ABS LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2859 of 4087

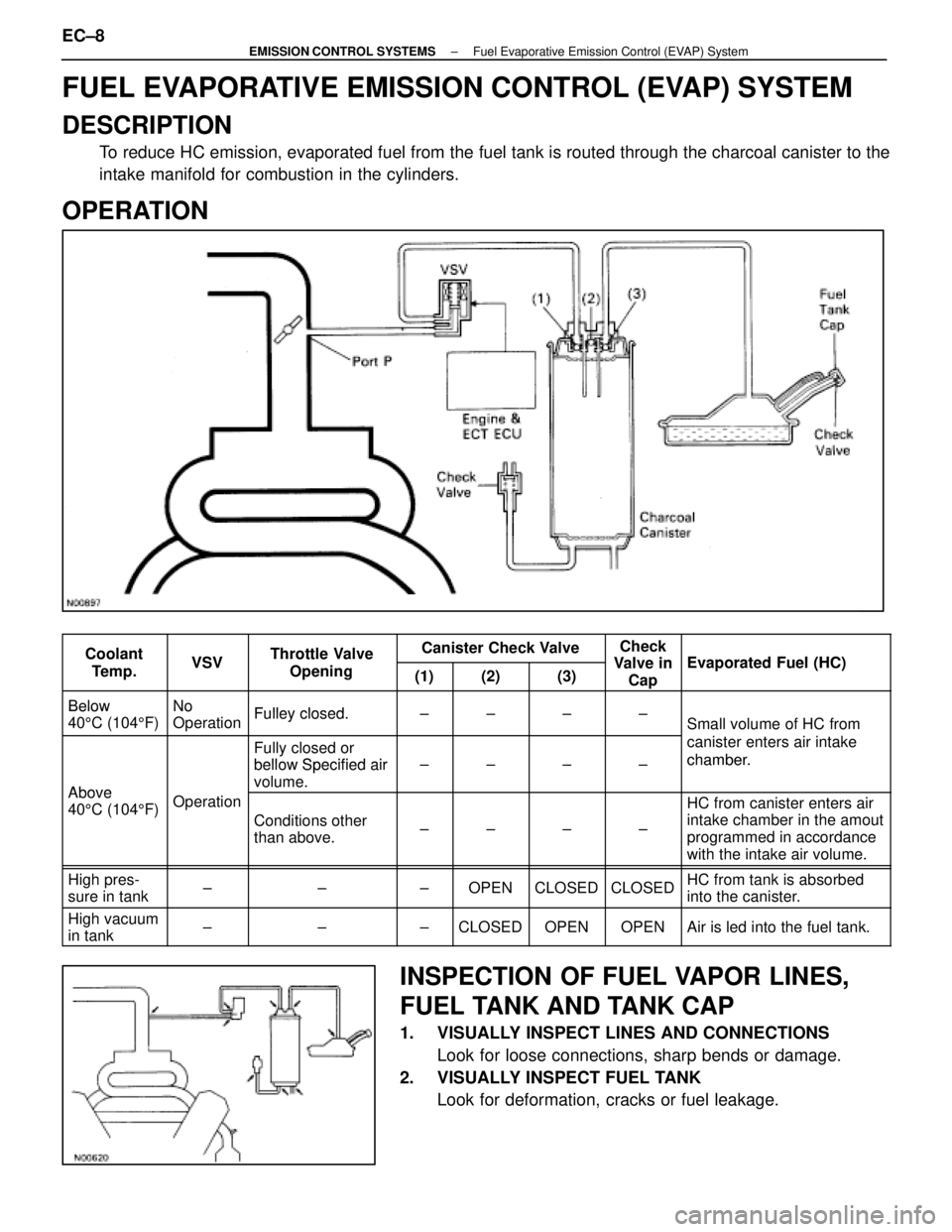

FUEL EVAPORATIVE EMISSION CONTROL (EVAP) SYSTEM

DESCRIPTION

To reduce HC emission, evaporated fuel from the fuel tank is routed throug\

h the charcoal canister to the

intake manifold for combustion in the cylinders.

OPERATION

CoolantVSVThrottle ValveCanister Check ValveCheck

Valve inEvaporated F el (HC)Coolant

Te m p .VSVThrottle Valve

Opening(1)(2)(3)Valve inCapEvaporated Fuel (HC)

BelowNoFulley closedBelow

40 5C (104 5F)

No

OperationFulley closed.±±±±Small volume of HC from

Fully closed or

bellow Specified air

canister enters air intake

chamber.

Above

bellow Specified air

volume.±±±±chamber.

Above

40 5C (104 5F)Operation

Conditions other

than above.±±±±

HC from canister enters air

intake chamber in the amout

programmed in accordance

with the intake air volume.

High pres-

sure in tank±±±OPENCLOSEDCLOSEDHC from tank is absorbed

into the canister.

High vacuum

in tank±±±CLOSEDOPENOPENAir is led into the fuel tank.

INSPECTION OF FUEL VAPOR LINES,

FUEL TANK AND TANK CAP

1. VISUALLY INSPECT LINES AND CONNECTIONS

Look for loose connections, sharp bends or damage.

2. VISUALLY INSPECT FUEL TANK Look for deformation, cracks or fuel leakage.

EC±8

±

EMISSION CONTROL SYSTEMS Fuel Evaporative Emission Control (EVAP) System

WhereEverybodyKnowsYourName

Page 3012 of 4087

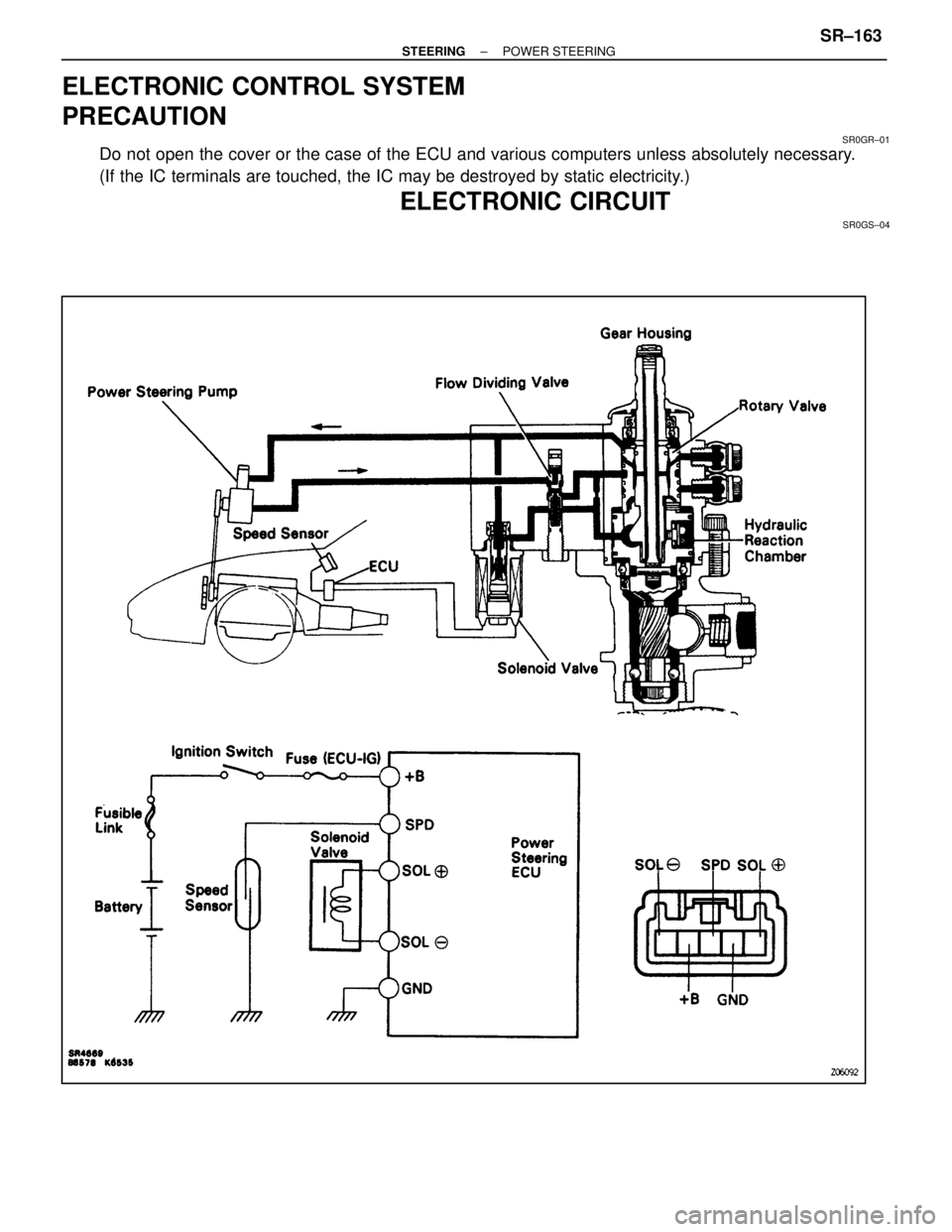

ELECTRONIC CONTROL SYSTEM

PRECAUTION

SR0GR±01

Do not open the cover or the case of the ECU and various computers unless \

absolutely necessary.

(If the IC terminals are touched, the IC may be destroyed by static ele\

ctricity.)

ELECTRONIC CIRCUIT

SR0GS±04

±

STEERING POWER STEERINGSR±163

WhereEverybodyKnowsYourName

Page 3150 of 4087

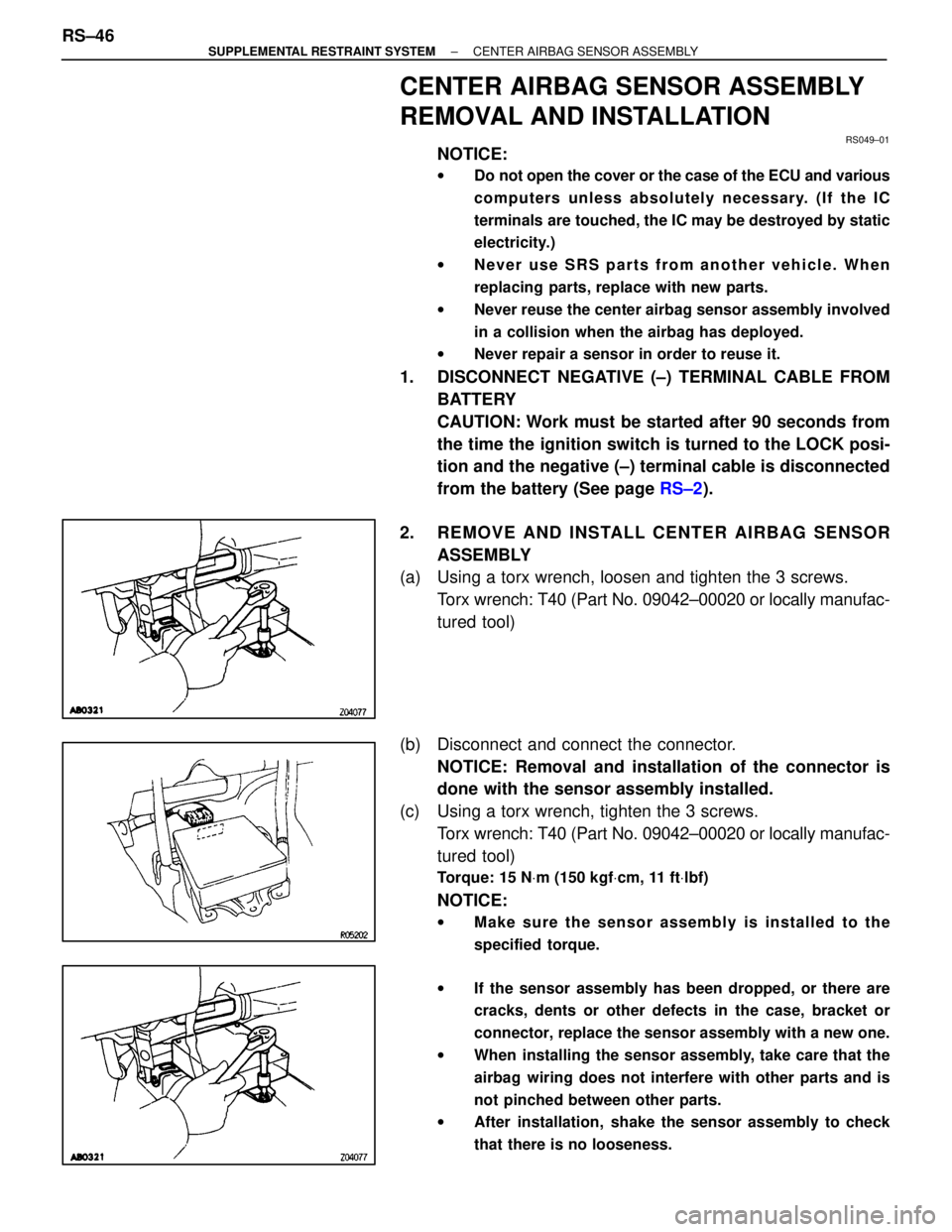

CENTER AIRBAG SENSOR ASSEMBLY

REMOVAL AND INSTALLATION

RS049±01

NOTICE:

wDo not open the cover or the case of the ECU and various

computers unless absolutely necessary. (If the IC

terminals are touched, the IC may be destroyed by static

electricity.)

w Never use SRS parts from another vehicle. When

replacing parts, replace with new parts.

w Never reuse the center airbag sensor assembly involved

in a collision when the airbag has deployed.

w Never repair a sensor in order to reuse it.

1. DISCONNECT NEGATIVE (±) TERMINAL CABLE FROM

BATTERY

CAUTION: Work must be started after 90 seconds from

the time the ignition switch is turned to the LOCK posi-

tion and the negative (±) terminal cable is disconnected

from the battery (See page RS±2).

2. REMOVE AND INSTALL CENTER AIRBAG SENSOR ASSEMBLY

(a) Using a torx wrench, loosen and tighten the 3 screws.

Torx wrench: T40 (Part No. 09042±00020 or locally manufac-

tured tool)

(b) Disconnect and connect the connector. NOTICE: Removal and installation of the connector is

done with the sensor assembly installed.

(c) Using a torx wrench, tighten the 3 screws. Torx wrench: T40 (Part No. 09042±00020 or locally manufac-

tured tool)

Torque: 15 N Vm (150 kgf Vcm, 11 ft Vlbf)

NOTICE:

w Make sure the sensor assembly is installed to the

specified torque.

w If the sensor assembly has been dropped, or there are

cracks, dents or other defects in the case, bracket or

connector, replace the sensor assembly with a new one.

w When installing the sensor assembly, take care that the

airbag wiring does not interfere with other parts and is

not pinched between other parts.

w After installation, shake the sensor assembly to check

that there is no looseness.

RS±46±

SUPPLEMENTAL RESTRAINT SYSTEM CENTER AIRBAG SENSOR ASSEMBLY

WhereEverybodyKnowsYourName

Page 3167 of 4087

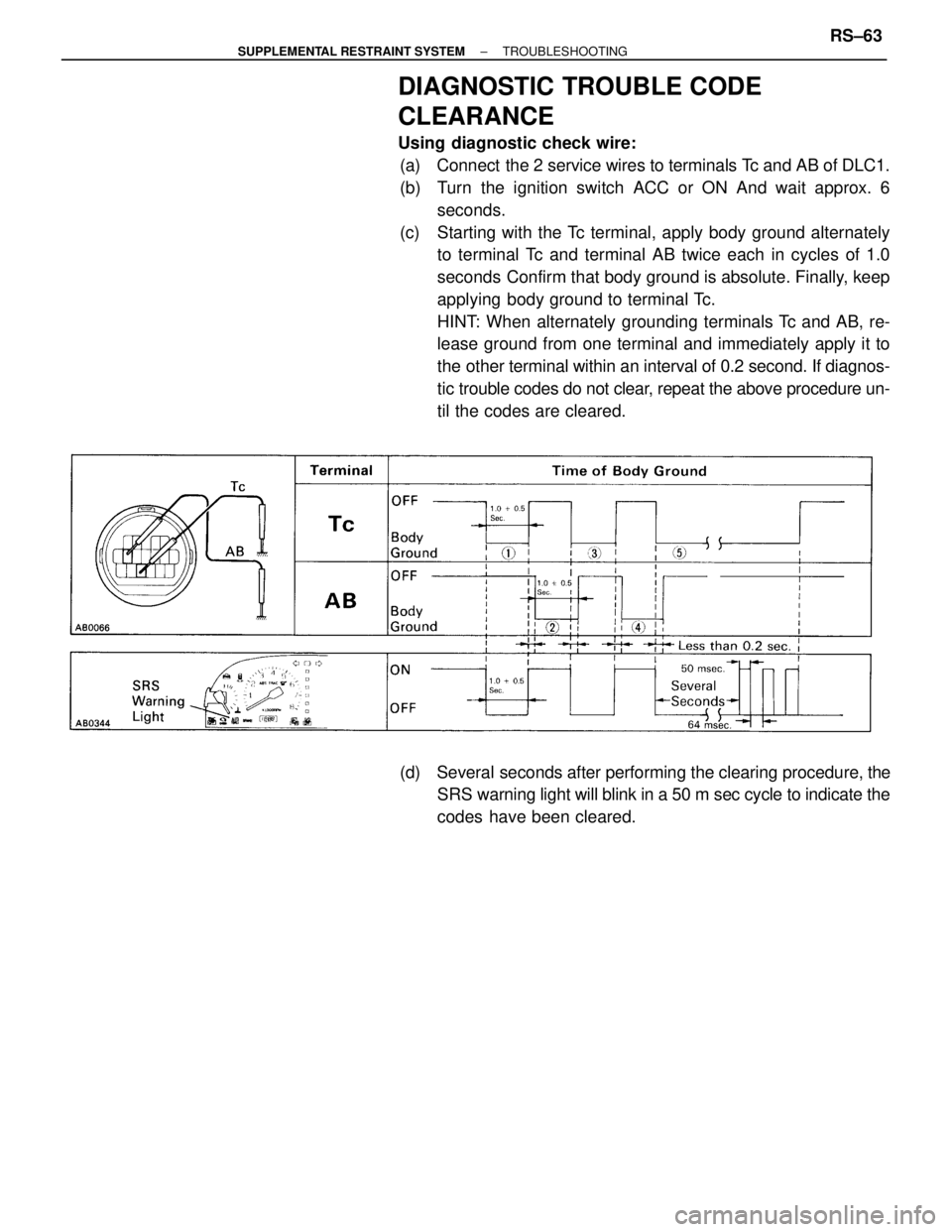

DIAGNOSTIC TROUBLE CODE

CLEARANCE

Using diagnostic check wire:(a) Connect the 2 service wires to terminals Tc and AB of DLC1.

(b) Turn the ignition switch ACC or ON And wait approx. 6 seconds.

(c) Starting with the Tc terminal, apply body ground alternately to terminal Tc and terminal AB twice each in cycles of 1.0

seconds Confirm that body ground is absolute. Finally, keep

applying body ground to terminal Tc.

HINT: When alternately grounding terminals Tc and AB, re-

lease ground from one terminal and immediately apply it to

the other terminal within an interval of 0.2 second. If diagnos-

tic trouble codes do not clear, repeat the above procedure un-

til the codes are cleared.

(d) Several seconds after performing the clearing procedure, theSRS warning light will blink in a 50 m sec cycle to indicate the

codes have been cleared.

±

SUPPLEMENTAL RESTRAINT SYSTEM TROUBLESHOOTINGRS±63

WhereEverybodyKnowsYourName

Page 3240 of 4087

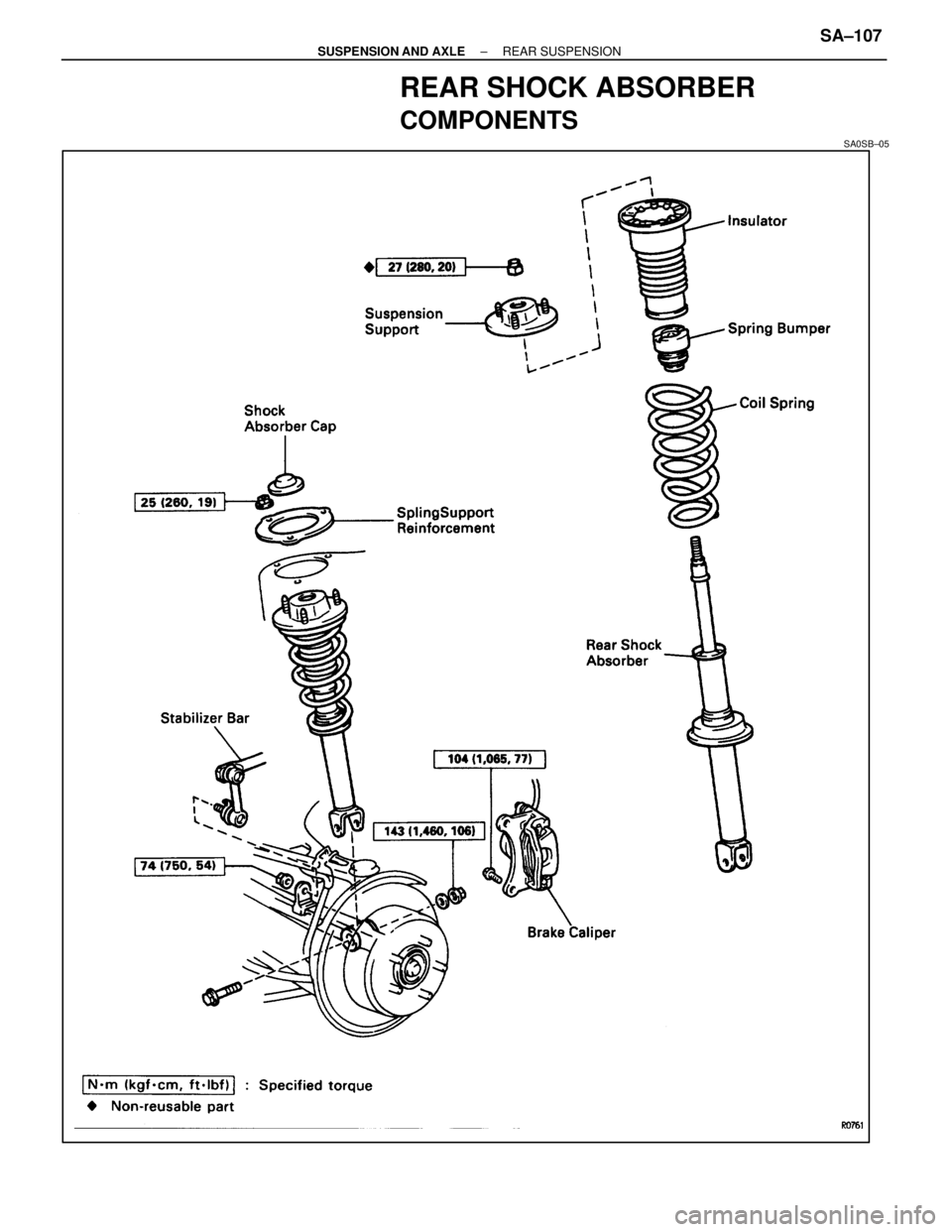

REAR SHOCK ABSORBER

COMPONENTS

SA0SB±05

±

SUSPENSION AND AXLE REAR SUSPENSIONSA±107

WhereEverybodyKnowsYourName

Page 3241 of 4087

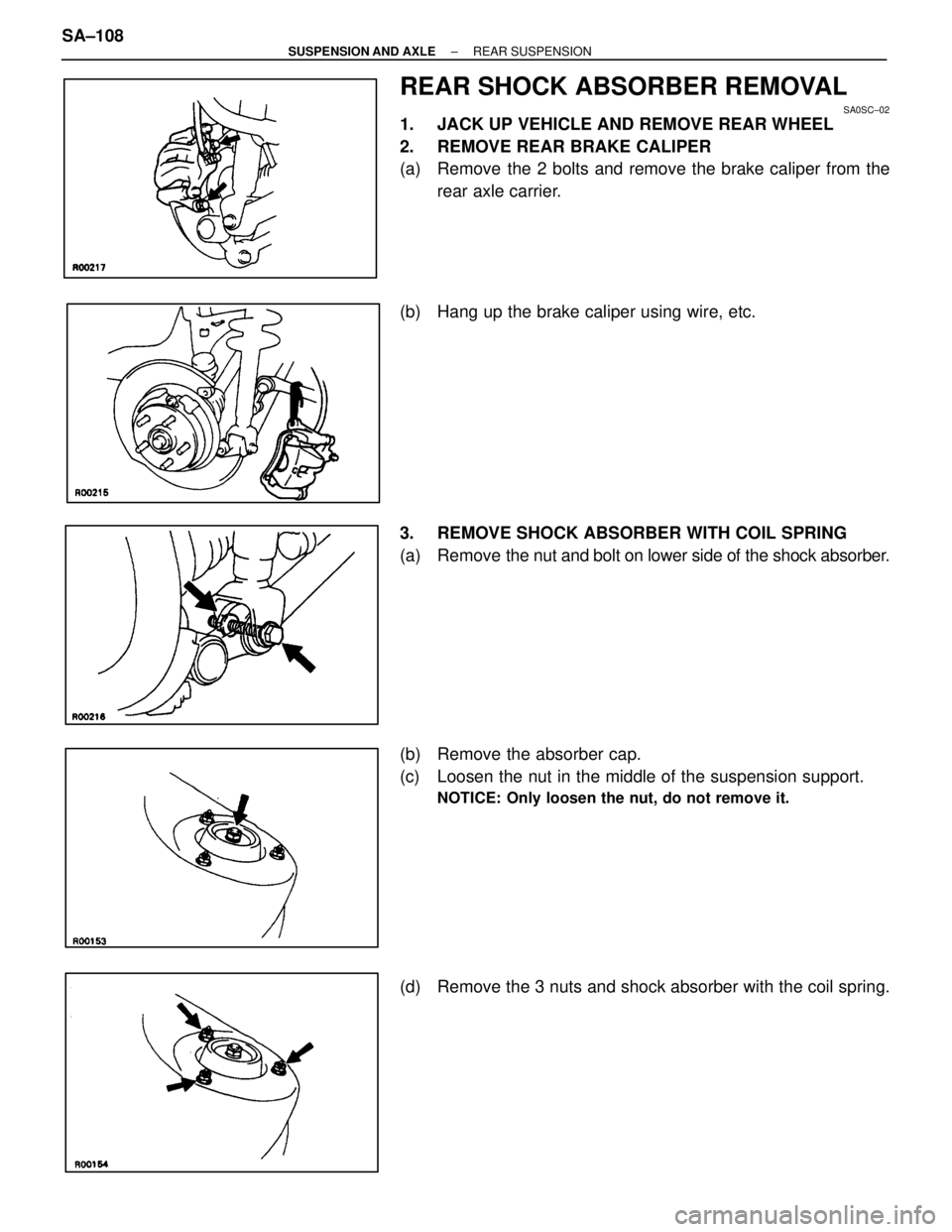

REAR SHOCK ABSORBER REMOVAL

SA0SC±02

1. JACK UP VEHICLE AND REMOVE REAR WHEEL

2. REMOVE REAR BRAKE CALIPER

(a) Remove the 2 bolts and remove the brake caliper from therear axle carrier.

(b) Hang up the brake caliper using wire, etc.

3. REMOVE SHOCK ABSORBER WITH COIL SPRING

(a) Remove the nut and bolt on lower side of the shock absorber.

(b) Remove the absorber cap.

(c) Loosen the nut in the middle of the suspension support.

NOTICE: Only loosen the nut, do not remove it.

(d) Remove the 3 nuts and shock absorber with the coil spring.

SA±108

±

SUSPENSION AND AXLE REAR SUSPENSION

WhereEverybodyKnowsYourName

Page 3242 of 4087

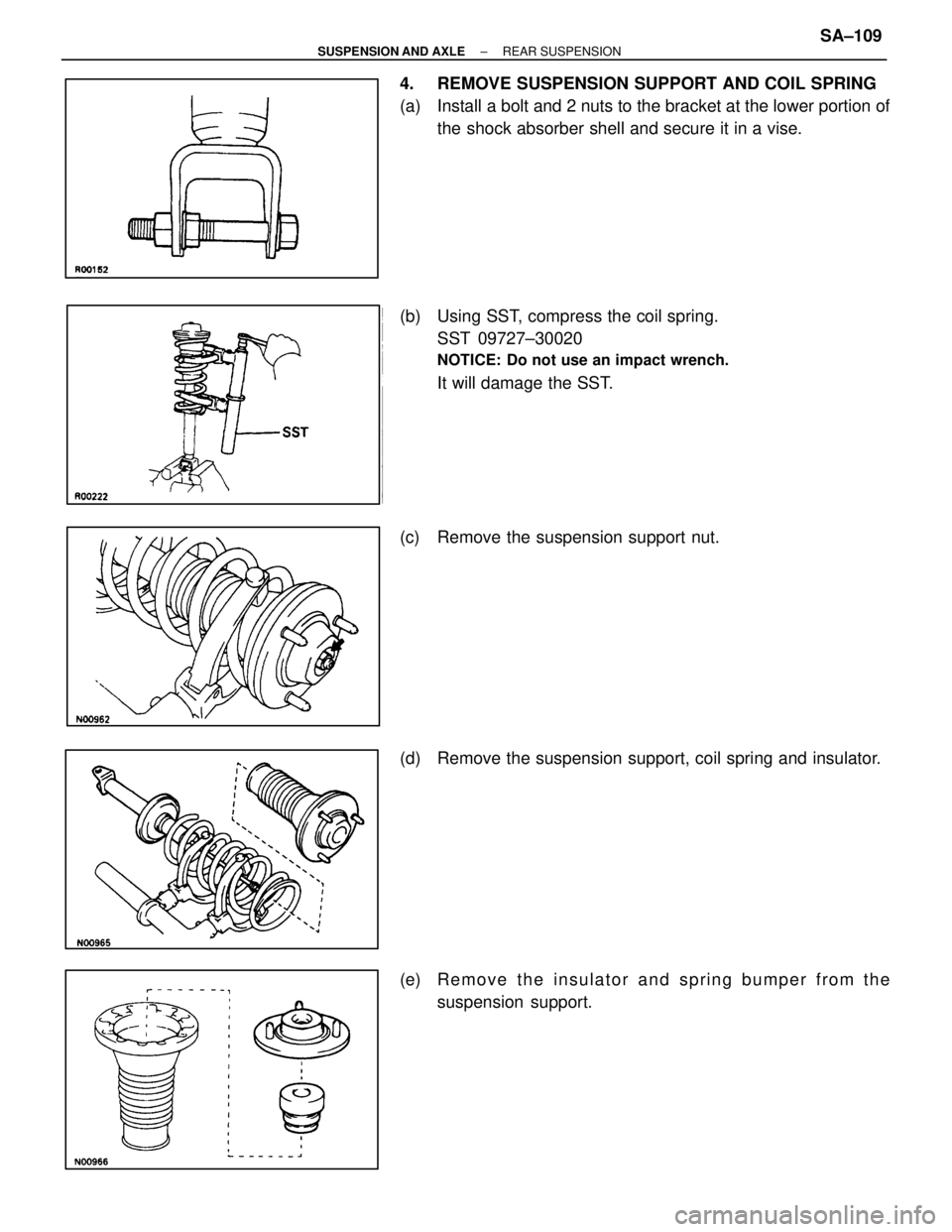

4. REMOVE SUSPENSION SUPPORT AND COIL SPRING

(a) Install a bolt and 2 nuts to the bracket at the lower portion ofthe shock absorber shell and secure it in a vise.

(b) Using SST, compress the coil spring. SST 09727±30020

NOTICE: Do not use an impact wrench.

It will damage the SST.

(c) Remove the suspension support nut.

(d) Remove the suspension support, coil spring and insulator.

(e) R e m o v e t h e i n s u l a t o r a n d s p r i n g b u m p e r f r o m t h e suspension support.

±

SUSPENSION AND AXLE REAR SUSPENSIONSA±109

WhereEverybodyKnowsYourName

Page 3243 of 4087

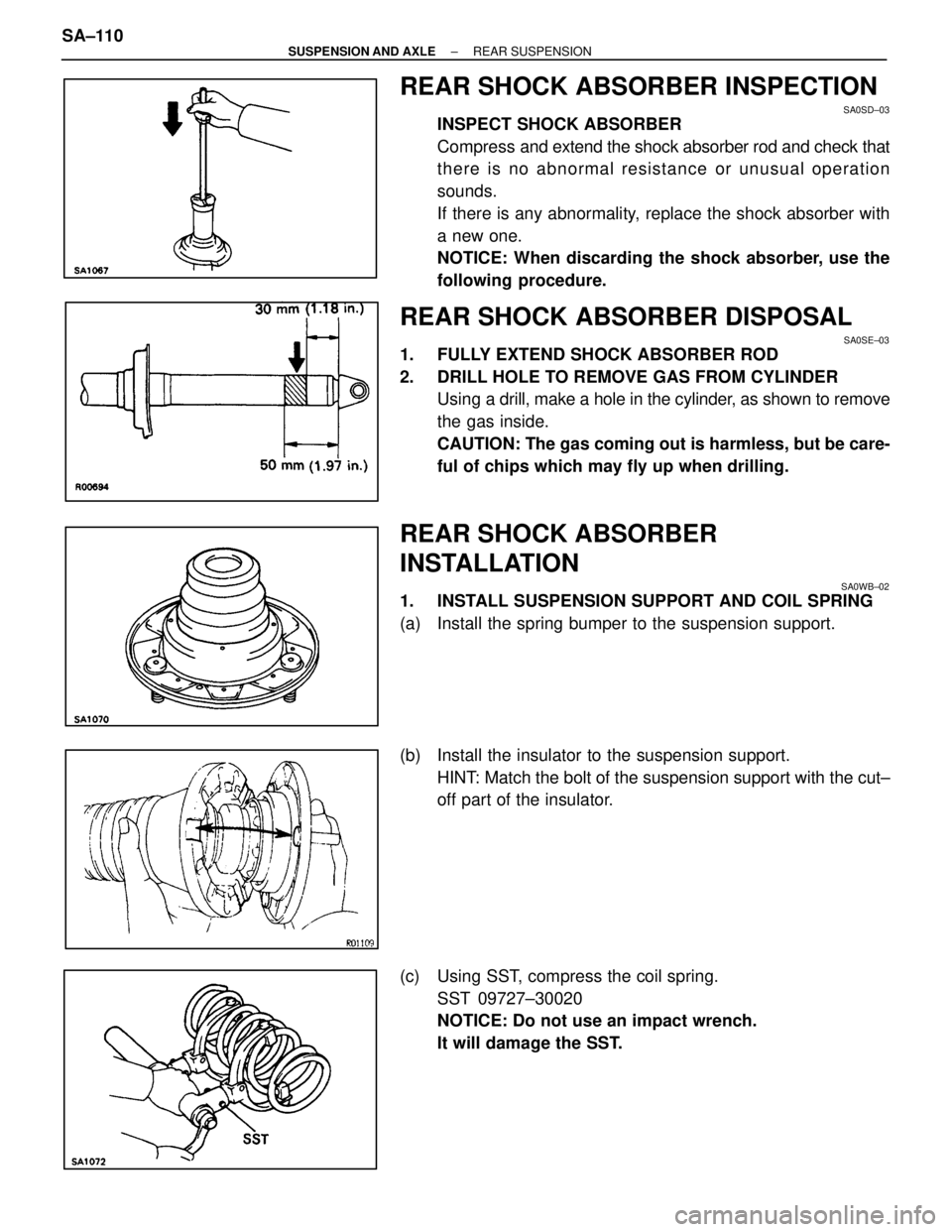

REAR SHOCK ABSORBER INSPECTION

SA0SD±03

INSPECT SHOCK ABSORBER

Compress and extend the shock absorber rod and check that

there is no abnormal resistance or unusual operation

sounds.

If there is any abnormality, replace the shock absorber with

a new one.

NOTICE: When discarding the shock absorber, use the

following procedure.

REAR SHOCK ABSORBER DISPOSAL

SA0SE±03

1. FULLY EXTEND SHOCK ABSORBER ROD

2. DRILL HOLE TO REMOVE GAS FROM CYLINDERUsing a drill, make a hole in the cylinder, as shown to remove

the gas inside.

CAUTION: The gas coming out is harmless, but be care-

ful of chips which may fly up when drilling.

REAR SHOCK ABSORBER

INSTALLATION

SA0WB±02

1. INSTALL SUSPENSION SUPPORT AND COIL SPRING

(a) Install the spring bumper to the suspension support.

(b) Install the insulator to the suspension support. HINT: Match the bolt of the suspension support with the cut±

off part of the insulator.

(c) Using SST, compress the coil spring. SST 09727±30020

NOTICE: Do not use an impact wrench.

It will damage the SST.

SA±110

±

SUSPENSION AND AXLE REAR SUSPENSION

WhereEverybodyKnowsYourName

Page 3244 of 4087

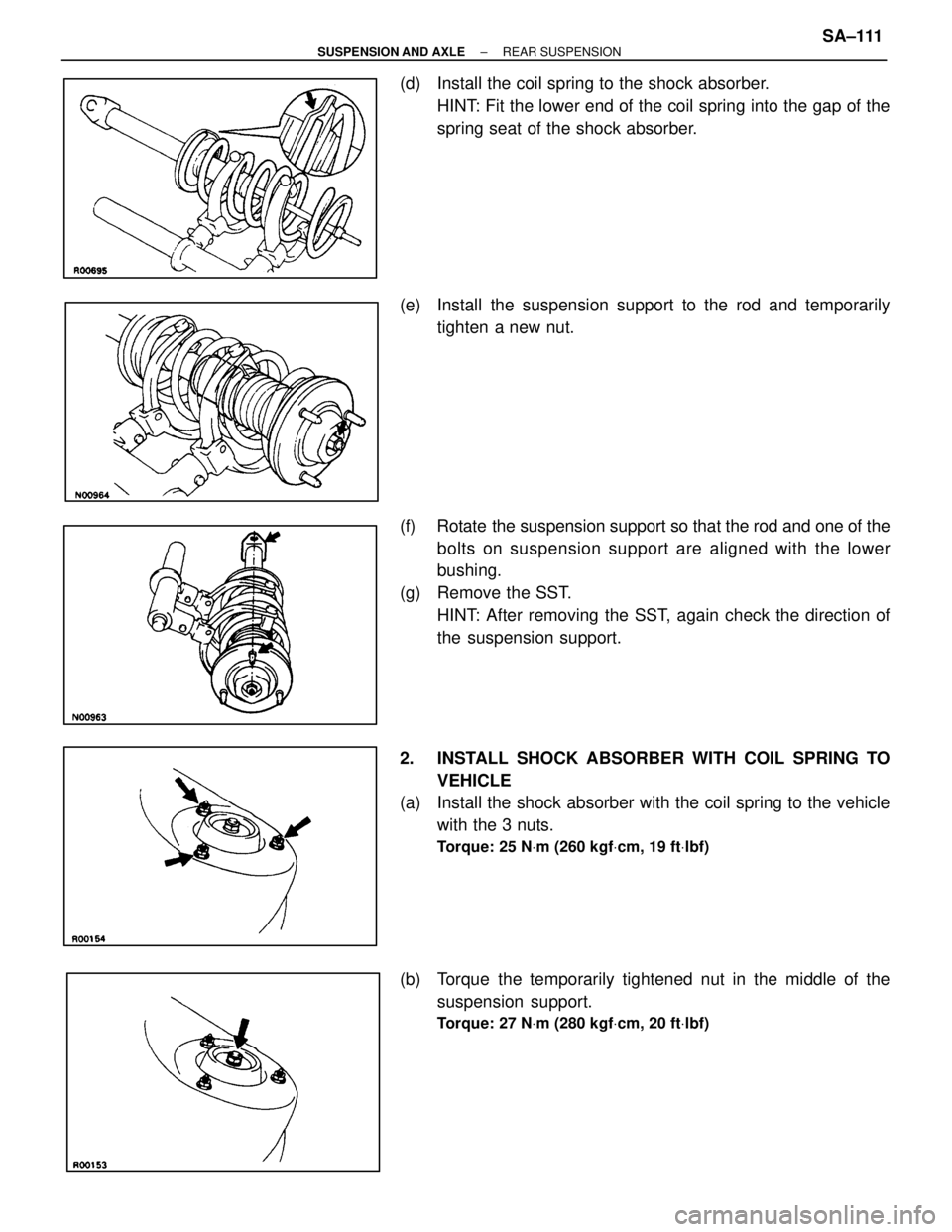

(d) Install the coil spring to the shock absorber.HINT: Fit the lower end of the coil spring into the gap of the

spring seat of the shock absorber.

(e) Install the suspension support to the rod and temporarily tighten a new nut.

(f) Rotate the suspension support so that the rod and one of the bolts on suspension support are aligned with the lower

bushing.

(g) Remove the SST. HINT: After removing the SST, again check the direction of

the suspension support.

2. INSTALL SHOCK ABSORBER WITH COIL SPRING TO VEHICLE

(a) Install the shock absorber with the coil spring to the vehicle

with the 3 nuts.

Torque: 25 N Vm (260 kgf Vcm, 19 ft Vlbf)

(b) Torque the temporarily tightened nut in the middle of the

suspension support.

Torque: 27 N Vm (280 kgf Vcm, 20 ft Vlbf)

±

SUSPENSION AND AXLE REAR SUSPENSIONSA±111

WhereEverybodyKnowsYourName

Page 3245 of 4087

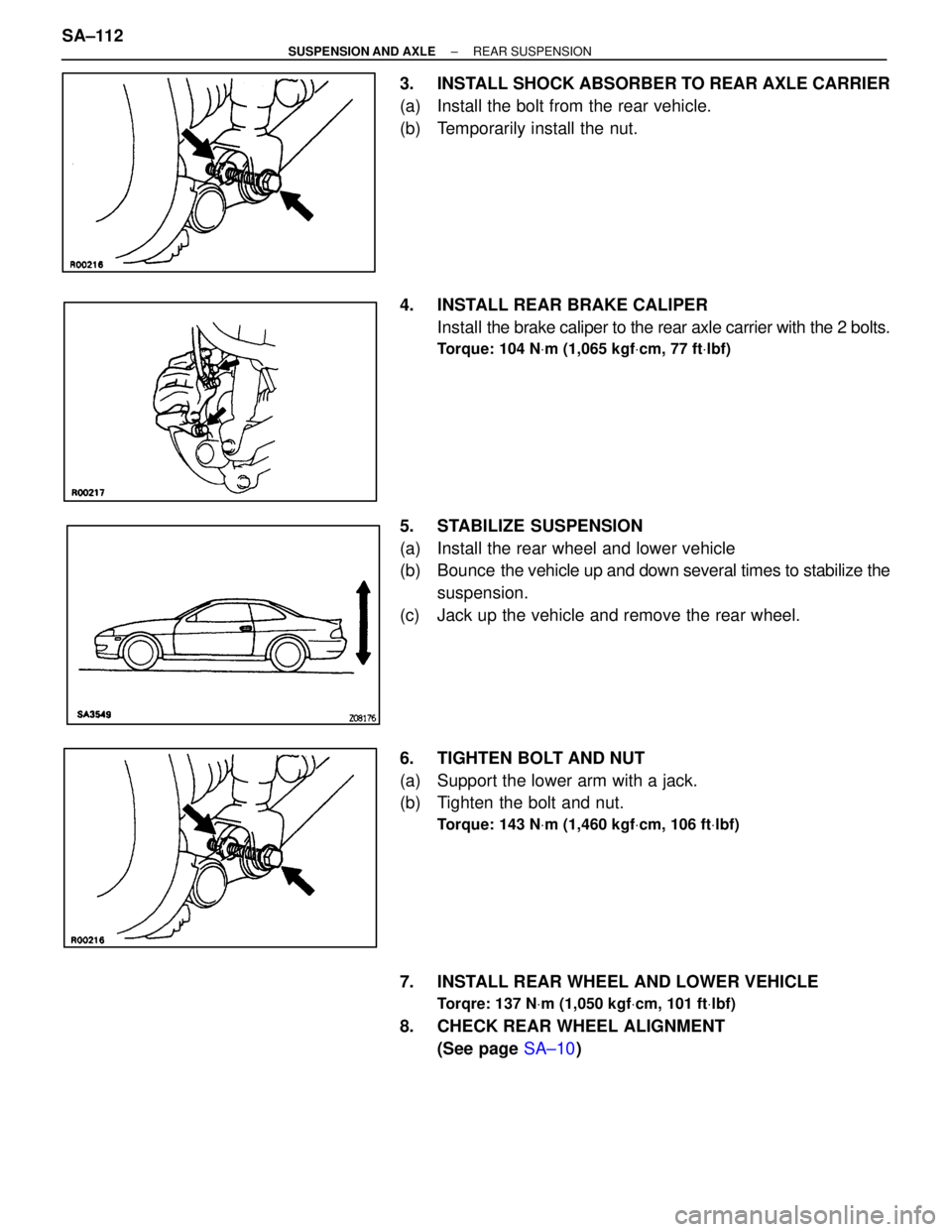

3. INSTALL SHOCK ABSORBER TO REAR AXLE CARRIER

(a) Install the bolt from the rear vehicle.

(b) Temporarily install the nut.

4. INSTALL REAR BRAKE CALIPERInstall the brake caliper to the rear axle carrier with the 2 bolts.

Torque: 104 N Vm (1,065 kgf Vcm, 77 ft Vlbf)

5. STABILIZE SUSPENSION

(a) Install the rear wheel and lower vehicle

(b) Bounce the vehicle up and down several times to stabilize the

suspension.

(c) Jack up the vehicle and remove the rear wheel.

6. TIGHTEN BOLT AND NUT

(a) Support the lower arm with a jack.

(b) Tighten the bolt and nut.

Torque: 143 N Vm (1,460 kgf Vcm, 106 ft Vlbf)

7. INSTALL REAR WHEEL AND LOWER VEHICLE

Torqre: 137 N Vm (1,050 kgf Vcm, 101 ft Vlbf)

8. CHECK REAR WHEEL ALIGNMENT

(See page SA±10)

SA±112

±

SUSPENSION AND AXLE REAR SUSPENSION

WhereEverybodyKnowsYourName