ABS LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1157 of 4087

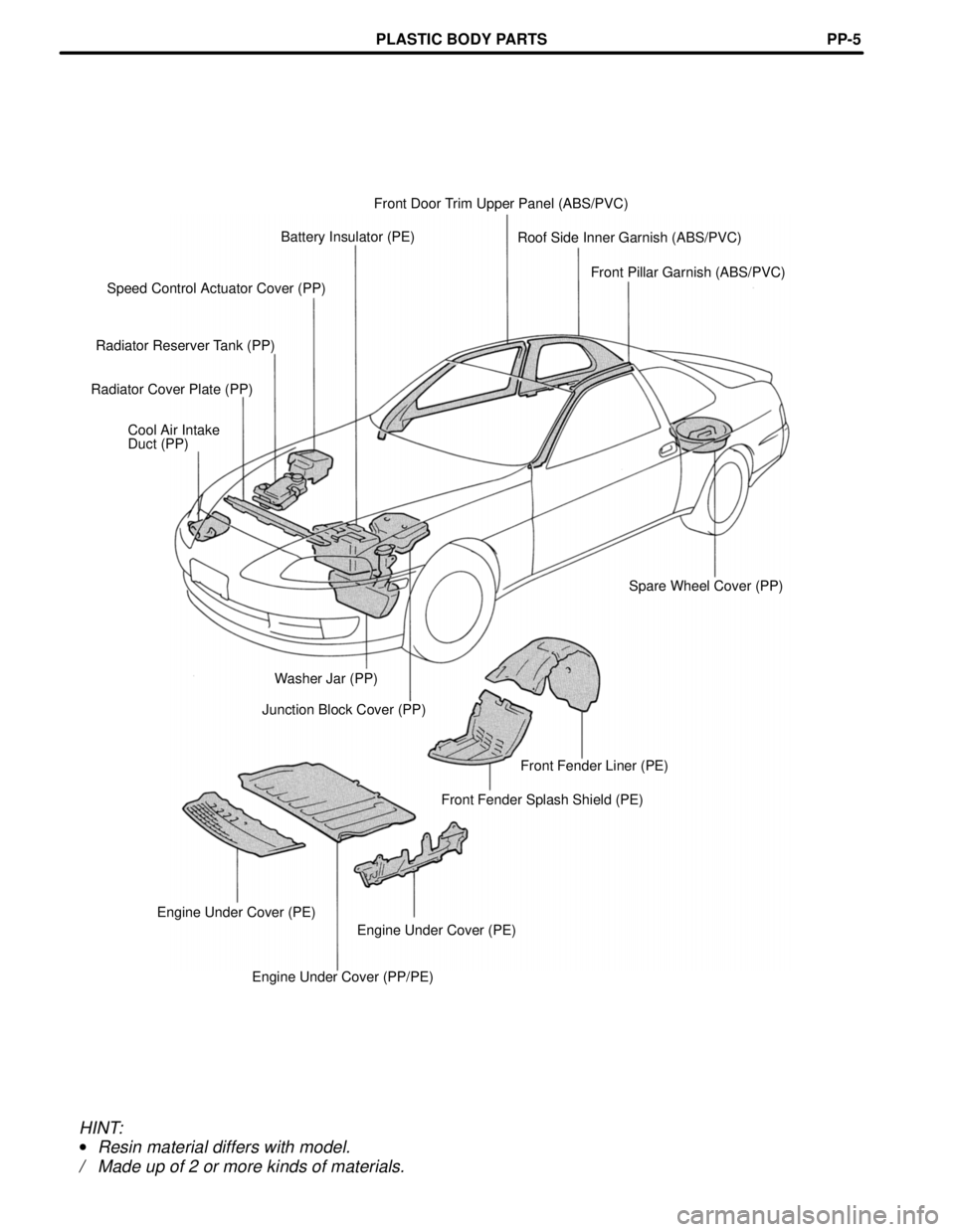

Front Door Trim Upper Panel (ABS/PVC)

Battery Insulator (PE) Roof Side Inner Garnish (ABS/PVC)

Front Pillar Garnish (ABS/PVC)

Speed Control Actuator Cover (PP)

Radiator Reserver Tank (PP)

Radiator Cover Plate (PP) Cool Air Intake

Duct (PP)

Spare Wheel Cover (PP)

Washer Jar (PP)

Junction Block Cover (PP)

Front Fender Liner (PE)

Front Fender Splash Shield (PE)

Engine Under Cover (PE) Engine Under Cover (PE)

Engine Under Cover (PP/PE)

HINT:

wResin material differs with model.

/ Made up of 2 or more kinds of materials.

PLASTIC BODY PARTSPP-5

WhereEverybodyKnowsYourName

Page 1248 of 4087

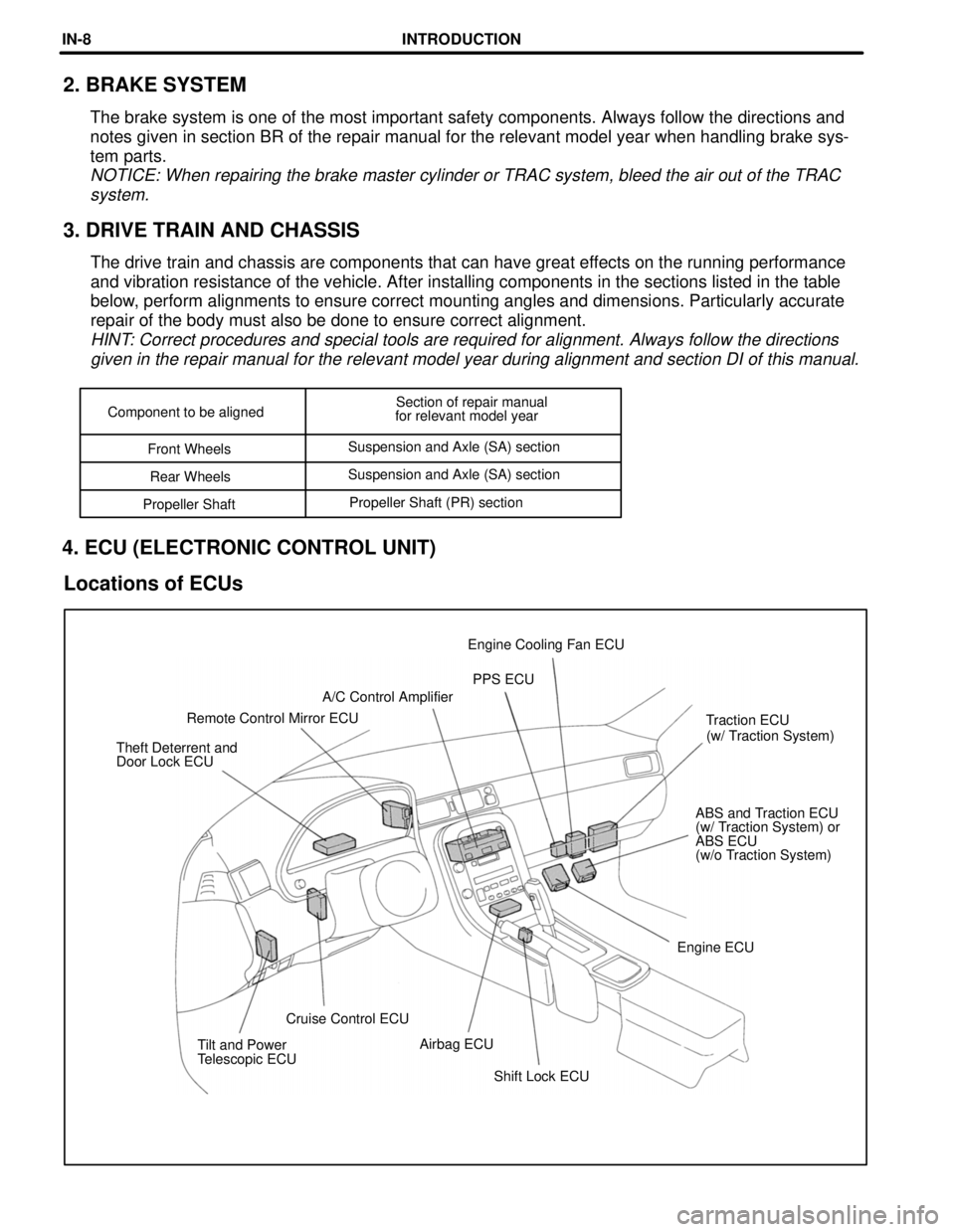

Shift Lock ECU

Tilt and Power

Telescopic ECU

Airbag ECU

Cruise Control ECU Engine ECUABS and Traction ECU

(w/ Traction System) or

ABS ECU

(w/o Traction System)

Theft Deterrent and

Door Lock ECU

(w/ Traction System)

Traction ECU

Remote Control Mirror ECU A/C Control Amplifier

PPS ECU

Engine Cooling Fan ECU

Component to be aligned

Section of repair manual

for relevant model year

Front Wheels Suspension and Axle (SA) section

Rear Wheels Suspension and Axle (SA) section

Propeller Shaft Propeller Shaft (PR) section

2. BRAKE SYSTEM

The brake system is one of the most important safety components. Always \

follow the directions and

notes given in section BR of the repair manual for the relevant model ye\

ar when handling brake sys-

tem parts.

NOTICE: When repairing the brake master cylinder or TRAC system, bleed t\

he air out of the TRAC

system.

3. DRIVE TRAIN AND CHASSIS

The drive train and chassis are components that can have great effects on the running performance

and vibration resistance of the vehicle. After installing components in \

the sections listed in the table

below, perform alignments to ensure correct mounting angles and dimensions. P\

articularly accurate

repair of the body must also be done to ensure correct alignment.

HINT: Correct procedures and special tools are required for alignment. Alway\

s follow the directionsgiven in the repair manual for the relevant model year during alignment \

and section DI of this manual.

4. ECU (ELECTRONIC CONTROL UNIT)

Locations of ECUs

INTRODUCTIONIN-8

WhereEverybodyKnowsYourName

Page 1342 of 4087

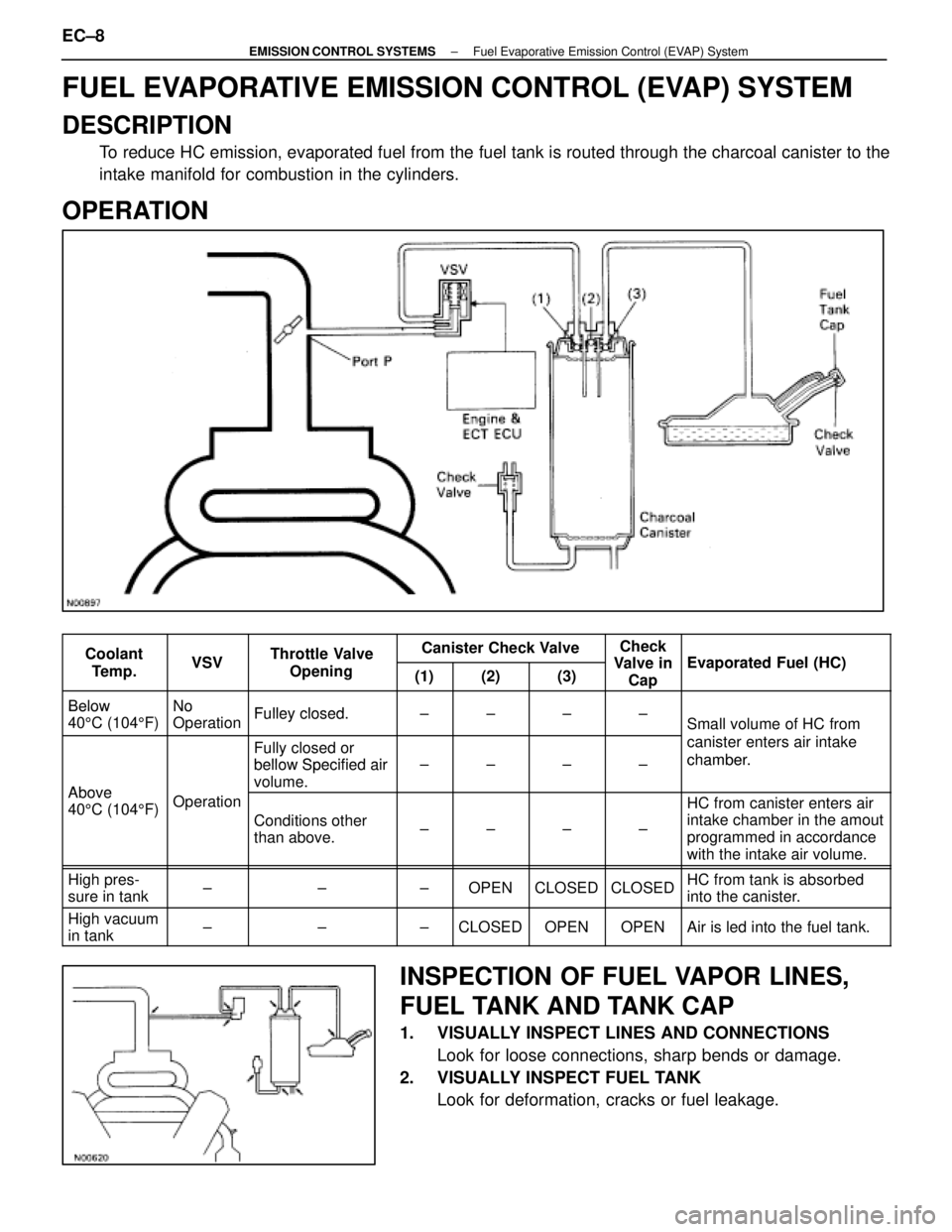

FUEL EVAPORATIVE EMISSION CONTROL (EVAP) SYSTEM

DESCRIPTION

To reduce HC emission, evaporated fuel from the fuel tank is routed throug\

h the charcoal canister to the

intake manifold for combustion in the cylinders.

OPERATION

CoolantVSVThrottle ValveCanister Check ValveCheck

Valve inEvaporated F el (HC)Coolant

Te m p .VSVThrottle Valve

Opening(1)(2)(3)Valve inCapEvaporated Fuel (HC)

BelowNoFulley closedBelow

40 5C (104 5F)

No

OperationFulley closed.±±±±Small volume of HC from

Fully closed or

bellow Specified air

canister enters air intake

chamber.

Above

bellow Specified air

volume.±±±±chamber.

Above

40 5C (104 5F)Operation

Conditions other

than above.±±±±

HC from canister enters air

intake chamber in the amout

programmed in accordance

with the intake air volume.

High pres-

sure in tank±±±OPENCLOSEDCLOSEDHC from tank is absorbed

into the canister.

High vacuum

in tank±±±CLOSEDOPENOPENAir is led into the fuel tank.

INSPECTION OF FUEL VAPOR LINES,

FUEL TANK AND TANK CAP

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK Look for deformation, cracks or fuel leakage.

EC±8

±

EMISSION CONTROL SYSTEMS Fuel Evaporative Emission Control (EVAP) System

WhereEverybodyKnowsYourName

Page 1522 of 4087

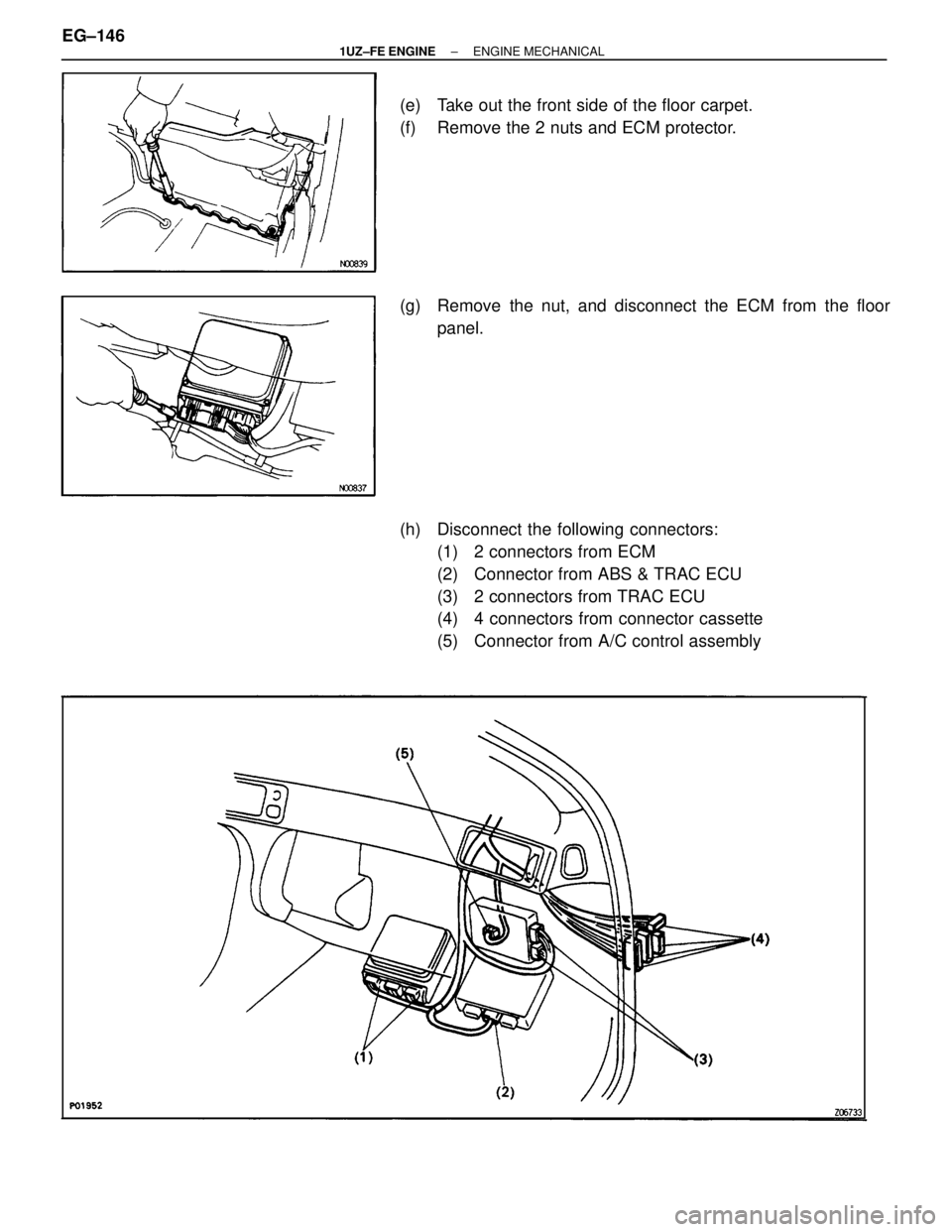

(e) Take out the front side of the floor carpet.

(f) Remove the 2 nuts and ECM protector.

(g) Remove the nut, and disconnect the ECM from the floorpanel.

(h) Disconnect the following connectors: (1) 2 connectors from ECM

(2) Connector from ABS & TRAC ECU

(3) 2 connectors from TRAC ECU

(4) 4 connectors from connector cassette

(5) Connector from A/C control assembly

EG±146

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1525 of 4087

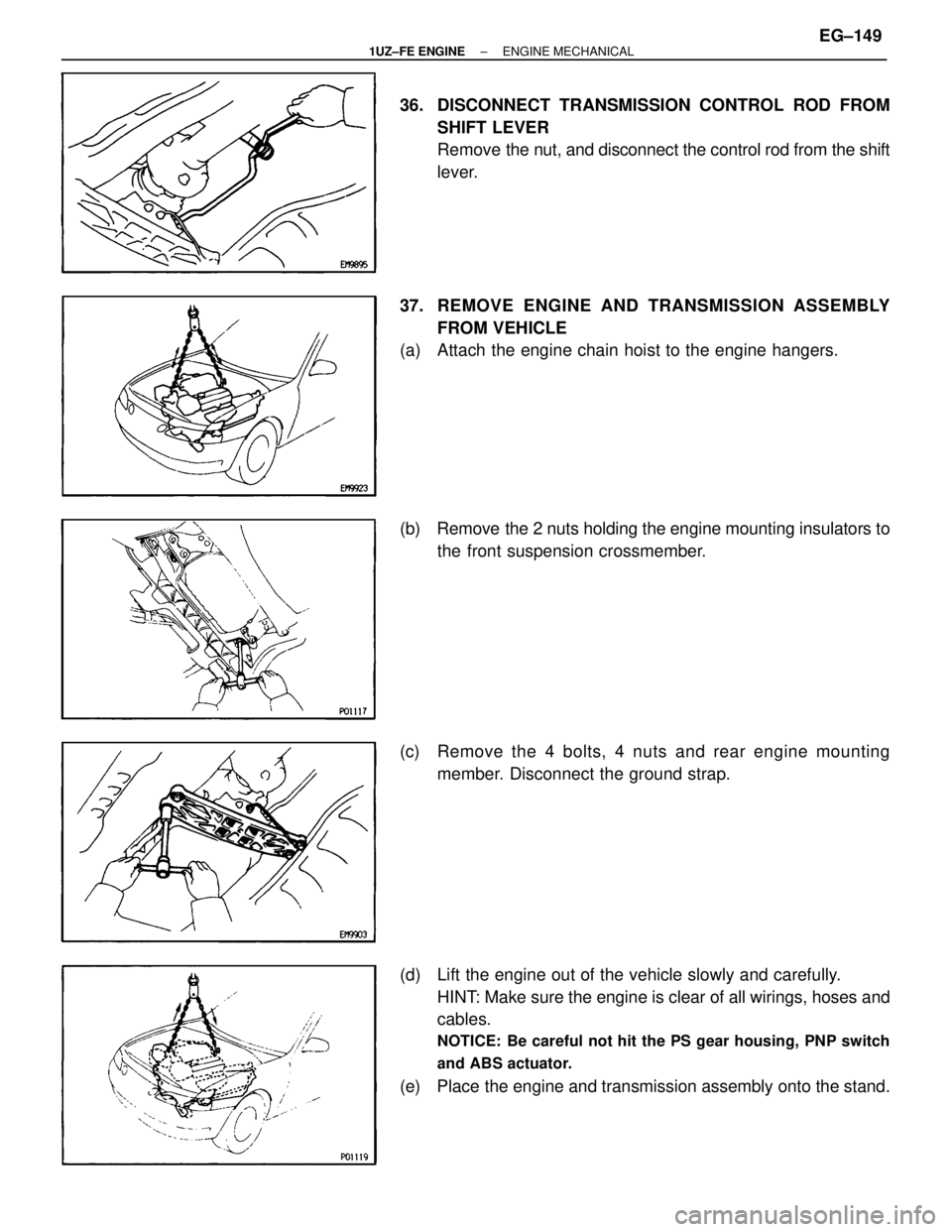

36. DISCONNECT TRANSMISSION CONTROL ROD FROMSHIFT LEVER

Remove the nut, and disconnect the control rod from the shift

lever.

37. REMOVE ENGINE AND TRANSMISSION A SSEMBLY

FROM VEHICLE

(a) Attach the engine chain hoist to the engine hangers.

(b) Remove the 2 nuts holding the engine mounting insulators to

the front suspension crossmember.

(c) Remove the 4 bolts, 4 nuts and rear engine m ounting

member. Disconnect the ground strap.

(d) Lift the engine out of the vehicle slowly and carefully. HINT: Make sure the engine is clear of all wirings, hoses and

cables.

NOTICE: Be careful not hit the PS gear housing, PNP switch

and ABS actuator.

(e) Place the engine and transmission assembly onto the stand.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±149

WhereEverybodyKnowsYourName

Page 1571 of 4087

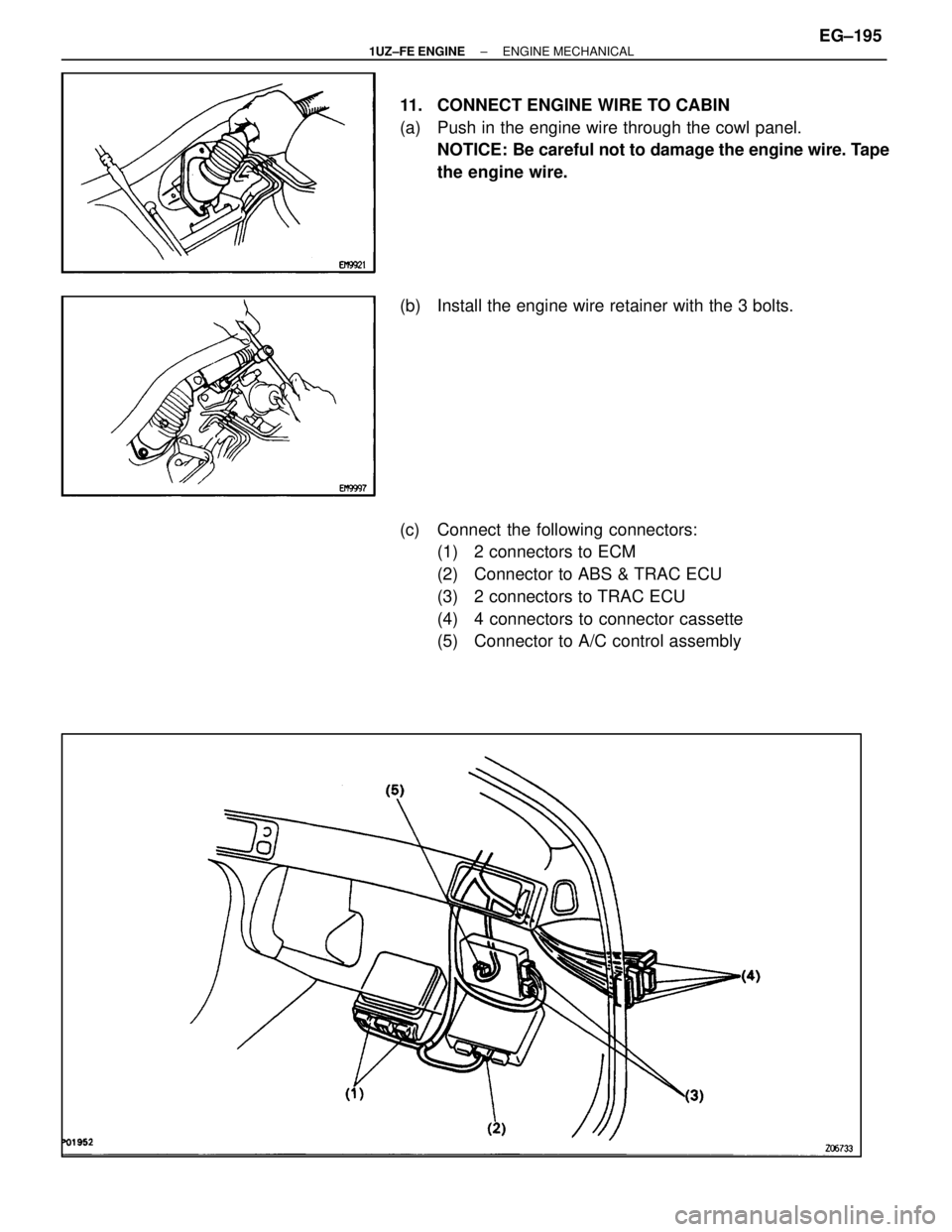

11. CONNECT ENGINE WIRE TO CABIN

(a) Push in the engine wire through the cowl panel.NOTICE: Be careful not to damage the engine wire. Tape

the engine wire.

(b) Install the engine wire retainer with the 3 bolts.

(c) Connect the following connectors: (1) 2 connectors to ECM

(2) Connector to ABS & TRAC ECU

(3) 2 connectors to TRAC ECU

(4) 4 connectors to connector cassette

(5) Connector to A/C control assembly

±

1UZ±FE ENGINE ENGINE MECHANICALEG±195

WhereEverybodyKnowsYourName

Page 1590 of 4087

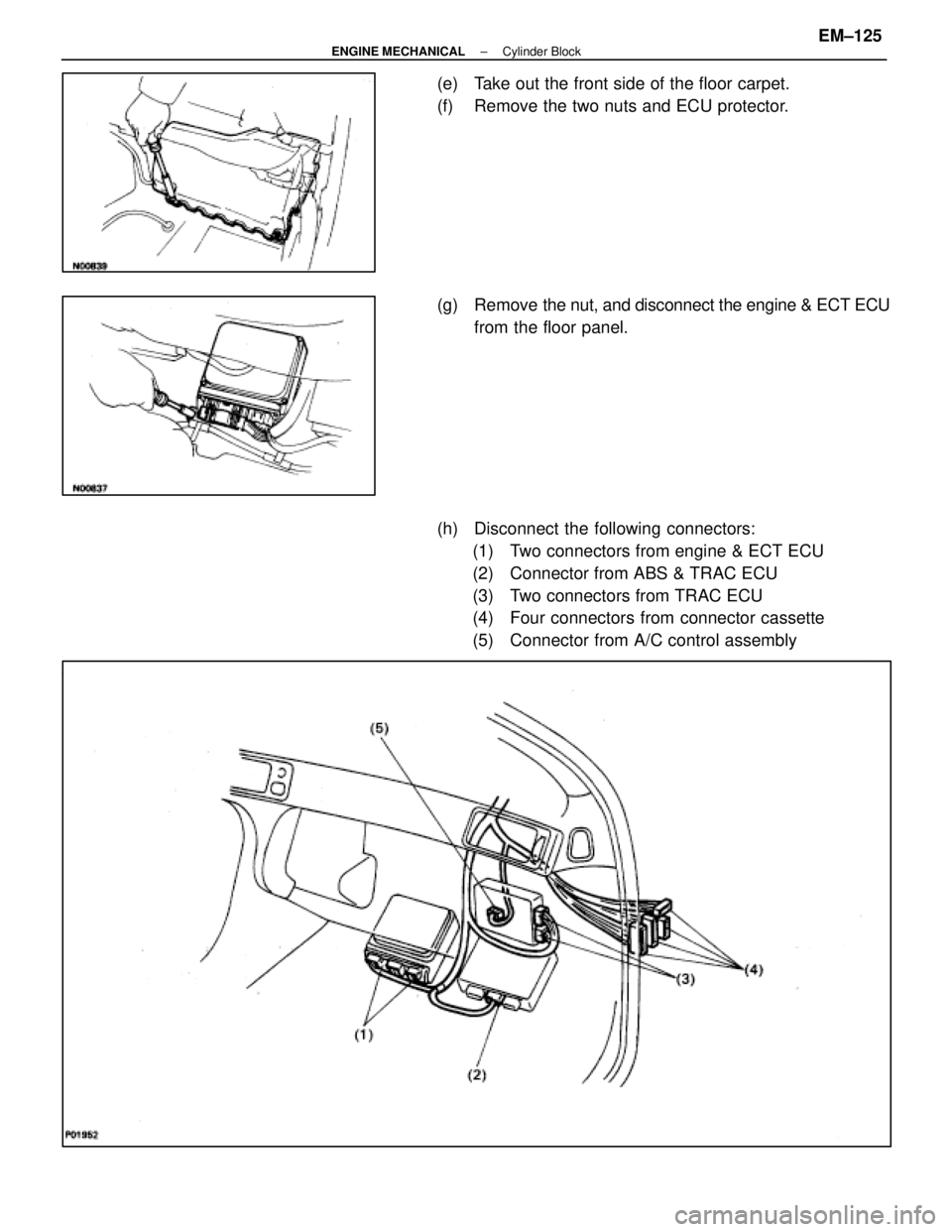

(e) Take out the front side of the floor carpet.

(f) Remove the two nuts and ECU protector.

(g) Remove the nut, and disconnect the engine & ECT ECU

from the floor panel.

(h) Disconnect the following connectors: (1) Two connectors from engine & ECT ECU

(2) Connector from ABS & TRAC ECU

(3) Two connectors from TRAC ECU

(4) Four connectors from connector cassette

(5) Connector from A/C control assembly

±

ENGINE MECHANICAL Cylinder BlockEM±125

WhereEverybodyKnowsYourName

Page 1593 of 4087

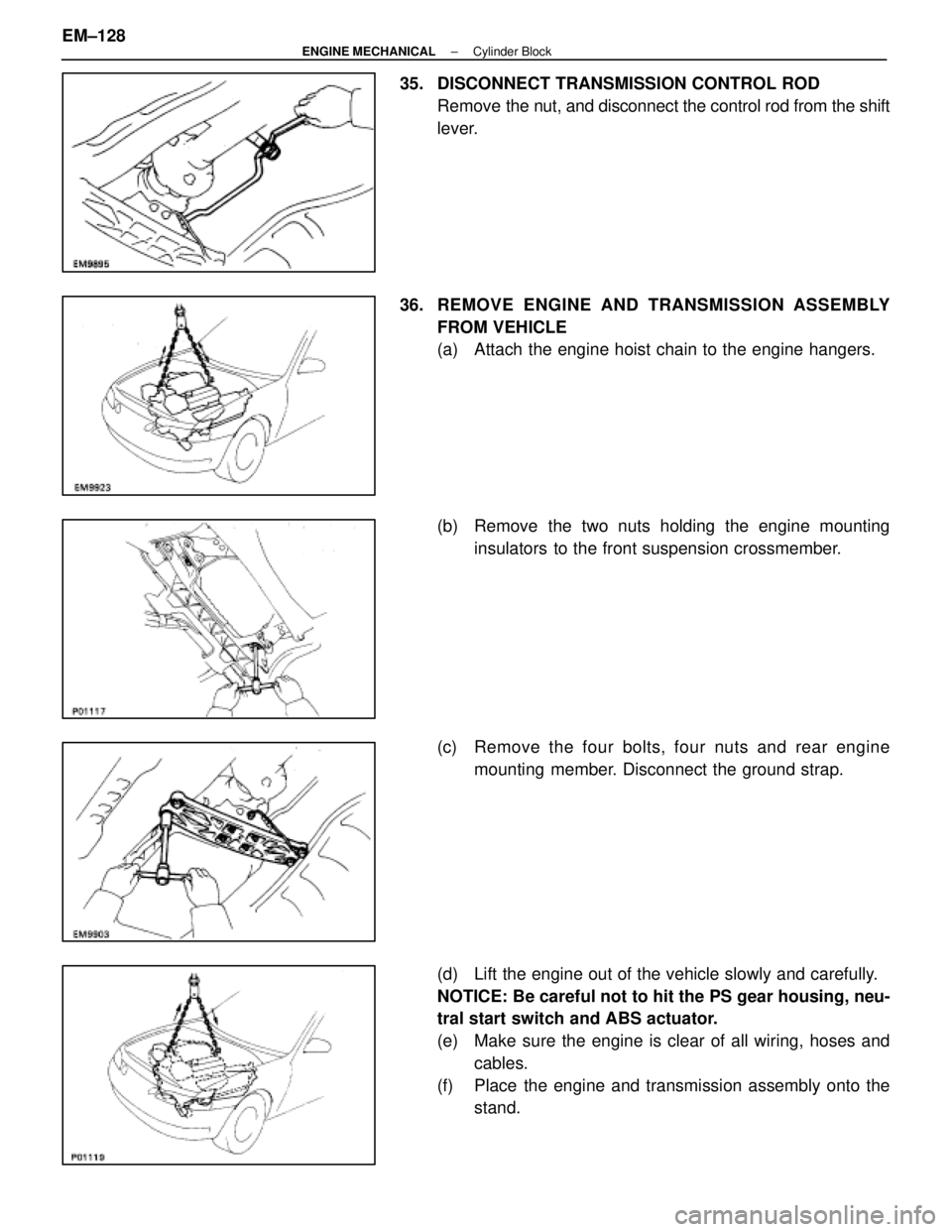

35. DISCONNECT TRANSMISSION CONTROL RODRemove the nut, and disconnect the control rod from the shift

lever.

36. REMOVE ENGINE AND TRANSMISSION A SSEMBLY

FROM VEHICLE

(a) Attach the engine hoist chain to the engine hangers.

(b) Remove the two nuts holding the engine mounting insulators to the front suspension crossmember.

(c) Remove the four bolts, four nuts and rear engine mounting member. Disconnect the ground strap.

(d) Lift the engine out of the vehicle slowly and carefully.

NOTICE: Be careful not to hit the PS gear housing, neu-

tral start switch and ABS actuator.

(e) Make sure the engine is clear of all wiring, hoses and cables.

(f) Place the engine and transmission assembly onto the stand.

EM±128

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1635 of 4087

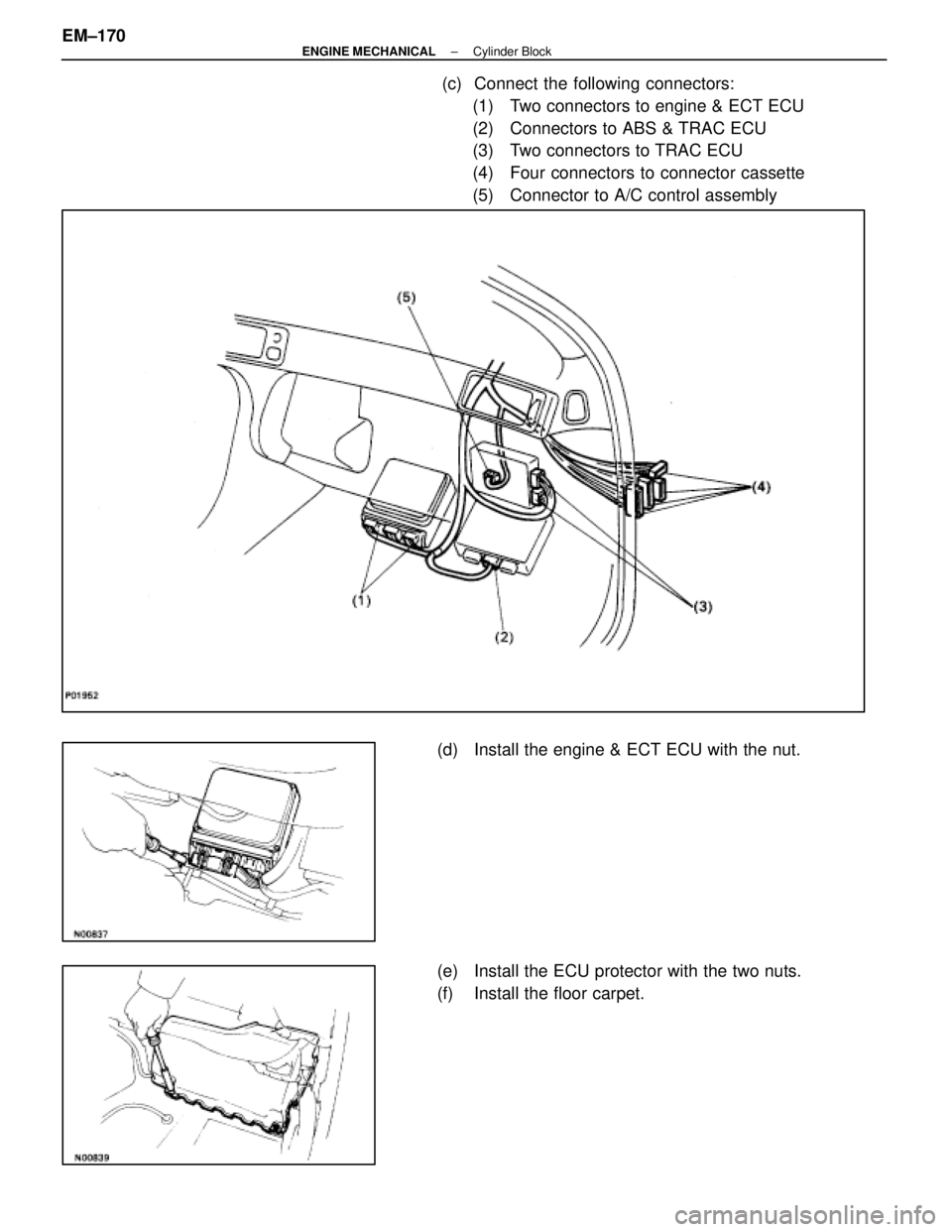

(c) Connect the following connectors:(1) Two connectors to engine & ECT ECU

(2) Connectors to ABS & TRAC ECU

(3) Two connectors to TRAC ECU

(4) Four connectors to connector cassette

(5) Connector to A/C control assembly

(d) Install the engine & ECT ECU with the nut.

(e) Install the ECU protector with the two nuts.

(f) Install the floor carpet.

EM±170

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1825 of 4087

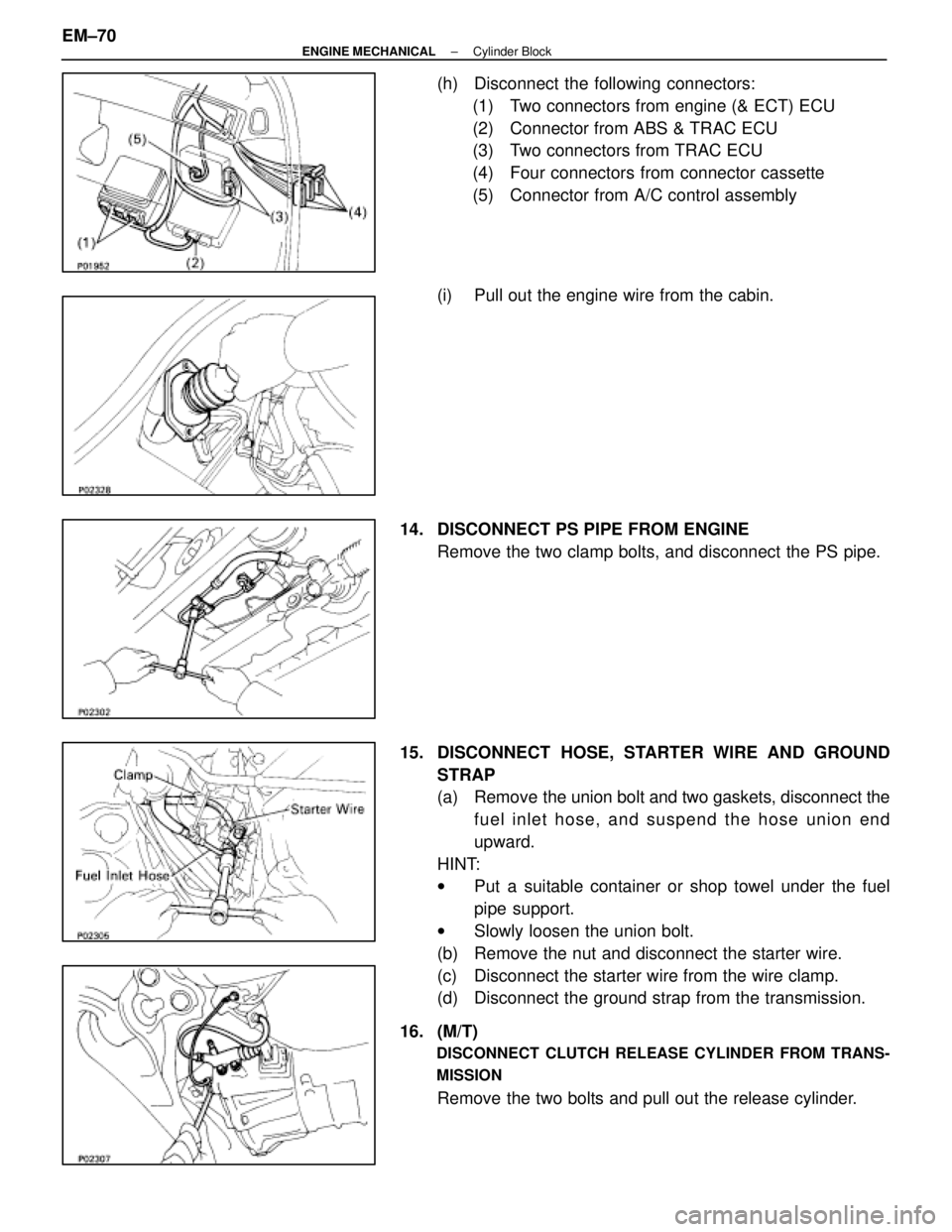

(h) Disconnect the following connectors:(1) Two connectors from engine (& ECT) ECU

(2) Connector from ABS & TRAC ECU

(3) Two connectors from TRAC ECU

(4) Four connectors from connector cassette

(5) Connector from A/C control assembly

(i) Pull out the engine wire from the cabin.

14. DISCONNECT PS PIPE FROM ENGINE Remove the two clamp bolts, and disconnect the PS pipe.

15. DISCONNECT HOSE, STARTER WIRE AND GROUND STRAP

(a) Remove the union bolt and two gaskets, disconnect thefuel inlet hose, and suspend the hose union end

upward.

HINT:

w Put a suitable container or shop towel under the fuel

pipe support.

w Slowly loosen the union bolt.

(b) Remove the nut and disconnect the starter wire.

(c) Disconnect the starter wire from the wire clamp.

(d) Disconnect the ground strap from the transmission.

16. (M/T)

DISCONNECT CLUTCH RELEASE CYLINDER FROM TRANS-

MISSION

Remove the two bolts and pull out the release cylinder.

EM±70

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName