ignition switch LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 819 of 4087

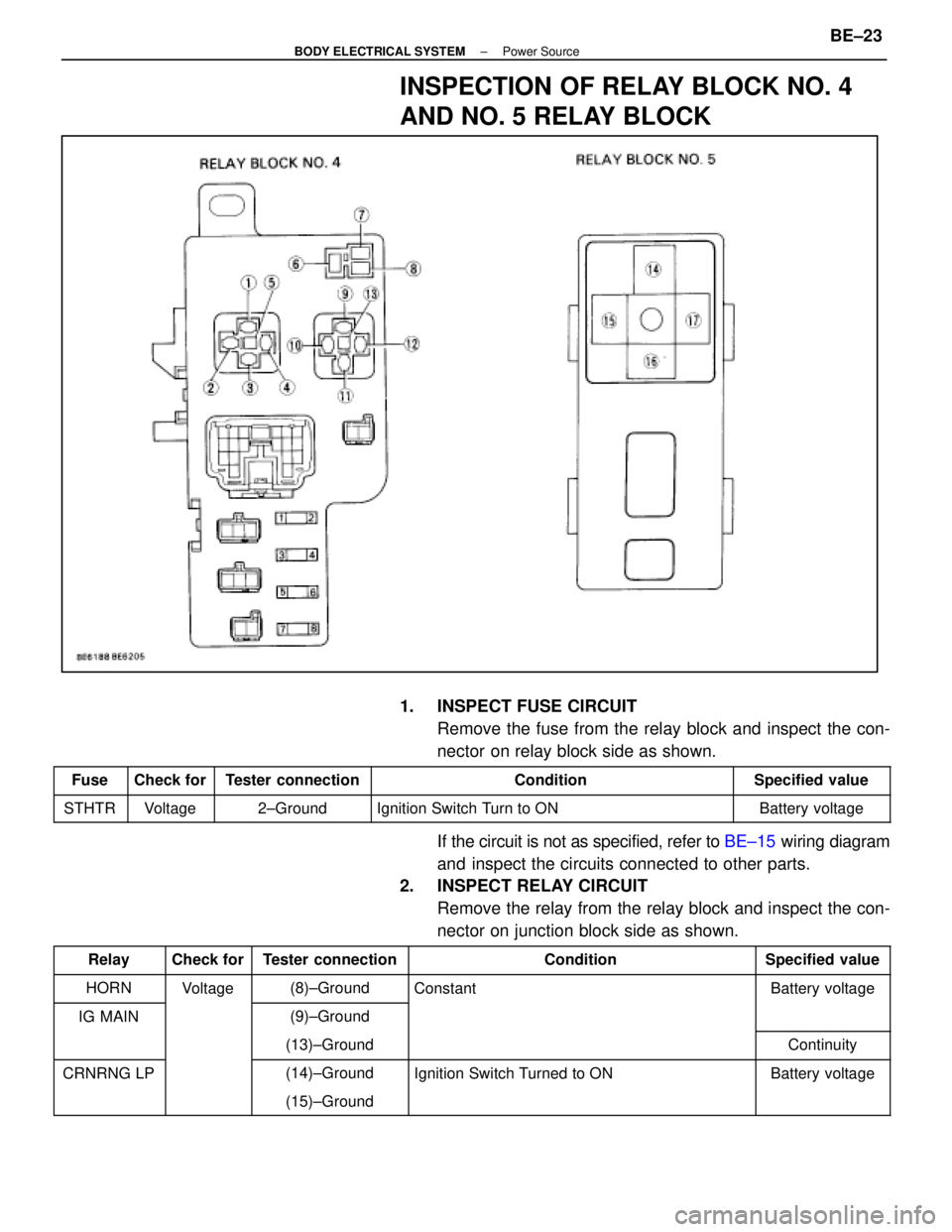

INSPECTION OF RELAY BLOCK NO. 4

AND NO. 5 RELAY BLOCK

1. INSPECT FUSE CIRCUITRemove the fuse from the relay block and inspect the con-

nector on relay block side as shown.

FuseCheck forTester connectionConditionSpecified value

STHTRVoltage2±GroundIgnition Switch Turn to ONBattery voltage

If the circuit is not as specified, refer to BE±15 wiring diagram

and inspect the circuits connected to other parts.

2. INSPECT RELAY CIRCUIT

Remove the relay from the relay block and inspect the con-

nector on junction block side as shown.

RelayCheck forTester connectionConditionSpecified value

HORNVoltage(8)±GroundConstantBattery voltage

IG MAIN(9)±Ground

(13)±GroundContinuity

CRNRNG LP(14)±GroundIgnition Switch Turned to ONBattery voltage

(15)±Ground

±

BODY ELECTRICAL SYSTEM Power SourceBE±23

WhereEverybodyKnowsYourName

Page 821 of 4087

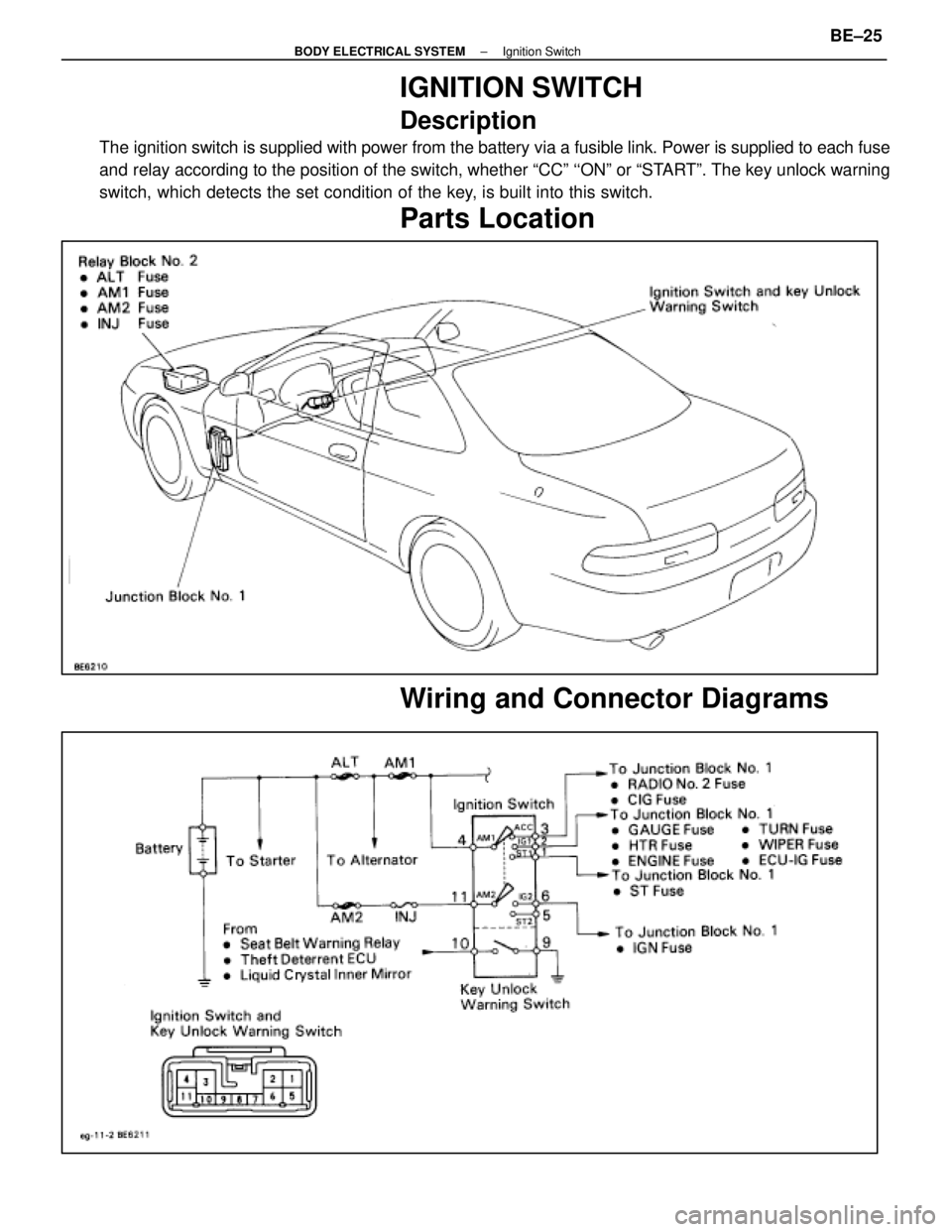

IGNITION SWITCH

Description

The ignition switch is supplied with power from the battery via a fusible l\

ink. Power is supplied to each fuse

and relay according to the position of the switch, whether ªCCº ``ONº or ªSTARTº. The key unlock warning

switch, which detects the set condition of the key, is built into this switch.

Parts Location

Wiring and Connector Diagrams

±

BODY ELECTRICAL SYSTEM Ignition SwitchBE±25

WhereEverybodyKnowsYourName

Page 822 of 4087

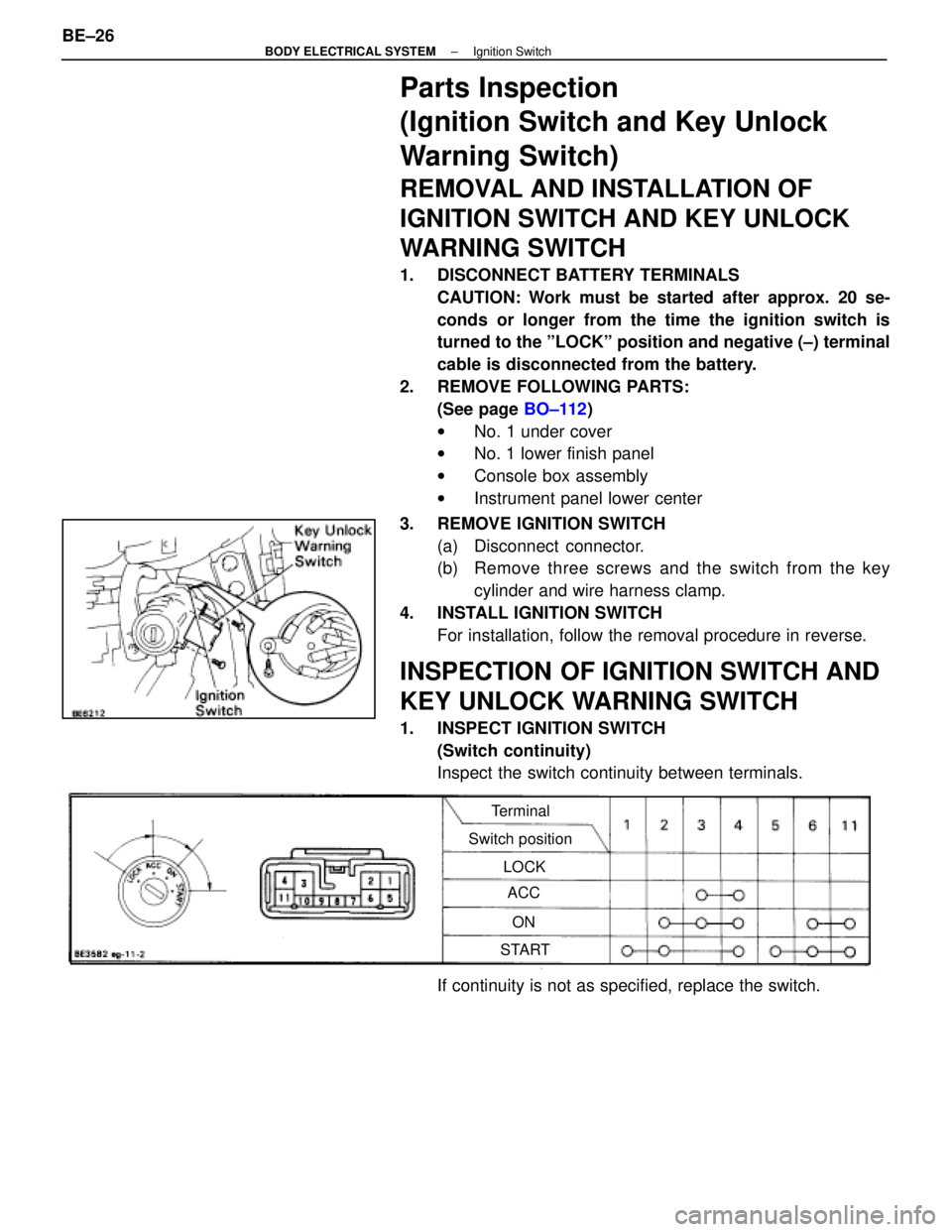

Parts Inspection

(Ignition Switch and Key Unlock

Warning Switch)

REMOVAL AND INSTALLATION OF

IGNITION SWITCH AND KEY UNLOCK

WARNING SWITCH

1. DISCONNECT BATTERY TERMINALSCAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

2. REMOVE FOLLOWING PARTS: (See page BO±112)

w No. 1 under cover

w No. 1 lower finish panel

w Console box assembly

w Instrument panel lower center

3. REMOVE IGNITION SWITCH (a) Disconnect connector.

(b) Remove three screws and the switch from the keycylinder and wire harness clamp.

4. INSTALL IGNITION SWITCH For installation, follow the removal procedure in reverse.

INSPECTION OF IGNITION SWITCH AND

KEY UNLOCK WARNING SWITCH

1. INSPECT IGNITION SWITCH(Switch continuity)

Inspect the switch continuity between terminals.

Terminal

Switch position LOCKACC

ON

START

If continuity is not as specified, replace the switch.

BE±26

±

BODY ELECTRICAL SYSTEM Ignition Switch

WhereEverybodyKnowsYourName

Page 823 of 4087

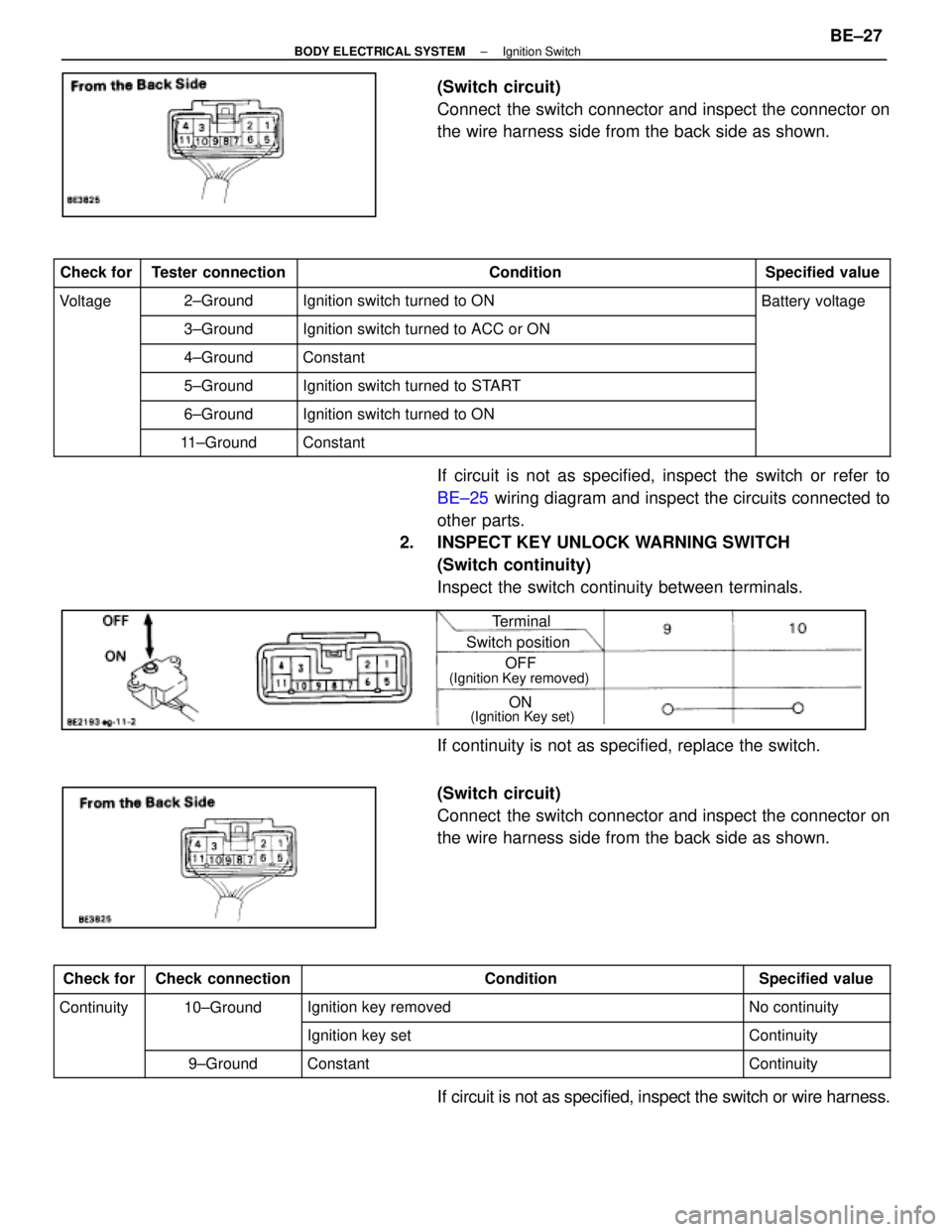

(Switch circuit)

Connect the switch connector and inspect the connector on

the wire harness side from the back side as shown.

Check forTester connectionConditionSpecified value

Voltage2±GroundIgnition switch turned to ONBattery voltage

3±GroundIgnition switch turned to ACC or ON

4±GroundConstant

5±GroundIgnition switch turned to START

6±GroundIgnition switch turned to ON

11±GroundConstant

If circuit is not as specified, inspect the switch or refer to

BE±25 wiring diagram and inspect the circuits connected to

other parts.

2. INSPECT KEY UNLOCK WARNING SWITCH

(Switch continuity)

Inspect the switch continuity between terminals.

Terminal

Switch position

ON

OFF

(Ignition Key removed)

(Ignition Key set)

If continuity is not as specified, replace the switch.

(Switch circuit)

Connect the switch connector and inspect the connector on

the wire harness side from the back side as shown.

Check forCheck connectionConditionSpecified value

Continuity10±GroundIgnition key removedNo continuity

Ignition key setContinuity

9±GroundConstantContinuity

If circuit is not as specified, inspect the switch or wire harness.

±

BODY ELECTRICAL SYSTEM Ignition SwitchBE±27

WhereEverybodyKnowsYourName

Page 826 of 4087

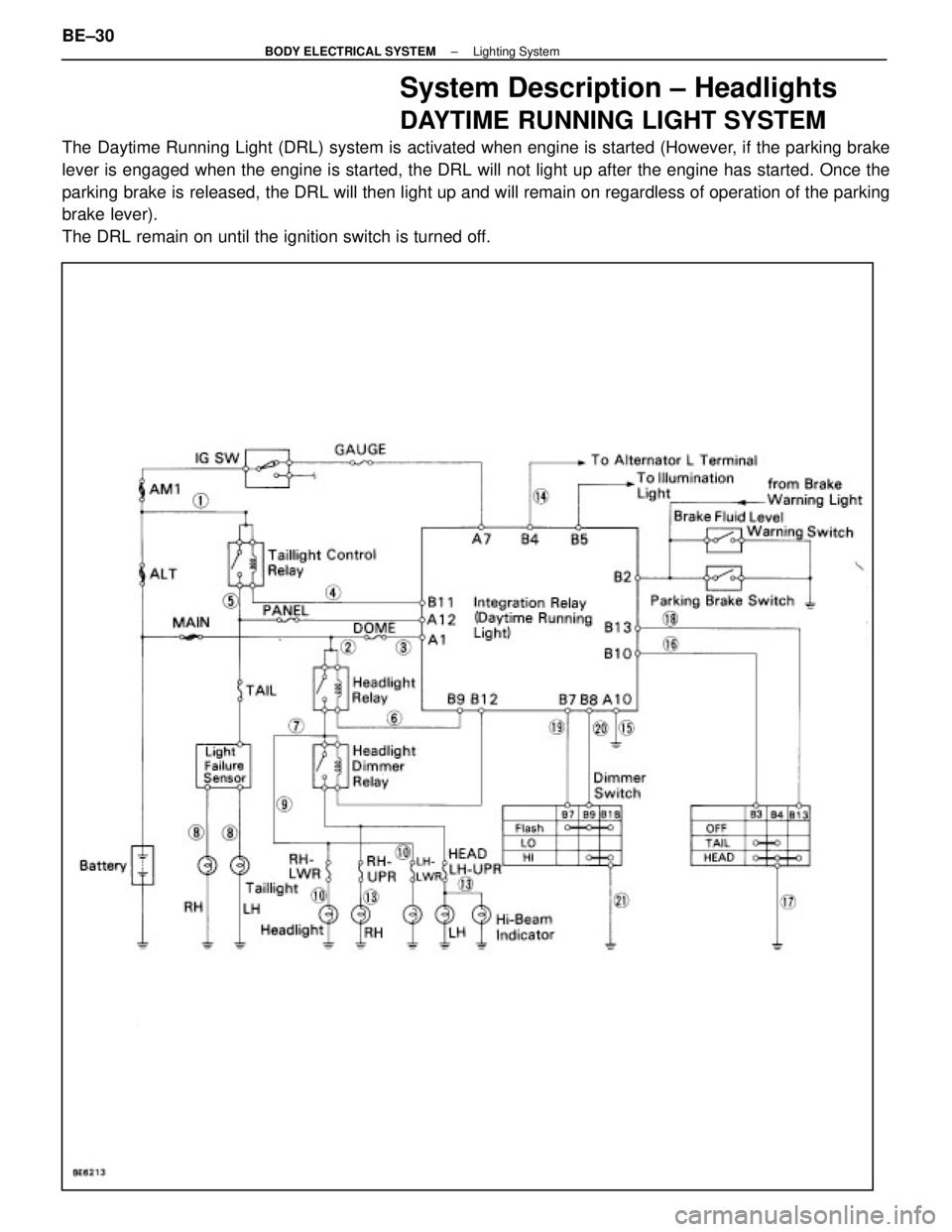

System Description ± Headlights

DAYTIME RUNNING LIGHT SYSTEM

The Daytime Running Light (DRL) system is activated when engine is started (However, if the parking brake

lever is engaged when the engine is started, the DRL will not light up a\

fter the engine has started. Once the

parking brake is released, the DRL will then light up and will remain on regardless of operation of\

the parking

brake lever).

The DRL remain on until the ignition switch is turned off.

BE±30±

BODY ELECTRICAL SYSTEM Lighting System

WhereEverybodyKnowsYourName

Page 827 of 4087

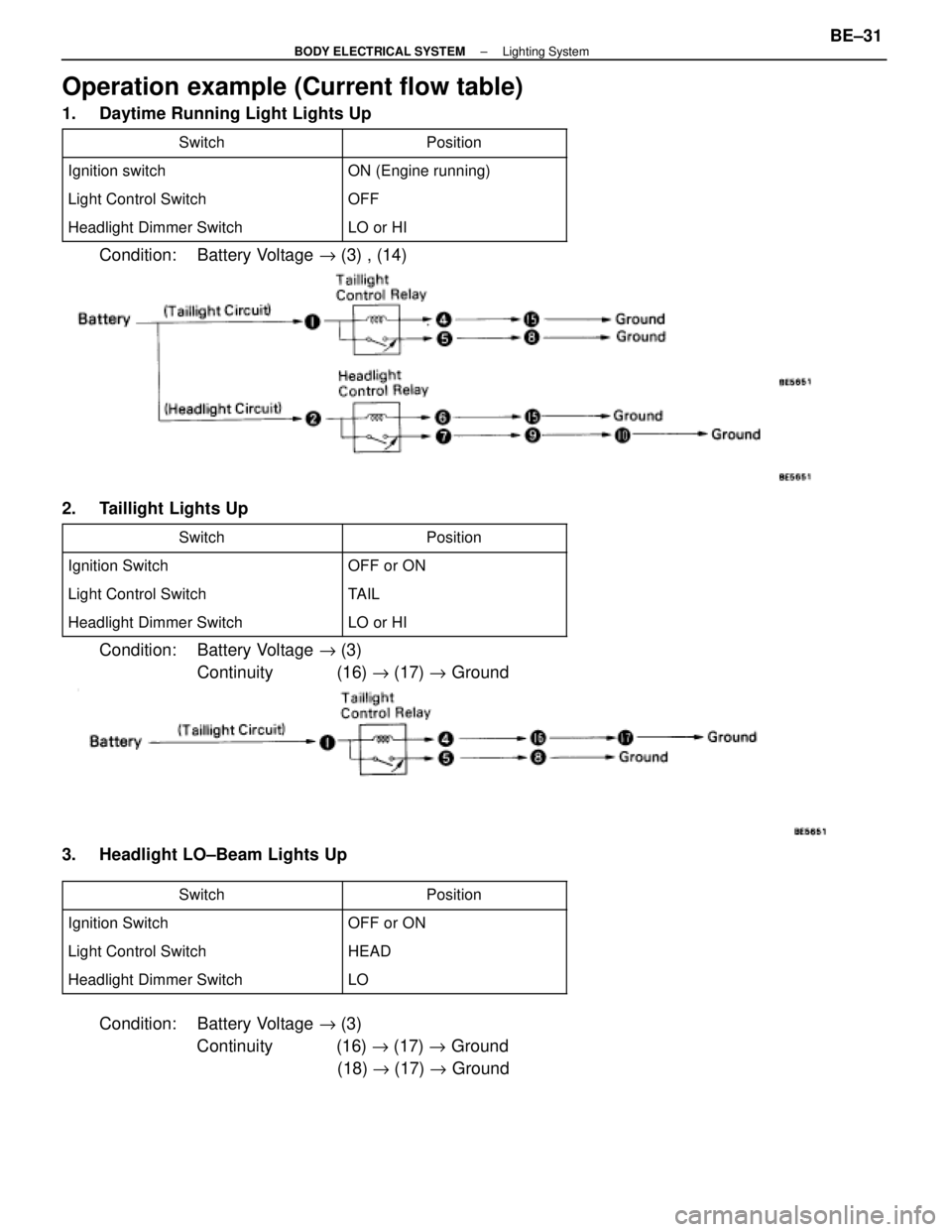

Operation example (Current flow table)

1. Daytime Running Light Lights Up

SwitchPosition

Ignition switchON (Engine running)

Light Control SwitchOFF

Headlight Dimmer SwitchLO or HI

Condition: Battery Voltage " (3) , (14)

2. Taillight Lights Up

SwitchPosition

Ignition SwitchOFF or ON

Light Control SwitchTAIL

Headlight Dimmer SwitchLO or HI

Condition: Battery Voltage " (3)

Continuity (16) " (17) " Ground

3. Headlight LO±Beam Lights Up

SwitchPosition

Ignition SwitchOFF or ON

Light Control SwitchHEAD

Headlight Dimmer SwitchLO

Condition: Battery Voltage " (3)

Continuity (16) " (17) " Ground

(18) " (17) " Ground

±

BODY ELECTRICAL SYSTEM Lighting SystemBE±31

WhereEverybodyKnowsYourName

Page 828 of 4087

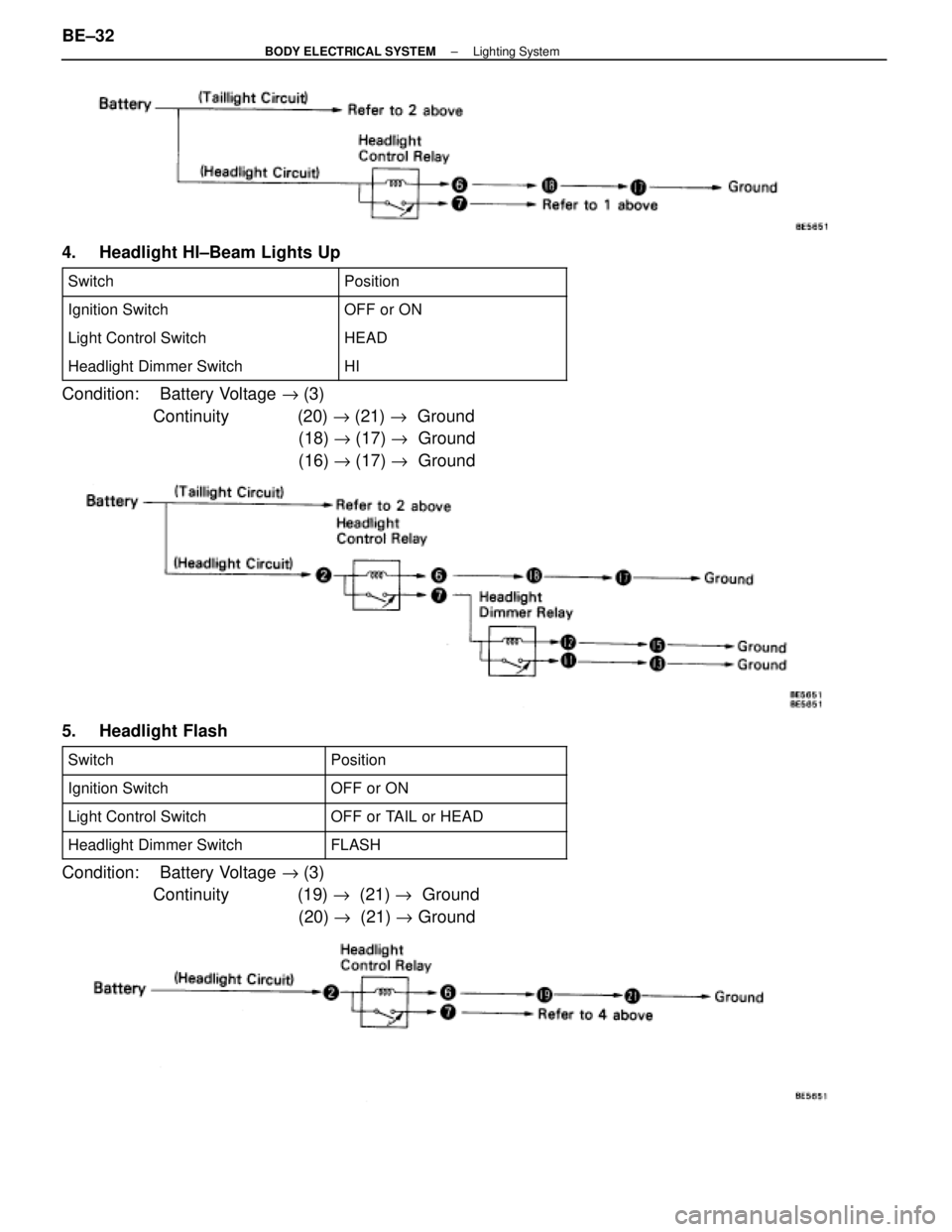

4. Headlight HI±Beam Lights Up

SwitchPosition

Ignition SwitchOFF or ON

Light Control SwitchHEAD

Headlight Dimmer SwitchHI

Condition: Battery Voltage " (3)

Continuity (20) " (21) " Ground

(18) " (17) " Ground

(16) " (17) " Ground

5. Headlight Flash

SwitchPosition

Ignition SwitchOFF or ON

Light Control SwitchOFF or TAIL or HEAD

Headlight Dimmer SwitchFLASH

Condition: Battery Voltage " (3)

Continuity (19) " (21) " Ground

(20) " (21) " Ground

BE±32±

BODY ELECTRICAL SYSTEM Lighting System

WhereEverybodyKnowsYourName

Page 833 of 4087

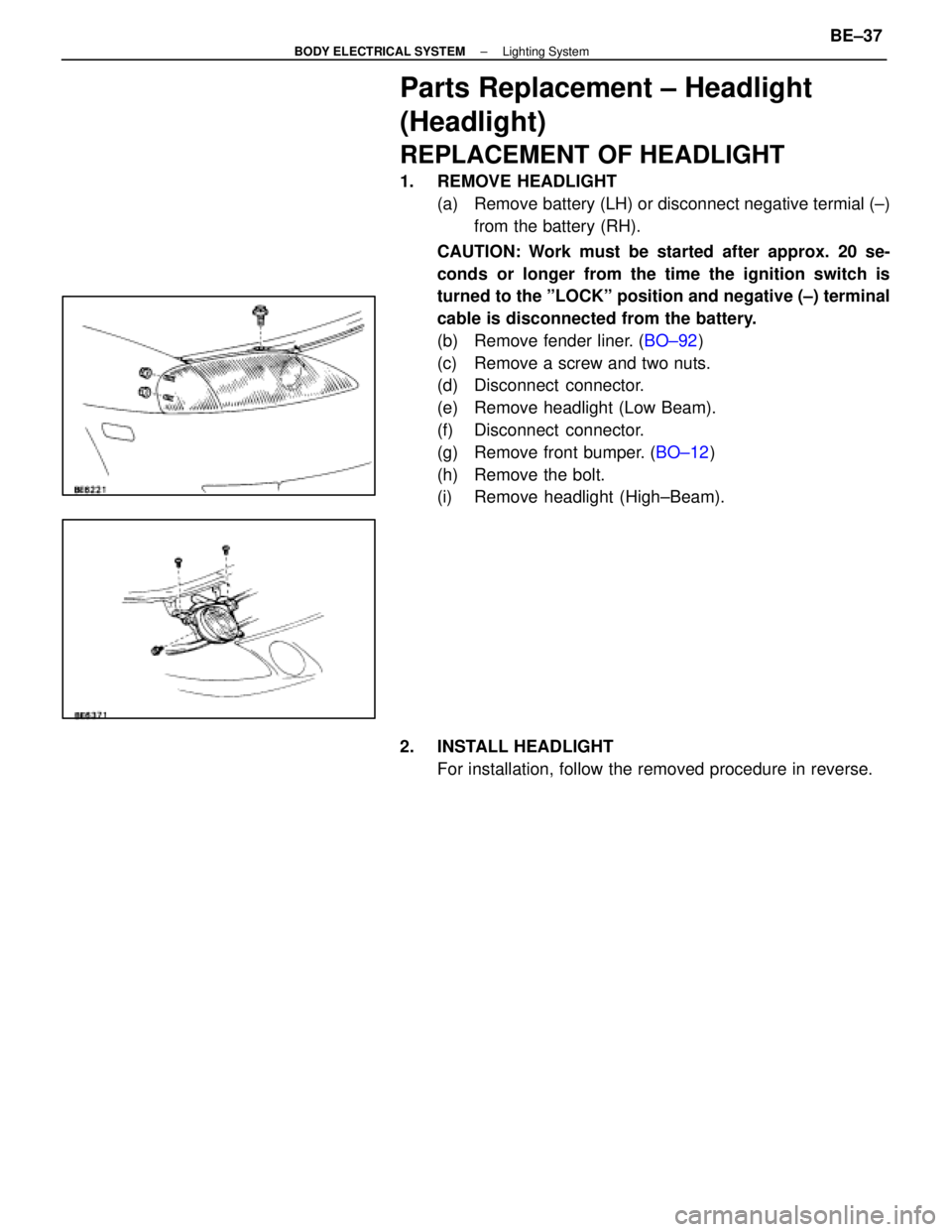

Parts Replacement ± Headlight

(Headlight)

REPLACEMENT OF HEADLIGHT

1. REMOVE HEADLIGHT(a) Remove battery (LH) or disconnect negative termial (±)from the battery (RH).

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

(b) Remove fender liner. ( BO±92)

(c) Remove a screw and two nuts.

(d) Disconnect connector.

(e) Remove headlight (Low Beam).

(f) Disconnect connector.

(g) Remove front bumper. ( BO±12)

(h) Remove the bolt.

(i) Remove headlight (High±Beam).

2. INSTALL HEADLIGHT For installation, follow the removed procedure in reverse.

±

BODY ELECTRICAL SYSTEM Lighting SystemBE±37

WhereEverybodyKnowsYourName

Page 835 of 4087

Parts Inspection ± Headlight System

(Combination Switch Assembly)

REMOVAL OF COMBINATION SWITCH

ASSEMBLY

1. REMOVAL FOLLOWING PARTS:(See page BO±112)

w No. 1 under cover

w No. 1 lower finish Panel

NOTICE:

w Turn the steering wheel and front wheels to the straight

ahead position.

w Turn the ignition switch to the OFF position, then remove

the battery negative terminal.

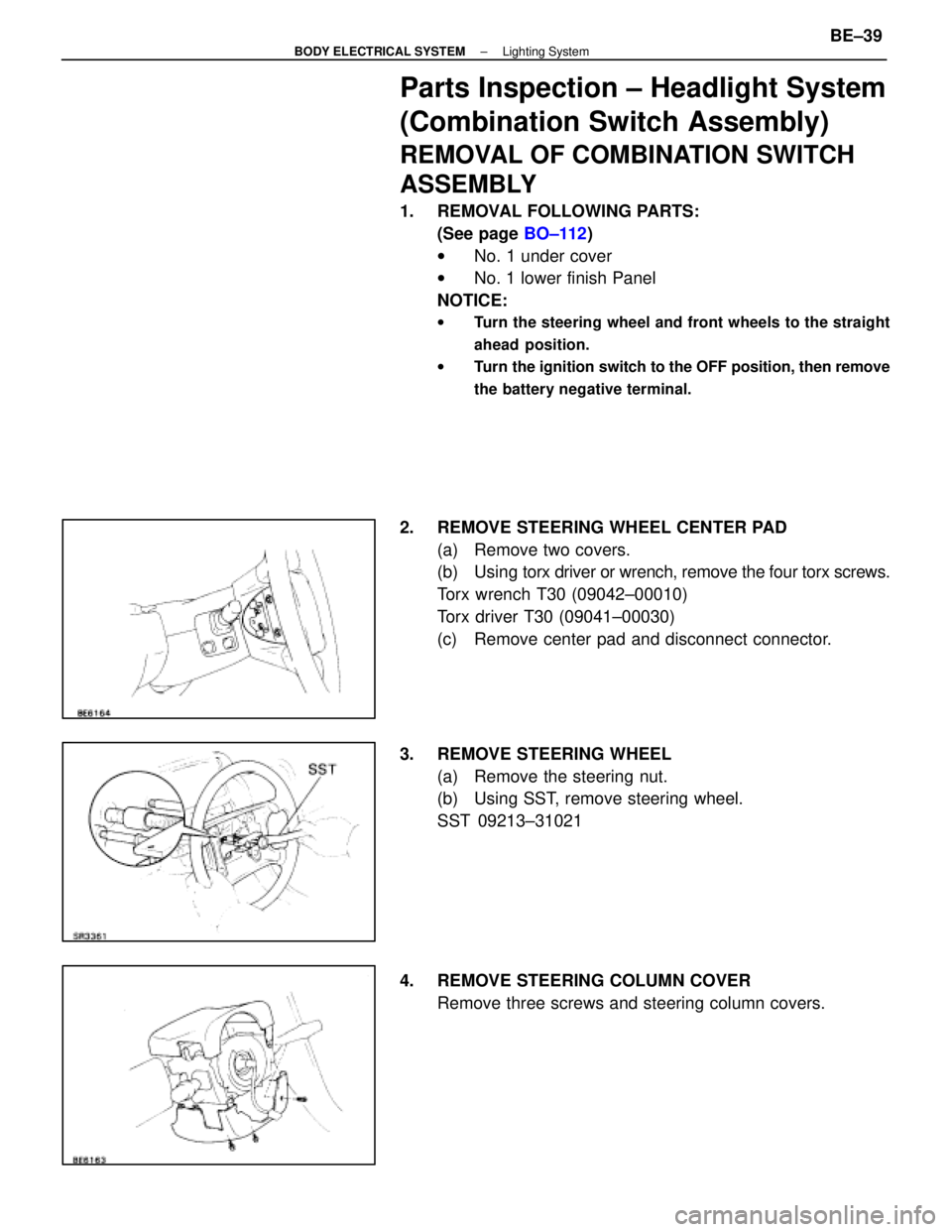

2. REMOVE STEERING WHEEL CENTER PAD

(a) Remove two covers.

(b) Using torx driver or wrench, remove the four torx screws.

Torx wrench T30 (09042±00010)

Torx driver T30 (09041±00030)

(c) Remove center pad and disconnect connector.

3. REMOVE STEERING WHEEL (a) Remove the steering nut.

(b) Using SST, remove steering wheel.

SST 09213±31021

4. REMOVE STEERING COLUMN COVER Remove three screws and steering column covers.

±

BODY ELECTRICAL SYSTEM Lighting SystemBE±39

WhereEverybodyKnowsYourName

Page 843 of 4087

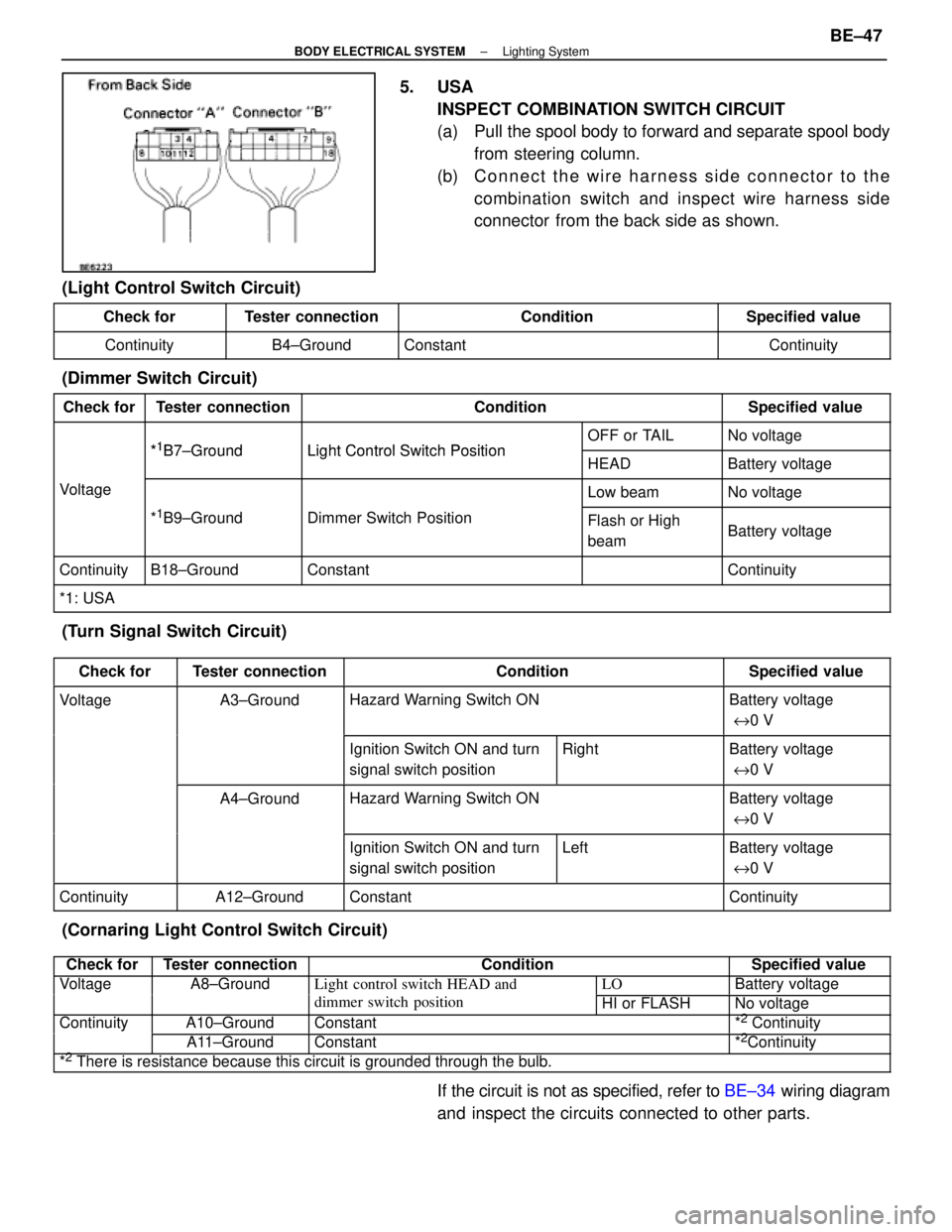

5. USAINSPECT COMBINATION SWITCH CIRCUIT

(a) Pull the spool body to forward and separate spool bodyfrom steering column.

(b) C onnect the wire harness side connector to the

combination switch and inspect wire harness side

connector from the back side as shown.

(Light Control Switch Circuit)

Check forTester connectionConditionSpecified value

ContinuityB4±GroundConstantContinuity

(Dimmer Switch Circuit)

Check forTester connectionConditionSpecified value

*1B7 GroundLight Control Switch PositionOFF or TAILNo voltage*1B7±GroundLight Control Switch PositionHEADBattery voltage

VoltageLow beamNo voltage

*1B9±GroundDimmer Switch PositionFlash or High

beamBattery voltage

ContinuityB18±GroundConstantContinuity

*1: USA

(Turn Signal Switch Circuit)

Check forTester connectionConditionSpecified value

VoltageA3±GroundHazard Warning Switch ONBattery voltage

e 0 V

Ignition Switch ON and turn

signal switch positionRightBattery voltage

e 0 V

A4±GroundHazard Warning Switch ONBattery voltage

e 0 V

Ignition Switch ON and turn

signal switch positionLeftBattery voltage

e 0 V

ContinuityA12±GroundConstantContinuity

(Cornaring Light Control Switch Circuit)

Check forTester connectionConditionSpecified value

VoltageA8±GroundLight control switch HEAD andLOBattery voltagegg

dimmer switch positionHI or FLASHNo voltage

ContinuityA10±GroundConstant*2 Continuityy

A11±GroundConstant*2Continuity

*2 There is resistance because this circuit is grounded through the bulb.

If the circuit is not as specified, refer to BE±34 wiring diagram

and inspect the circuits connected to other parts.

±

BODY ELECTRICAL SYSTEM Lighting SystemBE±47

WhereEverybodyKnowsYourName