lock LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2131 of 4087

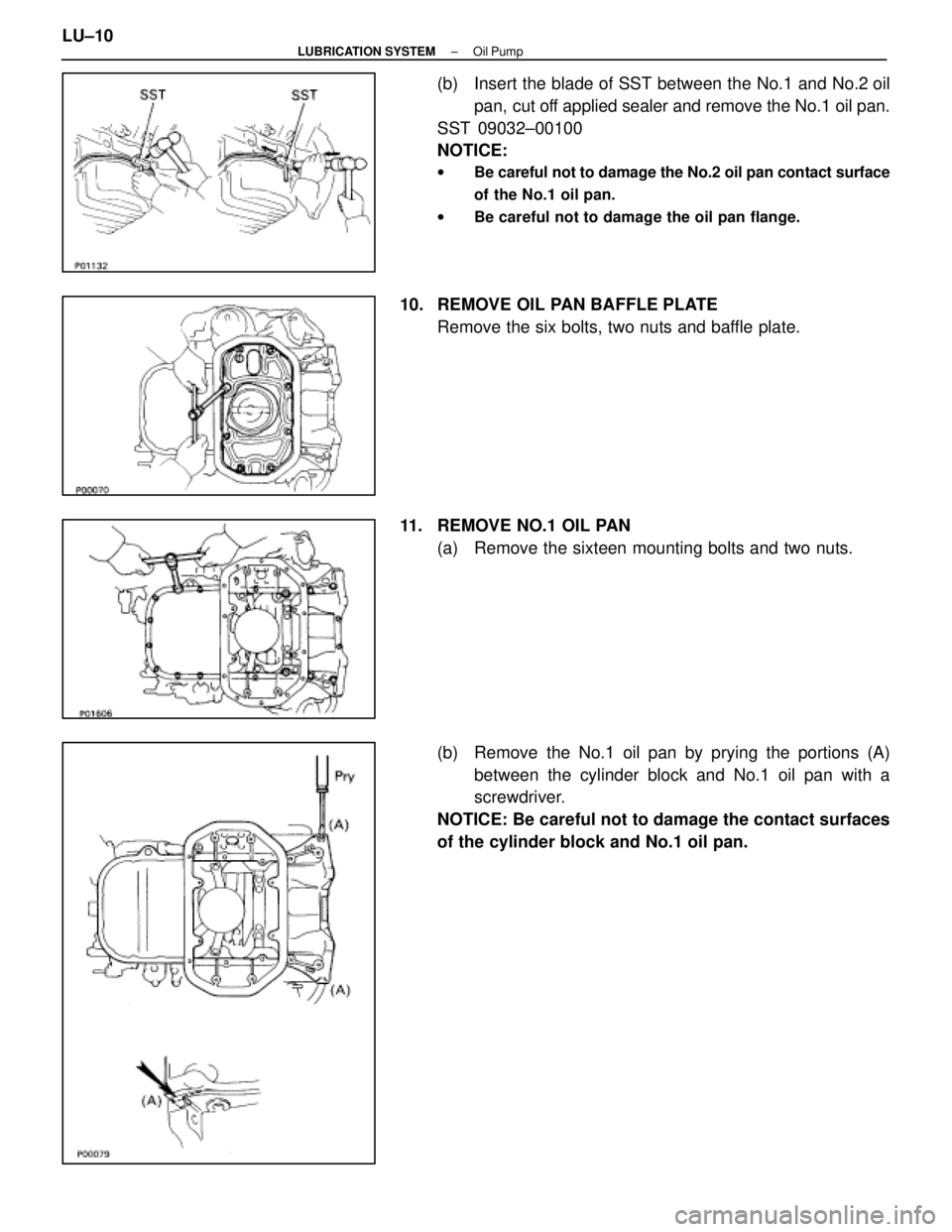

(b) Insert the blade of SST between the No.1 and No.2 oilpan, cut off applied sealer and remove the No.1 oil pan.

SST 09032±00100

NOTICE:

w Be careful not to damage the No.2 oil pan contact surface

of the No.1 oil pan.

w Be careful not to damage the oil pan flange.

10. REMOVE OIL PAN BAFFLE PLATE

Remove the six bolts, two nuts and baffle plate.

11. REMOVE NO.1 OIL PAN (a) Remove the sixteen mounting bolts and two nuts.

(b) Remove the No.1 oil pan by prying the portions (A)between the cylinder block and No.1 oil pan with a

screwdriver.

NOTICE: Be careful not to damage the contact surfaces

of the cylinder block and No.1 oil pan.

LU±10

±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2132 of 4087

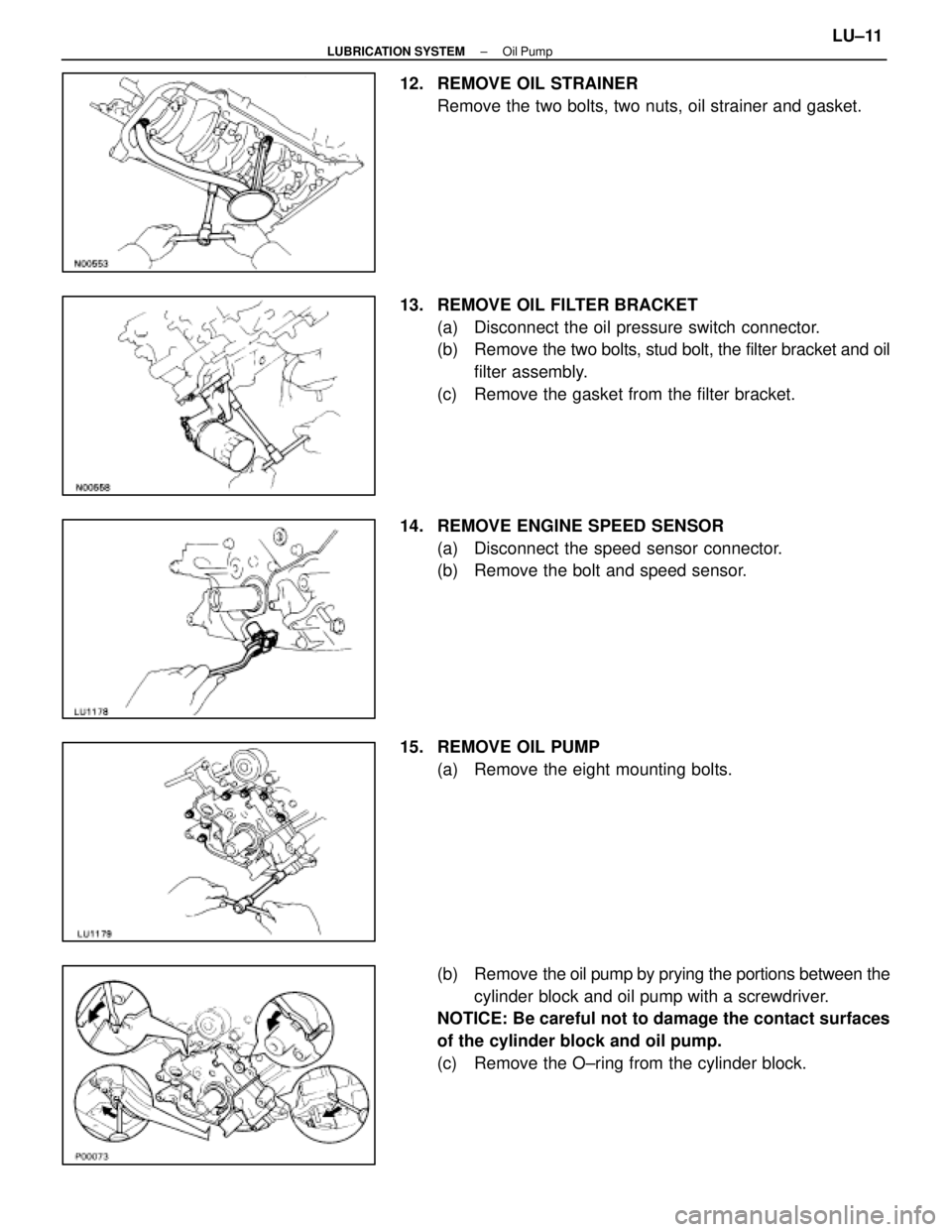

12. REMOVE OIL STRAINERRemove the two bolts, two nuts, oil strainer and gasket.

13. REMOVE OIL FILTER BRACKET (a) Disconnect the oil pressure switch connector.

(b) Remove the two bo lts, stud bolt, the filter bracket and oil

filter assembly.

(c) Remove the gasket from the filter bracket.

14. REMOVE ENGINE SPEED SENSOR (a) Disconnect the speed sensor connector.

(b) Remove the bolt and speed sensor.

15. REMOVE OIL PUMP (a) Remove the eight mounting bolts.

(b) Remove the oil pump by prying the portions between the

cylinder block and oil pump with a screwdriver.

NOTICE: Be careful not to damage the contact surfaces

of the cylinder block and oil pump.

(c) Remove the O±ring from the cylinder block.

±

LUBRICATION SYSTEM Oil PumpLU±11

WhereEverybodyKnowsYourName

Page 2136 of 4087

INSTALLATION OF OIL PUMP

(See Components on page LU±8)

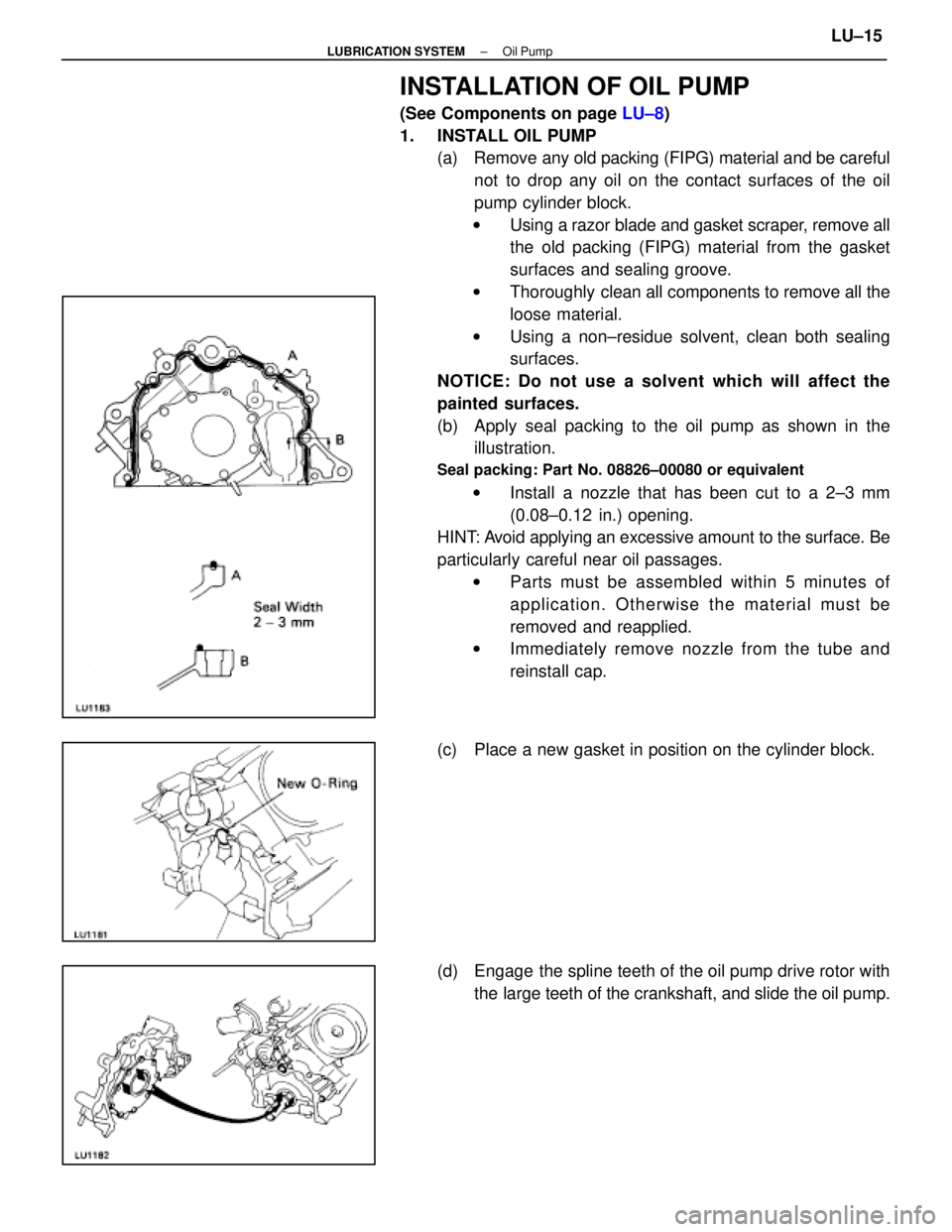

1. INSTALL OIL PUMP (a) Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the oil

pump cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(b) Apply seal packing to the oil pump as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. Be

particularly careful near oil passages.

w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Place a new gasket in position on the cylinder block.

(d) Engage the spline teeth of the oil pump drive rotor with the large teeth of the crankshaft, and slide the oil pump.

±

LUBRICATION SYSTEM Oil PumpLU±15

WhereEverybodyKnowsYourName

Page 2138 of 4087

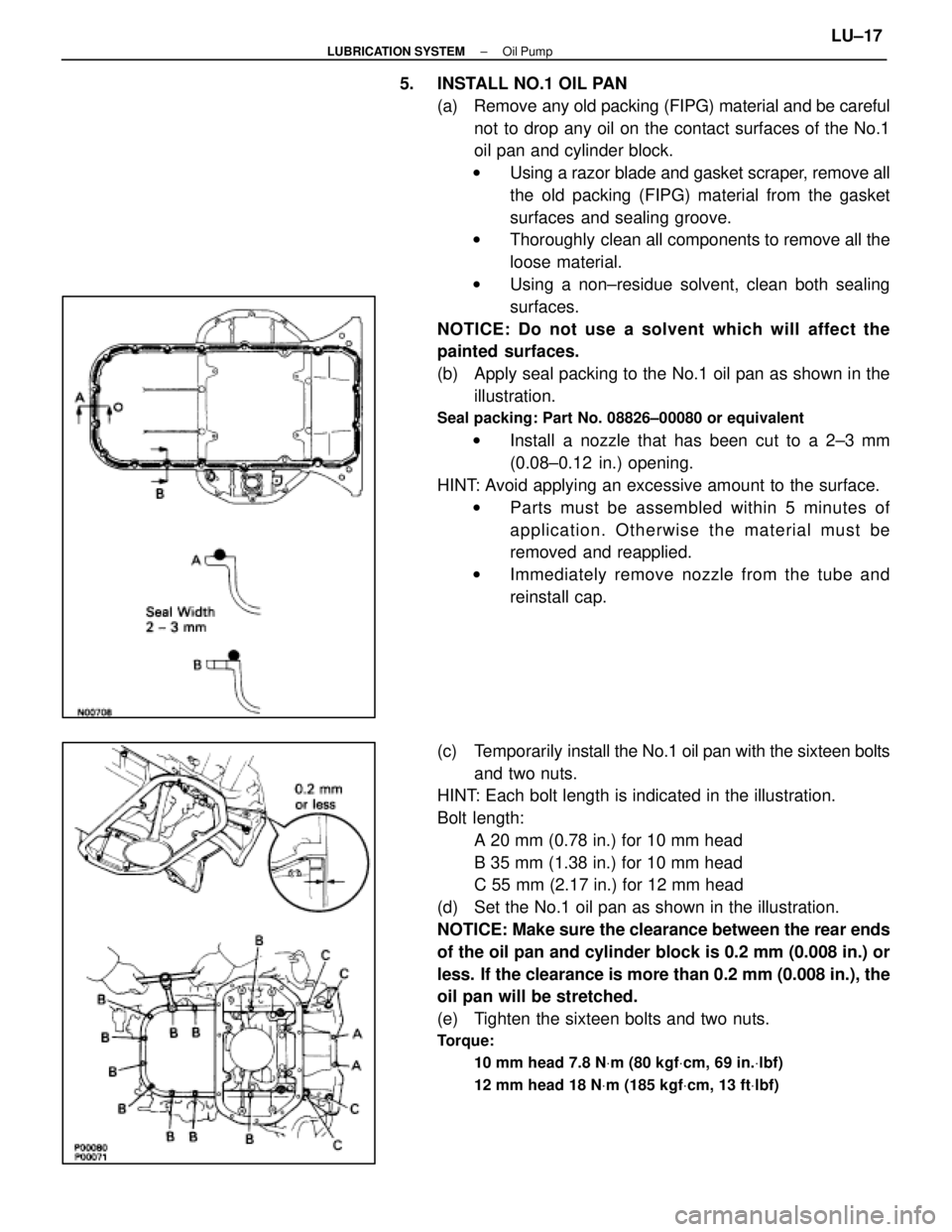

5. INSTALL NO.1 OIL PAN(a) Remove any old packing (FIPG) material and be carefulnot to drop any oil on the contact surfaces of the No.1

oil pan and cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

loose material.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(b) Apply seal packing to the No.1 oil pan as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(c) Temporarily install the No.1 oil pan with the sixteen bolts

and two nuts.

HINT: Each bolt length is indicated in the illustration.

Bolt length:

A 20 mm (0.78 in.) for 10 mm head

B 35 mm (1.38 in.) for 10 mm head

C 55 mm (2.17 in.) for 12 mm head

(d) Set the No.1 oil pan as shown in the illustration.

NOTICE: Make sure the clearance between the rear ends

of the oil pan and cylinder block is 0.2 mm (0.008 in.) or

less. If the clearance is more than 0.2 mm (0.008 in.), the

oil pan will be stretched.

(e) Tighten the sixteen bolts and two nuts.

Torque:

10 mm head 7.8 N Vm (80 kgf Vcm, 69 in. Vlbf)

12 mm head 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

±

LUBRICATION SYSTEM Oil PumpLU±17

WhereEverybodyKnowsYourName

Page 2143 of 4087

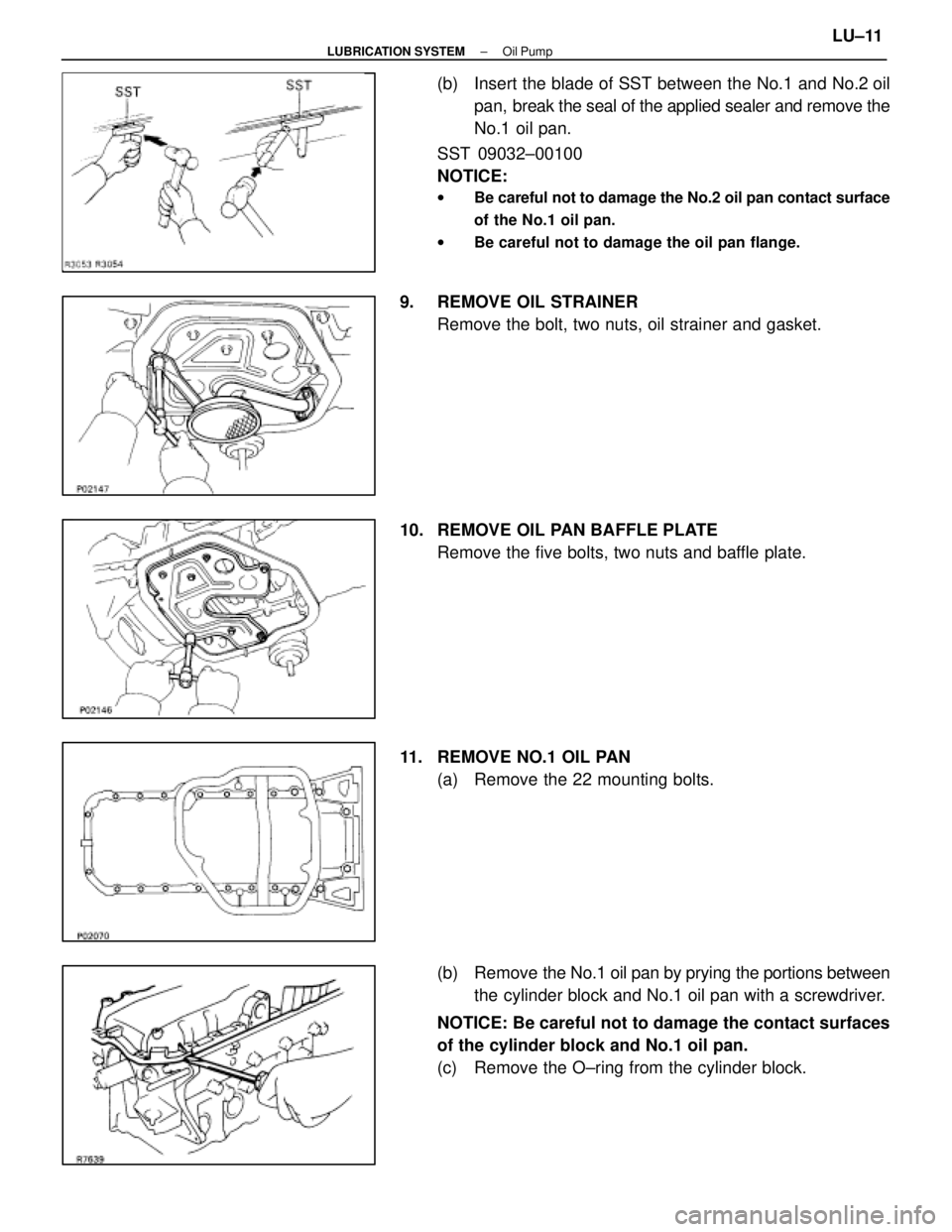

(b) Insert the blade of SST between the No.1 and No.2 oilpan, break the seal of the applied sealer and remove the

No.1 oil pan.

SST 09032±00100

NOTICE:

w Be careful not to damage the No.2 oil pan contact surface

of the No.1 oil pan.

w Be careful not to damage the oil pan flange.

9. REMOVE OIL STRAINER

Remove the bolt, two nuts, oil strainer and gasket.

10. REMOVE OIL PAN BAFFLE PLATE Remove the five bolts, two nuts and baffle plate.

11. REMOVE NO.1 OIL PAN (a) Remove the 22 mounting bolts.

(b) Remove the No.1 oil pan by prying the portions between

the cylinder block and No.1 oil pan with a screwdriver.

NOTICE: Be careful not to damage the contact surfaces

of the cylinder block and No.1 oil pan.

(c) Remove the O±ring from the cylinder block.

±

LUBRICATION SYSTEM Oil PumpLU±11

WhereEverybodyKnowsYourName

Page 2144 of 4087

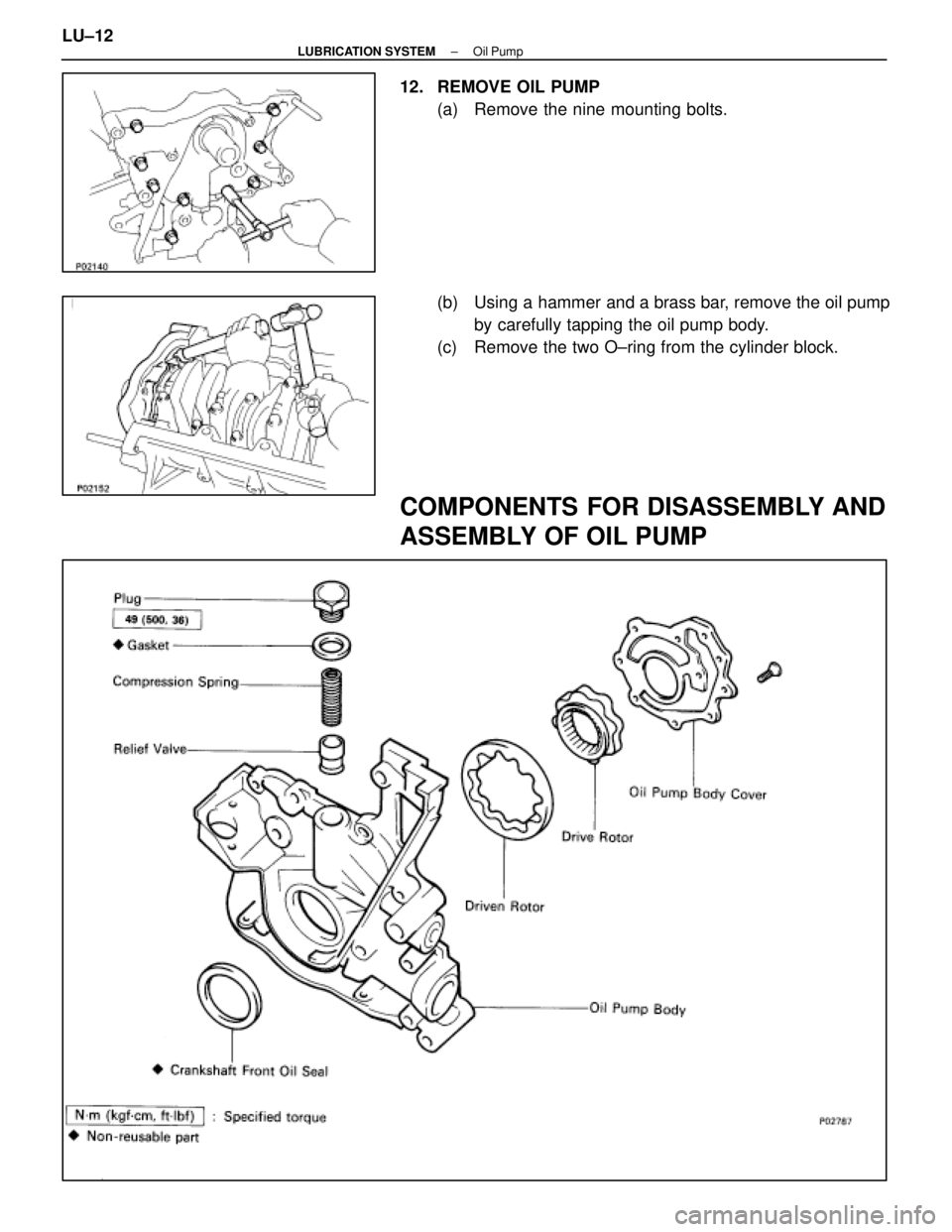

12. REMOVE OIL PUMP(a) Remove the nine mounting bolts.

(b) Using a hammer and a brass bar, remove the oil pumpby carefully tapping the oil pump body.

(c) Remove the two O±ring from the cylinder block.

COMPONENTS FOR DISASSEMBLY AND

ASSEMBLY OF OIL PUMP

LU±12±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2147 of 4087

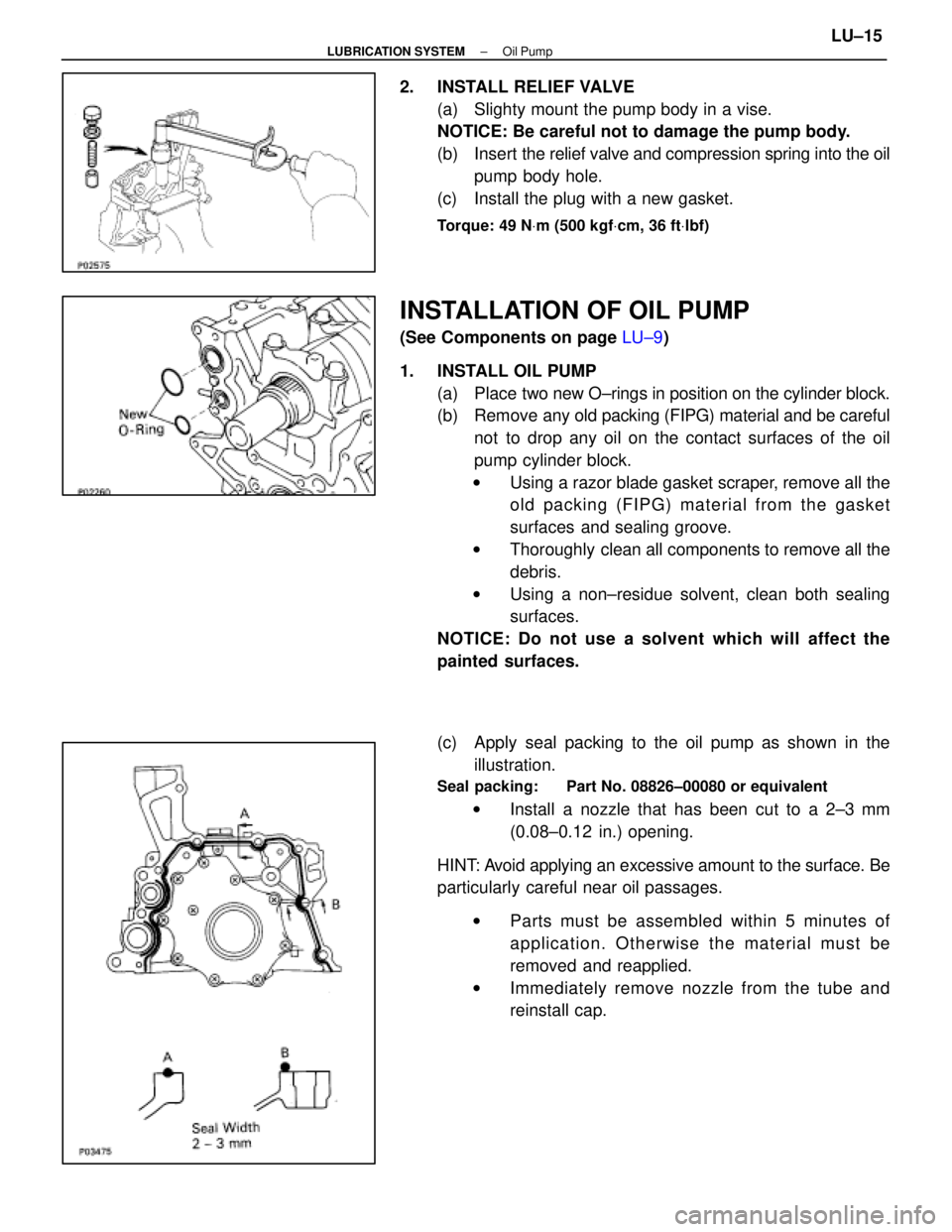

2. INSTALL RELIEF VALVE(a) Slighty mount the pump body in a vise.

NOTICE: Be careful not to damage the pump body.

(b) Insert the relief valve and compression spring into the oil

pump body hole.

(c) Install the plug with a new gasket.

Torque: 49 N Vm (500 kgf Vcm, 36 ft Vlbf)

INSTALLATION OF OIL PUMP

(See Components on page LU±9)

1. INSTALL OIL PUMP (a) Place two new O±rings in position on the cylinder block.

(b) Remove any old packing (FIPG) material and be careful

not to drop any oil on the contact surfaces of the oil

pump cylinder block.

w Using a razor blade gasket scraper, remove all the

old packing (FIPG) material from the gasket

surfaces and sealing groove.

w Thoroughly clean all components to remove all the

debris.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(c) Apply seal packing to the oil pump as shown in the illustration.

Seal packing: Part No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 2±3 mm

(0.08±0.12 in.) opening.

HINT: Avoid applying an excessive amount to the surface. Be

particularly careful near oil passages. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

±

LUBRICATION SYSTEM Oil PumpLU±15

WhereEverybodyKnowsYourName

Page 2148 of 4087

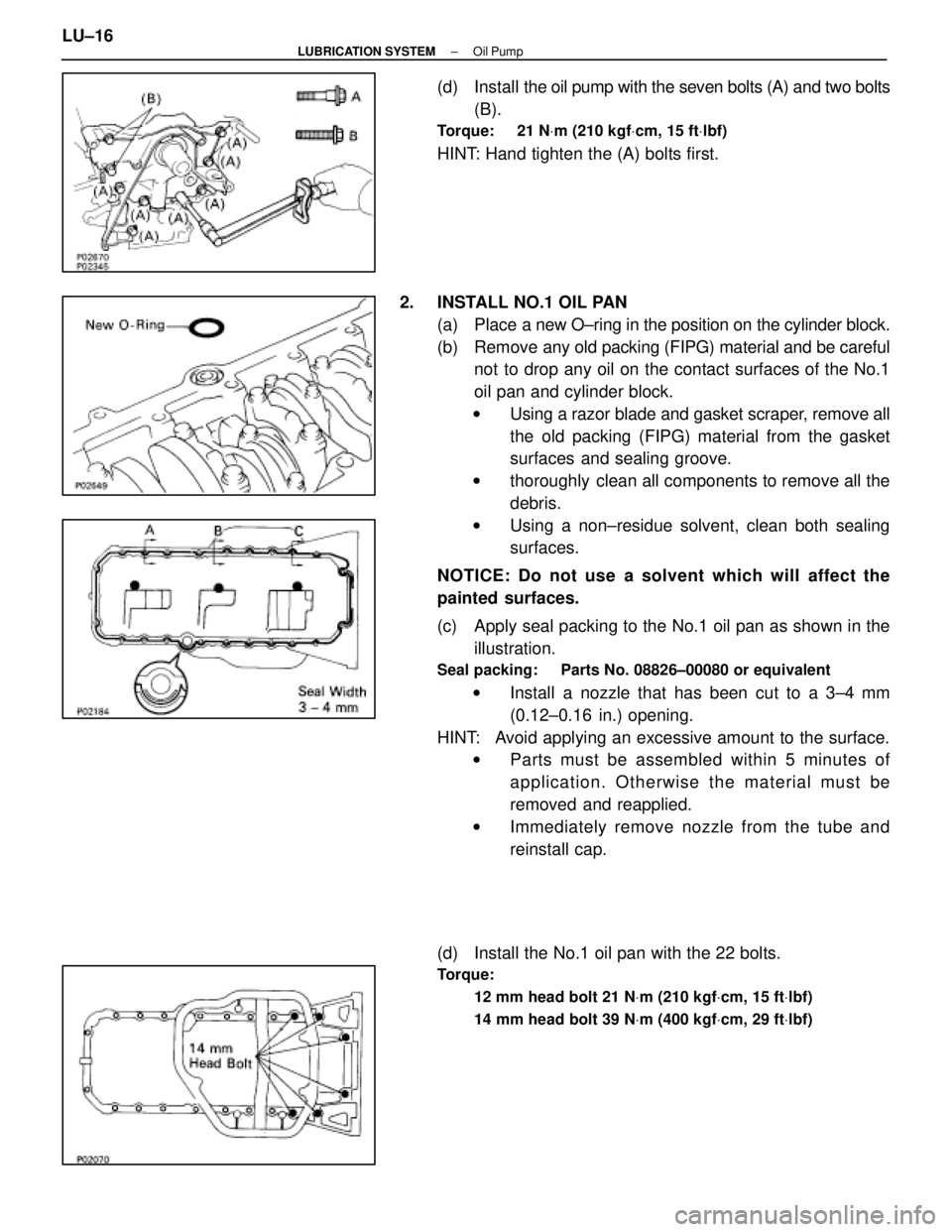

(d) Install the oil pump with the seven bolts (A) and two bolts

(B).

Torque: 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

HINT: Hand tighten the (A) bolts first.

2. INSTALL NO.1 OIL PAN (a) Place a new O±ring in the position on the cylinder block.

(b) Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the No.1

oil pan and cylinder block.

w Using a razor blade and gasket scraper, remove all

the old packing (FIPG) material from the gasket

surfaces and sealing groove.

w thoroughly clean all components to remove all the

debris.

w Using a non±residue solvent, clean both sealing

surfaces.

NOTICE: Do not use a solvent which will affect the

painted surfaces.

(c) Apply seal packing to the No.1 oil pan as shown in the illustration.

Seal packing: Parts No. 08826±00080 or equivalent

w Install a nozzle that has been cut to a 3±4 mm

(0.12±0.16 in.) opening.

HINT: Avoid applying an excessive amount to the surface. w Parts must be assembled within 5 minutes of

application. Otherwise the material must be

removed and reapplied.

w Immediately remove nozzle from the tube and

reinstall cap.

(d) Install the No.1 oil pan with the 22 bolts.

Torque: 12 mm head bolt 21 N Vm (210 kgf Vcm, 15 ft Vlbf)

14 mm head bolt 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

LU±16±

LUBRICATION SYSTEM Oil Pump

WhereEverybodyKnowsYourName

Page 2157 of 4087

MAINTENANCE OPERATIONS

MA035±04

ENGINE

Cold Engine Operations

1. REPLACE TIMING BELT

(a) Remove the timing belt.(See page EG±46)

(b) Install the timing belt. (See page EG±59)

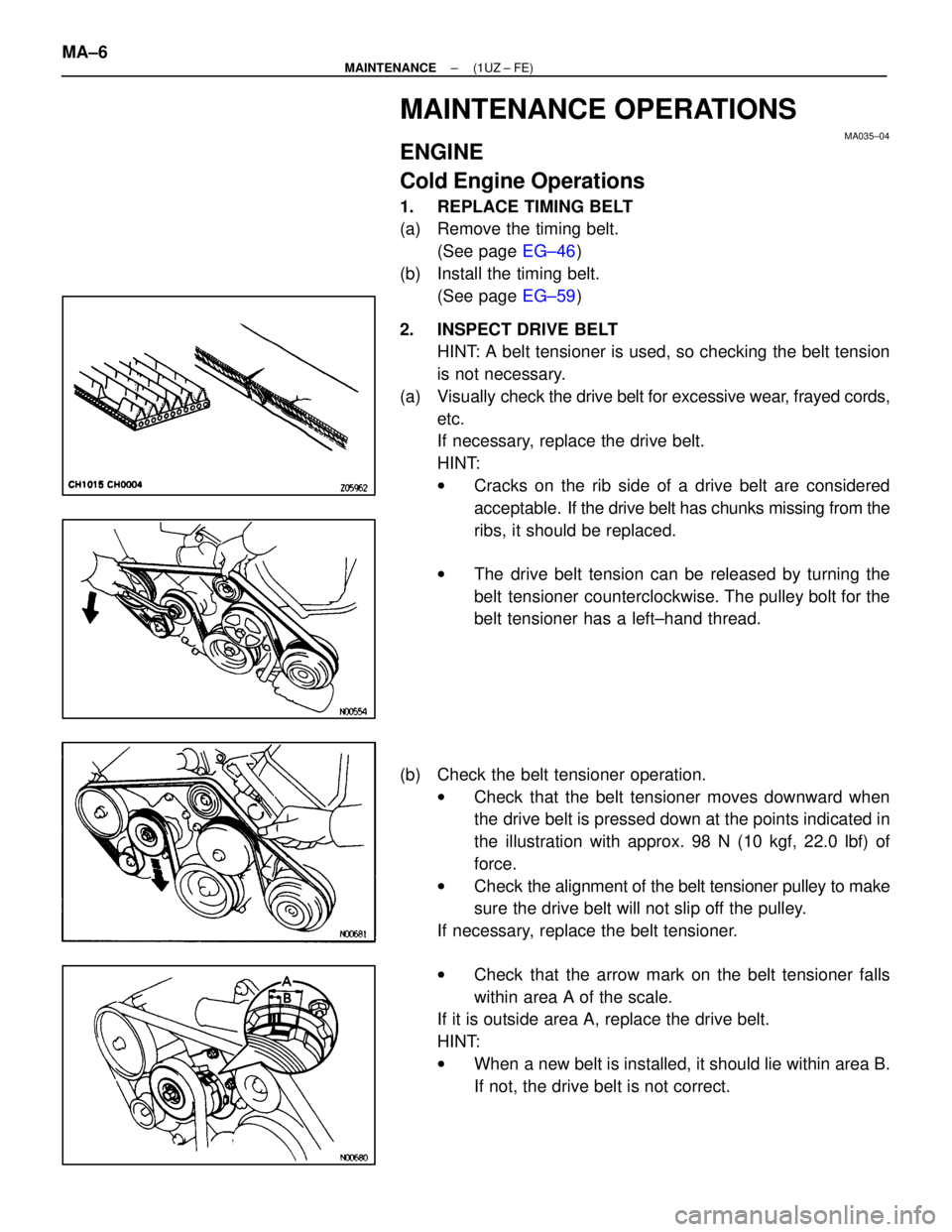

2. INSPECT DRIVE BELT HINT: A belt tensioner is used, so checking the belt tension

is not necessary.

(a) Visually check the drive belt for excessive wear, frayed cords,

etc.

If necessary, replace the drive belt.

HINT:

w Cracks on the rib side of a drive belt are considered

acceptable. If the drive belt has chunks missing from the

ribs, it should be replaced.

w The drive belt tension can be released by turning the

belt tensioner counterclockwise. The pulley bolt for the

belt tensioner has a left±hand thread.

(b) Check the belt tensioner operation. wCheck that the belt tensioner moves downward when

the drive belt is pressed down at the points indicated in

the illustration with approx. 98 N (10 kgf, 22.0 lbf) of

force.

w Check the ali gnment of the belt tensioner pulley to make

sure the drive belt will not slip off the pulley.

If necessary, replace the belt tensioner.

w Check that the arrow mark on the belt tensioner falls

within area A of the scale.

If it is outside area A, replace the drive belt.

HINT:

w When a new belt is installed, it should lie within area B.

If not, the drive belt is not correct.

MA±6

±

MAINTENANCE (1UZ ± FE)

WhereEverybodyKnowsYourName

Page 2169 of 4087

26. FINAL INSPECTION

(a) Check the operation of the body parts:wHood:

Auxiliary catch operates properly Hood locks securely

when closed

w Doors:

Door locks operate properly Doors close properly

w Luggage compartment door:

Door lock operates properly

w Seats:

Seat adjusts easily and locks securely in any position

Front seat back locks securely in any position Folding±

down rear seat backs lock securely

(b) Be sure to deliver a clean car. Especially check: wSteering wheel

w Shift lever knob

w All switch knobs

w Seats

MA±18

±

MAINTENANCE (1UZ ± FE)

WhereEverybodyKnowsYourName