clock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 12 of 4087

When the negative (±) terminal cable is disconnected from

the battery, memory of the clock and audio systems will be

cancelled. So before starting work, make a record of the con-

tents memorized by each memory system. Then when work

is finished, reset the clock and audio systems as before.

When the vehicle has power tilt and power telescopic steer-

ing, power seat, power outside rear view mirror and power

shoulder belt anchorage, which are all equipped with

memory function, it is not possible to make a record of the

memory contents. So when the operation is finished, it will be

necessary to explain this fact to the customer, and ask the

customer to adjust the features and reset the memory.

To avoid erasing the memory of each memory system, never

use a back±up power supply from outside the vehicle.

3. Even in cases of a minor collision where the airbag does not deploy, the front airbag sensors and the steering wheel pad

should be inspected. (See page AB±9)

4. Never use airbag parts from another vehicle. When replacing parts, replace them with new parts.

5. Before repairs, remove the airbag sensors if shocks are likely

to be applied to the sensors during repairs.

6. The center airbag sensor assembly contains mercury. After

performing replacement, do not destroy the old part. When

scrapping the vehicle or replacing the center airbag sensor

assembly itself, remove the center airbag sensor assembly

and dispose of it as toxic waste.

7. Never disassemble and repair the front airbag sensors, center airbag sensor assembly or steering wheel pad in order

to reuse it.

8. If the front airbag sensors, center airbag sensor assembly or steering wheel pad have been dropped, or if there are cracks,

dents or other defects in the case, bracket or connector,

replace them with new ones.

9. Do not expose the front airbag sensors, center airbag sensor assembly or steering wheel pad directly to hot air or flames.

10. U s e a v o l t / o h m m e t e r w i t h h i g h i m pedance (10 kW/V

minimum) for troubleshooting of the electrical circuit.

11. Information labels are attached to the periphery of the airbag components. Follow the notices.

12. After work on the airbag system is completed, perform the

airbag warning light check (See page AB±30).

±

INTRODUCTION Precautions for Vehicles Equipped with SRS AirbagIN±9

WhereEverybodyKnowsYourName

Page 216 of 4087

GENERAL DESCRIPTION

The LEXUS SC400 is equipped with an SRS (Supplemental Restraint System) a\

irbag.

Failure to carry out service operations in the correct sequence could cause the\

airbag system to unex-

pectedly deploy during servicing, possibly leading to a serious accident.

Further, if a mistake is made in servicing the airbag system, it is possible the\

airbag may fail to operate

when required.

Before performing servicing (including removal or installation of parts, insp\

ection or replacement), be

sure to read the following items carefully, then follow the correct procedure described in the repair

manual.

1. Malfunction symptoms of the airbag system are difficult to confirm, so the diagnostic codes become themost important source of information when troubleshooting.

When troubleshooting the airbag system, always inspect the diagnostic co\

des before disconnecting the

battery (See page AB±25).

2. Work must be started after approx. 20 seconds or longer from the time the ig\

nition switch is turned to the LOCK position and the negative (±) terminal cable is disconnec\

ted from the battery. (The

airbag system is equipped with a back±up power source so that if work is sta\

rted within 20 seconds

of disconnecting the negative (±) terminal cable of the battery, the airbag may be deployed.)

When the negative (±) terminal cable is disconnected from the battery, memory of the clock and audio sys-

tems will be cancelled. So before starting work, make a record of the conten\

ts memorized by the audio

memory system. Then when work is finished, reset the audio systems as before a\

nd adjust the clock. When

the vehicle has power tilt and power telescopic steering, power seat, power \

outside rear view mirror and

power shoulder belt anchorage, which are all equipped with memory function, it\

is not possible to make

a record of the memory contents. So when the work is finished, it will be\

necessary to explain this fact to

the customer, and ask the customer to adjust the features and reset the memory. To avoid erasing the

memory of each memory system, never use a back±up power supply from outside\

the vehicle.

3. Even in cases of a minor collision where the airbag does not deploy, the front airbag sensors and

the steering wheel pad should be inspected (See page AB±9).

4. Never use airbag parts from another vehicle. When replacing parts, replace them with new parts.

5. Before repairs, remove the airbag sensors if shocks are likely to be applied to the sensors during repairs.

6. Never disassemble and repair the front airbag sensors, center airbag sensor a\

ssembly or steering

wheel pad in order to reuse it.

7. If the front airbag sensors, center airbag assembly or steering wheel pa\

d have been dropped, or if there are cracks, dents or other defects in the case, bracket or conn\

ector, replace them with new

ones.

8. Do not expose the front airbag sensors, center airbag sensor assembly or\

steering wheel pad directly to hot air or flames.

9. Use a volt/ohmmeter with high impedance (10 kW/V minimum) for troubleshoo\

ting of the electrical circuit.

10. Information labels are attached to the periphery of the airbag components. Follow t\

he instructions

on the notices.

11. After work on the airbag system is completed, perform the airbag warning\

light check (See page AB±30 ).

AB±2

SRS AIRBAG

± General Description

WhereEverybodyKnowsYourName

Page 229 of 4087

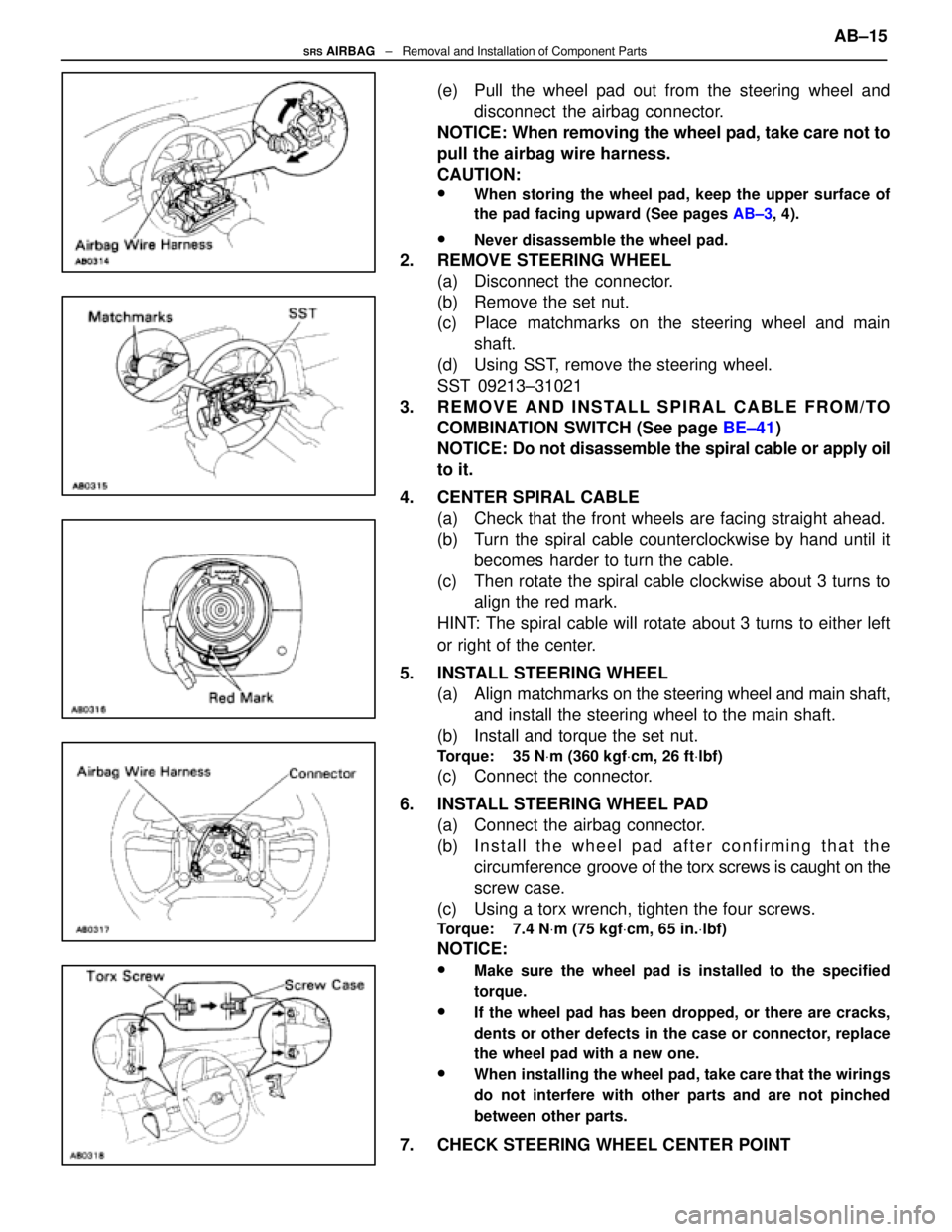

(e) Pull the wheel pad out from the steering wheel anddisconnect the airbag connector.

NOTICE: When removing the wheel pad, take care not to

pull the airbag wire harness.

CAUTION:

wWhen storing the wheel pad, keep the upper surface of

the pad facing upward (See pages AB±3, 4).

wNever disassemble the wheel pad.

2. REMOVE STEERING WHEEL

(a) Disconnect the connector.

(b) Remove the set nut.

(c) Place matchmarks on the steering wheel and mainshaft.

(d) Using SST, remove the steering wheel.

SST 09213±31021

3. REMOVE AND INSTALL SPIRAL CABLE FROM/TO COMBINATION SWITCH (See page BE±41)

NOTICE: Do not disassemble the spiral cable or apply oil

to it.

4. CENTER SPIRAL CABLE (a) Check that the front wheels are facing straight ahead.

(b) Turn the spiral cable counterclockwise by hand until it

becomes harder to turn the cable.

(c) Then rotate the spiral cable clockwise about 3 turns to align the red mark.

HINT: The spiral cable will rotate about 3 turns to either left

or right of the center.

5. INSTALL STEERING WHEEL (a) Align matchmarks on the steering wheel and main shaft,

and install the steering wheel to the main shaft.

(b) Install and torque the set nut.

Torque: 35 N Vm (360 kgf Vcm, 26 ft Vlbf)

(c) Connect the connector.

6. INSTALL STEERING WHEEL PAD (a) Connect the airbag connector.

(b) I n s t a l l t h e w heel pad after confirming that the

circumference groove of the torx screws is caught on the

screw case.

(c) Using a torx wrench, tighten the four screws.

Torque: 7.4 N Vm (75 kgf Vcm, 65 in. Vlbf)

NOTICE:

wMake sure the wheel pad is installed to the specified

torque.

wIf the wheel pad has been dropped, or there are cracks,

dents or other defects in the case or connector, replace

the wheel pad with a new one.

wWhen installing the wheel pad, take care that the wirings

do not interfere with other parts and are not pinched

between other parts.

7. CHECK STEERING WHEEL CENTER POINT AB±15

SRS AIRBAG

± Removal and Installation of Component Parts

WhereEverybodyKnowsYourName

Page 246 of 4087

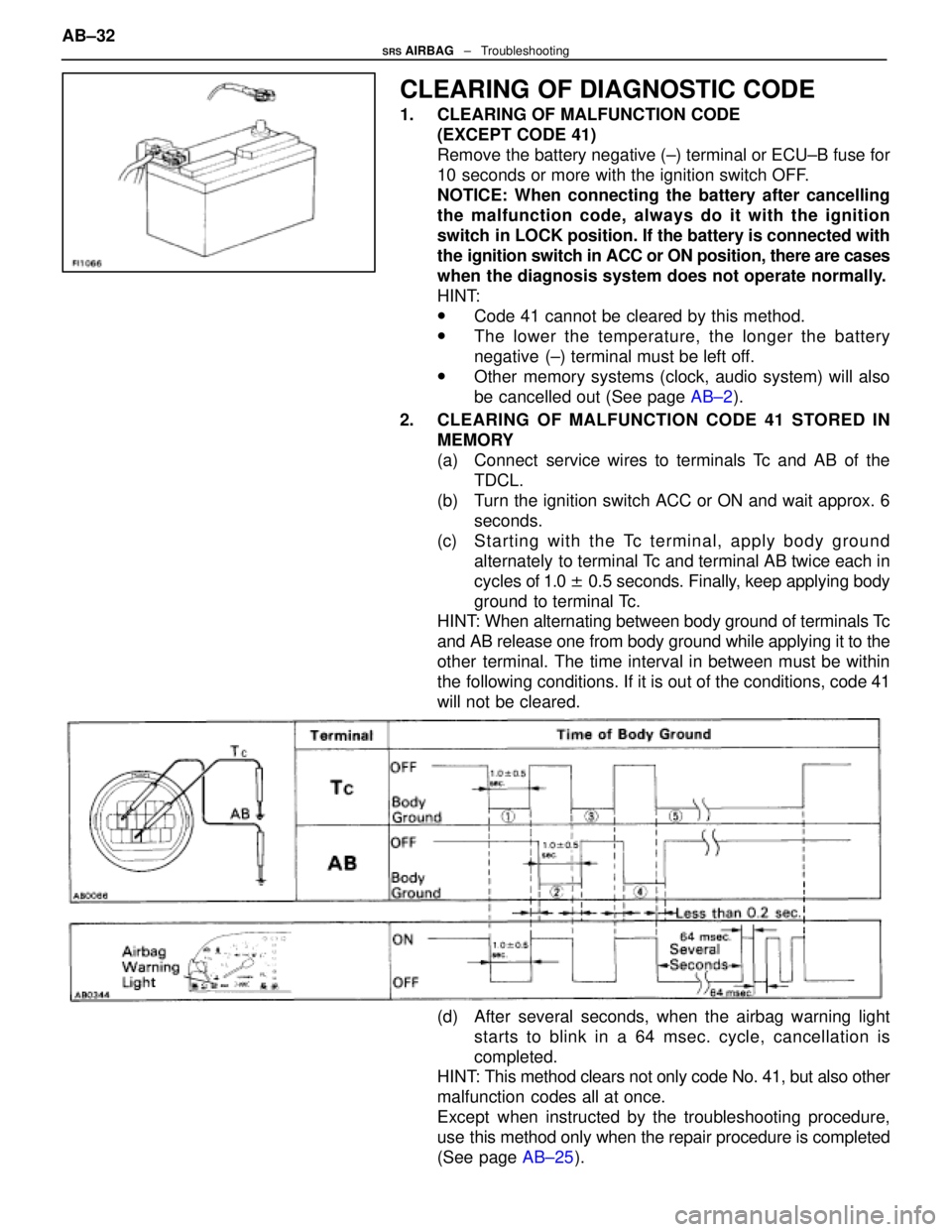

CLEARING OF DIAGNOSTIC CODE

1. CLEARING OF MALFUNCTION CODE(EXCEPT CODE 41)

Remove the battery negative (±) terminal or ECU±B fuse for

10 seconds or more with the ignition switch OFF.

NOTICE: When connecting the battery after cancelling

the malfunction code, always do it with the ignition

switch in LOCK position. If the battery is connected with

the ignition switch in ACC or ON position, there are cases

when the diagnosis system does not operate normally.

HINT:

wCode 41 cannot be cleared by this method.

wThe lower the temperature, the longer the battery

negative (±) terminal must be left off.

wOther memory systems (clock, audio system) will also

be cancelled out (See page AB±2).

2. CLEARING OF MALFUNCTION CODE 41 STORED IN MEMORY

(a) Connect service wires to terminals Tc and AB of theTDCL.

(b) Turn the ignition switch ACC or ON and wait approx. 6 seconds.

(c) S ta rtin g with th e Tc te rmin a l, ap p ly bo d y gr ound

alternately to terminal Tc and terminal AB twice each in

cycles of 1.0 ± 0.5 seconds. Finally, keep applying body

ground to terminal Tc.

HINT: When alternating between body ground of terminals Tc

and AB release one from body ground while applying it to the

other terminal. The time interval in between must be within

the following conditions. If it is out of the conditions, code 41

will not be cleared.

(d) After several seconds, when the airbag warning light

starts to blink in a 64 msec. cycle, cancellation is

completed.

HINT: This method clears not only code No. 41, but also other

malfunction codes all at once.

Except when instructed by the troubleshooting procedure,

use this method only when the repair procedure is completed

(See page AB±25).

AB±32

SRS AIRBAG

± Troubleshooting

WhereEverybodyKnowsYourName

Page 388 of 4087

TORQUE CONVERTER CLUTCH

CLEANING

AT079±04

If the transmission is contaminated, the torque converter

clutch and transmission cooler should be thoroughly flushed

with ATF.

TORQUE CONVERTER CLUTCH AND

DRIVE PLATE INSPECTION

AT00J±01

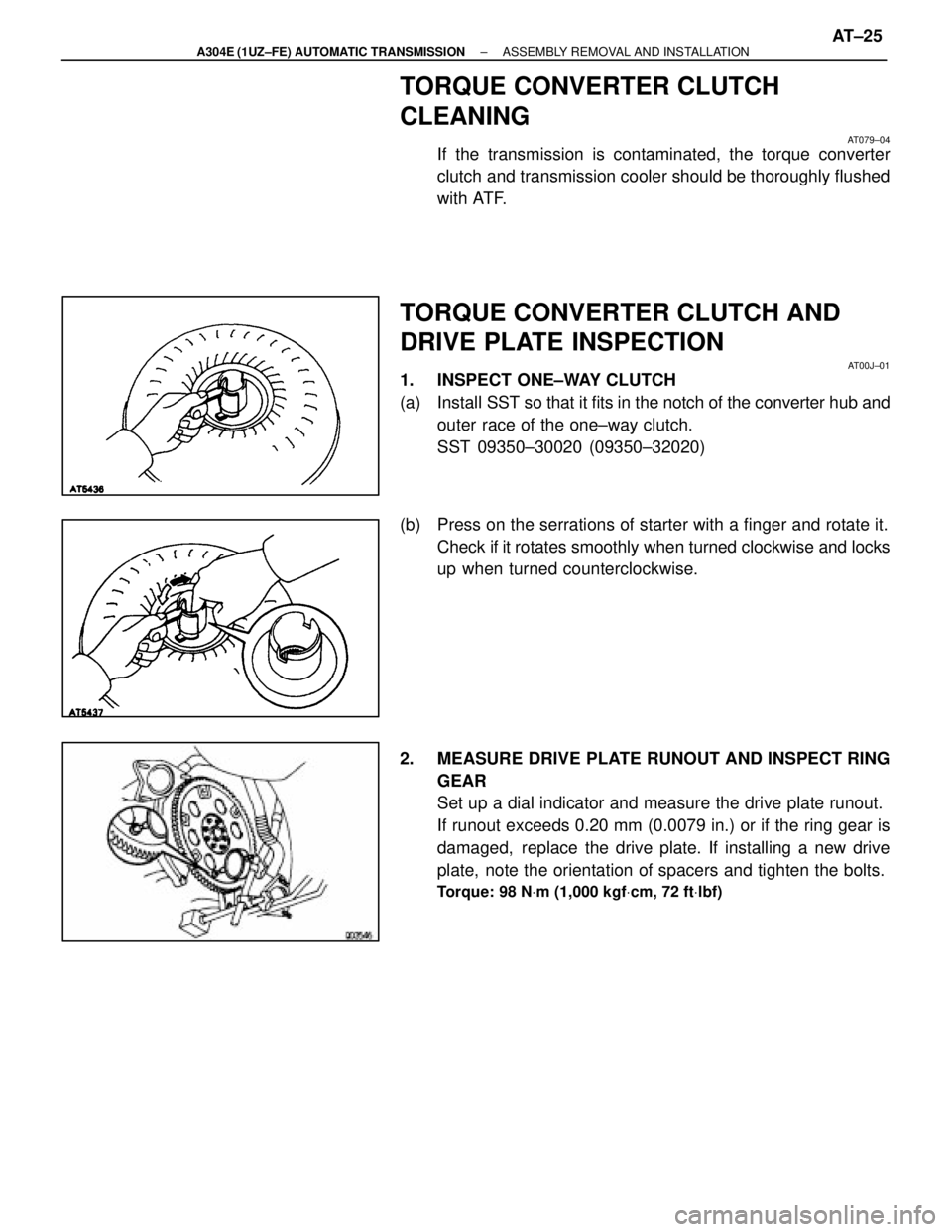

1. INSPECT ONE±WAY CLUTCH

(a) Install SST so that it fits in the notch of the converter hub and

outer race of the one±way clutch.

SST 09350±30020 (09350±32020)

(b) Press on the serrations of starter with a finger and rotate it. Check if it rotates smoothly when turned clockwise and locks

up when turned counterclockwise.

2. MEASURE DRIVE PLATE RUNOUT AND INSPECT RING GEAR

Set up a dial indicator and measure the drive plate runout.

If runout exceeds 0.20 mm (0.0079 in.) or if the ring gear is

damaged, replace the drive plate. If installing a new drive

plate, note the orientation of spacers and tighten the bolts.

Torque: 98 N Vm (1,000 kgf Vcm, 72 ft Vlbf)

±

A304E (1UZ±FE) AUTOMATIC TRANSMISSION ASSEMBLY REMOVAL AND INSTALLATIONAT±25

WhereEverybodyKnowsYourName

Page 515 of 4087

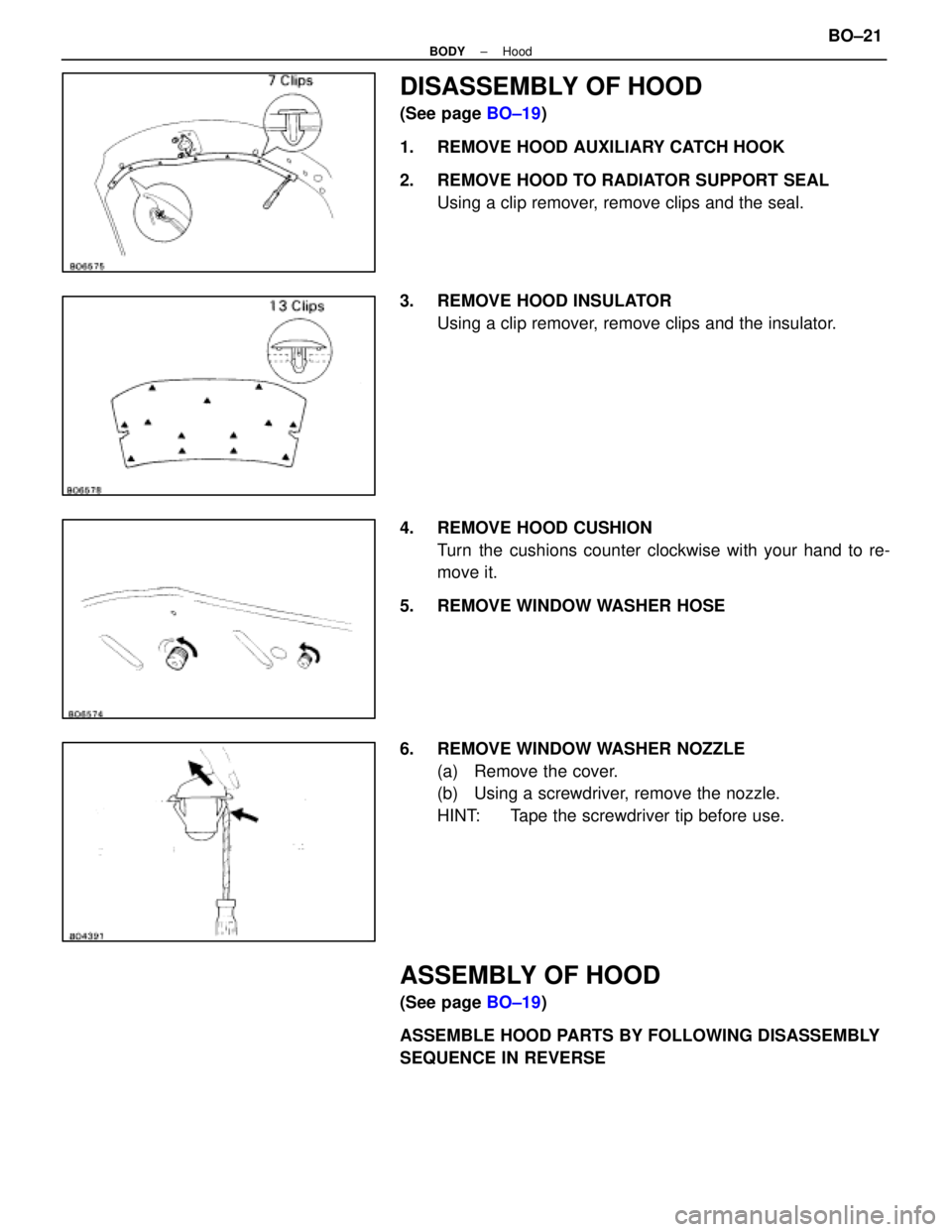

DISASSEMBLY OF HOOD

(See page BO±19)

1. REMOVE HOOD AUXILIARY CATCH HOOK

2. REMOVE HOOD TO RADIATOR SUPPORT SEAL Using a clip remover, remove clips and the seal.

3. REMOVE HOOD INSULATOR Using a clip remover, remove clips and the insulator.

4. REMOVE HOOD CUSHION Turn the cushions counter clockwise with your hand to re-

move it.

5. REMOVE WINDOW WASHER HOSE

6. REMOVE WINDOW WASHER NOZZLE (a) Remove the cover.

(b) Using a screwdriver, remove the nozzle.

HINT: Tape the screwdriver tip before use.

ASSEMBLY OF HOOD

(See page BO±19)

ASSEMBLE HOOD PARTS BY FOLLOWING DISASSEMBLY

SEQUENCE IN REVERSE

±

BODY HoodBO±21

WhereEverybodyKnowsYourName

Page 538 of 4087

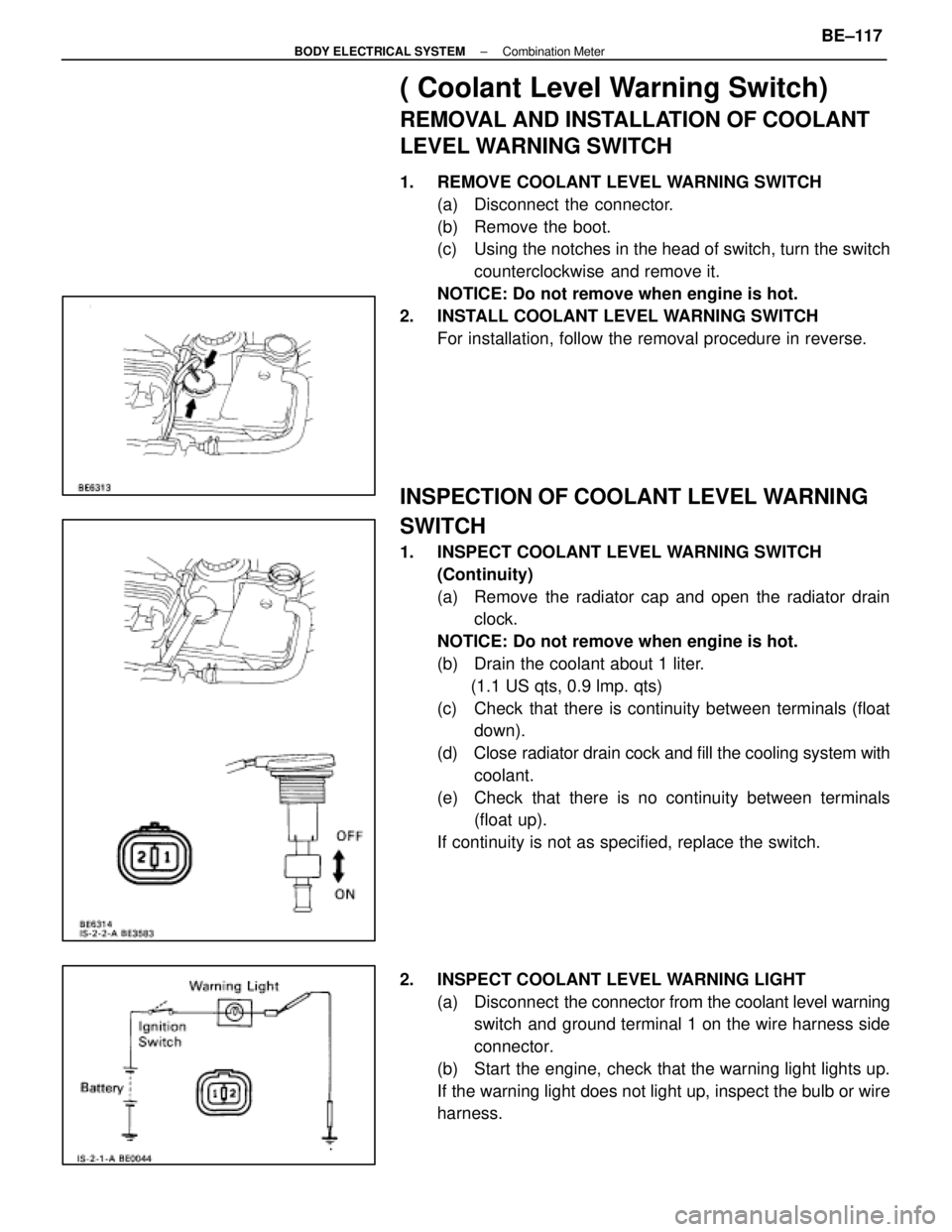

( Coolant Level Warning Switch)

REMOVAL AND INSTALLATION OF COOLANT

LEVEL WARNING SWITCH

1. REMOVE COOLANT LEVEL WARNING SWITCH(a) Disconnect the connector.

(b) Remove the boot.

(c) Using the notches in the head of switch, turn the switchcounterclockwise and remove it.

NOTICE: Do not remove when engine is hot.

2. INSTALL COOLANT LEVEL WARNING SWITCH For installation, follow the removal procedure in reverse.

INSPECTION OF COOLANT LEVEL WARNING

SWITCH

1. INSPECT COOLANT LEVEL WARNING SWITCH(Continuity)

(a) Remove the radiator cap and open the radiator drainclock.

NOTICE: Do not remove when engine is hot.

(b) Drain the coolant about 1 liter. (1.1 US qts, 0.9 lmp. qts)

(c) Check that there is continuity between terminals (float down).

(d) Close radiator drain cock and fill the cooling system with

coolant.

(e) Check that there is no continuity between terminals (float up).

If continuity is not as specified, replace the switch.

2. INSPECT COOLANT LEVEL WARNING LIGHT (a) Disconnect the connector from the coolant level warning

switch and ground terminal 1 on the wire harness side

connector.

(b) Start the engine, check that the warning light lights up.

If the warning light does not light up, inspect the bulb or wire

harness.

±

BODY ELECTRICAL SYSTEM Combination MeterBE±117

WhereEverybodyKnowsYourName

Page 544 of 4087

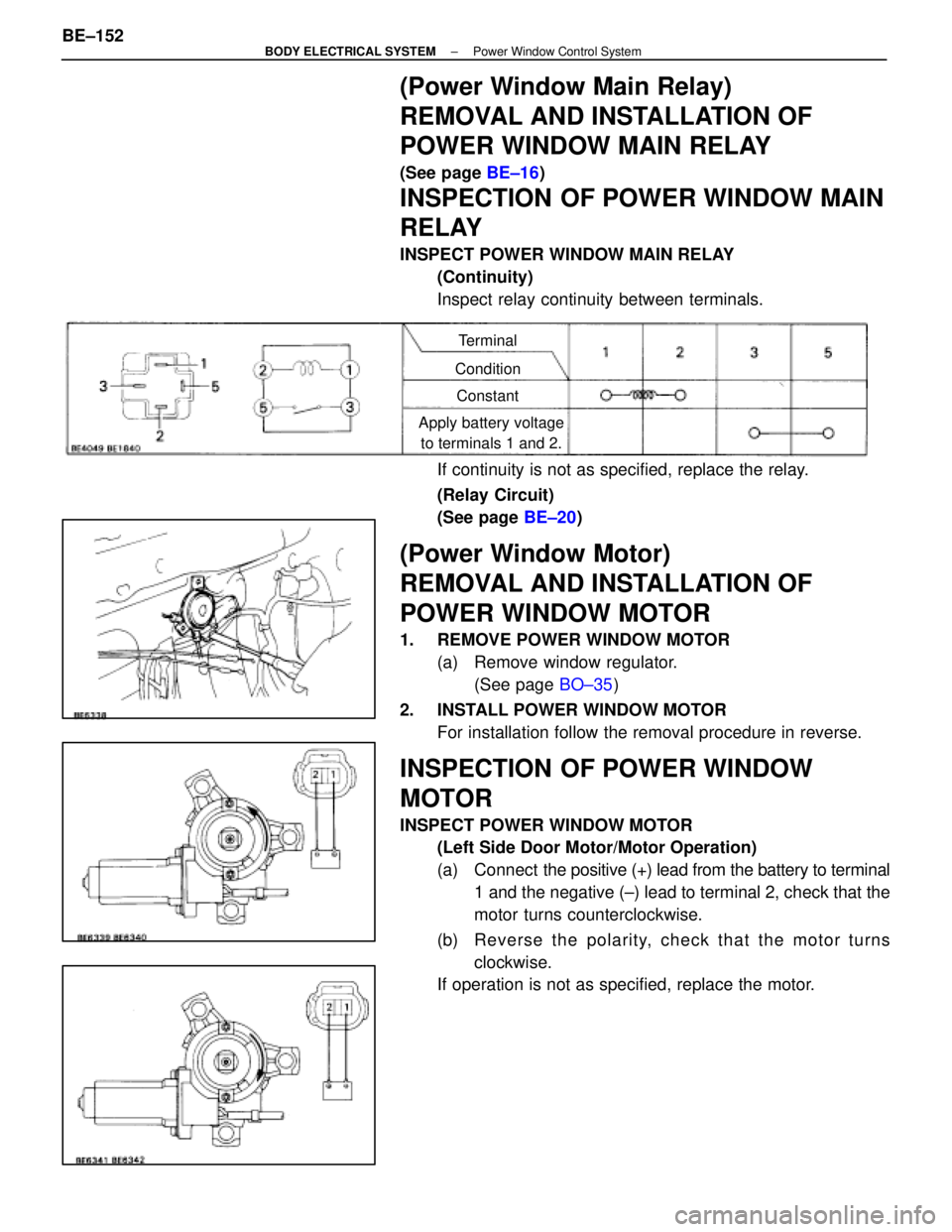

(Power Window Main Relay)

REMOVAL AND INSTALLATION OF

POWER WINDOW MAIN RELAY

(See page BE±16)

INSPECTION OF POWER WINDOW MAIN

RELAY

INSPECT POWER WINDOW MAIN RELAY

(Continuity)

Inspect relay continuity between terminals.

Terminal

Condition Constant

Apply battery voltage to terminals 1 and 2.

If continuity is not as specified, replace the relay.

(Relay Circuit)

(See page BE±20)

(Power Window Motor)

REMOVAL AND INSTALLATION OF

POWER WINDOW MOTOR

1. REMOVE POWER WINDOW MOTOR

(a) Remove window regulator.(See page BO±35)

2. INSTALL POWER WINDOW MOTOR For installation follow the removal procedure in reverse.

INSPECTION OF POWER WINDOW

MOTOR

INSPECT POWER WINDOW MOTOR(Left Side Door Motor/Motor Operation)

(a) Connect the positive (+) lead from the battery to terminal

1 and the negative (±) lead to terminal 2, check that the

motor turns counterclockwise.

(b) Re ve rse th e po la rity, ch e ck th a t th e mo to r tu rn s clockwise.

If operation is not as specified, replace the motor.

BE±152

±

BODY ELECTRICAL SYSTEM Power Window Control System

WhereEverybodyKnowsYourName

Page 546 of 4087

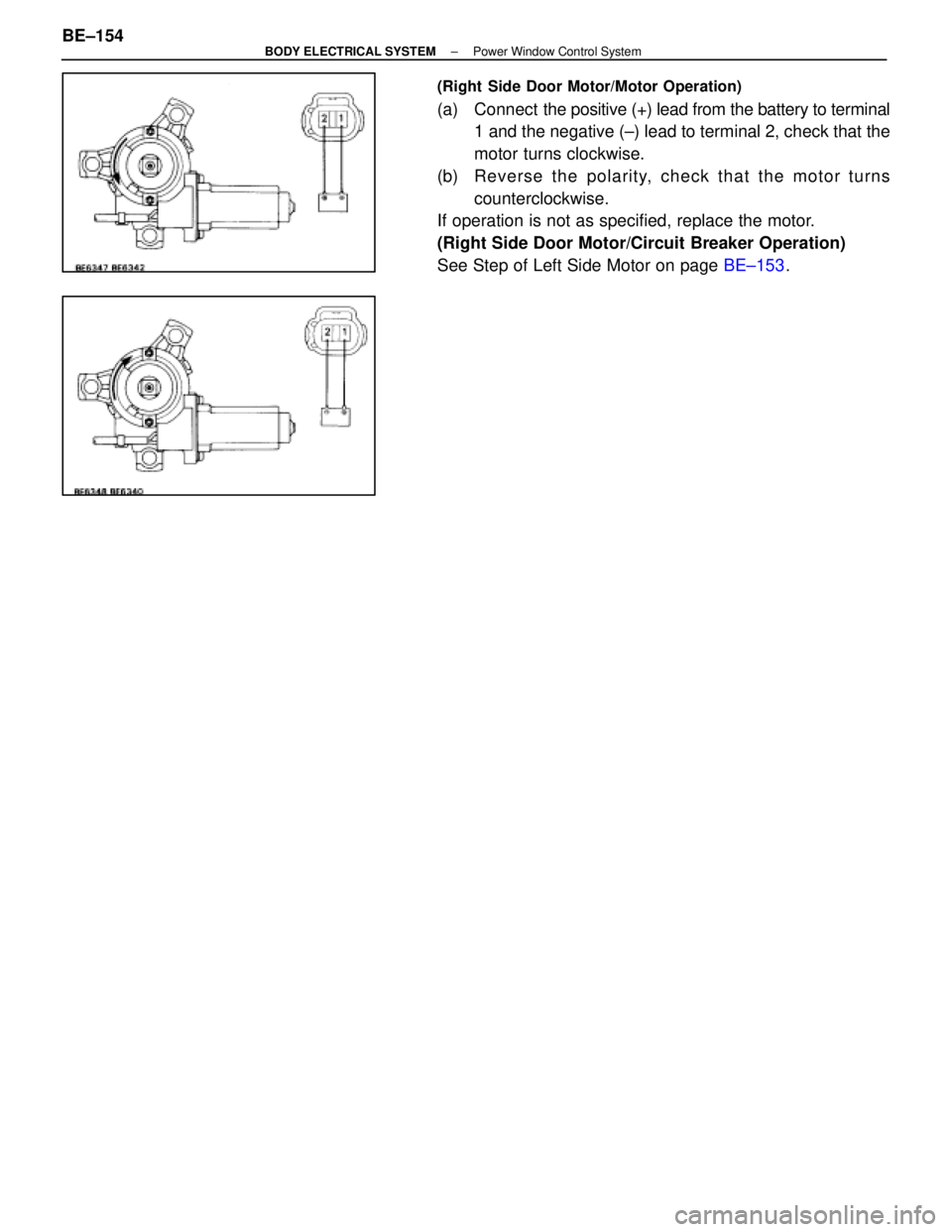

(Right Side Door Motor/Motor Operation)

(a) Connect the positive (+) lead from the battery to terminal

1 and the negative (±) lead to terminal 2, check that the

motor turns clockwise.

(b) Re ve rse th e po la rity, ch e ck th a t th e mo to r tu rn s counterclockwise.

If operation is not as specified, replace the motor.

(Right Side Door Motor/Circuit Breaker Operation)

See Step of Left Side Motor on page BE±153.

BE±154

±

BODY ELECTRICAL SYSTEM Power Window Control System

WhereEverybodyKnowsYourName

Page 565 of 4087

Parts Inspection

(Power Window Main Relay)

INSPECTION OF POWER WINDOW MAIN

RELAY

(See Power Window Main Relay on page BE±152)

(Sliding Roof Switch)

REMOVAL AND INSTALLATION OF

SLIDING ROOF SWITCH

(See Sliding Roof on page BO±85)

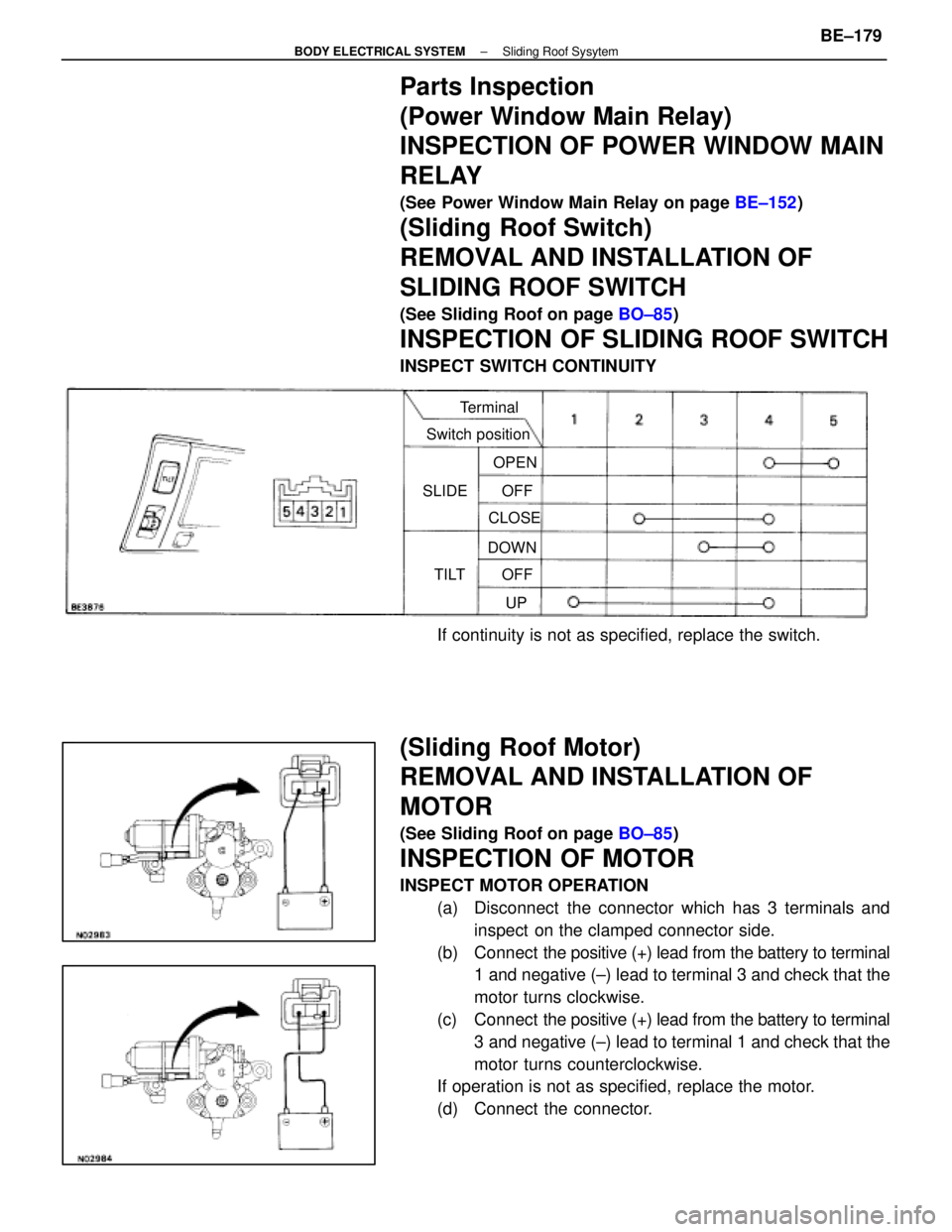

INSPECTION OF SLIDING ROOF SWITCH

INSPECT SWITCH CONTINUITY

Terminal

Switch position

SLIDE

TILT OFF

OPEN

CLOSE

OFFUP

DOWN

If continuity is not as specified, replace the switch.

(Sliding Roof Motor)

REMOVAL AND INSTALLATION OF

MOTOR

(See Sliding Roof on page

BO±85)

INSPECTION OF MOTOR

INSPECT MOTOR OPERATION

(a) Disconnect the connector which has 3 terminals andinspect on the clamped connector side.

(b) Connect the positive (+) lead from the battery to terminal

1 and negative (±) lead to terminal 3 and check that the

motor turns clockwise.

(c) Connect the positive (+) lead from the battery to terminal

3 and negative (±) lead to terminal 1 and check that the

motor turns counterclockwise.

If operation is not as specified, replace the motor.

(d) Connect the connector.

±

BODY ELECTRICAL SYSTEM Sliding Roof SysytemBE±179

WhereEverybodyKnowsYourName