lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1513 of 4087

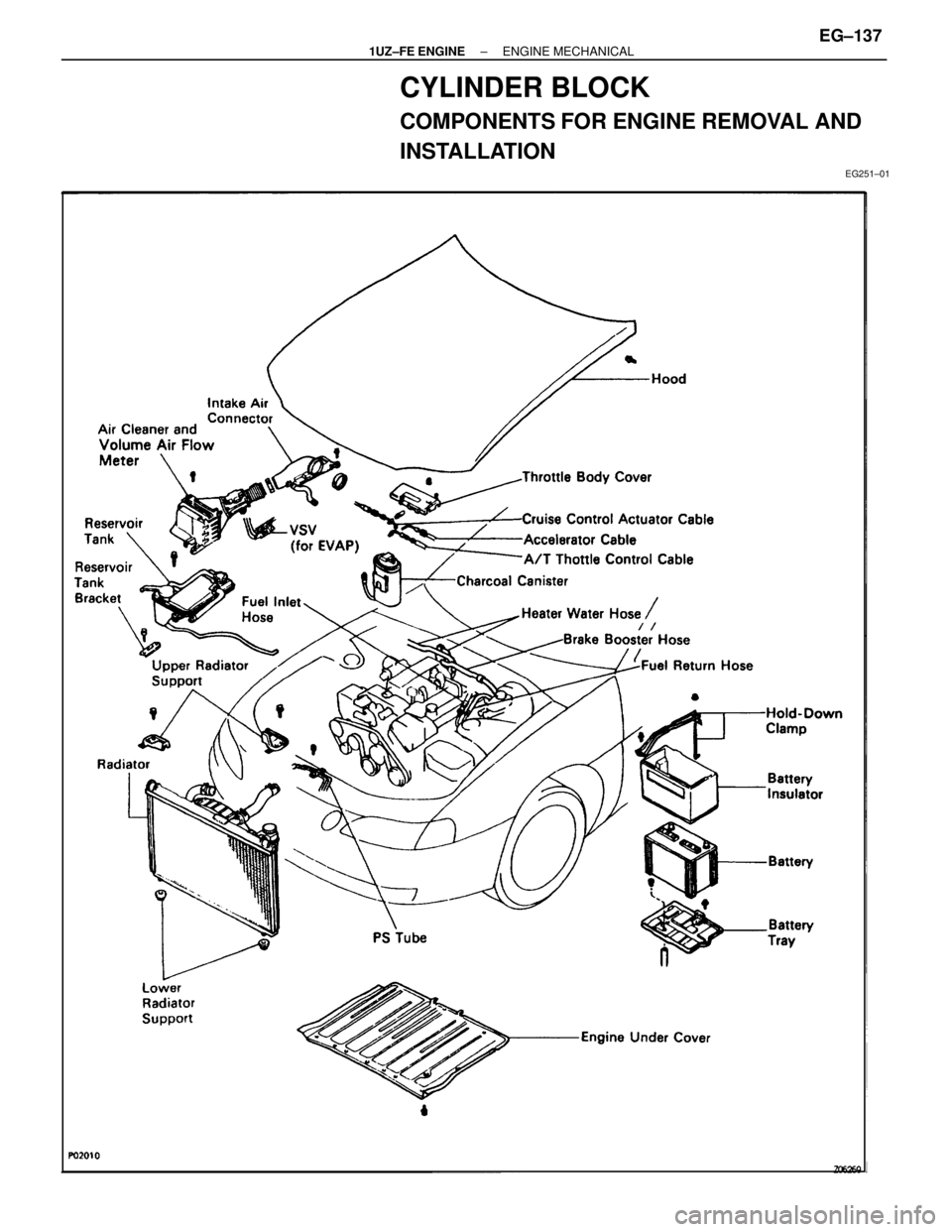

CYLINDER BLOCK

COMPONENTS FOR ENGINE REMOVAL AND

INSTALLATION

EG251±01

±

1UZ±FE ENGINE ENGINE MECHANICALEG±137

WhereEverybodyKnowsYourName

Page 1515 of 4087

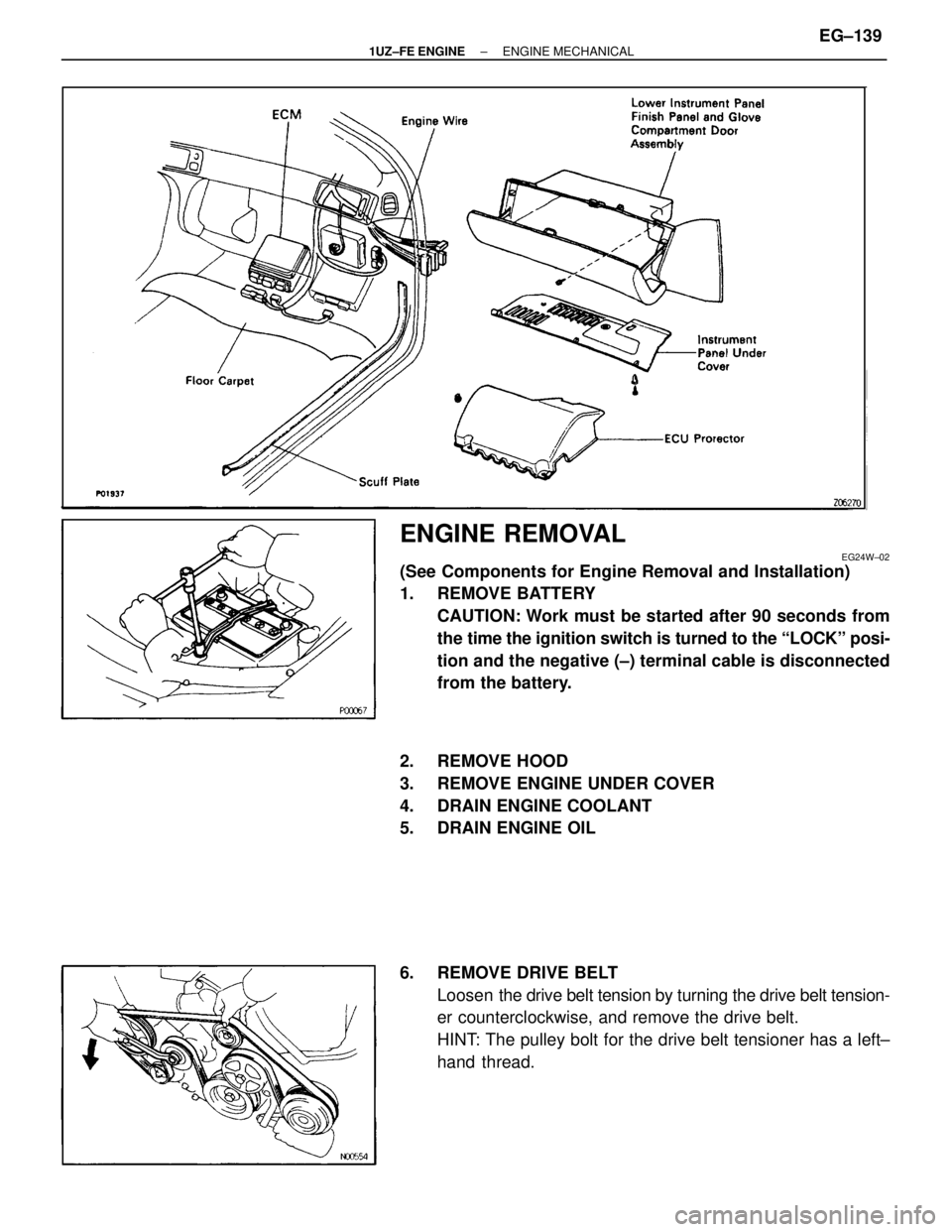

ENGINE REMOVAL

EG24W±02

(See Components for Engine Removal and Installation)

1. REMOVE BATTERYCAUTION: Work must be started after 90 seconds from

the time the ignition switch is turned to the ªLOCKº posi-

tion and the negative (±) terminal cable is disconnected

from the battery.

2. REMOVE HOOD

3. REMOVE ENGINE UNDER COVER

4. DRAIN ENGINE COOLANT

5. DRAIN ENGINE OIL

6. REMOVE DRIVE BELT Loosen the drive belt tension by turning the drive belt tension-

er counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the drive belt tensioner has a left±

hand thread.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±139

WhereEverybodyKnowsYourName

Page 1528 of 4087

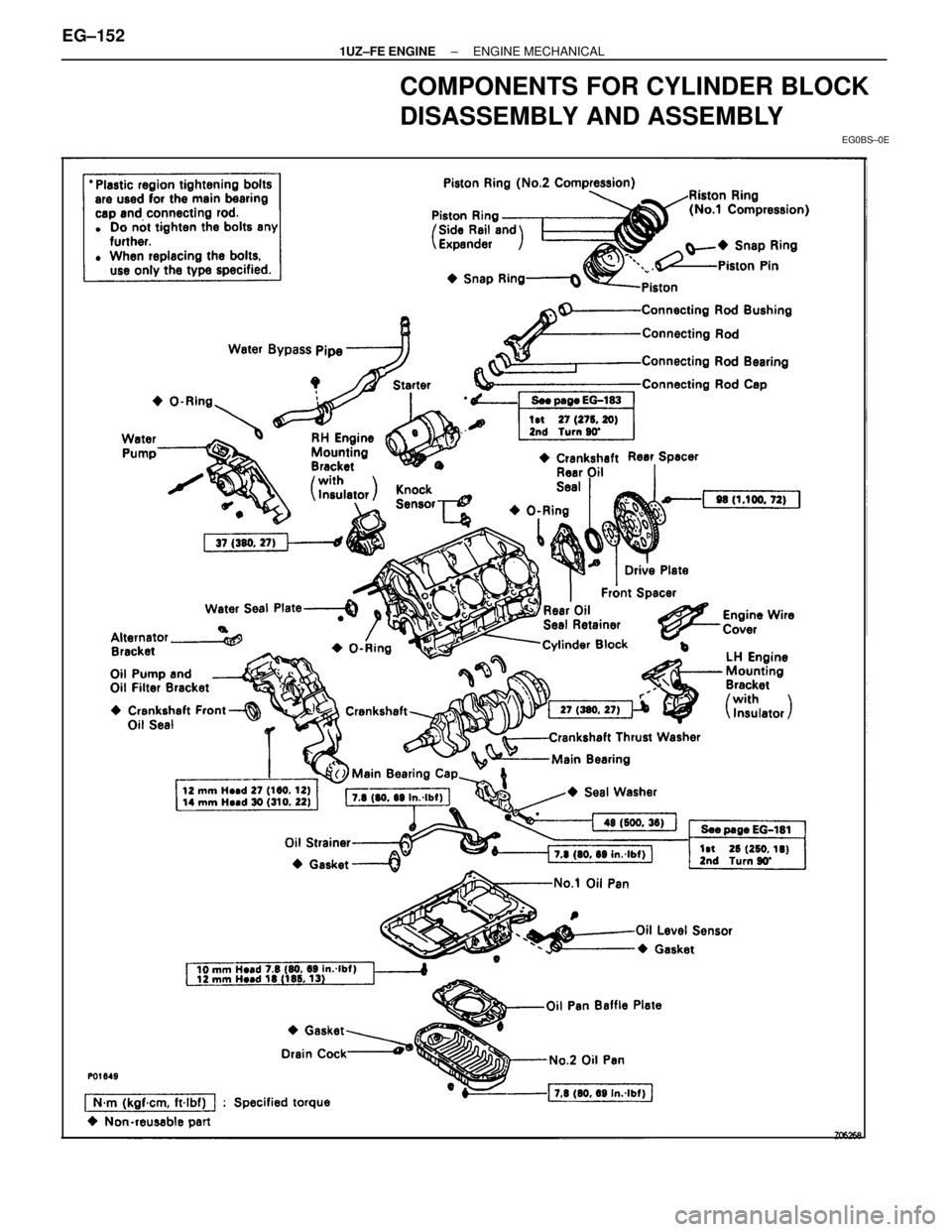

COMPONENTS FOR CYLINDER BLOCK

DISASSEMBLY AND ASSEMBLY

EG0BS±0E

EG±152±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1529 of 4087

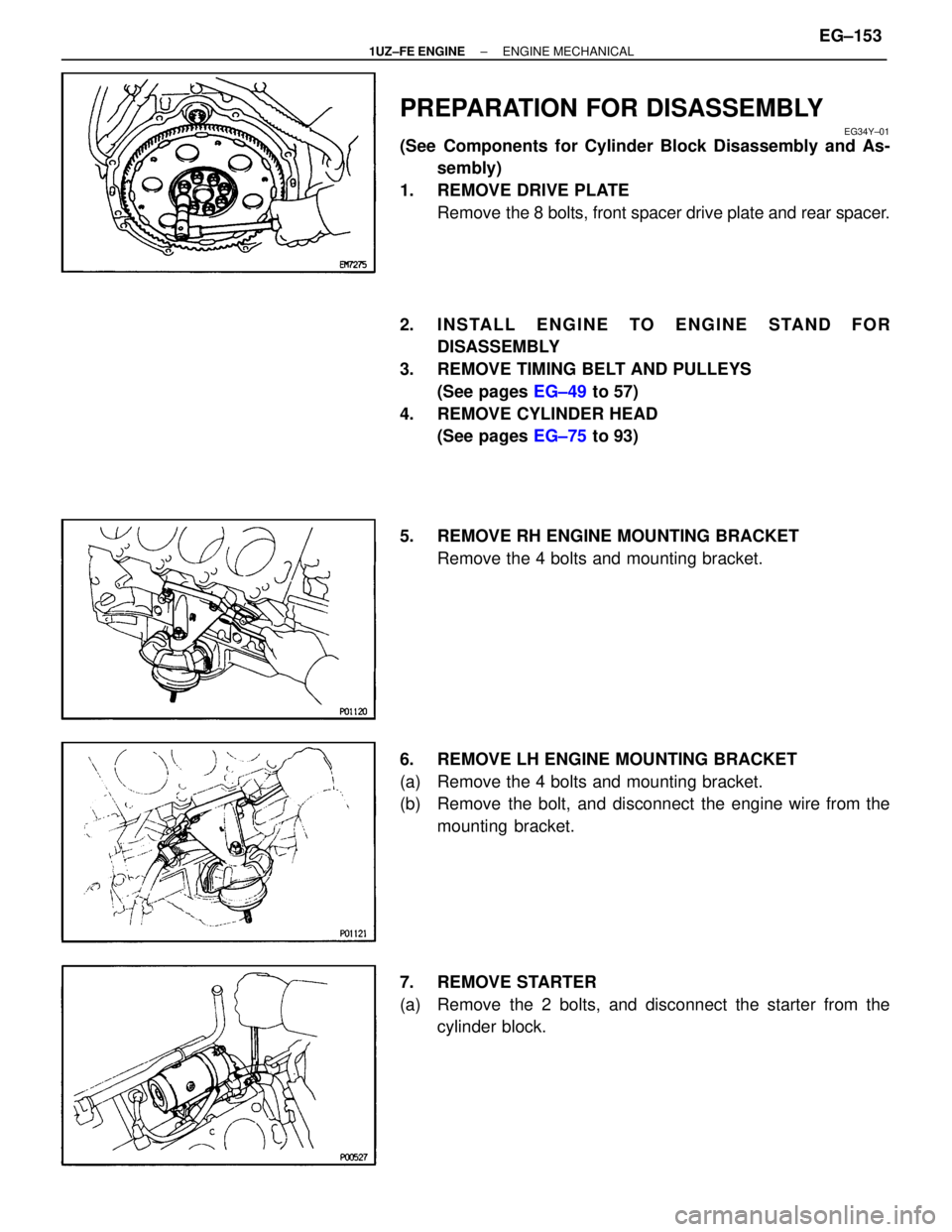

PREPARATION FOR DISASSEMBLY

EG34Y±01

(See Components for Cylinder Block Disassembly and As-sembly)

1. REMOVE DRIVE PLATE Remove the 8 bolts, front spacer drive plate and rear spacer.

2. INSTALL ENGINE TO ENGINE STAND FOR DISASSEMBLY

3. REMOVE TIMING BELT AND PULLEYS (See pages EG±49 to 57)

4. REMOVE CYLINDER HEAD (See pages EG±75 to 93)

5. REMOVE RH ENGINE MOUNTING BRACKET Remove the 4 bolts and mounting bracket.

6. REMOVE LH ENGINE MOUNTING BRACKET

(a) Remove the 4 bolts and mounting bracket.

(b) Remove the bolt, and disconnect the engine wire from the mounting bracket.

7. REMOVE STARTER

(a) Remove the 2 bolts, and disconnect the starter from the cylinder block.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±153

WhereEverybodyKnowsYourName

Page 1530 of 4087

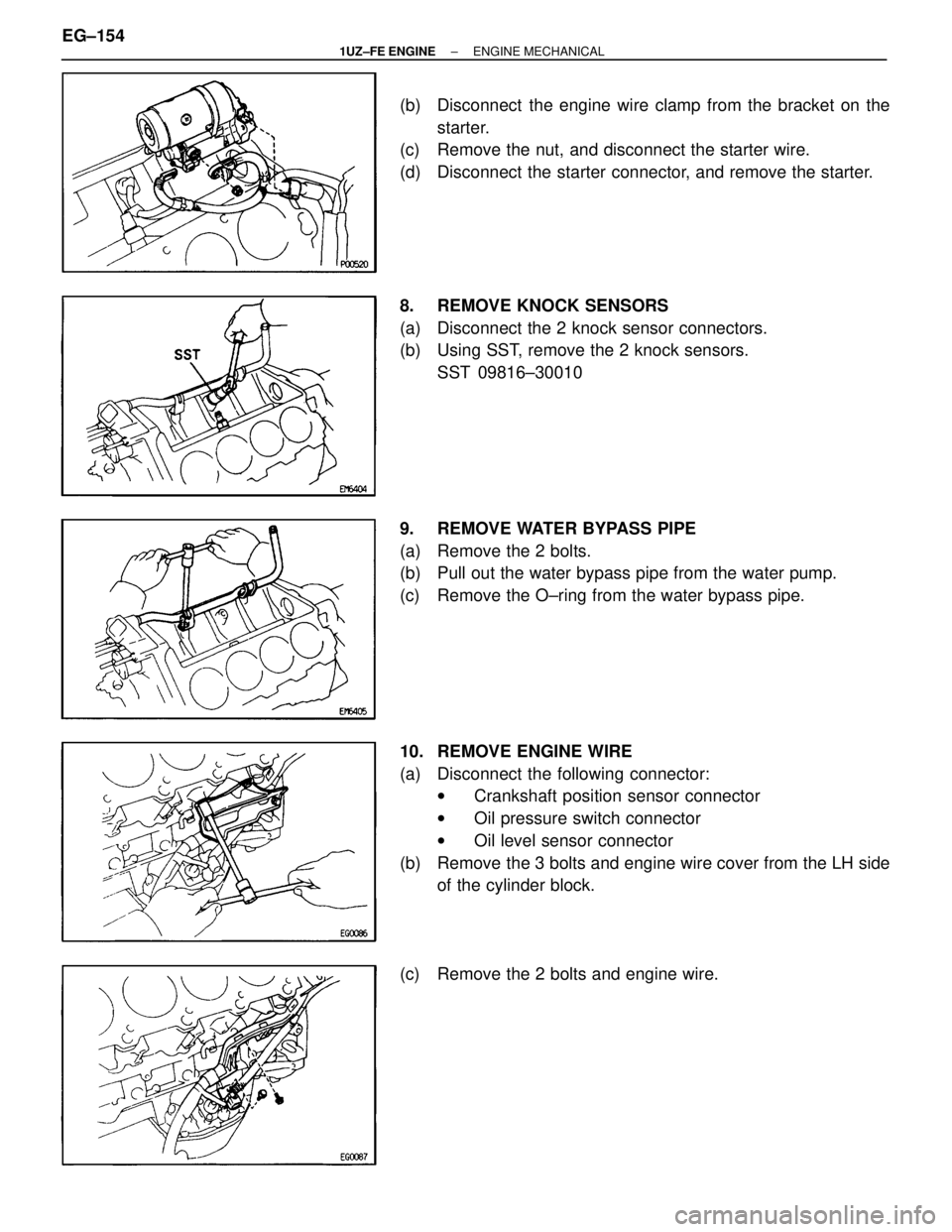

(b) Disconnect the engine wire clamp from the bracket on thestarter.

(c) Remove the nut, and disconnect the starter wire.

(d) Disconnect the starter connector, and remove the starter.

8. REMOVE KNOCK SENSORS

(a) Disconnect the 2 knock sensor connectors.

(b) Using SST, remove the 2 knock sensors.

SST 09816±30010

9. REMOVE WATER BYPASS PIPE

(a) Remove the 2 bolts.

(b) Pull out the water bypass pipe from the water pump.

(c) Remove the O±ring from the water bypass pipe.

10. REMOVE ENGINE WIRE

(a) Disconnect the following connector: wCrankshaft position sensor connector

w Oil pressure switch connector

w Oil level sensor connector

(b) Remove the 3 bolts and engine wire cover from the LH side of the cylinder block.

(c) Remove the 2 bolts and engine wire.

EG±154

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1531 of 4087

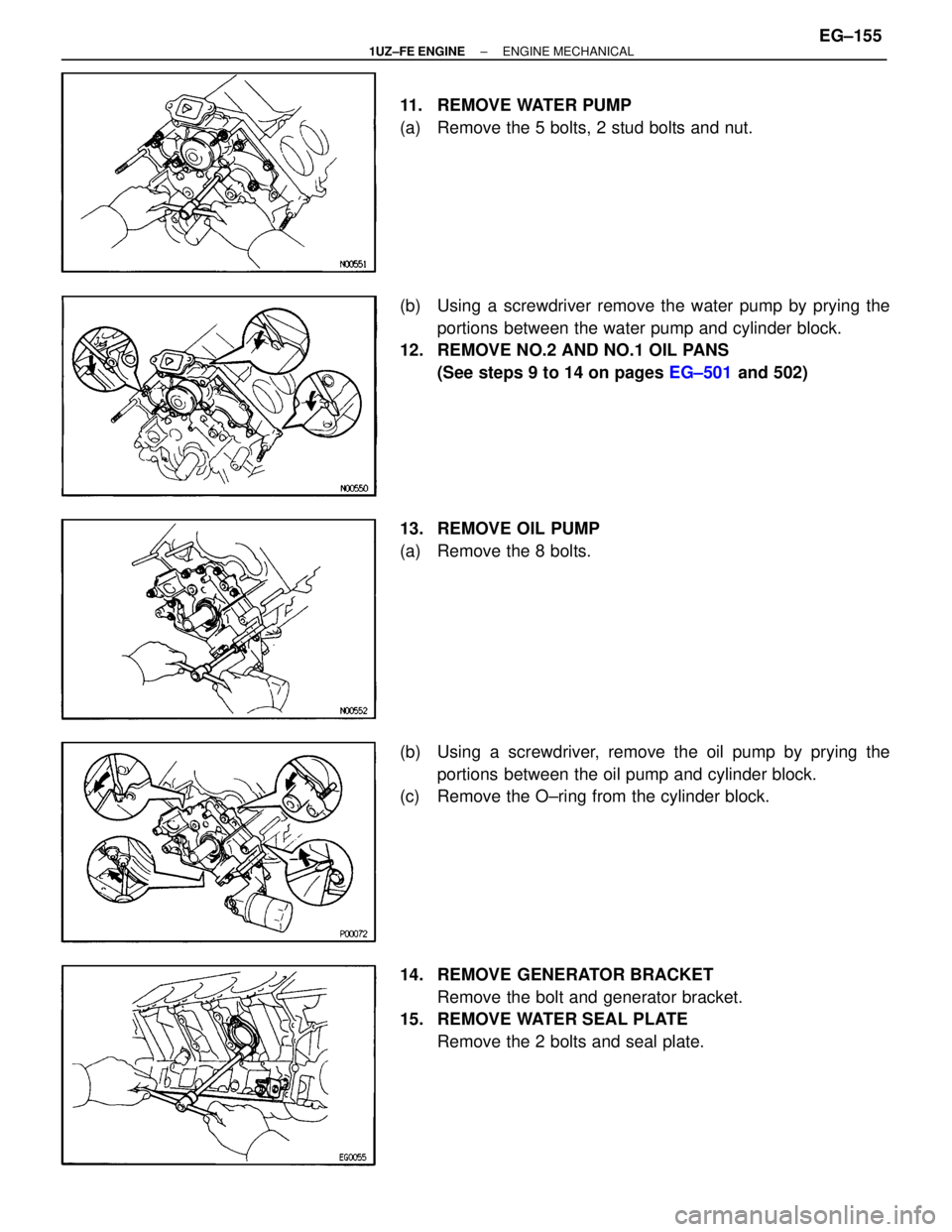

11. REMOVE WATER PUMP

(a) Remove the 5 bolts, 2 stud bolts and nut.

(b) Using a screwdriver remove the water pump by prying theportions between the water pump and cylinder block.

12. REMOVE NO.2 AND NO.1 OIL PANS

(See steps 9 to 14 on pages EG±501 and 502)

13. REMOVE OIL PUMP

(a) Remove the 8 bolts.

(b) Using a screwdriver, remove the oil pump by prying the portions between the oil pump and cylinder block.

(c) Remove the O±ring from the cylinder block.

14. REMOVE GENERATOR BRACKET

Remove the bolt and generator bracket.

15. REMOVE WATER SEAL PLATE

Remove the 2 bolts and seal plate.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±155

WhereEverybodyKnowsYourName

Page 1532 of 4087

CYLINDER BLOCK DISASSEMBLY

EG1KT±04

(See Components for Cylinder Block Disassembly and As-sembly)

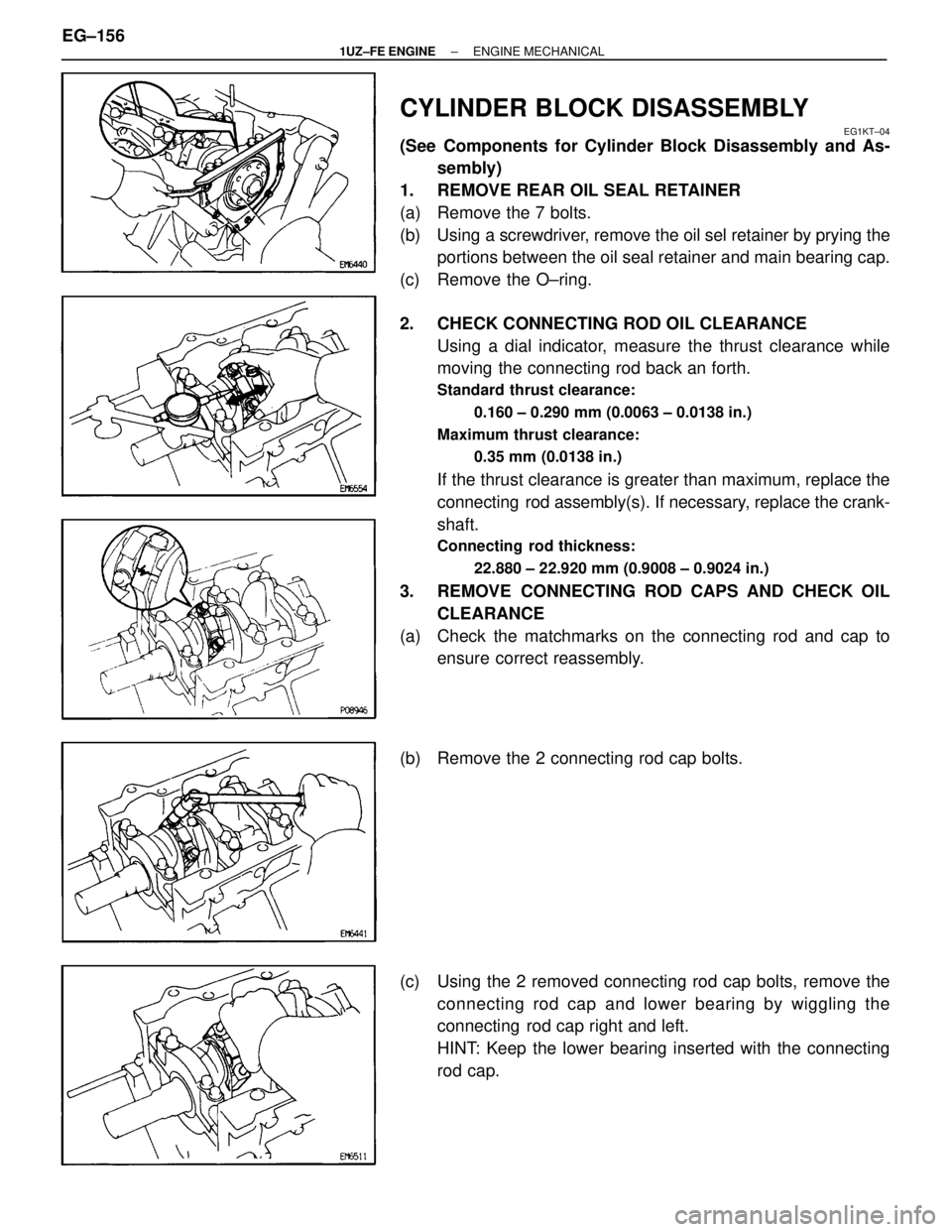

1. REMOVE REAR OIL SEAL RETAINER

(a) Remove the 7 bolts.

(b) Using a screwdriver, remove the oil sel retainer by prying the portions between the oil seal retainer and main bearing cap.

(c) Remove the O±ring.

2. CHECK CONNECTING ROD OIL CLEARANCE Using a dial indicator, measure the thrust clearance while

moving the connecting rod back an forth.

Standard thrust clearance:

0.160 ± 0.290 mm (0.0063 ± 0.0138 in.)

Maximum thrust clearance: 0.35 mm (0.0138 in.)

If the thrust clearance is greater than maximum, replace the

connecting rod assembly(s). If necessary, replace the crank-

shaft.

Connecting rod thickness:

22.880 ± 22.920 mm (0.9008 ± 0.9024 in.)

3. REMOVE CONNECTING ROD CAPS AND CHECK OILCLEARANCE

(a) Check the matchmarks on the connecting rod and cap to ensure correct reassembly.

(b) Remove the 2 connecting rod cap bolts.

(c) Using the 2 removed connecting rod cap bolts, remove the connecting rod cap and lower bearing by wiggling the

connecting rod cap right and left.

HINT: Keep the lower bearing inserted with the connecting

rod cap.

EG±156

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1535 of 4087

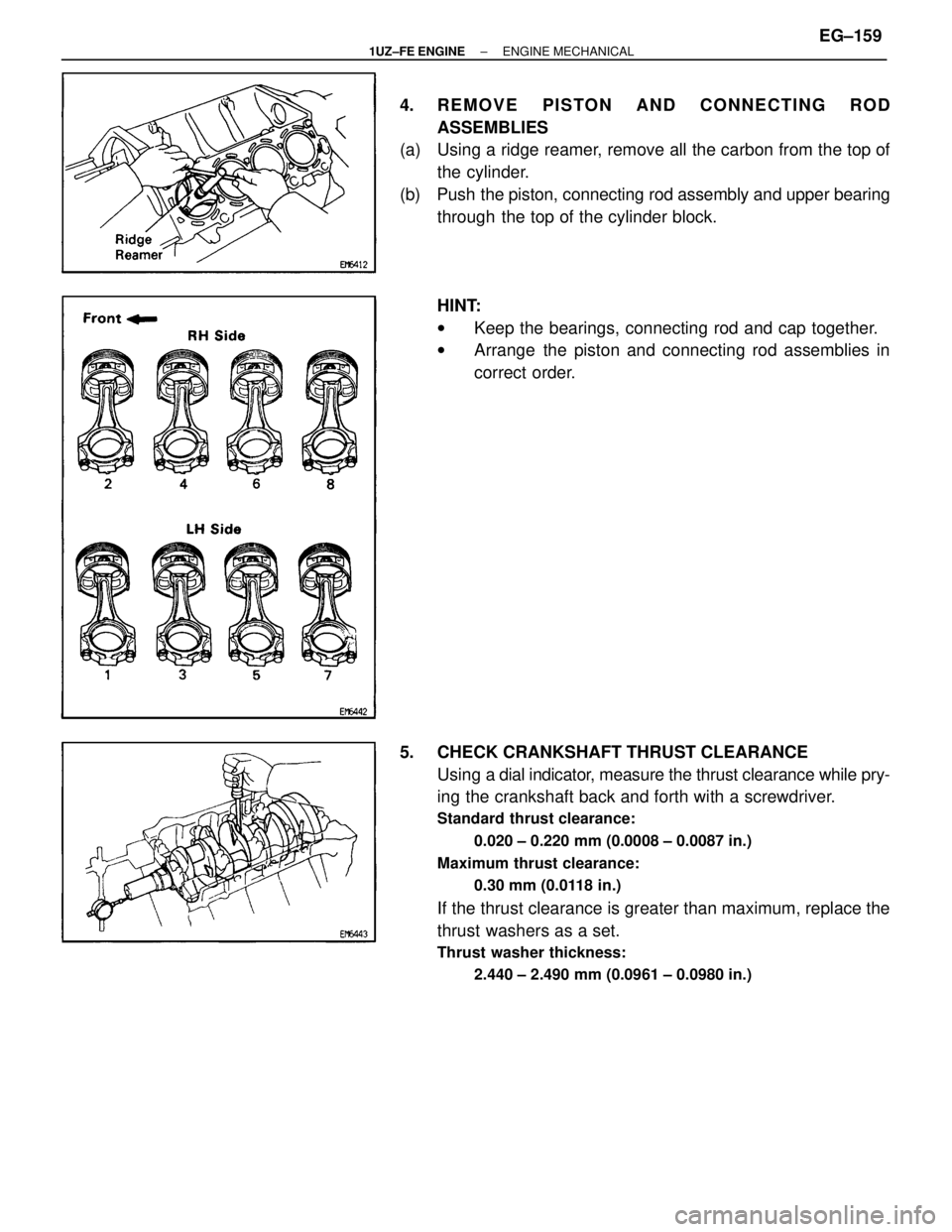

4. REMOVE PISTON AND CONNECTING RODASSEMBLIES

(a) Using a ridge reamer, remove all the carbon from the top of

the cylinder.

(b) Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block.

HINT:

wKeep the bearings, connecting rod and cap together.

w Arrange the piston and connecting rod assemblies in

correct order.

5. CHECK CRANKSHAFT THRUST CLEARANCE Using a dial indi cator, measure the thrust clearance while pry-

ing the crankshaft back and forth with a screwdriver.

Standard thrust clearance:

0.020 ± 0.220 mm (0.0008 ± 0.0087 in.)

Maximum thrust clearance: 0.30 mm (0.0118 in.)

If the thrust clearance is greater than maximum, replace the

thrust washers as a set.

Thrust washer thickness:2.440 ± 2.490 mm (0.0961 ± 0.0980 in.)

±

1UZ±FE ENGINE ENGINE MECHANICALEG±159

WhereEverybodyKnowsYourName

Page 1536 of 4087

6. REMOVE MAIN BEARING CAPS AND CHECK OILCLEARANCE

(a) Remove the 10 main bearing cap bolts.

(b) Uniformly loosen and remove the 20 main bearing cap nuts

in several passes, in the sequence shown.

(c) Using 2 screwdrivers, pry out the main bearing cap, and remove the 5 main bearing caps, lower bearings and lower

thrust washers (No.3 main bearing cap only).

NOTICE: Be careful not to damage the cylinder block.

HINT:

wKeep the lower bearing and main bearing cap together.

w Arrange the main bearing caps and lower thrust

washers in correct order.

(d) Lift out the crankshaft.

(e) Remove the 2 upper thrust washers. HINT:

wArrange the upper thrust washers in correct order.

w Keep the upper bearings together with the cylinder

block.

(f) Clean each main journal and bearing.

(g) Ch e ck ea ch ma in jo u rn a l an d be a rin g fo r pittin g an d scratches.

If the journal or bearing is damaged, replace the bearings. If

necessary, replace the crankshaft.

EG±160

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1538 of 4087

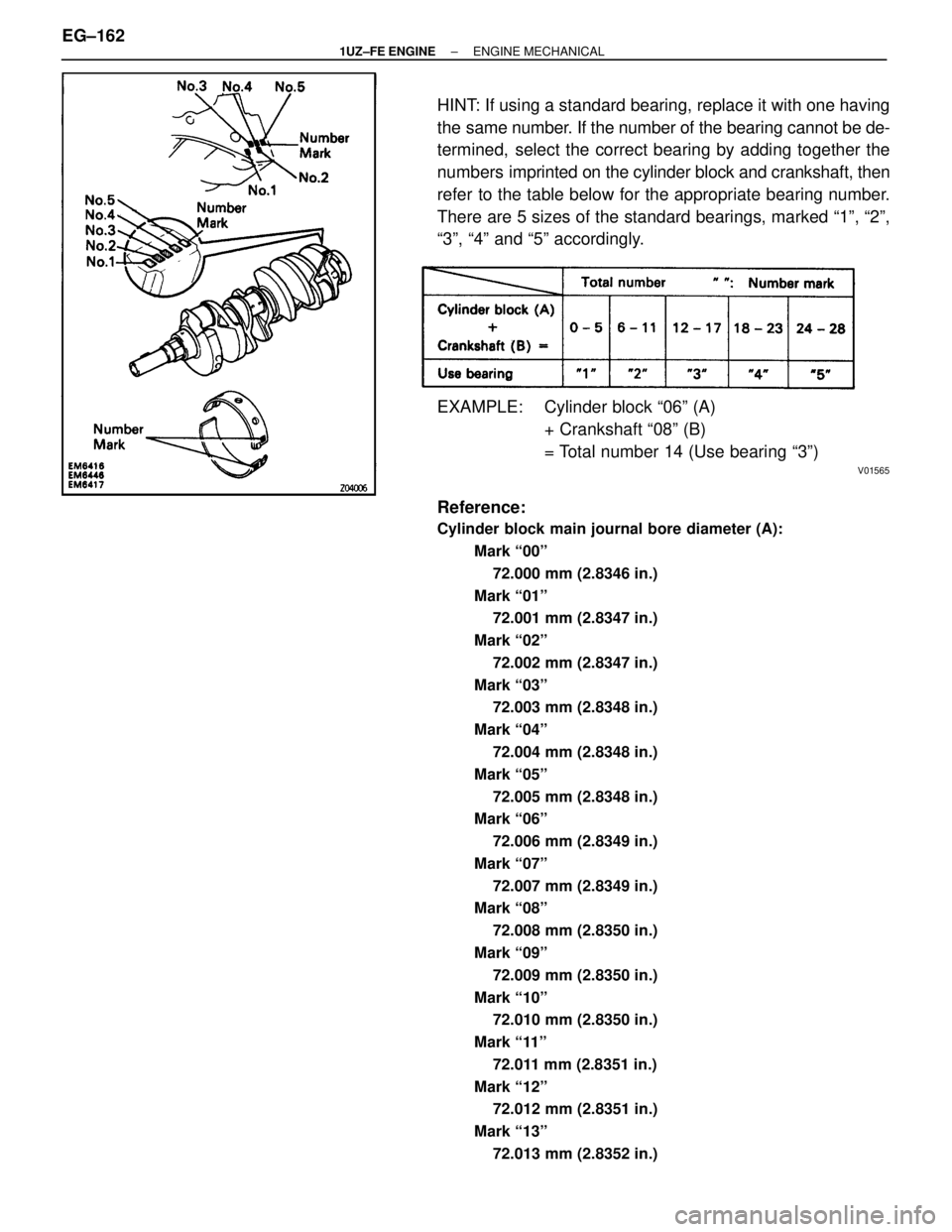

HINT: If using a standard bearing, replace it with one having

the same number. If the number of the bearing cannot be de-

termined, select the correct bearing by adding together the

numbers imprinted on the cylinder block and crankshaft, then

refer to the table below for the appropriate bearing number.

There are 5 sizes of the standard bearings, marked ª1º, ª2º,\

ª3º, ª4º and ª5º accordingly.

EXAMPLE: Cylinder block ª06º (A) + Crankshaft ª08º (B)

= Total number 14 (Use bearing ª3º)

V01565

Reference:

Cylinder block main journal bore diameter (A):

Mark ª00º72.000 mm (2.8346 in.)

Mark ª01º 72.001 mm (2.8347 in.)

Mark ª02º 72.002 mm (2.8347 in.)

Mark ª03º 72.003 mm (2.8348 in.)

Mark ª04º 72.004 mm (2.8348 in.)

Mark ª05º 72.005 mm (2.8348 in.)

Mark ª06º

72.006 mm (2.8349 in.)

Mark ª07º 72.007 mm (2.8349 in.)

Mark ª08º

72.008 mm (2.8350 in.)

Mark ª09º 72.009 mm (2.8350 in.)

Mark ª10º 72.010 mm (2.8350 in.)

Mark ª11º 72.011 mm (2.8351 in.)

Mark ª12º 72.012 mm (2.8351 in.)

Mark ª13º 72.013 mm (2.8352 in.)

EG±162±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName