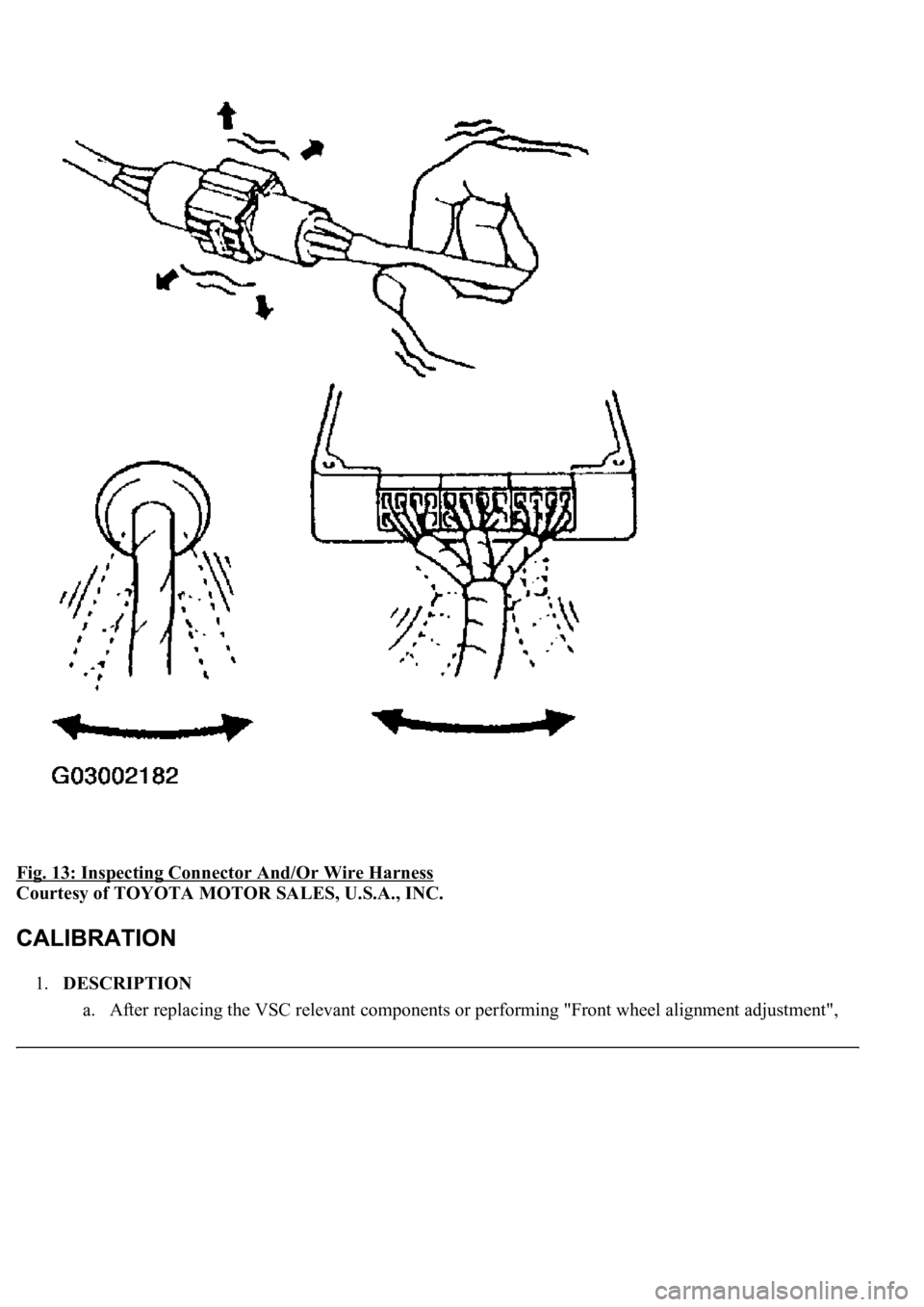

Fig. 129: Connecting Skid Control Sensor Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

12.INSTALL FRONT WHEEL

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

13.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT (SEE ADJUSTMENT

)

14.CHECK ABS SPEED SENSOR SIGNAL (SEE TEST MODE PROCEDURE

)

REPLACEMENT

1.REMOVE CONSOLE UPPER REAR PANEL SUB-ASSY (SEE REPLACEMENT

)

2.REMOVE CONSOLE BOX CARPET

3.REMOVE REAR CONSOLE ARMREST ASSY (SEE REPLACEMENT

)

4.REMOVE YAWRATE SENSOR

a. Disconnect the

yawrate sensor connector.

Page 2045 of 4500

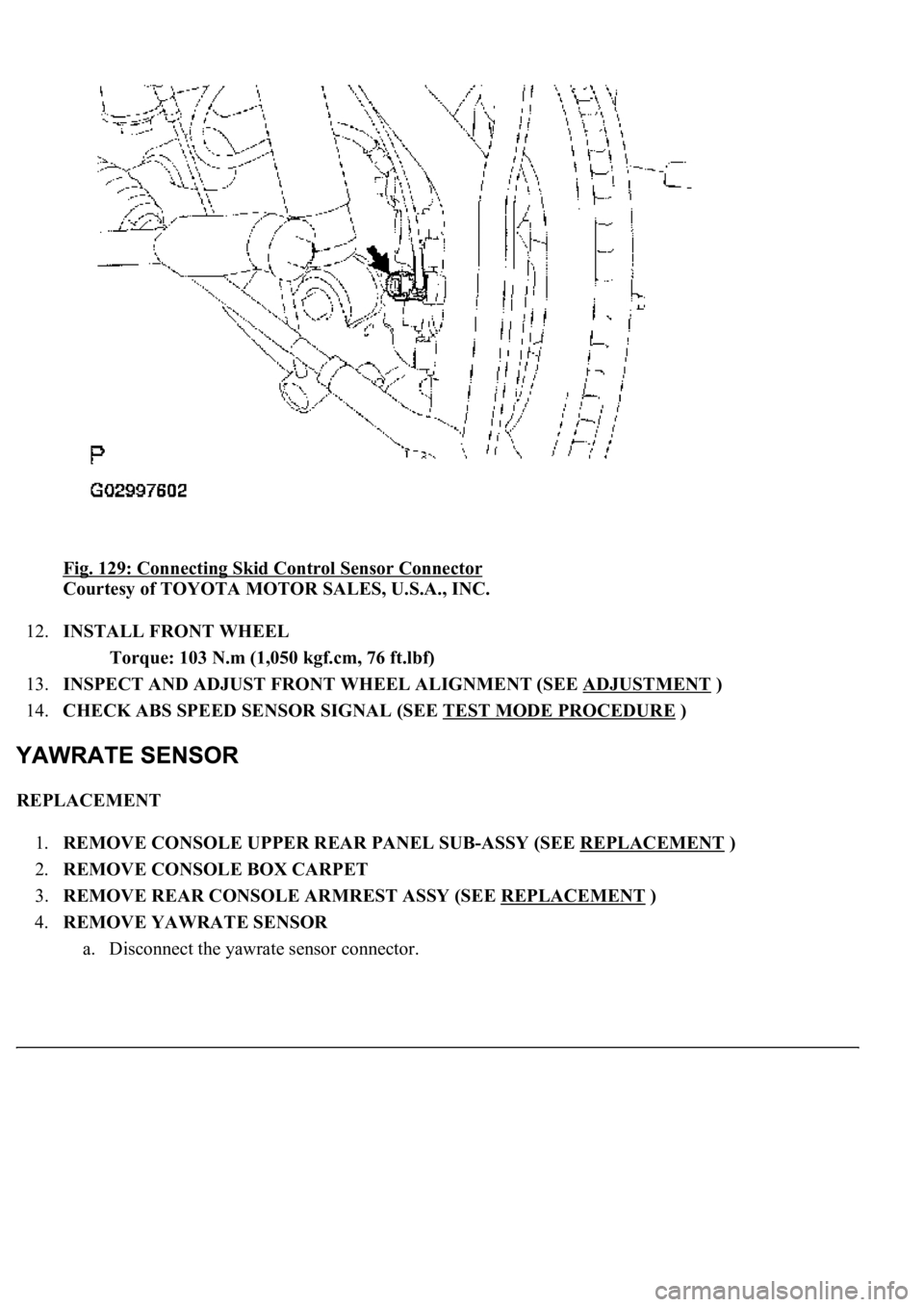

Fig. 6: Installing Rear Differential Side Gear Shaft Oil Seal

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

7.INSTALL REAR DRIVE SHAFT ASSY LH (SEE REPLACEMENT

)

8.INSTALL REAR DIFFERENTIAL DRAIN PLUG

a. Using a hexagon wrench (10 mm), install the drain plug with a new gasket.

Torque: 49 N.m (500 kgf.cm, 36 ft.)

9.ADD DIFFERENTIAL OIL

a. Fill the rear differential carrier assy with differential gear oil.

Oil type: Differential synthetic gear oil GL-5 75W-90 or equivalent.

<00260044005300440046004c0057005c001d000300140011001600180003000e00120010000300130011001300180003004f004c00570048005500560003000b00140011001700160003000e00120010000300130011001300180003003800360003005400

570056000f0003001400110014001c0003000e001200100003[0.04 Imp. qts)

10.INSPECT DIFFERENTIAL OIL (SEE ADJUSTMENT

)

11.INSTALL REAR DIFFERENTIAL FILLER PLUG

a. Using a hexagon wrench (10 mm), install the filler plug with a new gasket.

Torque: 49 N.m (500 kgf.cm, 36 ft.lbf)

12.STABILIZE SUSPENSION (SEE ADJUSTMENT

)

13.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (SEE ADJUSTMENT

)

14.CHECK ABS SPEED SENSOR SIGNAL (SEE TEST MODE PROCEDURE

)

Page 2177 of 4500

a. Fill the rear differential carrier assy with differential gear oil equivalent.

Oil type: Differential synthetic gear oil GL-5 75W-90 or equivalent

Capacity: 1.35 +/- 0.05 liters (1.43 +/- 0.05 US qts, 1.19 +/- 0.04 Imp. qts)

67.INSPECT DIFFERENTIAL OIL (SEE ADJUSTMENT

)

68.INSTALL REAR DIFFERENTIAL FILLER PLUG

a. Using a hexagon wrench (10 mm), install the filler plug with a new gasket.

Torque: 49 N.m (500 kgf.cm, 36 ft.lbf)

69.INSTALL REAR DRIVE SHAFT ASSY LH (SEE REPLACEMENT

)

70.INSTALL REAR DRIVE SHAFT ASSY RH

HINT:

Installation procedure of the RH side is the same as that of the LH side.

71.INSTALL FRONT FLOOR HEAT INSULATOR NO.1

a. Install the front floor heat insulator No.1 with the 4 bolts.

Torque: 5.4 N.m (55 kgf.cm, 48 in..lbf)

72.INSTALL REAR WHEEL

a. Install the rear wheel with the 5 nuts.

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

73. Install the ornament with the 10 bolts.

Torque: 20 N.m (204 kgf.cm, 15 ft.lbf)

74.INSTALL PROPELLER W/CENTER BEARING SHAFT ASSY (SEE OVERHAUL

)

75.FULLY TIGHTEN CENTER SUPPORT BEARING ASSY NO.1 (SEE OVERHAUL

)

SST 09922-10010

76.INSPECT AND ADJUST NO.2 AND NO.3 JOINT ANGLE (SEE OVERHAUL

)

77.INSTALL PROPELLER SHAFT HEAT INSULATOR (SEE OVERHAUL

)

78.INSTALL EXHAUST PIPE ASSY (SEE REPLACEMENT

)

79.INSTALL OXYGEN SENSOR (SEE REPLACEMENT

)

80.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (SEE ADJUSTMENT

)

81.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (SEE ON

-VEHICLE INSPECTION )

82.INSPECT HEADLIGHT AIM ONLY (SEE ADJUSTMENT

)

83.CHECK ABS SPEED SENSOR SIGNAL (SEE TEST MODE PROCEDURE

)

84.INSPECT AIR LEAK (W/ AIR SUSPENSION) (SEE REPLACEMENT

)

HINT:

Perform this operation onl

y when the rear differential mount cushion is replaced.

Page 2356 of 4500

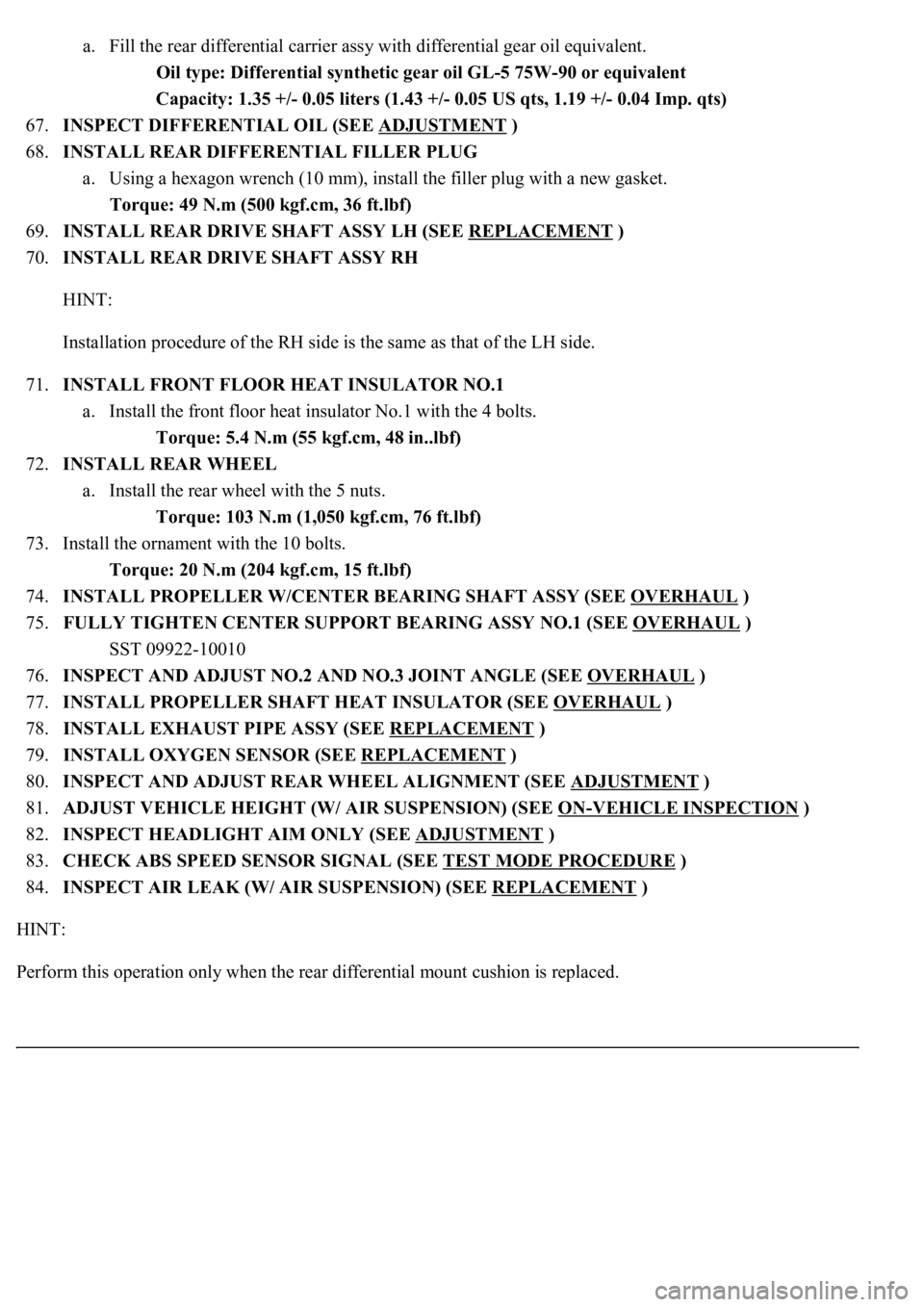

Fig. 51: Installing Disc Brake Caliper Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

13.INSTALL SKID CONTROL SENSOR WIRE

a. Connect the connector.

14.INSTALL FRONT WHEELS

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

15.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT (See ADJUSTMENT

)

16.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

HINT:

Page 2362 of 4500

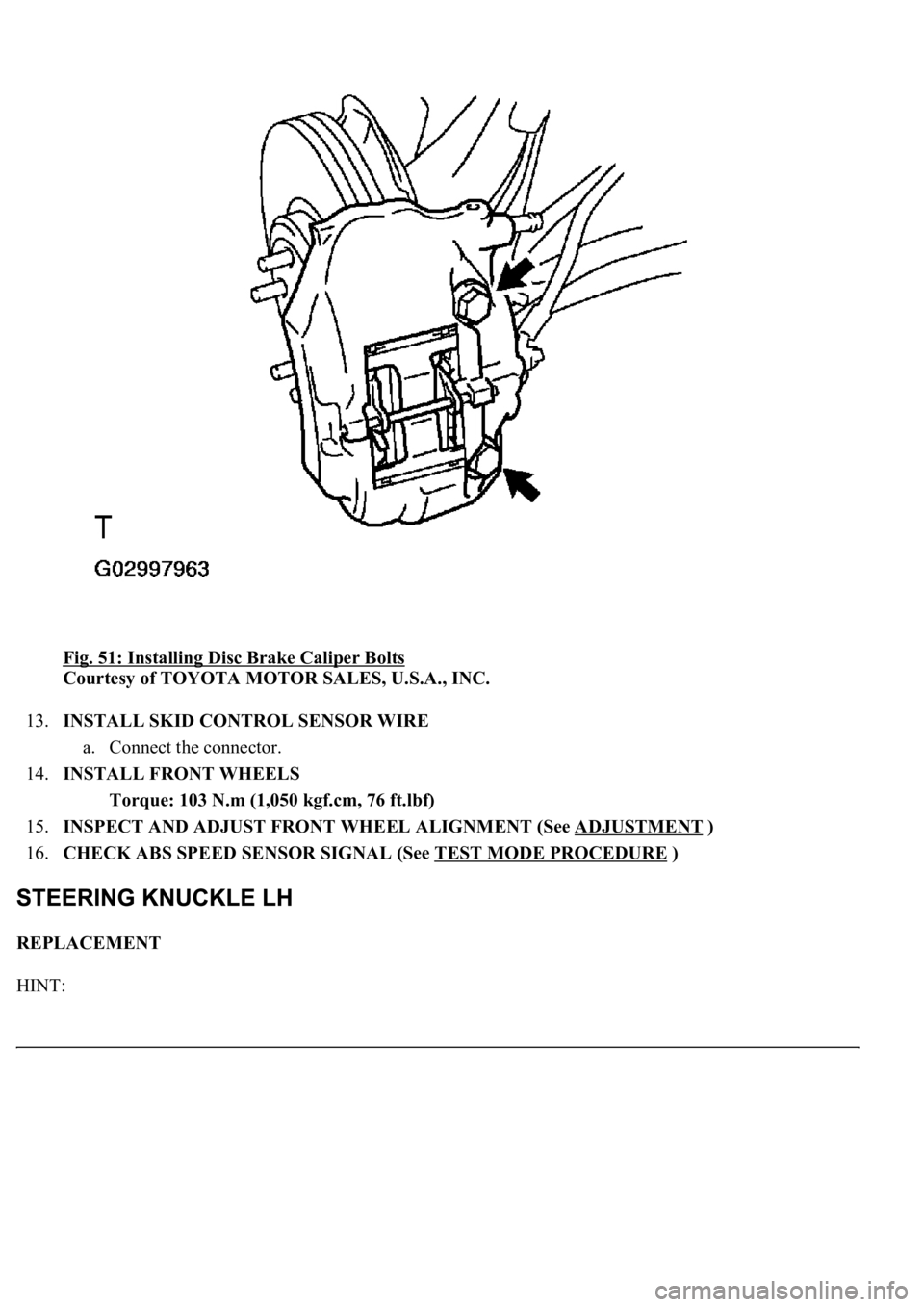

Fig. 56: Installing Skid Control Sensor Wire

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

10.INSTALL FRONT DISC (See step 15 on OVERHAUL

)

11.INSTALL FRONT DISC BRAKE CALIPER ASSY LH (See REPLACEMENT

)

12.INSTALL FRONT WHEELS

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

13.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT (See ADJUSTMENT

)

14.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

Page 2391 of 4500

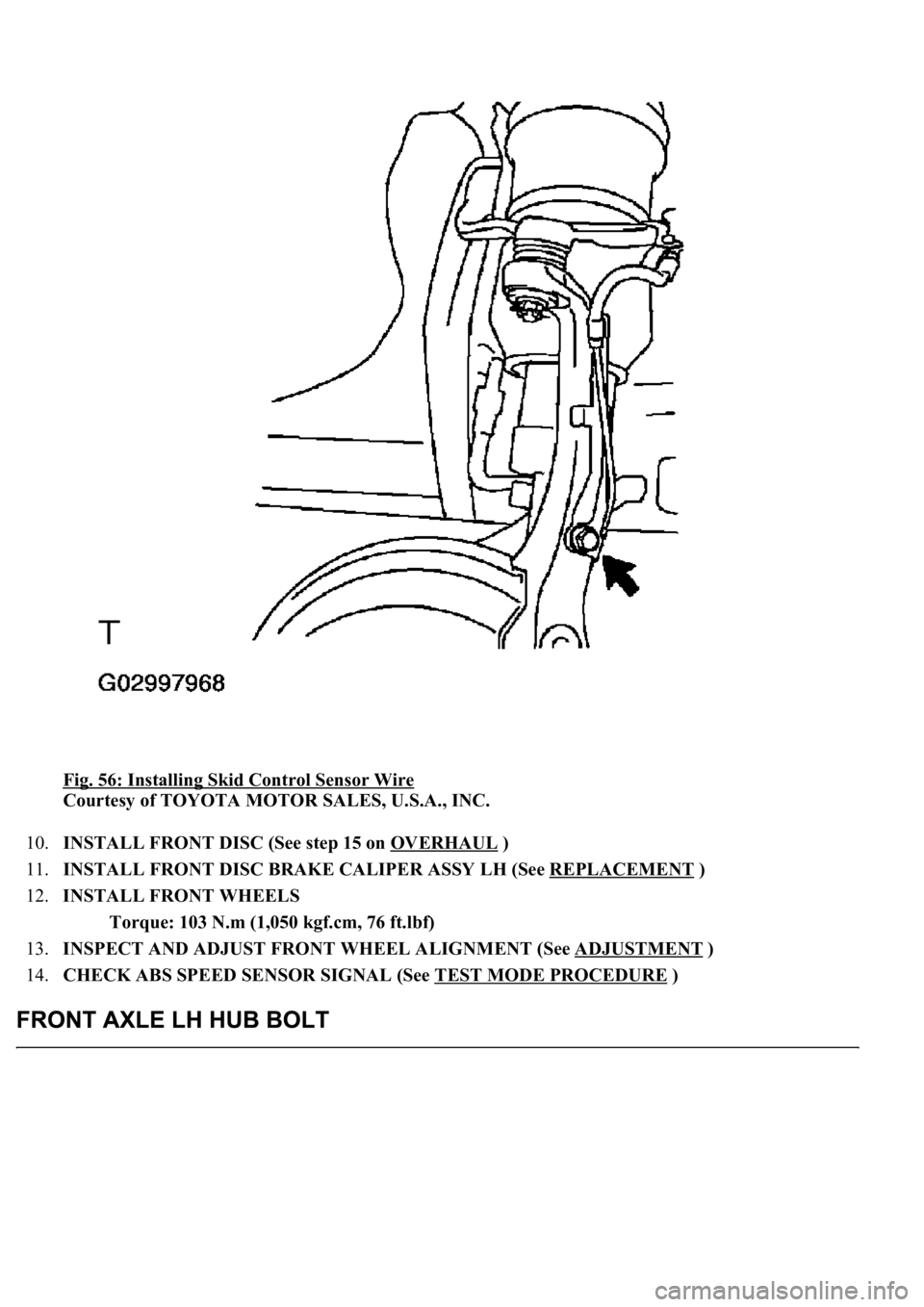

Fig. 85: Aligning Matchmarks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

33.INSTALL REAR TIRE

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

34.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (See ON

-VEHICLE INSPECTION )

35.INSPECT HEADLIGHT AIM ONLY (See ADJUSTMENT

)

36.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (See ADJUSTMENT

)

37.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

HINT:

See COMPONENTS

<00380056004800030057004b00480003005600440050004800030053005500520046004800470058005500480056000300490052005500030057004b004800030035002b00030056004c0047004800030044005100470003002f002b00030056004c004700

4800110003[

Page 2408 of 4500

42.ADJUST PARKING BRAKE PEDAL TRAVEL (See step 5 on ADJUSTMENT )

43.INSTALL SPEED SENSOR REAR LH

a. Install the speed sensor with the bolt.

Torque: 8.0 N.m (82 kgf.cm, 71 in.lbf)

44.INSTALL REAR DISC (See step 16 on OVERHAUL

)

45.ADJUST PARKING BRAKE SHOE CLEARANCE (See step 21 on OVERHAUL

)

46.INSTALL REAR DISC BRAKE CALIPER ASSY LH (See step 20 on REPLACEMENT

)

47.INSTALL REAR AXLE SHAFT NUT (See REPLACEMENT

)

48.INSPECT AXLE HUB BEARING LOOSENESS (See ON

-VEHICLE INSPECTION )

49.INSPECT AXLE HUB BEARING RUNOUT (See ON

-VEHICLE INSPECTION )

50.STABILIZE SUSPENSION (See step 23 on REPLACEMENT

)

51.FULLY TIGHTEN SHOCK ABSORBER ASSY REAR LH

a. Fully tighten the shock absorber assy LH with the new nut.

Torque: 70 N.m (714 kgf.cm, 52 ft.lbf)

52.INSTALL REAR TIRE

Torque: 103 N.m (1,050 kgf.cm, 76 ft.lbf)

53.ADJUST VEHICLE HEIGHT (W/ AIR SUSPENSION) (See ON

-VEHICLE INSPECTION )

54.INSPECT HEADLIGHT AIM ONLY (See ADJUSTMENT

)

55.INSPECT AND ADJUST REAR WHEEL ALIGNMENT (See ADJUSTMENT

)

56.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

REPLACEMENT

HINT:

See COMPONENTS

Use the same procedures for the RH side and LH side.

The procedures listed below are for the LH side.

1.REMOVE REAR TIRE

2.REMOVE REAR DISC BRAKE CALIPER ASSY LH (See REPLACEMENT

)

3.REMOVE REAR DISC (See step 15 on OVERHAUL

)

4.REMOVE REAR AXLE LH HUB BOLT

a. Using SST and a screwdriver or an equivalent to hold, remove the hub bolt.

SST 09628-10011

Page 3361 of 4500

140.INSTALL ENGINE UNDER COVER NO.2

141.INSTALL ENGINE UNDER COVER NO.1

142.INSTALL FRONT WHEEL

143.INSTALL AIR CLEANER ASSY

144.INSTALL INTAKE AIR CONNECTOR PIPE

145.INSTALL AIR CLEANER INLET NO.1

146.INSTALL V-BANK COVER

147.INSTALL HOOD SUB-ASSY (See ADJUSTMENT

and OVERHAUL )

148.CONNECT BATTERY NEGATIVE TERMINAL

149.ADD AUTOMATIC TRANSMISSION FLUID

150.ADD ENGINE COOLANT (See REPLACEMENT

)

151.ADD ENGINE OIL (See ON

-VEHICLE INSPECTION )

152.ADD POWER STEERING FLUID

153.BLEED POWER STEERING FLUID

154.INSPECT AUTOMATIC TRANSMISSION FLUID (See ADJUSTMENT

)

155.INSPECT ENGINE OIL LEAKS

156.CHECK FOR ENGINE COOLANT LEAKS

157.INSPECT FOR FUEL LEAKS

158.CHECK FOR EXHAUST GAS LEAKS

159.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

160.INSPECT IGNITION TIMING

161.INSPECT ENGINE IDLE SPEED

162.INSPECT CO/HC

163.ADJUST ENGINE (See INSPECTION

)

164.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

OVERHAUL

1.REMOVE SPARK PLUG

2.REMOVE OIL FILLER CAP SUB-ASSY

3.REMOVE CYLINDER HEAD COVER SUB-ASSY LH

a. Remove the 9 bolts, 9 seal washers, cylinder head cover and gasket.

4.REMOVE CYLINDER HEAD COVER SUB-ASSY

a. Remove the 9 bolts, 9 seal washers, c

ylinder head cover and gasket.