torque LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2135 of 4087

REPLACEMENT OF CRANKSHAFT

FRONT OIL SEAL

(See page EM±152)

ASSEMBLY OF OIL PUMP

(See Components on page LU±12)

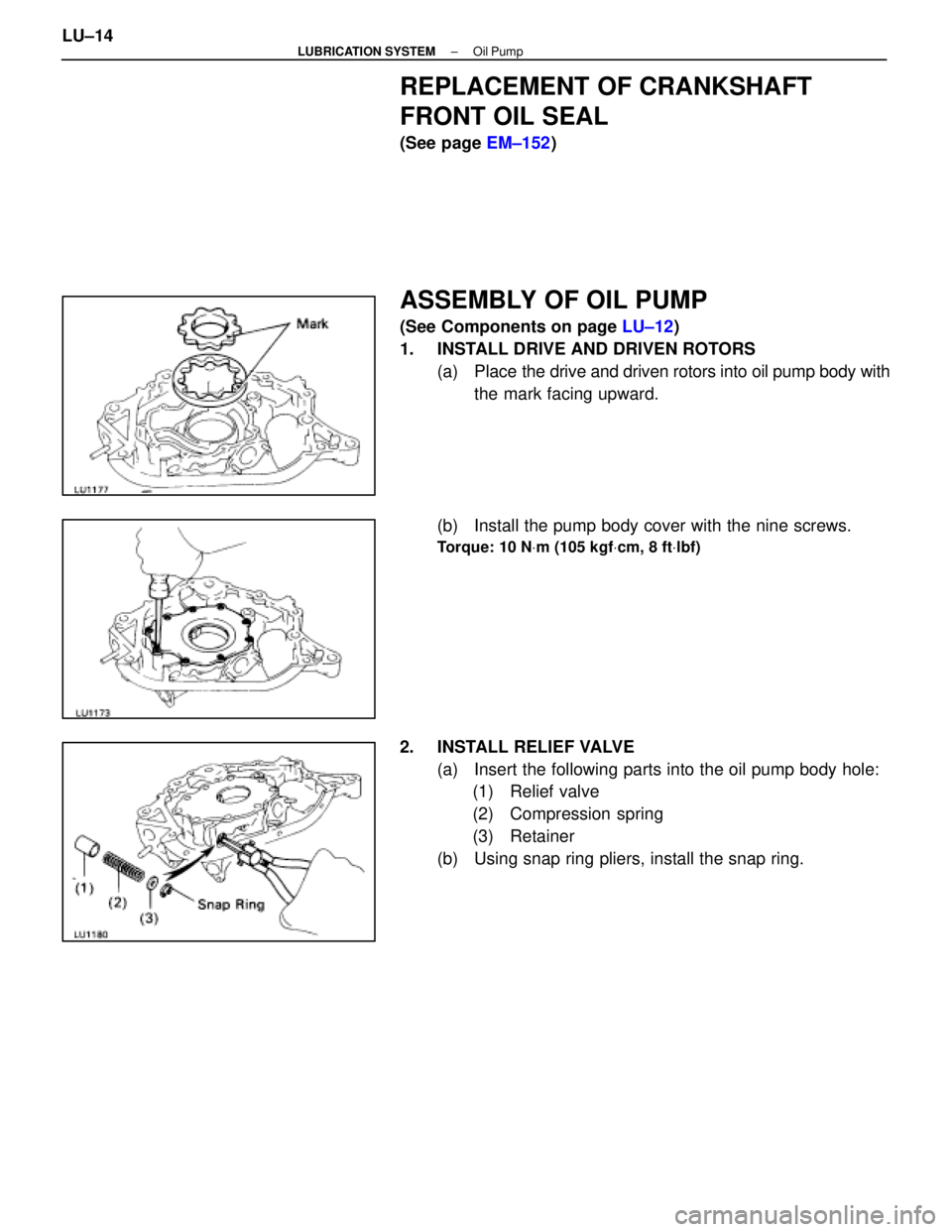

1. INSTALL DRIVE AND DRIVEN ROTORS (a) Place the drive and driven rotors into oil pump body with

the mark facing upward.

(b) Install the pump body cover with the nine screws.

Torque: 10 N Vm (105 kgf Vcm, 8 ft Vlbf)

2. INSTALL RELIEF VALVE

(a) Insert the following parts into the oil pump body hole:(1) Relief valve

(2) Compression spring

(3) Retainer

(b) Using snap ring pliers, install the snap ring.

LU±14

±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2137 of 4087

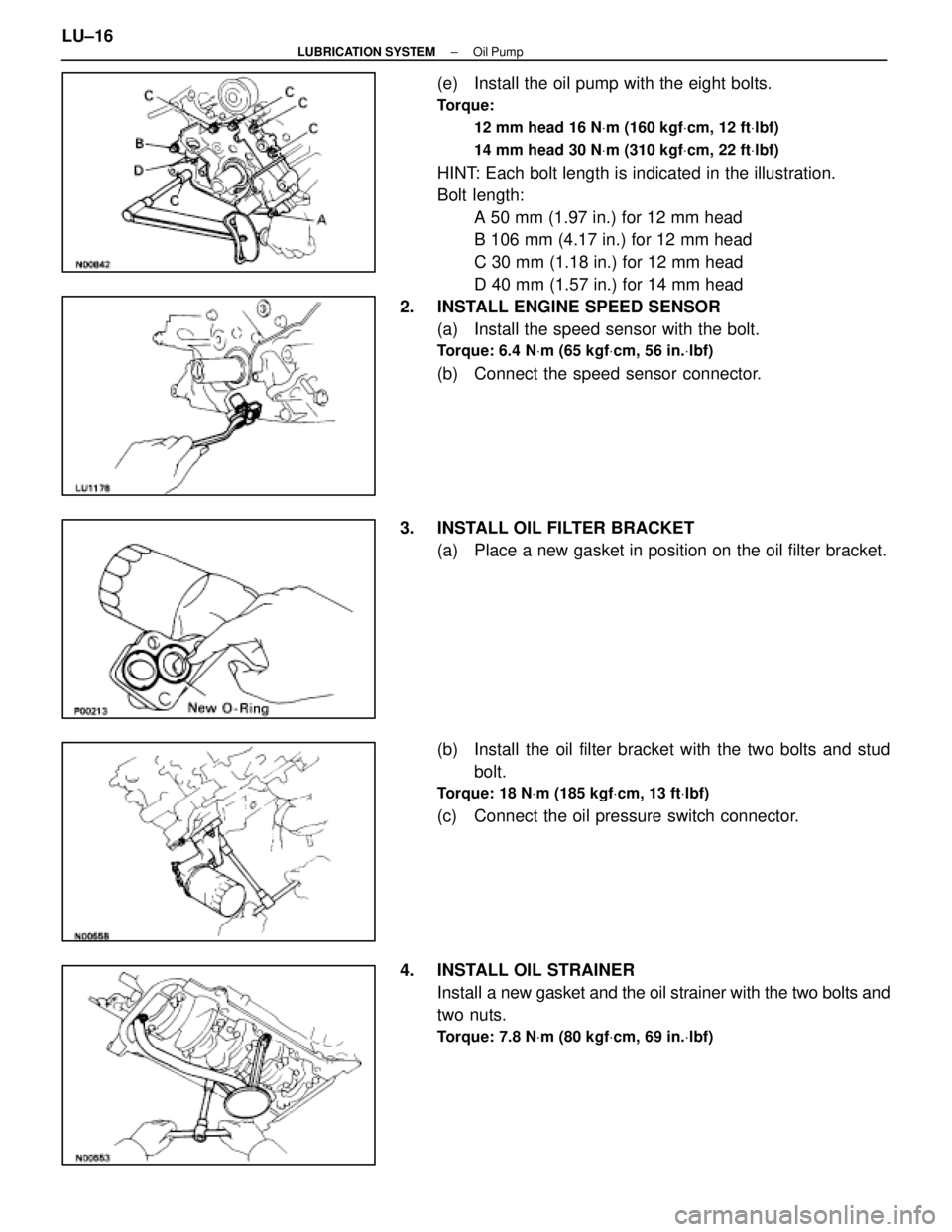

(e) Install the oil pump with the eight bolts.

Torque:12 mm head 16 N Vm (160 kgf Vcm, 12 ft Vlbf)

14 mm head 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Each bolt length is indicated in the illustration.

Bolt length:

A 50 mm (1.97 in.) for 12 mm head

B 106 mm (4.17 in.) for 12 mm head

C 30 mm (1.18 in.) for 12 mm head

D 40 mm (1.57 in.) for 14 mm head

2. INSTALL ENGINE SPEED SENSOR (a) Install the speed sensor with the bolt.

Torque: 6.4 N Vm (65 kgf Vcm, 56 in. Vlbf)

(b) Connect the speed sensor connector.

3. INSTALL OIL FILTER BRACKET (a) Place a new gasket in position on the oil filter bracket.

(b) Install the oil filter bracket with the two bolts and studbolt.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

(c) Connect the oil pressure switch connector.

4. INSTALL OIL STRAINER Install a new gasket and the oil strainer with the two bolts and

two nuts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

LU±16±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2138 of 4087

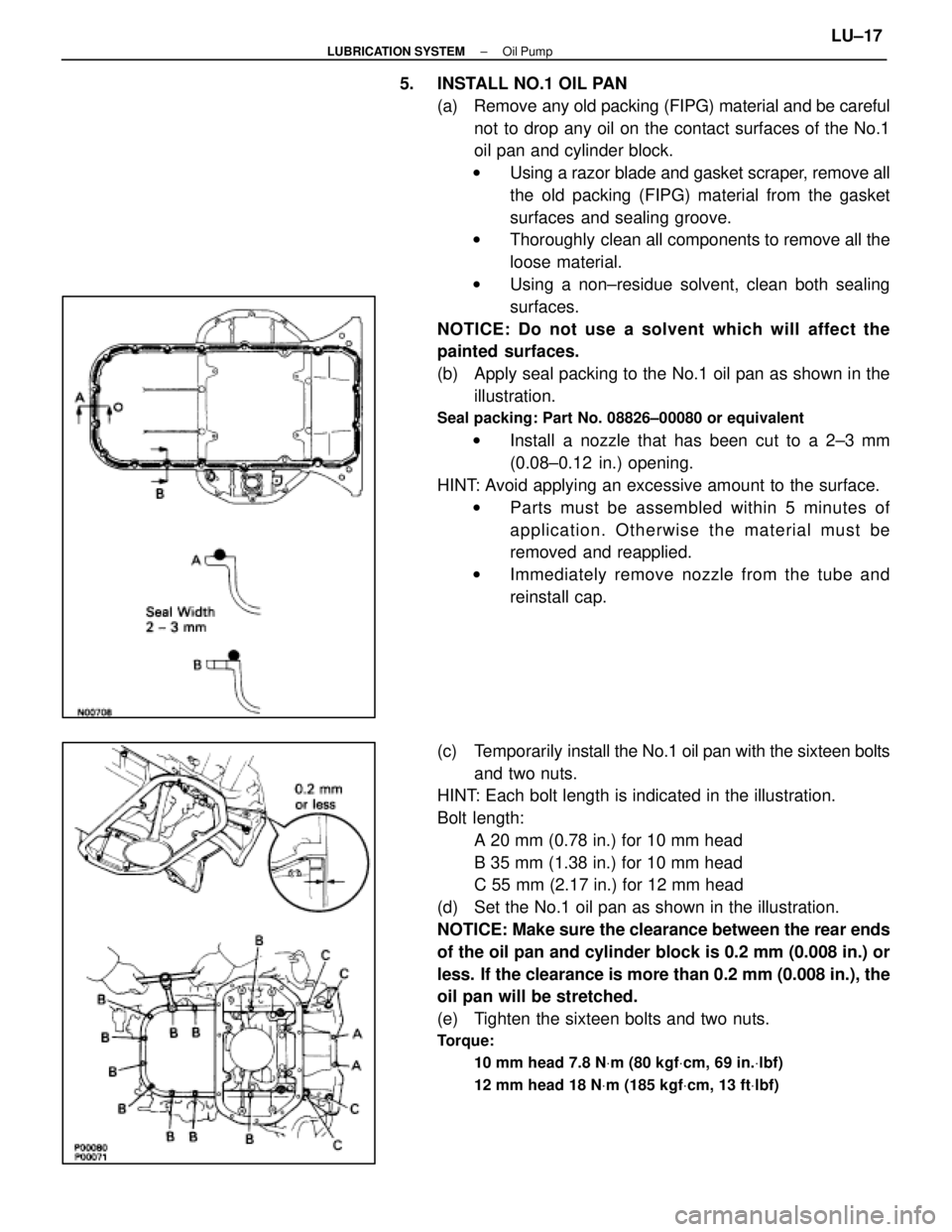

5. INSTALL NO.1 OIL PAN(a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the No.1

oil pan and cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(b) Apply seal packing to the No.1 oil pan as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Temporarily install the No.1 oil pan with the sixteen bolts

and two nuts.

HINT: Each bolt length is indicated in the illustration.

Bolt length:

A 20 mm (0.78 in.) for 10 mm head

B 35 mm (1.38 in.) for 10 mm head

C 55 mm (2.17 in.) for 12 mm head

(d) Set the No.1 oil pan as shown in the illustration.

NOTICE: Make sure the clearance between the rear ends

of the oil pan and cylinder block is 0.2 mm (0.008 in.) or

less. If the clearance is more than 0.2 mm (0.008 in.), the

oil pan will be stretched.

(e) Tighten the sixteen bolts and two nuts.

Torque:

10 mm head 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

12 mm head 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

±

LUBRICATION SYSTEM Oil PumpLU±17

WhereEverybodyKnowsYourName

Page 2139 of 4087

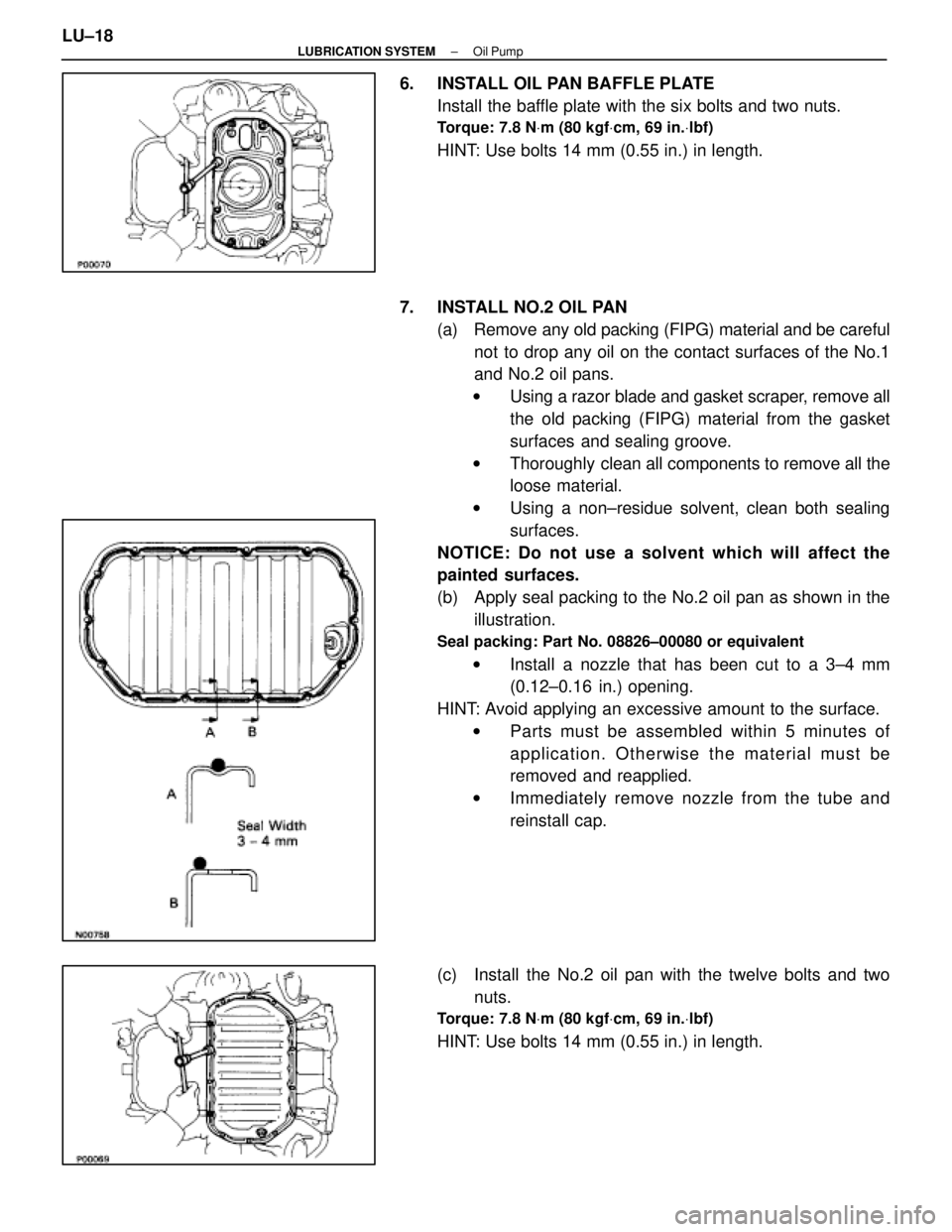

6. INSTALL OIL PAN BAFFLE PLATEInstall the baffle plate with the six bolts and two nuts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

HINT: Use bolts 14 mm (0.55 in.) in length.

7. INSTALL NO.2 OIL PAN (a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the No.1

and No.2 oil pans.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(b) Apply seal packing to the No.2 oil pan as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 3±4 mm

(0.12±0.16 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Install the No.2 oil pan with the twelve bolts and two nuts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

HINT: Use bolts 14 mm (0.55 in.) in length.

LU±18

±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2140 of 4087

8. INSTALL OIL LEVEL SENSOR(a) Install a new gasket to the level sensor.

(b) Install the level sensor with the four bolts.

Torque: 5.4 N Vm (55 kgf Vcm, 48 in. Vlbf)

HINT: Use bolts 16 mm (0.63 in.) in length.

(c) Connect the level sensor connector.

9. INSTALL BRACKET OF MAIN OXYGEN SENSOR CONNECTOR TO NO.1 OIL PAN

Install the connector bracket with bolt.

10. INSTALL OIL DIPSTICK GUIDE AND DIPSTICK (a) Install a new O±ring to the dipstick guide.

(b) Apply soapy water to the O±ring.

(c) Push in the dipstick guide into the guide hole of the No.1

oil pan.

(d) Install the engine wire bracket and dipstick guide with bolt.

(e) Install the oil dipstick.

11. INSTALL CRANKSHAFT TIMING PULLEY, NO.1 IDLER PULLEY AND NO.2 IDLER PULLEY

(See steps 1 to 3 on pages EM±46 and 47)

12. INSTALL TIMING BELT

(See steps 4 to 35 on pages EM±47 to 56)

13. REMOVE ENGINE STAND FROM ENGINE

14. ASSEMBLE ENGINE AND TRANSMISSION (See pages EM±165 and 166)

15. INSTALL ENGINE WITH TRANSMISSION (See pages EM±167 to 177)

±

LUBRICATION SYSTEM Oil PumpLU±19

WhereEverybodyKnowsYourName

Page 2146 of 4087

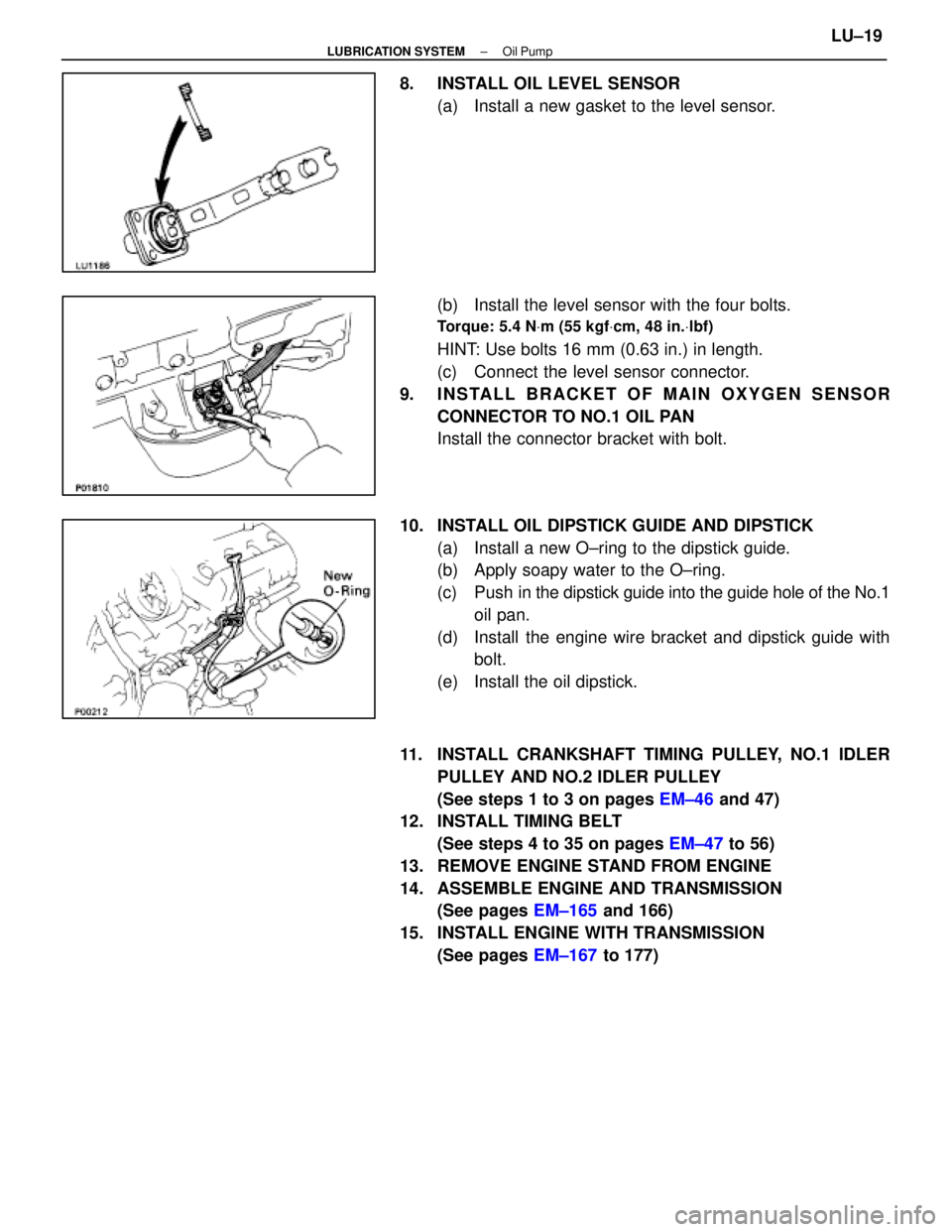

C. Inspect rotor body clearanceUsing a feeler gauge, measure the clearance between the

driven rotor and pump body.

Standard body clearance: 0.100±0.175 mm

(0.0039±0.0069 in.)

Maximum body clearance: 0.20 mm (0.0079 in.)

If the body clearance is greater than maximum, replace the

rotors as a set. If necessary, replace the oil pump assembly.

D. Inspect rotor side clearance Using a feeler gauge and precision straight edge, measure

the clearance between the rotors and precision straight

edge.

Standard side clearance: 0.030±0.090 mm

(0.0012±0.0035 in.)

Maximum side clearance: 0.12 mm (0.0047 in.)

If the side clearance is greater than maximum, replace the ro-

tors as a set. If necessary, replace the oil pump assembly.

E. Remove drive and driven rotors

REPLACEMENT OF CRANKSHAFT

FRONT OIL SEAL

(See page EM±92)

ASSEMBLY OF OIL PUMP

(See Components on page LU±12)

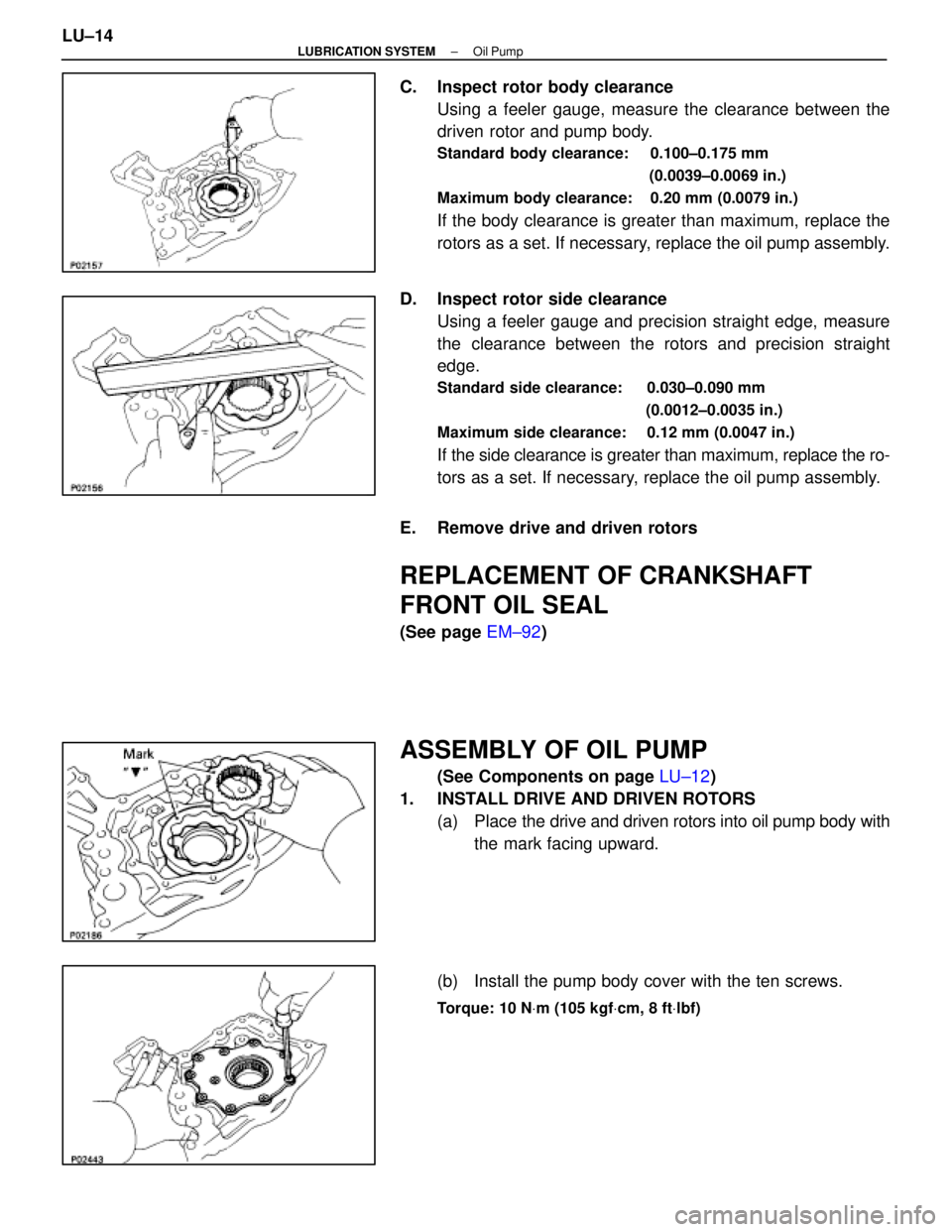

1. INSTALL DRIVE AND DRIVEN ROTORS (a) Place the drive and driven rotors into oil pump body with

the mark facing upward.

(b) Install the pump body cover with the ten screws.

Torque: 10 N Vm (105 kgf Vcm, 8 ft Vlbf)

LU±14±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2147 of 4087

2. INSTALL RELIEF VALVE(a) Slighty mount the pump body in a vise.

NOTICE: Be careful not to damage the pump body.

(b) Insert the relief valve and compression spring into the oil

pump body hole.

(c) Install the plug with a new gasket.

Torque: 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

INSTALLATION OF OIL PUMP

(See Components on page LU±9)

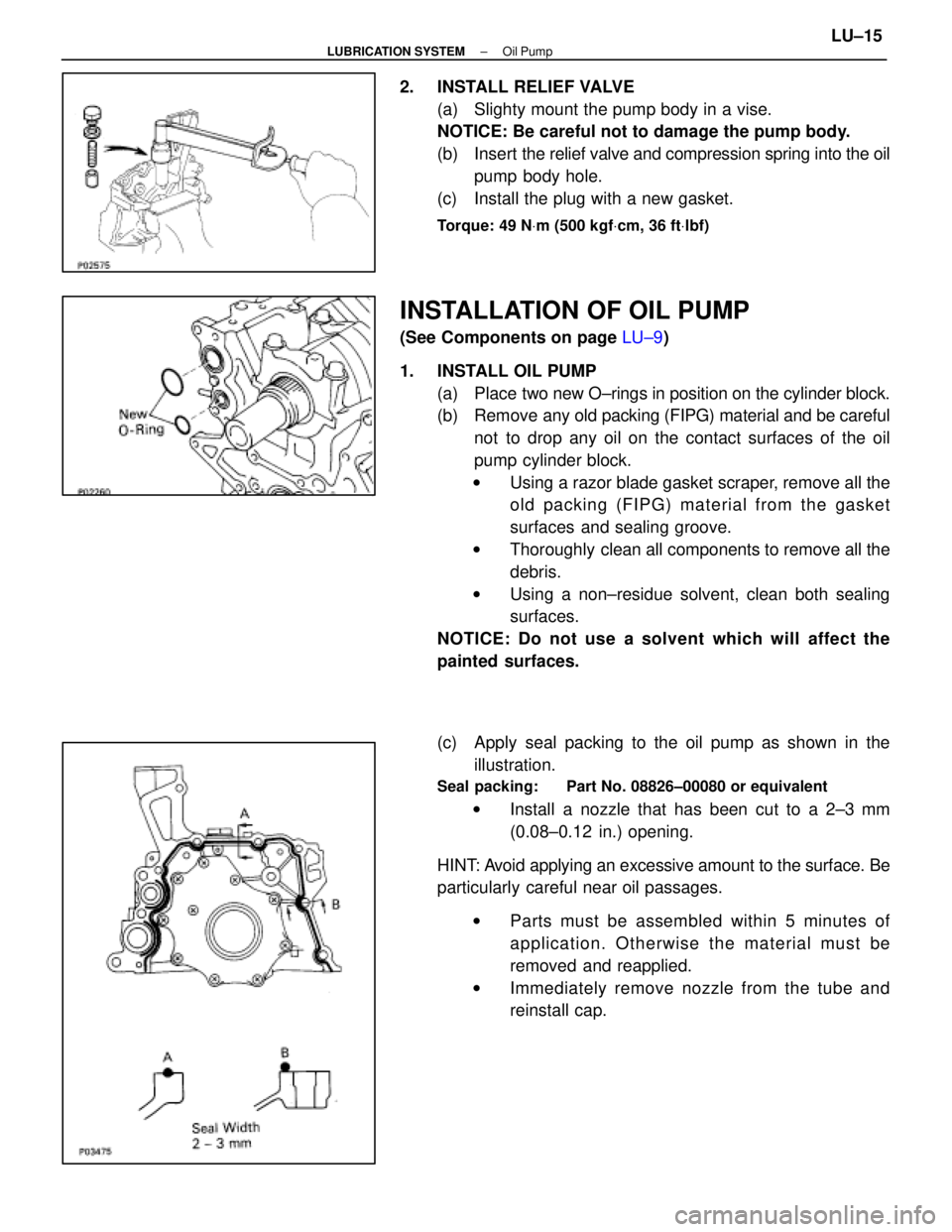

1. INSTALL OIL PUMP (a) Place two new O±rings in position on the cylinder block.

(b) Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the oil

pump cylinder block.

w Using a razor blade gasket scraper, remove all the

old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

debris.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(c) Apply seal packing to the oil pump as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. Be

particularly careful near oil passages. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

±

LUBRICATION SYSTEM Oil PumpLU±15

WhereEverybodyKnowsYourName

Page 2148 of 4087

(d) Install the oil pump with the seven bolts (A) and two bolts

(B).

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

HINT: Hand tighten the (A) bolts first.

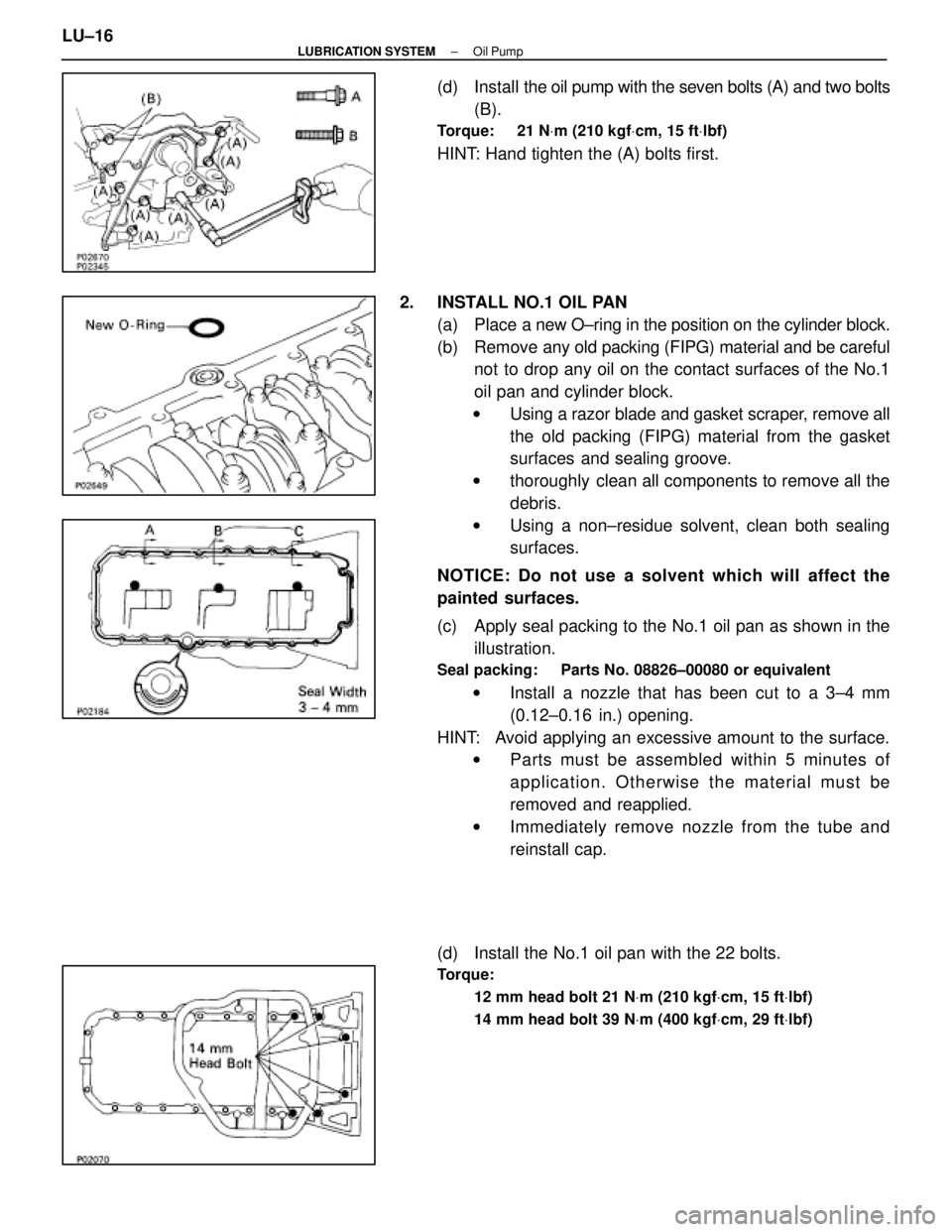

2. INSTALL NO.1 OIL PAN (a) Place a new O±ring in the position on the cylinder block.

(b) Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1

oil pan and cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w thoroughly clean all components to remove all the

debris.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(c) Apply seal packing to the No.1 oil pan as shown in the illustration.

Seal packing: Parts No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 3±4 mm

(0.12±0.16 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(d) Install the No.1 oil pan with the 22 bolts.

Torque: 12 mm head bolt 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

14 mm head bolt 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

LU±16±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2149 of 4087

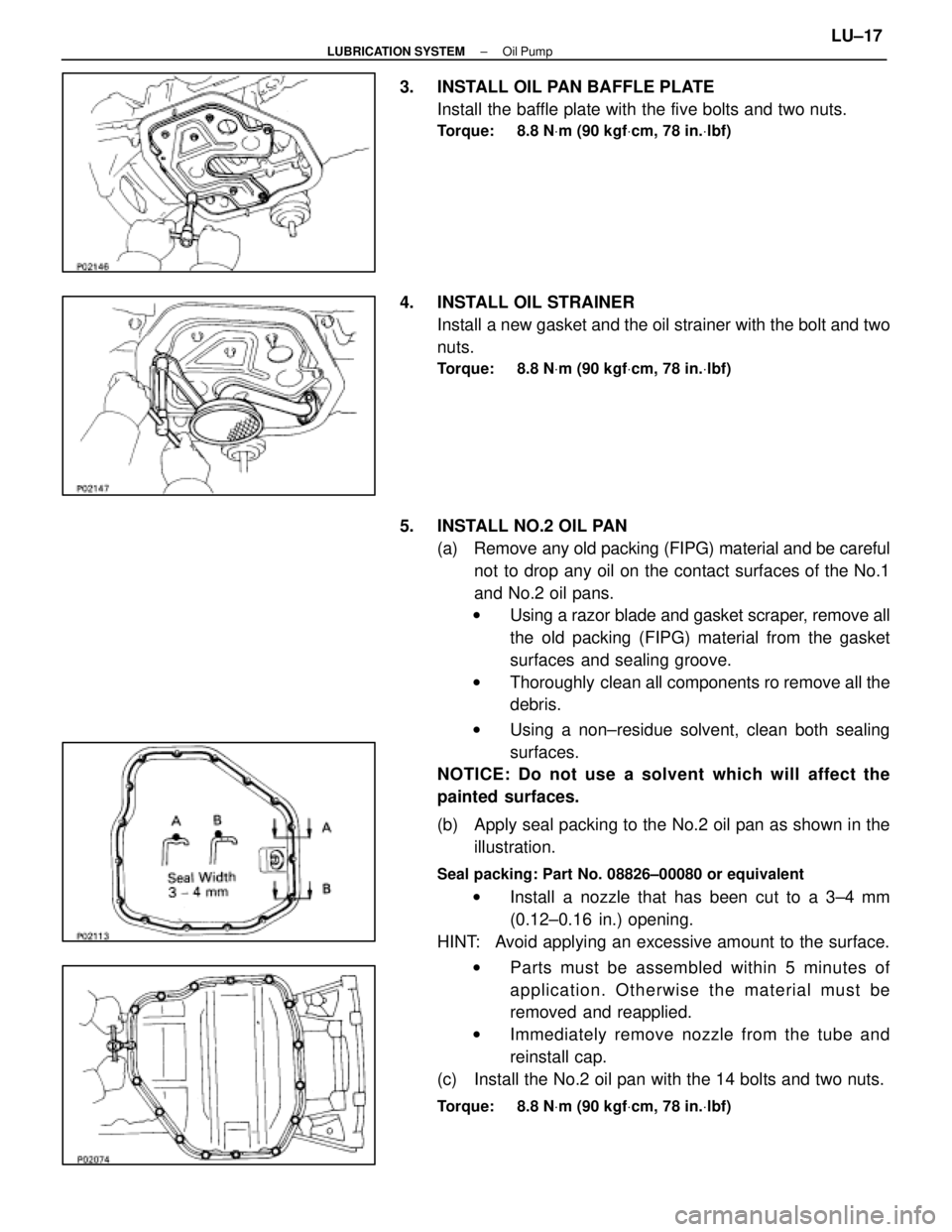

3. INSTALL OIL PAN BAFFLE PLATEInstall the baffle plate with the five bolts and two nuts.

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

4. INSTALL OIL STRAINER

Install a new gasket and the oil strainer with the bolt and two

nuts.

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

5. INSTALL NO.2 OIL PAN

(a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the No.1

and No.2 oil pans.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components ro remove all the

debris.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(b) Apply seal packing to the No.2 oil pan as shown in the

illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 3±4 mm

(0.12±0.16 in.) opening.

HINT: Avoid applying an excessive amount to the surface.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Install the No.2 oil pan with the 14 bolts and two nuts.

Torque: 8.8 N Vm (90 kgf Vcm, 78 in. Vlbf)

±

LUBRICATION SYSTEM Oil PumpLU±17

WhereEverybodyKnowsYourName

Page 2150 of 4087

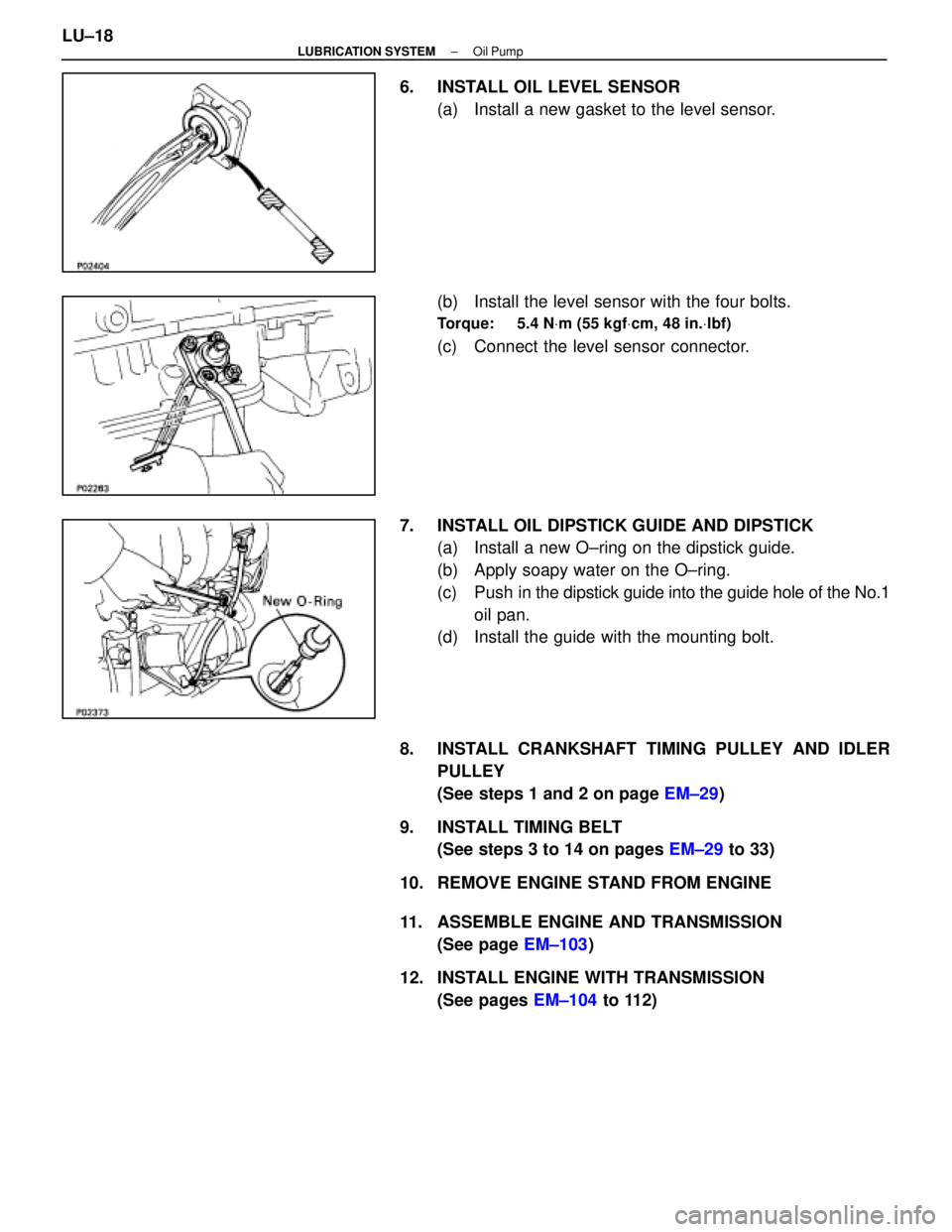

6. INSTALL OIL LEVEL SENSOR(a) Install a new gasket to the level sensor.

(b) Install the level sensor with the four bolts.

Torque: 5.4 N Vm (55 kgf Vcm, 48 in. Vlbf)

(c) Connect the level sensor connector.

7. INSTALL OIL DIPSTICK GUIDE AND DIPSTICK (a) Install a new O±ring on the dipstick guide.

(b) Apply soapy water on the O±ring.

(c) Push in the dipstick guide into the guide hole of the No.1

oil pan.

(d) Install the guide with the mounting bolt.

8. INSTALL CRANKSHAFT TIMING PULLEY AND IDLER PULLEY

(See steps 1 and 2 on page EM±29)

9. INSTALL TIMING BELT (See steps 3 to 14 on pages EM±29 to 33)

10. REMOVE ENGINE STAND FROM ENGINE

11. ASSEMBLE ENGINE AND TRANSMISSION (See page EM±103)

12. INSTALL ENGINE WITH TRANSMISSION (See pages EM±104 to 112)

LU±18

±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName