LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 221 of 4087

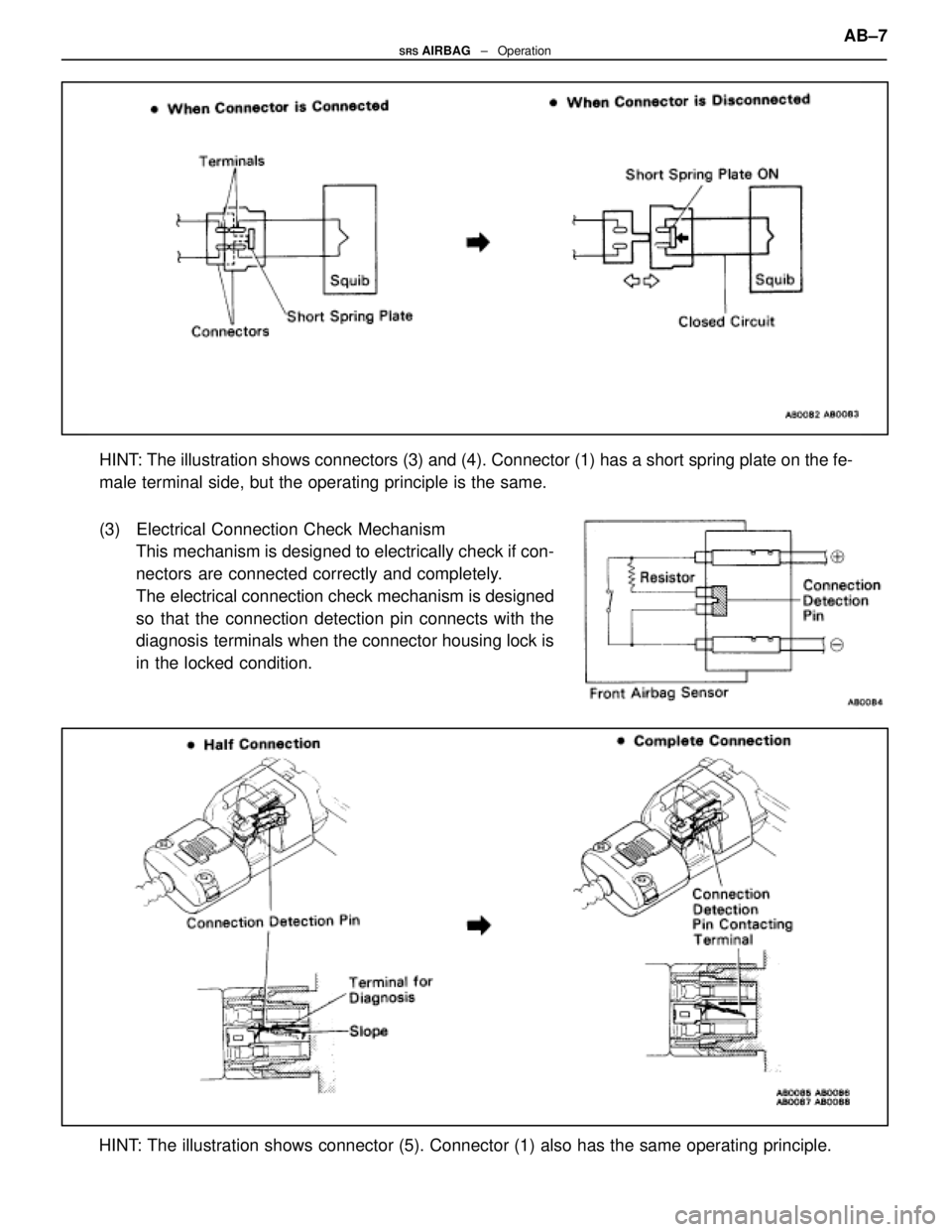

HINT: The illustration shows connectors (3) and (4). Connector (1) has \

a short spring plate on the fe-

male terminal side, but the operating principle is the same.

(3) Electrical Connection Check MechanismThis mechanism is designed to electrically check if con-

nectors are connected correctly and completely.

The electrical connection check mechanism is designed

so that the connection detection pin connects with the

diagnosis terminals when the connector housing lock is

in the locked condition.

HINT: The illustration shows connector (5). Connector (1) also has the s\

ame operating principle.

AB±7SRS AIRBAG ± Operation

WhereEverybodyKnowsYourName

Page 222 of 4087

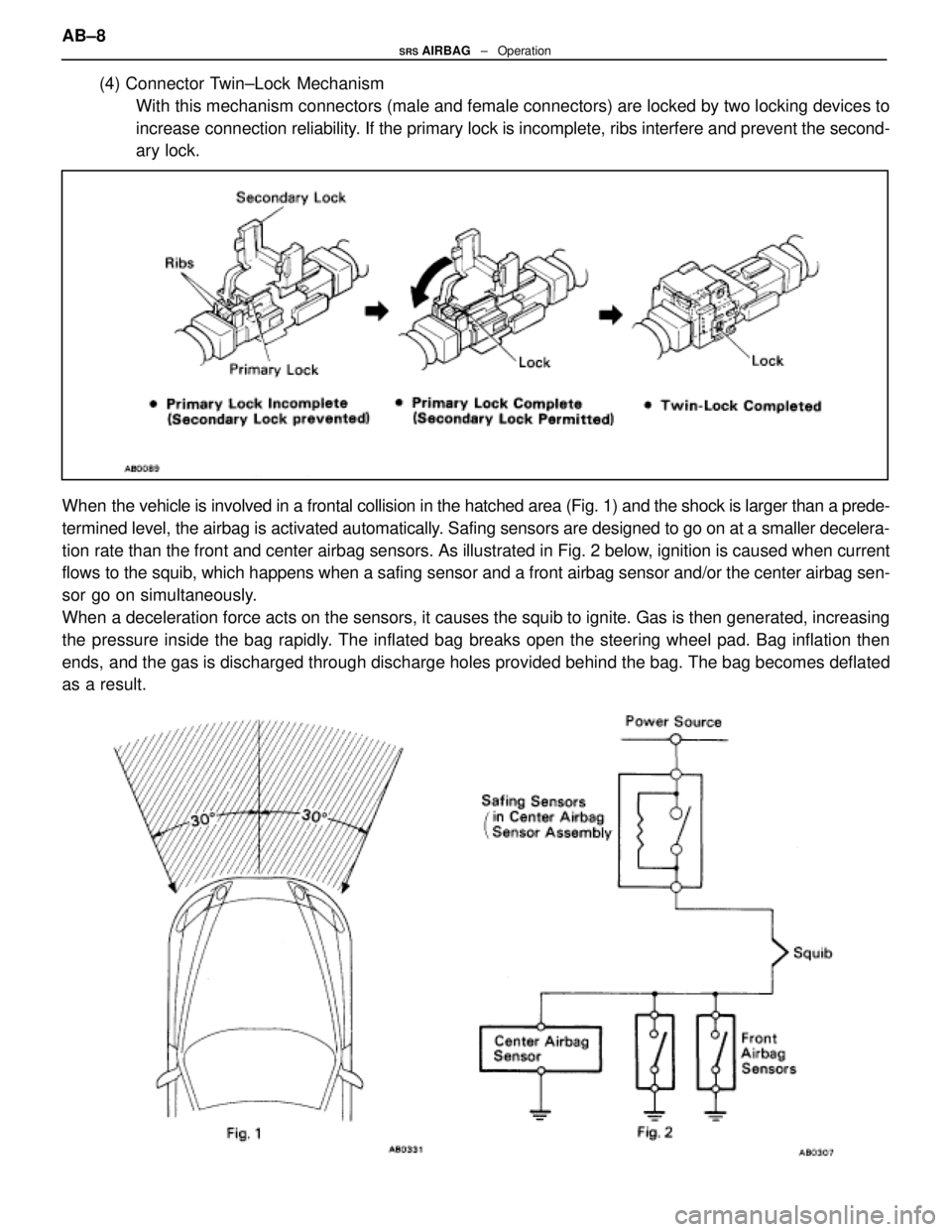

(4) Connector Twin±Lock MechanismWith this mechanism connectors (male and female connectors) are locked by \

two locking devices to

increase connection reliability. If the primary lock is incomplete, ribs interfere and prevent the seco\

nd-

ary lock.

When the vehicle is involved in a frontal collision in the hatched area (Fi\

g. 1) and the shock is larger than a prede-

termined level, the airbag is activated automatically. Safing sensors are designed to go on at a smaller decelera-

tion rate than the front and center airbag sensors. As illustrated in Fig. 2\

below, ignition is caused when current

flows to the squib, which happens when a safing sensor and a front airbag sen\

sor and/or the center airbag sen-

sor go on simultaneously.

When a deceleration force acts on the sensors, it causes the squib to ignite\

. Gas is then generated, increasing

the pressure inside the bag rapidly. The inflated bag breaks open the steering wheel pad. Bag inflation then

ends, and the gas is discharged through discharge holes provided behind the b\

ag. The bag becomes deflated

as a result.

AB±8SRS AIRBAG ± Operation

WhereEverybodyKnowsYourName

Page 223 of 4087

INSPECTION ITEMS AND REPLACEMENT REQUIREMENTS

If a Vehicle is brought in for an airbag system inspection, or if a vehicle wh\

ich has been involved in a collision

is inspected, perform the inspection in accordance with the following proc\

edure. If any problems are discovered,

replace the affected part with a new one.

Steering Wheel Pad (with Airbag), Steering Wheel and Spiral

Cable

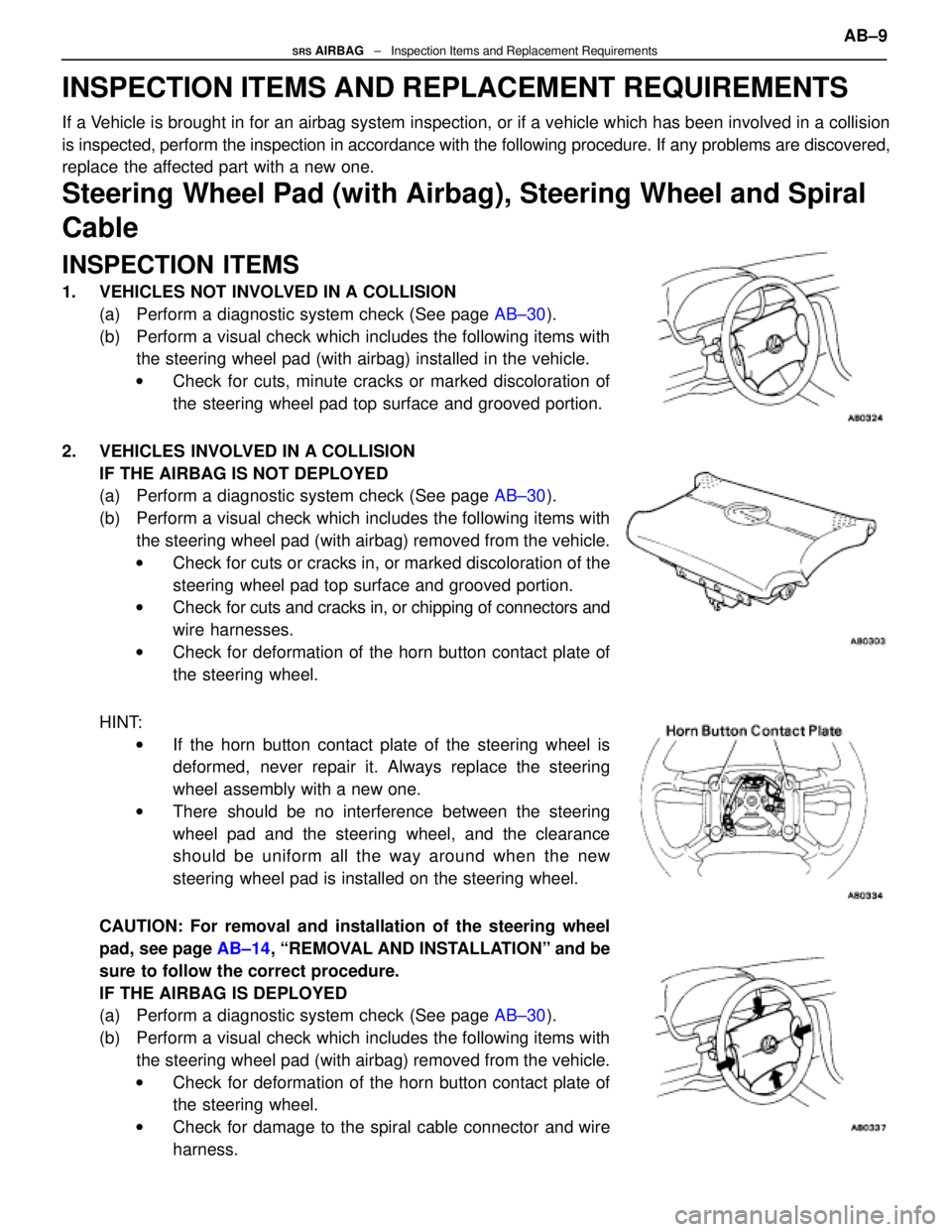

INSPECTION ITEMS

1. VEHICLES NOT INVOLVED IN A COLLISION(a) Perform a diagnostic system check (See page AB±30).

(b) Perform a visual check which includes the following items with the steering wheel pad (with airbag) installed in the vehicle.

w Check for cuts, minute cracks or marked discoloration of

the steering wheel pad top surface and grooved portion.

2. VEHICLES INVOLVED IN A COLLISION IF THE AIRBAG IS NOT DEPLOYED

(a) Perform a diagnostic system check (See page AB±30).

(b) Perform a visual check which includes the following items with the steering wheel pad (with airbag) removed from the vehicle.

w Check for cuts or cracks in, or marked discoloration of the

steering wheel pad top surface and grooved portion.

w Check for cuts and cracks in, or chipping of connectors and

wire harnesses.

w Check for deformation of the horn button contact plate of

the steering wheel.

HINT: w If the horn button contact plate of the steering wheel is

deformed, never repair it. Always replace the steering

wheel assembly with a new one.

w There should be no interference between the steering

wheel pad and the steering wheel, and the clearance

should be uniform all the way around when the new

steering wheel pad is installed on the steering wheel.

CAUTION: For removal and installation of the steering wheel

pad, see page AB±14, ªREMOVAL AND INSTALLATIONº and be

sure to follow the correct procedure.

IF THE AIRBAG IS DEPLOYED

(a) Perform a diagnostic system check (See page AB±30).

(b) Perform a visual check which includes the following items with the steering wheel pad (with airbag) removed from the vehicle.

w Check for deformation of the horn button contact plate of

the steering wheel.

w Check for damage to the spiral cable connector and wire

harness.

AB±9SRS AIRBAG ± Inspection Items and Replacement Requirements

WhereEverybodyKnowsYourName

Page 224 of 4087

HINT:

w If the horn button contact plate of the steering wheel is deformed, never \

repair it. Always replace the

steering wheel assembly with a new one.

w There should be no interference between the steering wheel pad and the steeri\

ng wheel, and the

clearance should be uniform all the way around when the new steering wheel pad is\

installed on the

steering wheel.

REPLACEMENT REQUIREMENTS

In the following cases, replace the steering wheel pad, steering wheel or \

spiral cable.

CAUTION: For replacement of the steering wheel pad, see page AB±16, ªREMOVAL AND INSTALLA-

TIONº and be sure to follow the correct procedure.

w If the airbag has been deployed.

w If the steering wheel pad or spiral cable has been found to be faulty in\

troubleshooting.

w If the steering wheel pad, steering wheel or spiral cable has been found t\

o be faulty during the check

in item 1±(b) or 2±(b).

w If the steering wheel pad has been dropped.

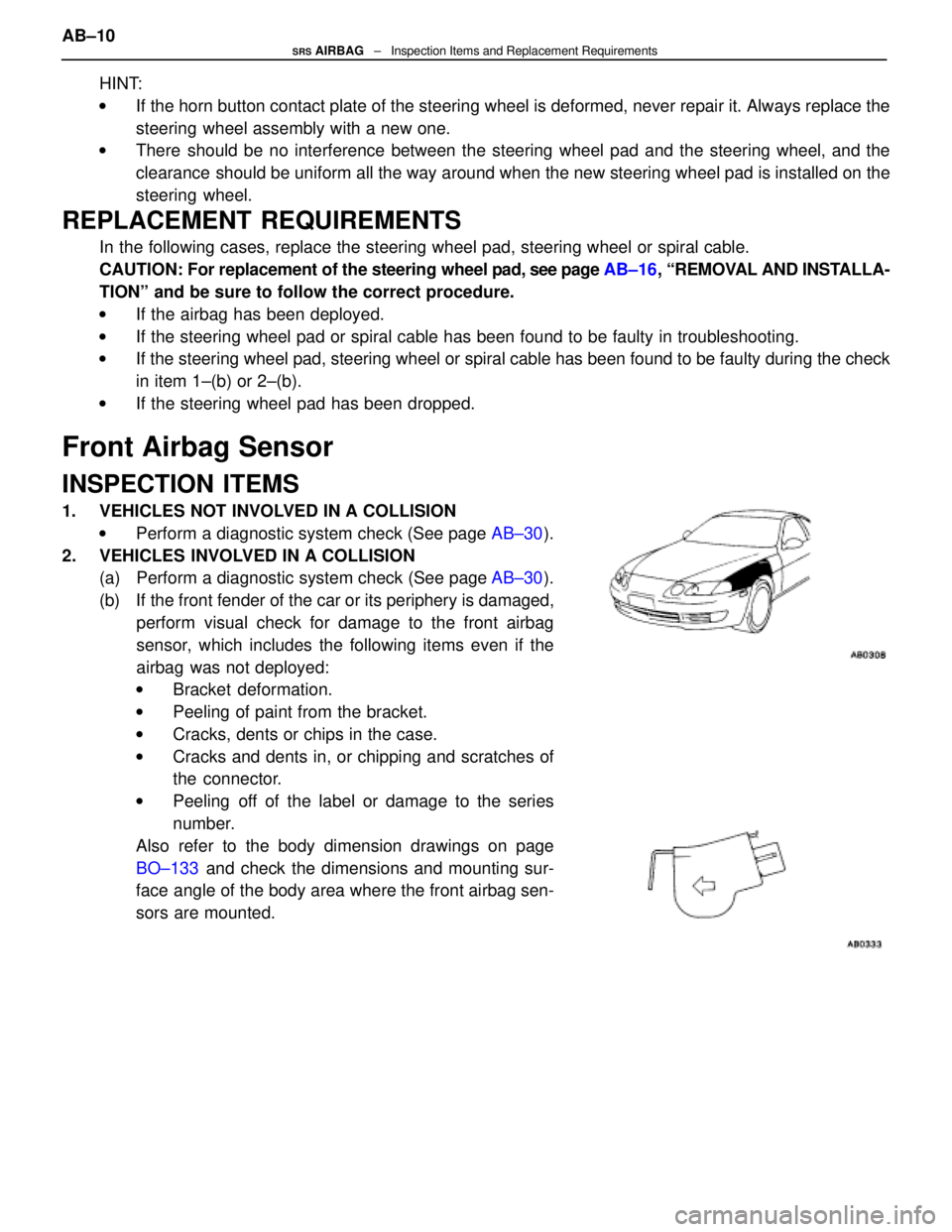

Front Airbag Sensor

INSPECTION ITEMS

1. VEHICLES NOT INVOLVED IN A COLLISION

w Perform a diagnostic system check (See page AB±30).

2. VEHICLES INVOLVED IN A COLLISION (a) Perform a diagnostic system check (See page AB±30).

(b) If the front fender of the car or its periphery is damaged, perform visual check for damage to the front airbag

sensor, which includes the following items even if the

airbag was not deployed:

w Bracket deformation.

w Peeling of paint from the bracket.

w Cracks, dents or chips in the case.

w Cracks and dents in, or chipping and scratches of

the connector.

w Peeling off of the label or damage to the series

number.

Also refer to the body dimension drawings on page

BO±133 and check the dimensions and mounting sur-

face angle of the body area where the front airbag sen-

sors are mounted.

AB±10SRS AIRBAG ± Inspection Items and Replacement Requirements

WhereEverybodyKnowsYourName

Page 225 of 4087

REPLACEMENT REQUIREMENTS

In the following cases, replace the front airbag sensor.

NOTICE: For replacement of the front airbag sensor, see page AB±16, ªREMOVAL AND

INSTALLATIONº.

w If the airbag has been deployed in a collision.

(Replace both the left and right airbag sensors.)

w If the front airbag sensor has been found to be faulty in troubleshootin\

g.

w If the front airbag sensor has been found to be faulty during the check \

in item 2±(b).

w If the front airbag sensor has been dropped.

Center Airbag Sensor Assembly

INSPECTION ITEMS

1. VEHICLES NOT INVOLVED IN A COLLISION

w Perform a diagnostic system check (See page AB±30).

VEHICLES INVOLVED IN A COLLISION

IF THE AIRBAG IS NOT DEPLOYED

w Perform a diagnostic system check (See page AB±30).

IF THE AIRBAG IS DEPLOYED

w Replace the airbag sensor assembly certainly.

AB±11SRS AIRBAG ± Inspection Items and Replacement Requirements

WhereEverybodyKnowsYourName

Page 226 of 4087

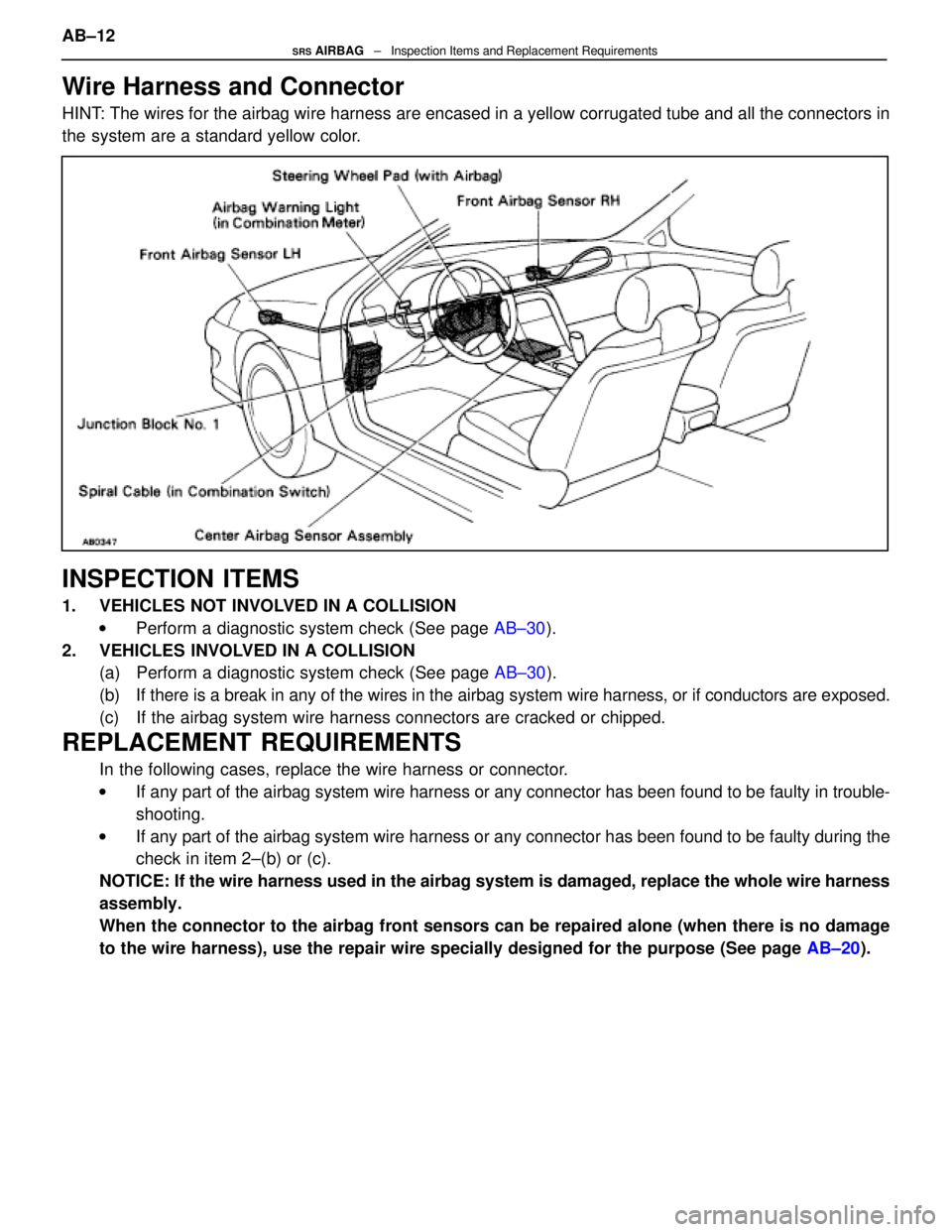

Wire Harness and Connector

HINT: The wires for the airbag wire harness are encased in a yellow corrugate\

d tube and all the connectors in

the system are a standard yellow color.

INSPECTION ITEMS

1. VEHICLES NOT INVOLVED IN A COLLISIONw Perform a diagnostic system check (See page AB±30).

2. VEHICLES INVOLVED IN A COLLISION (a) Perform a diagnostic system check (See page AB±30).

(b) If there is a break in any of the wires in the airbag system wire harness,\

or if conductors are exposed.

(c) If the airbag system wire harness connectors are cracked or chipped.

REPLACEMENT REQUIREMENTS

In the following cases, replace the wire harness or connector.

w If any part of the airbag system wire harness or any connector has been fo\

und to be faulty in trouble-

shooting.

w If any part of the airbag system wire harness or any connector has been \

found to be faulty during the

check in item 2±(b) or (c).

NOTICE: If the wire harness used in the airbag system is damaged, replace the w\

hole wire harness

assembly.

When the connector to the airbag front sensors can be repaired alone (when \

there is no damage

to the wire harness), use the repair wire specially designed for the pu\

rpose (See page AB±20).

AB±12

SRS AIRBAG

± Inspection Items and Replacement Requirements

WhereEverybodyKnowsYourName

Page 227 of 4087

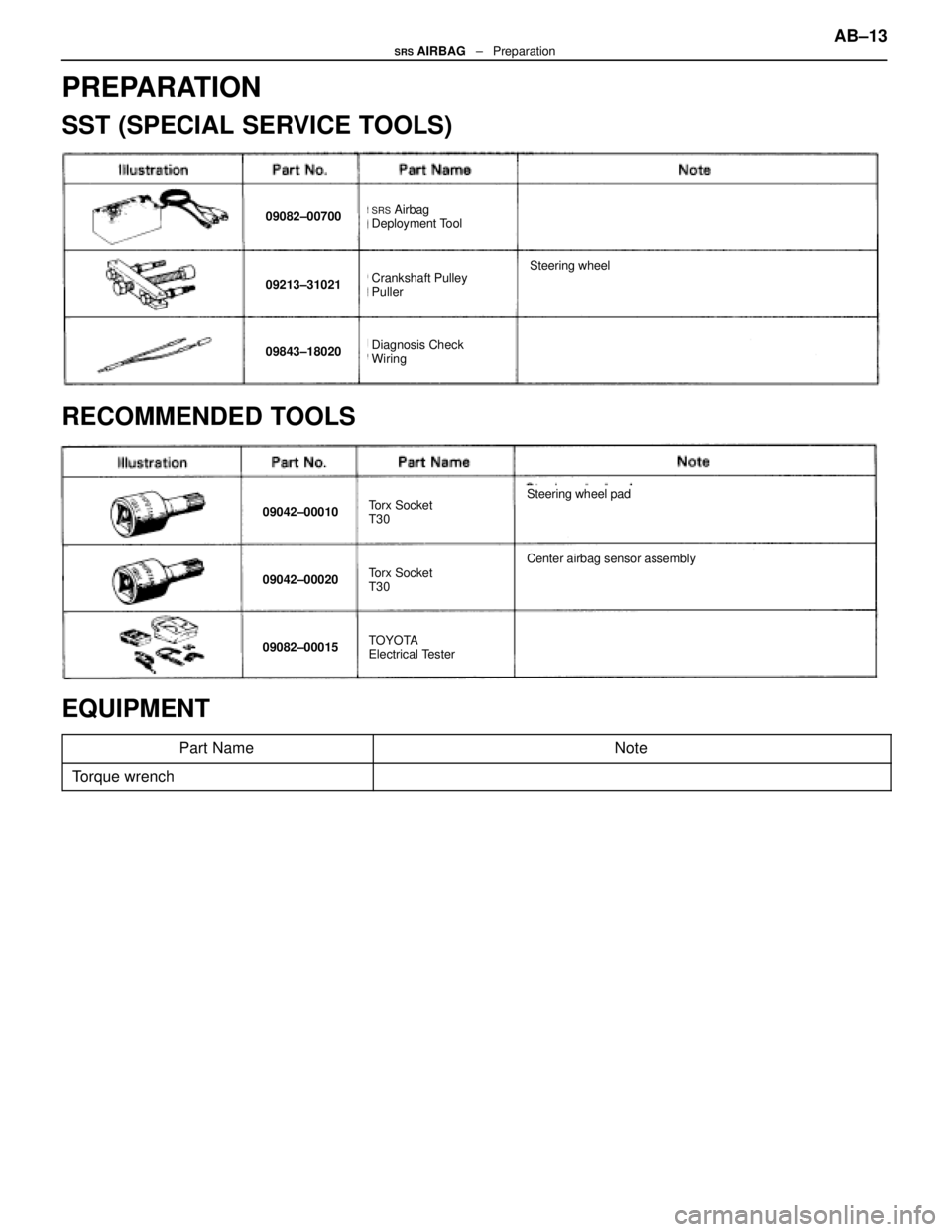

PREPARATION

SST (SPECIAL SERVICE TOOLS)

09082±00700SRS Airbag

Deployment Tool

09213±31021Crankshaft Pulley

Puller

09843±18020Diagnosis Check

Wiring

Steering wheel

RECOMMENDED TOOLS

09042±00010Torx Socket

T30

09042±00020Torx Socket

T30

09082±00015TOYOTA

Electrical Tester

Center airbag sensor assembly

Steering wheel pad

EQUIPMENT

Part NameNote

Torque wrench

AB±13SRS AIRBAG ± Preparation

WhereEverybodyKnowsYourName

Page 228 of 4087

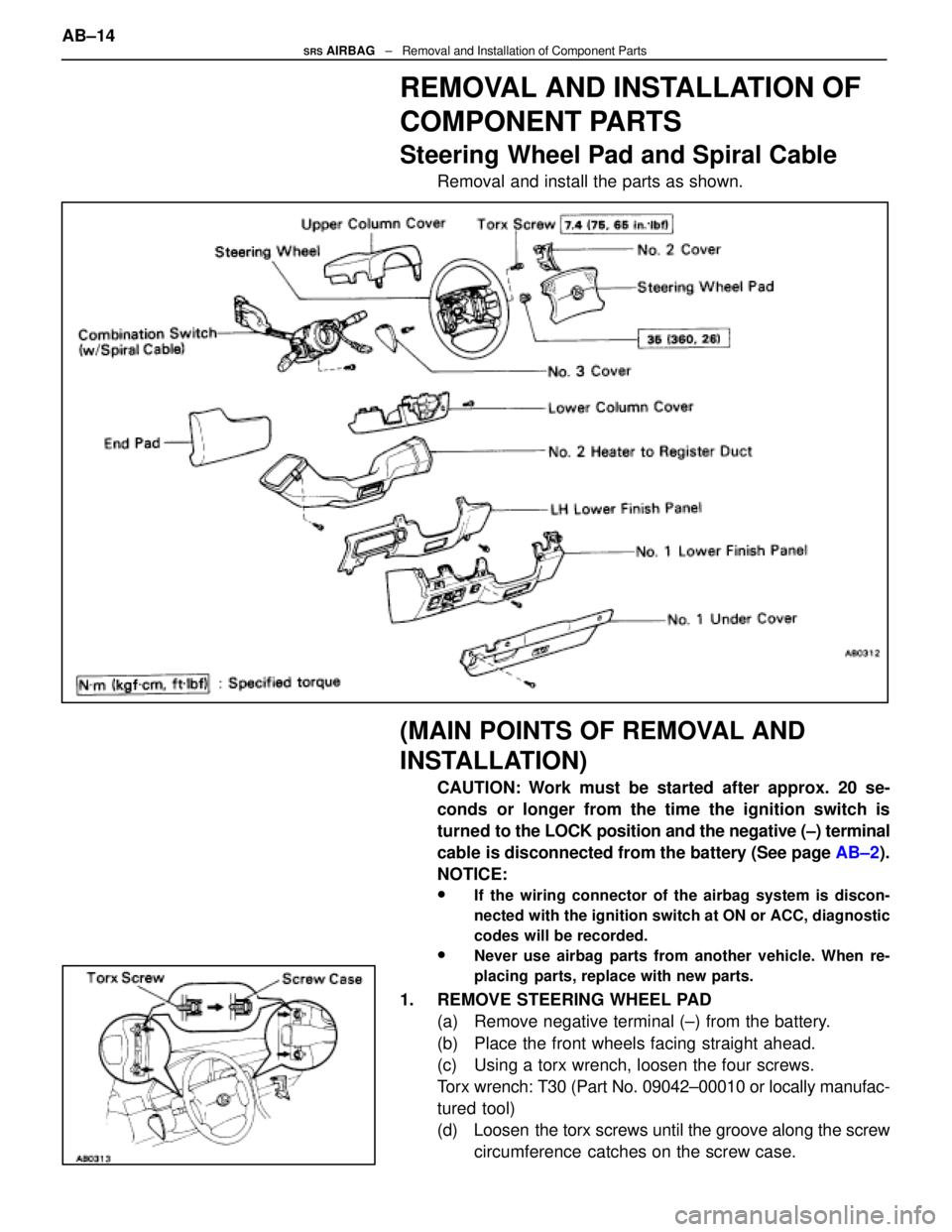

REMOVAL AND INSTALLATION OF

COMPONENT PARTS

Steering Wheel Pad and Spiral Cable

Removal and install the parts as shown.

(MAIN POINTS OF REMOVAL AND

INSTALLATION)

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the LOCK position and the negative (±) terminal

cable is disconnected from the battery (See page AB±2).

NOTICE:

wIf the wiring connector of the airbag system is discon-

nected with the ignition switch at ON or ACC, diagnostic

codes will be recorded.

wNever use airbag parts from another vehicle. When re-

placing parts, replace with new parts.

1. REMOVE STEERING WHEEL PAD (a) Remove negative terminal (±) from the battery.

(b) Place the front wheels facing straight ahead.

(c) Using a torx wrench, loosen the four screws.

Torx wrench: T30 (Part No. 09042±00010 or locally manufac-

tured tool)

(d) Loosen the torx screws until the groove along the screwcircumference catches on the screw case.

AB±14

SRS AIRBAG

± Removal and Installation of Component Parts

WhereEverybodyKnowsYourName

Page 229 of 4087

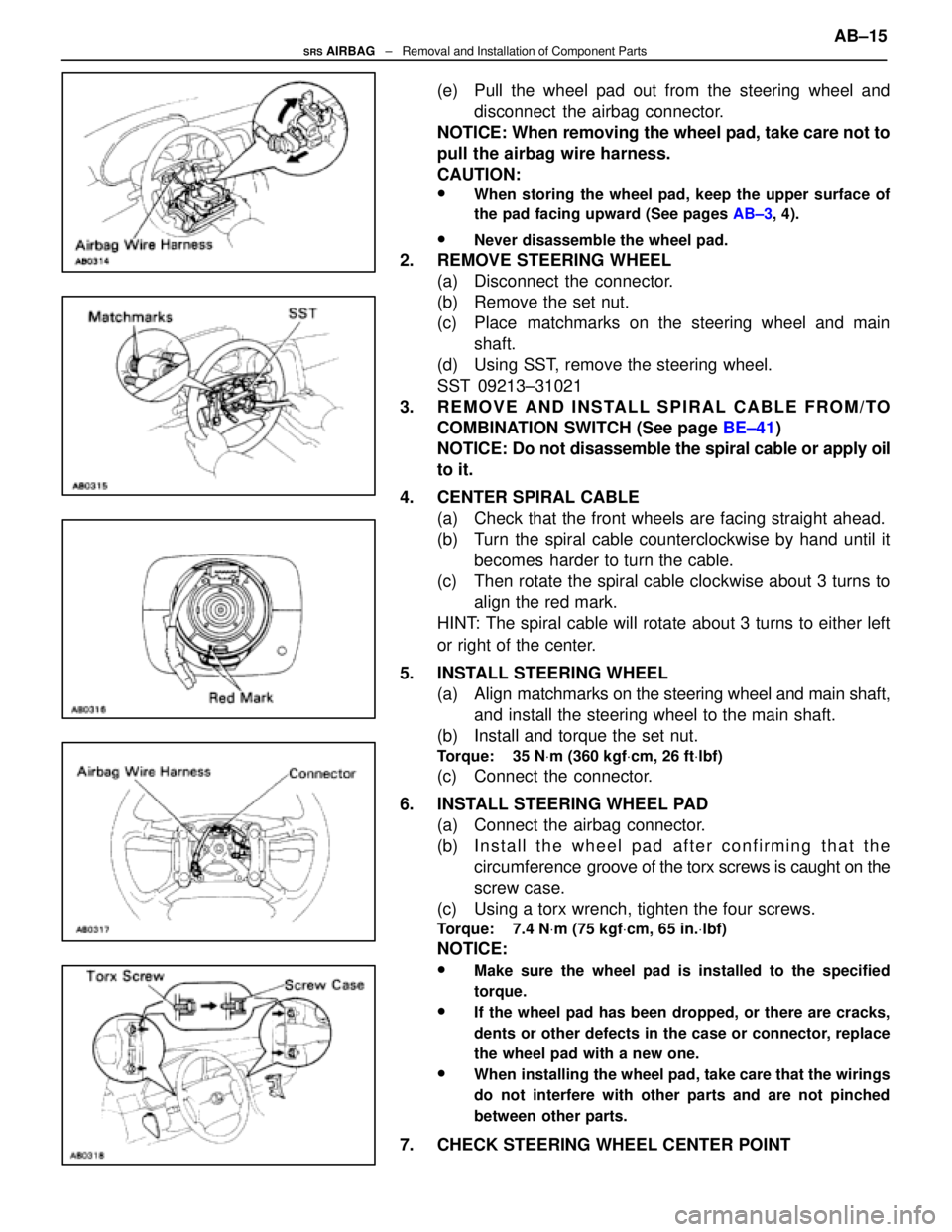

(e) Pull the wheel pad out from the steering wheel anddisconnect the airbag connector.

NOTICE: When removing the wheel pad, take care not to

pull the airbag wire harness.

CAUTION:

wWhen storing the wheel pad, keep the upper surface of

the pad facing upward (See pages AB±3, 4).

wNever disassemble the wheel pad.

2. REMOVE STEERING WHEEL

(a) Disconnect the connector.

(b) Remove the set nut.

(c) Place matchmarks on the steering wheel and mainshaft.

(d) Using SST, remove the steering wheel.

SST 09213±31021

3. REMOVE AND INSTALL SPIRAL CABLE FROM/TO COMBINATION SWITCH (See page BE±41)

NOTICE: Do not disassemble the spiral cable or apply oil

to it.

4. CENTER SPIRAL CABLE (a) Check that the front wheels are facing straight ahead.

(b) Turn the spiral cable counterclockwise by hand until it

becomes harder to turn the cable.

(c) Then rotate the spiral cable clockwise about 3 turns to align the red mark.

HINT: The spiral cable will rotate about 3 turns to either left

or right of the center.

5. INSTALL STEERING WHEEL (a) Align matchmarks on the steering wheel and main shaft,

and install the steering wheel to the main shaft.

(b) Install and torque the set nut.

Torque: 35 N Vm (360 kgf Vcm, 26 ft Vlbf)

(c) Connect the connector.

6. INSTALL STEERING WHEEL PAD (a) Connect the airbag connector.

(b) I n s t a l l t h e w heel pad after confirming that the

circumference groove of the torx screws is caught on the

screw case.

(c) Using a torx wrench, tighten the four screws.

Torque: 7.4 N Vm (75 kgf Vcm, 65 in. Vlbf)

NOTICE:

wMake sure the wheel pad is installed to the specified

torque.

wIf the wheel pad has been dropped, or there are cracks,

dents or other defects in the case or connector, replace

the wheel pad with a new one.

wWhen installing the wheel pad, take care that the wirings

do not interfere with other parts and are not pinched

between other parts.

7. CHECK STEERING WHEEL CENTER POINT AB±15

SRS AIRBAG

± Removal and Installation of Component Parts

WhereEverybodyKnowsYourName

Page 230 of 4087

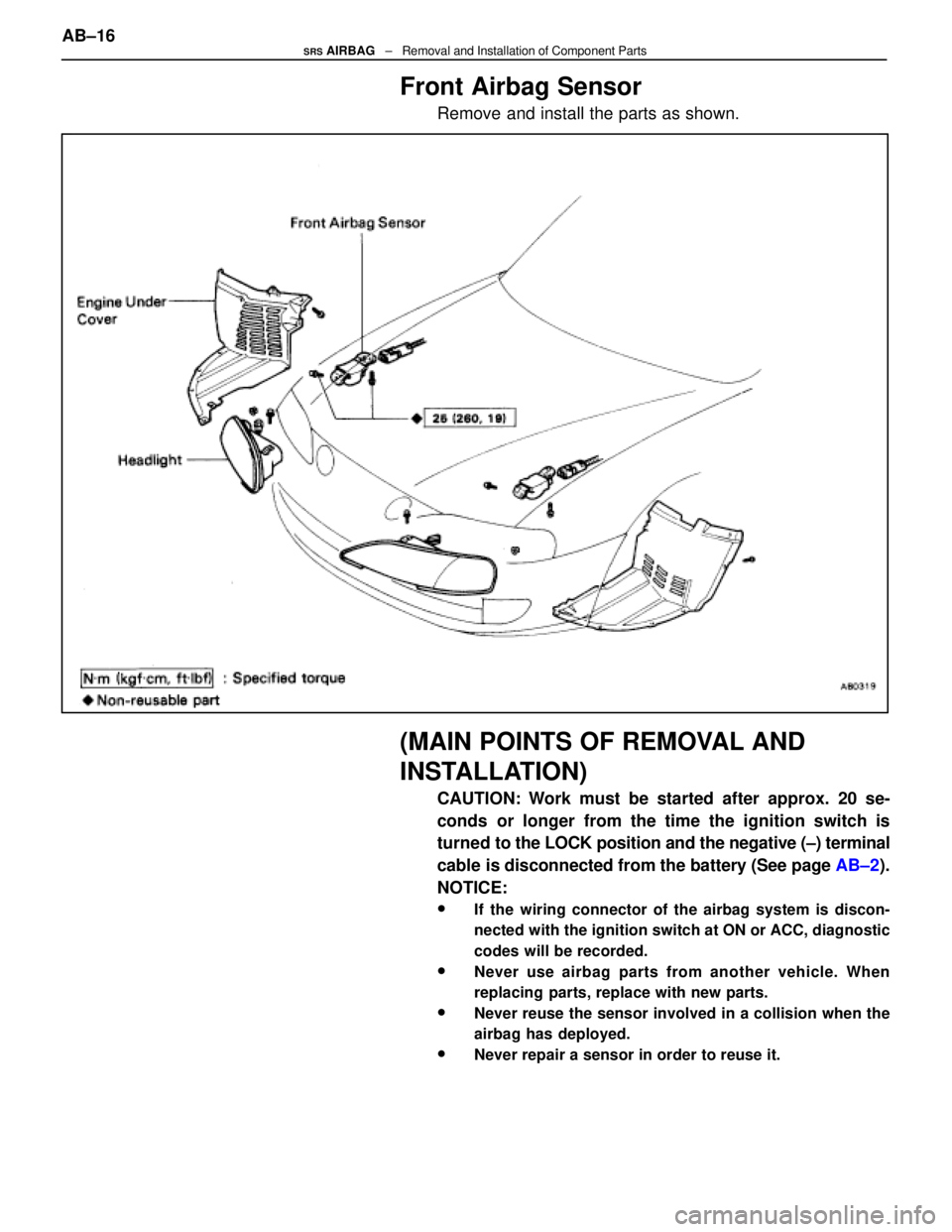

Front Airbag Sensor

Remove and install the parts as shown.

(MAIN POINTS OF REMOVAL AND

INSTALLATION)

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the LOCK position and the negative (±) terminal

cable is disconnected from the battery (See page AB±2).

NOTICE:

wIf the wiring connector of the airbag system is discon-

nected with the ignition switch at ON or ACC, diagnostic

codes will be recorded.

wNever use airbag parts from another vehicle. When

replacing parts, replace with new parts.

wNever reuse the sensor involved in a collision when the

airbag has deployed.

wNever repair a sensor in order to reuse it.

AB±16SRS AIRBAG ± Removal and Installation of Component Parts

WhereEverybodyKnowsYourName