LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: battery replacement, vacuum, traction control, fuses, water pump, display, four wheel drive

Page 3411 of 4087

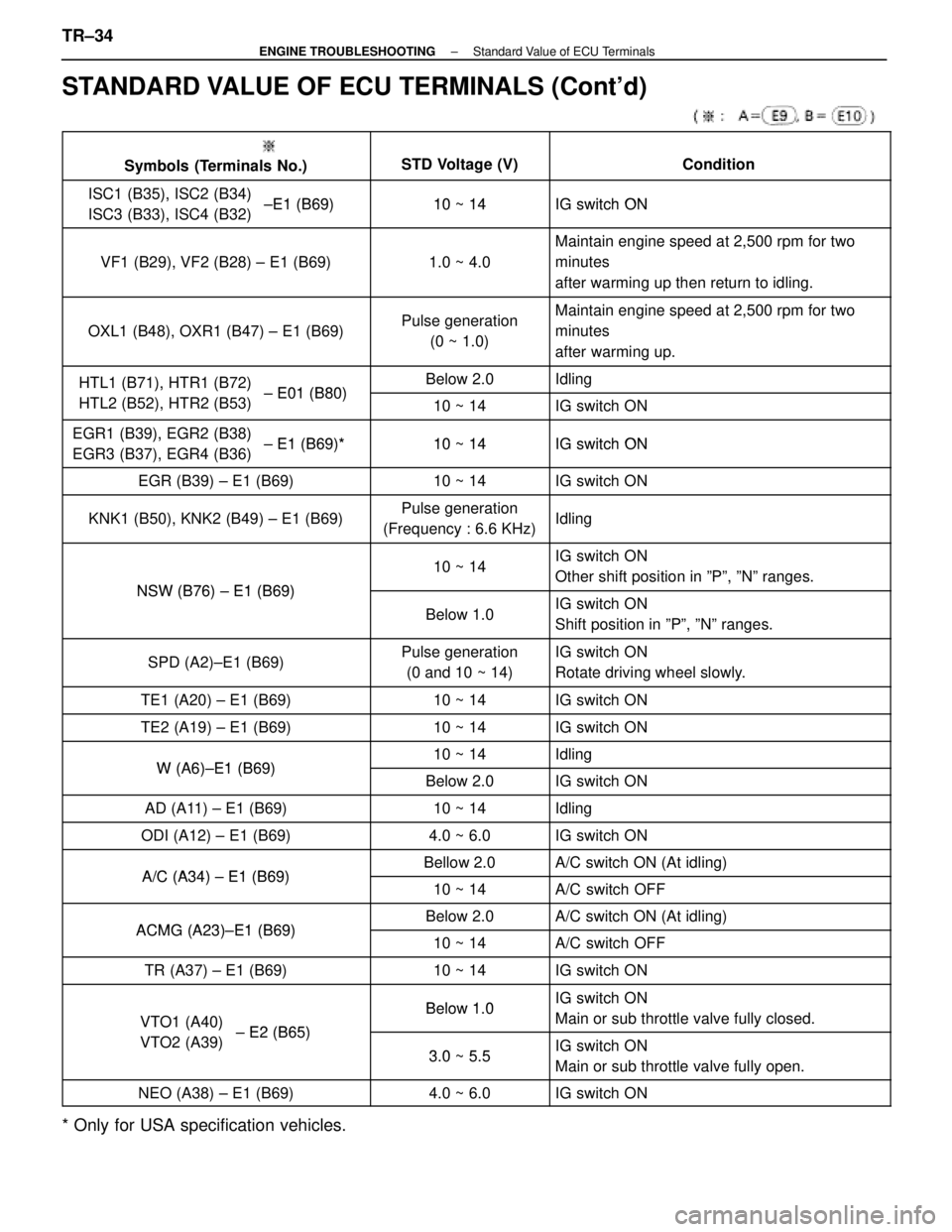

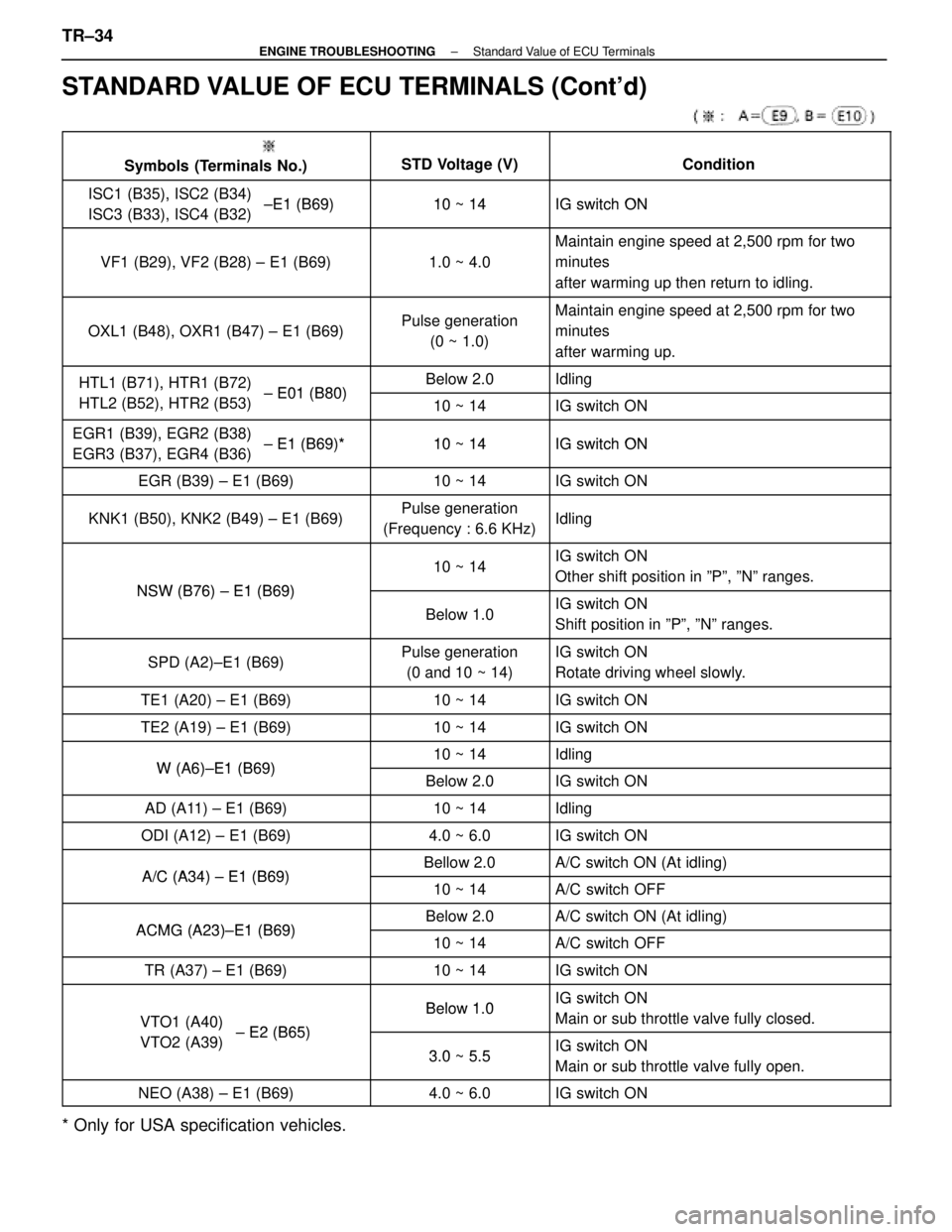

STANDARD VALUE OF ECU TERMINALS (Cont'd)

Symbols (Terminals No.)STD Voltage (V)Condition

ISC1 (B35), ISC2 (B34)E1 (B69)10 14IG switch ONISC1 (B35), ISC2 (B34)

ISC3 (B33), ISC4 (B32)±E1 (B69)10 ~ 14IG switch ON

VF1 (B29), VF2 (B28) ± E1 (B69)1.0 ~ 4.0

Maintain engine speed at 2,500 rpm for two

minutes

after warming up then return to idling.

OXL1 (B48), OXR1 (B47) ± E1 (B69)Pulse generation(0 ~ 1.0)Maintain engine speed at 2,500 rpm for two

minutes

after warming up.

HTL1 (B71), HTR1 (B72)E01 (B80)Below 2.0IdlingHTL1 (B71), HTR1 (B72)

HTL2 (B52), HTR2 (B53)± E01 (B80)10 ~ 14IG switch ON

EGR1 (B39), EGR2 (B38)E1 (B69)*10 14IG switch ONEGR1 (B39), EGR2 (B38)

EGR3 (B37), EGR4 (B36)± E1 (B69)* 10 ~ 14IG switch ON

EGR (B39) ± E1 (B69)10 ~ 14IG switch ON

KNK1 (B50), KNK2 (B49) ± E1 (B69)Pulse generation

(Frequency : 6.6 KHz)Idling

NSW (B76) E1 (B69)

10 ~ 14IG switch ON

Other shift position in ºPº, ºNº ranges.

NSW (B76) ± E1 (B69)

Below 1.0IG switch ON

Shift position in ºPº, ºNº ranges.

SPD (A2)±E1 (B69)Pulse generation (0 and 10 ~ 14)IG switch ON

Rotate driving wheel slowly.

TE1 (A20) ± E1 (B69)10 ~ 14IG switch ON

TE2 (A19) ± E1 (B69)10 ~ 14IG switch ON

W (A6) E1 (B69)10 ~ 14IdlingW (A6)±E1 (B69)Below 2.0IG switch ON

AD (A11) ± E1 (B69)10 ~ 14Idling

ODI (A12) ± E1 (B69)4.0 ~ 6.0IG switch ON

A/C (A34) E1 (B69)Bellow 2.0A/C switch ON (At idling)A/C (A34) ± E1 (B69)10 ~ 14A/C switch OFF

ACMG (A23) E1 (B69)Below 2.0A/C switch ON (At idling)ACMG (A23)±E1 (B69)10 ~ 14A/C switch OFF

TR (A37) ± E1 (B69)10 ~ 14IG switch ON

Below 1 0IG switch ON

VTO1 (A40)E2 (B65)

Below 1.0IG switch ON

Main or sub throttle valve fully closed.VTO1 (A40)

VTO2 (A39)± E2 (B65)

30 55IG switch ON()3.0 ~ 5.5IG switch ON

Main or sub throttle valve fully open.

NEO (A38) ± E1 (B69)4.0 ~ 6.0IG switch ON

* Only for USA specification vehicles. TR±34

±

ENGINE TROUBLESHOOTING Standard Value of ECU Terminals

WhereEverybodyKnowsYourName

Page 3412 of 4087

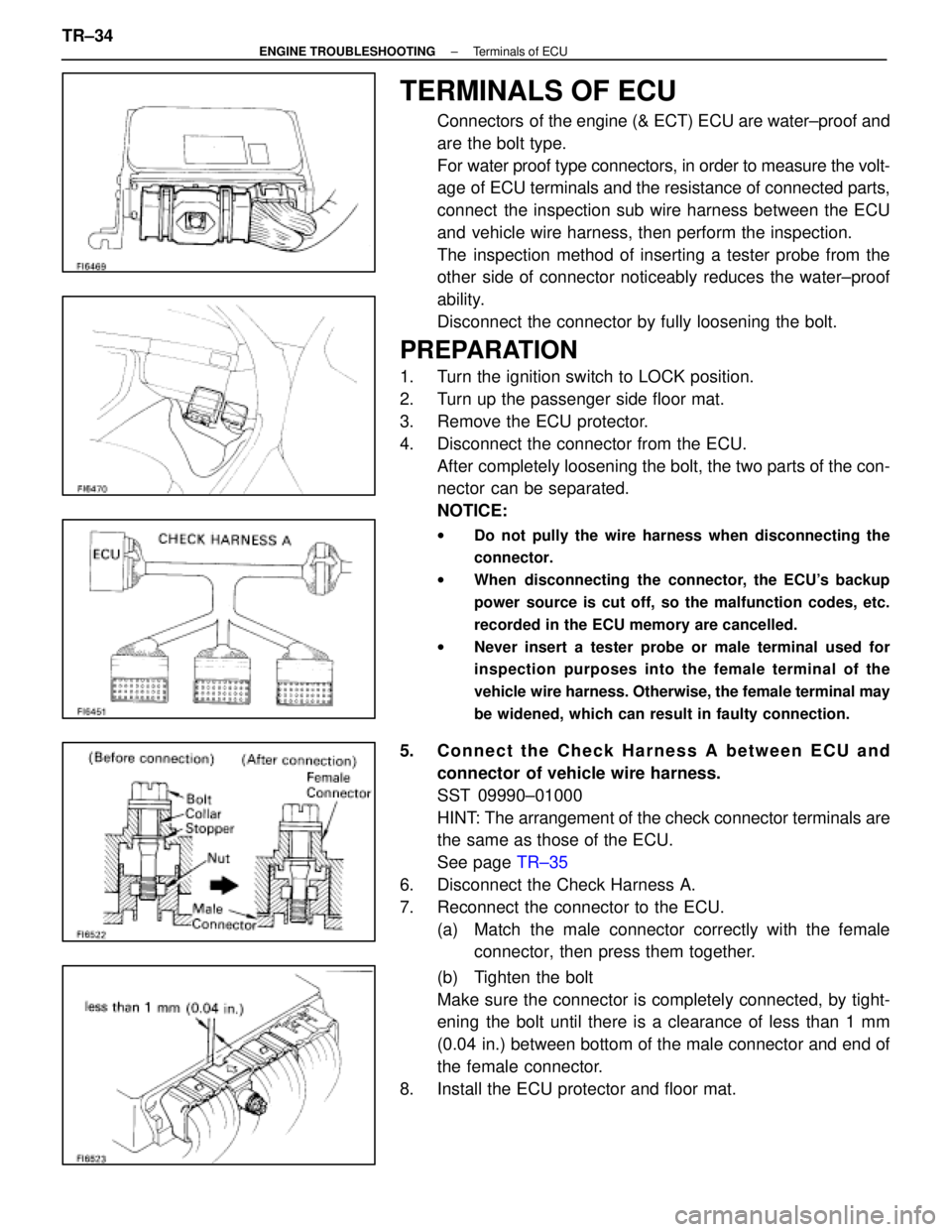

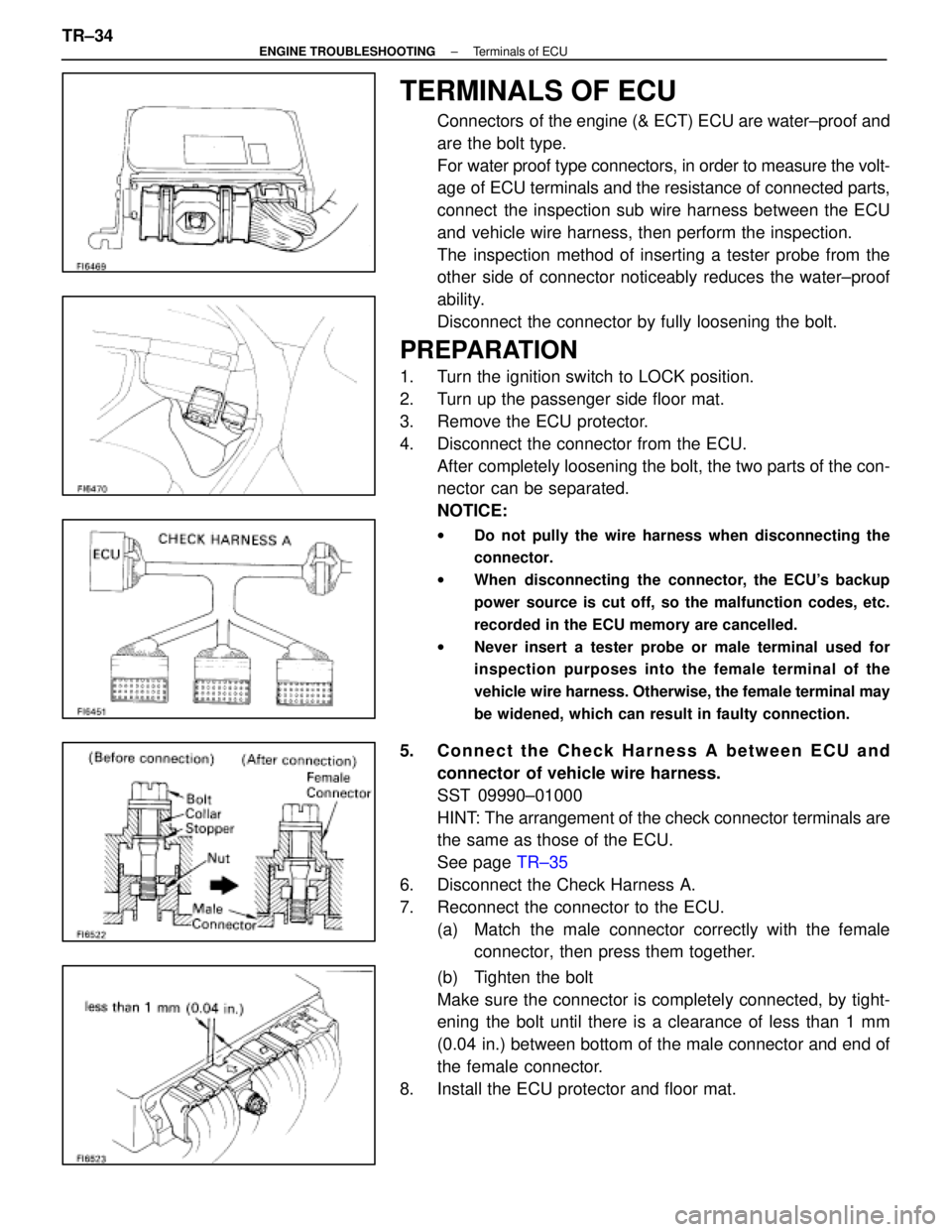

TERMINALS OF ECU

Connectors of the engine (& ECT) ECU are water±proof and

are the bolt type.

For water proof type connectors, in order to measure the volt-

age of ECU terminals and the resistance of connected parts,

connect the inspection sub wire harness between the ECU

and vehicle wire harness, then perform the inspection.

The inspection method of inserting a tester probe from the

other side of connector noticeably reduces the water±proof

ability.

Disconnect the connector by fully loosening the bolt.

PREPARATION

1. Turn the ignition switch to LOCK position.

2. Turn up the passenger side floor mat.

3. Remove the ECU protector.

4. Disconnect the connector from the ECU.After completely loosening the bolt, the two parts of the con-

nector can be separated.

NOTICE:

w Do not pully the wire harness when disconnecting the

connector.

w When disconnecting the connector, the ECU's backup

power source is cut off, so the malfunction codes, etc.

recorded in the ECU memory are cancelled.

w Never insert a tester probe or male terminal used for

inspection purposes into the female terminal of the

vehicle wire harness. Otherwise, the female terminal may

be widened, which can result in faulty connection.

5. Connect the Check Harness A between ECU and

connector of vehicle wire harness.

SST 09990±01000

HINT: The arrangement of the check connector terminals are

the same as those of the ECU.

See page TR±35

6. Disconnect the Check Harness A.

7. Reconnect the connector to the ECU. (a) Match the male connector correctly with the femaleconnector, then press them together.

(b) Tighten the bolt

Make sure the connector is completely connected, by tight-

ening the bolt until there is a clearance of less than 1 mm

(0.04 in.) between bottom of the male connector and end of

the female connector.

8. Install the ECU protector and floor mat.

TR±34

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3413 of 4087

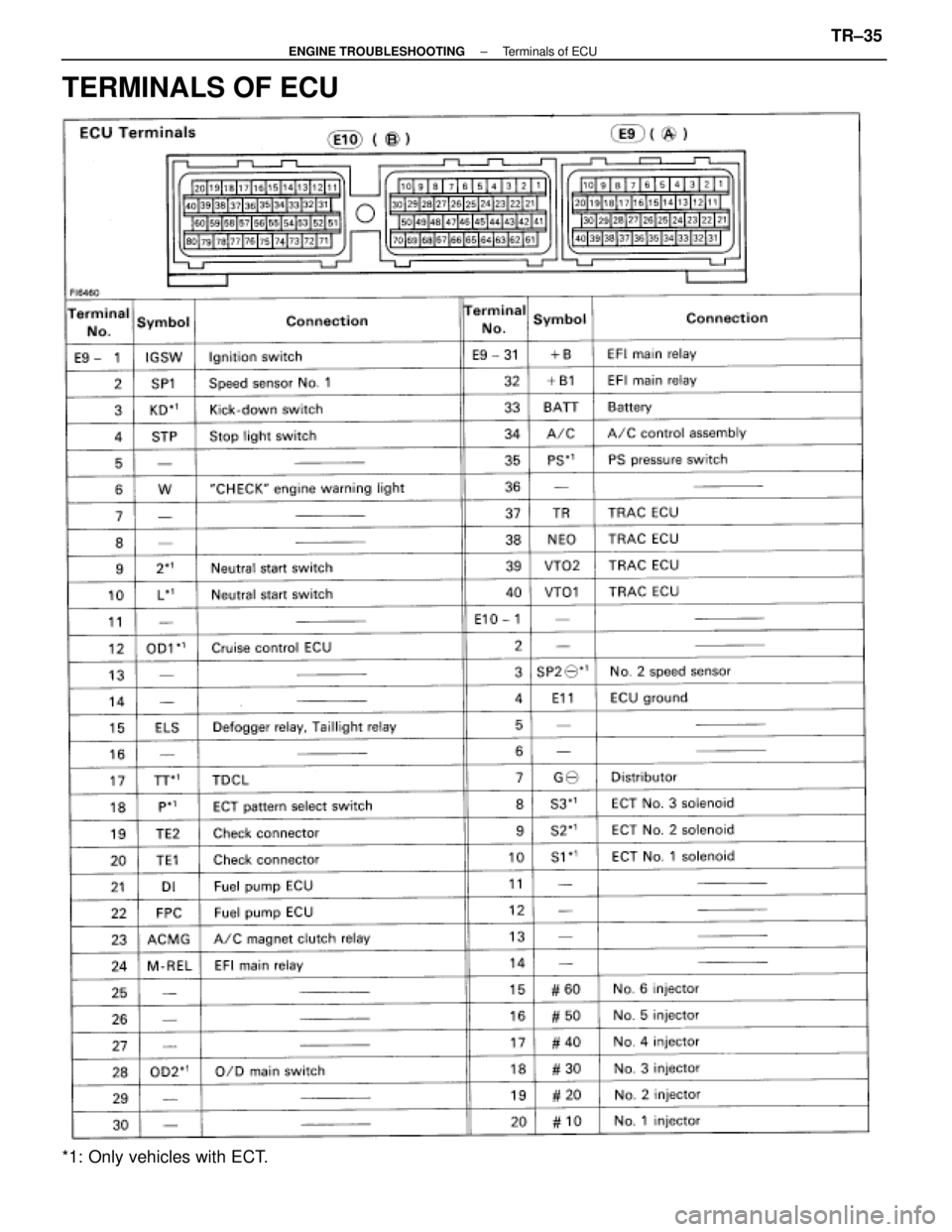

TERMINALS OF ECU

*1: Only vehicles with ECT.

±

ENGINE TROUBLESHOOTING Terminals of ECUTR±35

WhereEverybodyKnowsYourName

Page 3414 of 4087

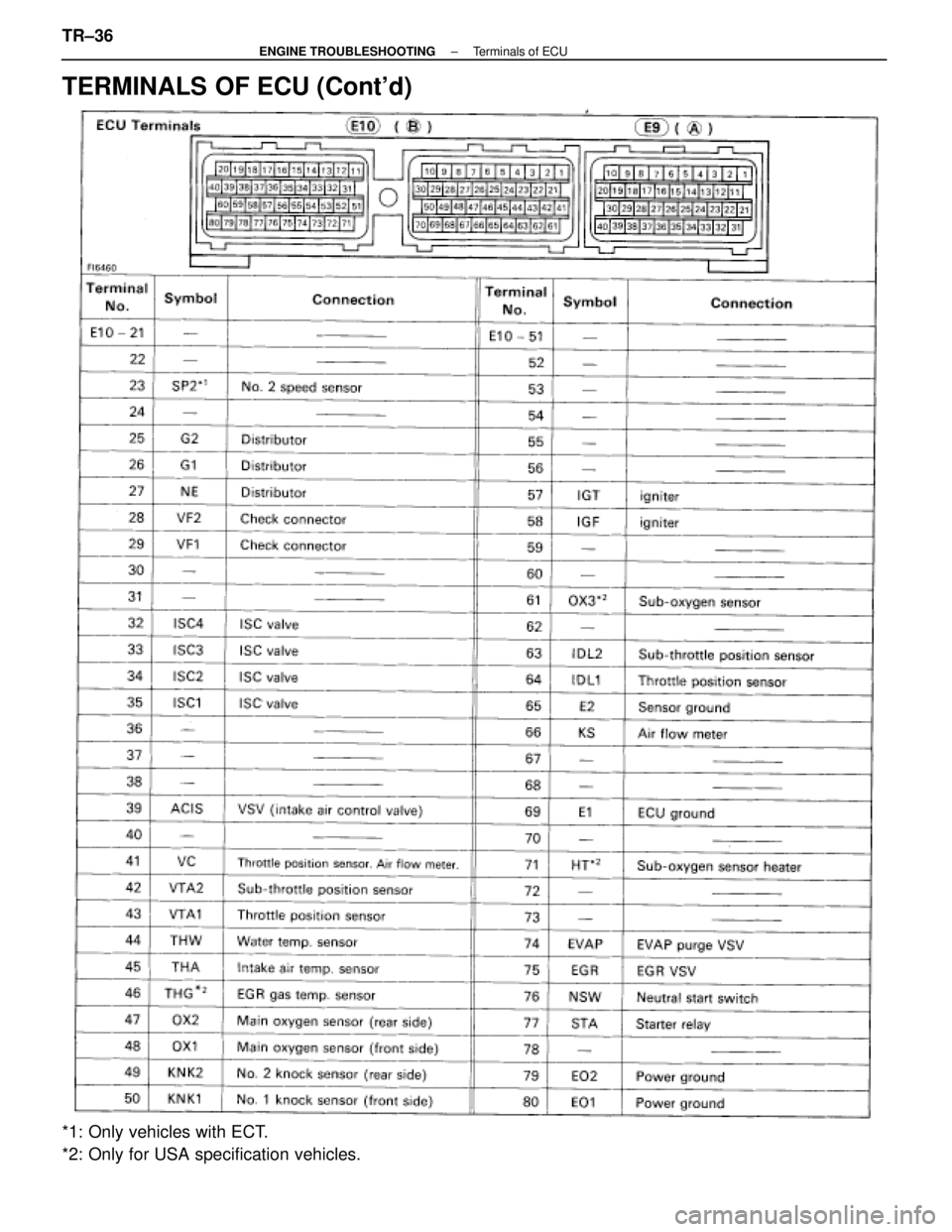

TERMINALS OF ECU (Cont'd)

*1: Only vehicles with ECT.

*2: Only for USA specification vehicles. TR±36

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3415 of 4087

TR±88

TR±10

0

TR±12

2

TR±13

0

TR±13

6

TR±14

0

TR±11

4

TR±14

2 TR±108

TR±11

8

TR±12

4

TR±13

2

AC±84

ST±24

IG±24 IG±6

EM±30

AT±66

IN±32BE±381IG±7

IG±9

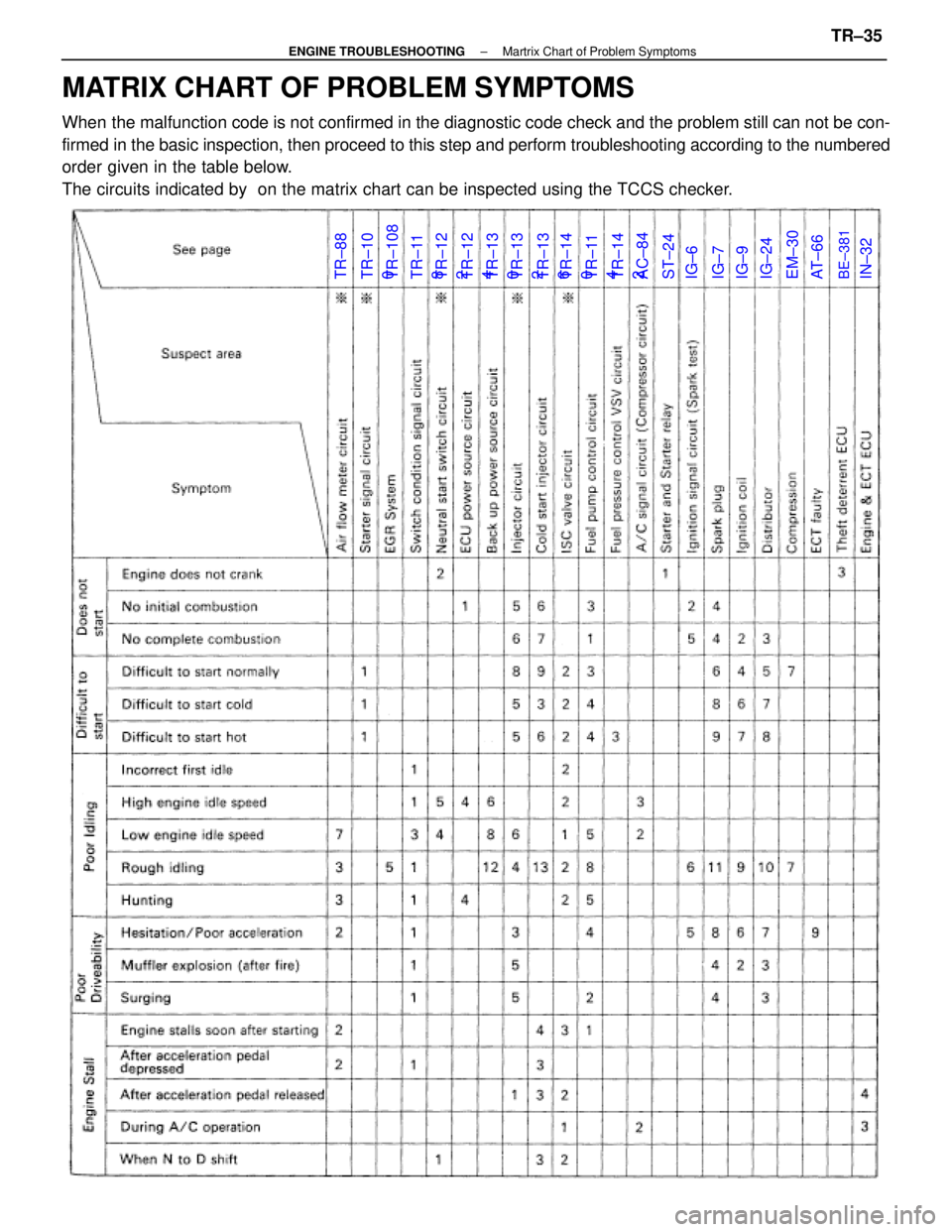

MATRIX CHART OF PROBLEM SYMPTOMS

When the malfunction code is not confirmed in the diagnostic code check and \

the problem still can not be con-

firmed in the basic inspection, then proceed to this step and perform troubles\

hooting according to the numbered

order given in the table below.

The circuits indicated by on the matrix chart can be inspected using th\

e TCCS checker.

±

ENGINE TROUBLESHOOTING Martrix Chart of Problem SymptomsTR±35

WhereEverybodyKnowsYourName

Page 3416 of 4087

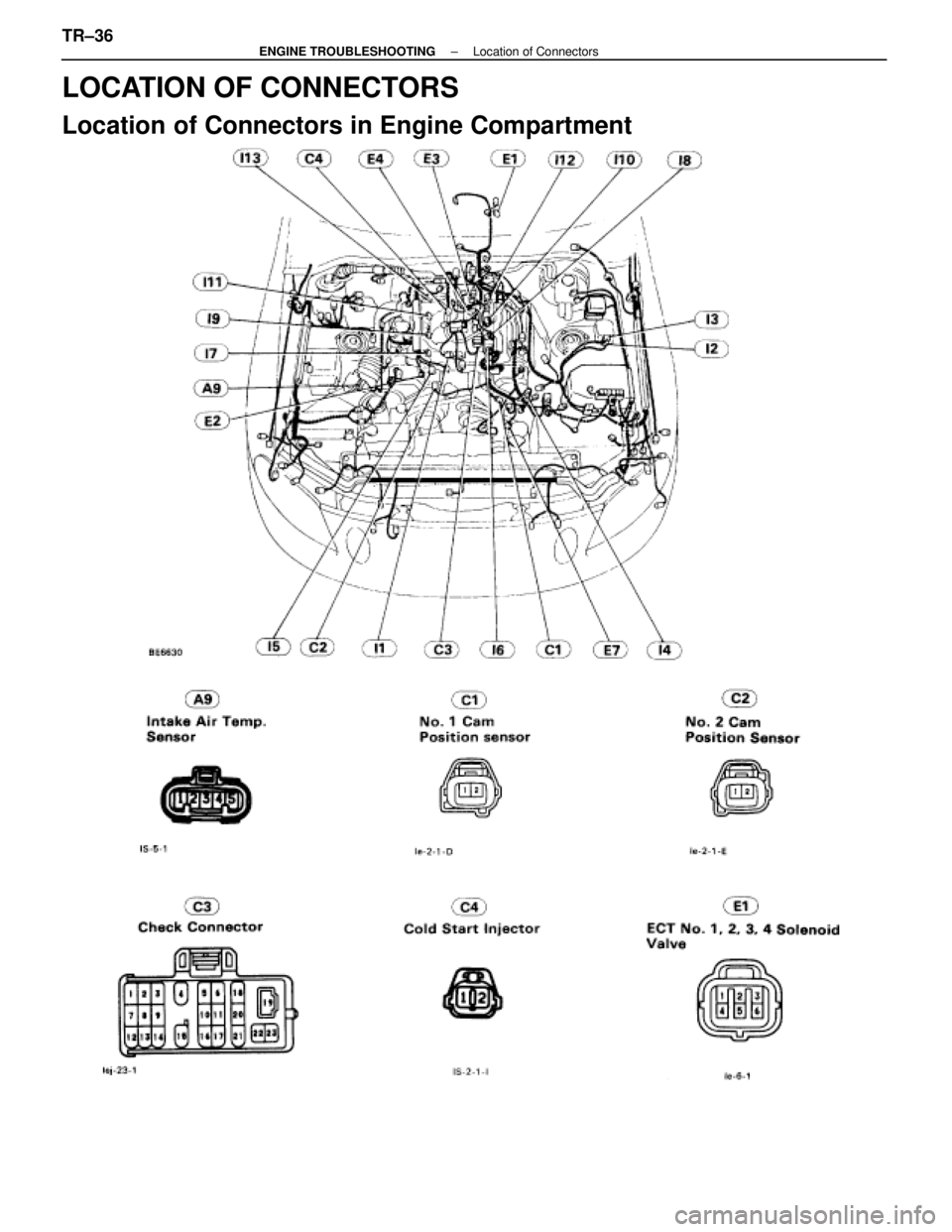

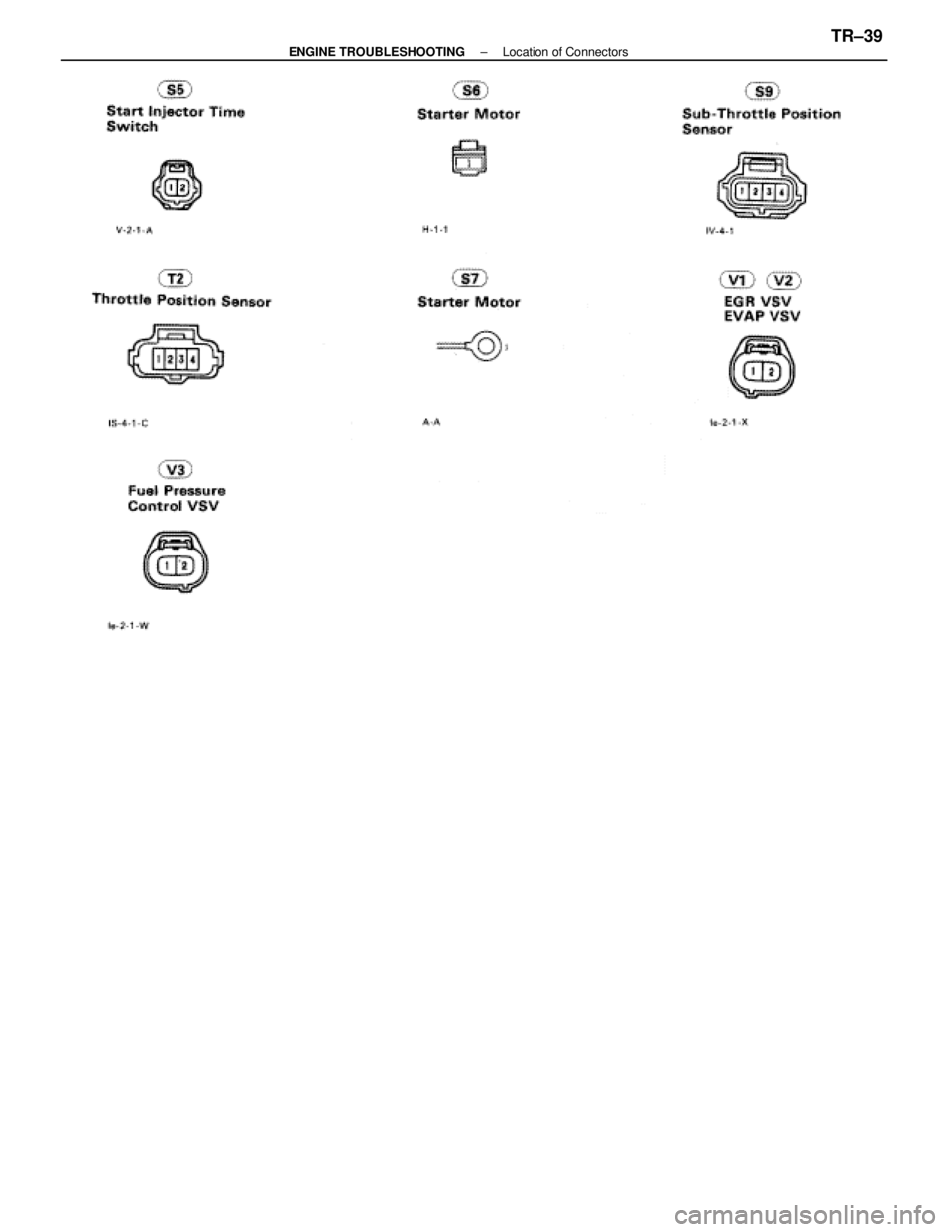

LOCATION OF CONNECTORS

Location of Connectors in Engine Compartment

TR±36±

ENGINE TROUBLESHOOTING Location of Connectors

WhereEverybodyKnowsYourName

Page 3417 of 4087

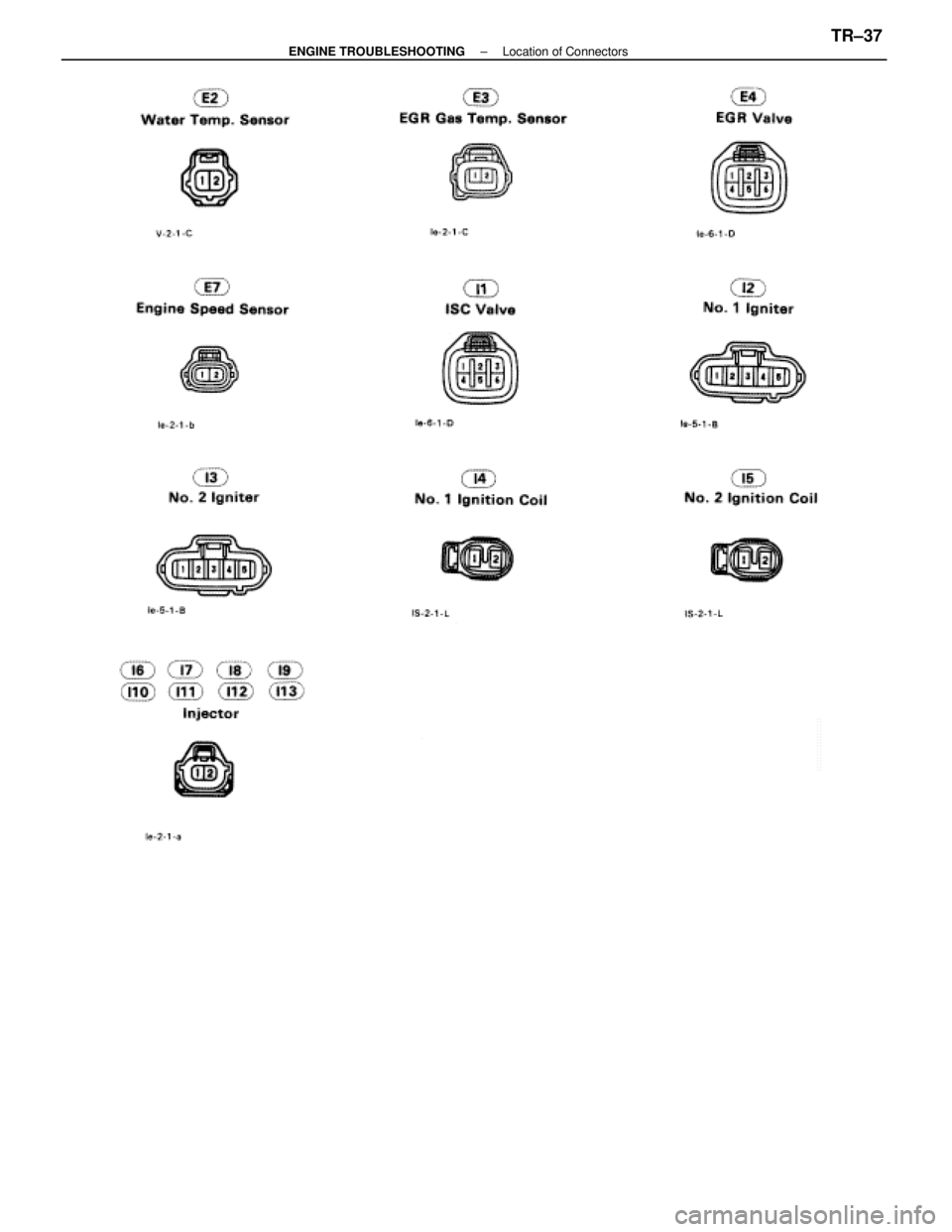

±

ENGINE TROUBLESHOOTING Location of ConnectorsTR±37

WhereEverybodyKnowsYourName

Page 3418 of 4087

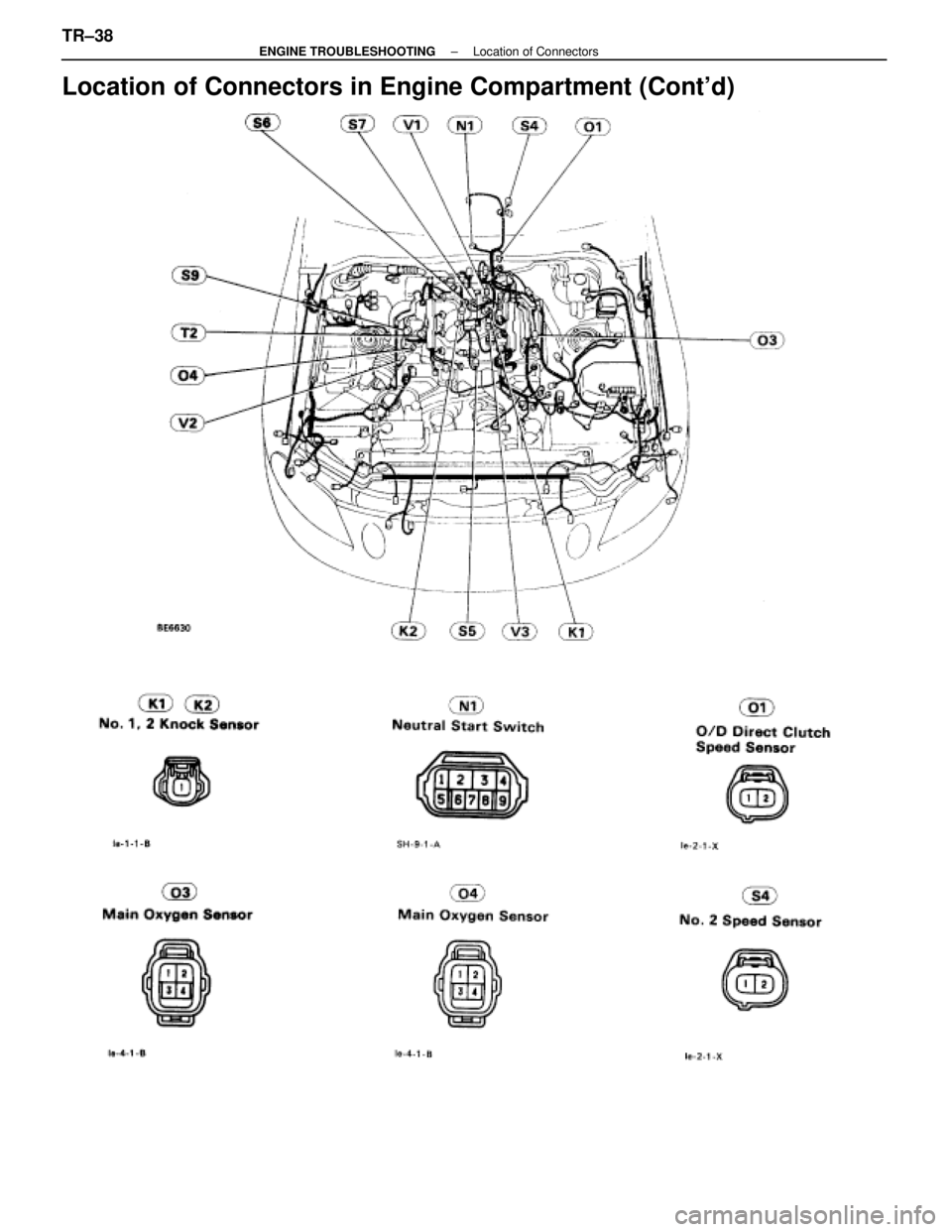

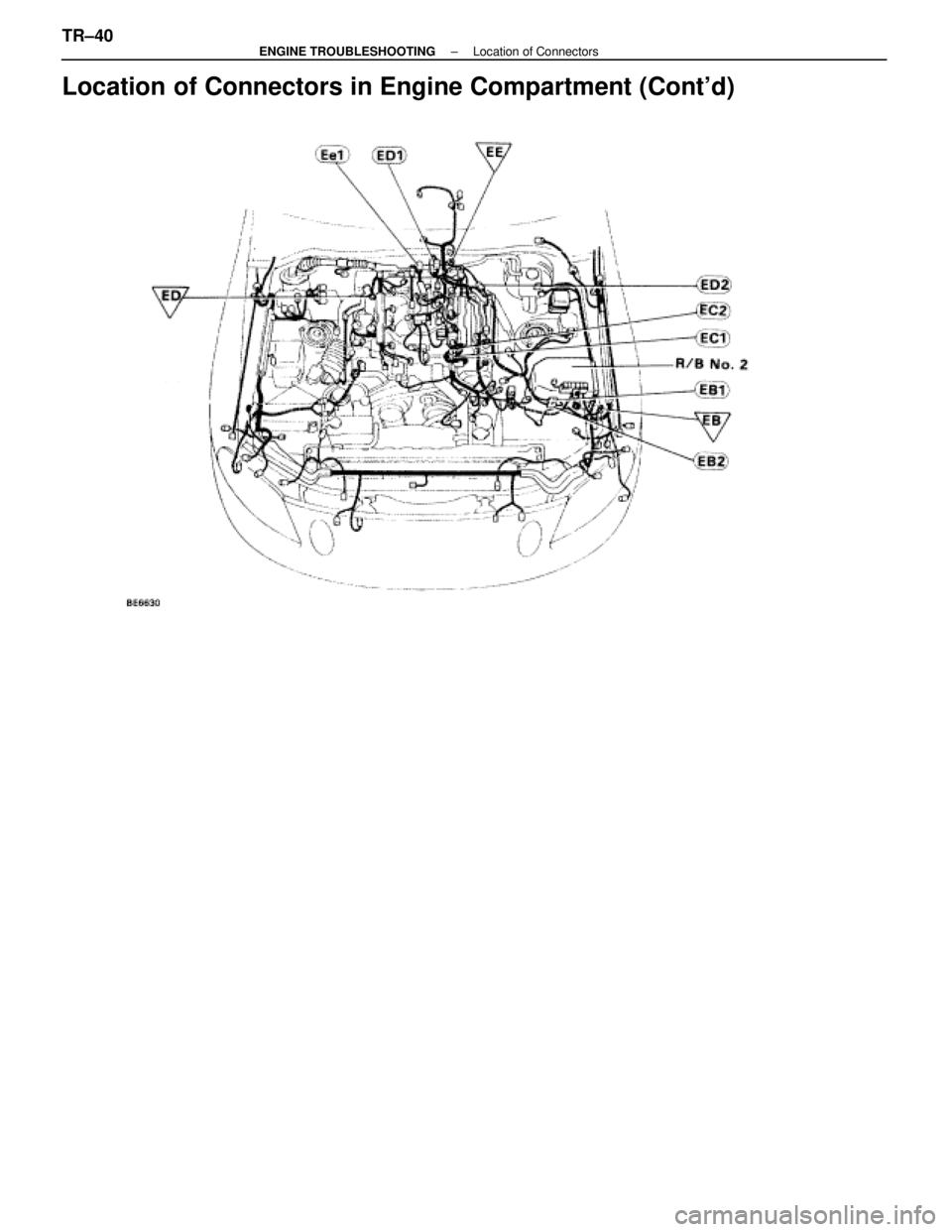

Location of Connectors in Engine Compartment (Cont'd)

TR±38±

ENGINE TROUBLESHOOTING Location of Connectors

WhereEverybodyKnowsYourName

Page 3419 of 4087

±

ENGINE TROUBLESHOOTING Location of ConnectorsTR±39

WhereEverybodyKnowsYourName

Page 3420 of 4087

Location of Connectors in Engine Compartment (Cont'd)

TR±40±

ENGINE TROUBLESHOOTING Location of Connectors

WhereEverybodyKnowsYourName

Trending: remove seats, brake sensor, engine, headlight bulb, bulb, high beam, brake pads