LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: length, brake fluid, tire size, compression ratio, Brake Pedal, boot, bulb

Page 3371 of 4087

±MEMO±

±

ENGINE TROUBLESHOOTING Circuit InspectionTR±145

WhereEverybodyKnowsYourName

Page 3372 of 4087

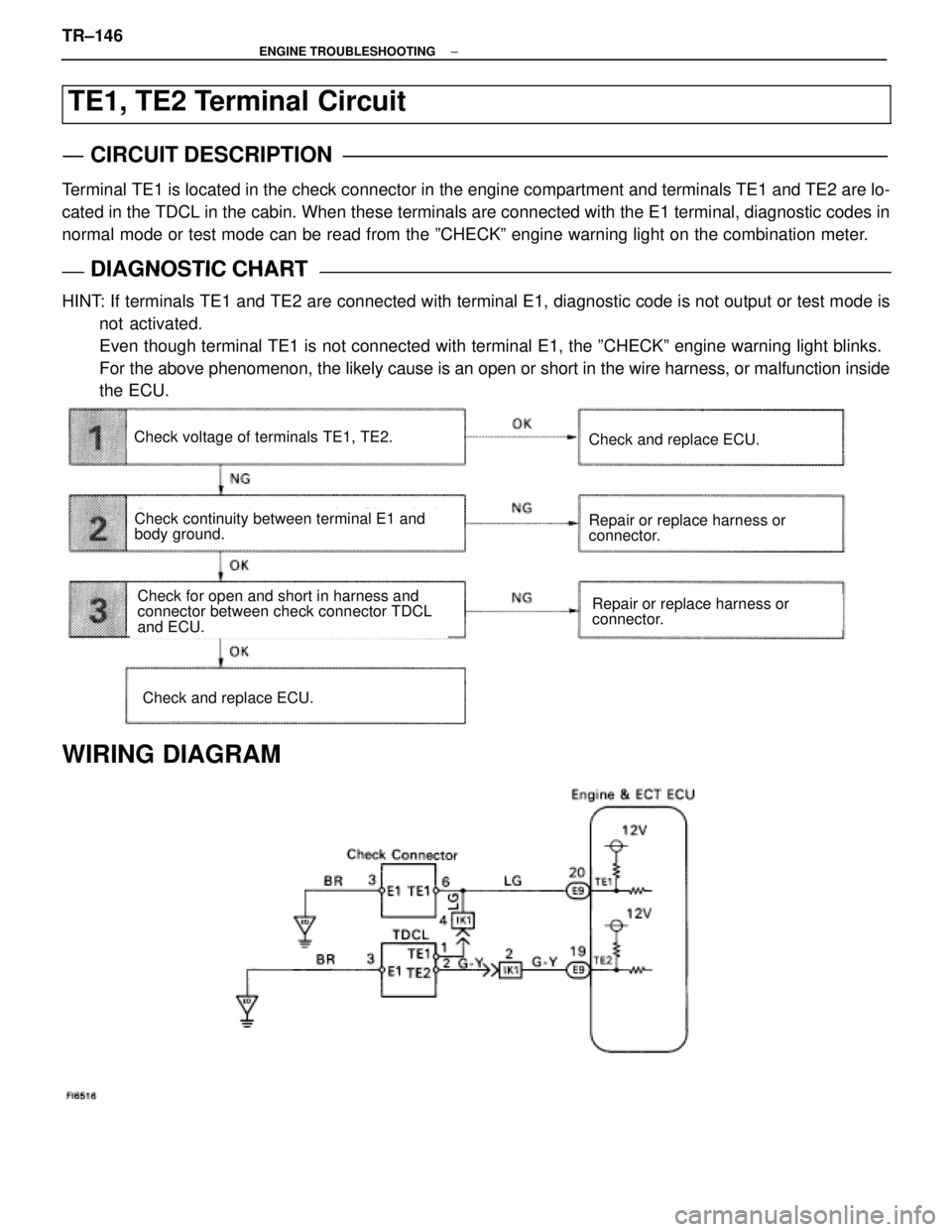

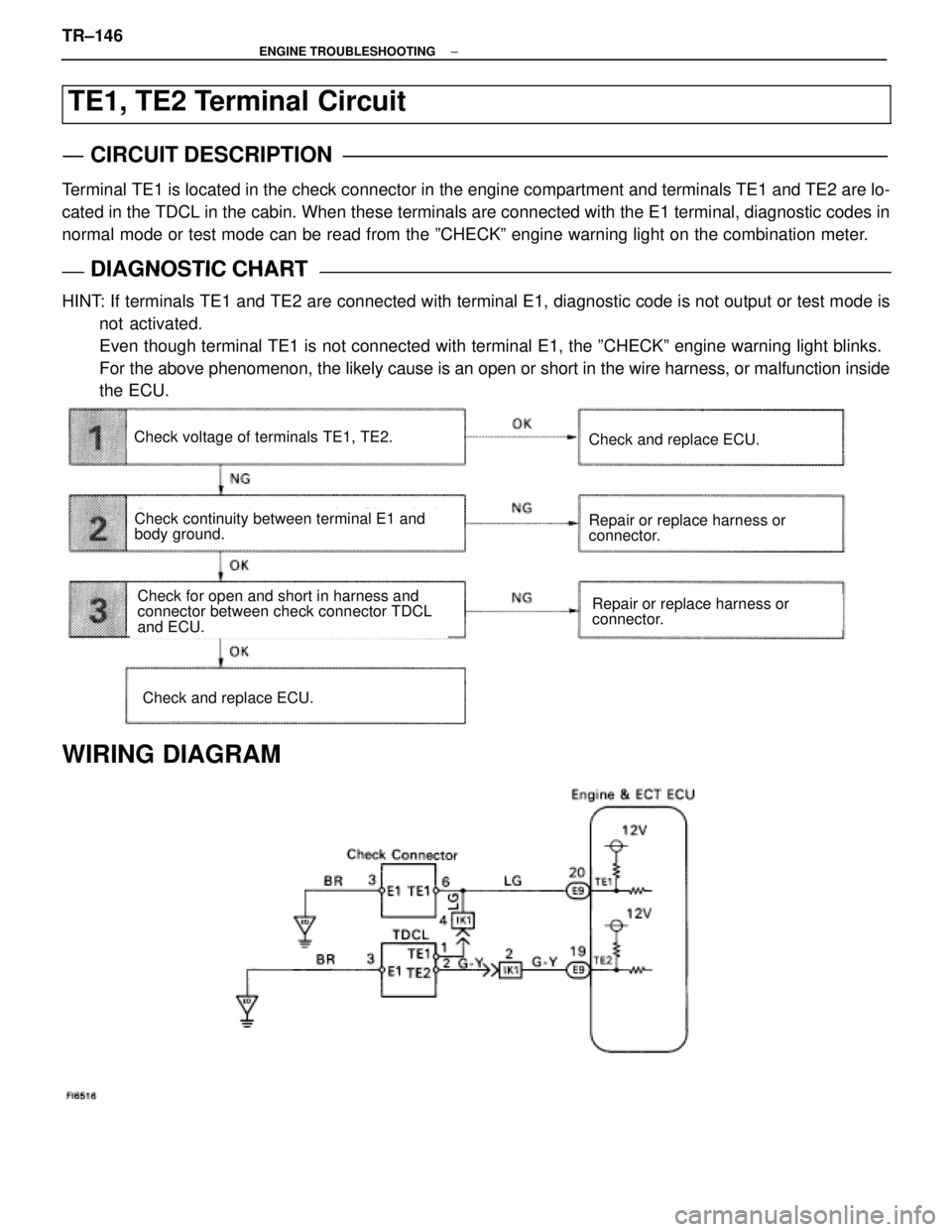

TE1, TE2 Terminal Circuit

CIRCUIT DESCRIPTION

Terminal TE1 is located in the check connector in the engine compartment and terminals T\

E1 and TE2 are lo-

cated in the TDCL in the cabin. When these terminals are connected with \

the E1 terminal, diagnostic codes in

normal mode or test mode can be read from the ºCHECKº engine warning lig\

ht on the combination meter.

DIAGNOSTIC CHARTDIAGNOSTIC CHART

HINT: If terminals TE1 and TE2 are connected with terminal E1, diagnostic code is not output or test mode isnot activated.

Even though terminal TE1 is not connected with terminal E1, the ºCHEC\

Kº engine warning light blinks.

For the above phenomenon, the likely cause is an open or short in the wire \

harness, or malfunction inside

the ECU.

Check continuity between terminal E1 and

body ground.

Repair or replace harness or

connector.Check for open and short in harness and

connector between check connector TDCL

and ECU.

Check voltage of terminals TE1, TE2.

Check and replace ECU.

Repair or replace harness or

connector.

Check and replace ECU.

WIRING DIAGRAM

TR±146±

ENGINE TROUBLESHOOTING

WhereEverybodyKnowsYourName

Page 3373 of 4087

NGOK

OKNG

OKNG

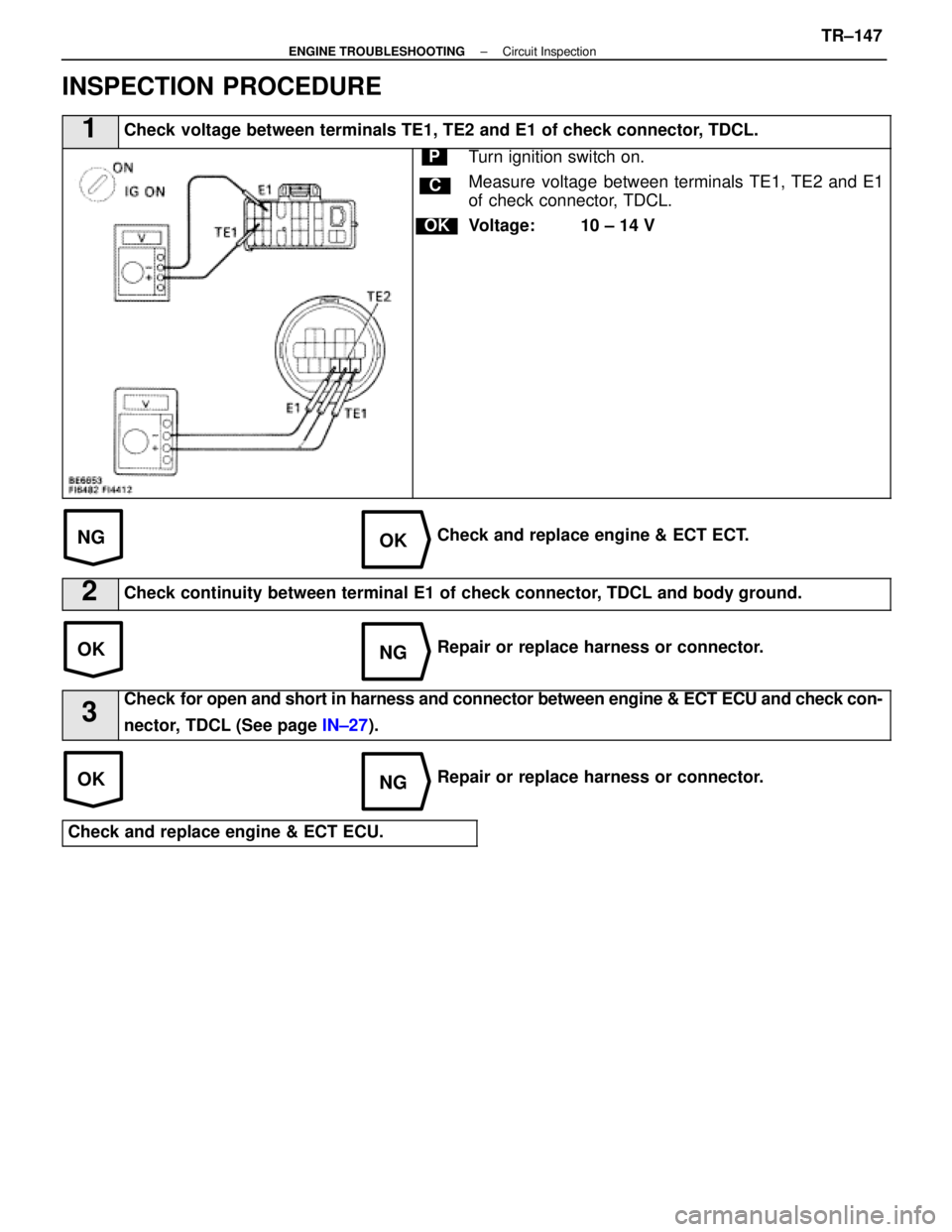

INSPECTION PROCEDURE

1Check voltage between terminals TE1, TE2 and E1 of check connector, TDCL.

C

OK

PTurn ignition switch on.

Measure voltage between terminals TE1, TE2 and E1

of check connector, TDCL.

Voltage: 10 ± 14 V

Check and replace engine & ECT ECT.

2Check continuity between terminal E1 of check connector, TDCL and body ground.

Repair or replace harness or connector.

3

Check for open and short in harness and connector between engine & ECT ECU and che\

ck con-

nector, TDCL (See page IN±27).

Repair or replace harness or connector.

Check and replace engine & ECT ECU.

±

ENGINE TROUBLESHOOTING Circuit InspectionTR±147

WhereEverybodyKnowsYourName

Page 3374 of 4087

ENGINE TROUBLESHOOTING

TR±1

WhereEverybodyKnowsYourName

Page 3375 of 4087

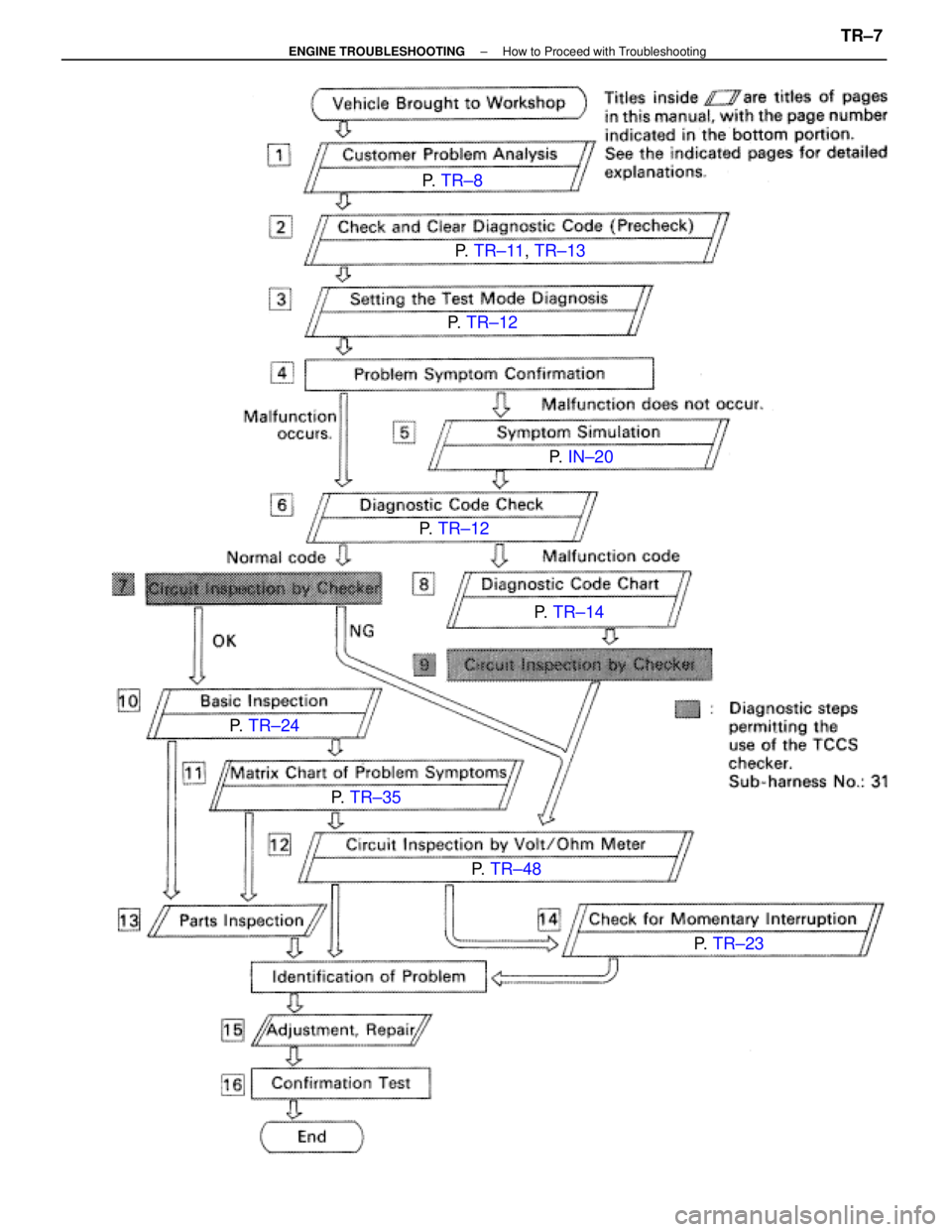

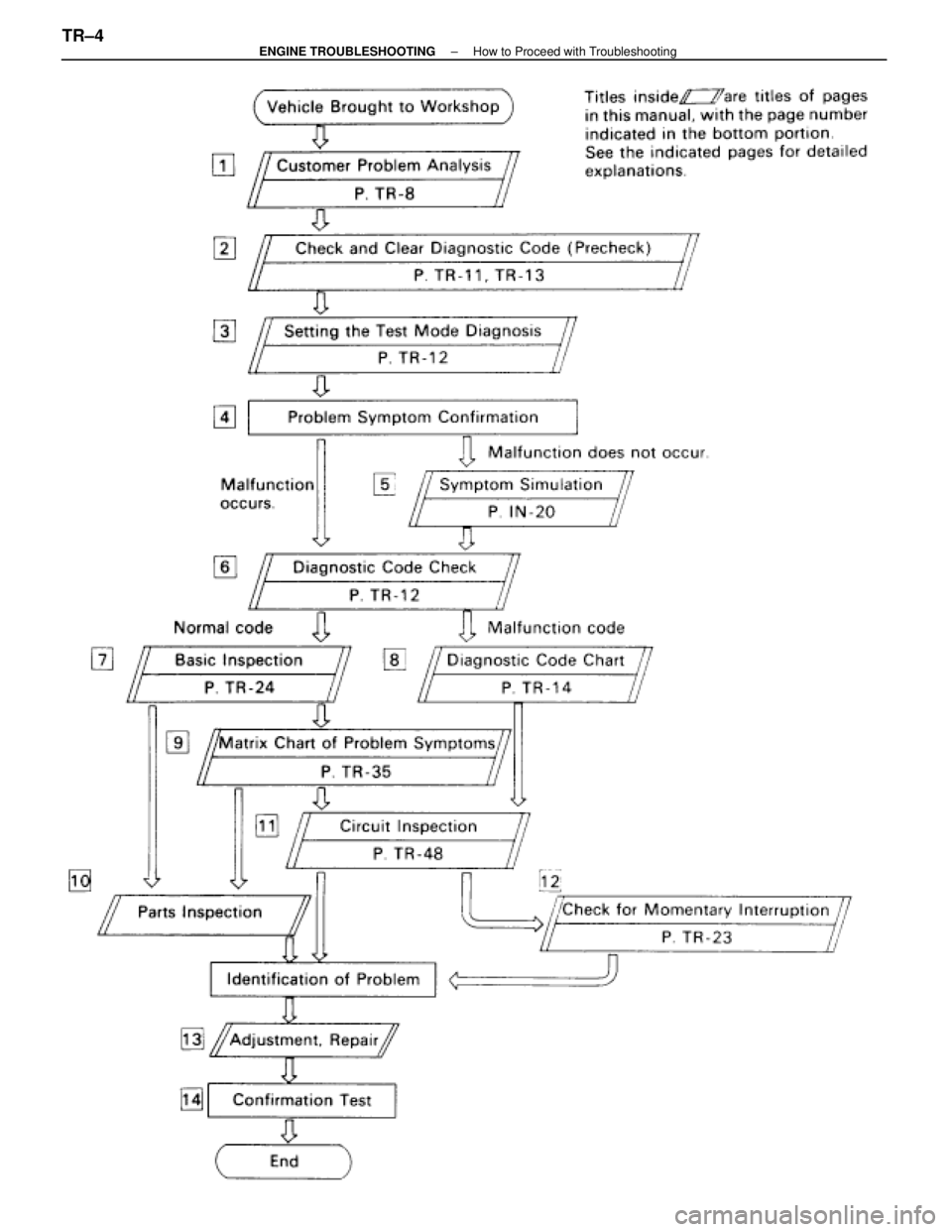

HOW TO PROCEED WITH TROUBLESHOOTING

The Engine Control System broadly consists of the sensors, ECU and actuator\

s. The ECU receives signals from

various sensors, judges the operating conditions and determines the opti\

mum injection duration, timing, ignition

timing and idle speed.

In general, the Engine Control System is considered to be a very intricate\

system to troubleshoot. But, the fact

is that if you proceed to inspect the circuit one by one following the p\

rocedures directed in this manual, trouble-

shooting of this system is not complex.

This section explains the most ideal method of troubleshooting and tells how\

to carry out the necessary repairs.

[1] CUSTOMER PROBLEM ANALYSISUsing the customer problem analysis check sheet for reference, ask the c\

ustomer in as much details as

possible about the problem.

[2] CHECK AND CLEAR DIAGNOSTIC CODE (PRECHECK) Before confirming the problem symptom, first check the diagnostic code and mak\

e a note of any malfunc-

tion code which is output, then clear the code.

HINT: Output of the malfunction code indicates that there is a malfunction in\

the circuit indicated. However,

it does not indicate whether the malfunction is still occurring or occur\

red in the past and returned to normal.

In order to determine this, the problem symptoms should be confirmed in 4 \

first and the diagnostic code

be rechecked in [6].

Accordingly, if troubleshooting is begun based on the malfunction code only in diag\

nostic code check in

[2] , it could result in a misdiagnosis, leading to troubleshooting of circuits which are normal \

and making

it more difficult to locate the cause of the problem.

[3] SETTING THE TEST MODE DIAGNOSIS, [4] PROBLEM SYMPTOM CONFIRMATION, [5] SYMPTOM SIMULATION

In order to find out the trouble more quickly, set the diagnosis check in test mode and with higher sensing

ability of the ECU, confirm the problem symptoms. If the trouble does not reappear, use the symptom simu-

lation method to make sure the trouble is reproduced.

[6] DIAGNOSTIC CODE CHECK IN TEST MODE Check the diagnostic code in test mode. If the malfunction code is output, pr\

oceed to ºstep [8] Diagnostic

Code Chartº. If the normal code is output, proceed to ºstep [7] Basic Inspectionº.

[7] BASIC INSPECTION Carry out basic inspection such as the spark check and fuel pressure che\

ck, etc.

[8] DIAGNOSTIC CODE CHART If the malfunction code is displayed, proceed to inspect the circuit ind\

icated by the chart for each code.

[9] MATRIX CHART OF PROBLEM SYMPTOMS If the normal code is displayed in the diagnosis in test mode, perform tro\

ubleshooting according to the in-

spection order in the Matrix Chart of Problem Symptoms.

[10] PARTS INSPECTION When the Matrix Chart of Problem Symptoms instructs to check the parts, proc\

eed to parts inspection sec-

tion included in this manual.

[11] CIRCUIT INSPECTION Determine if the malfunction is the sensor, actuator, wire harness, connector or the ECU.

TR±2

±

ENGINE TROUBLESHOOTING How to Proceed with Troubleshooting

WhereEverybodyKnowsYourName

Page 3376 of 4087

[12] CHECK FOR MOMENTARY INTERRUPTIONBy performing the check for momentary interruption, the place where moment\

ary interruptions or momen-

tary shorts are occurring due to poor contacts can be isolated.

[13] ADJUSTMENT, REPAIR After the cause of the problem is located, perform adjustment or repairs\

by following the inspection and

replacement procedures in this manual.

[14] CONFIRMATION TEST After completing adjustment or repairs, confirm not only that the malfunction\

is eliminated, but also conduct

a test drive, etc., to make sure the entire Engine Control System is oper\

ating normally.

±

ENGINE TROUBLESHOOTING How to Proceed with TroubleshootingTR±3

WhereEverybodyKnowsYourName

Page 3377 of 4087

TR±4±

ENGINE TROUBLESHOOTING How to Proceed with Troubleshooting

WhereEverybodyKnowsYourName

Page 3378 of 4087

±MEMO±

ENGINE TROUBLESHOOTINGTR±5

WhereEverybodyKnowsYourName

Page 3379 of 4087

![LEXUS SC400 1991 Service Repair Manual

How to Proceed with Troubleshooting Using Volt/Ohm Meter

and TCCS Checker

For the explanation of steps [1] ~ [6], [8] and [10] ~ [16], see the explan\

ation of steps with the same title on page

TR±2 LEXUS SC400 1991 Service Repair Manual

How to Proceed with Troubleshooting Using Volt/Ohm Meter

and TCCS Checker

For the explanation of steps [1] ~ [6], [8] and [10] ~ [16], see the explan\

ation of steps with the same title on page

TR±2](/img/36/57051/w960_57051-3378.png)

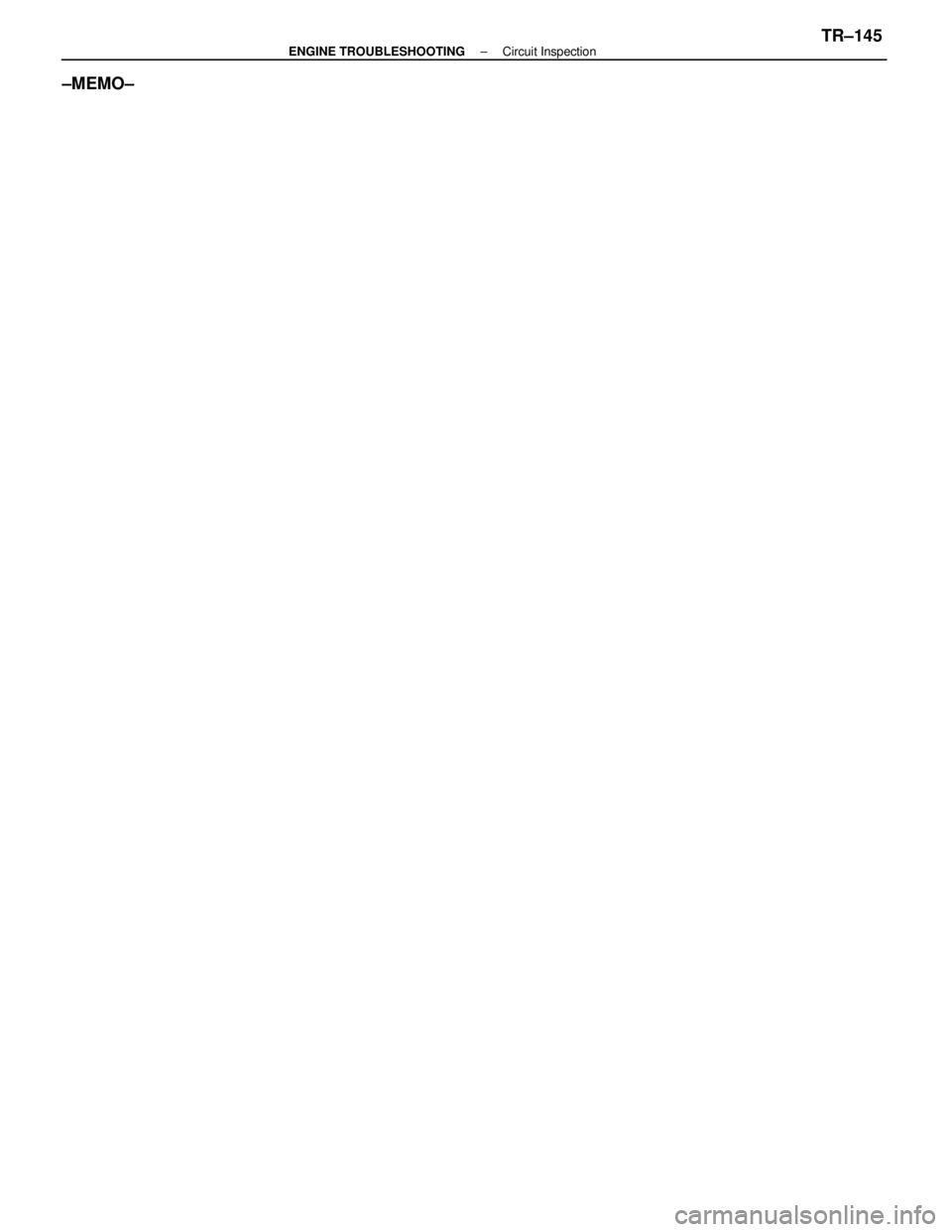

How to Proceed with Troubleshooting Using Volt/Ohm Meter

and TCCS Checker

For the explanation of steps [1] ~ [6], [8] and [10] ~ [16], see the explan\

ation of steps with the same title on page

TR±2.

[7] [9] CIRCUIT INSPECTION BY CHECKER If the Normal code is displayed in the diagnostic code check, connect the \

checker to the vehicle and check

all the circuits which can be inspected using the checker.

If a malfunctioning circuit is then detected, proceed to ºCircuit Ins\

pection by Volt/Ohm Meterº and check

the applicable circuit using a volt/ohm meter. Determine if the malfunction is in the sensor, actuator, wire

harness, connector or the ECU. If the malfunctioning circuit cannot be detected u\

sing the checker, proceed

to ºBasic Inspectionº and perform troubleshooting.

If a malfunction code is displayed in the diagnostic code check, use the c\

hecker to inspect the circuit indi-

cated by the diagnostic code chart for the displayed code.

For instructions on how to connect the checker to the vehicle and how to us\

e the checker, please refer to

the Instruction Manual for TCCS checker.

TR±6

±

ENGINE TROUBLESHOOTING How to Proceed with Troubleshooting

WhereEverybodyKnowsYourName

Page 3380 of 4087

P. TR±8

P. TR±11 , TR±13

P. TR±12

P. IN±20

P. TR±12

P. TR±14

P. TR±24

P. TR±35

P. TR±48

P. TR±23

±

ENGINE TROUBLESHOOTING How to Proceed with TroubleshootingTR±7

WhereEverybodyKnowsYourName

Trending: engine coolant, headlight bulb, fuel cap, brake sensor, bolt pattern, steering, brake rotor

![LEXUS SC400 1991 Service Repair Manual

[12] CHECK FOR MOMENTARY INTERRUPTIONBy performing the check for momentary interruption, the place where moment\

ary interruptions or momen-

tary shorts are occurring due to poor contacts can be iso LEXUS SC400 1991 Service Repair Manual

[12] CHECK FOR MOMENTARY INTERRUPTIONBy performing the check for momentary interruption, the place where moment\

ary interruptions or momen-

tary shorts are occurring due to poor contacts can be iso](/img/36/57051/w960_57051-3375.png)

![LEXUS SC400 1991 Service Repair Manual

How to Proceed with Troubleshooting Using Volt/Ohm Meter

and TCCS Checker

For the explanation of steps [1] ~ [6], [8] and [10] ~ [16], see the explan\

ation of steps with the same title on page

TR±2 LEXUS SC400 1991 Service Repair Manual

How to Proceed with Troubleshooting Using Volt/Ohm Meter

and TCCS Checker

For the explanation of steps [1] ~ [6], [8] and [10] ~ [16], see the explan\

ation of steps with the same title on page

TR±2](/img/36/57051/w960_57051-3378.png)