lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1560 of 4087

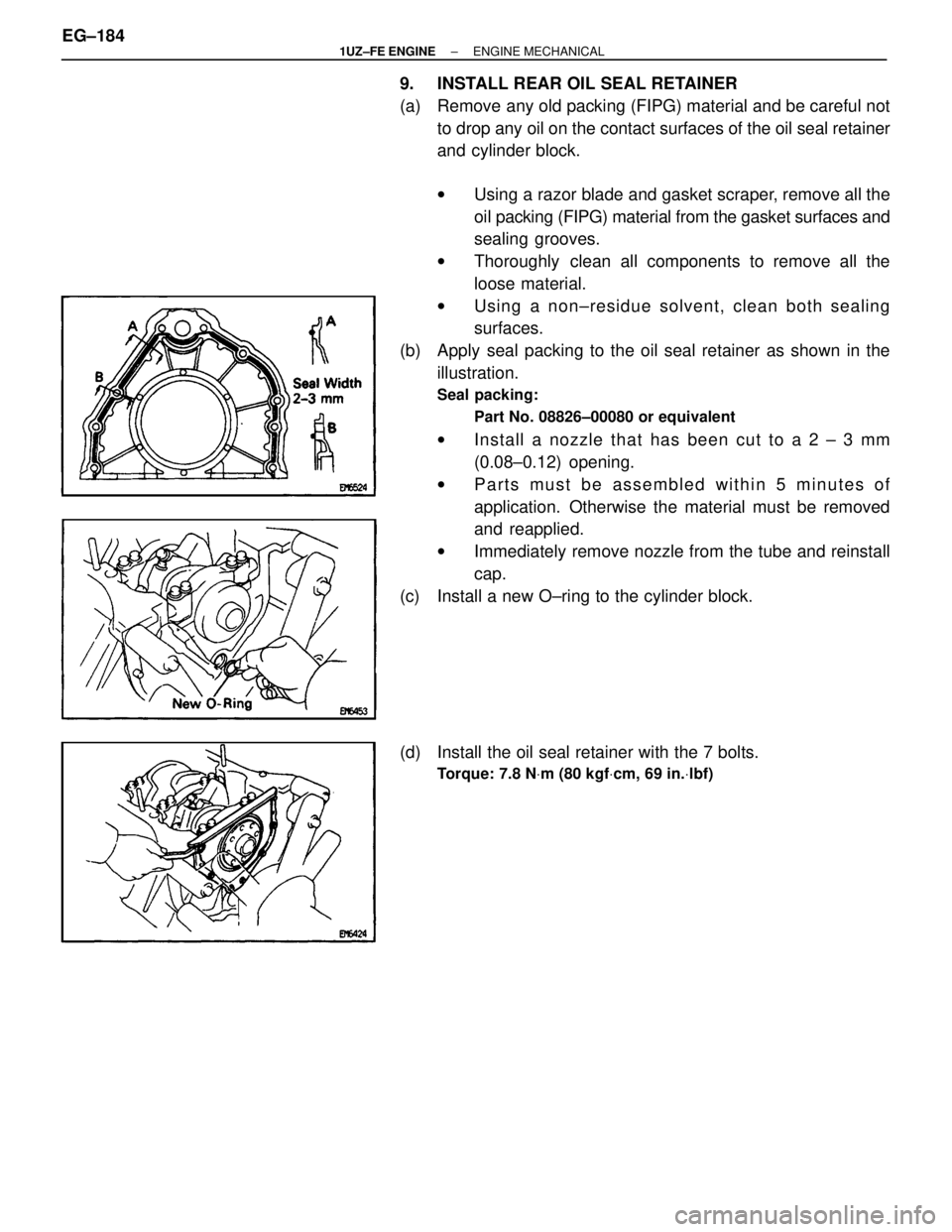

9. INSTALL REAR OIL SEAL RETAINER

(a) Remove any old packing (FIPG) material and be careful notto drop any oil on the contact surfaces of the oil seal retainer

and cylinder block.

wUsing a razor blade and gasket scraper, remove all the

oil packing (FIPG) material from the gasket surfaces and

sealing grooves.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the oil seal retainer as shown in the illustration.

Seal packing:

Part No. 08826±00080 or equivalent

wIn sta ll a no zzle th a t ha s be e n cu t to a 2 ± 3 mm

(0.08±0.12) opening.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be removed

and reapplied.

w Immediately remove nozzle from the tube and reinstall

cap.

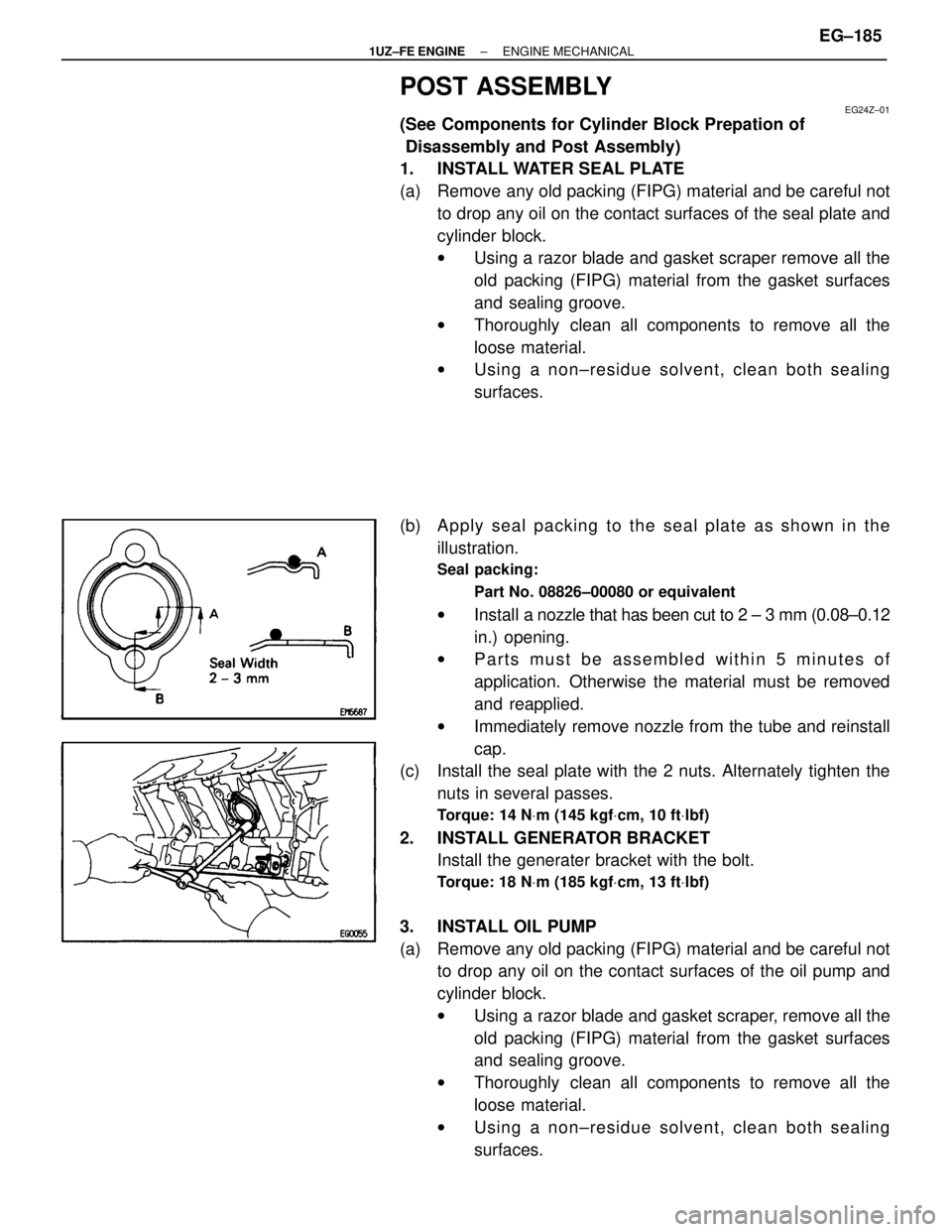

(c) Install a new O±ring to the cylinder block.

(d) Install the oil seal retainer with the 7 bolts.

Torque: 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

EG±184±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1561 of 4087

POST ASSEMBLY

EG24Z±01

(See Components for Cylinder Block Prepation of

Disassembly and Post Assembly)

1. INSTALL WATER SEAL PLATE

(a) Remove any old packing (FIPG) material and be careful notto drop any oil on the contact surfaces of the seal plate and

cylinder block.

wUsing a razor blade and gasket scraper remove all the

old packing (FIPG) material from the gasket surfaces

and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the seal plate as shown in the illustration.

Seal packing:

Part No. 08826±00080 or equivalent

wInstall a nozzle that has been cut to 2 ± 3 mm (0.08±0.12

in.) opening.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be removed

and reapplied.

w Immediately remove nozzle from the tube and reinstall

cap.

(c) Install the seal plate with the 2 nuts. Alternately tighten the

nuts in several passes.

Torque: 14 N Vm (145 kgf Vcm, 10 ft Vlbf)

2. INSTALL GENERATOR BRACKET

Install the generater bracket with the bolt.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

3. INSTALL OIL PUMP

(a) Remove any old packing (FIPG) material and be careful not

to drop any oil on the contact surfaces of the oil pump and

cylinder block.

wUsing a razor blade and gasket scraper, remove all the

old packing (FIPG) material from the gasket surfaces

and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±185

WhereEverybodyKnowsYourName

Page 1562 of 4087

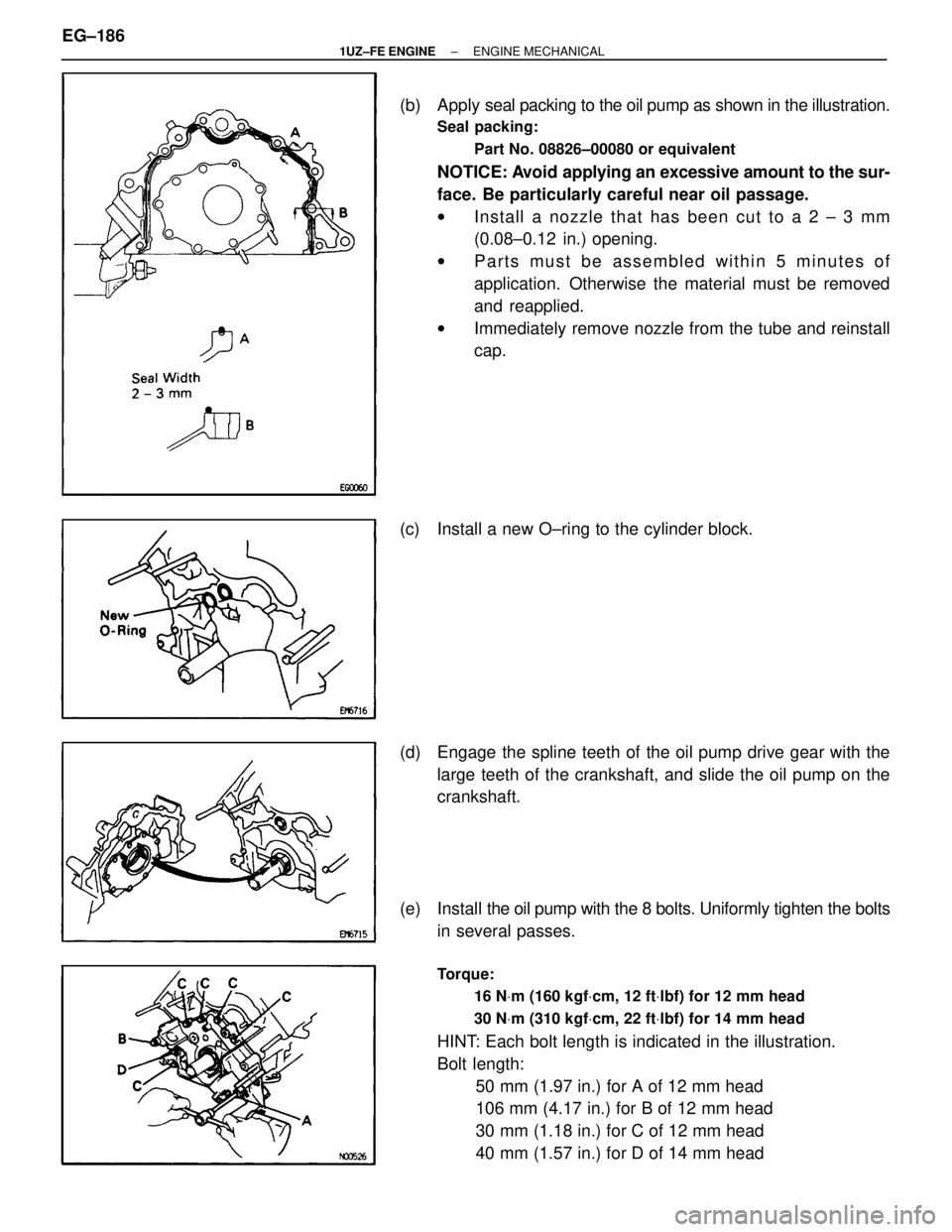

(b) Apply seal packing to the oil pump as shown in the illustration.

Seal packing:

Part No. 08826±00080 or equivalent

NOTICE: Avoid applying an excessive amount to the sur-

face. Be particularly careful near oil passage.

w In sta ll a no zzle th a t ha s be e n cu t to a 2 ± 3 mm

(0.08±0.12 in.) opening.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be removed

and reapplied.

w Immediately remove nozzle from the tube and reinstall

cap.

(c) Install a new O±ring to the cylinder block.

(d) Engage the spline teeth of the oil pump drive gear with the large teeth of the crankshaft, and slide the oil pump on the

crankshaft.

(e) Install the oil pump with the 8 bolts. Uniformly tighten the bolts

in several passes.

Torque:

16 NVm (160 kgf Vcm, 12 ft Vlbf) for 12 mm head

30 N Vm (310 kgf Vcm, 22 ft Vlbf) for 14 mm head

HINT: Each bolt length is indicated in the illustration.

Bolt length:

50 mm (1.97 in.) for A of 12 mm head

106 mm (4.17 in.) for B of 12 mm head

30 mm (1.18 in.) for C of 12 mm head

40 mm (1.57 in.) for D of 14 mm head

EG±186

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1563 of 4087

4. INSTALL NO.1 AND NO.2 OIL PANS(See steps 1 to 7 on pages EG±509 to 511)

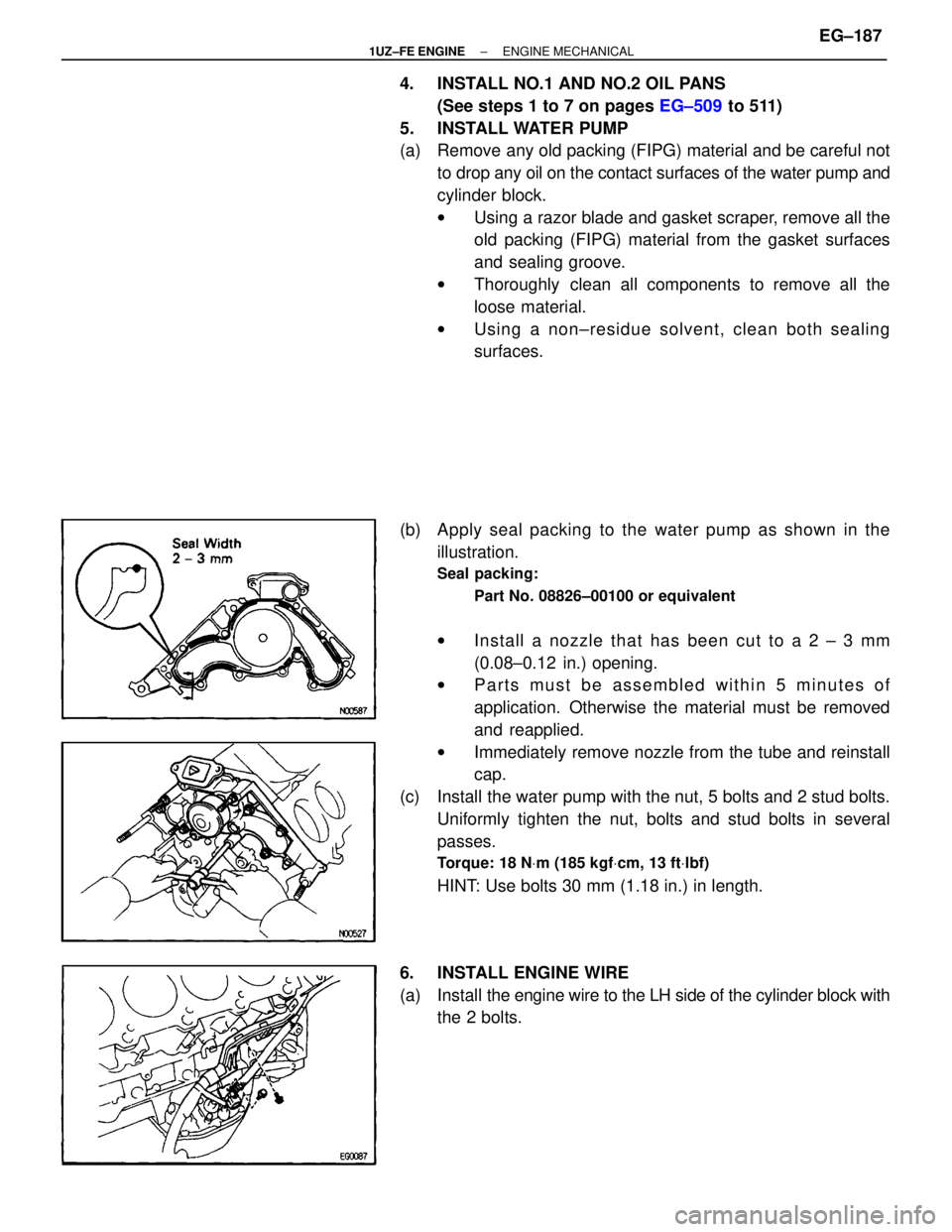

5. INSTALL WATER PUMP

(a) Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the water pump and

cylinder block.

wUsing a razor blade and gasket scraper, remove all the

old packing (FIPG) material from the gasket surfaces

and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

(b) Apply seal packing to the water pump as shown in the illustration.

Seal packing:

Part No. 08826±00100 or equivalent

wIn sta ll a no zzle th a t ha s be e n cu t to a 2 ± 3 mm

(0.08±0.12 in.) opening.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be removed

and reapplied.

w Immediately remove nozzle from the tube and reinstall

cap.

(c) Install the water pump with the nut, 5 bolts and 2 stud bolts. Uniformly tighten the nut, bolts and stud bolts in several

passes.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 30 mm (1.18 in.) in length.

6. INSTALL ENGINE WIRE

(a) Install the engine wire to the LH side of the cylinder block with

the 2 bolts.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±187

WhereEverybodyKnowsYourName

Page 1570 of 4087

7. INSTALL TAILPIPE

(a) Install the hook of the tailpipe to the ring on the tailpipebracket.

(b) Install a new gasket and tailpipe to the center exhaust pipe with 2 bolts. Install the 2 tailpipes.

Torque: 19 N Vm (195 kgf Vcm, 14 ft Vlbf)

8. INSTALL TWC (FRONT)

Using a 14 mm deep socket wrench, install a new gasket and

the TWC with 3 new nuts. Install the 2 TWC.

Torque: 62 N Vm (630 kgf Vcm, 46 ft Vlbf)

9. INSTALL FRONT EXHAUST PIPE

(a) Temporarily install the pipe support bracket with the 4 bolts.

(b) Temporarily install 3 new gaskets and the exhaust pipe with

the 6 bolts and nuts.

(c) Tighten the 4 bolts and nuts holding the TWC to the front exhaust pipe.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(d) Tighten the 2 bolts and nuts holding the front exhaust pipe to

the center exhaust pipe.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(e) Tighten the 4 bolts holding the pipe support bracket to the

transmission.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

10. INSTALL SUB HEATED OXYGEN SENSORS

Install the 2 oxygen sensors to the front exhaust pipe.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

HINT:

w Before installing the oxygen sensor, twist the sensor

wire counterclockwise 3 1/2 turns.

w After installing the oxygen sensor, check that the sensor

wire is not twisted. If it is twisted, remove the oxygen

sensor and reinstall it.

EG±194

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1578 of 4087

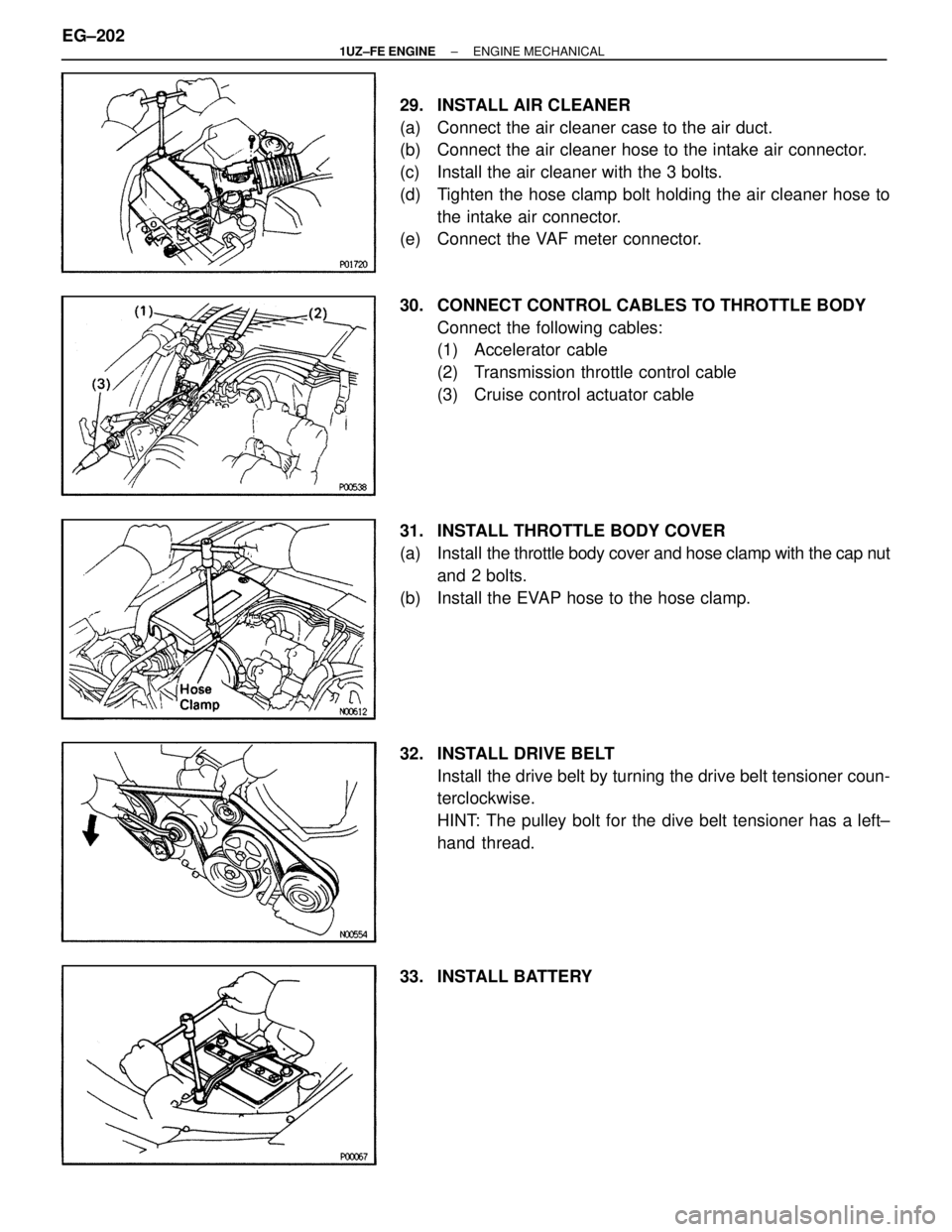

29. INSTALL AIR CLEANER

(a) Connect the air cleaner case to the air duct.

(b) Connect the air cleaner hose to the intake air connector.

(c) Install the air cleaner with the 3 bolts.

(d) Tighten the hose clamp bolt holding the air cleaner hose tothe intake air connector.

(e) Connect the VAF meter connector.

30. CONNECT CONTROL CABLES TO THROTTLE BODY

Connect the following cables:

(1) Accelerator cable

(2) Transmission throttle control cable

(3) Cruise control actuator cable

31. INSTALL THROTTLE BODY COVER

(a) Install the thro ttle body cover and hose clamp with the cap nut

and 2 bolts.

(b) Install the EVAP hose to the hose clamp.

32. INSTALL DRIVE BELT Install the drive belt by turning the drive belt tensioner coun-

terclockwise.

HINT: The pulley bolt for the dive belt tensioner has a left±

hand thread.

33. INSTALL BATTERY

EG±202

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1581 of 4087

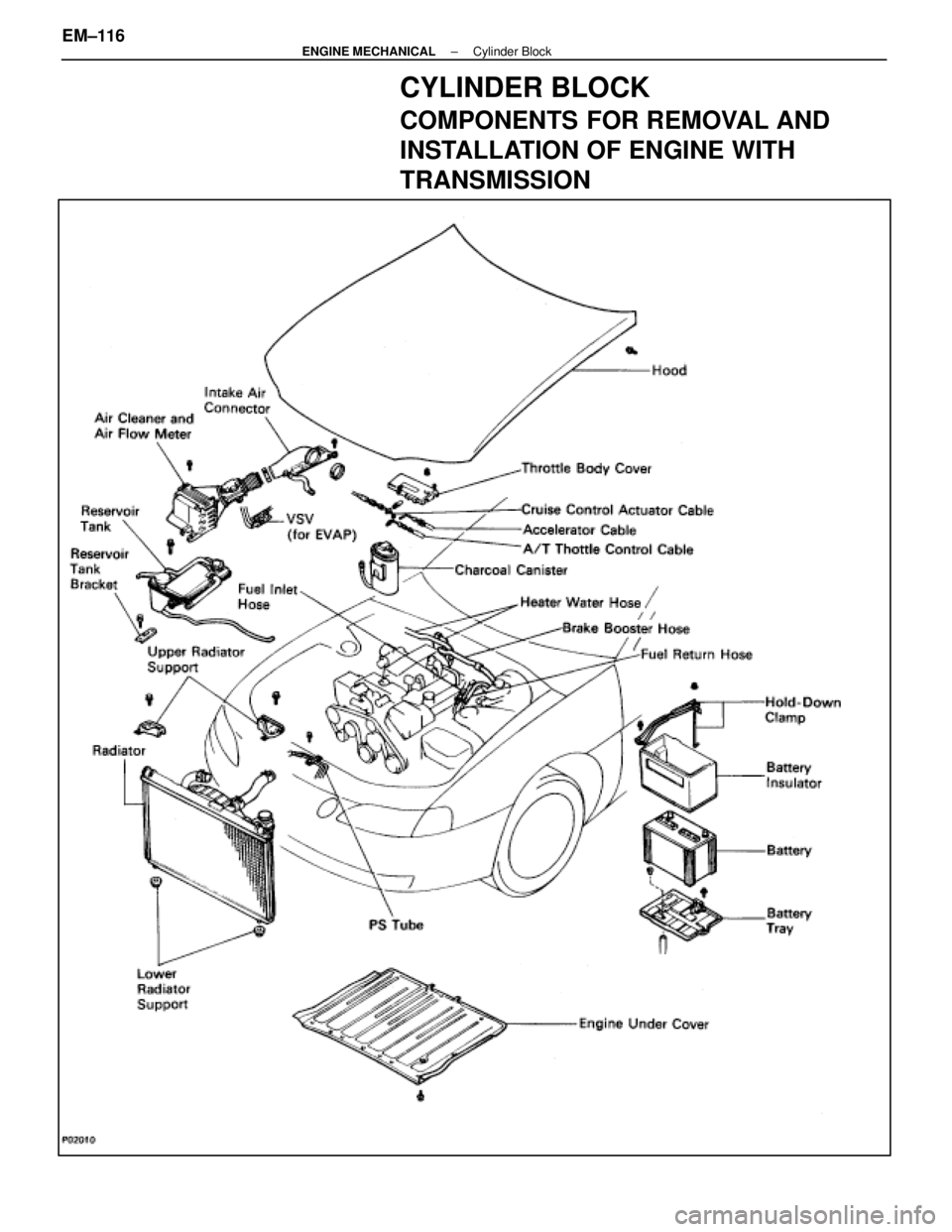

CYLINDER BLOCK

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION

EM±116±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1582 of 4087

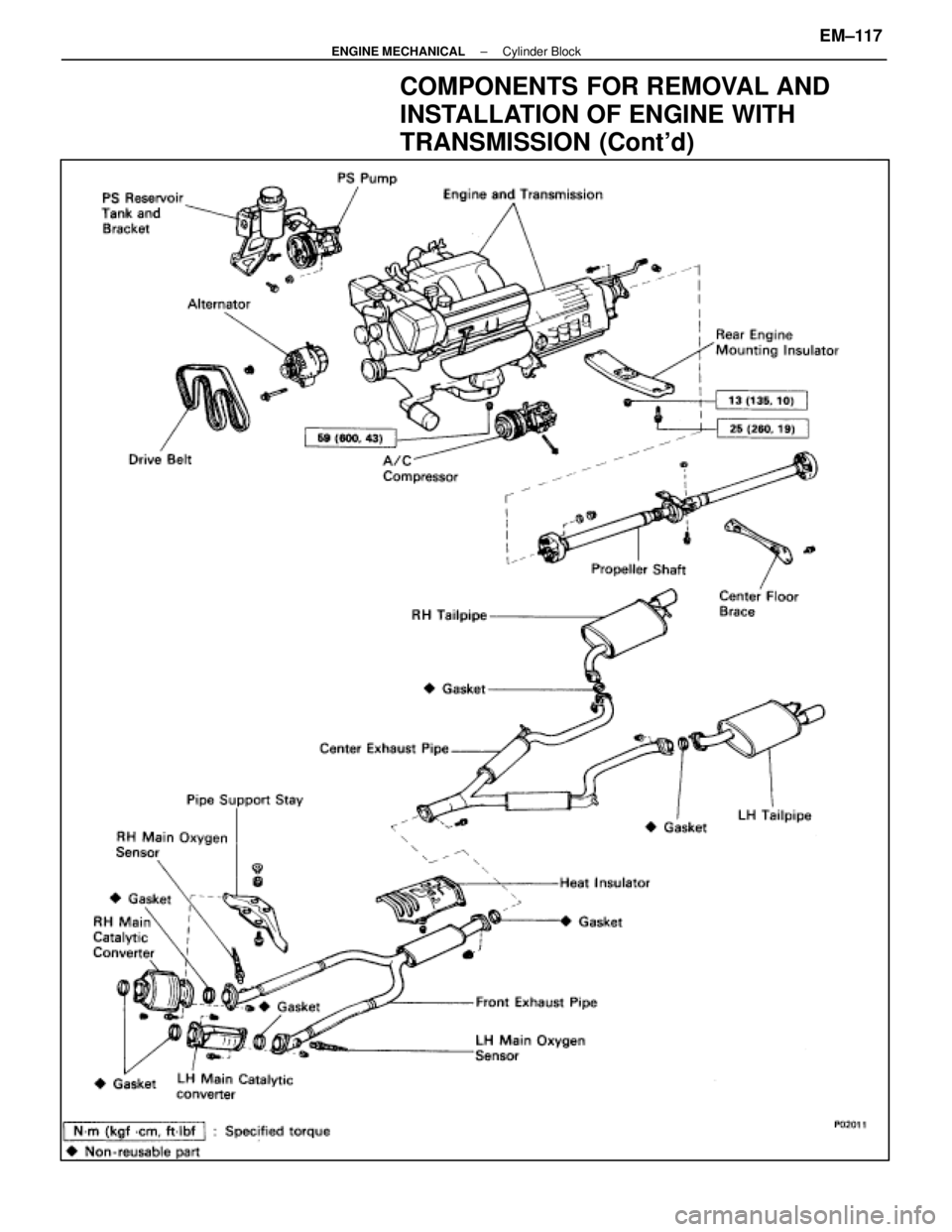

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

±

ENGINE MECHANICAL Cylinder BlockEM±117

WhereEverybodyKnowsYourName

Page 1583 of 4087

COMPONENTS FOR REMOVAL AND

INSTALLATION OF ENGINE WITH

TRANSMISSION (Cont'd)

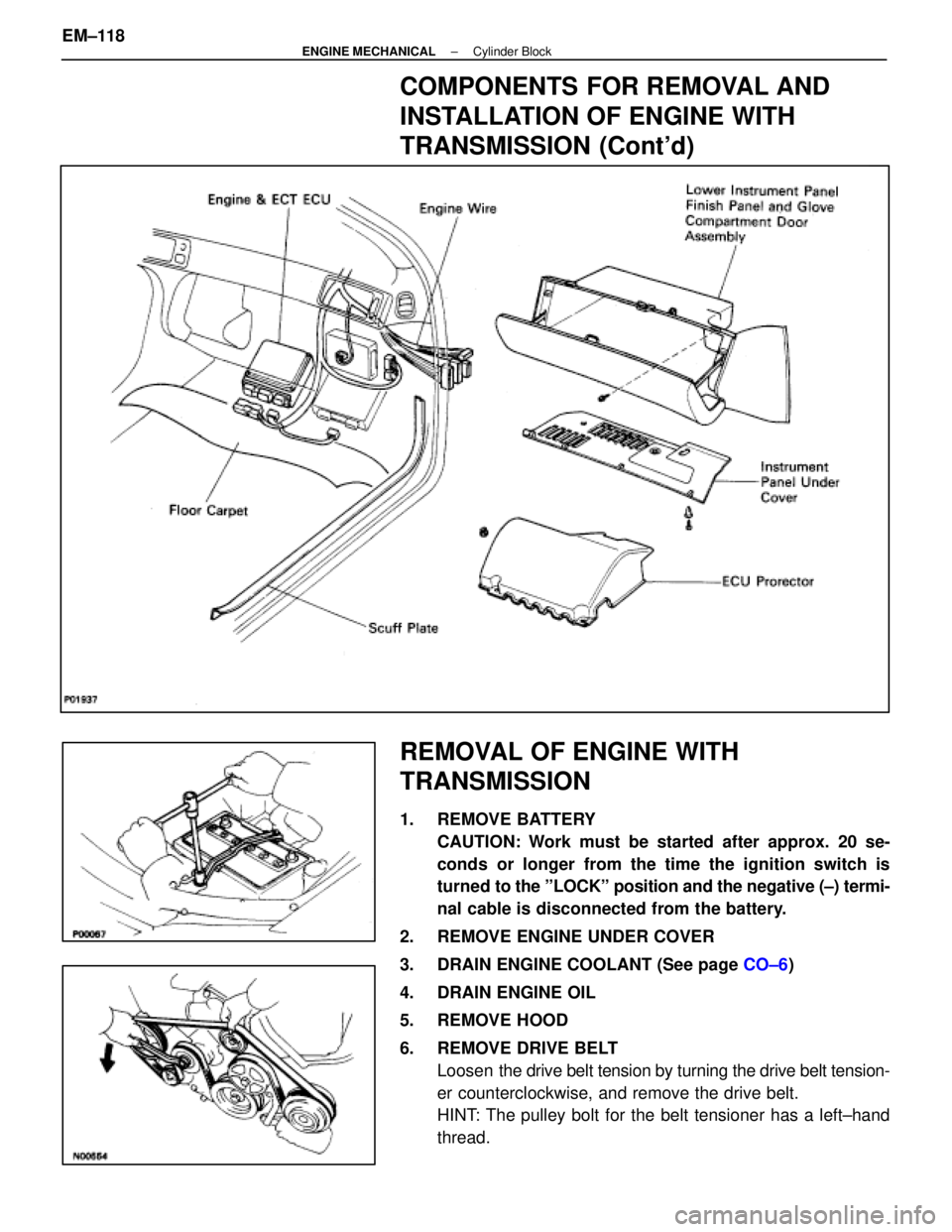

REMOVAL OF ENGINE WITH

TRANSMISSION

1. REMOVE BATTERYCAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE ENGINE UNDER COVER

3. DRAIN ENGINE COOLANT (See page CO±6)

4. DRAIN ENGINE OIL

5. REMOVE HOOD

6. REMOVE DRIVE BELT Loosen the drive belt tension by turning the drive belt tension-

er counterclockwise, and remove the drive belt.

HINT: The pulley bolt for the belt tensioner has a left±hand

thread.

EM±118

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1584 of 4087

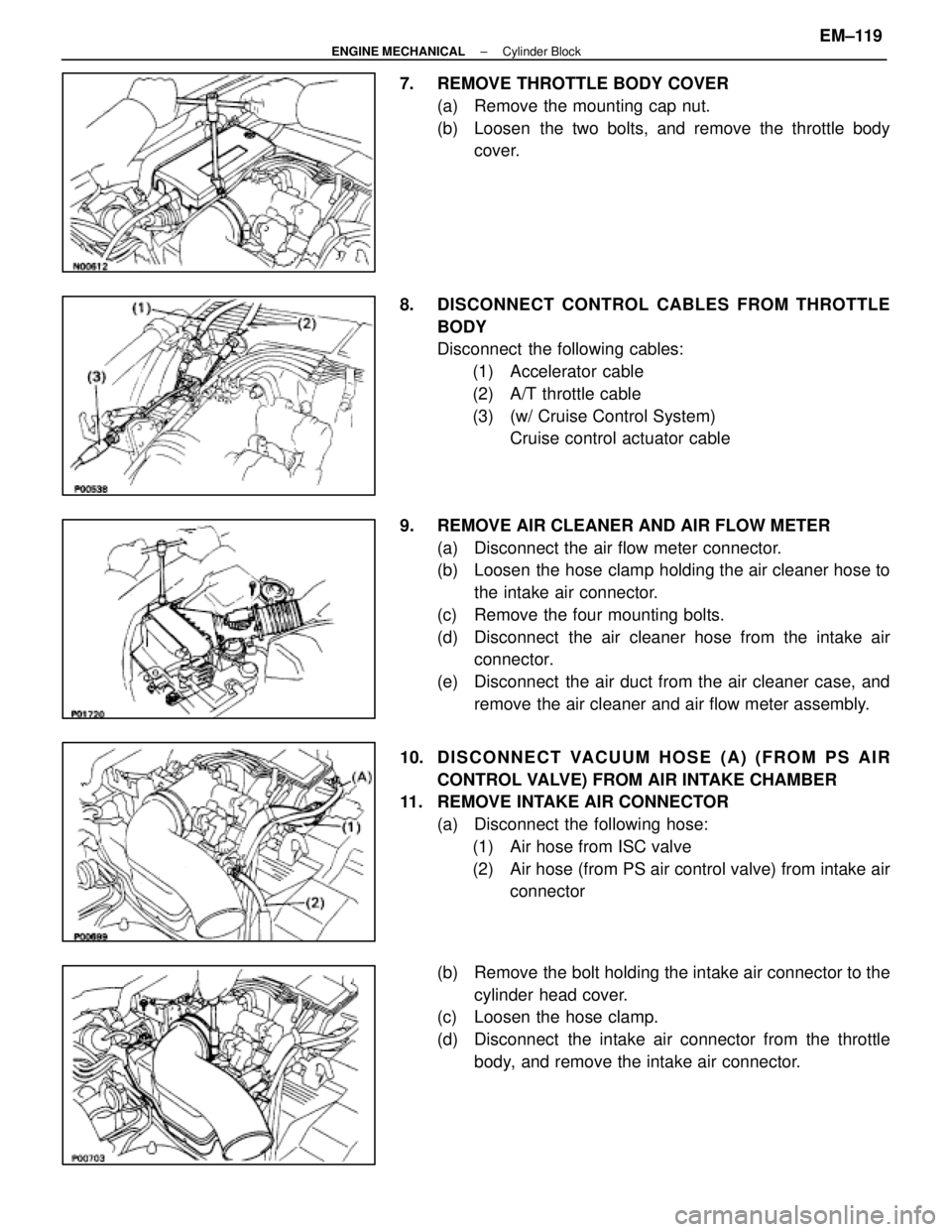

7. REMOVE THROTTLE BODY COVER(a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle bodycover.

8. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle cable

(3) (w/ Cruise Control System) Cruise control actuator cable

9. REMOVE AIR CLEANER AND AIR FLOW METER (a) Disconnect the air flow meter connector.

(b) Loosen the hose clamp holding the air cleaner hose tothe intake air connector.

(c) Remove the four mounting bolts.

(d) Disconnect the air cleaner hose from the intake air connector.

(e) Disconnect the air duct from the air cleaner case, and remove the air cleaner and air flow meter assembly.

10. D I S C O N N E C T VA CUUM HOSE (A) (FROM PS AIR

CONTROL VALVE) FROM AIR INTAKE CHAMBER

11. REMOVE INTAKE AIR CONNECTOR

(a) Disconnect the following hose:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the hose clamp.

(d) Disconnect the intake air connector from the throttle

body, and remove the intake air connector.

±

ENGINE MECHANICAL Cylinder BlockEM±119

WhereEverybodyKnowsYourName