torque LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 1 of 4500

LS430 SPECIFICATIONS INDEX

SystemSpecification/Procedure

Air Conditioning

ServiceSERVICE DATA

TorqueTORQUE SPECIFICATION

Axle Nut/Hub Nut

Front69 N.m (700 kgf.cm, 51 ft.lbf)

Rear290 N.m (2,960 kgf.cm, 214 ft.lbf)

BatteryNA

Brakes

Bleeding

SequenceBLEEDING

Disc BrakesSERVICE DATA

TorqueTORQUE SPECIFICATION

Charging

GeneratorSERVICE DATA

TorqueTORQUE SPECIFICATION

Drive Belts

AdjustmentREPLACEMENT

Belt RoutingDRIVE BELT

Engine Cooling

General Service

SpecificationsSERVICE DATA

Radiator Cap

PressureStandard Value

93 to 123 kPa (0.95 to 1.25 kgf/cm

2 , 13.5 to 17.8 psi)

Minimum Standard Value

78 kPa (0.8 kgf/cm

2 , 11.4 psi)

Thermostat R & ITHERMOSTAT

Water Pump R &

IWATER PUMP

Engine Mechanical

CompressionSERVICE DATA

Oil Pressureat idle, 29 kPa (0.3 kgf.cm2 , 43 psi) or more

at 3,000 rpm, 294 to 588 kPa (3.0 to 6.0 kgf.cm

2 , 43 to 85 psi)

OverhaulSERVICE DATA

TorqueTORQUE SPECIFICATION

Page 2 of 4500

Fluid SpecificationsSee FLUIDS under MAINTENANCE tab.

Flywheel/Flex Plate

(Drive Plate) TorqueStep1: 49 N.m (500 kgf.cm, 36 ft lbs)

Step2: Turn 90°

Fuel System

Pressure

Specification304 to 343 kPa (3.1 to 3.5 kgf/cm2 , 44 to 50 psi)

Fuel Pressure Test

ProcedureON-VEHICLE INSPECTION

Fuel Filter

LocationCOMPONENTS

Ignition

Firing Order &

Cylinder

IdentificationFIRING ORDER & CYLINDER IDENTIFICATION

Spark Plug

TypeND SK20R11

NGK 1FR6A11

GapStandard electrode gap: 1.0 - 1.1 mm (0.039 - 0.043 in.)

Maximum electrode gap: 1.3 mm (0.051 in.)

Torque7.5 N.m (76 kgf.cm, 66 ft.lbf)

Starting

StarterSERVICE DATA

TorqueTORQUE SPECIFICATION

Wheel Alignment

Front

Adjustment

SpecificationsSERVICE DATA

TorqueTORQUE SPECIFICATION

Rear

Adjustment

SpecificationsSERVICE DATA

TorqueTORQUE SPECIFICATION

Wheel & Tire

Wheel Lug Nut

Torque103 N.m (1,050 kgf.cm 76 ft.lbf)

Page 11 of 4500

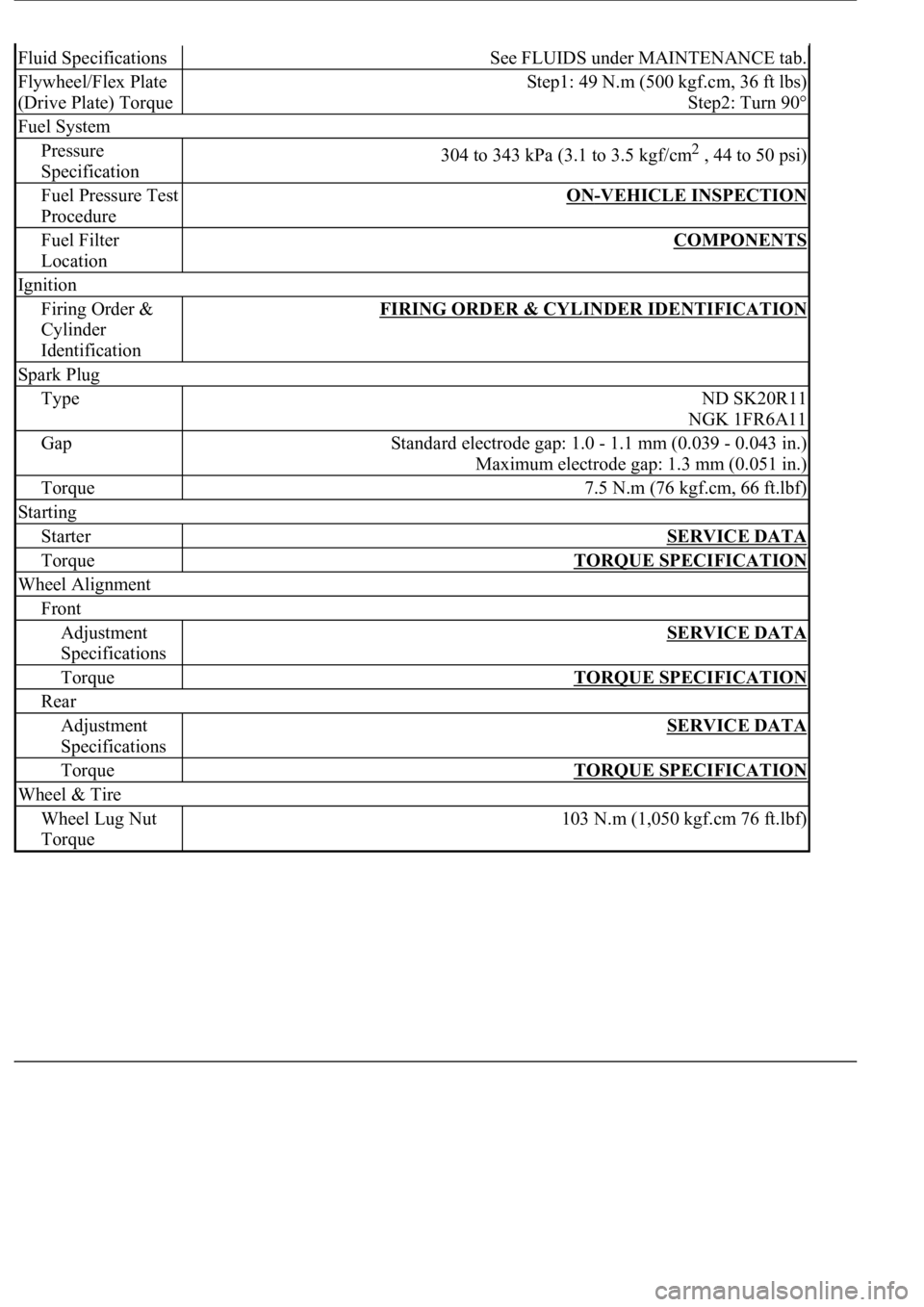

Fig. 7: ABS & TRACTION Actuator - Traction Control

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Operation description

The skid control ECU detects vehicle's slip condition by receiving signals from the speed sensor

<004400510047000300280026003000030059004c004400030026002400310003004600520050005000580051004c004600440057004c00520051001100030037004b004800030056004e004c00470003004600520051005700550052004f00030028002600

380003004600520051005700550052004f0056000300480051[gine torque with the ECM,

vehicle position with suspension control ECU via CAN communication, and oil pressure with the

pump and solenoid valve. The SLIP indicator lamp blinks when the system is operating. TRAC

OFF switch stops traction control operation.

e. VSC (Vehicle Stability Control)

The VSC system helps prevent the vehicle from slipping sideways as a result of strong front wheel skid or

stron

g rear wheel skid during cornering.

Page 12 of 4500

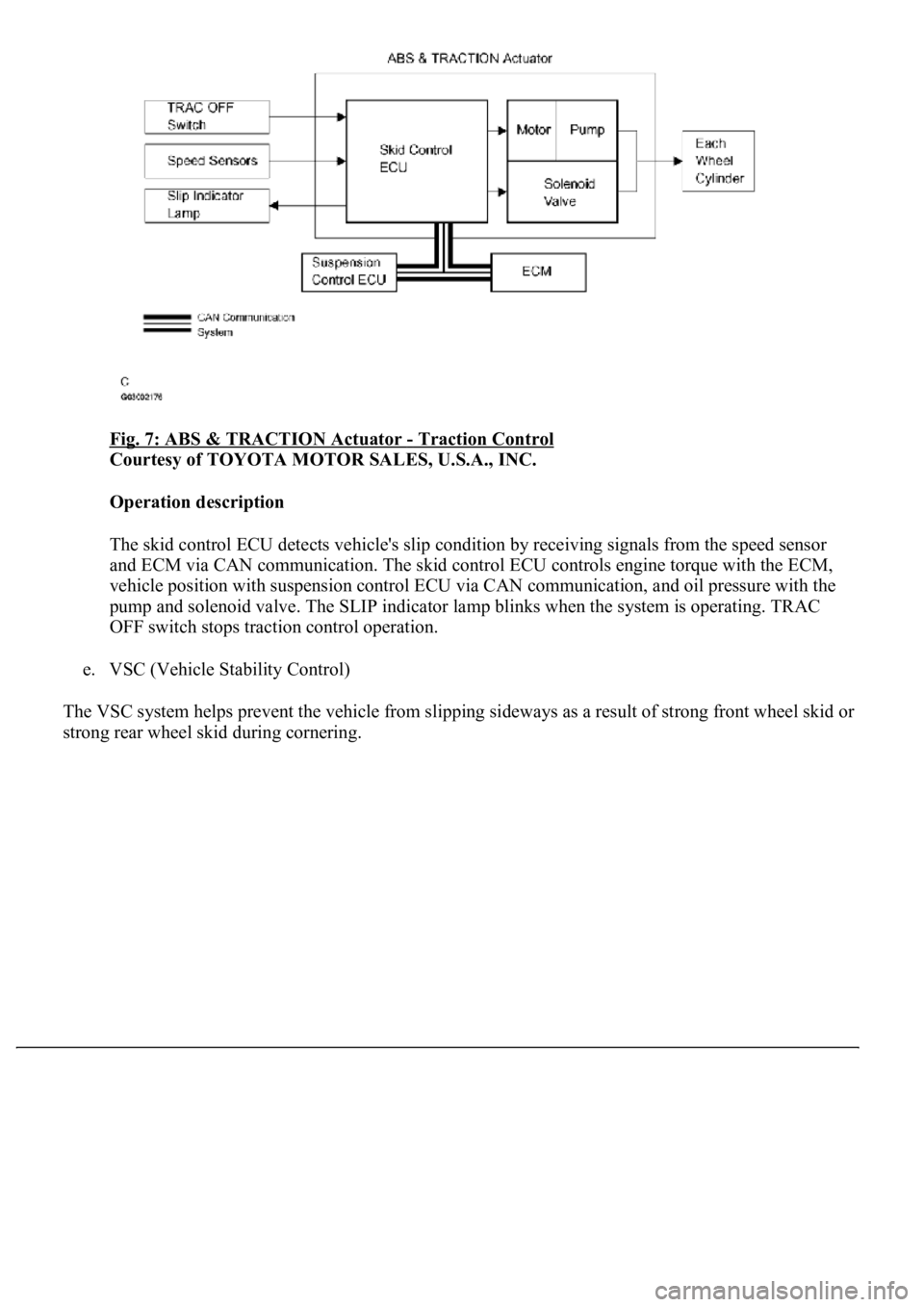

Fig. 8: ABS & TRACTION Actuator - Vehicle Stability Control

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Operation description

The skid control ECU determines vehicle condition by receiving signals from the speed sensor, yaw rate

and deceleration sensor and steering angle sensor. The skid control ECU controls engine torque with the

ECM, vehicle position with suspension control ECU via CAN communication, and oil pressure with the

pump and solenoid valve. The warning light comes on and the buzzer sounds when the system is

operating.

2.ABS with EBD & BA & TRAC & VSC OPERATION

a. Skid control ECU calculates vehicle stability tendency based on the signal of sensors, speed sensor,

yaw rate and deceleration sensor and steering angle sensor. And it judges whether the control of

engine output torque by electronic control throttle and of wheel brake pressure by brake actuator

will operate or not by the calculation results.

b. The SLIP indicator blinks and the VSC buzzer sounds to inform the driver that the VSC system is

operating. The SLIP indicator also blinks when TRAC is operating, and the operation being

performed is displayed.

3.FAIL SAFE FUNCTION

a. When a failure occurs in the ABS with BA & TRAC & VSC systems, the ABS warning light and

the VSC warning light turns on and the ABS with BA & TRAC & VSC operations are prohibited.

In addition to this, when there is a failure that disables the EBD operation, the brake warning light

also comes on and the EBD operation is prohibited (see FAIL

-SAFE CHART ).

b. If some control is prohibited due to a malfunction during it's operation, that control will be cut off

gradually not to change stability of vehicle suddenly.

4.PRE-COLLISION BRAKE ASSIST SYSTEM (w/ PRE-COLLISION BRAKE ASSIST SYSTEM)

Page 82 of 4500

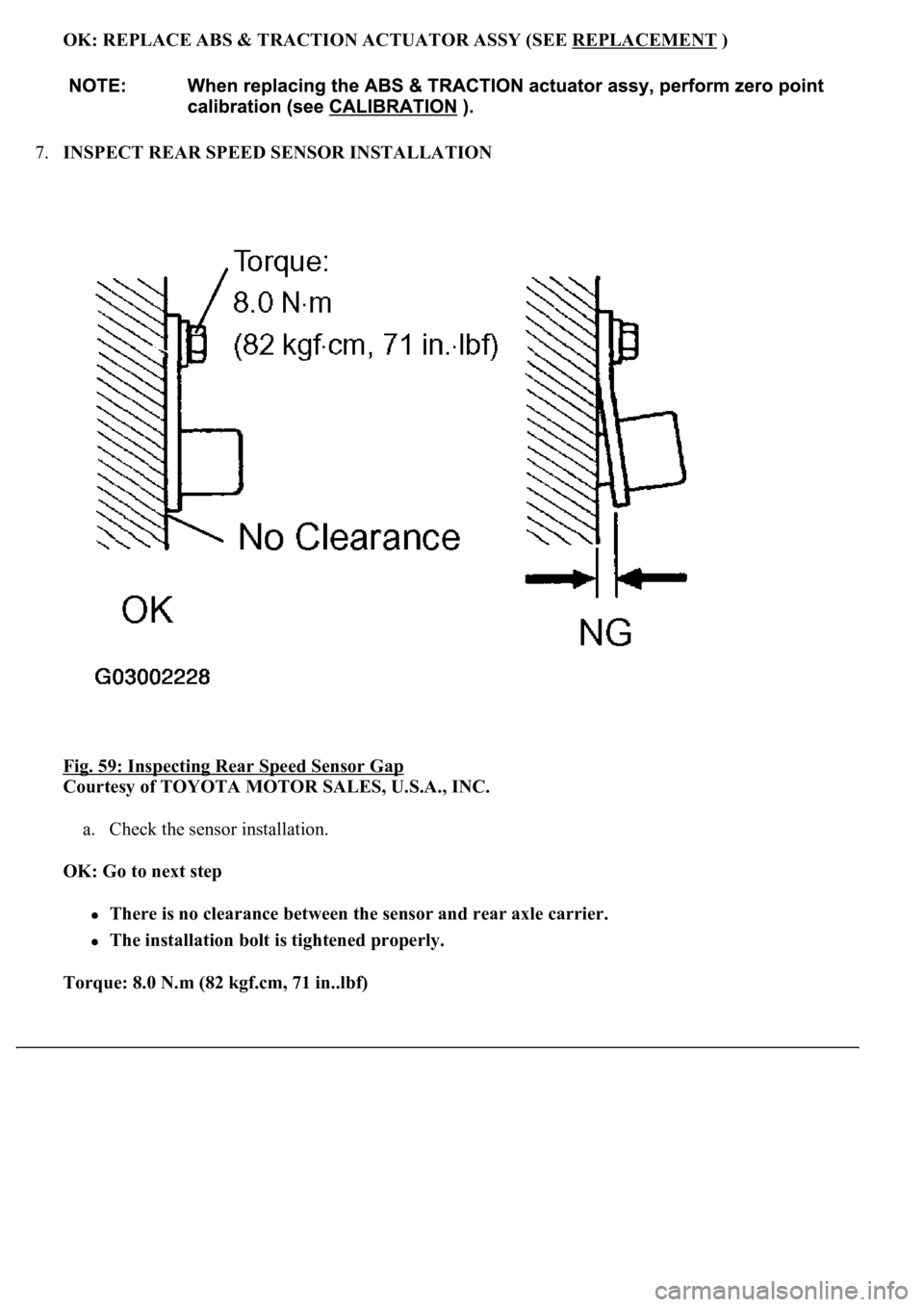

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT )

7.INSPECT REAR SPEED SENSOR INSTALLATION

Fig. 59: Inspecting Rear Speed Sensor Gap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

a. Check the sensor installation.

OK: Go to next step

There is no clearance between the sensor and rear axle carrier.

The installation bolt is tightened properly.

Torque: 8.0 N.m (82 kgf.cm, 71 in..lbf)

Page 104 of 4500

INSPECTION PROCEDURE

HINT:

<003a004b00480051000300380013001400150016001200190015000f0003003800130014001500170012001c001800030052005500030038001300140015001900120019001600030044005500480003005200580057005300580057000300440046004600

520050005300440051004c004800470003005a004c0057004b[ C1210/36 or C1336/39, inspect and

repair the trouble areas indicated by U0123/62, U0124/95 or U0126/63 first.

1.PERFORM ZERO POINT CALIBRATION OF YAW RATE SENSOR AND DECELERATION

SENSOR

a. Perform the zero point calibration of the yaw rate sensor and deceleration sensor (see

CALIBRATION

).

NEXT

2.RECONFIRM DTC

a. Clear the DTCs.

b. Turn the ignition switch to the ON position.

c. Check that the same DTCs are recorded (see DTC CHECK/CLEAR

).

OK: Go to next step

The same DTCs are recorded.

NG: END

HINT:

The DTCs are recorded because zero point calibration has not been completed.

End the procedure since the same DTCs are not recorded after completion of the zero point calibration.

OK: Go to next step

3.CHECK SENSOR INSTALLATION

Check that the yaw rate and deceleration sensor has been installed properly (see

REPLACEMENT

).

OK:

The sensor is tightened to the specified torque.

The sensor is not tilted.

NG: INSTALL YAW RATE SENSOR CORRECTLY

OK: REPLACE YAW RATE SENSOR (SEE REPLACEMENT

)

Page 113 of 4500

When U0123/62, U0124/95 or U0126/63 are output together with C1232/32, C1234/34, C1243/43, C1244/44,

C1245/45, and C1381/97 inspect and repair the trouble areas indicated by U0121/94, U0123/62, U0124/95 or

U0126/63 first.

1.CHECK SENSOR INSTALLATION (YAW RATE SENSOR)

a. Check that the yaw rate and deceleration sensor has been installed properly (see

REPLACEMENT

).

OK: Go to next step

The sensor is tightened to the specified torque.

The sensor is not tilted.

NG: INSTALL YAW RATE SENSOR CORRECTLY

OK: Go to next step

2.CHECK HARNESS AND CONNECTOR (IG TERMINAL)

a. Disconnect the yaw rate and deceleration sensor connector.

b. Turn the ignition switch to the ON position.

c. Measure the voltage according to the value (s) in the table below.

Standard:

Page 819 of 4500

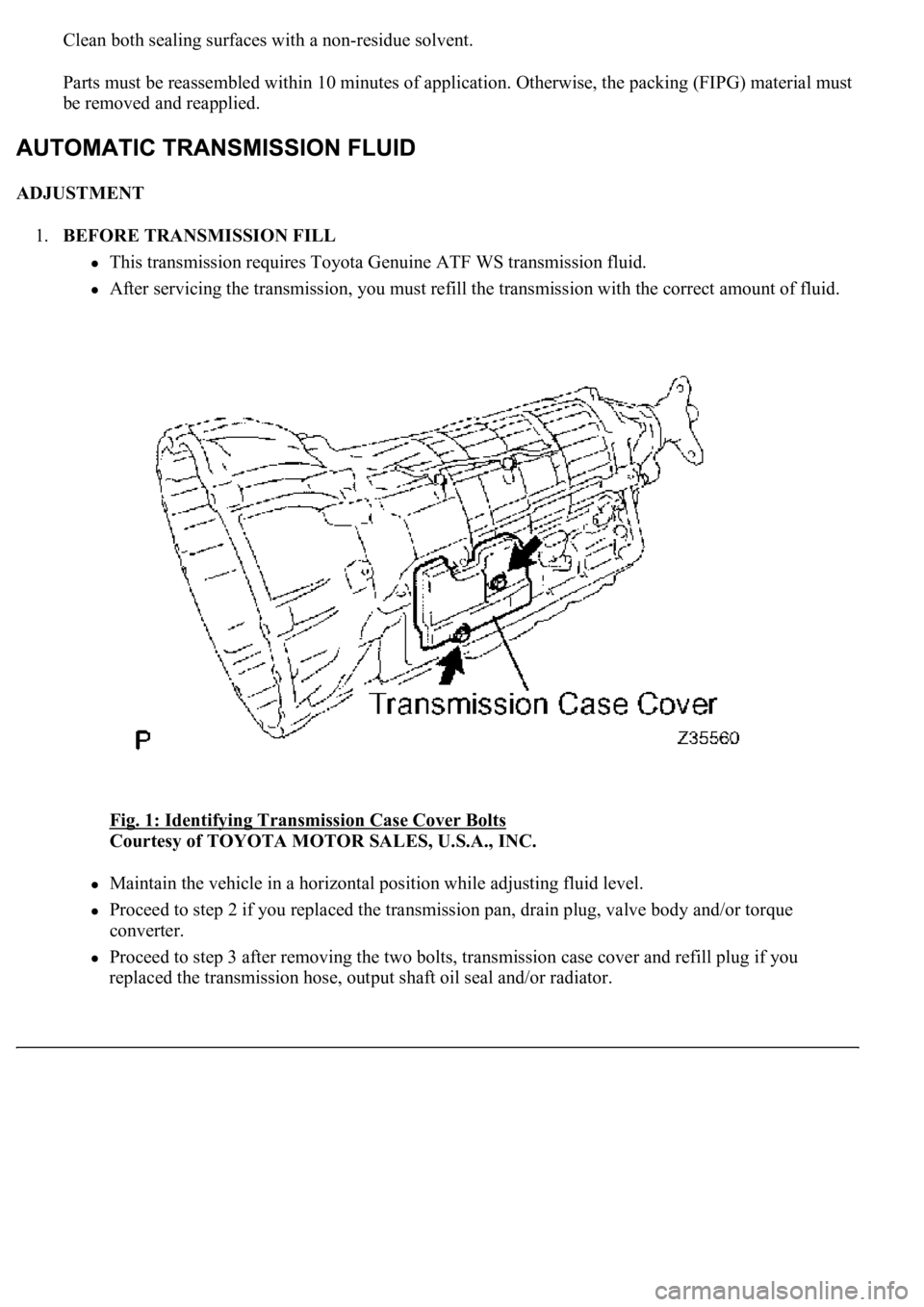

Clean both sealing surfaces with a non-residue solvent.

Parts must be reassembled within 10 minutes of application. Otherwise, the packing (FIPG) material must

be removed and reapplied.

ADJUSTMENT

1.BEFORE TRANSMISSION FILL

This transmission requires Toyota Genuine ATF WS transmission fluid.

After servicing the transmission, you must refill the transmission with the correct amount of fluid.

Fig. 1: Identifying Transmission Case Cover Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Maintain the vehicle in a horizontal position while adjusting fluid level.

Proceed to step 2 if you replaced the transmission pan, drain plug, valve body and/or torque

converter.

Proceed to step 3 after removing the two bolts, transmission case cover and refill plug if you

replaced the transmission hose, output shaft oil seal and/or radiator.

Page 822 of 4500

HINT:

If you cannot add the listed amount of fluid, do the following:

1. Install the refill plug.

2. Allow the engine to idle with air conditioning OFF.

3. Move the shift lever through entire gear range to circulate fluid.

4. Wait for 30 seconds with the engine idling.

5. Stop the engine.

6. Remove the refill plug and add fluid.

7. Reinstall the refill plug.

4.FLUID CIRCULATION

a. Allow the engine to idle with the air conditioning OFF.

b. Move the shift lever through entire gear range to circulate fluid.

5.FLUID TEMPERATURE CHECK

a. With hand-held tester

1. Connect the han

d-held tester to the DLC3.

Output shaft oil seal replacement0.4 liters (0.42 US qts, 0.35 Imp. qts)

Transmission pan and drain plug removal1.3 liters (1.37 US qts, 1.14 Imp. qts)

Transmission valve body removal3.9 liters (4.12 US qts, 3.43 Imp. qts)

Torque converter replacement5.3 liters (5.60 US qts, 4.66 Imp. qts)

Entire transmission assembly7.2 liters (7.61 US qts, 6.34 Imp. qts)

Page 825 of 4500

7.TRANSMISSION

a. Install the overflow plug.

b. Stop the engine.

c. Remove the refill plug.

d. Add 0.4 liters (0.42 US qts, 0.35 Imp. qts) of fluid.

e. Allow the engine to idle and wait for 10 seconds.

f. Proceed to next step.

8.COMPLETE

a. Install the overflow plug with a new gasket.

b. Stop the engine.

c. Install the refill plug with a new gasket.

d. Install the transmission case cover with the two bolts.

Torque:

20 N.m (204 kgf.cm, 15 ft.lbf) for overflow plug

39 N.m (400 kgf.cm, 53 ft.lbf) for refill plug

REPLACEMENT

1.DISCONNECT BATTERY NEGATIVE TERMINAL

2.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO.2 (SEE REPLACEMENT

)

3.REMOVE INSTRUMENT PANEL GARNISH SUB-ASSY LH (SEE REPLACEMENT

)

4.REMOVE INSTRUMENT PANEL FINISH PANEL (SEE REPLACEMENT

)

5.REMOVE INSTRUMENT PANEL UNDER COVER SUB-ASSY NO.1 (SEE REPLACEMENT

)

6.REMOVE SWITCH BRACE HOLE COVER (SEE REPLACEMENT

)

7.REMOVE INSTRUMENT PANEL SAFETY PAD SUB-ASSY NO.1 (SEE REPLACEMENT

)

8.REMOVE INSTRUMENT PANEL CUP HOLDER ASSY (SEE REPLACEMENT

)

9.REMOVE CONSOLE UPPER REAR PANEL SUB-ASSY (SEE REPLACEMENT

)

10.REMOVE CONSOLE BOX CARPET (SEE REPLACEMENT

)

11.REMOVE REAR CONSOLE ARMREST ASSY (SEE REPLACEMENT

)

12.REMOVE INSTRUMENT PANEL FINISH PANEL LOWER CENTER (SEE REPLACEMENT

)

13.REMOVE INSTRUMENT CLUSTER FINISH PANEL SUB-ASSY CENTER (SEE

REPLACEMENT

)

14.REMOVE CONSOLE PANEL SUB-ASSY UPPER (SEE REPLACEMENT

)

15.REMOVE CONSOLE BOX (SEE REPLACEMENT

)

16.SEPARATE OXYGEN SENSOR (SEE REPLACEMENT

)