ignition switch LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1087 of 4087

DTC

31, 32,

33, 34,35, 36

Speed Sensor Circuit

CIRCUIT DESCRIPTION

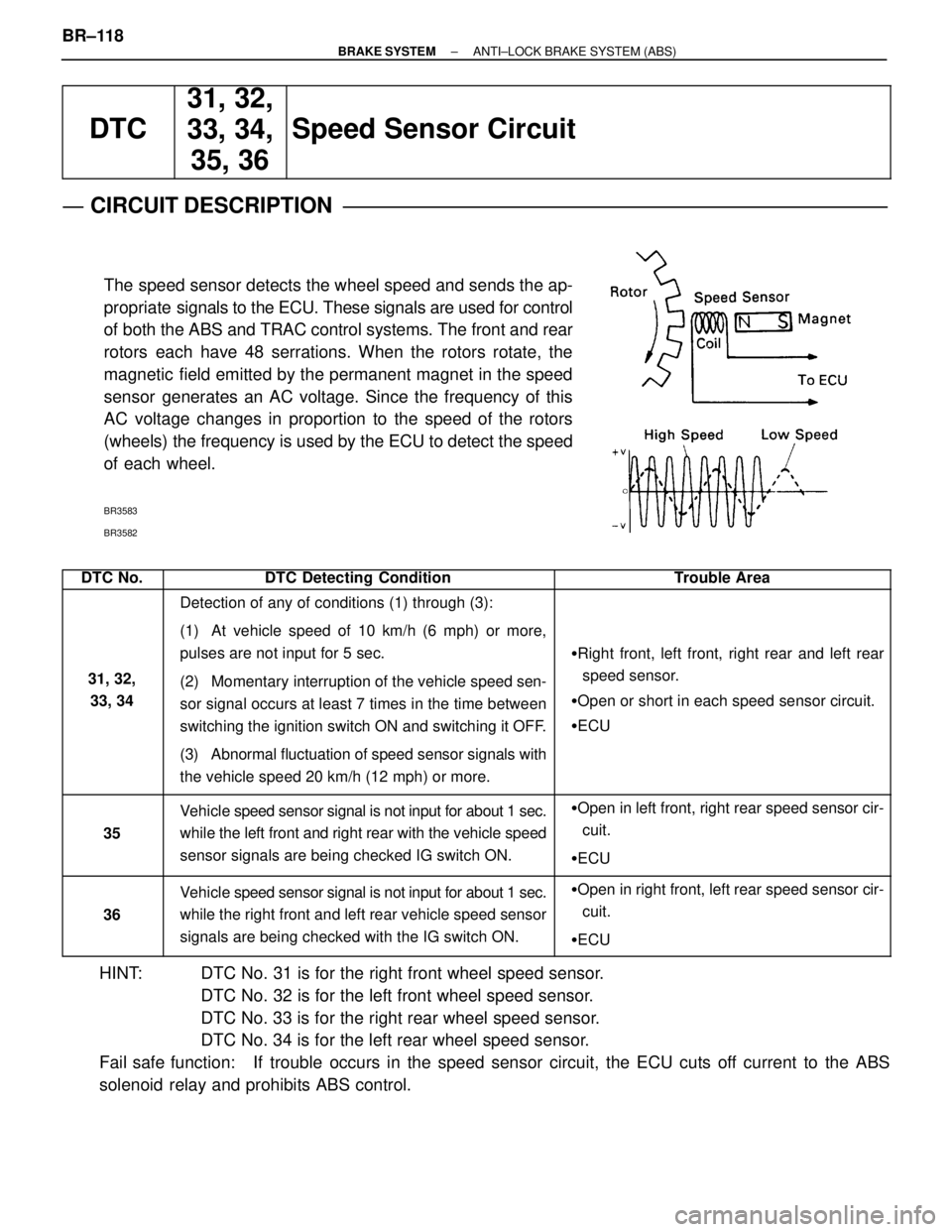

The speed sensor detects the wheel speed and sends the ap-

propriate signals to the ECU. These signals are used for control

of both the ABS and TRAC control systems. The front and rear

rotors each have 48 serrations. When the rotors rotate, the

magnetic field emitted by the permanent magnet in the speed

sensor generates an AC voltage. Since the frequency of this

AC voltage changes in proportion to the speed of the rotors

(wheels) the frequency is used by the ECU to detect the speed

of each wheel.

BR3583

BR3582

DTC No.DTC Detecting ConditionTrouble Area

31, 32,

33, 34

Detection of any of conditions (1) through (3):

(1) At vehicle speed of 10 km/h (6 mph) or more,

pulses are not input for 5 sec.

(2) Momentary interruption of the vehicle speed sen-

sor signal occurs at least 7 times in the time between

switching the ignition switch ON and switching it OFF.

(3) Abnormal fluctuation of speed sensor signals with

the vehicle speed 20 km/h (12 mph) or more.

Right front, left front, right rear and left rear

speed sensor.

Open or short in each speed sensor circuit.

ECU

35

Vehicle speed sensor signal is not input for about 1 sec.

while the left front and right rear with the vehicle speed

sensor signals are being checked IG switch ON.

Open in left front, right rear speed sensor cir-

cuit.

ECU

36

Vehicle speed sensor signal is not input for about 1 sec.

while the right front and left rear vehicle speed sensor

signals are being checked with the IG switch ON.

Open in right front, left rear speed sensor cir-

cuit.

ECU

HINT: DTC No. 31 is for the right front wheel speed sensor.

DTC No. 32 is for the left front wheel speed sensor.

DTC No. 33 is for the right rear wheel speed sensor.

DTC No. 34 is for the left rear wheel speed sensor.

Fail safe function: If trouble occurs in the speed sensor circuit, the ECU cuts off current to the ABS

solenoid relay and prohibits ABS control.

BR±118

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)

WhereEverybodyKnowsYourName

Page 1092 of 4087

OKNG

NGOK

INSPECTION PROCEDURE

1Check battery positive voltage.

Voltage: 10 ± 14 VOK

Check and repair the charging system.

2Check voltage between terminals IG1 and GND or ABS (& TRAC) ECU connec\

tor.

C

OK

PRemove ABS (& TRAC) ECU with connectors still con-

nected.

1. Turn ignition switch on.

2. Measure voltage between terminals IG1 and GNDof ABS (& TRAC) ECU connector.\

Voltage: 10 ± 14 V

Check and replace ABS (& TRAC) ECU.

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)BR±123

WhereEverybodyKnowsYourName

Page 1098 of 4087

OKNG

NGOK

OKNG

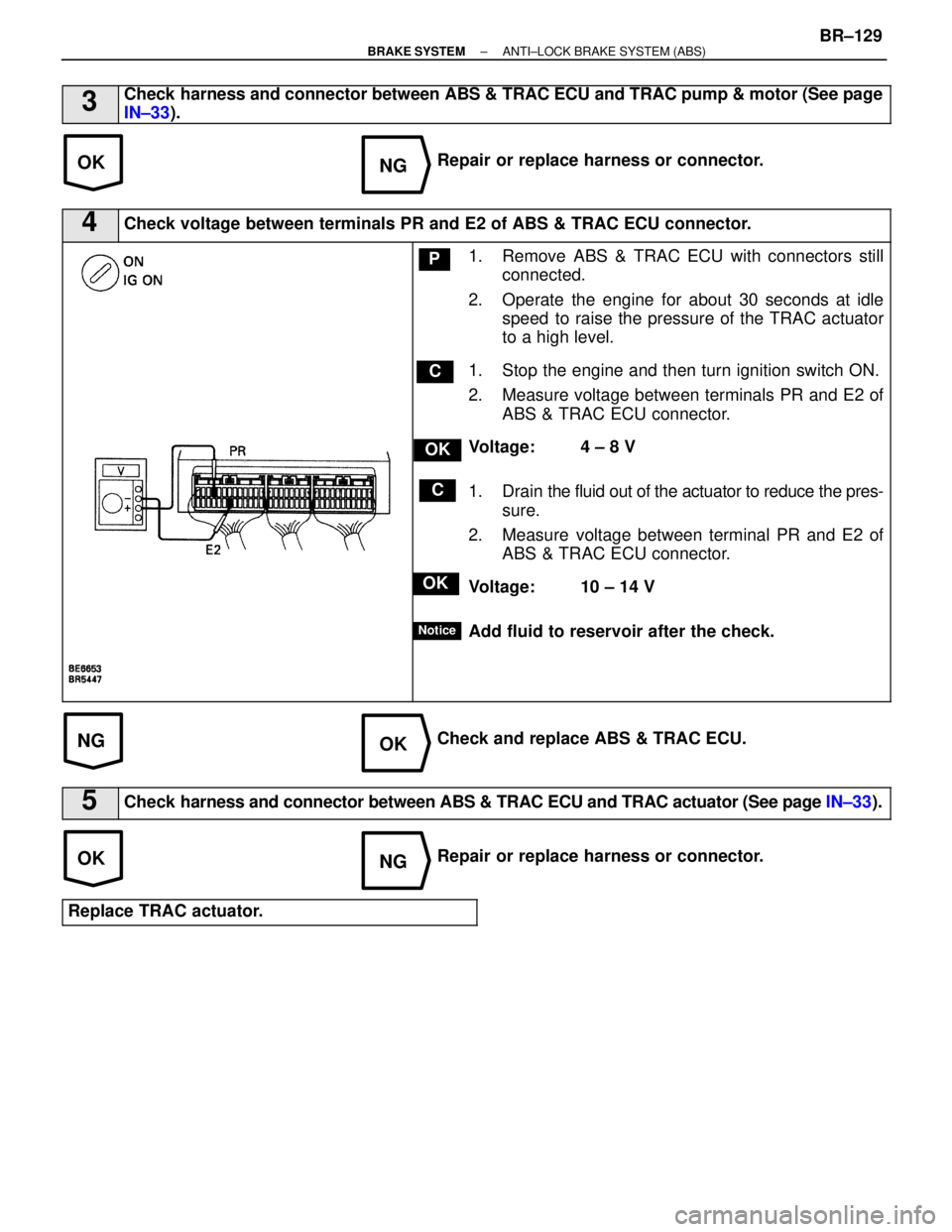

3Check harness and connector between ABS & TRAC ECU and TRAC pump & motor (Se\

e page

IN±33).

Repair or replace harness or connector.

4Check voltage between terminals PR and E2 of ABS & TRAC ECU connector.

C

OK

P

OK

C

Notice

1. Remove ABS & TRAC ECU with connectors still

connected.

2. Operate the engine for about 30 seconds at idle speed to raise the pressure of the TRAC actuator

to a high level.

1. Stop the engine and then turn ignition switch ON.

2. Measure voltage between terminals PR and E2 of ABS & TRAC ECU connector.

Voltage: 4 ± 8 V

1. Drain the fluid out of the actuator to reduce the pres-

sure.

2. Measure voltage between terminal PR and E2 of ABS & TRAC ECU connector.

Voltage: 10 ± 14 V

Add fluid to reservoir after the check.

Check and replace ABS & TRAC ECU.

5Check harness and connector between ABS & TRAC ECU and TRAC actuator (See page IN±33).

Repair or replace harness or connector.

Replace TRAC actuator.

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)BR±129

WhereEverybodyKnowsYourName

Page 1100 of 4087

NGOK

OKNG

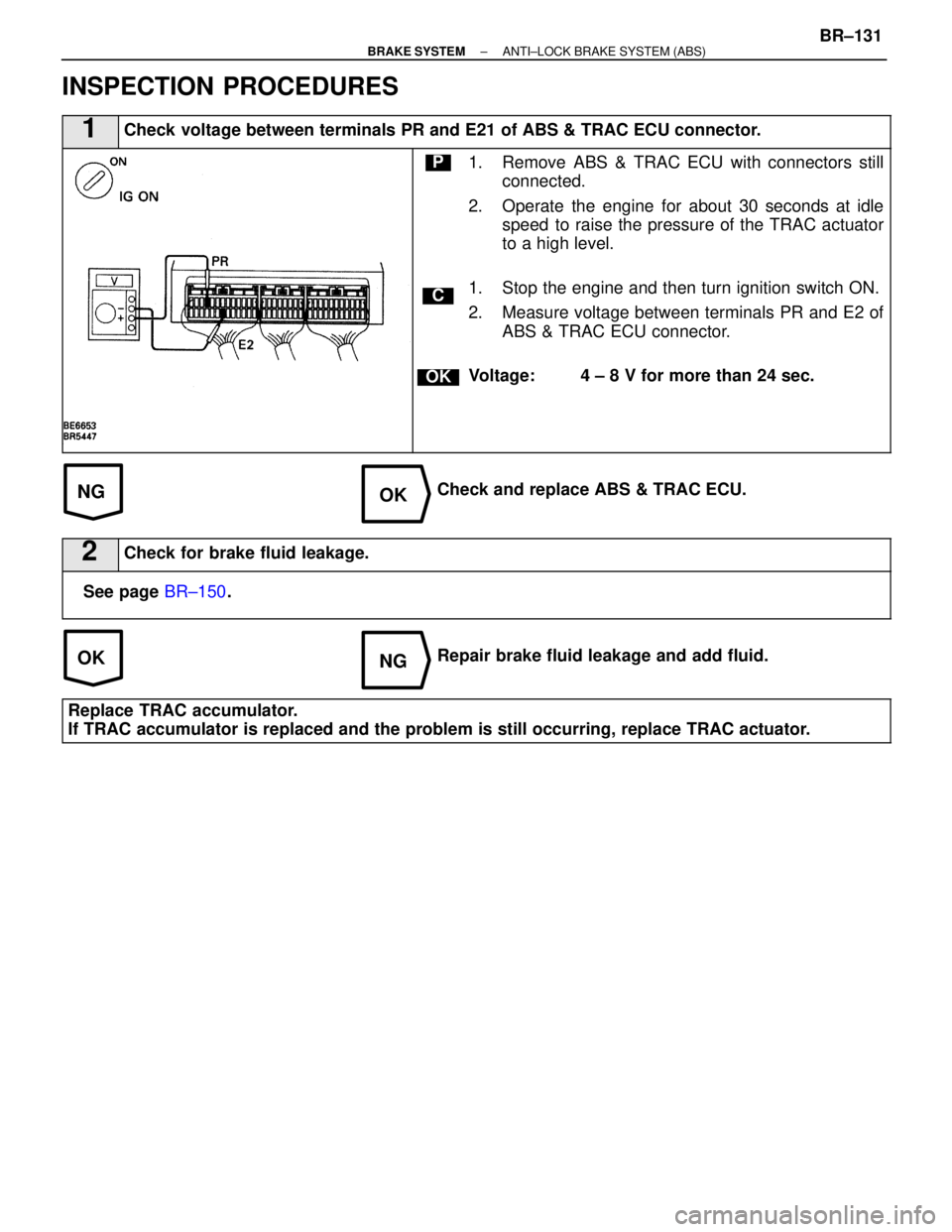

INSPECTION PROCEDURES

1Check voltage between terminals PR and E21 of ABS & TRAC ECU connector.

C

OK

P1. Remove ABS & TRAC ECU with connectors stillconnected.

2. Operate the engine for about 30 seconds at idle speed to raise the pressure of the TRAC actuator

to a high level.

1. Stop the engine and then turn ignition switch ON.

2. Measure voltage between terminals PR and E2 of ABS & TRAC ECU connector.

Voltage: 4 ± 8 V for more than 24 sec.

Check and replace ABS & TRAC ECU.

2Check for brake fluid leakage.

See page BR±150.

Repair brake fluid leakage and add fluid.

Replace TRAC accumulator.

If TRAC accumulator is replaced and the problem is still occurring, repl\

ace TRAC actuator.

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)BR±131

WhereEverybodyKnowsYourName

Page 1105 of 4087

NGOK

OKNG

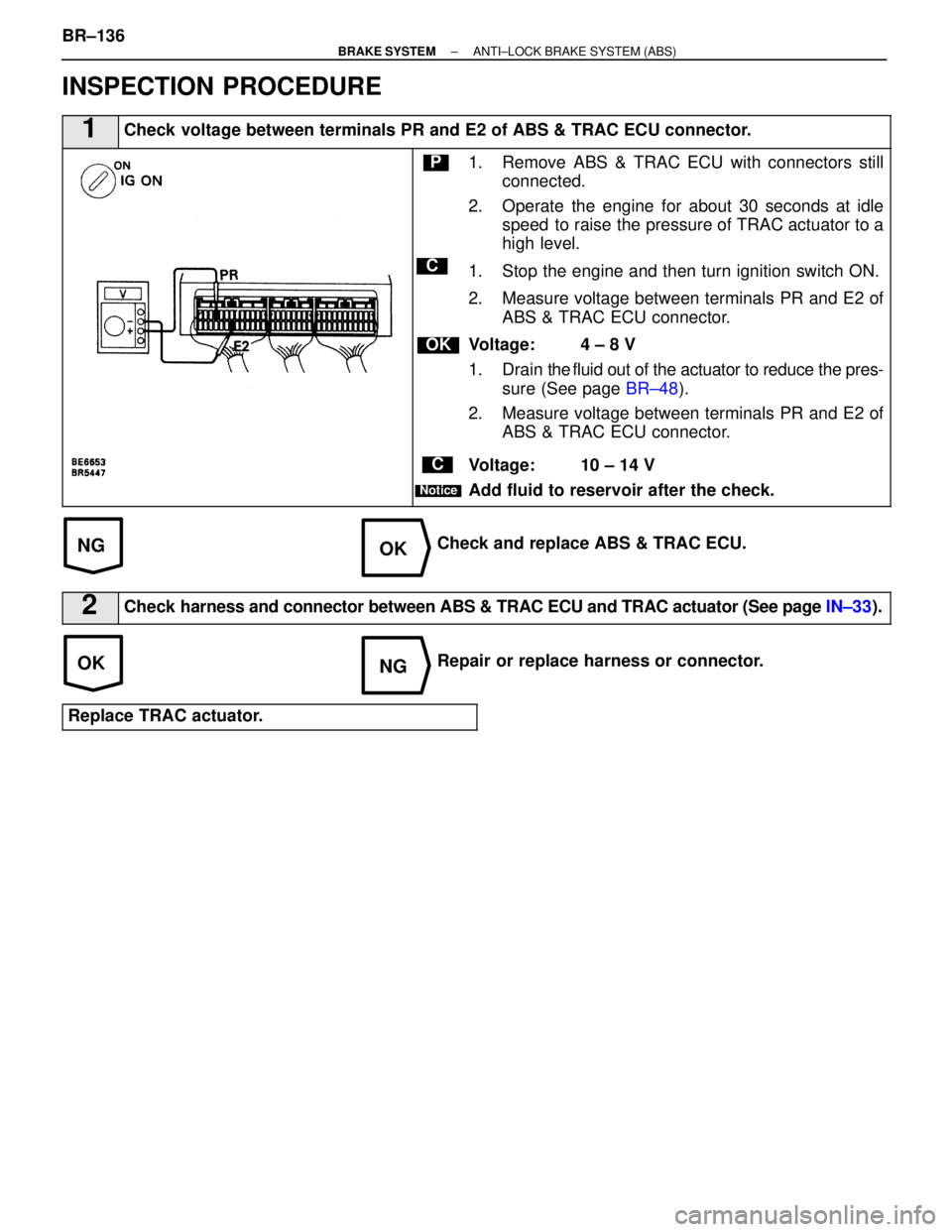

INSPECTION PROCEDURE

1Check voltage between terminals PR and E2 of ABS & TRAC ECU connector.

C

OK

P

C

Notice

1. Remove ABS & TRAC ECU with connectors stillconnected.

2. Operate the engine for about 30 seconds at idle speed to raise the pressure of TRAC actuator to a

high level.

1. Stop the engine and then turn ignition switch ON.

2. Measure voltage between terminals PR and E2 of ABS & TRAC ECU connector.

Voltage: 4 ± 8 V

1. Drain the fluid out of the actuator to reduce the pres-

sure (See page BR±48).

2. Measure voltage between terminals PR and E2 of ABS & TRAC ECU connector.

Voltage: 10 ± 14 V

Add fluid to reservoir after the check.

Check and replace ABS & TRAC ECU.

2Check harness and connector between ABS & TRAC ECU and TRAC actuator (See page IN±33).

Repair or replace harness or connector.

Replace TRAC actuator.

BR±136±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)

WhereEverybodyKnowsYourName

Page 1108 of 4087

OKOK

OKNG

OKNG

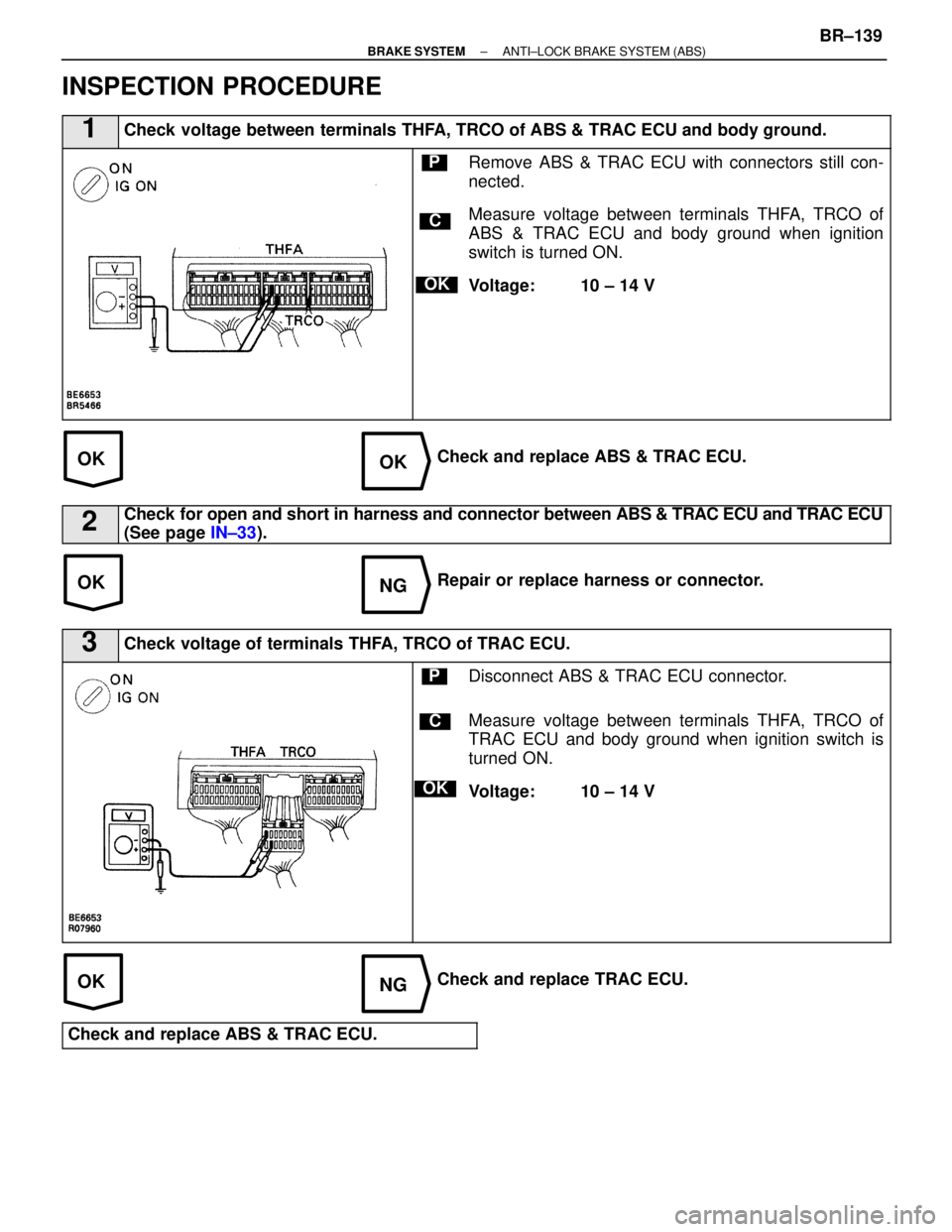

INSPECTION PROCEDURE

1Check voltage between terminals THFA, TRCO of ABS & TRAC ECU and body ground.

C

OK

PRemove ABS & TRAC ECU with connectors still con-

nected.

Measure voltage between terminals THFA, TRCO of

ABS & TRAC ECU and body ground when ignition

switch is turned ON.

Voltage: 10 ± 14 V

Check and replace ABS & TRAC ECU.

2Check for open and short in harness and connector between ABS & TRAC ECU and TRAC ECU

(See page IN±33).

Repair or replace harness or connector.

3Check voltage of terminals THFA, TRCO of TRAC ECU.

C

OK

PDisconnect ABS & TRAC ECU connector.

Measure voltage between terminals THFA, TRCO of

TRAC ECU and body ground when ignition switch is

turned ON.

Voltage: 10 ± 14 V

Check and replace TRAC ECU.

Check and replace ABS & TRAC ECU.

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)BR±139

WhereEverybodyKnowsYourName

Page 1118 of 4087

NGOK

OKNG

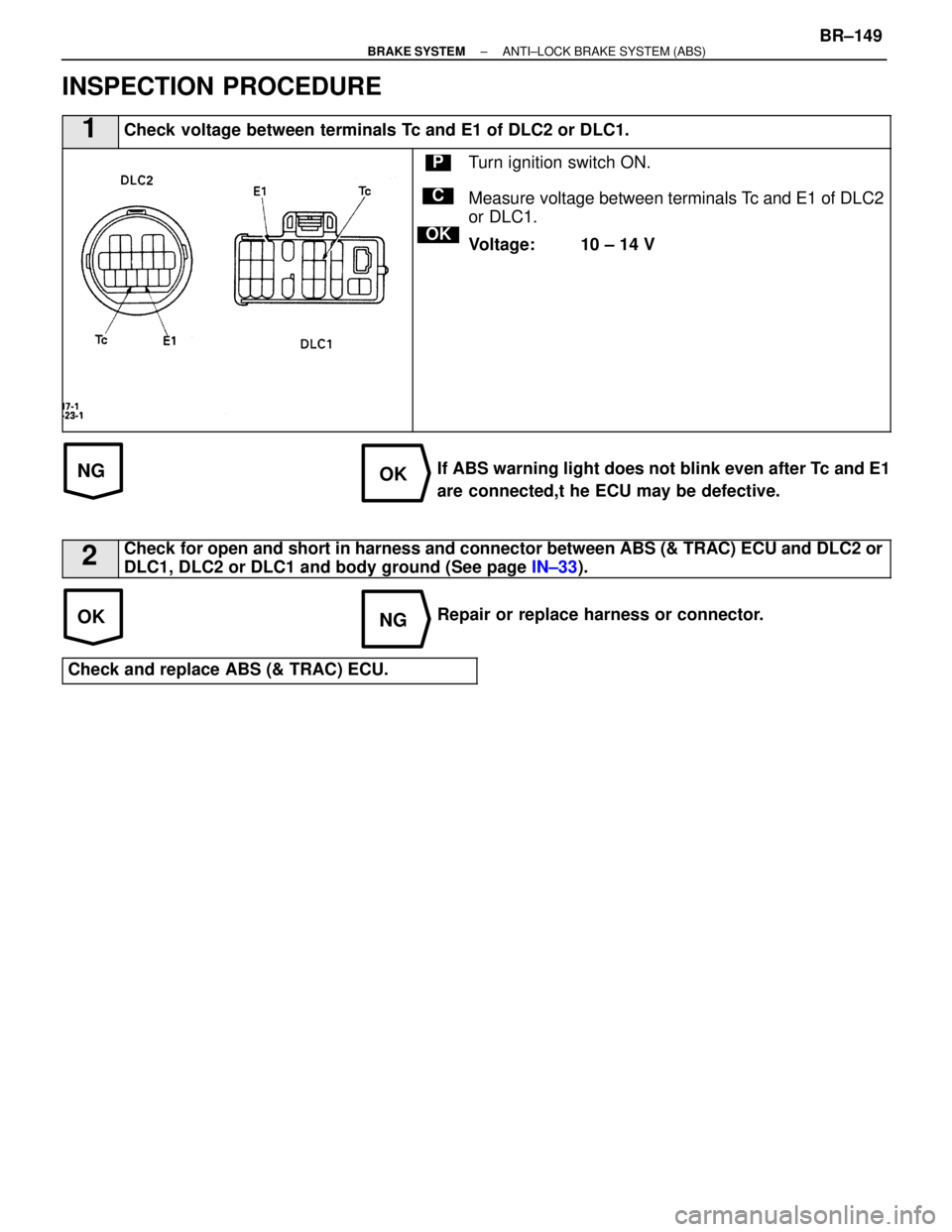

INSPECTION PROCEDURE

1Check voltage between terminals Tc and E1 of DLC2 or DLC1.

C

OK

PTurn ignition switch ON.

Measure voltage between terminals Tc and E1 of DLC2

or DLC1.

Voltage: 10 ± 14 V

If ABS warning light does not blink even after Tc and E1

are connected,t he ECU may be defective.

2Check for open and short in harness and connector between ABS (& TRAC) ECU \

and DLC2 or

DLC1, DLC2 or DLC1 and body ground (See page IN±33).

Repair or replace harness or connector.

Check and replace ABS (& TRAC) ECU.

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)BR±149

WhereEverybodyKnowsYourName

Page 1120 of 4087

NGOK

OKNG

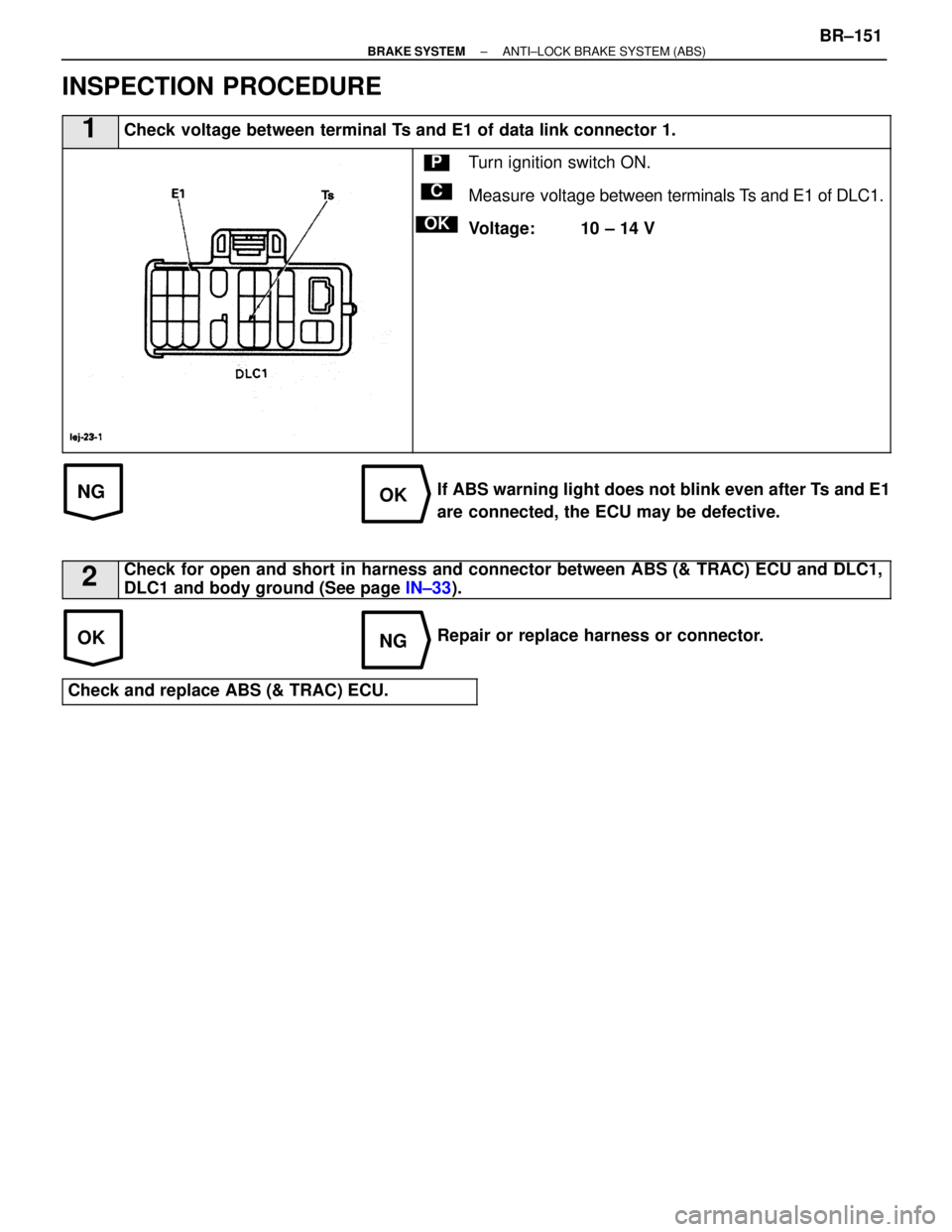

INSPECTION PROCEDURE

1Check voltage between terminal Ts and E1 of data link connector 1.

C

OK

PTurn ignition switch ON.

Measure voltage between terminals Ts and E1 of DLC1.

Voltage: 10 ± 14 V

If ABS warning light does not blink even after Ts and E1

are connected, the ECU may be defective.

2Check for open and short in harness and connector between ABS (& TRAC) ECU and D\

LC1,

DLC1 and body ground (See page IN±33).

Repair or replace harness or connector.

Check and replace ABS (& TRAC) ECU.

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)BR±151

WhereEverybodyKnowsYourName

Page 1135 of 4087

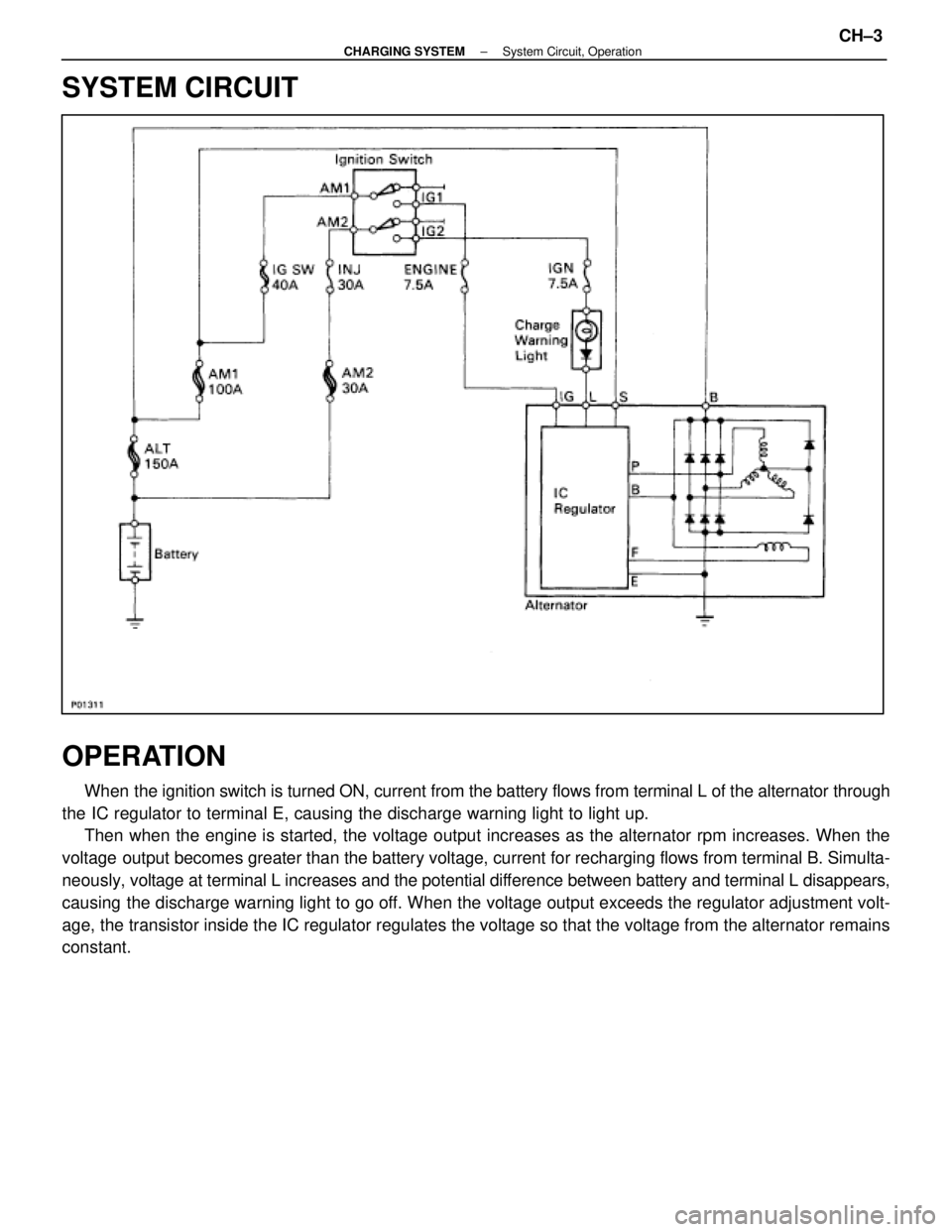

SYSTEM CIRCUIT

OPERATION

When the ignition switch is turned ON, current from the battery flows from t\

erminal L of the alternator through

the IC regulator to terminal E, causing the discharge warning light to ligh\

t up. Then when the engine is started, the voltage output increases as the alt\

ernator rpm increases. When the

voltage output becomes greater than the battery voltage, current for recharging\

flows from terminal B. Simulta-

neously, volt age at terminal L increases and the potential difference between battery and terminal L disappears,

causing the discharge warning light to go off. When the voltage output exceeds the regulator adjustment volt-

age, the transistor inside the IC regulator regulates the voltage so tha\

t the voltage from the alternator remains

constant.

±

CHARGING SYSTEM System Circuit, OperationCH±3

WhereEverybodyKnowsYourName

Page 1138 of 4087

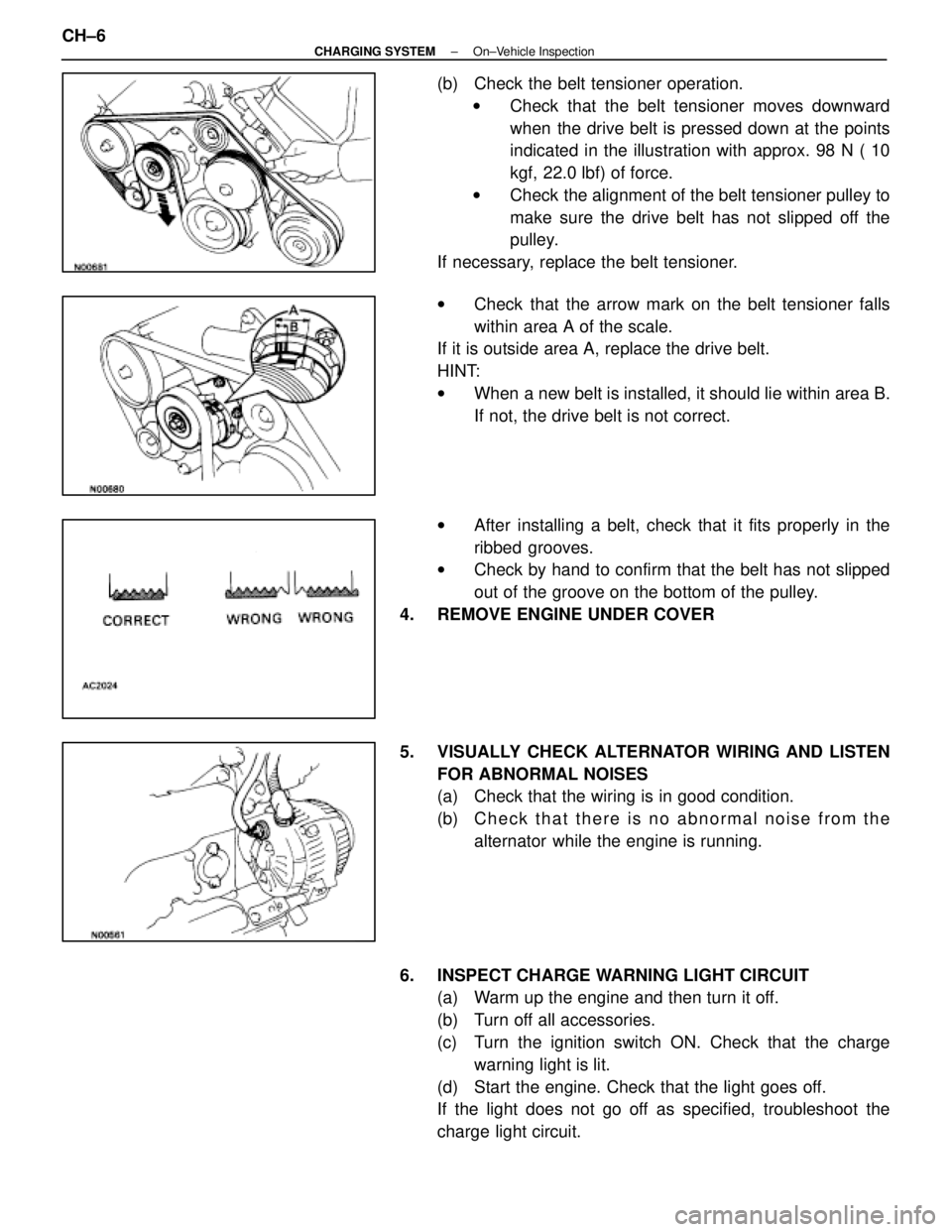

(b) Check the belt tensioner operation.w Check that the belt tensioner moves downward

when the drive belt is pressed down at the points

indicated in the illustration with approx. 98 N ( 10

kgf, 22.0 lbf) of force.

w Check the alignment of the belt tensioner pulley to

make sure the drive belt has not slipped off the

pulley.

If necessary, replace the belt tensioner.

w Check that the arrow mark on the belt tensioner falls

within area A of the scale.

If it is outside area A, replace the drive belt.

HINT:

w When a new belt is installed, it should lie within area B.

If not, the drive belt is not correct.

w After installing a belt, check that it fits properly in the

ribbed grooves.

w Check by hand to confirm that the belt has not slipped

out of the groove on the bottom of the pulley.

4. REMOVE ENGINE UNDER COVER

5. VISUALLY CHECK ALTERNATOR WIRING AND LISTEN FOR ABNORMAL NOISES

(a) Check that the wiring is in good condition.

(b) C h e c k t h a t t h e r e i s n o a bnormal noise from the

alternator while the engine is running.

6. INSPECT CHARGE WARNING LIGHT CIRCUIT (a) Warm up the engine and then turn it off.

(b) Turn off all accessories.

(c) Turn the ignition switch ON. Check that the charge

warning light is lit.

(d) Start the engine. Check that the light goes off.

If the light does not go off as specified, troubleshoot the

charge light circuit.

CH±6

±

CHARGING SYSTEM On±Vehicle Inspection

WhereEverybodyKnowsYourName